THE MEAT STREET BEAT

Sizzling product quality puts The Meat Factory bacon line a cut above the competition

Story on page 14

Albanese, Director of Marketing and Corporate Training

Sizzling product quality puts The Meat Factory bacon line a cut above the competition

Story on page 14

Albanese, Director of Marketing and Corporate Training

As the leaders in recycling and sustainable packaging for over 60 years, it only made sense that we be accredited by the world’s leading model for environmentally appropriate, socially beneficial and economically viable forestry stewardship.

After all, we save a forest of over 14,000,000 trees per year from being cut down to produce paper products.

By utilizing the latest technology and world class processes in our 100% recycled paper mills, we save the equivalent energy to power 100,000 homes for a full year, divert 3 million cubic yards of waste going to landfill, use 4.2 billion less gallons water and help to remove 1.2 million tons of carbon from the atmosphere.

Why purchase your Forest Stewardship Council® (FSC)® certified paper and packaging products from us? Because it demonstrates your personal commitment to our environment, it shows your customers that you care, and

Because you can!

Service Driven!TM

“Responsive to your needs”

VOLUME 64, NO. 12

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Stewart Thomas • (416) 442-5600 x3212

SThomas@bizinfogroup.ca

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

ADVERTISING SALES

Munira Khan • (416) 510-5199

MKhan@canadianpackaging.com

PRODUCTION MANAGER

Kim Collins • (416) 510-6779

KCollins@bizinfogroup.ca

CIRCULATION MANAGER

Diane Rakoff • (416) 510-5216

DRakoff@bizinfogroup.ca

EDITORIAL DIRECTOR Lisa Wichmann • (416) 442-5600 x5101 LWichmann@canadianmanufacturing.com

EXECUTIVE PUBLISHER

Tim Dimopoulos • (416) 510-5100 TDimopoulos@bizinfogroup.ca

BIG MAGAZINES LP Vice-President of Canadian Publishing • Alex Papanou President of Business Information Group • Bruce Creighton

Can there really be too much of a good thing when it comes to packaging? It’s a question that regularly keeps popping up in our corner around this time of the year, when we get literally bombarded with a multitude of press releases from companies celebrating the latest and greatest industry award they picked up for their respective packaging design or innovation.

While there is no doubt that competition is the essential fuel that drives innovation in packaging and other industries, it often seems that there are just too many competitions out there to showcase what is often a fairly marginal, mundane or incremental improvement on existing package design, rather than a bona fide breakthrough innovation.

If there are enough awards to go around to keep everyone happy, what is the point of having some of these competitions in the first place aside from simply satisfying some self-serving narcissistic urge? It really seems to a question of finding the right balance between filling a void and overkill, which is often easier said than done.

According to the World Packaging Organization (WPO), which administers the high-profile international WorldStar packaging competition, unchecked obsession with trying to win as many awards as possible for marketing and other competitive advantages can be fraught with danger for companies who have not fully grasped the general intent of these competitions, which at the end of the day is all about attracting new and exciting talent to the packaging profession.

“The risk of lack of success or underachievement also needs to be recognized as this can impact not only on those directly involved but also on customers and potential customers,” WPO adds. “Demotivation and disillusionment are very real possibilities for those who do not succeed, especially if close competitors are more successful.”

To avoid this trap, WPO suggests five simple rules for the potential glory-seekers to consider before filing their entries, to ensure that:

• Participation fits in with overall organization strategy or priorities;

• Necessary resources are identified and committed;

• A PR strategy is clearly defined and resourced;

• Clear senior management support is established;

• Management of success and/or failure is recognized and planned for.

Sounds like a winning strategy to us.

As a parting note for 2011, a big sincere Thank You to our sharp-eyed readers who were quick to draw our attention to a somewhat embarrassing falsehood in our last issue’s article on metal detection technologies (Metal Mettle, C anadian Packaging, November 2011, page 26 ) implying commercial availability of advanced X-Ray systems capable of detecting foodborne mold and bacteria.

Tel: (416) 442-5600; Fax (416) 510-5140.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information, contact us at 416-442-5600 or 1-800-387-0273 ext. 3258.

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $72.00 per year, Outside Canada $117.00 US per year, Single Copy Canada $10.00, Outside Canada $27.10. Canadian Packaging is published 11 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

©Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher.

DISCLAIMER: This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking speci c advice from quali ed engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its af liates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

PRIVACY NOTICE: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Phone: 1-800-668-2374 Fax: 416-442-2191 Email: privacyof cer@businessinformationgroup.ca Mail to: Privacy Of ce, 80 Valleybrook Drive, North York, ON M3B 2S9

PRINTED IN CANADA PUBLICATIONS MAIL AGREEMENT NO. 40069240, ISSN 0008-4654

We acknowledge the nancial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities. Canadian Packaging is indexed in the Canadian Magazine Index by Micromedia Limited. Back copies are available in microform from Macromedia Ltd., 158 Pearl St., Toronto, ON M5H 1L3

“It must also be acknowledged that participation is not without its downside and risks,” WPO says in a recently-published position paper evaluating the role and importance of packaging competitions. “Focus on preparing for entry is likely to be time-consuming, with the possibility that it can detract from other, perhaps more important, activities.

While we probably all agree that it is an excellent idea, as Doug Pedersen of S+S Inspection correctly points out: “Mold and bacteria and other types of organisms cannot be detected with the use of X-ray, because they do not displace any density within the product. Therefore, detecting pathogens on-line still remains the ‘Holy Grail’ of product inspection for now.”

Mea culpa, our sincere regrets for any confusion stemming from this inaccuracy, and here’s hoping for the Holy Grail being discovered sooner rather than later. Happy New Year!

Market By Andrew Joseph

Thriving Ontario pork processor using cutting-edge, high-performance product coding technology to leave a long-lasting mark of distinction on its new bacon packaging. Cover photography by Cole Garside

18 NEW CODES OF COMPLIANCE By George Guidoni Product traceability looms large as the next big hot-button issue for product ID technology manufacturers and end-users.

20 DULY IMPRESSED By Andrew Joseph New-generation exographic narrow-web presses a big performance enhancer for Quebec-based label manufacturer and converter.

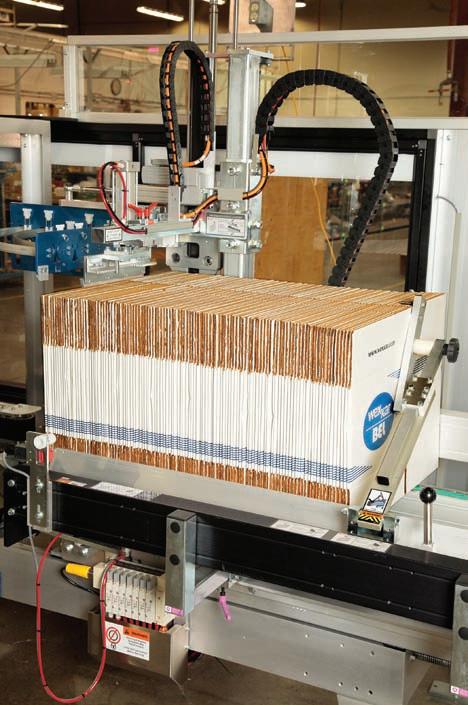

22 JUST IN CASE By Andrew Joseph West Coast boxmaking equipment manufacturer enhances its case-erector line with automatic, on-the- y changeover capabilities.

