Curran Renewable Energy shipped its first pellets to a Quebec client this past July, with a twist. The pellets are made from green roundwood chips from a sister company’s pulpwood operation. Plus our 2009 pelletizer guide.

Enerkem’s thermochemical process can turn just about any biomass into ethanol, including old wood and garbage. The innovative biofuel player is moving to the industrial demo plant stage with its Westbury plant.

The move to using off-species roundwood and a grinder service at this Nova Scotia greenhouse has all but eliminated the need for propane and drastically cut a $600,000 per year heating bill. Still, biomass quality and consistency is key to smooth boiler operation.

As the North American housing market fights to stay alive during these tough economic times, some Canadian loggers are rolling with the punches and taking advantage of environmental incentives from the government to stay ahead of the game.

“We’ve been looking at pellets to diversify our markets for years now. It’s a good fit with our existing operation, and we’re big believers in the future of renewable energy in this area.”

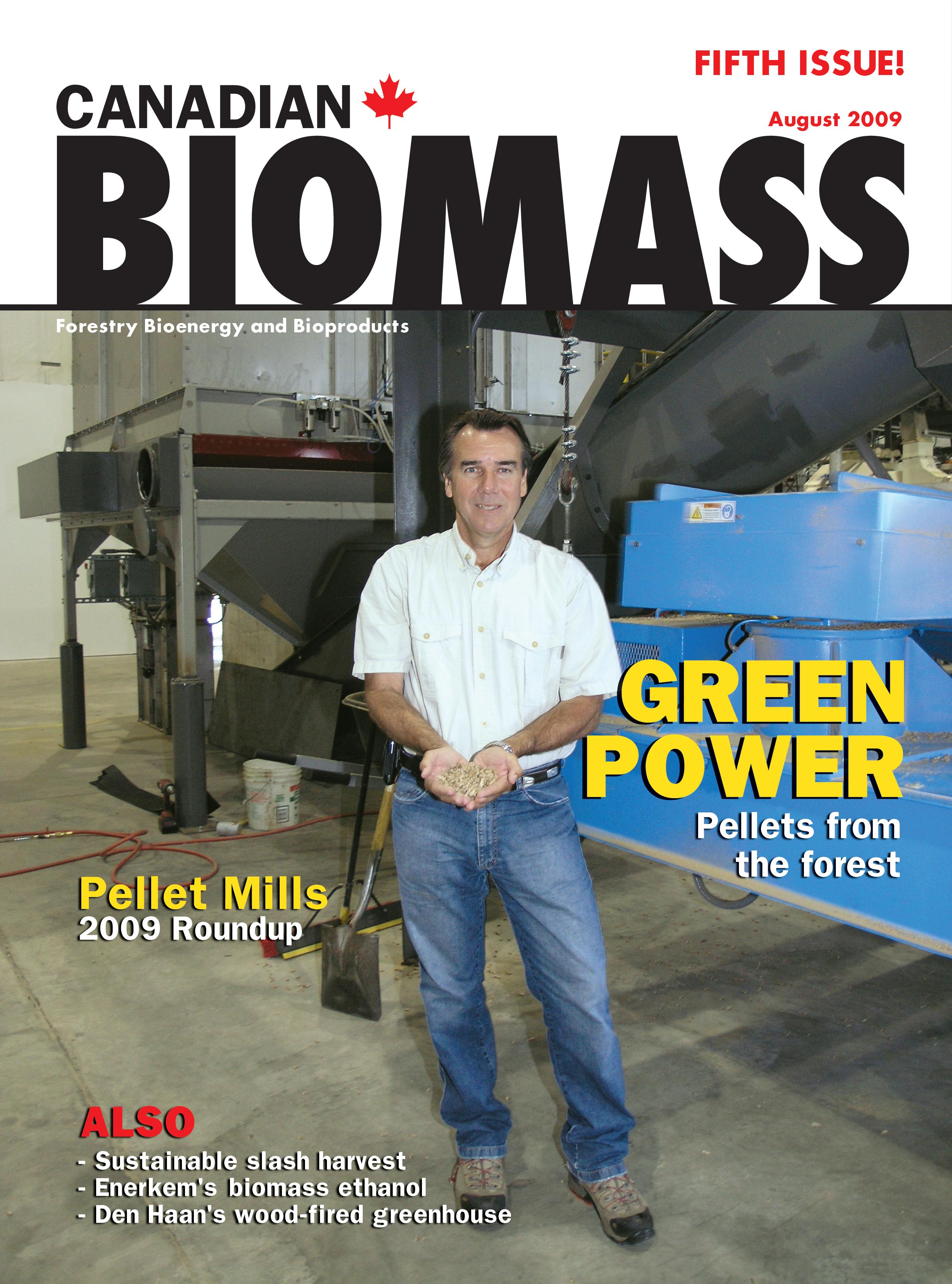

Pat Curran with some of the first wood pellets to come off the new line. The company is supplying the US Northeast with pellets made from green wood. Story on page 16. Photo: Scott Jamieson/Canadian Biomass.

Using roundwood fibre is already a reality, so what’s next?

t has been clear for some time that any major growth in the Canadian wood pellet industry will come from new fibre sources. With sawmill residues largely spoken for even before the current lumber market collapse, we’ve started eye-balling such alternatives as green roundwood or demolition/construction waste. As Wood Pellet Association of Canada president John Swann points out on page 15, the past few years of falling sawmilling production has only made the need to decouple the pellet sector from the forest products sector all the more urgent. In addition to providing John’s views on this new pellet business model, we’ve also gone out and found someone who’s doing just that.

shortages all last winter. In short, the new venture slides into the old one like a glove.

Our cover story this issue is on Curran Renewable Energy (page 16), a spanking new pellet mill owned and operated by seasoned log harvesting and bush chipping veterans Lee, Pat, and Tim Curran. They have invested over $10 million in a modern wood pellet facility just over the border in Massena, NY, and shipped their first order to a Quebec client in July. It’s a staggering investment for a logging company, but more to the point, it’s 100% based on a fibre supply of green roundwood chips. The goal is to compensate for a declining local pulp market by sending unwanted or offspecies chips to the pellet mill. The company can rely on an established and highly efficient transportation infrastructure, a skilled harvesting team, good relationships with local landowners, and a steady market for at least some of its pulp chips. It’s also perched on one of the largest domestic markets for wood pellets in North America, and one that suffered through

Yet the Currans’ situation is hardly unique. This scenario mirrors many struggling forest regions in Canada, from Newfoundland and New Brunswick to northern Quebec, Ontario, the prairies, and pockets of BC where beetle-kill fibre is not spoken for. Still, it’s not for the faint of heart. As Pat Curran says, they now own a company “with a lot of debt and not many assets.” Launching similar operations in Canada may require banding together several large contractors to get the deal done (already being discussed in BC), or may involve municipal or provincial incentives.

Above all, starting such operations in Canada will take imagination and daring, and not just from our forest entrepreneurs. Governments at all levels will have to get involved, even if only to remove barriers. Access to credit and fibre needs to be addressed, especially in areas where a crumbling old-guard forest industry still stands in the way. Finally, programs to encourage domestic pellet use for industrial and residential applications need to be developed for regions where the fibre is available and the fossil fuel alternatives unattractive.

Still, if one plucky logging company in upstate New York can do it, it can be done here too. Enjoy this first look at Curran Renewable Energy’s green chip pellet operation. We wish the Currans well, and will watch their progress closely. •

Scott Jamieson, Editor/Group Publisher sjamieson@annexweb.com

Volume 5

Editor/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Associate Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Contributors - Colleen Cross, Bill Tice

Market Production Manager

Josée Crevier (514) 457-2211 ext 21 jcrevier@forestcommunications.com

National Sales Managers Tim Tolton - ttolton@forestcommunications.com 514-237-6614

Guy Fortin - gfortin@forestcommunications.com 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8 Ph: (514) 457-2211 Fax: (514) 457-2558

Western Sales Manager Tim Shaddick - tootall1@shaw.ca 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Brooke Shaw

Canadian Biomass is published five times a year; March, June, August, October, and December. Published and printed by Annex Publishing & Printing Inc., and distributed as a supplement to Canadian Forest Industries and Canadian Wood Products magazines.

