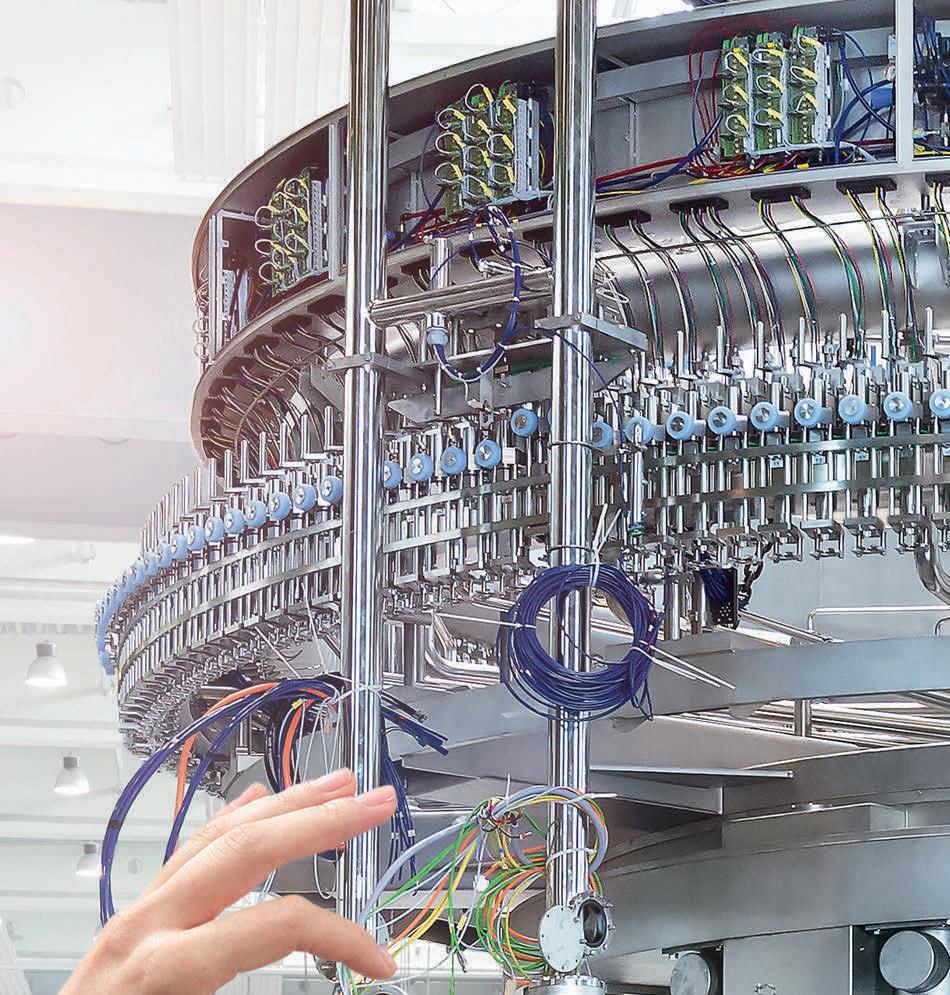

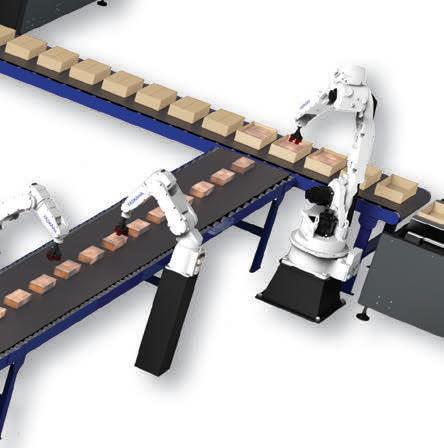

Canadian machinery manufacturer

Nuspark setting fast pace for industry’s automation transformation

Story on page 17

Canadian machinery manufacturer

Nuspark setting fast pace for industry’s automation transformation

Story on page 17

Videojet 1860 Continuous Inkjet Printer

1. True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

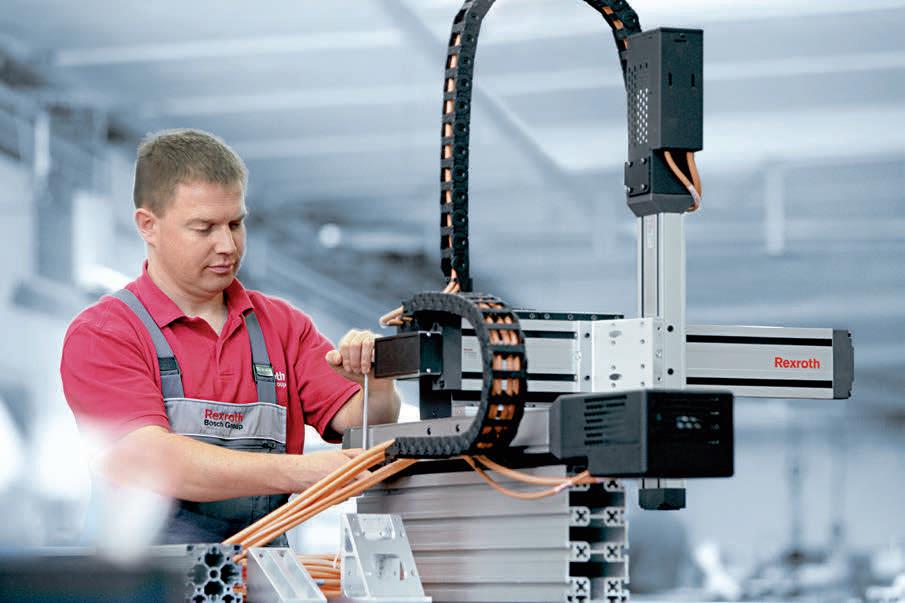

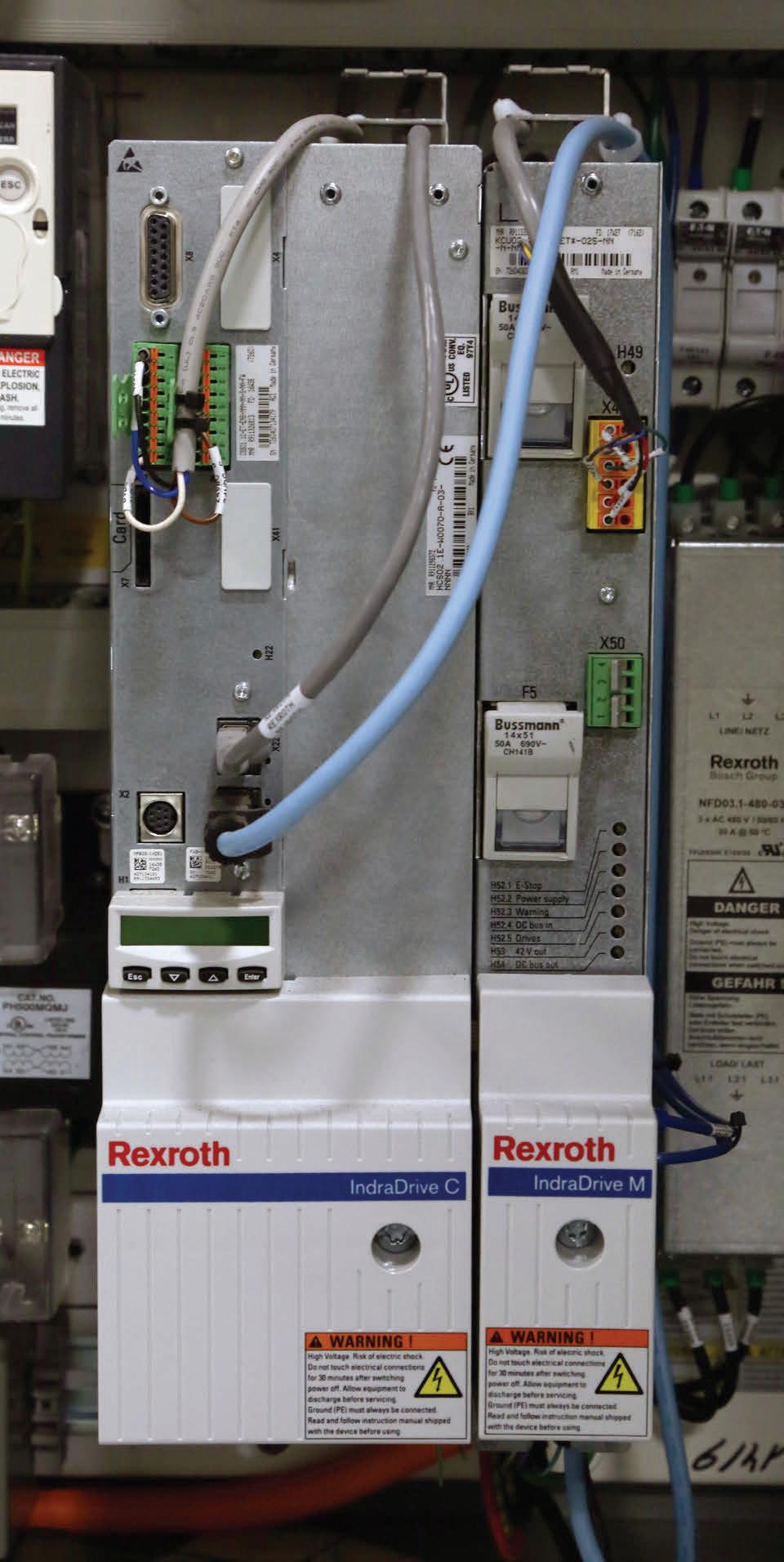

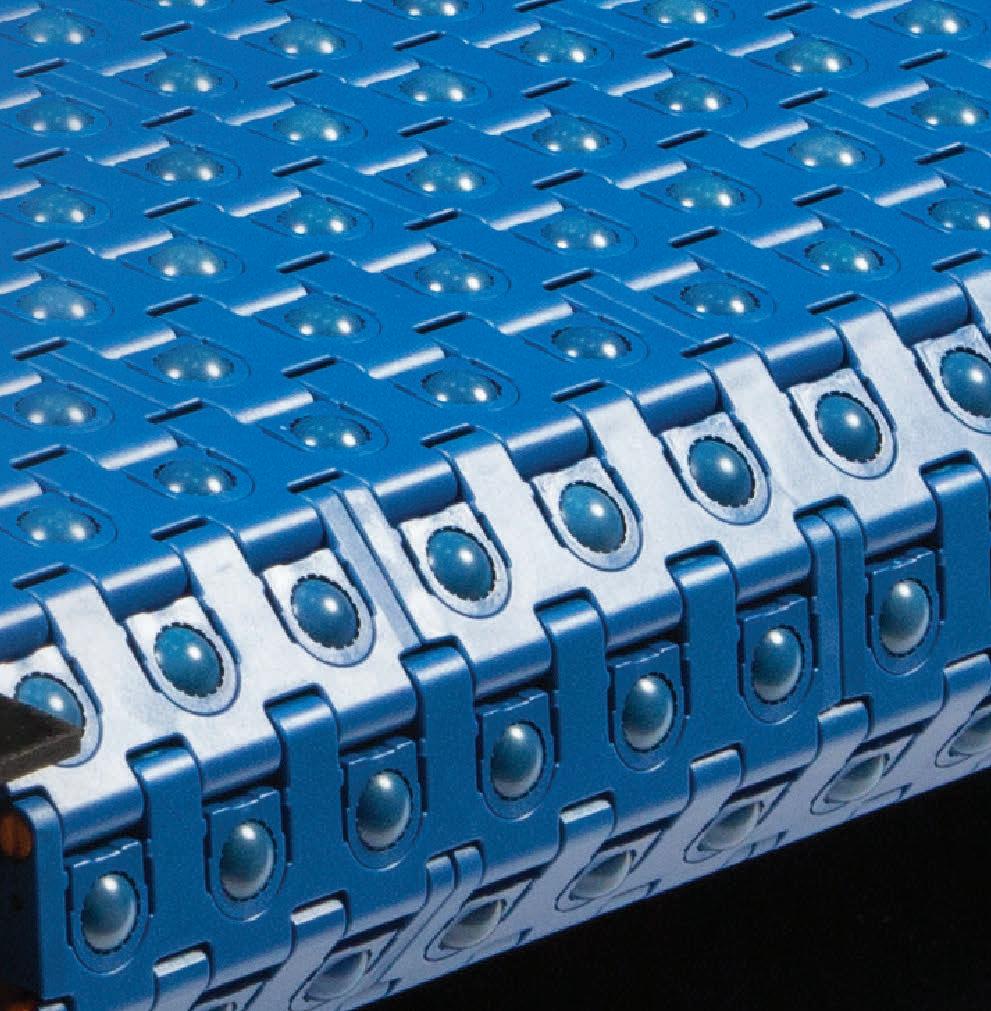

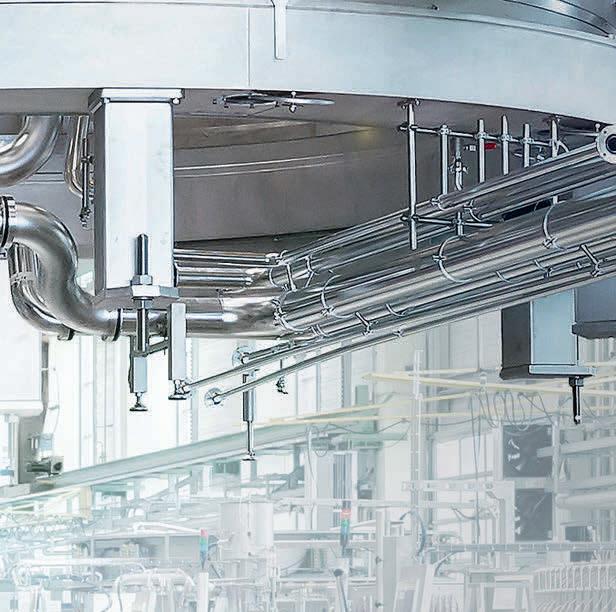

Complete motion control solutions - from Mechatronics, Conveyance, Assembly Handling, and Tightening Systems, to Linear and Electrical Drives and Controls Technology

Rely on Bosch Rexroth, the world leader in drive and motion control technologies that power today’s most advanced manufacturing systems.

Our automation solutions drive your manufacturing performance with fast throughput, precision, repeatable efficient motion control with maximum uptime. We’re set to help you achieve this with the industry’s most advanced conveyor technologies, electric drives and controls, linear motion components and systems, as well as production tools and tightening systems. All equipped for fast changeovers, and ready for Industry 4.0.

Smarter, more productive automation starts with the right technology. Make your move to Rexroth’s motion control solutions today. We Move. You Win!