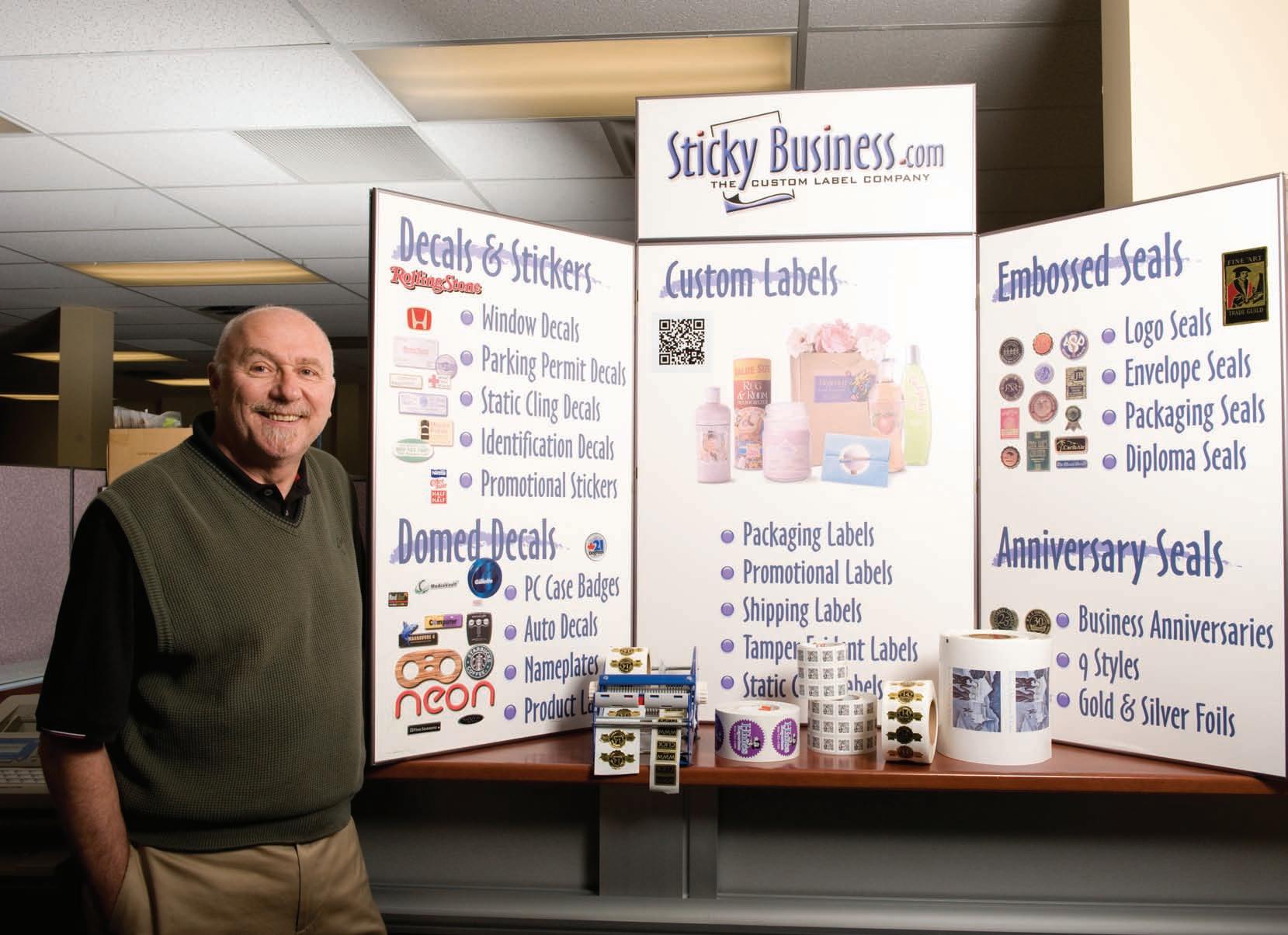

24 STICKY FINGERS By Andrew Joseph On-demand, digital label printing technology gives West Coast labeling converter an extra cutting edge to compete in a crowded marketplace.

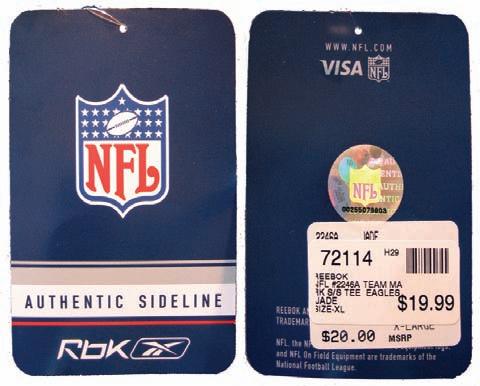

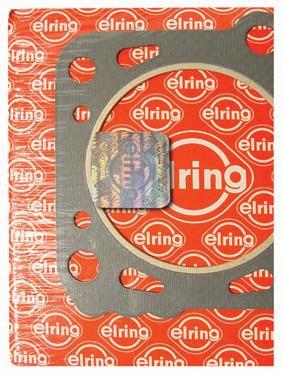

27 HOLO PURSUITS By Ian Lancaster Fighting brand thieves and counterfeiters with holographic track-and-trace technology.

The North American robotics industry is on course to post its best-ever year in terms of both shipments and sales, according to the Ann Arbor, Mich.-based industry group Robotic Industries Association (RIA), with orders for the first nine months of 2011 soaring by 41 per cent from the first three quarters a year ago.

“In the first nine months of the year the industry has received orders for more robots than in all of 2010, which was also a very good year,” says RIA president Jeff Burnstein, citing the rebounding automotive sector—accounting for 53 per cent of all industrial robot sales—as an important driver of the broad-based surge in demand for robotic technologies, recording a 56-percent gain in orders from the same nine-month period last year.

“The Tier suppliers to the automotive OEMs have really accelerated their purchases this year,

with orders jumping 84 per cent,” Burnstein notes.

According to RIA, North American manufacturing companies ordered a total of 13,616 robots valued at US$848.5 million between January and September, with offshore purchases added in boosting the figures to a total of 15,683 robots worth US$968 million.

The nonautomotive companies had also bought 26 per cent more robots than at this time a year ago, RIA says, as metalworking and general industries boosted their spending on new robotics by 55 and 45 per cent respectively.

During the first nine months of 2011, sales of assembly robots surged by 97 per cent from a year ago—complementing a 71-percent sales gain for coating and dispensing, a 66-percent rise for arc welding, 47-percent growth for spot welding, and a 28-percent increase for material handling robots.

“The long-term outlook for robotics in North America remains very strong as more and more companies in all industries become aware of the positive impact robots have on productivity, quality, manufacturing costs and time-to-market,” says John Dulchinos, president and chief executive of the Pleasanton, Ca.-based robot systems manufacturer Adept Technology

Optimized control; shorter time to market.

Material handling machines today need to be faster, more flexible, and able to solve more complex automation functions than ever before. OEM machine builders are constantly looking at innovative ways to build energy-efficient machines, reduce design and development costs, and improve their time to market.

Flexible machine control incorporates SoMachine™ , a single software suite that runs on multiple hardware control platforms, such as HMI, motion, drive, and logic controllers. With SoMachine you need only one software, one cable, and one download to design, commission, and service your machine. SoMachine minimizes your design time and reduces your time to market.

Flexible machine control is part of our brand new MachineStruxture™ solution, designed to take complexity out of the business. In addition to our new architecture, we also offer co-engineering services. With innovative help from our experts, you can design the optimal solutions for your customers. We implement the latest technological evolutions and provide unique hands-on industry application knowledge that helps you stay ahead of the competition.

Start designing, maintaining, and commissioning your machines in a single environment. Get your

Flexible machine control

To reach 100% flexibility and optimization, flexible machine control incorporates predefined and proven automation architectures and functions and embeds intelligence in multiple hardware control platforms. A single software suite helps you to develop, program, and commission your machines.

While the U.S. installation base of more than 210,000 industrial robots ranks second only after Japan, RIA says there are still vast market opportunities for robotics manufacturers across North America.

“Many industry observers believe that only about 10 per cent of the U.S. companies that could benefit from robots have installed any robotics so far,” according to Burnstein.

Good packaging ideas never really lose their fizz, as Puslinch, Ont.-based bev-

erage group Nestlé Waters Canada (NWC) is illustrating again this festive season with a Special Edition release of its S.Pellegrino Sparkling Natural Mineral Water brand in a 750-ml glass bottle—available until the end of December at selected retailers and fine dining establishments across Canada.

“The objective of bringing this distinctive packaging to market is to complement the special effort Canadian consumers and restaurateurs will put into planning and preparing their holiday celebrations,” says NWC group manager Tracey Peake, adding the fully-recyclable glass bottles of S.Pellegrino —the second-bestselling mineral water brand in the Canadian market—are priced on par with the standard PET (polyethylene terephthalate) plastic 750-ml containers.

Says Peake: “S.Pellegrino is the perfect sparkling water for fine dining and is served by restaurants and families all around the world to accompany the finest meals during the holiday season.”

Tracing its historic roots back to 12th Century Italy, the S.Pellegrino Sparkling Natural Mineral Water brand joined NWC’s beverage product portfolio in 1999 through the acquisition of its former owner Sanpellegrino SpA by the Paris, France-headquartered Nestlé Waters

Despite the lingering global economic woes unsettling the U.S. economy, U.S.-based packaging machinery manufacturers appear to be headed in the right direction toward a sustained recovery, according to new statistics from Packaging Machinery Manufacturers Institute (PMMI) showing a 12-percent increase in U.S. shipments in 2010 from the year before—reaching US$5.5 billion.

Albeit the gains came a year after a dramatic drop from the 2008 levels, PMMI president Charles Yuska says the figures analyzed in the group’s annual U.S. Packaging Machinery Shipments report—based on a survey of 178 U.S.-based PMMI member-companies—generally suggest a decent growth outlook.

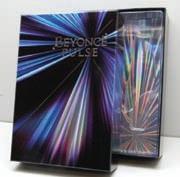

Renowned for her pulsating on-stage dance moves, pop-music diva Beyoncé projects the sort of radiant energy that’s virtually impossible to replicate, but a dazzling package design for her new Beyoncé ‘Pulse perfume collection just about does the trick—thanks to inspired use of holograms and holographic materials to achieve a visually stunning decorative shelf impact.