Printed in Canada ISSN 0318-4277

Circulation e-mail: cnixon@annexweb.com Tel: (514) 457-2211 Fax: (514) 457-2558

Mail: 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8

Subscription Rates:

Canada - 1 Yr $48; 2 Yr $85; 3 Yr $115 Single Copy - $6.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $44 US; 2 Yr $75 US Foreign – 1 Yr $75 US

From time to time, we at Canadian Biomass make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2009 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianbiomassmagazine.com

Missoula, MT – Rawlings Waste Wood Recovery Systems has completed one of the first wood waste recovery systems in the United States to introduce biomass as fuel to heat cement kilns at Mitsubishi Cement in Lucerne Valley, California. The system is capable of processing 50 TPH, with storage of up to 250 tons of premium biomass fuel to be burned along with coal to reduce the amount of greenhouse emissions. Wood biomass will replace part of the annual tons of coal the plant would otherwise use.

The Rawlings Electric portable wood hog is a rugged, high-performance hog that can reduce various types and sizes

of contaminated wood waste to biomass fuel. Once the wood waste has been processed through the hog, the metal is removed by an overhead self-cleaning magnet and the biomass conveyed to a walking floor stoker storage system. To ensure the optimal size end product, the wood waste is processed over two vibrating finger screens and then transferred to the kilns via a blower system. Rawlings Manufacturing has been manufacturing and installing the patented Rawlings Wood Hog and wood waste recycling systems for over 30 years. Both vertical and horizontal models are available in stationary, portable, and skidmounted systems.

Pikangikum, ON – Three northwestern Ontario First Nations and a Finnish company have teamed up to develop Two Feathers Forest Products (TFFP), a value-added enterprise. The Wabigoon Lake Ojibway Nation, Pikangikum First Nation, Eagle Lake First Nation, and Finland-based Wood Tech Group Canada have proposed a project involving the development of manufacturing facilities at two sites northwest of Thunder Bay, Ontario.

Timber from the Whitefeather Forest at Pikangikum would be processed at a sawmill with 9.9 MW biomass cogen plant at Red Lake. Excess electricity would be sold to the power grid and the lumber sent 200 km south to Eagle Lake, near Dryden, to make prefabricated building components for export to Asia and Europe. The Eagle Lake facility would also have a wood pellet plant.

In mid-July, TFFP released a draft Environmental Screening Report for public comment and review. An environmental assessment is required by the CanadianEnvironmentalAssessmentActas a result of federal funding for the project, as well as the location of the project on First Nations land. Site preparation is awaiting final federal government approvals, with a view to beginning construction in 2011.

Prince George, BC – The University of Northern British Columbia (UNBC) officially started its multi-million dollar Northern Forest Products and Bioenergy Innovation Centre with the June 30th opening of a wood pellet combustion system on campus. The pellet system is installed at the I.K. Barber Enhanced Forestry Laboratory and is the result of a partnership between UNBC and the Wood Pellet Association of Canada (WPAC). The installation includes a silo for

A silo stores wood pellets and feeds a recently installed combustion system that is part of UNBC’s new bioenergy program.

Vancouver, BC – Dynamotive Energy Systems Corporation was honoured with the 2009 Intergovernmental Renewable Energy Organization (IREO) Innovation Award for contributions to global sustainability through the development of its patented fast pyrolysis technology and its efforts towards the development of synthetic fuels from biomass. Mr. Richard Lin, chairman of Dynamotive, accepted the 2009 IREO award on behalf of the company on June 11 during a ceremony held at the UN headquarters in New York City.

The award was created to honour innovative leaders that are contributing to the research and development of sustainable energy solutions. It is bestowed following a review conducted by a committee chaired by UN ambassadors and selected experts from recognized and leading international authorities and organizations.

pellet storage, connections to the existing heating system of the Enhanced Forestry Lab, and a year’s worth of pellets provided by the local member companies of the WPAC. The project was funded by the Government of Canada’s Community Economic Diversification Initiative.

“This is an exciting day for UNBC as we embark on a program – together with industry, government, and northern communities – that will hopefully enable the development of new renewable energy opportunities,” says Dr. Charles Jago, UNBC’s interim president. “While the project will provide

heat to the Forestry Lab, it will be equally valuable as a platform for applied research.”

UNBC has also selected Nexterra Systems Corp. to supply and install a biomass gasification system to heat its main campus buildings. The gasification system will convert locally sourced wood residue into clean-burning syngas that will displace up to 85% of the natural gas currently used to heat the campus. Initial site preparation has begun, and the gasification system is expected to be operational by early 2011. The project is funded by the federal and provincial governments.

Saint-Philippe-de-Neri, QC - Groupe Dynaco, a food cooperative, became the first cooperative in Quebec to invest in equipment to supply energy from biomass to its mill. This is an investment of $1.5 million. The cost of the biomass combustion system amounted to nearly $650,000.

The plant includes a biomass combustion system model ST manufactured by Combustion Expert Inc., a manufacturing company specializing in the design, manufacture, installation and start-up of biomass equipment. The boiler power of Groupe Dynaco’s mill is 300 BHP (3 MW). The thermal energy released from burning wood heats up the water in the steam boiler. The steam is used for production purposes – for manufacturing livestock food – but could as well be used for heating.

Combustion Expert’s studies show that it can be four times more cost effective to use biomass as fuel compared to natural gas or propane. This is confirmed by Groupe Dynaco, which has seen significant savings in energy costs since the commissioning of the equipment. A rapid ROI was helped by the year-round energy consumption at the plant.

Sacré-Cœur, QC – Granluco Inc. has received $750,000 in repayable funding to start up a wood pellet plant in Sacré-Cœur, in the Côte-Nord region of Quebec. The funds were provided under Canada Economic Development’s Community Economic Diversification Initiative–Vitality program. This new company

will specialize in the manufacture of wood pellets for home heating and for horse litter. Two local sawmills will supply the company with sawdust and wood shavings to produce the pellets. Granluco intends to sell its products in Quebec, Ontario, and northeastern United States.

Nexterra Systems Corp., a supplier of biomass gasification solutions, has added three new executives to its North American sales force, strengthening the company’s strategic focus on regional biomass energy opportunities. The new senior sales executives will be responsible for supporting the growing demand for Nexterra’s commercial proprietary gasification technology in key markets within the institutional and industrial sectors.

New Brunswick Canadian Forces Base Gagetown is considering installing a biomass boiler and district heating system to heat 95 buildings on the base. The installation would occur as part of a 10-year, $40-million energy performance contract between Defence Construction Canada and Direct Energy Business Services Limited. If the installation goes ahead, biomass will likely be procured through a competitive request for proposals.

St. Marys Paper of Sault Ste. Marie, Ontario, is proposing a $170-million cogeneration plant to produce steam and electricity from wood waste to power the mill. The cogen plant is expected to require more than 500 tons/day of biomass. The company is hoping to sell electricity to the Ontario power grid as part of the project and has submitted an application to Ontario Power Authority for a 10-year 35-MW purchase agreement. A decision is expected in August.

BiomassEquipmentAuction.com has set up an Internet-based auction site geared towards the buying and selling of equipment and facilities for biomass, biodiesel, ethanol, and other alternative fuels. The site allows members to post equipment and gives buyers the opportunity to bid on the equipment they need in one central location, connecting buyers and sellers worldwide.

Michael O’Shea of Donnacona, Quebec, has founded Montreal-based AP Fuels, with a view to building five large-scale biorefineries to produce second-generation biofuels from wood, writes Globe and Mail reporter Konrad Yakabuski. If successful, the projects, estimated at $1.2-billion each, would provide new life to the hard-hit Quebec forestry industry. O’Shea’s idea is to use technology from Choren Industries of Germany to covert woody biomass to liquid biodiesel. He estimates that each AP Fuel biorefinery would produce 630 million litres of biodiesel annually.

