Plant Automation focus on Plant Automation

FLOW MEASUREMENT FROM OUTSIDE THE PIPE

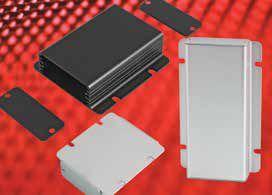

FLANGED EXTRUDED ALUMINUM ENCLOSURE

The U1000MKII-FM from Hoskin Scientific is an ultrasonic permanent/fixed clamp-on flow metering device for measuring flow rate and total flow with a volume pulse output and optional Modbus or 4-20 mA flow proportional output. The product can be used as a standalone meter or as part of an integral management system. The unit is said to be simple to install — connect power and enter the pipe inside diameter into the device, adjust the sensors and clamp-on the pipe —no specialist skills or tools required. A cost-effective alternative to traditional in-line meter installation, plus dry servicing, providing minimum downtime and maximum availability, the company says. Specifications include accuracy of ±1-3% of flow reading for >0.3 m/s, flow velocity range of 0.1 to 10 m/s and water temperature range from 0° to 85°C.

Hoskin Scientific

www.hoskin.ca

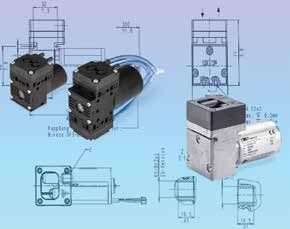

INDUSTRIAL VACUUM/COMPRESSOR PUMPS

The N 630 diaphragm vacuum/ compressor pump series from KNF is available in four versions for use in industrial coolant systems, gas recycling, gas and emissions measurement/analysis, and leak detection across a wide variety of industries, from chemical processing and energy to physics research. The series provides vacuum down to 0.74 inHg, positive pressure up to 174 psig and a flow rate up to 2.4 cfm. The diaphragm gas pumps are available either one- or two-headed and connected in series or parallel, as a vacuum pump, or as a compressor. All models come with EPDM or chemically resistant PTFE-coated diaphragms. Units handle ambient and media temperatures down to 5°C, and head water cooling systems make them suitable for use at ambient and media temperatures up to 60°C. All N 630 pumps are equipped with IP55-rated motors designed to be operated via a variable frequency drive which allows their rotational speed/performance to be set. The transfer rate is stable throughout the pressure range, enabling rapid gas compression inside containers. KNF Neuberger

www.knf.com

The 1455F flanged extruded aluminum enclosures from Hammond Manufacturing add a further variant to the company’s 1455 standard family. The 1455F has an extrusion that features a flat base with integral mounting flanges. The flanges, which extend beyond the body of the unit, have four notches to accept securing screws for mounting the units to a flat surface such as a wall, bulkhead or machine. Two sizes, 80 x 54 x 23 mm and 120 x 54 x 23 mm, are initially available in clear and black anodized finish, with additional sizes to be released over the coming months. The overall width is 77 mm, including the two mounting flanges. Both the launch sizes are designed to accept 50 mm wide, 1.6 mm thick PCBs with lengths of either 80 or 120 mm. There are two removable aluminum end panels, which are flat for easy machining for I/O components. The PCB mounts into horizontal slots in the body of the enclosure; four alternative vertical positions are available. Hammond Manufacturing www.hammondmfg.com

PRESSURE SENSOR WITH SWITCHING FUNCTION

The Vegabar 39 from VEGA is a universal pressure transmitter with a metallic measuring cell for measuring gases, vapours and liquids up 130°C. The pressure of the measured medium acts on a pressure measuring cell, which converts it into an electronic signal. The optional universal connection for hygiene adapters ensures reduced installation effort and leaner stock keeping, the company says. The sensor has a display with on-site operation and coloured 360° switching status indication. Unit signal outputs provide 4-20 mA in the two-wire configuration and the three-wire configuration provides PNP/NPN, 4-20 mA, IO-Link, Ex and approvals that include ATEX, IEC and cULus.

VEGA

www.vega.com/vegabar

As with most industrial control projects, cost is king, but you don’t have to sacri ce quality to keep your budget intact. C-more HMIs are built to last and provide many advanced capabilities, including object animations, logic and math operations, web server/mobile app access, and data logging, all for a surprisingly low price.

C-more Touch Panel HMIs starting at: $487.00 (EA9-T7CL-R)

Now with FREE software!

C-more HMI design software can now be downloaded free-of-charge. Get started on your project today or take it for a test drive.

Download as often as you need. No license or key needed.

Get your copy now at: www.go2adc.com/cmoresw

Research, price, buy at: www.automationdirect.com/cmore

Our shipping policies make it easier than ever to order direct from the

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Orders over $49 get FAST FREE SHIPPING

INTRINSICALLY SAFE DIGITAL CALIBRATOR DOCUMENTS

PRESSURE MEASUREMENTS IN HAZARDOUS AREAS

The FieldLab digital pressure calibrator from Ralston Instruments is an intrinsically safe digital pressure gauge that can perform in Class 1, Division 1, ATEX and IECEx Zone 0 locations. The calibrator can log pressure up to 128 times a second, create pressure logs for hydrostatic testing, log up to 2 million data points and for up to 2 months continuously, perform PSV test in the field or the shop and calibrate pressure gauges with on-screen instructions. Units are available with wireless radio for remote communica-

tion (optional) and in pressure ranges from 15 to 10,000 psi. Features include: IP67 (waterproof to 1 m); PC application for creating tests and downloading data via USB; on-screen keyboard allows entry of multiple tag numbers and test information; comes with 15 pressure units but custom units can be entered; and, companion calibration software allows users to create and manage customized tests and download data.

Ralston Instruments

www.ralstoninst.com

ULTRAPURE PRESSURE REGULATOR WITH SEMICONDUCTOR GRADE KALREZ

Plast-O-Matic Valves has introduced the series UPRS pressure regulator in a full shutoff design. The regulator is available with or without isolated pressure gauge and has an all-thermoplastic fluoropolymer construction. Components are treated with proprietary boil/acid/scavenge cleaning for minimal particle shedding, the company says. The downstream pressure reducing valve features full shutoff design —pressure will not equalize across the regulator in a no-flow condition, it adds. Kynar 740 body and Kalrez FFKM ultrapure grade perfluoroelastomer specification is said to provide the lowest metal ion contamination performance in semiconductor and other high purity applications. BCF spigots are standard and flare, sanitary and other connection types available. Sizes range from 25 to 63 mm and the set pressure ranges from 5 to 100 psi. The series UPRS complements the company’s series UPR non shutoff design to provide the purity in process control for deionized water and other critical applications.

Plast-O-Matic Valves www.plastomatic.com

NEAR IR ONLINE MOISTURE SENSOR INSENSITIVE TO MATERIAL VARIATIONS

The IR-3000 moisture transmitter from MoistTech is the company’s NIR (near infrared) online moisture sensor for non-contact measurement of products and raw materials in harsh environments. Insensitive to material variations such as particle size, material height and colour, the online process moisture analyzer is said to require one-time calibration, is maintenance free, and has a drift free optical design to allow operating personnel to confidently make immediate process adjustments based on real-time measurements. With thousands of measurements per second, the detector allows users to optimize on-line processes and improve product quality, providing both energy savings and potential increased productivity with lower material losses. Applications include conveyors, down chutes, storage bins and fluid-bed dryers. MoistTech www.moisttech.com

Editor’s Forum

Finance Minister Bill Morneau has announced that the Canada Emergency Wage Subsidy (CEWS) will be extended to December 19, 2020 and that the qualifying criteria for the program will be relaxed considerably.

According to the CME and CPCA, these changes to the program will mean any manufacturer that has seen a revenue decline will now be able to benefit from the CEWS. Here are the details of the changes:

The CEWS will be extended past the original August 29, 2020 end date to the new December 19, 2020 end date.

Going forward, a business can qualify by showing any decline in revenue. The CEWS will now consist of two parts:

A base subsidy available to all eligible employers that are experiencing a decline in revenues, with the subsidy amount varying depending on the scale of revenue decline; and

A top-up subsidy of up to an additional 25% for those employers that have been most adversely affected by the COVID-19 crisis.

The government must get these amendments passed by parliament.