Selected as the winner of the Best Applied Decorative Product award at last month’s Holopack•Holoprint show of the International Hologram Manufacturers Association’s (IHMA) in Las Vegas, Nev., the eye-catching package employs a holographic-based solution which seamlessly wraps all the panels of the box to create a 3D burst effect focused on the product name.

Jointly developed by the U.S.-based packaging converters Hazen Paper Company, Curtis

Packaging and Coty Inc, USA , the captivating package is produced in eight different sizes—along with a windowed boxed set featuring an unprinted hologram on the back internal wall of the pack to highlight the products in front of it—incorporating a hologram overprinted in radiant purple so that shafts of silver holographic light seem to radiate from the Beyoncé Pulse perfume.

“The winners’ work reflects the creativity, design excellence and quality which were the hallmarks of this year’s crop of entries, reflecting how holography continues to push forward the holographic boundaries technically and commercially,” says IHMA chairman Adam Scheer.

For full list of winners, go to: www.ihma.org

Leading material handling and end-ofline packaging equipment manufacturer Intelligrated says it will create up to 200 new jobs—including technical and engineering positions in R&D, system design and customer service—during a planned expansion of the company’s headquarters in Mason, Ohio, where it plans to construct a new 60,000- to 90,000-square-foot facility to double the size of the existing operations.

“In recent years, the packaging machinery market has reflected trends in the general economy, with 2008 shipments generally flat from 2007, and 2009 shipments dropping by about 16.3 per cent,” Yuska says. “Although the increase in 2010 shipments mimicked the slow economic recovery, the preliminary data shows significant growth in 2011.” Join other satisfied Reiser customers that trust Ross tray sealing equipment to protect the integrity of their product. Specially designed to produce modified atmosphere packages (MAP), the Ross high-impact seal bar system ensures the highest quality seals every time. Reiser offers a full line of Ross tray sealers to match any packaging requirement. Reiser is your solution – put us to the test. For more information, call Reiser at (905) 631-6611

According to Intelligrated, the expansion has been made possible with the help of an approval-pending, US$15million incentive package from the state and municipal governments extending the company’s existing Job Creation Tax Credit, along with state and local loans and property tax abatement.

“We aim to be the most technologically-advanced player in the material handling industry and to achieve this, we need an operation that houses the best mechanical, software and systems talent in the world,” says Intelligrated’s chief executive Chris Cole. “These incentives will directly support these efforts and help us create and keep more high-quality technical jobs in Ohio.”

Automated packaging technologies and systems integrator Plan Automation has been appointed as the exclusive Canadian distributor for the full line of X-Ray inspection equipment for foodand-beverage applications manufactured by the Tampa, Fla.-based Eagle Product Inspection, a MettlerToledo subsidiary formerly called Smiths Detection PID. “We have experienced continued and rapid growth in Canada, and to ensure that our expanded customer base is supported

around-the-clock, we have refined our distribution and service strategy by entering into an exclusive partnership with Plan Automation,” says Eagle Product Inspection general manager Terry Woolford. “With more than 30 years of experience in advising and supplying high-end package automation and food safety inspection solutions, Plan Automation is the ideal expert to provide superior levels of pre- and post-sales support so that our Canadian customers can continue to meet their food safety and productivity needs.”

Avery Dennison Corporation, Pasadena, Ca.headquartered manufacturer of pressure-sensitive labeling technology and materials, has commenced operations of the company’s newly-built Adhesives Center of Excellence research center in Mill Hall, Pa.—a 24,500-square-foot facility dedicated exclusively to advanced R&D (research-anddevelopment) activities in the adhesives field, one

of the core technologies driving Avery Dennison’s annual global revenues of about US$6.5 billion.

“Our company was founded on innovative use of adhesives, and we’re dedicated to remaining the innovation leader in this space,” says chief technology officer Dave Edwards. “Bringing our full team together in Mill Hall will facilitate collaboration and crosspollination—enabling us to work faster and smarter to meet the needs of our converter customers and end-users for more specialized, higherperformance, and more sustainable adhesives.”

• State of the art manufacturing of steel, polyester and polypropylene strapping.

• Steel and plastic strapping tools and accessories

• Semi-automatic and automatic strapping and stretch film equipment

• Custom fabrication of material handling solutions

• Made to order edge protection

• High quality cast stretch film

• Load securement solutions

• Product identification and labelling equipment

• Recycling equipment and baling wire

Samuel Strapping Systems manufactures and supplies a broad range of steel and plastic strapping, standard and custom engineered unitizing equipment – from manual and pneumatic tools, semi and fully automatic strapping machines to large turnkey packaging and unitizing systems.

Comprehensive in-house research and engineering capabilities, with state-of-the-art CAD systems technology, offers our customers complete packaging and unitizing solutions from a single source.

Our products and systems can be found in virtually every industry and are supported by a comprehensive sales, customer service and distribution network. Contact us today to find out how we can help eliminate packaging bottlenecks and improve productivity.

St. Louis, Mo.-headquartered rigid plastic packaging products group TricorBraun has been selected as one of the winners of the 2011 American Graphic Design Awards competition of the Graphic Design USA magazine for its design and engineering work in developing the recently-launched Winnie the Pooh Baby Care brand of all-natural infant toiletries, including shampoo, body-wash and skin lotion. Using a single HDPE (high-density polyethylene) oval 15-ounce bottle with a pinched-waist design, the brand’s products are differentiated by custom-colored closures—yellow, green and lavender— and in-mold labeling to achieve distinctive shelf presence and durable product identification, with disc-type dispensing closures used for shampoo and pumps for the lotion and wash bottles.

German-based packaging equipment manufacturing group Bosch Packaging Technology has announced plans to build the company’s second production plant in China as part of a $23-million expansion of its manufacturing operations in the country. Already employing about 400 people at its Hangzhou factory, Bosch plans to start up its Chengdu operations in early 2012 at a leased 66,000-squaremeter facility, and begin two-phase construction of a new 13,500-square-meter nearby plant that will employ about 300 people by the time of its 2015 startup. “Ten years ago we started up in China with 14 associates, but since then our sales have continuously increased,” says Bosch Packaging Technology president Friedbert Klefenz, estimating total sales of about $120 million in China for the current year.

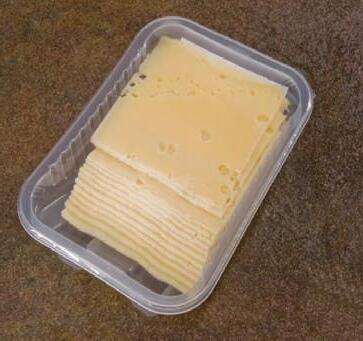

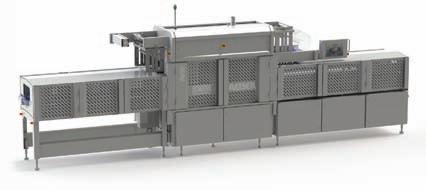

Developed by Reiser and Ross Industries, the new INPACK IN50 inline tray-sealing machine is a fully-automatic system for producing modifiedatmosphere packages (MAP) from pre-formed trays of virtually any size or shape, according to the manufacturers. Equally capable of packaging fresh, refrigerated or frozen-food products—including all types of sausage, meat, poultry, seafood, produce and cheese—the high-speed system utilizes a servo-controlled lift-station and tray-transport system to operate at up to 15 cycles per minute and run up to eight lanes of products, while producing attractive, leak-proof, tamper-evident packages with superior seal integrity and extended shelflife. Designed for quick tooling changeovers to accommodate a vast range of tray styles and sizes, IN50 system is said to be a much more efficient system than conventional die-box designs that fill the entire bottom tool with gas—achieving MAP gas savings of up to 70 per cent. The machine’s full-color HMI (human-machine interface) touchscreen uses icon-driven menus for easy navigation, storing stores hundreds of recipes and supporting multiple languages, as well as offering maintenance tutorial videos.

Reiser (Canada) Ltd. 401

The new Scotch brand Easy Open Carry Handle Tape 8643 from 3M Company features an innovative, patented easy-open feature that provides it with zipper-like ability to form integrated carrying handles—providing a consumer-friendly, convenient and portable alternative to shrinkwrap and other bundling methods, according to the company, even after the removal of a few cans or bottles out of the case. Reinforced with continuous polypropylene monofilaments in the backing, the padded, versatile external carry handles—which can be both machineor hand-applied on a broad variety of products or packages—can also be custom-printed with logos, coupons or special offers to enhance brand awareness and repeat purchase.

3M Canada Co. 402

Designed to combine the economy and accessibility of a floor-level palletizer with the speeds typically associated with high-level machines, A-B-C Packaging Machine Corporation’s new Model 72AE palletizer employs an extended accumulation table to maintain continuous layer forming even during stacking or layer transfer, according to the company, to achieve increased volumes of up to 35 units per minute. Equipped with energy-efficient electric motors for smooth, whisper-quiet operation and offering fully pre-programmed layer patterns and pallet configurations for easy startup and control, the Model 72AE system can handle a diverse array of cases, trays, bags or totes—with fullyautomatic changeover initiated by simple change

to another product configuration on the touchscreen panel. The machine’s builtin intelligent control capabilities provide flexibility for any additions of modifications of pallet, layer and product configurations by authorized personnel, along with independent adjustment of all the operating parameters.