The Township of Chapleau, Ontario, and the Superior East Community Futures Development Corporation held a one-day workshop in June for local industries, communities, First Nations, and the bioeconomy research sector to discuss the potential development of a cluster of valueadded forest product businesses. Such a bioeconomy industry cluster would provide a competitive advantage for businesses by facilitating synergies among the various entities. Funding of $8,500 for the workshop was provided by Ontario’s Northern Communities Investment Readiness Initiative.

In a June press release, the Township of White River and Pic Mobert First Nation announced that they have purchased the White River sawmill and assets from Domtar. The mill, which closed in July 2007, had an annual production capacity of 110 million board feet of lumber. The plan, pending approvals, is to expand the existing cogeneration plant, start up a wood pellet plant, and eventually restart the sawmill.

Regina, SK – An agreement has been reached that sets the stage for the potential redevelopment and innovative new use of Domtar’s Prince Albert Pulp Mill site in Saskatchewan, which has not been operated since April 2006. The government of Saskatchewan has signed a letter of intent with Iogen Energy and Domtar for the proposed development of a cellulosic ethanol plant and bioenergy facility at

the site. Under the agreement, Iogen will advance its business planning around a plant that would convert cereal straw to cellulosic ethanol. If the final investment decision is positive, the multi-million dollar project, in partnership with Royal Dutch Shell, will include a power plant producing electricity from forest and ethanol plant residues.

Iogen/Shell expects to make a final investment decision on the

project after design and feasibility work is completed. If the project proceeds, the company would purchase mill assets from Domtar that are required for the new facility. The government would also commit to purchase power produced from the plant and provide new growth tax incentives related to technology commercialization and transportation.

“Redevelopment of this mill

site has been a priority for us, our forest industry, and the people of the area,” says Energy and Resources Minister Bill Boyd. “A final decision still needs to be made by the company, but this agreement is an important first step in our commitment to find new uses for the mill facilities, new markets for our forest and agricultural resources, and new forestry jobs for Saskatchewan people.”

Vancouver, BC – In June 2009, Lignol Energy Corporation completed the first end-to-end production of cellulosic ethanol from its fully integrated industrial-scale biorefinery pilot plant in Burnaby, British Columbia. This production of cellulosic ethanol from Canadian woodchips followed the plant construction phase that

commenced in June 2008 and the start-up phase that commenced in April 2009.

Through planned production campaigns, Lignol intends to operate the pilot plant under a wide range of operating parameters to process various nonfood feedstocks. This will involve using various equipment configurations,

enzyme formulations, and process conditions to optimize the yield of cellulosic ethanol, as well as the quality and performance of related biochemicals.

“Achieving the first production of cellulosic ethanol from the pilot plant is a significant milestone for Lignol,” says Ross MacLachlan, president and CEO of Lignol.

“Operating the pilot plant to-date has allowed us to identify areas for process enhancement that we will be incorporating to further improve pilot plant operations.” The information generated from the pilot plant will allow the company to validate cost and performance assumptions involved in moving to commercialization.

our Biomass video at www.jeffreyrader.com/videoB

Vancouver, BC – In mid-June, the city council of Williams Lake, British Columbia, endorsed the development of a 60-MW biomass power project. The project is being spearheaded jointly by Run of River Power’s subsidiary Western Biomass Power Corp. and the Tsilhqot’in National Government. The project falls under phase II of BC Hydro’s Bioenergy Call for Power.

The proposed plant, to be located in nearby Hanceville, would generate electricity from trees damaged by the mountain pine beetle, as well as local logging and mill waste. The joint venture proposal includes construction of the $250-million power plant, plus $40 million for a new 230 KV transmission line.

Prince George, BC – An ongoing multi-institutional project to study the mountain pine beetle is yielding results that will contribute to more strategic investments in bioenergy. Researchers at the University of Northern British Columbia, University of British Columbia, University of Alberta, Natural Resources Canada Canadian Forest Service, and the Genome Sciences Centre in Vancouver are studying the beetle, its relationship to the pine trees it attacks, and the fungal pathogens that help it overcome a tree’s natural defenses. The goal of the work is to better predict the location of potential supplies of bioenergy. Better predictive models will help to guide control measures and will be an important contribution to a more stable supply of bioenergy products.

Drs. Brent Murray, Kathy Lewis, Brian Aukema, and Dezene Huber are some of the researchers studying the mountain pine beetle to better predict its spread and effects.

“Massive amounts of dead timber from the mountain pine beetle epidemic are a potential energy feedstock, but this won’t necessarily provide a sustainable supply in the future,” says Canadian Forest Service researcher Dr. Brian Aukema. “Improving current methods of predicting feedstock will help us make more focused investments in the forest industry.”

The current project, for which tens of thousands of beetle and larvae samples were collected, has a budget of nearly $4 million spread across the collaborating institutions. A new project building on the current work will start in Jan 2010. “Applied Genomics Research in Bioproducts or Crops” has a budget of $7.8 million and is funded by Genome Canada, Genome BC, and Genome Alberta.

JSome provinces are taking the bull by the horns and developing harvesting guidelines.

By Evelyne Thiffault

urisdictions around the world are developing or updating their biomass harvesting frameworks. Three Canadian provinces have recently issued new policies or guidelines: Ontario in August 2008, New Brunswick in October 2008, and Nova Scotia in May 2009. The latter is still in draft form, but I’m told the final version will be out shortly. Yet there is one question that many are burning (in a carbon-friendly way) to ask: With all the existing regulations governing forestry, why create additional guidelines specifically for biomass harvesting?

Well, the supervision of forest activities needs to mirror the evolution of forest management issues, scientific knowledge, and

What might these policies look like? Ontario’s biofibre policy explains why the province believes its current forest management policies are adequate, but explicitly mandates monitoring, an adaptive management approach, and a policy review in five years. New Brunswick’s policy focuses primarily on the sustainability of soil productivity. As a soil scientist, I am happy about this, but I imagine that my insect and mammal specialist colleagues are disappointed. However, the policy states that the province will strive to embrace other forest values in the future. It provides a list of high-risk areas on which forest biomass harvesting should not occur, including shallow, rocky, stony, dry, and poor soils, as well as wetlands. This is consistent with guidelines in other jurisdictions. It also rules out areas for which a GIS-based input-output model predicts that biomass harvesting will create a nutrient imbalance.

“I give a warm ‘bravo!’ to these two provinces for producing guidelines that are fairly clear and easy to apply in the field.”

public needs and demands. Intensive methods of harvesting such as full-tree-to-roadside, or whole-tree, harvesting have been around for almost four decades. However, existing regulations did not anticipate the increase in demand for low-quality fibre and the fact that slash and sub-merchantable stems are now being sought on harvested sites. Research has also become more targeted on the extent to which forests subjected to biomass harvesting can keep on providing clean water, sequestering carbon, supporting biodiversity, and growing healthy and productive stands. It is thus time to integrate new knowledge into policies suited to today’s demands.

By contrast, Nova Scotia’s draft guidelines take a broader view of sustainability. For example, they address soil productivity issues by defining a gradient of site productivity and matching it with a gradient of site retention targets for fine woody debris (material less than 10 cm in diameter): the poorer the site, the higher the retention target. Fine woody debris has higher concentrations of most nutrients than does coarser material. The guidelines also set separate retention targets for coarse woody debris (in volume per area) according to stand cover type; these targets chiefly aim at providing structure and cover for wildlife and attempt to emulate the amounts found in natural unmanaged stands.

Nova Scotia’s biomass harvesting and retention guidelines do not regulate the type of logging system to be used in forest operations; they are results oriented. In New Brunswick, full-tree chipping operations for pulpwood fibre are specifically excluded by the forest biomass policy, which is surprising because the ecological impacts are surely the same regardless of the industrial end-point (How long before the public and certified markets note this ecological contradiction?). Nevertheless, both New Brunswick and Nova Scotia are committed to optimizing the role of biomass (other provincial policy makers, please take note): if slash material is not recovered, it has to be redistributed evenly over the cutover area to support ecological functions, and not piled and left at the roadside to become a uselessly decaying eyesore. Also, and in my opinion the most critical and exciting part, all three policies include statements about monitoring biomass harvesting operations, with the results used to validate and improve future policies.