A draft piece of legislation has been shared with opposition parties and they are expected to vote on it next week. There is a “Safe Harbour” rule for CEWS periods 5 and 6. An employer who qualified for the 75% subsidy rate previously will not see their subsidy rate lowered because of the new rules.

For more new details, go to https:// bit.ly/39BF37V to see if your company now qualifies and to calculate its subsidy rate.

Mike Edwards medwards@cpecn.com

Founder

DIFFERENTIAL PRESSURE FLOW METERS

Orange Research fully integrated differential pressure flow meters from Cameron Instruments are said to be compact and rugged, with directly connected, large throated, non-clogging flow nozzles. The design reduces size and cost while minimizing errors and leaks, the company says. Simply select the flow rate and material, and the meter is ready — there is no need to choose a primary flow element, a differential pressure gauge, and then piping, it adds. Flow meter features include: 3.5 in. dial; 1/2, 1 and 2 in. NPT ports; and, brass, stainless steel, or aluminum bodies. Differential pressure flow meter Reed switches can accompany the meters. SPST switches are offered normally open (NO) or normally closed (NC). SPDT reed switches also are available.

Cameron Instruments www.cameroninstruments.com

BLUETOOTH UPGRADE FOR LEVEL MEASUREMENT DEVICES

PANEL METERS FOR PULSE/FREQUENCY DISPLAY

ProSense digital panel meters in 1/32 and 1/8 DIN sizes from AutomationDirect feature IP65-rated meter faces, simple menu-driven pushbutton configuration, and accept a wide variety of process inputs. Red, green or amber, 4 and 5-digit LED displays are available depending on model. All panels offer selectable decimal point location. Available input options include analog, temperature, AC/DC current and voltage, and pulse/frequency inputs. The new pulse/frequency input models are said to offer a simple, low cost digital display for frequency, tachometer, and rate applications. These pulse/frequency units accept input from AC voltage, magnetic sensors, NPN/PNP sensors, NAMUR sensors, TTL/24V encoders, or switched contacts, and provide selectable sensor excitation voltages. Process display options include analog process signals, load cell, or potentiometer inputs, and temperature inputs in either °F or °C from RTDs or thermocouples. Inputs from electrical parameters such as AC or DC voltage and amperage, as well as pulse and frequency inputs, are also available. Available output options include alarm relays, analog signal re-transmission, and sensor excitation voltage.

AutomationDirect

www.automationdirect.com

Ralston ControlPak

The Bluetooth upgrade for Endress+Hauser radar level measurement instruments is said to make it fast and simple to remotely commission one of these instruments or monitor their device, diagnostic and process data via an app on a standard smartphone or tablet. The upgrade is available for all FMR5x, FMR6x and FMP5x series devices with up-to-date HART 7 firmware. The instruments are used for continuous non-contact level measurement in a wide range of applications. The FMP5x series, for example, used for purposes such as assuring measuring for dry run protection and for providing overfill protection and range monitoring. The Bluetooth upgrade consists of the company’s Bluetooth module BT10 inserted in the CDI slot of an installed base in the field, and its SmartBlue App. Installation of the module is a three-step procedure that doesn’t require special expertise or tools. Bluetooth has a read range of up to 10 metres, so employees can generate readings from radar instruments — especially those located in hazardous or difficult-to-access places — from a safe distance. Endress+Hauser Canada www.ca.endress.com

Manual Pressure Controller

Precision manual pressure controller built for the way you work

• Engineered specifically for calibrating pressure instruments with compressed gas in the field

• Compact and portable — controls are in one light-weight, compact unit with included storage space for hoses, adapters and accessories

COMPACT PUMPS FOR SKIDS, SYSTEMS AND DOSING APPLICATIONS

The compact Wilden Velocity series from John Brooks Company are air-operated double-diaphragm (AODD) pumps. Featuring a detachable mounting foot, the pumps are said to easily be reoriented into a vertical or horizontal position with multiple inlet and discharge port options. The series also features a bore-seal design to eliminate the effects of torque decay and has a dry suction lift capability up to 5.1 m for better priming under a wide variety of system conditions, the company says. Applications for the 4-port design include, chemical dosing, paints and inks, surface treatment, clean-in-place (CIP) systems, additive injection and sampling. Watch demonstration video at https://youtu.be/jV7m7zmLVz4. John Brooks Company www.johnbrooks.ca

• Extremely precise, finger-tip control of pressure at 0.03 psi (2 mbar) to 3,000 psi (210 bar) with the pressure-balanced, fine adjustment piston

• Rugged and durable plastic case that will stand up to use in the mud, sun, and cold weather better than bench-mounted volume controllers

• Quick setup and breakdown with Ralston Quick-test™ hand-tightening outlet connections, hoses and adapters — without the need for thread sealant or a wrench

Visit ralstoninst.com/cpn-cp or scan the QR code to find out more +1-440-564-1430 | (US/CA) 800-347-6575

Proactive discontinuation management ensures long-term line operation

Supplier component discontinuation is a proactive service that prevents costly machine downtimes at beverage plants and safeguards the long service lives of its filling and packaging machinery.

With the availability of significant components becoming ever shorter, the KHS Group’s discontinuation management scheme makes sure plant equipment stays up and running. This topic is gaining in importance in our digital age, the company says, where electronic components have shorter product life cycles. KHS notes that it not only brings its systems into line with the state of the art — operators also benefit from increased machine efficiency thanks to the use of new technologies.

The service proactively tackles the problem of supplier components no longer being available and having to be replaced by new solutions.

“We support our partners with our knowledge of any technical changes required to make sure that machinery continues to function, and production runs smoothly at beverage bottling plant,” says Klaus Thatenhorst, head of the Standards Department at KHS. “By replacing the necessary components in good time, we ensure that our machines have long service lives and are thus sustainable.”

KHS says it is able to react fast to any changes thanks to its holistic system of data management. Through this the systems supplier always knows which part on which machine belonging to which customer is likely to be affected by a discontinuation. This shortens response times should new components be needed. This is especially relevant when modifications have to be made to the machine’s engineering. In 2019, for example, 1,700

discontinuation solutions had to be found. Half of these required much more than a simple replacement, with intensive technical work necessary.

So that it is better prepared for the possible discontinuation of system parts, KHS is in regular close contact with its suppliers. It is already common knowledge, for instance, that robot manufacturer KUKA will only be supplying its current KR C2 controller until 2024; this has an impact on two series of KHS palletizers, among other machinery. The engineering company is thus preparing itself and its customers for the pending conversion well in advance. The KHS Group is also able to offer fast and flexible systems and solutions for short-term discontinuations. Its parts management system stocks replacements for as long as possible for precisely this purpose.

This may all initially sound like an expensive and time-consuming undertaking for the bottler, yet it yields great benefits on several counts. By changing components quickly, the systems provider avoids unplanned downtimes over a longer period of time caused by the failure of a part no longer available. Furthermore, beverage producers can sometimes even improve line efficien-

cy by installing new replacement components and at the same time carry out other useful upgrades. When converting a machine, KHS Service not only removes and replaces discontinued components but also takes them back and reworks them.

In our digital day and age discontinuation management is an issue which is becoming increasingly important. While mechanical parts such as gear motors are usually available for up to ten years, according to the German Mechanical Engineering Industry Association (VDMA) some electronic components last just two years. Accordingly, the number of replacements for comparable parts required as a result of discontinuation is already currently increasing at shorter and shorter intervals.

This article was contributed by KHS Group of Dortmund, Germany. The company has a Canadian sales office in Toronto.

The KR C2 controller for KUKA palletizing robots will only be available until 2024. KHS is already preparing itself and its customers for the necessary machine conversion.

Klaus Thatenhorst

As Distributed Control Systems (DCS) age, there can be increasing risks to the process manufacturer. An old or obsolete DCS system may no longer be supported by the original supplier, spare parts may no longer be readily available, and system performance issues may begin to appear. With some DCS systems now decades old, system users often know they need to upgrade but find the task daunting given the cost and potential for disruption of operations while the new system is brought online.

Even if process manufactures have installed newer equipment alongside legacy components, there can be considerable challenges maintaining disparate legacy systems, associated spare parts and the different skill sets required to support multiple control system platforms. This can lead to “islands of automation” that diminish the effectiveness of a user to integrate, control and optimize the entire process from beginning to end. It may be that the system user has simply outgrown the existing control system due to increased production demands and/ or newly added processes.