A-B-C Packaging Machine Corporation 403

The new X-Series vertical form/fill/seal (VFFS) bagging machines from Triangle Package Machinery Co. were designed specifically to meet the USDA/3-A sanitary standards with advanced sanitation features such as electropolished stainless-steel frame with continuously welded frames; stainless-steel control box; washdown-rated servomotors; extended stainless-steel top plate with drain and cross members rotated 45 degrees to facilitate ‘drip-drain-draw’; and patent-pending, stainlesssteel, laser-sealed bearingfree film rollers. Built to facilitate full operational flexibility with quickand-easy tube size and film rols changes, as well as switching from laminated to non-supported film structures, the X-Series baggers are claimed to be especially well-suited for high-volume poultry packaging applications—from fresh breasts to chicken nuggets and portion-controlled pieces—providing convenience of an open-frame design, a pivoting control box for 360-degree access, and having no enclosures within the machine to provide clear sightlines for visual inspections.

Triangle Package Machinery Co.

404

The new PrimoWeigher 360 combination scales from CombiScale, Inc. feature an innovative open-frame design and various time-saving machine functions to facilitate simplified setup and operation by users—enhanced with a large, easy-to-read 15-inch color touchscreen display easily seen from a distance. In the event of a new recipe not being properly entered, the machine’s Wizard function will ‘walk’ the operator through the step-by-step on-screen procedure. According to CombiScale, an unlimited number of recipes can be entered in the system and easily retrieved using flip-through images of each recipe, which can also include a photograph of the actual product for quick identification. The machine operators can also switch between different languages without losing any data or set-up parameters, with additional languages added when needed. Available in 10-, 14-, 16-, 20- and 24-head configurations with 1.5-, 2.5-, and five-liter bucket sizes, the PrimoWeigher 360 combination scales can operate at speeds of more than 200 cycles per minute, according to the company.

CombiScale Inc.

The new Contiform 3 stretch blowmolding machine from Krones AG is available in sizes ranging from eight to 36 blowmolding stations—enabling users to obtain superior output capacities of up to 81,000 containers per hour, according to the company. Featuring a completely revamped blowmolding module and an enhanced liner oven to reduce total air and energy consumption, increase production output per blowmolding station, and provide greater operational flexibility, Contiform 3 be can directly monobloc-synchronized with a filler, or employed in the ErgoBloc L configuration with both a labeler and a filler for more turnkey operation.

Krones Machinery Co. Ltd. 406

405

The new compact EM10 and EM 11 series energy meters from Carlo Gavazzi are designed to provide a cost-effective solution in most metering applications for effective energy measurement without the need for an external current transformer. Designed for monitoring 120 or 230 VAN, the EM10 device can easily be interfaced with a PLC (programmable logic controller), thanks to its optional pulse output (1 Wh resolution) and IP40 protection rating. Well-suited for metering most industrial and commercial applications, the EM11 is also a 120 or 230 VAC single-phase device designed to provide accurate data concerning the status of the power supply, along with precise power measurement—helping effectively prevent line overload con-

ditions by switching off selected non-priority loads through its alarm output before a shutdown of the entire electrical system can occur.

Carlo Gavazzi (Canada) Inc. 407

The new model PA2000t/b tamp-blow label printer-applicator from Tharo Systems, Inc. is designed as an accessory for the company’s H-Series of thermal/thermal-transfer barcode label printers, which can print and apply labels with or without being attached to a computer, according to the company. Featuring a small footprint, a remote front panel for easy access regardless of the orientation of the applicator’s orientation, and highly durable all-metal construction, the model PA2000t/b printerapplicator is capable of applying labels to convex, concave or flat surfaces, according to Tharo, on either the top or the side of the product.

Tharo Systems, Inc.

408

While they are hardly ever recycled, food trays made from polystyrene foam are not nearly as environmentally-unfriendly as they’re often portrayed to be, according to new LCA (life-cycle analysis) research commissioned by the Kingsey Falls, Que.-headquartered Cascades Specialty Products Group, a major manufacturer of foam food trays.

Conducted by researchers at the Montrealbased CIRAIG ( University Research Centre for the Life Cycle of Products, Processes and Services), the study compared the entire environment footprint—from raw material extraction to end-of-life—of polystyrene foam trays made by Cascades to competing food trays made from six different types of plastic and molded pulp.

The surprising findings reveal that Cascadesmade foam trays produce the least amount of

GHG (greenhouse gas) emissions through the entire product life-cycle—basing its calculations on giving more weight to production factors such as the amount of material used and the type of energy use to manufacture it, with less emphasis on the end-of-life impact, which in any case was found to be minimal.

Because polystyrene foam is made mostly from air—more than 90 per cent—the material “has an irrefutable ecological advantage, despite the fact that it is rarely recycled,” according to the study.

“In addition, using recycled materials in the fabrication of food packaging trays, as is the case with the rPET (recycled polyethylene terephthalate) and molded pulp, results in tangible environmental benefits, as doing so reduces the impact resulting from raw material extraction,” the

CIRAIG report states.

“This analysis provides a new perspective on food packaging, with the environmental performance of our trays much better than popular belief suggests,” says Cascades Specialty Products Group president Luc Langevin.

“Polystyrene foam can now be part of our environmental packaging solution,” Langevin states, adding the CIRAIG findings will enable the company to place greater emphasis on operational aspects with the greatest scientificallyproven environmental benefits.

Many food brand-owners talk about sustainable packaging for their products, but few are really embracing it to the extent of Danone GmbH , German subsidiary of the Paris, Franceheadquartered multinational Groupe Danone that is now packaging more than half of its products sold in Germany in bioplastics, including its

bestselling Activia and Actimel yogurts.

Recently chosen as this year’s winner of the sixth annual Bioplastics Award of the bioplastics MAGAZINE, Danone says it is thoroughly committed to reducing its GHG emissions through greater use of bio-based or partially bio-based packaging materials—using PLA (polylactic acid) bioplastics for Activia and the so-called “green HDPE” (sugar cane-derived polyethylene) for the Actimel products.

“These findings have us taking stock of our current situation so that we can better understand our impact,” says Langevin, “and thereby improve our efforts to reduce the environmental footprint left by our products.”

“We are very pleased about the award,” says Danone’s director of corporate communications, health and sustainability Andreas Knaut. “A highly valued acknowledgement like this is wonderful confirmation of our achievement over years of research, and of our commitment in the field of bioplastics.

“We must get away from our dependence on petroleum and focus on packaging materials that come from renewable resources,” adds Knaut.

“We therefore hope that the award will motivate other companies to select bioplastics.

“It is only in this way that we will be able to establish a full recycling system, for example for PLA, and make full use of the material’s potential.”

There’s hardly ever too much of a good thing when it comes to sustainable packaging, and Flemington, N.J.-based juice producer Johanna Foods, Inc. is sparing no effort to make a loud environmental statement with the recent launch of its Earth Wise premium juices and juice drinks in aseptic drink cartons boasting both Forest Stewardship Council (FSC) and Rainforest Alliance eco -labels.

Manufactured by the German aseptic packaging products group SIG Combibloc, the 125-ml and 150-ml combiblocMini drink-boxes (see picture) used to package six different flavors of the Earth Wise Entirely Natural beverages are said to be the very first aseptic packages marketed in the U.S. to use fully-accredite eco -labels from two of the world’s leading environmental groups:

• The FSC symbol, located in the bottom-right corner of the carton’s front panel, certifying that all of the wood fibers used to make the boxes were sourced from responsibly-managed forests in accordance with the council’s Principles & Criteria guidelines, or from other controlled sources managed in accordance with FSC standards;

• The RACTM symbol of the Rainforest Alliance above the brand logo— featuring a stylized image of a green frog—to certify that the package has been has been critically scrutinized and positively endorsed by the organization mandated to helping protect sensitive ecosystems, conserve biodiversity, and promote the sustainable conservation of the shared habitats of humans, animals and plants.

Leading Swedish paperboard packaging producer Iggesund Paperboard is shifting a large portion of its shipments to European mainland from sea to rail, citing significant environmental benefits and far superior customer service that has often been hampered by unpredictable winter weather in the Baltic Sea region.

“It isn’t just a matter of keeping our costs in check but also very much about improving our customer service,” explains director of logistics Christina Törnquist, adding the company expects to ship 80,000 to 90,000 tonnes of its flagship Invercote paperboard via rail per year—or about 35 to 40 percent of the company’s previous seaborne shipments. “With the rail network we can supply our customers in central and southern Europe more quickly and efficiently.

“The environment will also benefit, since in terms of emissions per tonne kilometer, the European rail network as a whole produces much less fossil carbon-dioxide than Baltic Sea transport,” Törnquist points out.