Order your free Factory Automation Resource Kit: www.boschrexroth.ca/factoryautokit

For expert advice call 1-855-REXROTH (739-7684) or email us at info@boschrexroth.ca

The Internet of Things is transforming manufacturing operations on the factory floor – and we’ve developed a solution to accelerate its adoption. The benefits of internet enablement in manufacturing industries are well known.The Internet of Things (IoT) can bring production equipment online so that, once isolated machinery, can now be interrogated, monitored and managed remotely or from a central control point on-site.

However, many industrial plants haven’t caught up with the digital age yet.What’s needed is a simple and streamlined approach to the introduction of this new technology – and that’s just what the IoT Gateway from Rexroth aims to provide.

The IoT Gateway works with OPC UA, the open Industry 4.0 standard. It sits between devices such as sensors and process controllers on the one hand and processing applications on the other. It’s a building block that enables machine builders to add knowledge and connect equipment that can then be sold to their manufacturing customers.

The technology is already being applied or tested in several sectors, including automotive, furniture and consumer manufacturing. One of our customers in the packaging industry, Bosch Packaging Technology, has been using the IoT Gateway to monitor equipment performance and make small remote adjustments to improve productivity, quality and efficiency.

A team of experts scoped the project, embedded the sensors, installed the IoT Gateway, configured the network, tested connections and commissioned the solution.

The IoT Gateway itself, comprising the host hardware, bus housing and peripherals, gathers the sensor and controller data, filters it as required and forwards it to a central control point for analysis of parameters including torque, safety clearances, acceleration data, humidity and temperature. The system then compares performance against target production values and recommends a course of action as required: for instance, the callout of an engineer for service or re-

pair. This analysis is conducted not just for live data but over time, so trends can be identified to make continuous improvements.

Our plan is to provide connectivity to machinery in all areas of factory automation, and we have a worldwide infrastructure of experts, services and support that can work with equipment manufacturers everywhere to make IoT enablement a reality.

“Now machine builders will be able to offer something new to their customers that’s powerful, productive and smart,” says Hans Michael Krause, our Director of Market and Product Management PLC and IoT Systems.

Article by Hans Michael Krause, Director of Market and Product Management, PLC and IoT Systems

Custom Built Specialty Equipment

Vac/Fill Applications

Automated Packaging Equipment

Hazardous Location Filling Equipment

Automated Assembly and Feeding Systems

High Speed Assembly Equipment

Robotic Filling

JULY/AUGUST 2018

VOLUME 71, NO. 8&9

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT),

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s

It may have been slightly amusing and entertaining at first, but the U.S. president Donald Trump’s intensifying efforts to disrupt continental and global trade flows through heavy-handed imposition of punishing tariffs on just about every conceivable essential commodity and manufactured goods has long lost its early charm of shock value.

Seeing that the widely reported 10-percent spike in the price of Coca-Cola cans in the U.S. itself—a direct consequence of hefty tariffs applied to imported aluminum and steel—was never going to be enough to entice this White House administration to give its trade policy a sober second thought, Canadian companies weaned on export sales to the U.S. will be wise to prepare themselves for some serious turbulence and market share erosion in the months ahead.

This is particularly true for Canadian exporters of steel and aluminum—slapped with hefty 25- and 10-percent tariffs respectively—along with producers of softwood lumber and uncoated newsprint, who will have to find ways to cope with tariff hikes of up to 20 per cent. And things are likely to get far worse if and when the widely rumoured 25-percent tariffs on cars and auto parts come into effect, as promised.

We acknowledge the [financial] support of the Government of Canada

Given the country’s less-than-rosy full-time employment numbers, fickle consumer confidence and virtually no real growth in disposable income, this rather unfortunate series of events may yet manifest itself in a made-abroad consumer recession that is the very last thing the country needs right now.

According to a new report from leading U.S. market research firm The Freedonia Group, the real effect of Canada’s response to U.S. tariffs so far is largely symbolic, and symbolism, we all know, does not really pay the rent at day’s end.

“Though Canada taxed additional goods largely to meet U.S tariffs with equal force, in general the country focused on consumer goods in an effort to strike at the heart of U.S. consumerism in hopes economic stress will incite the public to pressure the U.S government to end its current tariff policies,” says The Freedonia study, titled U.S. & Canada: Tariff Impact Report. “More specifically, it sent a direct political message to important senators, congressmen, and members of the Trump administration by targeting products sourced from their states and districts.”

This may or may not work in the long run, but with the U.S. mid-term elections now only a few weeks away, let’s at least give hope a chance, eh?

George Guidoni, Editor

While Ottawa’s response has so far been reasonably measured in the grand scheme of things, most of the countervailing duties it has enacted so far have been limited to consumer goods—household appliances, yogurt, whiskies, non-alcoholic beverages, beef, plastic bags, paper/paperboard and personal-care items—meaning that average Canadian consumers will bear the brunt of the inevitable price inflation.

17 GET CRACKING! by George Guidoni

Relentless innovation and meticulous attention to detail help Toronto-based packaging machinery manufacturer accelerate its brisk growth in global markets. Cover photography by Naomi Hiltz 5 UPFRONT By George Guidoni 6 NEWSPACK

25

Packaging news round-up.

8-10 NOTES & QUOTES

Noteworthy industry briefs.

12-13 FIRST GLANCE

New solutions for packaging applications.

14-15 imPACt

A monthly insight from PAC, Packaging Consortium

83 PEOPLE Career moves in packaging world.

83 EVENTS

Upcoming industry functions.

36 CHECKOUT By Elena Langlois

Hardworking Quebec dairy product manufacturer literally captures packaging lighting in a bottle with new premium

30 A BERRY GOOD IDEA By Pierre Deschamps

Organic dairy farmer aims to extend its market reach for premium-quality yogurts through thoughtful packaging line automation.

34 BUILDING A FORTRESS By George Guidoni

Canadian metal detection technology innovator serves up a masterclass of cutting-edge technological prowess and worldclass customer service.

38 HAPPY ENDINGS By George Guidoni

Quebec manufacturer of stretchwrapping machinery makes impressive market inroads despite being a relative newcomer to the industry.

40 DAY AT THE RACES By George Guidoni

Automation giant Schneider Electric eager to set the pace and agenda in the unfolding digitalization renaissance.

45 PLEASED TO MEAT YOU!

Leading meat industry stalwarts team up to serve up a sizzling display of new-generation processing and packaging technologies.

47 THE SPICIER THE BETTER

Leading Canadian packaging and graphic arts distributor just keeps getting better with age.

Beer is beer, some may say, but with Canadian brewers allowed to use over 100 different ingredients to make their studs, how can consumers really be sure about what they are in fact consuming over a cold one, or not?

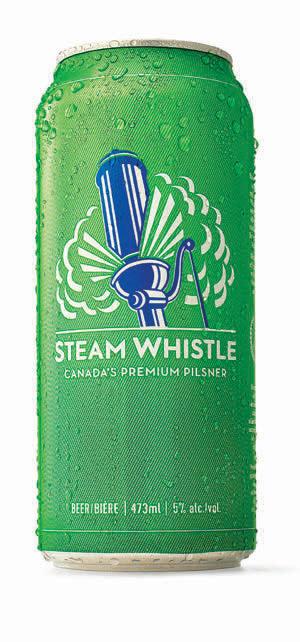

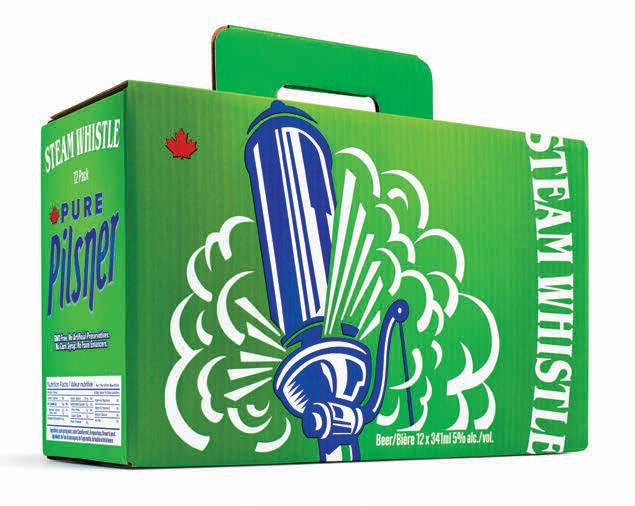

For Toronto-based craft brewing stalwart Steam Whistle Brewing, such ambiguity has no place in a market increasingly driven by consumers’ demands for greater product transparency, and its latest packaging update is a telling testament to the privately-owned company’s nothing-to-hide mindset.

Launched in early July, the new packaging look for the company’s flagship Steam Whistle Pilsner features what’s claimed to be the first nutritional and ingredients label for a beer product—applied to the secondary packaging— along with a streamlined and more prominent display of the iconic steam whistle graphic as the centerpiece of the company’s logo.

“Canadian brewers are not required to list their ingredients on their label, but we are proud of what goes in our beer and, almost more importantly, what doesn’t go into our beer,” says Steam Whistle’s director of marketing Tim McLaughlin.

“The government may permit brewers to use up to 109 ingredients in the making of beer, including foam enhancers, corn syrup, filler, additives and artificial flavors,” McLaughlin points out. “It makes you wonder, ‘If no one else is listing their ingredients, then what is in your beer?”

Now incorporating platinum as a complementing brand color to enhance the brand’s traditional bright-green backdrop, the label also features a newly added Canada’s Premium Pilsner tagline to reflect the use of top-quality ingredients, according to McLaughlin.

“We have also introduced platinum-colored caps to our beer bottles and platinum rims to our branded glassware,” he notes, “but the most notable changes have

been made to our cans and beer cases, which is where consumers will find our all-new, voluntary ingredients disclose and nutritional information.”

While the company used in-house creative talent to update the 355-ml and 473-ml can graphics, it also collaborated with the Torontobased studio Blacksmith Design Co. Ltd. to extend the message and additional product information onto the company’s secondary packaging— namely the pre-printed stretch film used for canned six-packs, and the signature briefcase-style corrugated cases with built-in carrying handles. (See Picture)

Produced and printed for Steam Whistle by the brewer’s long-time packaging partner Packaging Technologies Inc. (PTI) in Concord, Ont., the cases now feature a standard Nutrition Facts box—mandatory for the vast majority of food products sold in Canada—and an accompanying product disclosure proclaiming the absence of any GMOs (generically-modified organisms), artificial preservatives, corn syrup or foam enhancers from the products.

While incorporating a more playful graphic display of the white steam clouds and brand lettering, the eye-catching briefcase—assembled without using any adhesives—also features a special velvety ‘soft touch’ finish to play up the brand’s premium status.

“The cleaner appearance connects directly with our beer—all-natural, nothing added, nothing watered down, and nothing to hide,” McLaughlin states.

“It makes for a more pure pint of pilsner, and you will see the difference in the taste.”

Says McLaughlin: “Our ultimate hope is that the federal government will eventually mandate ingredient labeling on all beer packaging.

“There is no valid logical reason why such a big part of the food-and-beverage industry should be exempt from rules that apply to everyone else,”’ he reasons.

“Doing so would definitely benefit a company like ours and other smaller beer producers who only use all-natural ingredients to make their product the right way, without any short cuts.”

Squeezed in between bitter cold Canadian winters and increasingly hot and humid summers, the fresh natural scents of spring— such as lavender, vanilla, citrus and eucalyptus—have a relatively brief window of opportunity to refresh and reinvigorate Canadians with the pleasant smells of spring-time flora.

But thanks to the innovative Armor All Essential Blends line of air fresheners from the Mississauga, Ont.-based car-care products distributor Spectrum Brands Inc., Canadian drivers can now easily spruce up the way their car interiors smell at any time of year with one of the brand’s many scent varieties packaged in vibrant colors and high-impact graphics.

Formulated to last up to 30 days, the 2.5-ml oil concentrates come in plastic round domes dome with special vent-clip attachments for instant enjoyment inside the vehicle.

Packaged in cheerfully-colored paperboard sleeves adorned with lush botanical graphics designed by Pleasantville, N.Y.-based studio LAM Design, the Essential Blends air fresheners are infused with essential oil blends of lemon bergamot, eucalyptus mint, pink grapefruit, citrus pomegranate, and vanilla lavender to offer something for everyone, according to Spectrum Brands.

“The inspiration behind Essential Blends came from looking at the average person’s daily to-do list and thinking of how we could make those little in-between moments relaxing,” says Megan Currie, Spectrum Brands director of marketing for the Armor All product range.

“A lot of people are spending time in their cars for a good portion of their day, whether they are commuting to work or doing errands.

“We wanted to transform that daily routine into a comforting experience,” says Currie, noting that essential oils are well-known for their refreshing and restorative properties, with some touted benefits extending to relieving headaches, relaxing the mind, and even energizing the body.

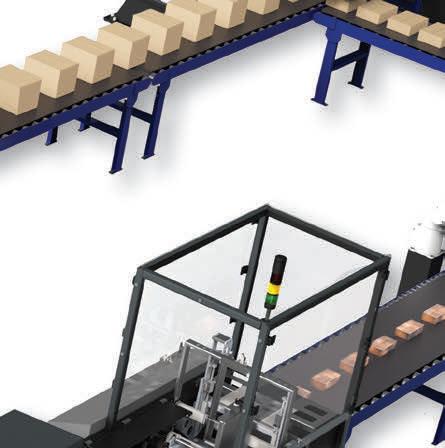

SKU proliferation, limited space, rigorous uptime requirements – why not meet that complexity with flexibility? Honeywell Intelligrated robotic palletizing solutions can handle a variety of SKUs, packaging types and stacking patterns, all in the most restrictive layout requirements. That’s automation that delivers.