“Most process manufacturers are looking to maximize their automation investments and run them as long as they can before upgrading or replacing,” explains Dwight Wood, VP Global Sales for Owings Mills, MD-based NovaTech LLC Process Division whose D/3 DCS system solution was introduced 38 years ago as the first hybrid batch and continuous control architecture. “A

number of process manufacturers have come to us with I/O, controllers and even servers that are 30 to 40 years old.”

When process manufacturers ultimately decide to move forward on an upgrade, however, they often find that their DCS supplier has implemented a new generation of technology that lacks a cost and mission effective migration path to update the existing system often requiring a rewrite of applications programming or a complete “rip and replace.”

turing execution level and/or the enterprise ERP level.”

A DCS system is a hub of a processor’s operations monitoring key variables such as flow, applied temperatures, pressure, level and material conveying/handling. The operator user interface brings all the data that is collected from production equipment and the controllers process and present it in a highly “human factored” manner for an operator, generating trends, alarms, etc.

data from multiple plant sites from anywhere in the world.

A DCS replacement is a significant investment that is designed as a long-term contribution to operations. Two key considerations are the system’s migration path and the overall DCS lifecycle cost.

“A DCS sits on top of an inherently dynamic processing environment made more so as new equipment is added, production lines are expanded, and as issues like obsolescence and cybersecurity present new challenges over time,” explains Wood.

Fortunately, ripping and replacing a dead-ended DCS system is not required. “Addressing the vulnerabilities that are present with a legacy DCS does not always require a disruptive all-at-once approach,” says Wood. “For a plant of any scale running at or near capacity, taking down processing lines for any amount of time can be extremely expensive in terms of lost production and business impact.”

Instead, many engineering, operations and procurement teams are opting for a multi-stage implementation over a total system overhaul by phasing in newer DCS servers, controllers and applications. This approach is more affordable and less disruptive, while still allowing gaps, points of pain and cybersecurity risks to be addressed immediately.

The multi-stage migration approach can often begin by integrating new DCS components with new and existing I/O devices. As I/O is one of the most significant investments in an automation upgrade, I/O drops can be replaced in a phased manner over time allowing for spare parts capture from decommissioned drops, phased implementation aligned with plant outage limitations and staggered financial investment.

Another consideration is the need to integrate the DCS system with the existing enterprise systems. “Customers want more than an effective implementation of the Level 2 automation system,” says Wood. “They often want improved data capture and the conversion of that data into useful knowledge presented in desktop KPI dashboards that can be utilized at the manufac-

Standard Operating Procedures, maintenance records, and other information are also available in desktop application formats. The information can be viewed using common Web browsers to display

“That is easier to navigate if there is a well-defined system life cycle plan and migration path forward that includes a carefully thought-out execution plan for success.”

This article was contributed by NovaTech.

NovaTech LLC www.novatechweb.com

traceability ensured with

Improve your plant availability, and ensure quality with optimized calibration

• Traceable on-site and laboratory calibration of various parameters

• We are a leading manufacturer of process instrumentation – uniquely qualified to calibrate

• Our global, harmonized calibration standards provide consistent service quality

Wood: "replacing an old DCS does not always require a disruptive all-at-once approach." (PCM 4200 Process Control Module shown)

Dwight Wood

MOTOR CONTROL RELAYS AND

Swagelok has announced the release of the full-bore, bidirectional flow-capable GB series ball valve. The valve is engineered to provide flow rates at a working pressure of 6000 psig while simplifying installation, the company says, minimizing rework requirements, and delivering the reliable shutoff performance. The ball valve can be widely deployed as a general-purpose ball valve. Examples of applications include: hydraulic, injection and fire suppression systems in the oil and gas industry; and

isolation in highly corrosive alkylation operations in the chemical and petrochemical industry. The series ball valve is available in a variety of alloy materials such as 6-Moly, Alloy 2507, and Alloy C-276, as well as materials selected in accordance with NACE MR0175 for sour gas applications. The valve also complies with ASME B31.1 and B31.3 standards for power and process piping systems. Swagelok Central Ontario https://centralontario.swagelok.com

The Full Gauge MT-543E LOG temperature controller from Ecotherm has four configurable outputs: cooling, heating, minimum ventilation, and alarm and timer (cyclic). It has an internal audible alarm (buzzer), a configurable digital filter, and accept three types of sensors: NTC thermistor (-50° to 105°C), PT100, and PT1000 (-99° to 300°C). The instrument provides for the rotation of up to four devices. The controller also has a fifth relay that can be used as a power fault alarm and/or alert. In addition, it features a clock and internal memory (datalogger), which allows storage of the temperature

value at specified periods of time, the variation of temperature and the status of the outputs. It also features a built-in rechargeable battery, which allows the data recorded to be kept even after a power fault. The unit also allows monitoring of HACCP critical points by means of records in the controller’s memory of high temperature alarm, power failure, and digital input. The product offers Sitrad serial communication and is UL certified. For a video demonstration, watch https://youtu.be/6LnjXde4_Sc. Ecotherm www.ecotherm.ca

The Dräger X-am 8000 personal gas detector from Draeger Safety Canada simultaneously measures up to 7 toxic/flammable gases (including benzene), as well as vapours and oxygen, either in pump or diffusion mode. For benzene-specific measurements, the instrument can be used with a PID (pre-tube). The use of pretubes is supported by the detector’s wizard, a built-in assistant that guides users through each process step by step. The gas detector also has built-in assistants (wizards) for clearance measurements and leak detection.

Draeger Safety Canada www.draeger.com

ADAPTERS FOR DIAPHRAGM VALVES

With static GEMÜ PPF (pressure, passivation, flushing) multifunction adapters in 1.4435 stainless steel, the penetration of foreign particles during the installation of diaphragm valves is said to be prevented. Immediately following disassembly of the actuator and diaphragm, the adapter is mounted on the valve body, thereby offering protection for the seat. The adapter must be removed after installation is complete but before sterilization of the plant. The sealing over the weir and to the outside is created by an EPDM seal, which is approved according to FDA and USP Class VI. The fixing method uses four screws, or for a diaphragm size 100, eight screws. After the multifunction adapter has been mounted on the valve body, this can be used as a weld gas pipeline for welding the body. The subsequent introduction or conveying of the passivation media to protect the surface against corrosion can also be performed via an adapter. The reusable adapters have been designed for various membrane sizes and are available from diaphragm sizes MG 8 to MG 100.

GEMÜ Valves Canada

www.gemu.com

The MT300 three channel transformer temperature monitor and alarm system from Mod-Tronic controls three relay outputs based on user-programmable set points to help safeguard expensive transformers and machinery. The unit provides users a programmable transformer temperature monitor and alarm with improved measurement range of -50° to 300°C and universal inputs of either 100Ω or 1000Ω Platinum RTDs or Types E or K thermocouples. The system is said to maintains accuracy over a wide range of tempera-

tures and conducts regular self-checks to ensure correct operation. Additionally, one of the relay outputs is designed for control of a cooling fan with a 30 A rating. The user-configurable fan exercise option extends the fan life and reduces bearing lock-up. The monitor can be configured via Modbus over a USB connection to your PC or Modbus/RS-485 using the included PC software that also provides data logging. Mod-Tronic Instruments www.mod-tronic.com

Screw Conveyor Corporation has published its new bucket elevator catalog. The bucket elevators are used in industrial and agricultural environments. The catalog presents information on both the company’s centrifugal and continuous bucket elevator models. Included is a segment on how to select the proper elevator for the application as well as complete specifications. The bucket elevators feature capacities from 290 to 6929 cubic feet per hour (10 to 260 tons per hour) in heights from 12 to 200 ft. Non-abrasive or highly abrasive materials can be conveyed in a wide variety of temperatures. Belt driven and chain driven models are available, depending on application. A bucket elevator data sheet can be filled out and sent in to the company help find the right elevator for the application and ease the quoting process.