To conclude, I respect that Ontario has chosen to defend its current practices, rather than drift with the status quo as some other provinces are doing, and I predict that we will see site-specific guidelines in its revised policy in five years. Although the New Brunswick and Nova Scotia biomass harvesting policies and guidelines are not perfect, I give a warm ‘bravo!’ to these two Maritime provinces for taking a proactive stance and producing guidelines that are fairly clear and easy to apply in the field. As long as they, and Ontario, stay true to their ‘monitor-validate-review’ commitment, they provide fine examples of how the wheel of adaptive management can be set in motion. •

Dr. Evelyne Thiffault of Natural Resources Canada contributes thoughts on biomass harvesting sustainability on behalf of the Canadian Research Group on Ecosystem Sustainability.

Enerkem’s thermochemical process can turn just about any biomass into ethanol, including old wood and garbage.

By André Dumont

Inthe race for successful commercial production of second-generation ethanol, Enerkem has chosen a radically different approach than most competitors. Its “carbon recycling technology” is based on a thermochemical process that has nothing to do with finding the best enzymes to break down cellulose and produce ethanol from specific feedstocks such as wheat straw or wood chips. Instead, Enerkem uses gasification to turn carbon-rich feedstocks into synthetic gas, or syngas, which is then converted to ethanol using a catalyst.

More than 20 types of feedstock have been tested successfully in the Quebec-based company’s research facility and pilot plant. Woodchips, wheat straw, chicken manure, dewatered municipal sludge, and even glycerin can be fed into the gasifier and turned into ethanol. However, Enerkem has chosen to pursue nonhomogenous biomass that has little or no value. “Our scientific vision of biofuel production makes a clear distinction between homogenous and nonhomogenous biomass,” says company cofounder Dr. Esteban Chornet. “Our company will get carbon where it’s cheapest.” For now, the most attractive source of carbon is household waste: municipalities are paying to get rid of it.

Now retired from the University of Sherbrooke, Quebec, where he held the Industrial Research Chair in Second-Generation Biofuels, Chornet has made it his life-long mission to develop an efficient, logical, and sustainable alternative to fossil fuels. The best way of achieving this, he found, was through gasification.

Just like first-generation ethanol technology, the technology of gasification is not new. Coal, for instance, can easily be gasified, and the gas burned to produce energy. But Enerkem goes a few steps further. After gasifying the feedstock in an autothermal fluidized bed gasifier that reaches a temperature of 800°C, the resulting syngas is cleaned and conditioned before entering a catalytic reactor that turns it into alcohol. The beauty of Enerkem’s technology is that it can accept “dirty” biomass like treated wood, municipal sludge, or what’s left of municipal solid waste (MSW) after most recyclables and compostables have been removed.

Feedstock pre-treatment is limited to drying and shredding. In the case of MSW, metal and glass must be removed. The byproducts of the biofuel process are water and inert materials that can be used as aggregates for construction materials such as bricks.

Enerkem calls its second-generation ethanol an advanced biofuel. Even though most feedstocks that the company has tested contain cellulose, Enerkem tends to avoid the cellulosic ethanol label, leaving it for companies that focus on efficient ways of breaking down cellulose using

biochemical processes.

Second-generation biofuels are all about using feedstocks that have less value than corn or sugar cane. What differentiates Enerkem from other second-generation biofuel developers is its main interest in what it calls negative-value biomass, which usually requires a tipping fee for disposal. “We get paid to receive our feedstock,” says Marie-Hélène Labrie, government affairs and communications vice-president. “What we do is unique. We are the only industry player going for garbage.”

Enerkem’s intriguing technology draws dozens of visitors to its pilot plant in downtown Sherbrooke. The plant was started in 2003, three years after Esteban Chornet founded the company with his son Vincent, who was previously involved in assisting start-up companies in the chemical, energy, and biotech sectors.

The Sherbrooke plant has now completed over 3600 hours of operation. Its capacity of 475,000 litres/year makes it ideal for testing, but too small for continuous operation. “This is our playground,” says Daniel Arguin, vice-president of engineering and implementation.

After working for 25 years in key positions with Canadian, U.S., and European industrial giants, Arguin is back to his alma mater, where Chornet once taught him chemical engineering. He is so confident about Enerkem’s technology that his tour of the pilot plant includes a candid admission that most of the equipment was bought on eBay.

“Delivery times are very short,” he says with a smile.

The gasification and catalytic conversion technologies use standard industrial equipment. Tweaking it is what takes time and effort. The results are analyzed in University of Sherbrooke laboratories.

“We run a lot of trials,” says Arguin. “Results are not always good, but we learn a lot.”

The company’s credibility and ability to draw investors stems from its rigorous scientific approach, says Arguin. Few bioenergy start-ups can boast to have been running a pilot plant for more than six years with such a high number of hours of operation.

In 2007, Enerkem began construction of an industrial demonstration plant in Westbury, located 25 km east of Sherbrooke. This facility stands next to a sawmill that recycles used utility poles and provides the shredded outer layer to Enerkem; prior to this, the outer layer was sent to a landfill. “The inner core is recycled into four-by-fours or six-by-sixes,” says Arguin. “We take the outer part and turn it into ethanol.”

The Westbury facility is expected to produce five million litres/year of second-generation ethanol when operational. More importantly, it will demonstrate the technological and commercial good sense of using negative-cost materials that are usually landfilled. The plant is currently producing syngas and should become fully operational in the fall of 2009, when it installs catalytic reactors to produce ethanol from the syngas.

Enerkem’s first full-scale plant will be built in Edmonton, Alberta, with construction beginning in the fall of 2009. The plant will be 10 times bigger than the one at Westbury and will be “the world’s first commercial municipal waste-to-biofuel facility,” the company says. A 25-year agreement has been signed with the City of Edmonton, which will supply 100,000 tonnes/year of sorted MSW.

The plant, which is expected to start production in 2010, is being implemented in partnership with Ontario-based Greenfield Ethanol, a corn-ethanol producer. Upon completion, the $70-million plant will produce 36 million litres/year of ethanol. This will reduce Edmonton’s carbon dioxide footprint by six

TOP: Over 20 types of biomass feedstock have been tested in the Sherbrooke pilot plant.

LEFT: To produce ethanol, Enerkem gasifies any type of biomass and reacts the syngas with a catalyst.

million tons over 25 years, the equivalent of taking 12,000 cars off the road each year.

“Edmonton will really be the gate-opener for us,” says Arguin. “That plant will become a worldwide reference.”

With the Edmonton project, Enerkem will be showcasing the first of an unlimited number of 36-million-litre ethanol plants it hopes to build. By standardizing the size and outfitting of its facilities, Enerkem hopes to reduce costs and risks associated with each new project.

Arguin admits that Enerkem’s typical ethanol production module will be relatively small. By processing only 400 tonnes/day of refuse, this limits the number of garbage trucks entering the site to about 30. However, Arguin notes that this size makes the financing and public acceptance of new plants easier. This scale of approach will also allow Enerkem to use existing standard industrial equipment. All tailor-made parts will be manufactured in the Sherbrooke area in machine shops that are looking for new business now that the pulp and paper industry is on the decline. Everything will be small enough to be freighted in one piece to a plant’s construction site, says Arguin.

After Edmonton, Enerkem’s next major project will be located in the state of Mississippi. In March, the company signed a memorandum of understanding with a five-county regional waste management authority for the supply of 189,000 tons of unsorted MSW. Under the current scenario, Enerkem will assemble two of its standard waste-to-ethanol modules at a landfill site. It also plans to build recycling units for paper, metal, and glass; whatever cannot be recycled will be turned into ethanol. The plant will also accept forestry biomass from area companies.