For more information, please visit www.intelligrated.com or call

nSt-Hyacinthe, Que.-headquartered pork and poultry processor Olymel L.P. has completed the acquisition of Triomphe Foods, a prominent Quebec producer of deli meats and specialty hams employing over 250 people at production facilities in Laval, Blainville and Québec City, along with two distribution centers in Blainville and StLéonard. With the acquisition, Olymel becomes the owner of popular national brands such as Tour Eiffel, Chef Georges and La Belle Bretagne (hams and pâtés), Nostrano (Italian deli meats), Alpina (Eastern European deli meats), Bilopage (cretons and head cheese), and the Mother Hen range of baby foods that includes meat purées and organic fruit and vegetable purées. “Olymel is proud to acquire a Quebec company renowned for the quality of its products and thus broaden our presence in several market segments, including baby food in particular,” says Olymel president and chief executive officer Réjean Nadeau. “Through this acquisition and our own brands, Olymel will now have an even wider and more diversified range of value-added products, enabling us to serve a broad customer base, in addition to increasing our production capacities.”

nLeading German beverage production and packaging equipment manufacturer Krones AG has opened up a five-hectoliter, state-of-the-art on-site brewery at the company’s manufacturing facility in Freising to give the company’s beer industry customers a state-of-the-art option for collaborative brewing, conducting trials, and testing new technologies. Comprising five different vessels, the $3-million Steinecker Brew Center features the latest in IT (information technology) networking and digitalization capabilities—integrated by the company’s subsidiary Syskron—to help clients develop new products faster and to test them under real-life conditions, according to Krones. “While the system is small, it offers maximum flexibility by combining different technologies to demonstrate the large band-

width of solutions offered by Krones,” says Krones project manager Konrad Müller-Auffermann. “We can, for example, reproduce an ultra-wide range of internationally employed processes on the one hand, while also familiarizing our own commissioning engineers and clients’ staff with the technologies concerned on the other.”

nW. Amsler

Equipment Inc., manufacturer of all-electric linear PET stretch blowmolding equipment and auxiliary technologies, has completed the move of its headquarters and manufacturing operations from Richmond Hill, Ont., to a new 34,000-square-foot facility at 31 Parr Boulevard in Bolton, Ont., to accommodate the company’s brisk growth. “We’ve experienced rapid growth over the last five years and we’ve outgrown our current space,” explains the company’s marketing manager Heidi Amsler. “The new stand-alone facility will provide room to grow and more space for collaboration with customers, while also housing business development and project management activities, as well as all our sales, engineering, manufacturing, and service personnel.” Tel. (905) 951-9559

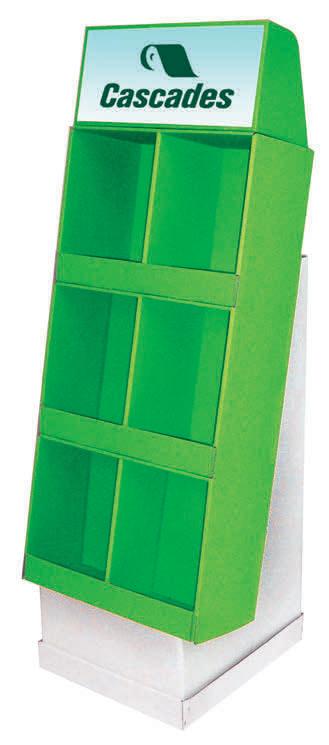

REDEFINING PACKAGING WHILE PRESERVING THE ENVIRONMENT. Cascades relies on facilities and equipment that are at the cutting edge of technology. We pride ourselves in making high-quality products designed to match our clients’ needs and expectations and we do all that while continiously surpassing our ambitious goals in our efforts to preserve our planet. So when you choose to do business with Cascades, you also become greener, naturally.

nAutomated Packaging Systems, Streetsboro, Ohioheadquartered manufacturer of bagging machinery, protective packaging systems, weighscales and other packaging technologies and materials, has received the prestigious the President’s “E” Award for Exports in recognition of the company’s solid track record of growing export sales and opening up new international markets. According to the U.S. Secretary of Commerce Wilbur Ross, “The “E” Awards Committee was very impressed with Automated Packaging Systems’ flexible international sales model, which supported consistent growth in export sales over the past four years.” Considered to be the highest recognition any U.S. enterprise can achieve in recognition of its contribution to the growth of U.S. exports, the President’s “E” Award was introduced in 1961 under then-president John Kennedy’s administration, whereby the revived World War II ‘E’ symbol of excellence was selected to honor U.S. businesses for their success in the world markets.

nGerman packaging machine-builder Gerhard Schubert GmbH has announced plans to launch its first subsidiary in China with the opening of a distribution and service center in Shanghai by the end of 2018. “We want to establish a position for ourselves in the largest market in the world,” explains Gerhard Schubert managing director Marcel Kiessling, noting China is the third-largest export market for German food and packaging machinery after the U.S. and France. “Automation in secondary packaging is becoming increasingly important for Chinese producers of food, pharmaceutical products and cosmetics, and we want to take an active part in shaping the Chinese market, with its constantly growing need for automation. With our highly flexible, robot-based packaging machines, we offer automation solutions that can be used by manufacturers in every industry to make significant increases in productivity and overall competitiveness.”

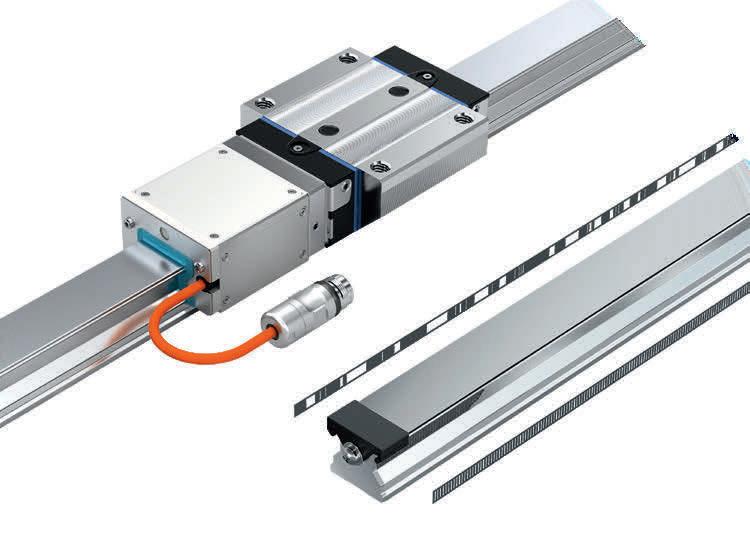

The third generation of MKK and MKR Linear Modules from Bosch Rexroth Canada provides a considerably expanded range of equipment options for the familiar space-saving dimensions of the previous series, according to the company, with ready-to-install linear axes designed to be easily connected to one-point lubrication systems. In the corrosion-resistant versions, the hard chromeplated ball screw drives and ball rails help ensure a high resistance to chemicals. The Linear Modules consist of an anodized aluminum profile body with integrated ball rails and the option of a ball screw drive or a belt drive. As ready-to-install assemblies, Linear Modules reduce the construction and instal-

lation effort in all types of machines and systems, with the one-point lubrication system connectivity helping achieve a longer service life of the axes. For their part, the corresponding components, ball screw drives and runner blocks are also ready for one-point lubrication with liquid grease or oil. The ball screw drive variant of the Linear Module is offered in lengths up to 5,400-mm, while Linear Modules with belt drives are available in lengths up to 9,400-mm. Also, a new switch concept simplifies assembly and saves time because the magnetic field sensors for limit switches fit directly into the profile frame without additional mounting accessories, while the two carriages with variable centerline-to-centerline distance accommodate larger attachments with enhanced system rigidity.

Bosch Rexroth Canada

Distributed and serviced in Canada by Shawpak Systems Ltd., the new DLSOHD + EK1600 ERGOLINE hygiene station from German-based Kohlhoff Hygiene Technology comprises a the pass-through sole cleaning machine DLSO-HD and the motor-driven entry control device EK 1600 with a tamperproof, two-hand disinfection stage connected to an unlocked turnstile. Featuring a multifunctional LED light to display updated user information about the level of disinfectant or to convey fault messages, the EX 1600 ERGOLINE boasts a highly ergonomic design that is said to reduce physical exertions by the users’ upper body by about 50 per cent, according to the company, due to the optimally positioned two-hand disinfection assembly that is pointed just under 45 degrees to the direction of movement. Shawpak Systems Ltd.

Designed as a cost-effective and safe product delivery system, the new Synchronized Staging Transfer Model PSST/120 from Propack uses robust uses stepper servo technology to receive randomly presented products from baggers, pouchers and flowwrappers to synchronize product delivery to high-speed cartoning machines. Boasting a maximum packing rate of 120 single packs per minute and up to 80 twin-packs per minute, depending on product size, the intelligent PSST/120 delivery system is designed to monitor and phase products on multiple motion-controlled staging sections to either a single or dual product transfer module. Handling products between four and 16 inches in length and up to eight inches in width, the PSST/120 delivery system can be easily configured to synchronize, stage and transfer single or twin pack product formats with precise product speed and position control, according to the company, while allowing operators to switch to the optional pass-through delivery system for bulk packaging or WIP (work-in-progress) preparation. Propack

Designed for error-free product inspection with improved detection sensitivity to identify even the small-

est contaminants quicker and more reliably, the model X34 X-ray inspection system from Mettler Toledo Safeline features advanced software that enables automated product setup—dramatically decreasing the chance of human error and greatly reducing the number of false rejects. Engineered for high-speed inspection of a wide range of small and medium-sized packaged products, the single-lane system is equipped with a 100-W Optimum Power generator that automatically maximizes detection sensitivity, complemented by a 0.4-mm detector for highly accurate detection of very small contaminants. Programmed with the advanced ContamPlus inspection software to further enhance detection capabilities and enable manufacturers achieve zero FFR (false reject rate) performance, the model X-34 X-Ray inspection system can also be equipped with the advanced ProdX data management tool software that can store the images of foreign body contamination for remote viewing and analysis.

Mettler Toledo Safeline

HMI panels per a single PC with an SDL converter, the modular design of the company’s PCs and panel systems allow for any automation panel to be equipped with an SDL4 interface—making it easer to equip expansive machines and systems with multiple remote HMI panels.

B&R Industrial Automation

Videojet Technologies Inc. has launched the all-new iQMark brand of product marking inks and consumables that are intended to help companies meet their CSR (corporate social responsibility) goals, as well as remain compliant with the increasingly more stringent governmental and industry regulations worldwide. According to Videojet, the iQMark ink

Designed for manual control of critical machine functions by hand while the safety gate is opened, the new PITjog control unit from Pilz Canada features ergonomically molded plastic housing for comfortable operation with three pushbuttons—including two pushbuttons for two-hand function and one pushbutton for the reset function. Well-suited for a broad range of industrial environments, the device’s coiled cable provides a large operating range across a broad range of applications—including machine setup, servicing work, process monitoring and test operations.

Pilz Canada

The fourth-generation SDL (Smart Display Link) 4 HMI (human-machine interface) panel from B&R Industrial Automation is designed to transmit all communication channels between industrial PCc and HMI panels via a standard Ethernet cable independent of operating system and software. Accoring to B&R, this makes it possible to transmit display content and other data over much greater distances of up to 100 meters between PC and display. With capacity to connect up to four

range includes 20 different inks, including the iQMark V463 ink for CIJ (continuous inkjet) printers formulated to meet Japan’s strict Japan ISHL Class 2 Organic Solvent list and comply with the European Printing Ink Association (EuPIA)’s Exclusion List. Likewise, the new iQMark V930 cleaning solution for CIJ printers is a low-VOC (volatile organic compound) formulation developed to meet California’s South Coast Air Quality Management District (SCAQMD) regulation requiring low-VOC cleaners to improve air quality.

Videojet Technologies Inc.

Sometimes, increases in efficiency are so incremental they’re hard to see short-term. But with packaging that saves on labor, material, and distribution costs, you feel the impact immediately. And that’s exactly what you get with Cryovac ® Darfresh® On Tray, innovative vacuum packaging for meat, poultry, and seafood. It cuts material waste by up to 40%, increases throughput by up to 35%, and trims distribution costs by more than 20% through reduced packaging volume. Find out how much we can help increase your efficiency at SealedAir.com/o perational-efficiency

PAC TO THE FUTURE II, “RETAIL REINVENTED” is a two day event where attendees will learn, be inspired and connected to packaging industry leaders and decision-makers.

The demands of shoppers today have led to a tsunami in the retail, packaged goods and food service market place. How does your business fit in and what are your opportunities? Topics include the business of tomorrow, omnichannels, market leader ambitious 2025 recycling, renewable and composting goals, food service and retail trends, major packaging and design trends, the emerging cannabis market, green and zero waste initiatives, smart packaging and food waste and designing packaging for the circular economy.

Is using 100% reusable, recyclable or compostable packaging reachable by 2025 ...reality or perception?

Since January 2018 several leading brands, retailers, and packaging companies have announced they are working towards their ambitious goals - Amcor, The Coca-Cola Company, Procter & Gamble and Unilever will share their goals and call for action.

What will you and your company get out of this important packaging industry event?

Actionable takeaways will come from our international speakers, their thought-provoking presentations, interactive workshops, and fun business networking functions. A great fall day on the golf course or a tour of the 2M Ressources facility will precede the conference on September 25, and enjoy the warmth, Québécois cuisine and joie de vivre in Old Montréal.

DAY 1 STORYTELLERS - SEPTEMBER 26, 2018

DAY 2 STORYTELLERS - SEPTEMBER 27, 2018

We support Canada’s brand owners, package converters and packaging machine builders. As Canada’s home-grown adhesives manufacturer, we dig deeper than anyone else to formulate superior adhesives at the best prices. We support the efforts of Canadian companies to compete and win market share across the country, in the United States and around the world. Stick with Technical Adhesives and let us help you to compete in your marketplace.

We are proud to be our industry’s leader for nearly 60 years and we would like to thank all our customers for STICKING with us.

Tel: 905-625-1284 info@technicaladhesives.com

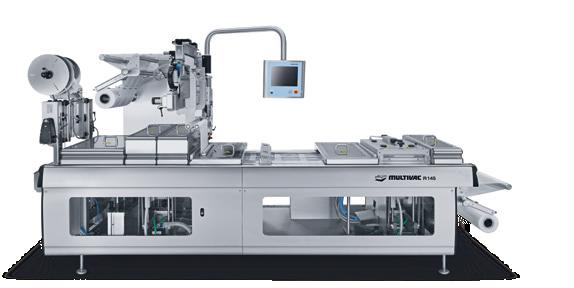

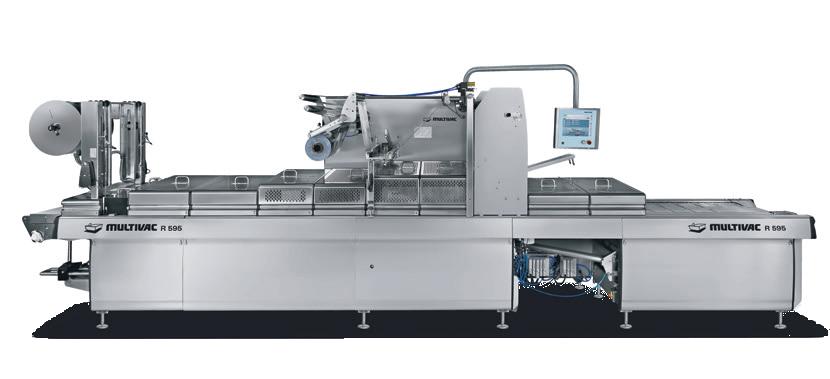

Packaging machines are undoubtedly the unsung heroes of the modern packaging business—a critical necessity but far removed from everyday consumer scrutiny, shelf impact and product marketing battles played out in the modern consumer retail marketplace.

For most people making this machinery, though, such behind-the-scenes anonymity does not lessen the professional pride and gratification derived from designing, assembling and launching new-generation technologies to produce an ever-growing array of packaging formats and structures with new levels of speed, efficiency and reliability to help keep the wheels of the global CPG (consumer packaged goods) industries spinning in full motion.