Screw Conveyor Corporation

www.screwconveyor.com

Yokogawa has introduced the TDLS8100 probe type tunable diode laser gas analyzer that continues to house the features from the TDLS8000, but now only requiring a single-flange installation. An in-situ measurement with a probe removes the requirement for sample extraction and conditioning and can be used in a variety of aggressive process conditions. Built upon the company’s second generation of TDLS analyzers, the platform still retains its improved reliability, ease of installation, and reduced maintenance requirements, the company says, but now does so with a lower total installed cost for O2, CO/CH4, and NH3 measurements. The single-flange design allows for installations where cross-duct TDLS technology was not feasible due to obstructions or accessibility issues. Onboard diagnostics with 50 days of data and spectral storage are said to ensure that minor issues can be identified before they become more serious problems. Units are explosion proof/flame proof for installation in CID1/Z1 or CID2/Z2 areas. HART and Modbus TCP are standard to maximize remote diagnostics and configuration capabilities with a single cable run. Yokogawa Canada www.yokogawa.com

Dust-Tight Grate-In-Housing

Eriez’ new Easy to Clean DSC (Dust-tight, Sanitary, Convertible) Grate-in-Housing Magnet combines the industry’s most powerful Rare Earth RE7 magnetic circuit with a new dust-tight housing design. Ideal for containment of fine powders and easily upgraded to automatic cleaning.

Industry News

BEAMEX OPENS CALIBRATION SUBSIDIARY IN CANADA

Beamex has announced the expansion of its services into Canada. Beamex Calibration Solutions Ltd., a new subsidiary based in Toronto, will be led by Tom Sonntag, president of Beamex Canada.

“There is an established process and engineering industry in Canada covering the core industries that we operate in such as pharma, oil and gas, power and energy, and mining," says Sonntag.

"We see a lot of synergies and interesting business opportunities here,” according to Tom Sonntag, president of Beamex Canada.

Beamex Oy is headquartered in Pietarsaari, Finland, and offers a wide range of products and services, from portable calibrators to workstations, calibration accessories, calibration software, industry-specific solutions and professional services.

Beamex Canada

www.beamex.com

HOSKIN PARTNERS WITH TRANSDUCER SPECIALIST KULITE

Kulite Semiconductor Products of Leonia, NJ, a transducers and pressure scanners developer and manufacturer for many industries, applications and environmental conditions, including process control, has partnered with Hoskin Scientific to sell Kulite products in Canada. In business over 60 years, Kulite holds over 350 patents. Hoskin operates out of offices in Burnaby, BC, Oakville, ON, Saint-Laurent, QC, and Edmonton.

Hoskin Scientific www.hoskin.ca

YOKOGAWA CANADA ADDED TO SUMMIT PRODUCT LINEUP

Summit Valve and Controls has announced the addition of Yokogawa Canada to its product lineup. Yokogawa is said to offer a complete line of instrumentation products and process control solutions that will complement Summit’s existing portfolio of instrumentation and valve automation solutions. Summit notes that Yokogawa provides equipment for analytical, control, data acquisition, flow, pressure, and temperature for industries such as oil & gas, petrochemical, pulp & paper, mining, chemical, food and beverage, water and wastewater, and power.

Summit says it looks forward to working with the Calgary-based Yokogawa Canada team to grow the company’s line in Western Canada.

Summit is based in Edmonton, with locations in Saskatoon, Winnipeg and Port Coquitlam, BC.

Summit Valve and Controls www.summitvalve.com

ENDRESS+HAUSER 2019 INCREASES LEAVE COMPANY PREPARED FOR PANDEMIC DISRUPTIONS

Endress+Hauser, a measurement and automation technology supplier for process and laboratory applications based in Reinach, Switzerland, states that it performed well across all fields of activity, industries and regions in 2019.

The Endress+Hauser Group reports that it created hundreds of new jobs, invested record amounts and improved in the area of sustainability. According to CEO Matthias Altendorf, the family company is thus in a strong position to address the challenges of the coronavirus crisis.

“2019 was a solid year for Endress+Hauser,” emphasized Altendorf. “Growth was broadbased and balanced.”

The measurement and automation technology specialist for process and laboratory applications increased net sales by 8.0 percent to €2.652 billion, despite a weakening global economy. During the annual media conference on financial statements in Basel, the CEO explained that instead of largescale orders, this growth was driven by smaller and medium-sized projects.

According to the CEO, this success is also tied to the company’s undiminished innovative spirit. In 2019 Endress+Hauser filed 318 patent applications and invested 7.6 percent of sales in research and development. More than 1,100 people are working on new products, solutions and services. By the end of 2019 Endress+Hauser had 14,328 employees worldwide, including Endress+Hauser based in Burlington, ON.

Endress+Hauser started 2020 with a further increase in incoming orders. However, the coronavirus pandemic makes it massively more difficult to achieve the original goals, the company says. “Although we are still unable to predict the economic impacts of the crisis, we and our customers will certainly feel the effects,” underlined Altendorf. The group responded early to the spread of the virus and used all means at its disposal to protect people’s health and continue to offer customers solid support.

“We bridge the physical distance through digital and emotional proximity,” said Altendorf. The CEO has been driving digitization at Endress+Hauser for years — in the product and services areas, as well as in customer interaction and internal collaboration. At peak periods, up to 10,000 employees are currently working from home. Customers can use the website to order instruments or track orders, and an online tool enables remote support aided by video.

“Our everyday heroes are those working in production, logistics and service, or under difficult conditions from home or in the office,” said Altendorf. Through hard work, the company has been successful in ensuring the availability of materials, keeping the logistics chains intact and supporting customers in all

respects. “The group’s plants are operating, and Endress+Hauser is still able to deliver.” The CEO therefore believes that the company is well prepared for difficult times.

Endress+Hauser devices, solutions and services are said to be at home in many industries. Customers use them to gain valuable knowledge from their applications. This enables them to improve their products, work economically and at the same time protect people and the environment, company says.

Endress+Hauser has its own sales companies in 50 countries as well as representatives in another 70 countries, as well as production facilities on five continents. The company was founded in 1953 and holds 8,000 patents and applications to protect the group’s intellectual property. Endress+Hauser Canada www.ca.endress.com

Endress+Hauser champions technical education amongst its workforce and customers.

Matthias Altendorf

Tom Sonntag

Industry News

WORLD’S LARGEST CAPACITY CO2 PIPELINE OPENS IN AB

The Alberta Carbon Trunk Line (ACTL) system, the world’s newest — and said to be the largest capacity — carbon capture, utilization, and storage (CCUS) project, is now fully operational. The ACTL system captures industrial emissions and delivers the CO2 to mature oil and gas reservoirs in Central Alberta for use in enhanced oil recovery and permanent storage.

The current supply of CO2 is captured at the North West Redwater Partnership (NWR) Sturgeon Refinery and the Nutrien Redwater Fertilizer Facility, offering a sustainable emissions solution for energy and agriculture sectors.

The initial supply of CO2 is captured and compressed from the bitumen refinery and a fertilizer plant. The CO2 then travels down a 240-kilometre pipeline, which is owned by Wolf Midstream, to a storage reservoir owned by Enhance Energy

The system includes the world’s largest capacity pipeline for CO2 from human activity, capable of transporting up to 14.6 million tonnes of CO2 per year. This is equal to the impact of capturing the CO2 from more than 2.6 million cars in Alberta. Designed with excess capacity, the system will connect more facilities and storage reservoirs in the future as demand increases for an effective solution to manage emissions.

Alberta Carbon Trunk Line

www.actl.ca

TRANS MOUNTAIN EXPANSION STARTS IN KAMLOOPS

Trans Mountain Corp. of Calgary has kicked off pipeline construction in British Columbia with work beginning in the City of Kamloops. Construction preparation has begun for the Kamloops Urban Area (KUA) pipeline section that is 7 km in length and will take approximately 7 months to complete.

Working co-operatively with the Kamloops Accommodations Association, Trans Mountain has identified local hotel and service providers who have confirmed their ability to meet the COVID-19 measures we require including food service, extra cleaning requirements and a dedicated area for our workforce to get COVID-19 screening before they go to the worksite.

Construction spending in the Kamloops area is expected to be more than $450 million over the next two years with additional workforce spending of more than $40 million for goods and services at local businesses.