Each production unit can be fed different types of feedstock. The major difference in handling various feedstocks is in the pre-treatment, to ensure

Some companies are avoiding ethanol altogether in a quest to produce drop-in synthetic hydrocarbon transportation fuels (like gasoline) from biomass. In this process, finely ground biomass is rapidly decomposed under high temperatures to yield pyrolysis oil and other products. The pyrolysis oil is then upgraded and refined to make synthetic gasoline, diesel, and jet fuel. This upgrading and refining technology is currently being developed and improved by various industry players.

Envergent Technologies, headquartered in Des Plaines, Illinois, is a new joint venture of Ensyn and UOP. The company has demonstrated that pyrolysis oil produced using Ensyn’s pyrolysis technology can be further upgraded to transportation fuels using UOP’s hydroprocessing technology. It claims that the process produces gasoline, diesel, and jet fuels that are virtually indistinguishable from their petroleum-based counterparts. The process has been demonstrated in the laboratory, and the company is developing commercial-scale technology that it anticipates could be available for licensing in 2012.

Dynamotive Energy Systems, headquartered in Vancouver, British Columbia, also uses a hydro-reforming process to upgrade its pyrolysis oil to liquid hydrocarbon fuels. In a recent press release, it states that independent and internal analyses of its stage 2 upgraded pyrolysis oil indicate that the mixture contains components similar to a crude oil fraction, with distillation fractions of approximately 20% gasoline, 30% jet, 30% diesel, and 20% vacuum gasoil by weight. Construction of a pilot plant may begin in late 2009, pending financing.

– Heather Hager

that the feedstock that enters the gasifier is in small enough pieces and at less than 25% moisture content. This flexibility is what could bring Enerkem to municipalities throughout Canada. In regions that have too little MSW available to operate a plant at capacity, the plant could also use locally available forestry or agricultural biomass. “The key is to secure a stable supply of feedstock,” says Labrie. Before investing, Enerkem requires a long-term agreement that indicates how much feedstock it will receive and how much money it will get for taking it.

Enerkem is ready to go big. “We want to have multiple facilities built every year,” says Arguin, without further revealing company objectives. He says that the current workforce of 56 employees is up to the challenge of managing exponential growth.

Financing so far has come in the form of private funds from company management, government subsidies, and venture capital (Rho Ventures and Braemar Energy Ventures of the United States, and Canada’s BDR Capital). Partnerships are sought for new projects, but Enerkem wants to own and operate all new facilities. “We are not selling our technology,” says Arguin.

Enerkem is already a world leader in second-generation biofuel generation, says Labrie. No one has been eyeing MSW as a feedstock for ethanol production for as long as Esteban Chornet has. Now, Enerkem is going commercial and it’s getting paid both for taking the feedstock and for making ethanol out of it, says Labrie. “The world is watching us!” •

TThis year will be a test of the management of all wood pellet manufacturing companies.

By John Swann

he year 2009 will be known as the “Best of Times and the Worst of Times.”

Canadian wood pellet manufacturers have hit limits to pellet production from sawmill residues because of the downturn in the forest industry of sawn lumber for the U.S. housing market. In fact, pellet producers in eastern Canada and the Maritimes began to experience sawmill residue reductions more than two years ago. Add to that the financial crisis of 2008 and you have the perfect storm to hit the pellet industry. Fortunately, the markets for both the U.S. Northeast and the European utilities are still strong, and demand is growing cautiously.

Wood pellet manufactures now need to go to the forest if they intend to survive the current biofibre issues and maintain and/or increase production capacities. A reversal of biomass raw material dependency will be required, changing from using sawmill residues as the primary source, with augmentation from forest harvest and noncommercial roundwood debris, to using harvest and noncommercial roundwood debris as the primary raw material resource, augmented by sawmill residues. The supply of forest harvest and noncommer-

cial roundwood debris resources in Canada is abundant. Canadian wood pellet production, capped at under 2 million tons, will be able to advance beyond 20 million tons on a sustainable basis over time. The transition from the dependency on sawmill residues to going to the forest will release the wood pellet industry from being captive to the forest industry.

The transition from low-cost sawmill residues to the higher cost forest debris resource will be the biggest challenge for Canadian wood pellet manufacturers, especially those exporting to European utilities. To accommodate the three- to fourfold higher raw material costs, longterm export contracts will need to increase by as much as 30 to 40%. Renegotiating these contracts will be a daunting task, but very necessary for financial success. Another major challenge, particularly for manufacturers in British Columbia, is direct access to the forest harvest and/or noncommercial-valued roundwood biomass resource. The BC Ministry of Forests, which is the

steward of the resource, and the major licensees in BC that control the forest land base have not realized the true potential of the forest to include bioenergy. Although there has been much discussion and debate over the past few years, a major shift in the mindset of the Ministry and government needs to occur before additional and continued new capacity can develop in BC.

“Wood pellet manufacturers now need to go to the forest if they intend to survive the current biofibre issues and increase production capacities.”

Ontario is leading the way to encourage growth for a bioenergy economy in Canada today, with the required legislative changes.

Canadian wood pellet production ranked number one in the world in 2007 at 1.6 million tons, but has dropped to fourth behind Sweden, United States, and Germany to 1.4 million tons. However, once the challenges of the worst of times are met, Canadian wood pellet production should rebound to become the world leader in production and exports. Canadian west coast manufacturers are expected to export over 800,000 tons to Europe in 2009 to the Netherlands, Belgium, and the UK. The balance of Canadian production is exported to the United States, with the exception of our embarrassingly low domestic consumption, still at less than 200,000 tons. •

John Swann is the executive director of the Wood Pellets Association of Canada and a former CANBIO board member.

Curran Renewable Energy shipped its first pellets to a Quebec client this past July, with a twist. The pellets are made from green roundwood chips from a sister company’s pulpwood operation.

By Scott Jamieson

pellets from roundwood

may seem like black magic to most of Canada’s growing forestry biomass sector, but for Pat Curran it’s all in a day’s work. It’s also a no-brainer. Driving into the yard at Curran Renewable Energy’s recently started pellet mill, the logger and forestry entrepreneur points to several piles of wood chips and summarizes his rationale for investing $10 million in one of North America’s first greenwood pellet plants.

“We could see where the local pulp wood market was going, especially for the less desirable species. Here’s a case right now where I have no market at all for the chips that are sitting there, except the hardwood. I also have a tremendous inventory of tree length piled in the woods waiting for us to get running here so

we can chip it. We’ll let nature suck some of the moisture out a bit while we wait. We had to find an alternative for some of our volumes like this if we were going to have a future.”

Curran, along with his brothers Tim and Lee, have owned and operated Seaway Timber Harvesting for over two decades now. It is a large bush chipping and transport company perched on the Canadian border in Massena, New York, with established roots in the state’s private forestland market and 15,000 acres of its own. Getting fibre and harvesting it has never been a major issue for the Currans. Lately, however, markets have been. A key client, Domtar’s pulp mill just over the border in Cornwall, Ontario, shut down in 2004, but even before that, currency fluctuations were wreaking havoc for a logger paid in Canadian dollars. While Domtar’s mill in Windsor, Quebec, has since become a key client for Seaway Timber Harvesting, the

The automated bagging line from Hamer has been designed for a quick change-over between pellets and mulch, with the latter entering via an outside infeed system.

dramatic industry downturn over the past three years has limited other outlets.

“We’ve been looking at pellets as a way to diversify our markets for a few years now, but it’s new to us, and a big investment, so it has taken a while to get off the ground. It’s a good fit with our existing operation, and we’re big believers in the future of renewable energy in this area.”

Curran Renewable Energy is an entirely separate company owned by the three brothers, along with a 10% equity stake by the New York State Power Authority “spec fund”.

“Basically, the investment is $10 million. We financed most of it, which was an adventure in itself. It amazed us how much money disappears up front just in financing charges. We put

A Peterson 4710B grinder with colouring unit works at Seaway Timber Harvesting’s main yard. The pellet mill’s bagging line has been designed to handle mulch as well, giving access to new markets.