“The Swedish railway system in particular produces almost no fossil emissions because it is powered solely by renewable energy sources, and our simulations show that by using rail, we should be able to halve our road shipments on the continent—thereby reducing the associated exhaust emissions by half.”

Despite the partial switch to rail, which required a $3 million logistics infrastructure upgrade at the company Iggesunds Bruk mill in southern Sweden, Törnquist says that Iggesund has no plans to completely abandon the maritime transport system which the company helped to build up.

Employing 900 people, the Iggesunds Bruk mill is one of the most advanced, fully-integrated pulp and paper mills in the world, with capacity to produce 330,000 tonnes of Invercote multilayered solid-bleached board sourced from responsibly-managed forestlands.

“However, the severe disruptions caused by the ice build-up in the Baltic during the last two winters made us realize that we must have alternative transport routes to make us less weather-dependent,” Törnquist explains.

“This joint project involves some very large-scale logistics,” Törnquist says, adding Iggesund has also acquired a stake in Sweden’s leading rail shipping transport and logistics company ScandFibre Logistics to facilitate the transition.

“When fully implemented, we will ship about 40 per cent by volume of the total goods shipments by rail across the Öresund Bridge from Sweden to Denmark for onward destinations on the Continent,” she adds.

“We can already see this will improve our service to our continental customers, as well as giving us significant flexibility and environmental benefits.”

If success in sustainability is rooted in having the right partners, then a joint-venture company owned by the diversified packaging product group Sonoco and the Kingsey Falls, Ont.-based paper products producer Cascades Inc. can look forward to setting quite a few benchmarks in coming years—having recently obtained landfill waste-free status for the Birmingham, Ala.based facility specializing in the development of customized coating and lamination solutions for package printing and converting applications.

As one of the latest recipients of Sonoco’s Gold Tier Sonoco Sustainability Star Award honors, the Cascades Sonoco plant not only surpassed the 99-percent landfill diversion target, according to the company, but actually managed to completely eliminate landfill-bound waste from the plant’s operations, through a combination of recycling, the use of waste-to-energy (WTE) alternatives and composting.

“Our initial goal was simply to reduce the waste we were landfilling as much as possible, without increasing our disposal costs,” says plant manager Emmanuel Boullay.

“But once we began, we just kept looking for ways to do more until we were landfill waste-free,” he adds.

Brian Roach, Sonoco Recycling representative for the Cascades Sonoco plant, says that achiev-

ing zero-waste status at the Birmingham plant provided a good working model for the company’s Sonoco CorrFlex facility in York, Pa., which has also picked up the Gold Tier Sonoco Sustainability Star Award last month—also using a combination of WTE landfill diversion and a comprehensive recycling program.

Says Roach: “One of our biggest challenges was food waste.

“Currently we’re composting, and have plans to install disposals in our sinks to better help us handle food,” says Roach, noting that the company’s WTE incineration program has been broadly accepted by its major customers as a valid and acceptable landfill diversion strategy.

“We were able to divert two landfill waste streams, ink printing cake waste and general plant waste, to WTE,” adds Randy Bergman, plant manager for the Sonoco CorrFlex facility, a prominent manufacturer of point-of-purchase (POP) displays and materials.

Operating as a wholly-owned subsidiary of Hartsville, S.C.-headquartered Sonoco, Sonoco Recycling currently operates 20 dedicated recycling facilities within the U.S., with three of them designated as material recovery facilities (MRFs), serving more than 125 local communities with active residential and commercial curbside materials collection programs.

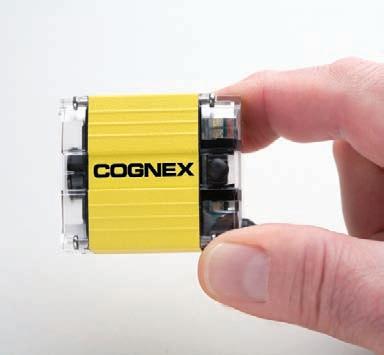

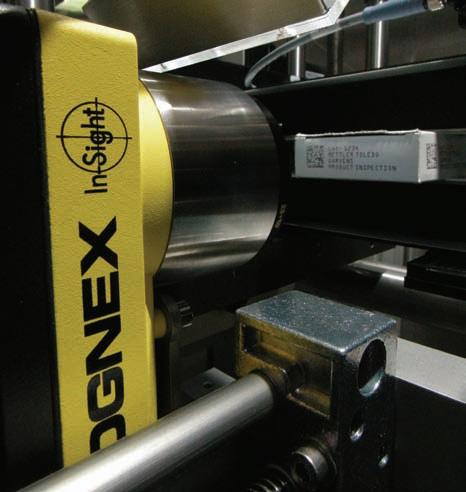

With Cognex, every read is an easy read.

Patented IDMax® technology allows Cognex readers to successfully read codes that other readers cannot. Regardless of code quality, size, marking method or material, we can read it!

1DMaxTM is our best-in-class reading tool optimized for omnidirectional barcode reading and can handle extreme variations to achieve unsurpassed read rates. Cognex 2DMaxTM technology helped trigger the adoption of 2D Data Matrix and QR coding in many industries.

Combined with the best performing hardware available, in both handheld and fixed reader formats, any code can be read quickly and reliably.

Which makes using Cognex an easy choice.

To find out more, download the “10 Reasons to Choose Image-based ID Readers” guide from www.wecanreadit.com

2011 has been a year of reinvention for PAC with the launch of PAC NEXT in August. For six decades we have been servicing the packaging community to help get products to market.

We will continue to provide our value-added services but this bold strategic initiative will focus our attention on finding ‘next life’ solutions for discarded packaging. The PAC NEXT vision is A World Without Packaging Waste

As of this note we are pleased to announce we have over seventy new PAC NEXT members since August.

The PAC biennial conference will be held in Ottawa at the Chateau Laurier on September 28-30, 2012. PAC NEXT will be the featured theme. Mark the date on your calendar now.

Join the PAC NEXT team today. For more information visit pacnext.com.

We wish our members a happy holiday, and prosperous 2012.

James D. Downham President & CEO PAC - The Packaging Association

PAC Safety Group receives honours safety report card by reducing claims by 23.8% while clawing back 4.6% of 2010 premiums.

PAC Safety Group receives honours safety report card by reducing claims 23.8% while clawing back 4.6% of 2010 premiums

These exceptional safety record achievements have been rewarded a collective real dollar rebate of $504,608 for 2010. Since the inception of the program the PAC Safety Group has returned over $5,048,958 to its members.

By joining the Safety Group’s Program, your business will gain access to a network of firms dedicated to improving workplace health and safety by sharing best practices and pooling resources. As an added bonus, the group also receives the services of a former WSIB safety expert. In this time of escalating WSIB costs and greater scrutiny by the Ministry of Labour joining this program just makes good business sense.

At the end of the year, the group may earn financial rebates on their WSIB insurance premiums over and above their New Experiemental Experience Rating (NEER) rebates.

Rebate upper range: $250,000

Rebate lower range: $5,000

Total rebate: $714,170

Average rebate: $31,000

*(after removal of the two largest and the three smallest rebates)

Contact us today

Evan Anthony Safety Group Co-ordinator PAC

evan_anthony@rogers.com 647-918-4123 or Larry Dworkin

Director of Government Relations PAC

larrywdworkin@gmail.com

416-645-3282

ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY COLE GARSIDE

To quote the immortal Homer Simpson: “Mmm… bacon.”

While the look and taste of bacon has remained fairly consistent on the grocery storeshelves for decades, Homer might make his own odyssey to Stoney Crek, Ont., just west of Toronto, to get ahold of a line of high-quality cured, smoked boneless sliced pork loin bacon processed by The Meat Factory ( TMF ), one of Canada’s major players in the cooked meats market renowned for its peameal bacon and other high-end bacon products.

“While it is true that TMF is one of Canada’s largest manufacturers of peameal bacon and awardwinning restaurant-style entrées, we are now becoming well-known for our new easy-to-prepare products,” plant manager Rocco Giorgio told Canadian Packaging magazine during a recent visit to the bustling, 80,000-square-foot TMF facility that employs over 130 people.

Each month, TMF processes over 500,000 kilograms of meat—mostly pork and beef—serving a fairly even 50-50 split for both the retail and foodservice markets across Canada, the U.S. and even into Hong Kong.

“We also do some private-label work, but really we focus on our own line of Lou’s products,” says Giorgio.

TMF opened its doors in 1978 as the brainchild of chief executive officer Lou Albanese—primar-

ily to work with the foodservice industry to supply fresh and fully-prepared meat products.

And while business was good, it was in 2001 when TMF realized that further growth was only going to be achieved by taking things to another level, successfully venturing into the retail market creating entrées that garnered the firm four Grand Prix new product awards, along with double-digit growth that continues even to this day.

In 2009 yet another epiphany struck TMF, this time in the form of Lou’s Quick-n-Easy product line comprising a wide range of unique entrées made with the consumer in mind.