Trans Mountain has signed a Community Benefit Agreement (CBA) with the City of Kamloops that will see a $700,000 contribution toward funding community projects.

Trans Mountain also has a partnership with Thompson Rivers University in Kamloops that will see a $500,000 contribution over 20 years toward funding annual awards for students in Trades, Social Work and Applied Research programs, and the Environmental Science graduate program.

Trans Mountain also has a Mutual Benefits Agreement (MBA) with the Tk’emlúps te Secwépemc nation that will provide significant employment and business benefits for the community. Trans Mountain Corp. www.transmountain.com

NEW PEO PRESIDENT AND GOVERNING COUNCIL INTRODUCED AT VIRTUAL AGM

Toronto-based Professional Engineers Ontario (PEO), the licensing and regulating body for professional engineers and engineering in the province, has installed Marisa Sterling, P.Eng., FEC, as its 101st president and eighth woman to lead its council during its virtual annual general meeting (AGM) on May 30.

Committed to promoting inclusion and modernization within the engineering profession, Sterling has over 20 years of experience working and volunteering in the engineering field, in both the private and public sectors. She is currently the assistant dean and director of diversity, inclusion and professionalism, at the University of Toronto’s Faculty of Applied Science and Engineering. Professional Engineers Ontario www.peo.ca

RITTAL EXPANDS PARTNERSHIPS WITH AZTEC ELECTRICAL AND FRANKLIN EMPIRE

Rittal Systems has welcomed Franklin Empire to its distribution/ partner network in Quebec. In 2017, Rittal also added Franklin Empire of Toronto to its network in Ontario.

Franklin Empire is said to be the largest independently owned electrical distributor in Canada, with over 500 employees and an inventory investment exceeding $35 million. In Quebec and Ontario, it has 23 branch locations and five assembly and repair shops.

In addition, Aztec Electrical Supply, a Rittal System electrical and automation distributor based in Concord, ON, has enhanced its enclosure modification capabilities. Aztec has acquired a Perforex machining centre, which can be deployed for drilling, thread tapping, wiring and milling when machining enclosures and panels of all sizes.

Aztec has a team of trained staff well versed with the operation of the Perforex, to be able to modify enclosures in record time, leading to cost-effective production and enhanced quality, while adding repeatability to processes and reducing lead-times for customers.

The Perforex machine enables 10 hours of typical panel production work to be completed in 90 minutes. It delivers not only time savings but increased accuracy and reduced waste with its CNC precision-capabilities, Rittal says. Rittal Systems

www.rittal.ca

Marisa Sterling

Above: Aztec's Perforex machine customizes enclosures from Rittal Systems.

Below: Order fulfillment at Franklin Empire distribution centre. The distributor will expand Rittal's reach into the Quebec marketplace.

Pipeline workers will be screened for COVID-19.

ROTORK ACTUATORS INSTALLED ON CANADIAN WELL PADS

Rotork Controls Canada of Mississauga, ON, has announced that over 80 Rotork model CP, GP and RC200 pneumatic actuators have been installed on well pads in Alberta, where they will be part of an in situ steam assisted gravity drainage (SAGD) oil sand extraction project.

SAGD technology is used to extract bitumen oil from 800 m below the surface of the earth. The process is a form of steam stimulation in which two horizontal wells drill into an oil reservoir, one a few metres above the other. High pressure steam is continuously injected into the upper wellbore to heat the oil and reduce its viscosity. The heated oil then drains into the lower wellbore where it can be pumped out. The water and oil are taken to a separation facility, where the water is then taken, recycled and re-converted into steam so the process can begin again. Rotork Controls Canada

www.rotork.com

ALBERTA EARMARKS $150M FOR WATER INFRASTRUCTURE GRANTS

The Alberta Municipal/Wastewater Partnership has announced close to $150 million in grants for 55 water and wastewater improvement projects. Of the total amount $137 million has been allocated for 54 projects, with $13 million for the First Nations Water Tie-in Program to support a water tie-in program for the Ermineskin Cree Nation to the Ponoka regional water pipeline.

The grants support improvements to water supply and treatment facilities, and upgrades to wastewater services, including lagoons, berms and sewage treatment.

Alberta Municipal/Wastewater Partnership www.alberta.ca

JORDAN BAST NAMED NEW RICHARDS INDUSTRIALS CEO

The board of directors at Richards Industrials of Cincinnati has appointed Jordan Bast as president and CEO. Bast brings a wealth of knowledge and experience in the valve industry on national and global levels, the company says, and has experience across process industries and discrete manufacturing.

Bast will succeed Bruce Broxterman, who is retiring after fifteen years as president/CEO but will remain a member of the board of directors. Broxterman is excited for this new chapter and says “Bast has the leadership skills, extensive experience and passion that perfectly positions him to lead Richards forward.”

Richards Industrials product lines include Jordan Valve, Steriflow Valve, Steriflow Food & Beverage, LowFlow Valve, Marwin Valve, Hex Valve and Bestobell Steam Traps.

Richards Industrials www.richardsind.com

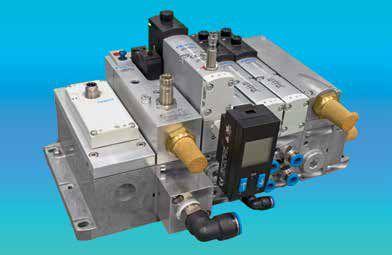

FESTO PANEL TALKS TECH VIRTUALLY IN THE OF ABSENCE OF HANNOVER MESSE 2020

In the absence of the annual Hannover Messe trade fair, Festo of Esslingen, Germany, took to the web for a “TechTalk” to brief the international press on developments at the automation component manufacturer.

As a virtual trade fair under the motto “Industrial Transformation” – Festo presented the topics of digitalization, individualization, climate protection and demography. In the TechTalk, four experts from Festo are giving answers how we support our customers in this

and technology management, Dr. Hans-Jörg Stotz, member of the management board Festo Didactic SE, Karoline von Häfen, head of bionic projects, and Marcus Stemler, product manager of Festo Motion Terminal.

According to Melzer, “Digitization makes our customers more efficient. Thanks to smart products such as the IoT Gateway, we have the ability to bring the data directly from the plant to our dashboards and work with it, whether at the machines, in the factory or in the cloud.”

transformation. In focus: smart products that help companies to produce energy-efficiently, educational measures that empower employees for lifelong learning as well as for the digital working world and, of course, our Bionic Projects 2020. The presentation is available for viewing at https://youtu.be/4jFkehKrESU.

This year’s speakers were Dr. Frank Melzer, member of the management board product

Stotz noted that education plays an important role in the age of digitization. “Technology in itself is useless if you can’t use it properly,” he says. “Digitization is not a flash in the pan. We will see a steady flow of new technologies and business models changing the industry at an ever faster pace. Many companies will have to train or further educate their employees in Industry 4.0.”

The presentation spoke to specific products from Festo that makes its customers more energy-efficient. The company’s digital valve terminal allows the compressed air to adapt to the actual demand without having to convert the system. In addition, the C2M module measures the consumption of a system and automatically switches to energy-saving mode when on standby. With the C2M module, leaks can be detected and repaired at machine level.

The Bionic Learning Network at Festo has also introduced two projects based on nature and natural movements — one that has potential in the burgeoning cobot development arena and another that mimics both an individual bird in flight and a coordinated flock. First, the BionicMobileAssistant moves autonomously in space and can independently recognize objects, grasp them adaptively and work on them together with humans. The processing of the acquired information is performed by a neural network that has been trained in advance using data augmentation. The mobile assistance system is modular and consists of three subsystems: a ballbot, an electric robot arm and the BionicSoftHand 2.0 – a pneumatic gripper inspired by the human hand.

The animal kingdom also served as a source of inspiration: as a second project, Festo is showing the BionicSwift, an artificial bird that can fly as a flock in a defined airspace using a radio-based indoor GPS.

Festo Canada www.festo.ca

Endress+Hauser champions technical education amongst its workforce and customers.

TechTalk panel: Dr. Frank Melzer (top), Dr. Hans-Jörg Stotz and Karoline von Häfen.

Rotork pneumatic actuators.