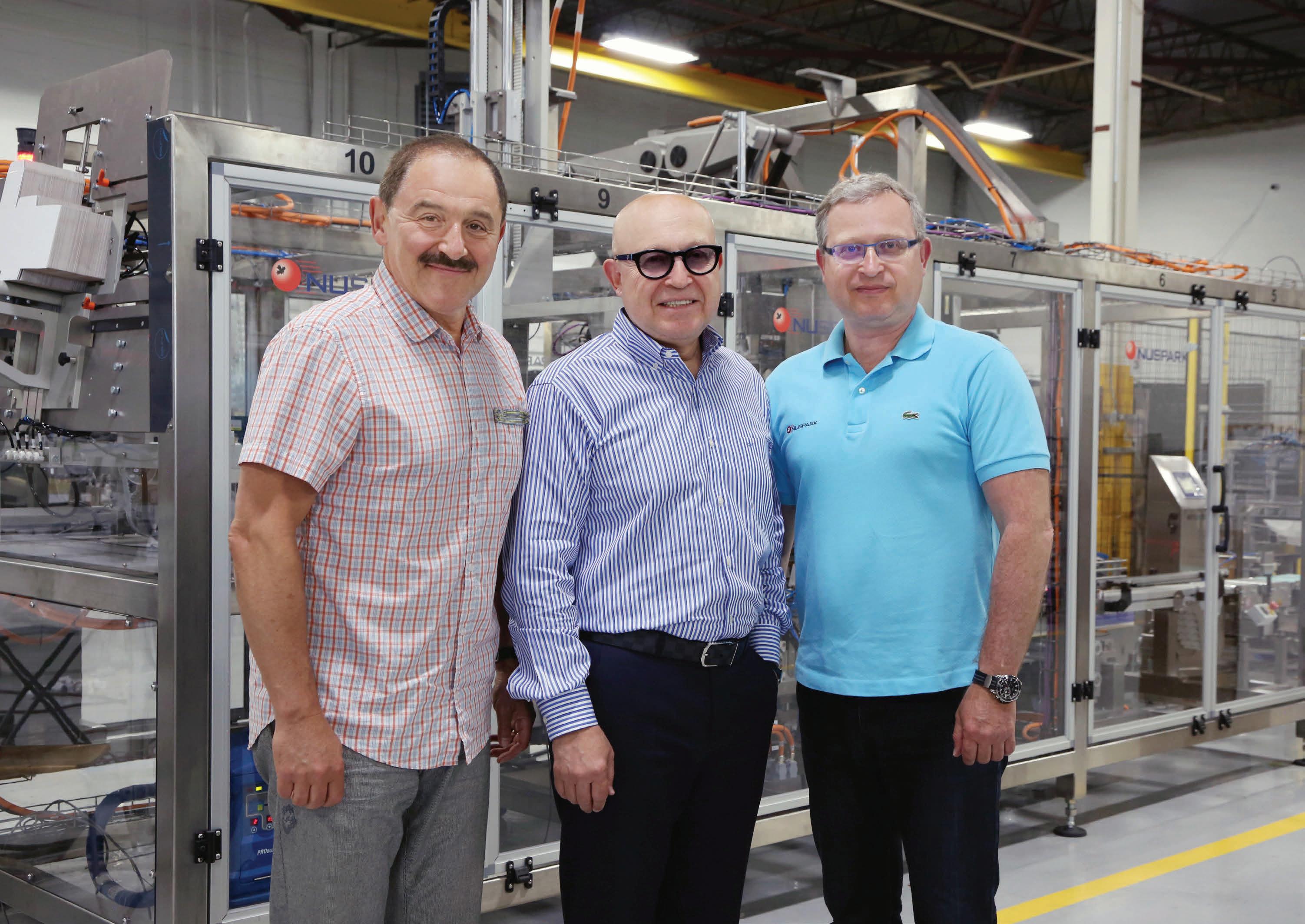

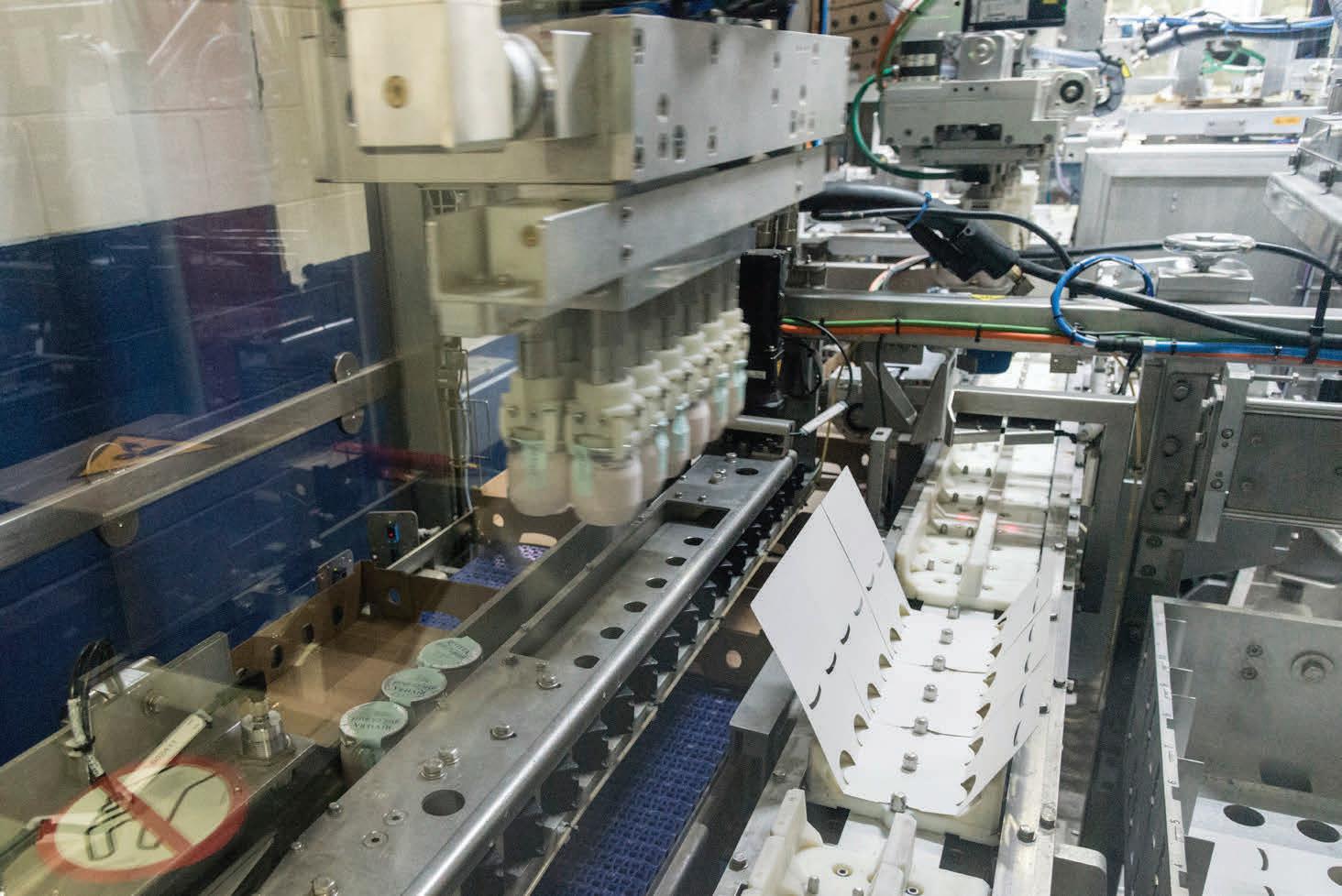

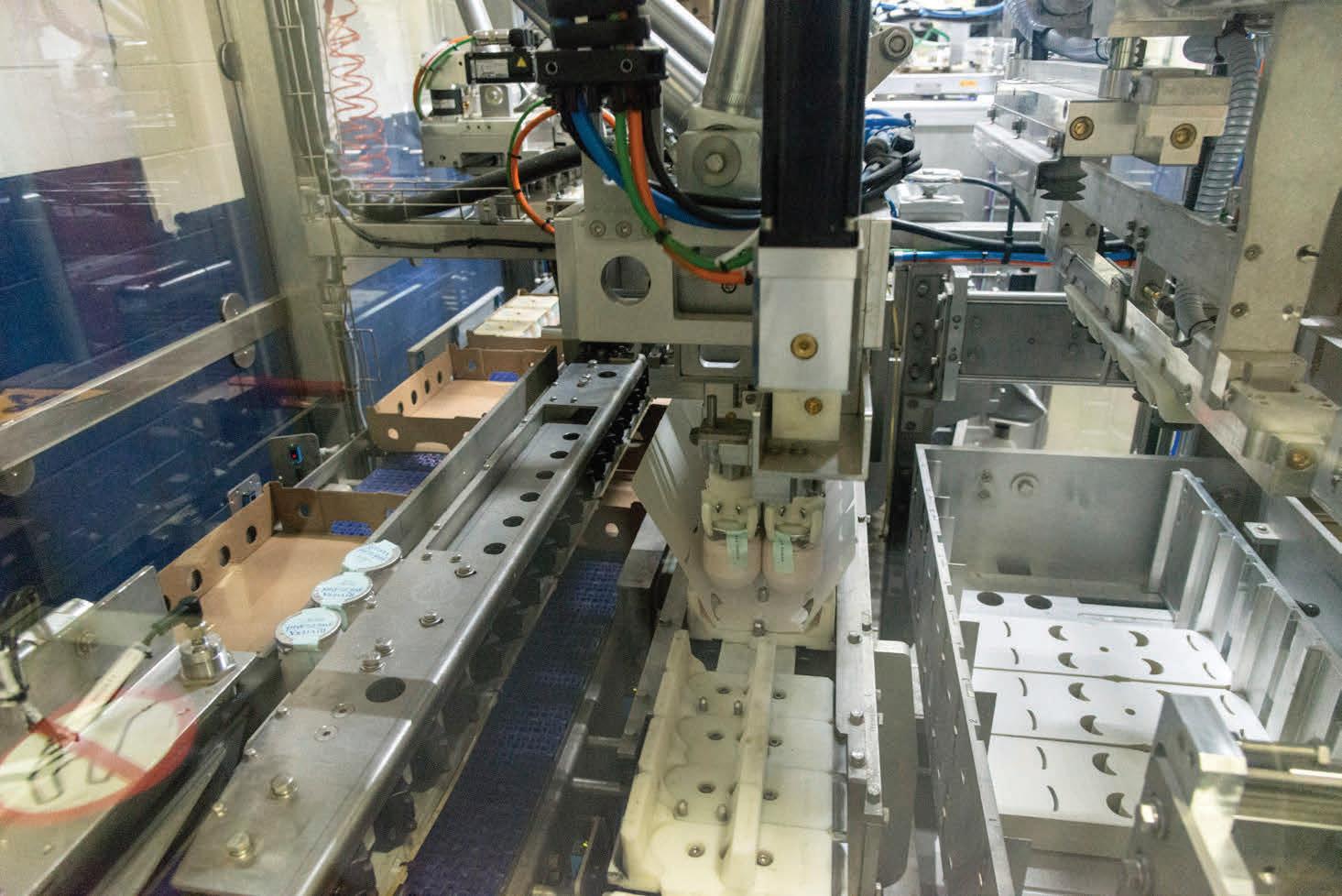

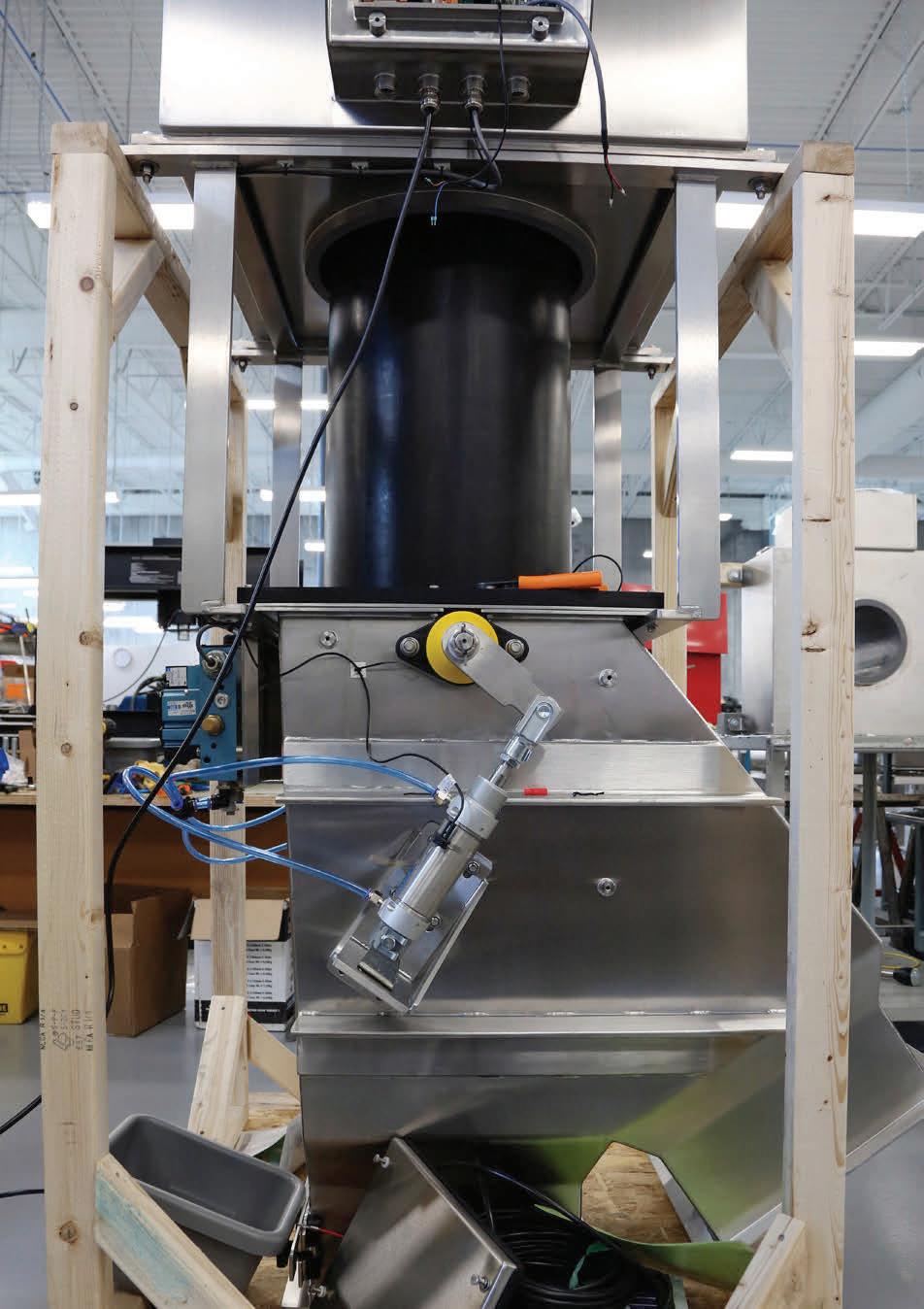

Such pride and sense of self-fulfillment are rarely in short supply at Nuspark Inc.’s lively 46,000-square-foot manufacturing facility in northern Toronto.