Products under the Quick-n-Easy brand label include the 400-gram packages of Slow Roasted Beef au Jus; Slow Roasted Pulled Pork; Beef au Jus; Asian Chicken; Pot Roast; Pork Back Ribs in BBQ Sauce; and Beef Tips

“However, considering the meat of TMF’s success has been its peameal bacon, it seems likely it would also create a specialty high-end bacon product,” says Giorgio. “And we do. Two products, in fact.”

Along with the Traditional Slice Bacon, TMF is also producing an Extra Thick Slice Bacon, both in 375-gram packs, but if you thought bacon was bacon, in this case you would be mistaken.

That’s because TMF uses cured, naturally-smoked, boneless, sliced, uncooked pork loin to create this style of bacon, which not only tastes and looks better on the plate, but also contains 32 per cent less sodium and 70 per cent less fat than regular bacon. And true to its name, it really is quick and easy to prepare.

“You just stove cook it for one minute per side, and it’s done to perfection,” exalts Giorgio, adding that TMF selects quality meats that are hand-trimmed and prepared using time-honored slow-roasting methods that create a tender product similar to what consumers would do if they had the time.

But with today’s consumer constantly on the go, with little time for proper meal preparation, the line of Lou’s Quick-n-Easy products are ideal for making eating not only a whole lot easier, but a whole lot more delicious too.

“We have over 25 years of experience creating ways to exceed the customer’s desire for innovative and tasty meals,” notes Giorgio.

“And with our full line of Quick-N-Easy meals as part of our long line of Lou’s quality products, the customers always get what they want,” he says, adding Lou’s Quick-n-Easy products are currently retailed at Sobey’s, No Frills and Walmart, along with a host of other major national grocery chains in Canada.

To create a high-end product, TMF utilizes a team of chefs to formulate recipes and cooking techniques for each of its products, as well as create an idea of what the packaging should look like. With 10 packaging lines of raw and fully-

cooked housed at TMF, Giorgio points to the CFS PowerPak line for the lovely packaging job of the Quick-n-Easy products that packs 12 bacon packages per case and 1,000 cases per week.

And despite it being a semi-automatic line, it still possesses quite the high-tech look about it, thanks to its Dutch-based manufacturer GEA CFS B.V., renowned as a leading player in the manufacture of thermoforming machinery for the food packaging segment.

In operation, select cuts of pork loin are placed into an ITM 3000, an intelligent trimming machine, manufactured by Dutch manufacturer Marel hf , featuring an IPM3 x 300 laser eye portioner that employs a laser beam to analyze the shape and size of the meat portion in order to determine where best to cut it to form the ideal loin cuts.

“The Marel has been pre-programmed to analyze the size of the meat per weight to shape it for us,” explains Giorgio adding that that once portioned, a Marel M2000 Series weigher can evaluate the portion of cut meats as it quickly moves along a conveyor, electronically informing one of four plastic arms to grab particular cuts of meat until it adds up to a pre-determined weight.

Giorgio says that while the sorting system is a key part of packaging the more complete entrée-style Quick-n-Easy products, it is not used for the bacon products. But he does acknowledge that Marel slicer placed ahead of it in the production line is a keen piece of equipment—offering some 20 perfectly formed servings of bacon at a very fast rate.

“The whole Marel line is a great machine for us,” offers Giorgio. “Not only does it provide maximum usage of the meats, it is also easy to maintain and clean.”

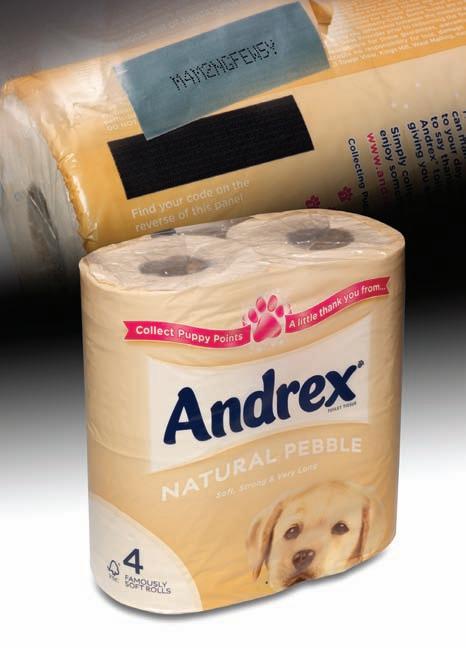

Front and reverse sides of the Lou’s Quick-n-Easy bacon packaging. (Inset )

A Linx 4900 continuous inkjet printer accurately places clear, non-smudge product code data onto a white waxless box on the pack’s back.

After slicing, the pork loin meat cuts are handplaced into CFS PowerPak thermoformer onto the bottom film tray.

Moving into the PowerPak , a reclosable red zipper is placed onto the tray before the top film comes atop of it—sealing the package air-tight closed via the thermoformer. Both the film and reclosable zipper are manufactured and supplied by Packall Packaging Inc. of Brampton, Ont.

Giorgio adds that just before the top film comes down atop the tray for sealing, an inkjet coder on the PowerPak has a coder to add a best-before date and other key product data.

“This CFS PowerPak is a jewel of a machine,” he exclaims. “It works so well in conjunction with our Marel, that we have essentially designed our whole production line around it.”

After sealing in the tasty goodness of the bacon, the packs are hand-placed into a high-quality, glossy paperboard sleeve outer packaging.

Hand-taped shut

at the top, the bacon packs are placed along a conveyor system and are whisked away to TMF’s new star of the production line, the Linx 4900 continuous inkjet coder manufactured by the UK-based Linx Printing Technologies Ltd., and purchased through Canadian distributor Coding Products of Canada Ltd. of Flamborough, Ont.

Giorgio says: “Since we are promoting a highquality line of products, we also want production line equipment that is going to help us achieve that. Along with reliability, we demand a consistent look to our packaging, and this Linx coder does that and more.”

The Linx 4900 can print up to two lines of text and logos at a production line speed up to 6.25 meters per second, and it can also print on virtually any surface thanks to the wide range of inks available from the company.

For TMF, the wide range of printable surfaces is not as big a deal, as its wax-covered outer packaging actually has a small waxless box on it where the bestbefore date and lot data is applied, but what is really impressive is how seconds after application, a thumb can be run over it without fear of smudging.

“There’s another function which we feel is a boon to our consistency requirements,” explains Giorgio. “After the machine is running, it will adjust itself to ensure the consistence of the ink being expelled always remains at room temperature. It gives us a perfect code every time.”

Prior to adding the Linx 4900 to the line, TMF utilized two people to hand-stamp each package— a time-consuming task that could never guaran-

After 300 years of combined experience from our heritage brands , CFS has proudly joined the GEA Group. This partnership will only increase our ability to meet our customer’s needs for any application. With a continued focus on innovation and performance, the future at GEA Convenience-Food Technologies is bright.

A TMF worker places pork loins into the Marel hf meat trimmer equippped with an IPM3 x 300 laser eye portioner (Inset) that analyzes each piece of meat passing by to determine the optimal way to cut it to ensure precise portion control.

“Theylisten.That’swhatmakes financingeasier.”

When you talk financing with Farm Credit Canada, we’ll listen Ready to expand your business? We’re ready to help. We get to know you and your business. Once we learn how you want to grow, we’ll create a financing package that helps you do it. Work with the leading lender to agriculture, agribusiness and agri-food in Canada. Let’s talk business. www.fccfinancing.ca

Bacon packages sealed using lm and reclosable zipper from Packall Packaging exit three at a time from the CFS thermoformer at the TMF plant before passing through a Loma IQ2 metal detection system.

tee that the stamping would be clear or precise.

According to Giorgio, after installation of the Linx 4900, Coding Products of Canada staff came in and helped TMF set up the parameters of the coding and continue to ensure things are working up to spec.

“We have only positive things to say about the Linx 4900,” exclaims Giorgio. “It’s been working great from Day One. We love the self-cleaning aspect of it— in fact we also bought a second one for another production line.”

After each bacon package is coded by the Linx 4900, it is hand-packed into a singlewall corrugated carton, manufactured by International Paper And while this system is working well for now, Giorgio confides that early in 2012 an automated cartoner system will make its way onto the line.

From a safety point of view, TMF is very gung-ho, having achieved certification from the CFIA (Canada Food Inspection Agency), HACCP (Hazard Analysis Critical Control Points) and the BRC (British Retail Consortium), having achieved the coveted A-rating for the only two years it has been involved.

“We take our responsibility for the safety of our customers and employees very strongly,” says Giorgio. “It all goes hand-in-hand in being the difference between a good company and a great company,” he concludes.

“And we’re a great company that is only going to continue to get better as we continue to automate our production lines with new and better equipment, while continuing to create recipes and products customers will love for their quality, convenience and taste.”

Need a simpler coder? Avoid the cost and inconvenience of routine service calls. The Easi-Change® Service Module means you service it yourself in minutes. No printhead cleaning for three months – just switch it on and code!