A John Deere wheel loader puts green chips into a hopper feeding the first Andritz Sprout hammer mill with 5/8” screens. The hammer mill is enclosed to reduce noise for local residents.

in some money ourselves, and the spec fund matched that to $1 million and took a 10% equity position, which we have the option to buy out. You’re looking at a company with lots of debt and not so many assets.”

In fact, the Currans are sitting on a few key assets, albeit not the kind you can slide into a balance sheet. First, they have transportation and chipping infrastructure established that allows them to bring the fibre in at as low a cost as anyone. That includes seasoned crews and relationships with area landowners. They are also integrating the pellet fibre operation with an established forest products operation and markets.

“Our relationship with Domtar Windsor is key. They have been a big factor in our survival over the past few years, and we won’t do anything to risk that. We will do what it takes to meet our fibre commitments there. But our crews have extra capacity right now in this market, and so we can use that to feed the pellet plant. That means that making pellets from green wood makes sense to us where it may not to others.”

Finally, the operation is sitting on the doorstep of one of the most vibrant residential pellet heating markets in North America. As far back as July 2008, shortages of wood pellets for

the coming winter became front-page news in newspapers from Maine to New Hampshire and Massachusetts. As a result, Curran Renewable Energy has built its plant with these regional residential and small commercial markets in mind.

The plant itself has been built in Massena’s industrial park right on the edge of town. It sits alongside a rail line, and future plans may well include a spur if an industrial bulk market develops.

“That’s what we hope, to give us a mix of the two markets, but for now the focus will be on the market for bagged pellets, including local sales right from the plant. We don’t expect to move a lot of pellets locally, since the population just isn’t here. On the other hand we’ll be moving a lot of trucks through town to get here, so it’d be nice to offer the local market a consistent supply of pellets in return.”

As a logging and chipping company with very little manufacturing expertise, Curran Renewable Energy turned to outside help for plant design and equipment selection. Still, the process was not without early hiccups

“The first thing John (John Lundell of Energy Unlimited) asked me was where we wanted our fire,” Pat Curran recalls. Fire and explosion protection has thus been given high priority, with a Firefly AB system installed front to back.

Curran says, admitting that his eagerness to get going almost cost the young company. Fortunately the curious mechanic and logger in Pat came out just at the right time and allowed for a timely change of direction.

“At one point we were set to buy a used drum dryer from the southern United States, and just to be sure, I went to a local hardware store and bought a wrench set to open it up and have a look. It was warped like a banana inside. So I called John Lundell at Energy Unlimited to ask about fixing it, and when we went through all the costs of pulling it out, shipping and repairing it, it made more sense to buy new. At that point I started checking some of what I had been told, and pretty soon after, John was handling the project.”

Energy Unlimited eventually assumed close to a turnkey relationship, providing design and equipment selection advice, handling mechanical installation and start-up, and even supplying much of the conveying and drying gear. The mill handled site prep and concrete work for the plant that will target 100 tons per year.

The process starts in the woods, where

Seaway Timber’s fleet of Morbark and Peterson flail debarker/chippers turn the region’s mixed wood diet into pulp chips. “The chips coming here are identical to those we make for the pulp market, so it’s very flexible. We can send the chips to either depending on markets.” Chips are moved to either Seaway Timber’s reload yard in Chateauguay, New York, for shipment to Windsor in Manac trailers loaded for heavier Canadian weights, or to the pellet mill. Bark goes to Seaway’s garage and office site in Massena, where a Peterson 4710B with colouring system makes landscape mulch.

Once the chips hit the pellet mill yard, the incoming vans are weighed on scales repurposed from a company gravel pit and then go to a Columbia tipper. From here a Cat wheel loader feeds a hopper bought used from the shuttered Domtar mill in Cornwall.

“Aside from this piece of used equipment, it’s all new gear,” Curran adds.

The hopper feeds the first hammer mill, an Andritz Sprout model with 5/8" screens contained in a stand-alone building. “We’re right in town at this location, so we’ve done what we can to try to isolate the noise,” he explains.

This fibre then goes to a 13 x 16 foot Baker Roman triple pass rotary dryer supplied by

The

cyclones and ending just ahead of the bagging storage silos. To avoid false alarms, the sensors are insensitive to daylight. Yet to make sure all potential risks are managed, the infrared sensors pick up both “dark” embers (those between 250 and 700 degrees Celsius that can still ignite the dry meal) and what we more traditionally think of as sparks (above 400 degrees Celsius). If an incident occurs, the system uses a full-cone spray that is able to handle the high-volume flows typical of pellet mill conveying systems.

Fibre is sent from the cyclones to the second hammer mill, another Andritz Sprout model with 1/4" or less screens. From this point the meal goes either to a bag house to feed the pellet mills or to the burner to heat the dryer. For start up, the plant brought in some animal bedding to fuel the burner, an exercise that gave Curran Renewable Energy other ideas.

Energy Unlimited along with one of the supplier’s own burner units. From the dryer, fibre is conveyed to cyclones, passing through the first of a series of Firefly AB spark detection sensors. Spark detection and fire mitigation has been an emphasis at the plant since day one.

“One of the first things John (Lundell) asked me was ‘where do you want your fire’. So we designed to handle that possibility throughout the plant. The detection system we put in was a little more expensive than others we looked at, but we felt it covered more in the plant.”

The Firefly system gives the plant full coverage, starting with sensors between the dryer and

“We’ve left a spot for a shaving line just outside the dryer,” Curran says. “We wanted to have an outlet for our dry meal if our pellet inventories ever get too high, and animal bedding is a good market here. But we saw that the bedding we were buying was actually very close in quality to the meal we’ll be making pellets with, so we hope we can avoid putting a shaver in altogether.”

Once inside the main building, pellets are made by three Andritz Sprout pellet mills. Room has also been left for a fourth down the road if needed. Pellets go to a MilPro cooling system from Quebec’s Law-Marot, through an Andritz Sprout shaker screen and then are sent across the yard to a solitary agricultural-style storage silo from Kramer Metal Products. Again, the designers left room for a second silo down the road if cash flow allows.

Throughout the process, the plant maintains

two distinct fibre sources, allowing the Currans to offer its clients Forest Stewardship Council (FSC) certified pellets. “Whether it helps us time will tell, but I believe it will. Unlike lumber that gets covered up, people will be accessing their pellets for heating daily or weekly, and they’ll see that label. We’re getting enquiries already, so I think it will be a factor for us down the road.”

Pellets are bagged on an automated line from US supplier Hamer Inc., including a robotic palletizer and a plastic wrap turntable. “We have some work to do on the latter to make the pack-

ages more windproof. We want the pellets to be completely protected before they get to the consumer, and the system isn’t doing the job we want as of yet. We’re adding a cover ourselves for now.”

The line was also designed on rails so that it can be slid back several feet to allow the plant to bag mulch as well. Mulch is brought in via an outside infeed, bagged, and then follows the line just as pellets would.

“We figure we can bag all our pellets on a 24/7 operation in just eight hours on this line,

so we’ll have time to bag the mulch too. We’ve been in the coloured mulch market for years, but this allows us to bag the product and sell into different markets. It will also allow us to back an inventory ahead of winter, so that when the garden centres start looking for bags in the early spring we’re not struggling with piles of frozen mulch.”

Changeover takes less than an hour, but in future they are hoping to add extra pellet storage silo capacity so they can run pellets for a full week before switching.

“So far the line runs well. We’ve done 20 bags per minute with mulch and we know with pellets it will go easier.”

Pellet inventory will be stored inside the rest of the 30,000 square foot building ahead of shipping. The company has also added four new Manac flatbeds to handle some of its own distribution. In the end, Curran feels that becoming a reliable, consistent heating supplier will be crucial to growing the wood pellet business in general.

“There is already interest and demand for wood pellets for heating in this part of the country, but regardless of what anyone thinks, we need a surplus to make this market work; not a glut, but a surplus. And for us that means everything from the fibre to delivery. Our focus starts on the fibre, and we believe that access to fibre will be a big factor going forward. Customers will be relying on me, and just like our traditional logging operations, some kind of inventory will be important to handle the surprises.”