Jordan Bast

Speaking the language of powder attributes and material handling

In industries such as cosmetics, pharmaceuticals, nutraceuticals, additive metals and plastics, the precise mixing and drying of powders can be critical to the color, consistency, performance, safety, and cost effectiveness of a wide range of products.

A host of variables, such as powder size, shape, density, chemistry, static charge, and moisture content can determine successful formulation. Because these variables can change during the supply chain, it is essential for manufacturers to consult powder specialists that essentially “speak the language of powders” – who can look at the entire process to help optimize product quality and the production process.

results every time.

“Having such a strategy along with specialized consultative powder expertise on hand is like knowing the answers to a test before taking it,” says Bickhardt. “For manufacturers, a more scientific approach provides confidence that they will reliably and consistently achieve their production and final product goals.”

The benefits of engaging in a

ty, Bickhardt recommends using a combination of macro and micro blending that produces a better distribution. Macro mixing is achieved by rotating the shaped vessel, allowing the material bed to fall away from the vessel’s walls. The blender moves at a precise speed, with the vessel wall at a precise angle, so that the material cascades over itself.

Continued on next page

Failing to do so can lead to sub-par product, potential failure in the field, and an array of inefficient efforts during production that attempt to correct deficiencies but do not address the root causes.

ous. This includes expedited product development and market entry, along with enhanced product quality and streamlined production, with tighter specification and control over raw ma terials and the elimination of rework.

In regards to raw powder ingredients, if a manufacturer does not know which factors must be within specification and what the specs should be, an operator can spend hours or days reworking the batch trying to get it right when guesswork alone may not resolve an issue, according to Casey Muench Bickhardt, president of Gemco, a Middlesex, NJ-based manufacturer of tumble blending and vacuum tumble-drying equipment.

“If a manufacturer using powdered materials does not take the time to look at the raw ingredients to ensure that they are properly prepared for a mix, an operator often may just try blending the ingredients longer, faster or with greater force,” says Bickhardt.

“More or less liquid may be added. More processing equipment may be added to the process train. All this guesswork and experimentation adds cost and complexity to production. However, guesswork plus a trial and error approach to problem solving is time consuming and seldom achieves the desired results.”

Instead, powder mixing/drying of raw ingredients and chemicals requires a strategy and knowledge of powder chemistry and physics that ensures manufacturers achieve the same desired

As such, the savings in materials, labor, and time spent on quality control is sues can be significant.

Examining the Factors in Powder/Product Quality

To cost effectively mix powders to achieve a quality product requires re viewing factors such as powder size, shape, density, chemistry, and mois ture content.

Powder Size, Shape and Density

When powders with different particle sizes are mixed, the larger particles will leave a space or gap where small er particles may “fall out,” making the blend difficult to keep together.

Alternatively, powder particles can come in various irregular shapes that can lead to particles interlocking or clumping that must be broken up to achieve uniformity.

Dissimilar powder density is also an issue that must be resolved for differ ent powders to blend homogeneously.

To help mix and balance particles with dissimilar size, shape or densi

A vacuum tumble dryer can scientifically control heat input, vacuum and powder flow which gives manufactur ers a consistent and predictable drying cycle. As a closed system, dangerous solvents can be captured.

While this occurs, micro mixing (if needed) simultaneously proceeds via agitator blades located in the mixing zone center of the vessel, where fine processing in the material transpires. Together, the macro and micro mixing evenly expose each particle to six times more active blending per revolution than traditional mixers.

Powder Chemistry

Another critical factor that manufactur ers need to understand to achieve quality blends and products is powder chemistry.

“For different powder particles, it is critical to understand the chemical characteristics of the particles,” says Bickhardt. “You could be looking at how they form chemical bonds, if they are polar or non-polar, etc. It is essential to pay attention to the science to get the powders fundamentally prepared to be blended.”

According to Bickhardt, understanding the chemistry of the raw powder ingredients to be mixed is vital for any time-release technologies, enrobing (enabling a powder coating to accumulate as it contacts other particles in a controlled process), and hydrophilic (tending to mix with/ dissolve in water), or hydrophobic (tending to repel/not mix with water) coatings.

Static

Finding out if powder particles may be affected by a static electrical charge is also essential and must be addressed in the blending units, according to Bickhardt.

“If you have powder particles that will be polarized by static electricity or any charge, then you literally have forces working inside the mixer that will compete against a good mix,” says Bickhardt. “In such cases, it is important to equip the unit with static electricity arresters.”

Moisture Content

Powder mixing and drying in particular will be affected by the presence of moisture in raw ingredients, which must be monitored and controlled to optimize the purchase price, processing, and end product.

“If moisture levels are too high in a raw ingredient, the manufacturer is overpaying for excess water that must be removed by extended drying,” says Bickhardt.

According to Bickhardt, manufacturers absolutely want to deal with excess external moisture in raw powder materials before it becomes inbound moisture.

“Once water is trapped inside a powder particle, you need exponentially more vacuum and heat directed inwards to remove inbound moisture than with surface moisture,” says Bickhardt.

On the other hand, if the moisture level is too low in a raw material powder input, it could negatively affect blending and end product performance which can be critical, particularly for regulated products like pharmaceuticals.

“So, it is really important to measure both moisture content and loss on drying,” says Bickhardt, whose company offers testing from a full analytical lab and provides consulting from on staff process and chemical engineers.

Ensuring Consistency

Bickhardt adds that in addition to the science behind mixing and drying powders, an unanticipated benefit of a consultative approach is helping manufacturers to identify and resolve issues with raw ingredient suppliers that may also affect the final product.

In terms of powder, raw material inputs can have variations in size, shape, density, etc. This can cause clumping and granulation, for instance, that results in improper mixing and drying. Left unaddressed, this can lead to end product quality problems,

involving diminished performance, aesthetics, durability, and safety in industries like cosmetics, pharmaceuticals and automotive paints.

Powder specialists that consult on powder attributes and material handling can help to optimize product quality and production

“If there are issues with raw ingredients there could be strategies to decrease particle size and remove oversize particles, such as by screening them out,” says Bickhardt. “But getting needed expertise on their raw materials ahead of time is an exponentially better approach because holding to tighter specifications and quality controls over their raw materials from suppliers will essentially eliminate rework in the plant.”

In addition, changes in temperature, moisture, and environment can affect powdered materials at all stages of the supply chain. However, a consultative approach will evaluate these areas as well.

“Controlling all stages of the supply chain and production is critical to achieve a quality end product reliably and consistently,” concludes Bickhardt. “But that starts with having the raw ingredient evaluated to see if it meets all necessary requirements and specifications, and it involves expert consultation as needed with powder specialists.” This article was contributed by Gemco. Gemco www.okgemco.com

Bulk Powders & Solids supplement

FLOW/NO FLOW DETECTION FOR POWDERS AND SOLIDS LOW VOLTAGE BIN LEVEL INDICATORS

The FD-2000 is a flow/no flow detector from BinMaster that is used to prevent cross contamination by detecting and alerting if solid material is still flowing through a distributor leg, chute, feeder, or pipeline. The product is designed to reduce downtime caused by blockages, loose slide gates, or conveyors running empty. The detector is said to ensure material flows to-andfrom a process, so each batch of product meets specifications to reduce production losses. Doppler microwave technology alerts to presence or absence of solids or

powders. NEMA 4X enclosure houses sensing element, power and output connections, and user adjustment controls. Units install through a 1.25-inch connection, with an LED light that indicates power, flow/no flow and fault conditions. With Class II, Div 1 and ATEX Zone 21 hazardous location approvals, the non-intrusive sensor is suitable for industries such as feed, grain, milling, food, cement, mining, power and plastics. BinMaster www.binmaster.com

DUST EXTRACTION STATIONARY EQUIPMENT CONTROLS

Dustcontrol has launched two comprehensive control systems that are set to cover up to 90 per cent of its stationary units. Both high on energy-saving and environmentally friendly, the new Smart Panel and Base Panel will offer a high degree of functionality and automation as standard, the company says. The Base Panel is a standardized and configurable product with a clear and simple definition of functions and built-in frequency drive. It has been developed as a compact and efficient control system suitable for the company’s central vacuum systems. The Smart Panel comes in a compact, standardized format and can be connected to its cloud-based solution, enabling data logging, monitoring, and control of the system. It will be used in combination with an energy-ef-

ficient, externally mounted frequency converter for starting and controlling the motor.