Need to move it around? At just 13.5kg, it’s the lightest continuous ink jet printer on the market. Compact, ergonomic and the easiest to carry between lines, the Linx CJ400 sets the standard in portability for fast, flexible product coding.

Need to set it up quickly? Fastest set-up with just one step. The colour touch screen with simple prompts gets you coding straight away.

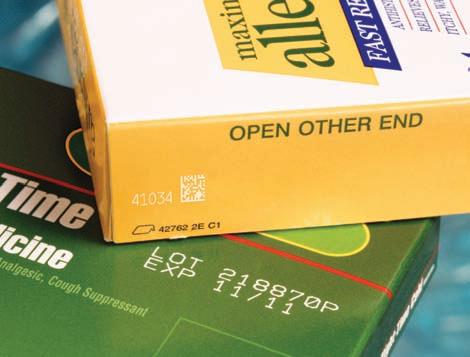

BY GEORGE GUIDONI, EDITOR

If universal acceptance is a hallmark of technological brilliance and foresight, then the rapid proliferation of Auto ID (automatic identification) technologies over the last three decades by consumers and industry alike is arguably one of the most compelling examples of pushing the technological envelope for the sake of greater, longenduring societal good.

The fact that it is today virtually impossible to find any legitimate consumer or commercial product package out in the market not bearing the ubiquitous UPC (universal product code) barcode or one of its many offspring symbologies almost belies the fact that widespread adoption of early liner barcodes in the grocery and other consumer industries did not take off until the mid-1980s, when the first generations of commercially-available barcode readers, scanners and printers made them truly “machine-readable” optical representations of vast amounts of variable product data and information that would be far too costly, time-consuming or otherwise inefficient to track manually.

Nowadays used across a staggering range of everyday applications—keeping track of objects, people, animals, medicines, hazardous waste, etc.—the omnipresent barcoding technology has become a permanent fixture of modern-day supply-chain management for an evergrowing multitude of commercial enterprises, large and small, relying on accurate, real-time and up-to-date information to make sound business decisions to retain their competitive edge.

With virtually zero tolerance for coding-related errors or quality issues, there is naturally an enormous weight of responsibility for product manufacturers and suppliers to use the best-available product coding, marking, identification and verification technologies in their packaging line operations—usually the point-of-origin for most commonly-used barcode symbologies today.

Naturally, there is no shortage of experienced, technologically-savvy, expert manufacturers and suppliers of high-quality product ID systems to help packaging line operators meet the increasingly high expectations of their customers with constantly improving system performance, reliability and ease-of-use.

“With the growing emphasis on data acquisition and traceability, product coding and marking is no

A two-dimensional barcode and product information generated on pharmaceutical carton by a Domino laser coder.

longer incidental to the packaging operation—it is very much a core function,” says Tara Abbott, marketing manager for North America at Oakville, Ont.-based Domino Canada, a subsidiary of the U.K.-headquartered product coding and printing group Domino Printing Sciences plc

“Without effective product codes and identification, the whole system would be reliant on guesses and checks, which is a highly inefficient way of doing things in today’s economy,” says Abbott, citing the company’s North American installation base of about 13,150 coding systems at healthcare, food, general manufacturing and printing companies, including over 2,500 installations in Canada.

“Product codes allows for the tracking of waste and efficiency within a process, and they also provide peace of mind to the manufacturer,” says Abbott. “With business organizations today being increasingly tasked to become ‘lean,’ it is imperative to ensure that quality of coding solutions and support is not an area that is sacrificed in this quest, in order to avoid negative long-term repercussions on productivity.”

Ron Butterman, director of marketing & communications for product coding systems manufacturer Videojet Technologies Inc., of Wood Dale, Ill., concurs that a well-operating, reliable product coding system and process is a key ingredient of any high-performance, highly flexible packaging line operation.

“The proliferation of different container sizes, shapes and materials, and the resulting variety of packaging running through a single production line, is driving the need for flexible coding installations that can accommodate a range of packaging sizes and materials, as well as ease the frequent line changeovers that all these different packages necessitate,” says Butterman, stressing the importance of maintaining high code integrity throughout the packaging process.

“Package and product coding are a commercial, and sometimes legal, necessity,” he explains, “so the information such as date/place of manufacture, bestbefore date, lot/batch number, and a wide range of both production and consumer information needs to be applied accurately and to be easily readable.

“Customers need to ensure accurate product identification, with the right code on the right product, each and every time, in order to increase production line efficiency, reduce operating costs and provide more accurate information throughout the enterprise,” Butterman adds.

Abbott and Butterman both agree that coming years will see unprecedented emphasis on product ID technologies by end-users as a key means of ensuring full compliance with the increasingly more stringent standards for product traceability across a broad range of industries—particularly in the pharmaceutical and food-and-beverage sectors.

Says Abbott: “Food safety appears to be the most prevalent development that seriously impacts our customers and end-users today.

“The focus for food manufacturers today to have a system in place to regulate the process and to ensures a higher level of accountability whenever food safety breaks down,” she explains, “and coding technologies are a vital step in this process.

“Many of the large retailers today are also mandating compliance as it relates to codes, including barcode standards, while the interest in adding serialized (unique) codes to pharmaceutical packages continues to grow, along with the general desire to authenticate products more effectively and consistently,” Abbott adds, stressing the importance of ensuring the appropriate verification system is in place to confirm the correct codes are placed where they should be, and when each one is actually produced.

“It is also critical to know, from a manufacturing perspective, what codes are required to be compliant as outlined by retailers they supply to, hence a key element to this effective implementation is to ensure alignment with the respective coding suppliers.

“This incorporates understanding what is to be coded, how the data is managed, and the overall flow across the production line.”

Butterman concurs: “Being able to trace a product back all the way to its origin will significantly help to limit scope of recalls and save producers time and the associated extra waste of nonaffected product.

“As the ability to prevent coding errors due to incorrect message set-up becomes an increasingly important purchasing consideration for a wide range of manufac-

Freshly- lled plastic milk bottles featuring coded product information applied by Domino’s A-Series continuous inkjet small-character coders.

turers,” he notes, “the very types of codes used by these manufacturers are becoming more complex, including multiline and multilanguage messages, or codes that mix font sizes and lines of print for easier readability or emphasis.”

With an estimated global installation base of over 275,000 units worldwide, Videojet coders are used to code well over 20 billion individual product per year, says Butterman, citing a comprehensive product portfolio that includes large- and smallcharacter continuous inkjet (CIJ) printers, thermal-transfer printers, laser-coding systems, label printers and print-and-apply systems, along with an extensive selection of inkjet inks and supplies.

“Many customers are simply not aware that they have a variety of options for their marking and coding needs,” Butterman points out. “Just because they may currently be using a continuous inkjet printer, they may feel they have to replace it with another inkjet printer, when in fact they maybe should be considering laser marking or a thermal printing process.

“Moreover, too many are still thinking of coder as a stand-alone device,” he asserts, “whereas many of today’s variable data printing devices can be networked for centralized operation.

“An older inkjet printer, for example, could use substantially more ink and make up fluid than new models, increasing total cost of operation.”

Linda Snowden, marketing director for product ID systems distributor Coding Products of Canada Ltd., agrees that end-users do not always consider the Big Picture implications of their purchasing decisions when upgrading their systems.

“Coding and marking equipment is often seen as a ‘necessary’ purchase, rather than one that adds value to the customer,” Snowden reflects.

“Therefore the equipment is often used until it breaks, and in some cases that can mean the customer is using equipment that is up to 15 years old.

“While such equipment may still work, it could be costing a lot more in downtime and running costs than a new printer, so keeping an old printer running may well be a false economy,” she explains.

“It is important for customers to consider trends in equipment as well as trends in coding requirements,” says Snowden, citing more demanding traceability requirements and total running costs as two key factors, along with the increasingly critical environmental considerations.

“Sustainability simply did not have such a headline focus five to 10 years ago, and while some larger organizations have always measured total

running costs, this was not considered in small to medium-sized companies as it is now,” she says.

“Previously, reliability and a focus on reducing downtime was the most important criteria, but now that they are taken as a ‘given,’ customers are now increasingly looking at the consumable and maintenance costs as well as capital costs, as well as at reducing all the waste associated with coding equipment and consumables,” Snowden states.

Based in Flamborough, Ont., Snowden’s company is the Canadian distributor of product coding and marking systems manufactured by the U.K.based Linx Printing Technologies Ltd., which boasts a current global installation based of more than 50,000 printers.

According to Snowden, ongoing technological innovation has facilitated fast global growth for Linx in the 25 years it has been in the auto ID business—today operating a global network of over 100 distribution partners—while launching some unique industry-first product features such as sealed printheads and solvent reduction without the use of condensers.

“Considering the current capital expenditure constraints and the need for quicker payback in the current economic climate,” she says, “finding a partner that can provide a consultative approach, rather than buying a one off piece of equipment, is more important in understanding which technology really does give the most reliable and costeffective solution for your coding needs.”