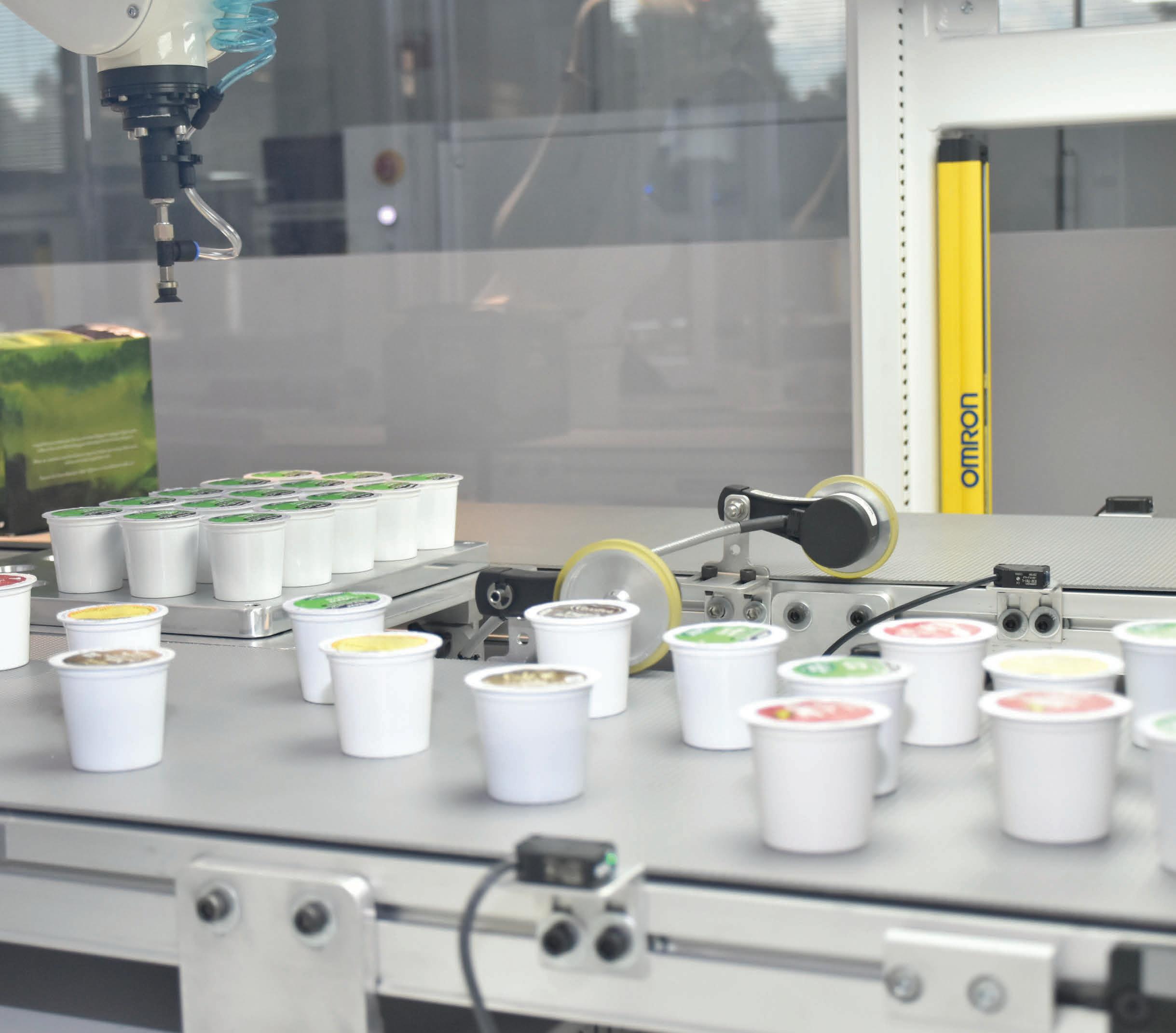

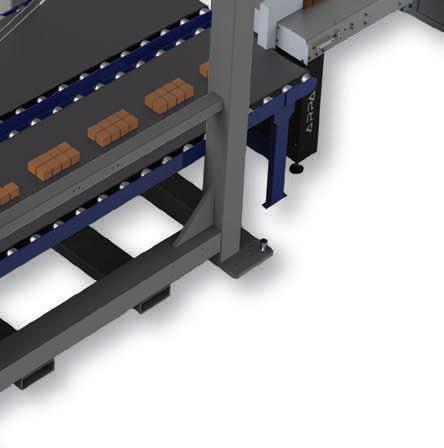

Opened up a little over a year ago as the privately-owned company’s new headquarters and production operations, the airy, high-ceiling factory employs about 60 full-time people—including several fully-accredited professional engineers—to produce a steadily expanding range of automatic, high-performance case- and tray-packers; vertical and horizontal cartoners; case erectors and trayformers; and full turnkey line solutions for high-throughput applications in the food-and-beverage, pharmaceutical and personal-care industries.

Founded in 1999 by a closely-knit three-person team comprising Michael Elent and his younger brother Felix, along with long-time family friend and colleague Valeri Bialler, Nuspark has grown in impressive leaps and bounds dur-

ing its relatively brief time in the Canadian packaging machinery.

Since starting out with a staff of four people, Nuspark proceeded to grow at a brisk rate of over 20 per cent annually right up until the onset of the Great Recession in 2008, with a downward spiral in the automotive sector temporarily stopping that growth in its tracks.

Since the following economic recovery, Nuspark quickly got back to its earlier fast-growing ways, while impressively boosting its packaging industry portfolio—now accounting for about 70 per cent of the company’s total revenues.

“We have seen about 15-percent annual growth since 2011,” co-founder Felix Elent told Canadian Packaging on a recent visit to the plant during a busy summer stretch requiring frequent overtime and Saturday shifts to keep up with seasonal work influx.

“Summers tend to be a busy time for us because that’s when a lot of new customer orders are actually finalized and approved for delivery,” explains Nuspark’s general manager Boris Motskin, adding the new plant currently has capacity to produce over 70 machines per year, in a broad array of designs and configurations to suit the end-users’ specific application requirements.

“All the electrical assembly and wiring is done right here at the factory, and all the machine frames are also fabricated in-house,” says Motskin, who joined Nuspark a few years after graduating with a degree in aerospace engineering from Ryerson University in Toronto in 2008.

“Doing a lot of business in the food industry, we

often get asked by clients about how they (frames) are welded, if they are fully welded, if they’re washdown-ready and so on,” Motskin relates.

“We have decided to make this function an internal process to give our customers a peace-of-mind about all these issues by welding, cleaning and polishing all the frames ourselves,” says Motskin, noting the vast majority of the frames are constructed of high-grade stainless steel to ensure optimal hygienic standards.

Motskin explains that Nuspark has built up a solid network of manufacturing vendors and service providers in the GTA (Greater Toronto Area) region to produce about 80 to 90 per cent of the custom-designed parts and subassemblies that go into each machine, using advanced CNC machining, 3D printing, laser- and waterjet-cutting, and other advanced manufacturing technologies.

The rest of the machine contents and related equipment accessories comprise an impressive assortment of best-ofbreed automation components and systems supplied from elite global industrial automation manufactures such as Bosch Rexroth (programmable logic controllers and drives); FANUC (robotics); Schneider Electric (electrical components and relays); B&R Industrial Automation (human-machine interface terminals and distributed I/Os), SMC Pneumatics and Festo (pneumatic components and controls); Omron (safety curtains) and other leading

automation specialists.

“Being in Toronto puts us within easy reach of the best available technologies in the market,” Motskin says, “and we have established some very good relationship with many reputable technology vendors to make sure we assemble the highest-quality machines we can for our customers.

Moreover, Motskin notes that virtually every machine shipped by Nuspark these days comes standard with all the required DNP circuitry and wiring to enable remote machine troubleshooting and diagnostics from virtually any place with an Internet connection.

Some of the company’s bestselling equipment brands include:

At Omron, we deliver a comprehensive range of products and services designed to increase the speed, versatility, and safety of your machines.

Empower your production with highly advanced solutions that have the proven reliability to maximize your customers’ loyalty.

When you are developing a new machine or upgrading an existing model, look to Omron as your complete automation partner.

Together we can create a more productive tomorrow with unique automation solutions that are integrated, intelligent and interactive.

• Model NTL-50 top-loading case-packer, featuring a delta-style two-axis robot to perform up to 50 repeatable, high-precision picks per minute;

• Model NTF-25 servo-driven tray-former, equipped with an active blank magazine and an on-board Nordson adhesive applicating system to form up to 25 trays per minute, with higher-speed variants available to handle over 60 trays per minute.

• Model NP-15 Polaris palletizer, outfitted with a four-axis robotic arm, singleor dual-head dispenser, a powered discharge conveyor and other value-added features enabling it to perform up to 15 pick per minute in continuous operation, enhanced with 10-pallet magazine capacity.

• Model VRC-60 vertical rotary cartoner, featuring an innovative vacuum nest design to ensure delicate carton handling at speeds of up to 60 cartons per minute.

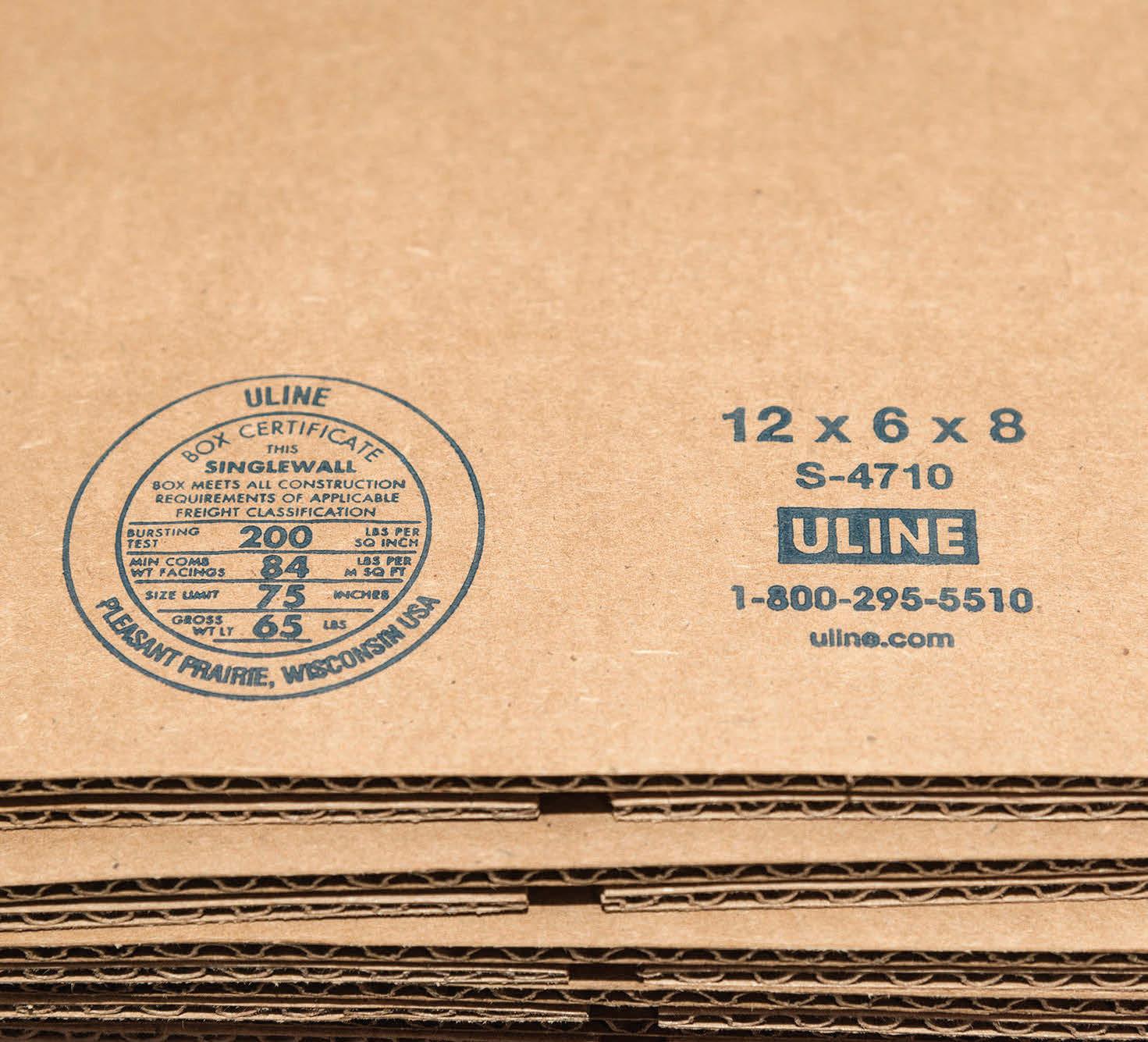

• Model NRCP-5 robotic case-packer, featuring an integrated FANUC six-axis robot with a multipurpose gripper that can both erect and load corrugated cases at up to five various-sized corrugated cases per minute.

≠≠As Motskin relates, the company’s familiarity and comfort levels with newgeneration automation technologies is rooted in the extensive combined engineering knowledge shared by the company’s founding partners—acquired at leading technical institutes and academies of the former Soviet Union—who all moved abroad soon after the country’s 1991 break-up and the outset of a chaotic transition to a market economy.

Adds Michel Elent: “We are rather blessed in having so much engineering knowhow at our disposal.

“Whereas the industry norm is having about 10 per cent of the workforces as engineers, our 16 engineers account for 25 per cent of our staff.

“Having such a strong engineering team gives us a competitive advantage in respect to speedy product development and further refinement of the high-quality case-packers, cartoners, tray-packers and many types of custom products we produce here,” Motskin proclaims.

With the U.S. market accounting for about half of Nuspark’s annual revenues, Elent says he is hopeful that the existing NAFTA (North American Free Trade Agreement) framework remains largely in place in spite of the recent trade tensions between the U.S. and Canada, but adds that the company is well-prepared to weather whatever comes next.

“There is no sense in worrying about something that we cannot control,” he acknowledges. “What we can control is the quality of the machines we make, and we believe that best-built machines will succeed in any market, even under difficult conditions.”

To date, Motskin relates, Nuspark has performed machine installations in 14 countries around the world, including China, India, England, Germany and Israel, with a new installation in Russia scheduled for startup later this year.