Dustcontrol Canada

www.dustcontrol.ca

Eriez has introduced CP-20 and TP-25 series suspended permanent magnets, designed for conveyor, aggregate and concrete recycling applications. CP-20 series magnets use a single-pole permanent magnet circuit to provide a uniform field across the feed belt to optimize separation efficiency of damaging tramp iron. TP-25 series magnets use a twin-pole permanent magnet circuit to provide maximum ferrous removal at higher suspension heights. The twinpole magnetic circuit used by the TP series allows for horizontal lift of longer ferrous objects, such as rebar or wire. Customers can choose from either manual or self-cleaning configurations for both series.

Eriez

www.eriez.com

Model KA and KAX rotary paddle bin level indicators from Monitor Technologies, powered by 12 or 24 Vdc, incorporate an AC motor said to make them a viable solution for process oriented systems requiring a low voltage power source, minimal installation cost, and frequent level cycling. This DC version of the company’s rotary paddle level sensor includes electronics that converts the 12/24 Vdc power source to 6 Vac energy that is used to operate a 6 VAC motor. Using an AC motor instead of a DC motor significantly improves the performance of these models by ensuring functional reliability and providing longer operational life than a DC motor, the company says. The rotary paddle level switches are said to be very versatile and can be used in a variety of powder & bulk solids storage applications. Other features include rugged construction, twist ON/OFF cover, motor shut-off when paddle becomes impeded and a Hazardous Location option (Model KAX).

Monitor Technologies

www.monitortech.com

Build it, See it, Price it, Order it.

Point and click or tap to specify valve type, end connections, actuator, and accessories. Model number, price, description, and photo all update instantly!

Weatherable discharger aids bio-cleanup project of contaminated groundwater

To treat contaminated groundwater at a New Jersey site, XDD Environmental designed and built a system that discharges high volumes of sodium bicarbonate from bulk bags automatically. The system pumps water from the ground, adds a variety of amendments to it, and re-injects the treated water into a different area of the site. The treated water promotes the growth of naturally occurring bacteria in the soil, which break down the contaminants.

Sodium bicarbonate acts as a pH buffer in the groundwater, which becomes more acidic as the bacteria metabolize the contaminants. “We’re giving the bacteria a better environment so they can thrive,” says Scott Crawford, senior project manager at XDD.

“Normally, we would take a bulk bag of sodium bicarbonate and manually add it to a mixing tank, but in this case, we had to deliver it in near-continuous fashion,” Crawford says. “There was no way to make those additions manually.” To accomplish the task automatically, the company installed a Bulk-Out bag discharger from Flexicon Corp.

The treatment system pumps between 75 and 227 L of groundwater per minute into a 15,141 L tank. There it is treated with sodium bicarbonate and pumped out at the same rate. Downstream, additions of emulsified oil and other amendments are made, and the treated water is injected into the ground. This semi-continuous process consumes 8,800 to 11,000 lb of sodium bicarbonate per eight-hour day.

Crawford’s specifications for the discharger focused on durability. “It operates outside, so we needed it to be rugged. It had to take a lot of abuse and stand up for a 3-year project life.” It also needed to remain stable on rough ground and be easy to move. The company opted for a half-frame unit with a separate bag-lifting bracket to be raised using a forklift. “A stable concrete pad for anchoring equipment with a high center of gravity isn’t available, so we went with a low-profile, quasi-manual system that we can move closer to other treatment areas when needed.”

At the hopper’s outlet, a 4.5 m long Model 1500 BEVCON flexible screw conveyor elevates the sodium bicarbonate to the 3 m high mixing tank. The conveyor’s screw geometry is designed to handle difficult materials. Vari-

Dual Output Isolated Signal Conditioner or Loop Extender

The ITC-XXX-XX-DC is a signal isolator with dual outputs providing high isolation from Input to Output1, to Output2, and to Power in a small easy to install package. It’s universal DIN rail mount makes it possible to install right next to the instrument that is to be isolated. The many different input and output configurations allow it to be used in a great variety of applications ranging from PLC front end conditioning to adding an extra loop with lots of drive to an existing, almost fully loaded loop.

able speed enables the operator to adjust the flow of sodium carbonate to match the flow of water. “We want to feed the bicarbonate at a rate that it can dissolve adequately,” Crawford says.

“On site, we set the right blending ratio, and all we need to do is keep an eye on the bag. When it’s empty, we put a new bag on.” The brief downtime between bags has no impact on the process.

The discharger’s hopper incorporates a bag dump station for adding 55 lb (25 kg) bags of trace nutrients. Crawford says, “No one has to climb a ladder to the mixing tank, and the hatch and grate at the bag station free the operators from having to balance bags on their knees.

“The operators running the discharger and conveyor have limited experience with any kind of powder handling, so the system needed to be very simple to operate,” he explains.

The discharger’s PLC communicates with the larger treatment system. If, for example, the proximity level switch senses a low level in the hopper, the conveyor stops. That information is shared system-wide, triggering the pumps and other equipment to pause until the issue is corrected. XDD can monitor the operation from its offices in New Hampshire.

“We can log into the system by PLC interface and see what the flow rate is and what the alarm conditions are. If the operators have any issues with the system, they can contact us, and we’ll help get them back up and running.” This article was contributed by Flexicon Corporation.

Flexicon www.flexicon.com

A fork truck holds the bulk bag over the half frame discharger while the flexible screw conveyor moves sodium bicarbonate to the mixing tank.

Scott Crawford

CUSTOM BULK BAG DISCHARGING SYSTEM

A patented system designed for discharging various food ingredients into customer’s existing process has been announced by Material Transfer. Unit features include sanitary stainless steel product contact surfaces with continuous welds, ground smooth, for accelerated contact surface sanitization and inspection, as well as an electric chain hoist and bag lifting frame, as well as a bulk bag massaging system to promote material flow, and the FloLock gate for partial bag discharge. Systems are custom designed for specific application requirements. Material Transfer www.materialtransfer.com

COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS

4B Components, a developer of components for bucket elevators and conveyors, has announced that the USPTO has issued U.S. Patent No. 10,556,748 to support the company’s ongoing efforts to make chain conveyors more efficient to operate. The patent covers a chain assembly technology specifically developed for round bottom conveyors and it features a fully bolt-on construction made up of plastic paddles, steel attachments, and chain links. Branded as Bolt-NGo RB, the new product expands the company’s Bolt-N-Go conveyor chain line currently available for Flat Bottom (FB) and Hi-Flite (HF) conveyors. Grain and feed operators currently using Bolt-NGo realize how much easier and safer it is to install, replace and maintain Bolt-N-Go chain compared to conventional welded steel chain, the company says. The new Round Bottom version of Bolt-N-Go expands this technology for use with a wider range of conveyors, allowing maintenance teams to be even more productive, it adds. 4B Components www.go4b.com/usa

INDUSTRIAL CYBERSECURE

LVDT

SIGNAL CONDITIONER

Alliance Sensors Group has introduced the model SC-200 LVDT signal conditioner. The signal conditioner is said to offer smart and fast LVDT/RVDT setup and has been engineered to work with the widest range of LVDTs, RVDTs, and inductive half-bridge sensors including 3-wire industrial LVRTs. The signal conditioning module has cyber security tamper prevention and notification features. The unit offers push button calibration, reducing set up time by a factor of 10, the company says. An operator simply finds null, then moves the LVDT core to one end of the range and presses the front panel Zero button.