Russell Bateman, marketing communications manager with the Pittsburgh, Pa.-based Matthews Marking Products, one of the oldest product coding equipment manufacturers still in business today, says he also expects product ID technology suppliers manufacturers to pay closer attention to the sustainability issues in coming years.

“Consumers today are becoming much more environmentally conscious, and they are demanding that manufacturers do the same,” Bateman says. “Manufacturers often attempt to improve their sustainability by reducing the amount of corrugate in their case-packs, replacing it with shrink wrap, and when they can’t decrease the amount of corrugate, they will try to increase the amount of recycled content in their corrugated cases.

“Many companies are also attempting to improve their sustainability performance by using corrugated cases with more recycled content,” he adds.

“Although this is better for the environment, it also creates a more challenging substrate on which to print and moreover, recycled corrugate tends to create much more dust than virgin corrugate,”

Developed for applications requiring easily readable variable data codes on dark or dif cult-to-mark materials, the Videojet 1710 small-character continuous inkjet printer uses high-contrast, pigmented inks to create bright, clean codes on surfaces for which dye-based inks are not effective, such as colored glass and dark paperboard.

Bathroom tissue packages of a U.K. brand of bathroom tissue are wrapped in plastic lm featuring sophisticated product codes generated by a Linx 7300 continuous inkjet printer, with the Linx Black ultra-fast drying ink 1405, developed speci cally for coding polyethylene lms.

says Bateman, adding that the company’s new 8000 series printheads were developed specifically to ensure reliable coding performance even in extremely dusty industrial environments.

Considering the intense low-wage competition from many emerging offshore manufacturing powerhouses, Bateman says that product ID technologies have an important role to play in enabling domestic producers to keep their costs of production at competitive levels, utilizing various OEE (overall equipment effectiveness) metrics to reduce operational costs.

“In essence, they try to get the most efficient use of their capital equipment possible,” he states.

Says Bateman: “Globalization has been a common theme for years, with increasing competition worldwide putting increasing pressure on productivity levels.

“High-wage countries must do everything they can to maximize the return on their capital equipment and optimize their processes, which drives the need for new metrics for operational effectiveness, as well as decreasing product changeover times.

“Continuously improving productivity requires end-users to continuously improve their OEE,” he reasons, “and product coding and ID equipment can help significantly by recording their production and reject rates, which are key metrics in calculating OEE.

“Over the next five to 10 years, the increasing pressure to improve productivity will drive many requirements for increasing levels of systems integration, and many of Matthews’ products will offer the capability to fully and seamlessly integrate primary, secondary and tertiary coding with enterprise systems that control manufacturing and warehousing,” Bateman predicts.

“These newer integrated products will offer traceability through the manufacturing and warehousing processes, traceability up and down the supply chain, and in-depth reporting on operational efficiency,” he says, while also helping manufacturers to decrease costs through meaningContinues on page 26

ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY PIERRE LONGTIN

With razor-thin margins being the norm in the label converting industry, companies are always looking for an edge on the competition. For one Montreal-based company, along with manufacturing high-quality labels in a plethora of styles and substrates, that ‘edge’ is found through lean manufacturing processes, offering additional product identification equipment, and continuous improvement through proactive capital investment in better equipment and technology.

The privately-owned Industrial Marking Systems (IMS), headquartered in a 33,000-squarefoot facility in Montreal with sales offices in Quebec City and Toronto, bills itself as a solutions provider for everything related to product identification— specifically labels offering a large range of manufactured products, including self-adhesive labels, prime labels, paper labels, polyester labels, vinyl labels, shrinksleeve labels, film labels and tags.

Annually pulling in about $15 million in revenues, IMS has made its mark selling to end-users and retail customers who are mainly involved in the food, apparel, hardware, durable products, cosmetics and household goods segments, mostly throughout Quebec and Ontario.

When IMS first opened its doors in 1958, it sold marking systems—stencils, rubber stamps, markers, etc.—that were considered state-of-the-art solutions for product identification at that time.

The company was purchased in 2007 by current IMS president and chief executive officer Jean Ethier, who worked at the company for years.

According to Ethier, since the 1970s the company had undergone several stages of evolution in the way it approached the marketplace.

“Our company was not content to remain successful but stagnant,” he recalls. “At that time, as opportunities began presenting themselves, we moved into the adhesive label market to provide a viable alternative to box-stamping for our customers,” says Ethier.

By 1978, Ethier notes that rather than rely on other companies to produce labels for them, IMS began manufacturing its own.

And as barcodes became the next great technology in the 1980s, IMS led the way in Quebec in intro-

ducing barcode-related products such as printers, software, readers, data collection terminals, printerapplicators and others.

“Since 2000, we began integrating products to manage product identification at the end of the processing line,” mentions Ethier, “working with some major cheesemakers in both Canada and the U.S.

“We recently added to our product capacity by becoming involved in shrinksleeve labels that correspond more to the marketing concerns of the food industry.”

The IMS plan for success has obviously worked. When the company moved into its present headquarters back in 1992, it only occupied 22,000-squarefeet, but has subsequently added an additional 11,000-square-feet of capacity for its 65 employees.

“I don’t wish to oversimplify things, but this is a difficult industry to compete in,” explains Ethier.

“There were many companies involved in price strategies, but now they have largely disappeared or have had the strategy questioned,” he says. “But because we still have to be concerned about the continuous price increases from our suppliers, we have to be very creative to avoid having to pass these costs on to our customers.

“We know it’s not a great thing to be forced to survive on smaller margins—and our customers understand that too—but that doesn’t mean they want to pay higher prices either.”

Ethier says that constant price increases of raw materials, and the failure to acknowledge them, can put the supplier at risk.

“Even if the customer wins in the short term, in

the long run nobody wins,” he states.

According to Ethier, IMS has always tried to offer more to its customers at a competitive price.

“This ‘more’ has been in our service, product offering, expertise and product integration,” notes Ethier. “We do not sell products: We sell solutions to help the customers gain better product identification.”

In order to compete with thin profit margins and to continue to offer customers more bang for its buck, IMS has always looked towards its capital expenditure purchases, specifically the type of manufacturing equipment it needs, to compete effectively.

In May of 2011, IMS purchased a Mark Andy Performance Series P7 press, having it installed and up-and-running by October.

Purchased through the Mark Andy agent Canflexographics Ltd. of Burlington, Ont., Ethier enthusiastically gives the modular press two thumbs up.

“The P7 is a very exciting machine. We tested it prior to purchasing it, and were very impressed by its performance,” says Ethier. “We found that this gearless and auto-registration press greatly reduces the set-up time for us in comparison to other conventional presses.”

Headquartered in Chesterfield, Mo., Mark Andy’s Comco and Mark Andy brands are considered to be one of the world’s leading lines of narrow-web printing equipment.

According to Mark Andy, the P7 press is a highend, efficient solution for the most complex print applications. Possessing multiple servos at each print station to allow it to perform more functions, the P7 has independent web pacing that ensures better web tension management than the more traditional flexographic presses.

“What we have found is that the Mark Andy P7 has a simple design and provides us with astonishing consistency and accuracy from job to job,” says Ethier, noting that along with two die-cutting stations, the new IMS press is also equipped with UV (ultraviolet) and water-based inks on its nine printing stations.

“It’s a fantastic machine that allows us to print on self-adhesive and shrink sleeves, which will help us grow our within these markets.”

Ethier notes that the P7 provides savings on ink usage and substrate waste and faster changeover times, which means increased efficiency for the busy label manufacturer, especially on short-run productions.

Not just limited to shrinksleeve or self-adhesive labels, the Mark Andy P7 is designed to work on bottle wraps, unsupported film, film labels, general labels, in-mold labels, light cartons, primary pressure-sensitive labels, roll-fed labels and wraps, tags, tickets, and other specialty products.

Able to handle printing widths of 17-inches (430mm), the P7 has a minimum print repeat of 5.5 inches (140-mm) and a 40 inch (1,016-mm) unwind capacity.

“The press was installed a month ago, but after the training we received from Mark Andy, we can now run it at 500 feet per minute with great quality,” explains Ethier.

All Mark Andy equipment is backed 100-percent by MAX , the company’s customer service and support arm staffed by the largest team of technicians and parts specialists in the narrow-web industry, accoding to Mark Andy.

Along with an Amadeus die-cutter and a Metronome UV eight-color press manufactured by ETI Converting Equipment of Boucherville, Que., other key presses utilized by IMS include:

• a six-color DBX Aquaflex (now under Paper Converting Machine Company, a part of Barry-Wehmiller Companies Inc.);

• A seven-color Aquaflex QX press;

• An eight-color Mark Andy 2200 press;

• Three Mark Andy 830 presses with three- to four-color capability.

“We’ve been able to be a successful company because we do provide more to our customers,” opines Ethier. “Along with supplying the labels, IMS can help customer efficiency with the fine equipment we offer, like our data collection terminals and readers to increase inventory management efficiency, or they can use our support department to maintain their equipment and reduce downtimes.”