To be ready for any packaging challenge that comes along, you need to be at PACK EXPO International 2018 in Chicago. It’s the event that keeps you ahead of the curve and able to innovate, with:

• 2,500+ exhibitors serving 40+ vertical markets

• 1.2 million net square feet of machinery in action—the size of 21 football fields

• Networking with 50,000 of your industry peers

• Over 100 free educational sessions

“One of the things our customers everywhere seem to appreciate about our machines is the aesthetics factor,” Motskin relates.

“With most of our customers being smaller or medium-sized businesses, at some point they will have to show the machine in action to their own customers, and that first impression can be very important for their business relationship from that point on.

“With our equipment design, there is literally nothing to hide.

“Also, the fact that our equipment comes standard with stainless-steel frames really resonates with our customers,” Motskin adds.

Beyond the machinery’s clean streamlined appearance, “The simplicity of use is another key selling point,” he states.

“The way we conceptualize and configure all the automation components in the machine is all geared toward optimal operator-friendliness and elimination of manual steps from the process to achieve greater productivity.

“Our equipment is fundamentally very simple,” Motskin states, “because it has to be.

“For about 90 per cent of the machines we build, the operator will use only one screen to monitor the full process, so it’s not even a full-time job for them.”

tion of continuous improvement and product innovation,” Motskin sums up, “and with the motivated, highly talented workforce at our disposal, there is really no limit to what we can achieve in coming years.

“We have already achieved a lot in a fairly brief time,” he concludes, “but for all intents and purposes we’re really just getting started.”

Please see Nuspark’s packaging machinery and custom-integrated packaging lines in operation on Canadian Packaging TV at www.canadianpackaging.com

Fabbri_2018June_MeatPkgAd_Sausage_CP_Layout

To use an example, Motskin cites a U.S.-based national cream cheese processor who installed a turnkey case-packing solution form Nuspark, comprising two lines, that is capably overseen by a single operator per shift, compared to the four people required to do the job before.

Always keen to stay on top of industry trends, Nuspark is also enhancing its machines with the requisite data sourcing and mining capabilities needed for successful Industry 4.0 methodology implementation, which is being increasingly adopted in the industrial machinery markets.

“This is one of the reasons we decided to standardize all our machines with the B&R industrial PC-based HMIs (human-machine interfaces,” Motskin explains.

“It gives users the flexibility to install any auxiliary software they need to upgrade their systems management, be it to implement a new diagnostics software, to hook up to a database, or to process and analyze incoming machine information.

“The thing about Industry 4.0 is that it all comes down to the user—whether or not they see value in having access to all that information,” Motskin opines.

“On our end, our job is to enable them to have that access should they choose to go that route, and we are doing just that with our industrial PC standardization.

“Naturally, it costs us money to build in this extra level of intelligence into our equipment,” he says, “so it becomes important for us to make sure that the customer sees the value in this upgrade, rather than just as another added cost.

“Manufacturers in many industries can achieve good results from obtaining useful real-time machinery data that will maximize their equipment uptime,” says Motskin, “and what we do is facilitate the effective machine interconnectivity they will need to make it happen.”

This machine interconnectivity becomes an even more important consideration as the company moves to provide more customized turnkey solution incorporating machines and subsystems from other manufacturers and vendors.

“Our company is built on a tradi-

Nuspark Inc.

Bosch Rexroth Canada

FANUC Robotics North America

B&R Industrial Automation Inc.

Schneider Electric Canada

SMC Pneumatics

Festo Inc.

Omron Canada Inc.

SEW-Eurodrive Co. of Canada Ltd.

Fabbri Automatic Stretch Wrappers produce highly attractive packages that make your products look fresh and “just packed”. Fabbri Stretch Wrappers use stretch film to package fresh sausage in preformed trays to provide an in-store wrapped appearance. They employ four-way stretch technology to produce tight, over-the-flange, wrinkle-free packages with securely sealed bottoms and a superb case presentation.

And here’s something you might find even more attractive: Fabbri Stretch Wrappers can help increase your profitability. Fabbri packaging is produced using low-cost packaging materials. And when you factor in its Best in Class low cost of ownership, the Fabbri Stretch Wrapper is your most economical and affordable packaging solution.

Compact and robust servo-driven Fabbri packaging machines are built for speed, versatility and the highest levels of productivity. Fabbri Stretch Wrappers can handle a wide range of tray sizes with no changeovers, producing up to 62 packs per minute. All models feature a user-friendly full-size control panel for easy operation and maintenance. Test the Fabbri at our Reiser Customer Center and see for yourself how it can improve your packaging. Contact Reiser today.

BY GEORGE GUIDONI, EDITOR PHOTOS BT PIERRE LONGTIN

Soaking in sunshine at the Riviera may be a dream holiday for many, but for the industrious folks at Maison Riviera in Sorel-Tracy, Que., work naturally must always come first.

Which is just how it goes for any company operating in today’s fast-growing, but increasingly crowded and fiercely competitive marketplace for premium yogurt products.

So while the privately-owned company is delighted to be approaching its 100th anniversary as an iconic stalwart of Quebec’s ever-evolving dairy industry, it’s been around long enough to know that a proud past is no guarantee of future success in a saturated dairy sector trying to come to grips with rising expectations of modern-day millennial consumers demanding good taste, sound nutrition and ethical brand messaging to come to them in a single package at will.

By any objective measure, though, that’s more or less exactly what Maison Riviera achieved late last year with the winter launch of a new, 40-percent less sugar, lactose free Riviera O% Greek M.F. line of yogurts loaded with rich natural flavors and free of milk fat and artificial sweeteners or additives.

Developed as a worthy follow-up to the company’s multiple award-winning Riviera GMO-Free Set Style yogurts, in addition to well-known distinct single–serving Petit Pot Collection glass jars, the new Greek O% M.F. (milk fat) yogurts check all the boxes for wholesome nutrition, inspired product innovation, and supreme packaging elegance.

Offering rich flavor variety—including raspberry, mango, banana, vanilla and plain—the new Greekstyle yogurts contain 40 per cent less sugar than traditional fat-free Greek yogurts, thereby reducing to caloric intake to 80 calories per 125-gram single serving. And rather than using stevia or artificial sweeteners, Riviera makes sure it uses only perfectly ripe naturally sweet fruit in its products, which is also macerated for a significant length of time before blending to achieve maximum natural sweetness.

Boasting an average 45-day shelf-life, the Greek O% M.F. yogurts are packaged in fully-recyclable 500- and 750-gram plastic tubs decorated with clean simple graphic designed by Montreal-based studio Caroline Reumont Design Inc., which also designed the paperboard sleeves used to nestle the four-packs of 125-gram single-serve plastic Petit Pots topped off with blue colored-flag, foil-lined lidding.

While the company originally decided to use glass 120-gram jars for the Petit Pot Collection yogurts accentuate the products’ premium credentials and authenticity, according to Riviera’s brand manager Kathleen Hébert, switching to 125-gram plastic jars for the Greek O% M.F. line made sense for consumers already having too many jars at home and feeling guilty of putting them in the recycling bin, and from a safety angle, in addition to being able to use the same-sized

of the company’s premium

products such as the reduced-sugar

M.F. product range and the awardwinning Riviera GMO-Free Set Style yogurts, including the single-serving yogurts packed in

lids as the glass bottles.

“Some parents told us they would prefer plastic jars to put in the kids’ lunch-boxes in order to avoid any risk of broken glass,” says Hébert.

That said, the original signature Petit Pot glass jars are not going anywhere soon.

As Hébert relates, the 2015 introduction of glass jars into the market was a resounding success for a company that prides itself of always striving to be a dairy industry trendsetter since it rebranded itself under the Riviera banner back in 1959.

(The original Laiteries Chalifoux creamery was founded by Alexandrina Chalifoux in 1920.)

“As a creator of food trends, we wanted to use a unique container that was not the usual plastic cup,” Hébert recalls.

“Choosing glass helped us to reflect the products’ original European inspiration that you’ll find across all our product ranges,” she explains, “while also projecting a sense of a return to the roots, the recipes of the past, and the good old dishes that grandma used to make.

“Glass really captures the promise of a unique taste experience and sheers the pleasure of eating, especially with the sound of the spoon clinking inside the pot,” she adds.

“Moreover, we wanted to create a continuity in the purchase by offering a product experience that’s not only tasty, but also gives a second life to the packaging.

“Our company is very concerned about environment,” Hébert states, “and for a smaller-sized product like that we thought that glass was the most eco-responsible solution.”

To date, the company has already gathered 1,001 tips, posted online, for reusing Petit Pot jars—covering the whole gamut of reusability from small flowerpots to Christmas decorations, candle holders and so on.

“These jars have become a brand emblem that we hope reinforces consumer

loyalty well after purchase,” says Hébert, noting that the plastic jars maintained exactly the same shapes as their glass counterparts, along with interchangeable color lids.

None of this, of course, would have been possible without considerable capital investment in new processing and packaging capabilities at the yogurt product area of the Sorel-Tracy plant, a fully HACCP (Hazard Analysis and Critical Control Points)-compliant and SQF (Safe Quality Food Institute)-certified facility that also houses the company’s fluid milk and cheese manufacturing operations.

While Riviera’s entry into the yogurt market is a fairly recent development, the company’s enduring presence in regional markets for milk, cream and a wide assortment of specialty cheeses has earned it widespread industry plaudits and acclaim long before then, according to plant manager Normand Champagne.

“Our dairy products are carried by many major retail chains like Loblaws, Sobeys, Metro, Walmart, etc.,” says Champagne, “as well as the smaller independents and specialty niche stores catering to niche consumer demographic segments.

“We also work with three of the country leading food distributors, strategically located in three different provinces, to ensure we cover the largest territory possible in order to reach most Canadian consumers,” Champagne adds.

Marketed nationally under the flagship Riviera brand label, as well as the Laiterie Chalifoux brand name for the local Quebec markets, the company’s extensive product portfolio comprises fresh cheese parfait, plain fresh cheese (a signature French-style fromage blanc), yogurts, creams, curd cheese, cheddar cheeses, Swiss cheese, Parmesan cheese, organic cheeses, and American mozzarella cheese, among others.

Champagne says the company’s expertise and success in other segments of the dairy industry give it a critical competitive edge in the yogurt category, which

continues to outpace growth in all other major dairy segments.

Says Champagne: “Riviera is clearly an innovation leader in the market, keeping its roots linked to French dairy traditions.

“One of our first rule is to always pick fresh, pure, simple and high-quality ingredients over what can be called ‘short cuts’ ingredients.

“Using fresh milk and the best fruit preparations on the market allows us to produce our sugar-reduced yogurts without using any edulcorants or other lowcalorie sweeteners,” Champagne states.

“Eating healthier should not be sacrifice: with our low-sugar yogurts, it remains a treat,” says Champagne, also lavishing praise on the Petit Pot jar packaging.

Competing is such a market naturally requires optimal production efficiencies, which Champagne is confident of optimizing them at the Sorel-Tracy with a fairly extensive range of new equipment installed over the last three years to boost its yogurt output.

“We have a complete range of processing equipment that includes pasteurizers, homogenizer, separators, RO (reverse osmosis) and UF (ultrafiltration) purifiers, cooling cells, cheese vats and yogurt processors,” Champagne relates.

“On the packaging side, we have installed a VFFS (vertical form/fill/seal) system, a flowwrapper, a vacuum-packer, a metal detector, an X-Ray inspection system, cup fillers, a pail filler, a jug filler, and a bulkbag filler.”

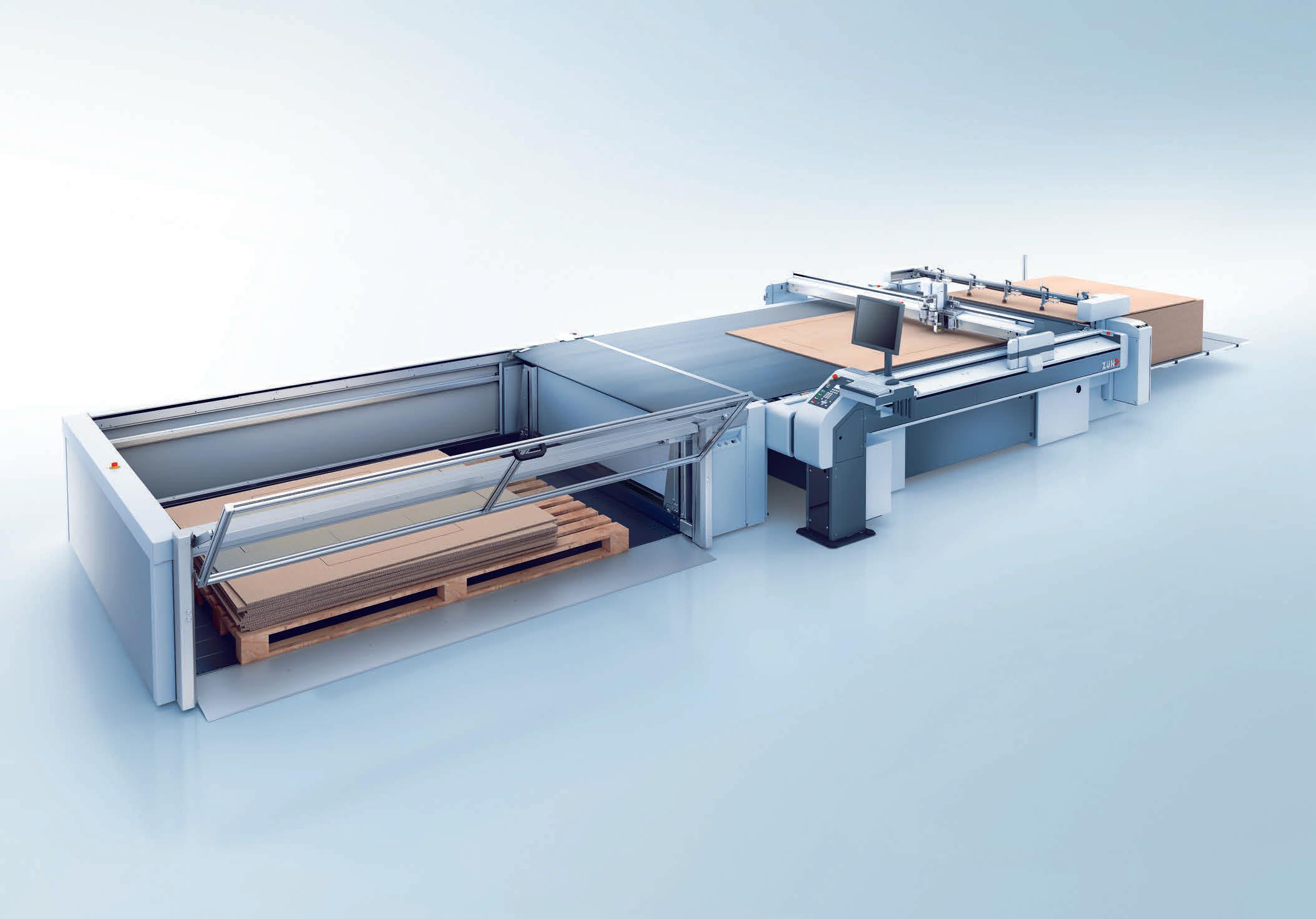

Among most recent installations, Champagne says he is very happy about the arrival of a new Nova volumetric rotary cup filler— manufactured by leading French machine-builder SERAC Group—capable of processing up to 4,000 glass jars per hour, as well as the fully-automatic ARP360 CPS 5 packaging workcell that packs individual jars into secondary-packaging paperboard sleeves to form the finished four-packs of Petit Pot jars at speeds of up to 6,000 units per hour.