And from what he’s seen of pellet manufacturing, surprises will not be unheard of. The mill originally hoped to start running in January, but a series of delays eventually pushed things back to late June. Curran says it’s not like they’ve been trying to make pellets since then, just fine tuning the design and dealing with unexpected delays.

“We’ve been working the kinks out of the flow, but just parts inventory has been a learning curve. We know what we need on hand to keep the chipping business running after all these years, but we haven’t built up a similar must-have inventory here yet. We had a faulty 500-hp motor go down on one of the hammer mills that cost us two days, and then no sooner did we fix that than a 1-hp motor failure cost us another two. As soon as cash-flow allows, we’ll be stocking critical items like that.”

Yet already the Currans have done what many logging operations in Canada have only been talking about – turned a lost customer base and excess fibre into a new biomass business opportunity. •

Bliss Industries is continually expanding its line of Pioneer Pellet Mills.

Bliss Industries manufactures biomass pelletizing equipment for residential, commercial, and industrial pellet fuel. Founded in 1981, the company maintains a reputation of manufacturing efficient, reliable, and well-built equipment. Developed from a design concept proven worldwide, the range of Pioneer Pellet Mills continues to expand. Overall reliability, maximum efficiency, and ease of operation and maintenance combine to make lower operating costs for the owner. With the ability to provide a wide range of die sizes, die speeds, and drive power, Bliss Industries delivers high quality at a reasonable cost. It also manufactures an extensive line of hammer mills and coolers for biomass size reduction, processing, and cooling. Its Eastern Canadian rep is Gaston Richard, who can be reached at 1-800-361-7907.

www.bliss-industries.com, sales@bliss-industries.com

Kahl pelleting plants successfully compact organic products of various particle sizes, moisture contents, and bulk densities. The company’s pelleting presses are particularly useful for products that are difficult to pellet. For this reason, the Kahl pellet press is uniquely designed to pellet wood waste, shavings, chips, sawdust, and sanding dust. Its great variety of input products and the different plant sizes available allow Kahl to plan and calculate its plants according to customer requirements, with capacity and local conditions in mind. The company specializes in producing a high pellet quality, which equals a high bulk density. High bulk density provides better combustibility. Kahl offers consultation, assistance in obtaining approval, engineering, commissioning, installation, and after-sales service at the local level. It also supplies turnkey plants for most applications and tests products at its pilot plant and test facility.

www.akahl.de, rbmacarthur@sympatico.ca

To complement our pellet manufacturing feature in this issue of Canadian Biomass, we provide an update of available pellet manufacturing equipment. This guide offers a concise summary of what’s available in technology levels and capacities to suit the needs of industry professionals, with all information provided by the equipment manufacturers and suppliers. Discover the benefits and operator/owner features of this new and updated technology. – Compiled by Colleen Cross.

Bühler’s RWPR-900.138 pelletizer offers conditioning and pelleting, with a motor of up to 450 hp.

Bühler, a supplier of pelleting technology to the feed industry, has been active in the biomass pelleting business since 1996 and has built one of Europe’s largest facilities. In 2007, the company was awarded a contract to supply the grinding and pelleting section of the world’s largest wood pelleting plant, located in Florida and producing pellets since April 2008. The plant produces 500,000 tonnes/year (550,000 tons/year) of industrial wood pellets. The scope of equipment supply encompassed mechanical and electrical equipment, the electrical control system, and installation supervision. The company also builds smaller facilities starting from approximately 3.5 to 4 t/hour pelleting, depending on wood type and species. Buhler specializes in engineering and supplying complete solutions for services and equipment after the wood yard, including the following features: belt or drum dryer from Bühler-Aeroglide; sizing with the Vertical Hammer Mill DFZK, which operates without aspiration air; conditioning and pelleting with the Wood Pellet Mill RWPR-900.138 (up to 450-hp motor); cooling with a countercurrent or belt cooler; screening with an Oscillating Sieve DFTA or a Round Sieve DFTD; bagging or bulk out-loading; electrical control system, including MCC and PLC; and installation supervision and commissioning/startup for the mechanical and electrical equipment. Bühler sells whole plants, plant sections, and single machines. www.buhlergroup.com, adrian.polman@buhlergroup.com

The Integrated Wood Pellet System from Kerry Die makes the most of the properties of raw material in a processor/condenser unit before feeding it into a high-capacity press. The press combines high output with low energy consumption to produce wood fuel pellets. The company has designed a new wood pellet system: the Calorific M6 Processor/Condenser and B-Mass 800 Wood Pellet System, available in both 6-TPH and 10-TPH sizes. The Chemical Analysis Electronic Meter measures the incoming raw material for precise properties. The Calorific 6M Processor & Condenser then activates these properties and removes excess moisture. The prepared material feeds into the high-capacity B-Mass 800 Pellet Press.

The Integrated Pellet System allows operators to quickly change the die without coming into contact with the die surface.

The external rolls and die speed are programmed and automatically adjustable to ensure maximum output and minimal energy consumption. The lack of contact between rolls and die ensures minimal wear on both elements, and the reduced rpm and processed raw material improves the life of key components. The simplified die clamping system allows the operator to avoid direct contact with the die surface while changing the die easily in about one hour. www.kerry-die.com, info@kerry-die.com

La Meccanica’s 48 years of experience in the design and manufacturing of machines for the pelleting industry encompasses mills, dehydration plants, sugar refineries, oil mills, organic and mineral-organic fertilizer processing plants, the waste and recycling industry, and wood pellet plants. Currently expanding its North American market within the wood processing industry, La Meccanica’s machinery is specifically designed to withstand the rigours of producing wood pellets.

The durability of components such as bearings, dies, and rolls contributes to the long life expectancy of La Meccanica’s machinery.

It offers low operational costs attributed in part to the durability of its components, which can increase the machinery’s life expectancy by about three times compared to others currently in the market. By keeping the design and production processes in-house, La Meccanica maintains direct control in real time and the ability to treat requirements on a case-by-case basis. www.lameccanica.it/page.jsp?idLingua=1, lameccanica@lameccanica.it

Nova’s range of pellet mills offers high pellet output combined with energy savings.

Nova Pellet manufactures a complete range of machinery, from small- to medium- and large-scale pellet production. The company’s pellet mills combine patented technology, efficiency, and environmental friendliness. Among its patented technology are a servo drive and programmable logic controller (PLC) system. Nova has increased efficiency by minimizing the electrical kilowatts consumed for each kilogram per hour of pellets produced, which results in significant energy savings. These mills will produce pellets without any additives, from natural origin, so DIN Plus standards can be reached easily. All machinery is developed to give low production costs and high-quality pellets to make owners competitive in both private and industrial markets. Nova Pellet also designs plant layouts and builds turnkey pellet plants, from chip reduction to pellet packaging. www.novapellet.it, commerciale@nova-srl.com

The SPC line includes this self-contained portable pellet mill seen at World Bioenergy in Sweden.

Silvana Trading specializes in small-scale pellet presses from Sweden Power Chippers (SPC) for production capacities of 1,000 to 15,000 tons/year of pellets. It can supply either the presses alone or full turnkey installation. SPC pellet mills offer fully automatic production with minimal supervision requirements. Production can be increased easily by adding parallel lines.

Pellet presses range from the PP300 Kompakt that converts wood into 8 mm diameter pellets, with a capacity of up to 250-350 kg/hour, to the PP450 Kompakt that converts wood into 6 or 8 mm diameter pellets, with a capacity of up to 500 kg/hour.

Small-scale pellet production is advantageous when the costs of raw materials and transportation are low such as when using dry wood shavings and sawdust from an existing planer mill or similar facility.

www.silvanatrading.com, info@silvanatrading.com

Biomass quality and consistency is key to smooth boiler operations at den Haan’s Greenhouses.