Alliance Sensors Group

www.alliancesensors.com

A line of heavy-duty rotary-electric vibrators and drives from Best Process Solutions has been designed for bins, hoppers, chutes, screeners, vibratory feeders, conveyors, tables and other vibratory applications. All provide continuous maximum-force operation, the company says, from 30 to more than 40,000 lb. The dusttight, splash-proof motors are said to provide excellent field performance in harsh environments including dirt, rain and snow. Units’ construction includes ductile-iron castings, steel end covers and high-alloy fasteners. Motors are available in 3600-, 1800-, 1200- and 900-rpm models, from 1/50th to 17½ hp. All units can be mounted horizontally or vertically. Best Process Solutions www.bpsvibes.com ROTARY

As we survive this unprecedented time, it amazes me how some aspects of our lives have not really changed all that much. As a communication company we have been able to continue to bring you both new and proven solutions to your manufacturing issues — all the while working remotely. Our suppliers have been excellent and have not missed a beat. Thank you to our readers who keep the lights on, allow me to fill up my truck (even though I don’t really have anywhere to go), sanitize everything in sight, keep us fed and watered and all the rest of the essential services that are provided by Processors across Canada. It has been a great reminder of how important the Process/Resource industries are in Canada and we are grateful to be the #1 magazine/digital information company serving these industries. We’re in this together. I was hoping to use this space to announce our fall Process & Automation Show schedule but as I write this it’s premature, so keep an eye on your inbox and mailbox for more

information on the shows.

Another revelation for many (readers and advertisers) during this pandemic is the importance of industry-specific trade publications. When we’re all bombarded with bad news everywhere you turn, it’s nice to know your copy of CPE&CN is in the mail and your inbox with the information that matters to you and your company. You know we’re not bringing the bad news — just solutions!

So, readers if you get a phone call from someone representing us don’t be alarmed — we have to update your information every 18 months for audit purposes. This will ensure there are no interruptions to either the print version or the digital version of your subscription.

Next up is our October issue with a Focus on Fluid Handling and editor Mike Edwards' Cloud Data Management. It closes Sept. 11. Stay safe everyone.

Cheers, Rob Sommerville

ELECTROMAGNETIC FLOWMETER READS FLOW OF CONDUCTIVE LIQUIDS

The MIS electromagnetic flowmeter from Kobold was developed for measuring and monitoring medium-sized flow of conductive liquids in pipes. The flow rate is calculated based on the cross sectional area of the pipe. The measurement does not depend on the process liquid and its properties such as density, viscosity and temperature, but requires some conductivity. The two outputs can be independently set to switch or provide an analog or frequency output. A batching function can also be selected, where output 1 is set to switch as NPN/PNP/PP and output 2 is set as the control input. Features include: accuracy is <± (0.5% of reading +0.5% of Full Scale); bidirectional measurement; and, connections of 2, 3, 4, 6 or 8 in. ANSI flanges. Kobold Instruments Canada www.kobold.ca

LIVE REMOTE ASSISTANCE IMPROVES PRODUCTIVITY AND SAFETY

Emerson has introduced augmented reality (AR) technology to its Plantweb Optics asset performance platform, now said to deliver enhanced access to real-time diagnostics and analytics, as well as live remote assistance, to industrial plant workers responsible for maintaining and optimizing plant equipment. With AR technology integrated into the platform, plants can improve productivity, collaboration and operational performance, without being limited by shortages of skilled workers or travel restrictions, the company says. Unlike standalone AR solutions that re-

quire custom engineering, AR is integrated into the platform, providing immediate access to a wealth of data and translating into easier, less costly implementation and a faster return on investment, it adds. For use by manufacturers in the life sciences, food and beverage, chemical, metals and mining, power and water, pulp and paper and energy industries, the platform is part of the company’s Plantweb digital ecosystem of technologies, software and services.

Emerson Electric Canada www.emerson.com

The 2020 ASHRAE Handbook – HVAC Systems and Equipment includes updated information to help system designers and operators select and use equipment that is the best fit for a particular application or scenario. The handbook discusses various systems and the equipment (components or assemblies) they comprise and describes features and differences. Subject matter experts on ASHRAE Technical Committees in each subject area have reviewed all chapters and revised them as needed for current technology and practice. A new feature of the Handbook is the annotatable PDF download. Users can highlight relevant text and add their own notes and comments. ASHRAE www.ashrae.org/bookstore

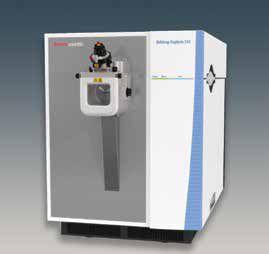

THERMO-PARAMAGNETIC OXYGEN ANALYZER

The Michell Instruments XTP501 oxygen analyzer from Rotronic is said to be a cost-effective quality-control analyzer for oxygen generators. The analyzer is small, lightweight and uses the same thermo-paramagnetic sensor as Michell’s premium XTP601 oxygen analyzer range, the company says. Suitable for installation in safe areas, the XTP501 provides stable, accurate measurements of oxygen from 500 ppm O2 up to 100% O2, it adds. The case is IP55 rated. Rotronic Canada www.rotronic.ca

The micro gas pump NMP 850 HP introduced by KNF Neuberger is said to deliver outstanding high-flow, pressure, and suction performance, yet remains compact and lightweight. Based on the same footprint as the existing NMP 850 series, the new NMP 850 HP (high performance) series offers a greater than 50 percent increase in flow performance. Even with this leap in performance, the pump is only 2.5 mm taller than its forerunner, the company says. The standard NMP 850 HP pump produces free flow up to 7 l/min with a single head and up to 9 l/min with a customized single head. It produces pressure greater than 36 psig (2.5 bar g) and vacuum down to 200 mbar absolute (24 inHg). Dual- and 4-head versions produce additional free flow of up to 16 l/min and 30 l/min, respectively. The pump is available with 2- and 4-wire brushless motors. Standard offerings include FDA-certified EPDM and PPS wetted components.

KNF Neuberger

www.knf.com

ON/OFF VALVES FOR HAZARDOUS CONDITIONS

Circor International has introduced R.G. Laurence 2500 series on/off control valves for applications demanding rapid opening and sealed closure. The ATEX-certified and Factory Mutual-approved two-way globe-type piston valves are operated by an external lever connecting the lifting action of the linear actuator to the valve piston via a rotary shaft. This mechanical advantage sets the valves apart, the company says, as more force can be leveraged when operating the valve. Direct, semi-direct, and pilot operated valve piston options make these valves suitable within light liquids and gases, such as hydrogen, oxygen, helium, and carbon dioxide. The rotary shaft also enables stronger return spring action, ensuring a reliable and fail-safe return, it adds. The valves can safely handle up to 425°F fluid temperature, including steam, without the coil insulation breakdown often associated with packless type solenoid valves.

Circor International

www.circor.com

PALLETIZER SIMPLIFIES COMPLEX PROCESSES

The RI20 semi-open palletizing cell with an industrial robot arm from FlexLink is said to simplify the complex processes of a traditional palletizer. The easy-to-use unit can be up-and-running in just a few hours, the company says, and its two loading docks permit a capacity increase of up to 5 percent. The palletizer is suitable for palletizing closed boxes and includes safety features that allow a safe coexistence between the robot and operators on the production floor. The presence of operators in the safety area dynamically adjusts the speed of the robot instead of stopping it, reducing downtime. The design of the unit is said to save up to 40 percent of floor space compared to heavy robot palletizers. The mainframe does not have to be attached to the floor and the unit can be moved using a forklift.

FlexLink Systems Canada www.flexlink.com

Corrosion Resistant

Innovative Solutions for Tough Water/Wastewater Applications!

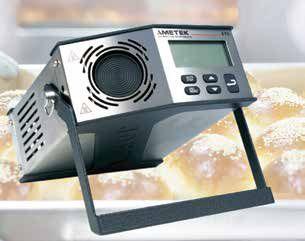

Ametek STC has announced the ETC Series of Easy Temperature Jofra temperature calibrators. The speed, simplicity, and small size of the calibrators is said to make them the perfect instrument to keep bakery ovens working at their highest efficiency. The block heats at up to 100°C per minute and stabilizes in 3 minutes. In addition to its ease of use and speed, its small size and light weight make it the ideal tool for verifying sensors in difficult to reach places, the company says. Temperature ranges are available from -10°C to 400°C. Accuracy is ± 0.5°C, and the stability is ± 0.05°C. A one-key-one-function user interface provides immediate access to temperature settings and the auto-step function.

Ametek STC

www.ametekcalibration.com

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

The Rotronic Hygrolab Analyzer from Alpha Controls & Instrumentation is laboratory analyzer used for water activity measurements. With up to four probe inputs, the company says, the unit has a modern interface for clear and simple measurements and has a high-quality touch screen. With its simultaneous and asynchronous measurement functions, the analyzer is suitable for the pharma-