“These are two very good machines,” Champagne

states, singling out the ARP360 machine—manufactured in France by Automation Robotic Packaging (ARP) and distributed in Canada by Montrealbased Geosaf Inc.—for special praise.

“It sleeves cups in a pack, prints the pack, and picksand-places the pack into a tray it already has erected, glued ant printed—all in perfectly-timed sequence,” Champagne relates.

“It then stacks the trays and conveys them towards the skid for stacking,” says Champagne, noting that all the corrugated shipping trays are clearly barcoded and printed with the required variable product information applied by an innovative model LCIJ solid wax case-coder manufactured by Markem-Imaje

Using patented hot-melt technology developed by

Manufactured by leading Canadian recycled paper packaging products group Cascades Inc., the corrugated trays used by the Riviera plant to ship its Petit Pot four-packs of yogurt have the product barcode and other required variable product information applied by an LCIJ solid wax case-coder manufactured by leading product coding systems group Markem-Imaje.

Markem-Imaje, the coder uses a special thermal ink formulation, supplied in so–called ‘wax pucks,’ that dries on contact to generate scannable barcodes.

“It generates very neat and legible printing that all our barcode scanners, as well as those of our clients, can read every time,” says Champagne, praising the system’s cost efficiency compared to paper label applicating.

“For us, it offers significant cost-savings over using a print-and-apply system,” he says, “since there is no need for us purchase labels and to maintain a label inventory.”

As Tony Stryker, Markem-Imaje sales manager for Canada, points out: “This technology represents a big cost-savings over labels. While labels normally will cost two to three cents per label, the direct printing method adds up to about one-third to half of that cost at most.

“The savings do not mean compromising quality either: these inks can now provide barcodes that pass the GS1-128 standard (commonly used barcode symbology in food retail) for grade C or higher,” Stryker adds.

“Moreover, the wax-based ink is environmentally safe and harmless, with no fumes, toxic chemicals or overspray to worry about.”

Champagne system says the direct printing system provides a nice finishing touch to all the hard work done by the ARP360 workcell.

“For me, the big three attributes that the ARP system provides are precision, efficiency and service levels,” says Champagne, noting that he has commissioned three ARP system installations in the last six years as plant manager.

“Despite a very high complexity of the application, starting it up always feels like a ‘plug-and-play’

to

operation,” he extols, “with every tiny detail taken into account.”

Geosaf vice-president of project development Jean Dion says he is pleased but not surprised to hear great things about the ARP360 system’s performance since it was fired up at the Riviera plant in July of 2017.

As ARP’s exclusive distributor for North America, Geosaf has already sold four ARP360 systems in Canada and eight in the U.S., Dion relates, describing the systems as “perfect robotic solutions” for busy dairy operators large and small.

“Not only does one ARP360 system essentially replace four machines—a lane diverter or partitioner, a sleever, a case-erector and a case-packer—it is also a very flexible system,” Dion explains. “It has special belt infeed that places the jars precisely where they need to be picked up.

“This provides a buffer to accommodate for any little differences in bottle shape of the bottle, since not all bottles are perfectly round.”

According to Dion, it only takes a few minutes to change over from producing four-packs of Petit Pot jars to two-packs, and virtually no downtime time to switch from glass Petit Pots to their plastic counterparts. Likewise, takes only a few minutes to switch from corrugated trays to full-height corrugated cases.

But above all, “A fully-automatic, high-performance robotic machine like this yields immediate dramatic improvements in productivity levels,” Dion proclaims.

“In addition to saving valuable floorspace, with its compact design, the fully-robotic ARP360 system only requires one operator to run it—instead of four people it used to require at Riviera to run the same process with all the different stand-alone machines.”

For his part, Riviera’s Champagne is keen to extend full credit to Geosaf’s technical staff for its expertly executed installation and startup of the new ARP unit, adding that Geosaf also supplied the plant with high-performance cooling cells manufactured in France by Fromfroid

“In both projects, the Geosaf people were of great help by playing a key role throughout the whole implementation process,” he states. “They have very good technical knowledge; they always keep an eye on our startup timetable; and they always do whatever it takes to make sure that our initial expectations are always met in the end.

“It was great working with them on these projects,” Champagne concludes, “and I look forward to the future ones to come.”

Geosaf Inc.

SERAC Group

Automation Robotic Packaging (ARP)

Caroline Reumont Design Inc.

Storcan International

Cascades Inc.

Markem-Imaje

Nordson Canada, Limited

Technical Adhesives Limited

Schneider Electric Canada

BY PIERRE DESCHAMPS

PHTOS BY PIERRE LONGTIN

While full ‘farm-to-fork’ product traceability remains a highly challenging task for many Canadian agrifood companies mandated to have such a system in place, it is largely a breeze for companies blessed full hands-on control of their farming, processing and distribution operations.

Companies like the Ferme Vallée Verte 1912 (Green Valley Farm), a family-owned and operated natural dairy products manufacturer located in SaintJean-de-Matha, Que., about 100 kilometers northeast of Montreal.

Founded in 1912 by brothers David and Samuel Gadoury, the company has aged very gracefully over the past century and a bit.

Meticulously maintained in its natural state by successive generations of the Gadoury clan, the four hundred acres of prime grazing land owned by the family have proved to be a fruitful ground for the manufacture of all-natural, premium-quality GMO-free products such as fluid milk, artisanal cheeses and yogurts.

Making home for a dairy herd of about 60 Holstein cows—renowned as the world’s highest-production dairy animal—and a few lactating Jersey cows, the land is lovingly cultivated to ensure comfortable walking around for the pampered creatures.

Moreover, the herd is fed a highly nutritious blends of hay, grass legume and forage silage, along with special dairy feed during milking, to promote robust all-natural milk production without the use of any chemicals, pesticides hormones, antibiotics, or the aforementioned genetically-modified organisms (GMOs).

When not wondering around outside, the herd is grouped together in a large building where they lay down not on loose straw, as is customary in the industry, but on sand—giving the cows better comfort keeping the unwelcome bugs, insects and parasites largely at bay.

As company co-owner David Gadoury explains, keeping the animals happy and stress-free lies at the heart of the company’s sustainable farming mindset aimed at ensuring reliable production of superior quality finished products that contain no coloring agents, preservatives or artificial flavors of any kind.

Moreover, Gadoury points out that the cows are not

milked at specific fixed times en masse by a big mechanized milking system that can stress out the animals.

Instead, the cows simply head to one of the two milking robots positioned nearby in the building whenever they themselves feel the need to be milked—all part of the so-called ‘voluntary’ milking process lauded as being much more ethically humane than mechanized mass milking.

“Doing things this way greatly reduces the stress of animals at the time of milking,” Gadoury proclaims, “and with two robots in operation, there is never congestion.

“Moreover, each cow is embedded with a unique microchip to collect all the pertinent data on when each of the cows was milked, the time of milking, and how much milk they produced—both in the morning and in the evening.

“Our two robots have definitely made herd management easier for us,” he says, “and we have all noticed that the animals are generally behaving less nervously than before.”

Once the milk has been collected in desired quantities inside large refrigerated tanks, it is sent directly to the company’s on-site dairy shop and processing facility, where it is bottled after being pasteurized at low temperature—without being ho-

mogenized—or set aside to be used for the production of cheese or yogurt.

Renowned for the superior freshness and wholesome taste of its all-natural products, Ferme Vallée Verte sells its milk—including the 3.8-percent white “milk of yesteryear” and the Choco Milk, made with real cocoa—in custom-made 500-ml and one-liter wide-moth glass bottles topped off with large-diameter tinplate screwcap closures.

Because the milk is never homogenized, there is always a layer of cream forming near the bottle opening, so consumers are advised to give the bottle a good shake before pouring out and enjoying the rich, smooth and wholesome milk boasting luxurious creamy texture and taste profile.

Naturally, the high quality of this milk makes a perfect base for the production of premium-quality yogurts—packaged in 500-ml or 750-ml glass pods—in a diverse array of flavors that includes vanilla, pineapple, blueberry, cherry, strawberry, peach, raspberry, cranberry and plain.

Likewise, the company’s inspired selection of artisanal sweet and flavored cheddars—along with its signature Paramd’Or (parmesan-and-cheddar) offering—make a compelling statement about the virtues of producing delicious dairy products

without any preservatives, colorings or artificial flavors.

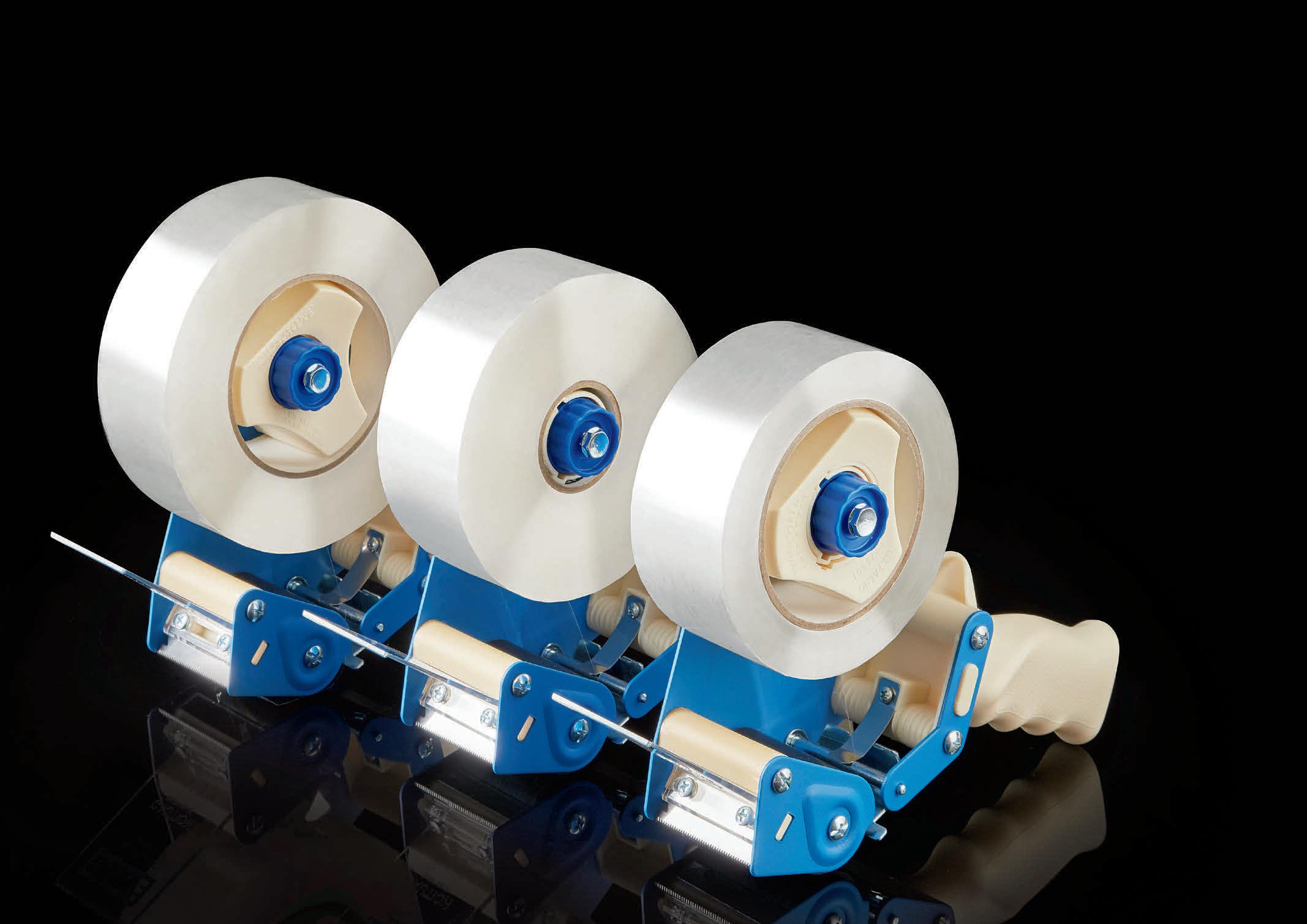

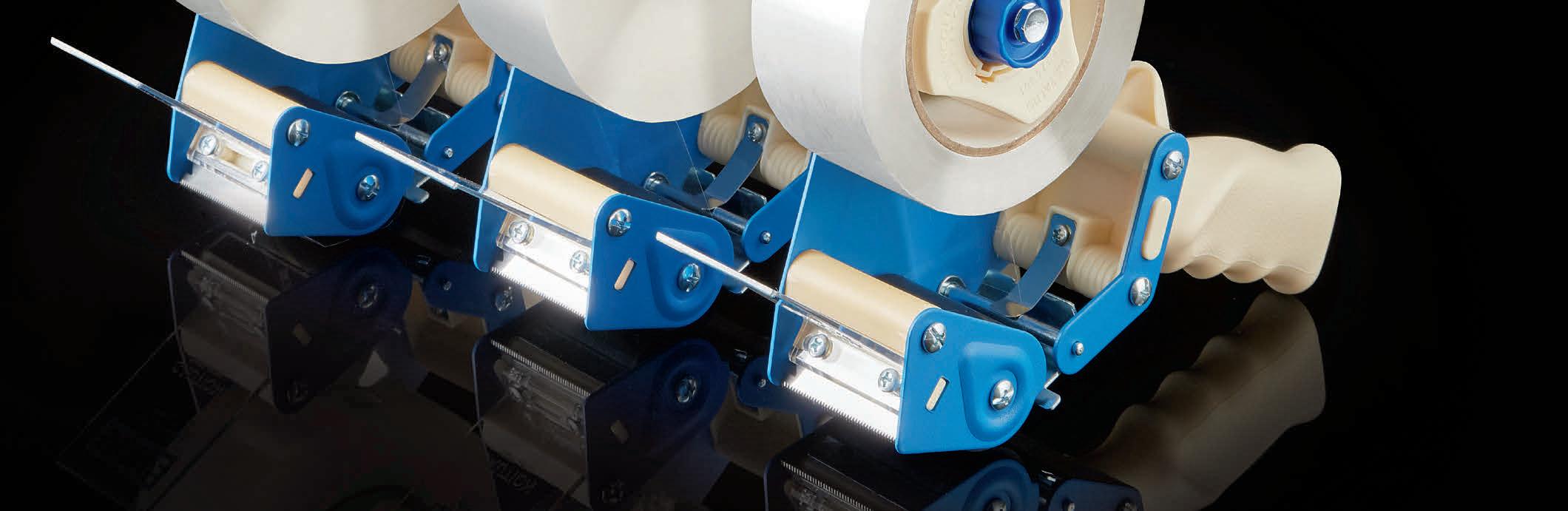

While the sweet cheddars are packaged in 200-, 300- and 600-gram vacuum-packed blocks, the varied flavoured cheeses—including mushroom, beer, pepper, tomato-and-pepper, crushed chilli pepper and garlic-onion-chive—are sold in 125-gram squares, also tightly vacuum-packed in clear see-through plastic to show off the pure natural ingredients to full aesthetic effect.

While the company’s products have long been warmly embraced in the local markets, it has long been constrained in terms of production capacity due to the outdated packaging equipment that it originally sourced from China.

In fact, Gadoury says that Ferme Vallée Verte was only able to use 60 per cent of all the milk its herd produced to manufacture its value-added yogurt and cheese products.

To bridge that gap, while also improving its packaging line efficiencies, the company turned to Montreal-based packaging machine-builder Capmatic Ltd. to come up with a reliable high-performance solution for its packaging needs.

“When we started looking for the new equipment, we initially looked at the machines made in China,” recalls company co-owner Samuel Gadoury.

“But although the pricing was interesting, we had our doubts about whether the quality of the equipment would match our needs and expectations, was the level of what we wanted,” says Gadoury, noting that the original made-in-China equipment rarely performed to his full satisfaction, with many parts of the system wearing out prematurely.

After learning about Capmatic’s stellar industry reputation as an elite manufacturer of stand-alone machines and turnkey packaging solutions the manufacturer supplies to the pharmaceutical, liquid-food and other consumer industries, Gadoury ultimately settled on installing a made-in-Canada solution that also offered impeccable local technical support and servicing capabilities.

“With the manufacturer located Montreal, we felt assured about having quick access to technical support and change parts,” he states.

To get the dairy producer’s packaging operations up to par, Capmatic proceeded to supply several of its high-quality packaging machines, including:

• An eight-head model Accurofill 8 filler—a fullyautomatic inline filling system capable of handling liquid, semi-viscous and viscous products

containing small particles up to halfinch in size.

Equipped with innovative nozzles designed to ensure optimal control of product foaming for high-precision filling, the Accurofill 8 at the Green Valley plant makes light work of packaging either milk or yogurts in 500-ml and oneliter glass jars at speeds of 20 to 40 bottles per minute.

• A Beltstar C capping and tightening system—a high-speed inline screwcap applicator incorporating innovative servo-drive belt systems for secure tightening of caps with superior gripping and precise torque application—ensuring no damage to the caps.

• A Labelstar 2/2 T double-head label applicator, designed to attach front and back pressure-sensitive product labels, with the flexibility to also apply a wraparound labels in 360-degree orientation, on any round bottles, as well as handling square, rectangular or oval bottles, with no change part required.

For the Ferme Vallée Verte installation, the Labelstar 2/2 T was supplied with an integrated Videojet Dataflex 6420 industrial thermal-transfer coder for instant application of all the required production codes and any other required variable product information.

• An automatic bottle dispenser and a 39-inch bottle accumulation table, manufactured by Storcan International, to facilitate uninterrupted process flow.

Says Gadoury: “These are top-of-theline stainless-steel machines manufactured under the highest quality standards anywhere.

“The new Capmatic equipment perfectly matched everything we were looking for,” he says, adding the new systems will play a key role in helping the dairy expand its market reach.

“It will definitely help us to improve the yield rates from our milk production so that not only we’ll be able to continue supplying our existing markets in Lanaudière and Montreal,” he concludes, “but also develop new markets in other parts of Quebec that we have not been

able to service in the past.”

Naturally, such praise is sweet music to the ears of Capmatic president Alioscia Bassani.

“Our objective at Capmatic is to continuously challenge ourselves to ascertain and provide the best solution for our customers, such as Green Alley Farm,” Bassani states.

“We take pride in always delivering the best innovations and the latest technology to help companies of all size to reach their full potential.

“Our passion for excellence is our prime priority,” he concludes, “and we’ll always do whatever it takes, at all costs, to help our customers achieve real success in the markets they serve.”

Capmatic Ltd.

Videojet Technologies, Inc.

SEW-Eurodrive Co. of Canada Ltd.

Uline

Storcan International SUPPLIERS

BY GEORGE GUIDONI, EDITOR

PHOTOS BY NAOMI HILTZ

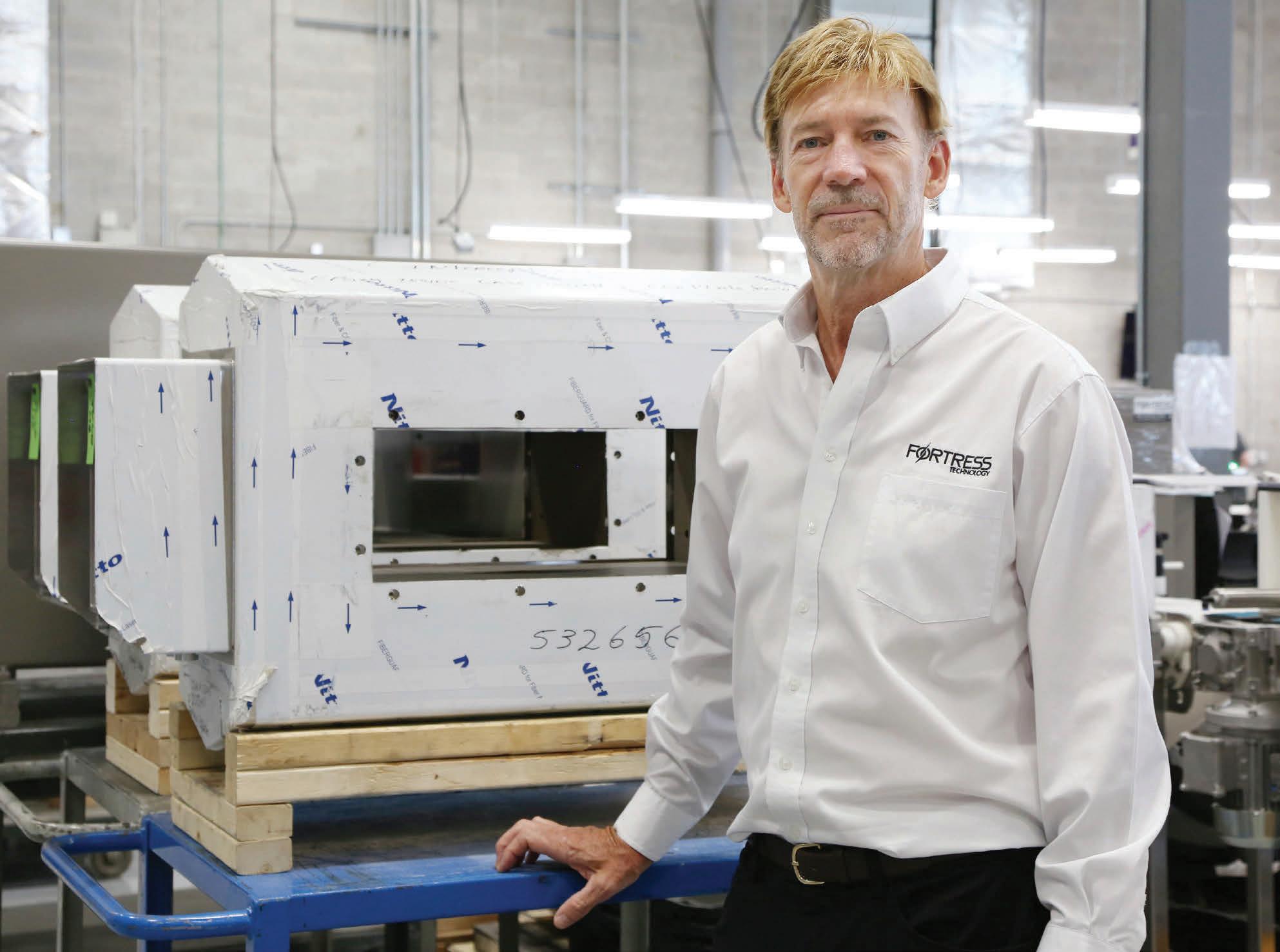

When it comes to food safety, a fortress mentality is undoubtedly a key prerequisite for a sound peaceof-mind insofar as keeping tiny metal particles and other unwanted contaminants from making their way inside a finished package headed for the retail shelf.

Founded in 1996, Toronto-based Fortress Technology Inc. is an embodiment of this uncompromising approach to product protection in the food industry—having shipped thousands of cuttingedge, high-sensitivity metal detection systems to food manufacturers around the world to help them avoid the unwanted glare of public shame and customer distress caused by embarrassing, yet mostly preventable product recalls prompted by unintentional inclusion of tiny metal particles making their way inside the product contents.

For Fortress founder and president Steve Gidman, who literally hand-assembled his first metal detection system in the family home’s garage to help a U.S. sawmill operator detect and remove metal particles from its manufacturing process, the firm’s steadfast ascent to the upper ranks of the global product inspection technologies business is a highly gratifying endorsement of the unique metal detection methodology he developed along with his original business partner Dino Rosatti.

In fact, the original metal detection system he supplied to the aforementioned sawmill is still in operation today, Gidman proudly pointed out during a recent Canadian Packaging visit to the company’s spacious 55,000-square-foot production facility in Toronto’s northeast suburbs.

Started up as a greenfield manufacturing facility back in 2001, the plant has recently been expanded to twice its original size to keep pace with the company’s robust growth and to provide additional amenities for the company’s highly dedicated 170 employees that manufacture about 2,500 metal detection machines per year, according to Gidman.

While Fortress still builds an occasional custommade system for lumber, plastics, textile and other challenging applications, Gidman says that over 75 per cent of its manufacturing output is now focused on production of metal detectors for the food industry—in a broad variety of configurations and designs as required by end-use customers.

Boasting superior sensitivity levels to enable high-precision detection of the smallest ferrous, nonferrous and stainless-steel contaminants, all For-

tress-metal detectors are equipped with many valueadded features and performance attributes to ensure user-friendly operation and full compliance with all the pertinent HACCP (Hazard Analysis Critical Control Points) hygienic and sanitary requirements.

“Everything we make here has to be simple, reliable and high-performance,” says Gidman, parlaying the company’s fundamental design principle as, “Keep it simple, but make it awesome underneath the hood.”

As Gidman explains, “Nearly every metal detector manufactured by us is customized to some extent to address the clients’ specific application needs, be it a single stand-alone metal detector sold to a fledgling specialty food startup or several dozen units shipped to a major multinational.

“We are extremely customer-focused—in large part because it is our customers who often help us develop new ideas all the time,” he relates.

“As a result, we have incredibly loyal customers,” Gidman proclaims, citing “exceptionally high repeat business.

“It is very rare for any of our customers not to

Fortress Technology has recently doubled the size of its manufacturing facility and global headquarters in Toronto to cope with fast-growing demand for its metal detectors.

come back to us at some point after original purchase,” he says, “and that goes for our many smallsized customers as well as some of the biggest food companies on the planet.

“Looking out for our customers is the key to our success.”

This success is amply reflected in the company’s expansive global installation base spanning over 50 countries worldwide and formations of two subsidiary companies to handle the overseas markets,

including Fortress Technology (Europe) Ltd. in the U.K. and Fortress Technology Sistemas de Inspecao Ltda. in Sao Paulo, Brazil.

While Gidman notes that there are plenty of the company’s first-generation Phantom range metal detectors plugging away around the world, capably backed up by the manufacturer’s lauded Never Obsolete Commitment guarantee for continual upgrades and service support, the majority of its machines are nowadays sold under its flagship Stealth series of state-of-the-art metal detectors that includes:

• Stealth Gravity metal detection systems for high-speed inspection of free-flowing granular and powdery dry products such as flour, rice, cereals, powders and sugar;

• Stealth Pipeline metal detectors for liquids, meats, dairy, soups, jams, sauce and paste;

• Stealth Big Bag metal detectors for inspecting large 25-kg to 50-kg bags of flour, grains, spices and other bulk products.

• Stealth Vertex metal detectors for high-speed inline inspection of free-falling chips, snackfoods, popcorn, cereal, etc.;

• Stealth Multi Aperture systems for multilane product inspection of baked goods, meats, prepared meal, fresh and frozen foods, confectioneries and pharmaceutical products.

About three years ago, Fortress launched the allnew Interceptor series of custom-made metal de-

Launched three years ago, the new Interceptor series metal

detector was developed to address challenging applications with ‘wet’ products such as meat and dairy.

tectors designed for addressing the challenging “wet product”applications by optimizing the company’s proprietary Simultaneous Multi-Frequency Technology for processing the transmission and reception of multiple frequencies continuously over a broad

spectrum—achieving virtually 100-percent detection of stainless-steel particles as little as one millimeter in size in various bakery, meat, dairy, prepared meals and fresh-food products.

“The Interceptor shares a lot of the common high-performance functionalities with the Stealth systems,” Gidman explains, “but the base technology it incorporates is a lot more sophisticated, with advanced networking capabilities to boot.

“It’s a very high-performance machine that covers virtually every application,” Gidman says.

“This naturally makes it more expensive than Stealth,” he acknowledges, “but there is no need to use the Interceptor for a great many applications with easy products like crackers, cookies or cereals, which can be easily handled by Stealth for a lot less money.

“The Interceptor is intended specifically for the difficult products like meat, dairy, cheese and other such conductive products that inherently produce a signal that may look like metal.

“For example, a block of cheese will produce a signal that is a thousand times bigger than the target we would be looking for, so the challenge is how to separate that from the process in order to avoid ‘false reject’ readings.

“Essentially, the Interceptor brings a whole new level of performance to the table,” he expands, “by allowing you to see the object from many different

We handle large, small or custom jobs from

points of view to create a more detailed profiles for analysis.

“And it does an amazing job with this.”

While Gidman concedes that he did not foresee the company’s remarkable growth and success in his “wildest dreams” back in the early days, he always held very firm beliefs about the inevitable rapid growth in market demand for metal detection systems in the food industry.

“It seems virtually a no-brainer now,” he reflects, “but things were different in the food industry back then.

“There were metal detectors there 20 years ago of course, but not for everybody. “They were mainly there used by big-brand food manufacturers with a big reputation on the line,” he relates, “so they could justify the investment.

“But today it is the supermarkets and Club stores who dictate the rules on food safety,” says Gidman, hence their food vendors are literally compelled to install metal detectors at their operation just to retain access the shelf space.