By Heather Hager

asenergy prices become less predictable and more prohibitive, many greenhouses are turning to biomass fuels to meet their heating needs and provide cost savings. Energy costs can make up 30 to 50% of greenhouse operating costs for Canadian vegetable producers, and reducing these costs can help growers to meet their bottom line. So when Luke den Haan received an annual fuel bill of almost $600,000 in the early 2000s, he knew something had to change.

Den Haan is the young production manager for den Haan’s Greenhouses, located in the Annapolis Valley of Nova Scotia. The family has been growing greenhouse products in Nova Scotia since 1960 and is onto its third generation of family operators. Luke den Haan’s parents, brother, and sister run the company’s retail garden centre, nursery, and original greenhouse, where Luke’s father, John, still grows English cucumbers and peppers. In 1999, the company built a modern 3.5-acre greenhouse to expand its hydroponic tomato production. Because natural gas is unavailable in the area, the greenhouse was initially outfitted with a propane-fuelled boiler.

“When we built this greenhouse, it was under the assumption that propane was going to stay around 22 cents/litre. As soon as we started using the greenhouse, propane jumped to 40 cents/litre,” says den Haan. Eventually, propane reached 80 cents/litre and even higher. Happily by then, a new biomass boiler was heating the greenhouse. This allowed a reduction in propane consumption from about 1.3 million litres/year for heat and carbon dioxide to about 75,000 litres/year to maintain carbon dioxide production to feed the plants, and virtually halved the greenhouse’s energy costs.

A 400 hp (~4 MW thermal), low-pressure, hot water Boilersmith boiler supplied by Ontario-based KMW was installed and fired up in 2005. Den Haan cites several reasons for this choice of boiler, including its multi-fuel versatility. “This boiler was designed for biomass. We wanted a versatile system that could burn different things. If I ran out of wood this month, I could chop up hay or whatever I want and burn it.” And after purchasing the greenhouse from Holland and having to deal with time delays and exchange rates to obtain parts from overseas, he says he appreciates the convenience of having a domestically manufactured boiler.

While researching potential boilers, den Haan also considered possible sources of biomass. He first began burning sawmill waste obtained from several local sawmills, but was unhappy with the quality and consistency of the biomass. “When we first started, I had a fair amount of boiler system alarms because the sawdust had big chunks of slabwood in it, which caused blockages,” he says. “And then the truck that brought it to me hauled steel when it wasn’t hauling wood, so pieces of steel that got left on the truck’s walking floor would come out with the wood.” These didn’t just cause blockages; they caused damage and broken parts. Fed up with these problems, mill closures, and irregular supply, he considered other options.

Unmarketable roundwood is purchased from local woodlot owners and ground to a consistent size for fuel. This remaining pile of ground biomass would supply about two weeks of greenhouse heating in midwinter.

Greenhouses are high energy at once. “When they need it, they need a lot of it, and you need a boiler that will give you the output,” says Luke den Haan, standing in front of the Boilersmith low-pressure boiler.

“There seemed to be a lot of wood producers around and not really a market for the waste wood,” says den Haan. Now, he purchases lowquality roundwood that before would have been left behind because there was no market for it. “It opened up a new industry for the wood producers and makes us feel good because all the money that we used to spend on propane is staying locally.”

The roundwood is delivered directly to the greenhouse, where it is later ground into fuel. Den Haan originally had a chipper service come to chip the wood, but says that it was too slow because the machine could only chip one log at a time. He burns about 2000 cord of wood per year and has it shredded 1000 cord at a time. He now has a grinding service, which he says is cheaper and faster, grind the fuel into small, consistent pieces that won’t clog the boiler.

The ground fuel is piled on an outdoor pad the size of a soccer field. “We have the pile rounded off so it sheds water, so in the spring, summer, and fall, we don’t worry about covering it,” explains den Haan. In winter, the pile is covered with a tarp to prevent the surface layer from getting too wet and freezing because chunks of ice will clog the boiler intake system. Each morning, a front-end loader scoops up biomass and fills the boiler intake area. On average, the boiler consumes about one tractor-trailer load of wood per day.

Other than having to move biomass manually to the boiler intake area, the boiler is highly automated, with auto start up, shut down, biomass infeed, and ash removal. It heats water that circulates to a huge heat storage tank, and shuts off when the heat storage tank is at 100% capacity. When the greenhouse needs heat, it draws hot water from the heat storage tank and circulates it through pipes located just above the floor between the rows of plants. When the stored heat supply gets low, the system tells the boiler to restart.

The greenhouse climate control system regulates the boiler system, and both systems can be accessed remotely, for example, from computers in the office or at den Haan’s home. The computer shows real-time boiler function, including the fuel infeed, the moving grate floor inside the boiler, and combustion and flue gas temperatures. A live camera feed monitors a key point along the infeed so that if there’s an alarm, den Haan can check for plugging without having to go to the site. “I hate to drive all the way here for an alarm and see I just could have reset it at home,” he says. “At two o’clock in the morning, you just feel like sleeping, rather than driving all the way to the greenhouse.”

“Biomass boilers take a bit more maintenance,” he admits. He says he’s heard the same story from almost every greenhouse that has gone into biomass—the first year is terrible, with lots of boiler alarms and little sleep. He can’t stress enough the importance of biomass quality. “If you have really poorly ground wood, you’ll have a lot of alarms and maintenance, and things will break. If you burn good wood that’s ground nicely and is the right moisture content for your system’s design, then it burns fine. Now, I might have an alarm only once every two or three weeks.”

Aside from biomass supply and quality, the most important change in moving from propane to biomass was the difference in payment structure, says den Haan. And it’s something they’re still getting used to. “With propane, we’d burn it and pay 60 days later. With wood, we have to buy it all in the summertime to burn in the fall and winter. With 2000 cord and grinding charges, it’s a lot of money to tie up, up front, and you’re not burning the wood for ages.”

Very few infrastructure changes were required to switch to the biomass boiler. A new boiler building was needed, but the former propane system already included a heat storage tank. So it was simply a matter of hooking into the existing system. The biomass boiler is more than big enough to handle its current load, says den Haan. “I would get more efficiency out of the boiler if I had a heat storage tank three times bigger.”

Den Haan has big plans for the future, including bringing the family’s English cucumber and pepper production into this newer facility and expanding the greenhouse’s production. What he would really like to do, however, is get away from using propane altogether. “We do still use a bit of propane for carbon dioxide production, but they are coming out with technology to extract the carbon dioxide from the flue gases of the biomass boiler, and that’s what we’re going to pursue next,” he states.

“I’m not a boiler operator; I’m a tomato grower. If I don’t have product to pack and sell, I have nothing,” says den Haan. Although the biomass boiler takes a bit more work than the propane boiler, he doesn’t feel that he’s wasting time working with it now that it’s running smoothly. “I’ve always looked for ways to do more for less and build our business, build our brand, talk to our customers. I couldn’t do that if I was tied up in the boiler room.”

Overall, den Haan seems delighted with biomass. “I’m very happy with my boiler system,” he repeats. “It works like a charm.” •

TIn this first of a series of columns looking at residue-handling equipment, Mark Ryans discusses methods for taking residues from forest to customer.

By Mark Ryans

here are three basic methods for handling forest residues: transportation of loose residues, compaction, or comminution. For the most part, transporting residues in a loose form is not practical or economical. The payload is very low, restricting their economical transport to very short haul distances. Loading, handling, and transporting loose debris is also problematic, requiring special trucks and unloading facilities. A number of companies are starting to ship full trees or roundwood as an energy source. In this case, conventional equipment is used, but full trees can raise safety concerns because of branches sticking out beyond the trailer. In trials, the wood was sent to a central landing to be chipped, so all transport was off-highway. Should highway travel be necessary, a walled trailer should be used.

Apart from bundling equipment, the art of compacting forest residues is not well developed. Bundlers were originally developed in Sweden, but their application has been more widespread in Finland. They are used to produce round bales, called compacted energy logs, from limbs and tops. At one time, there were a number of manufacturers, but today there are only the John Deere Energy Wood Harvester and the ABAB Rogbico. Forwarder-mounted bundlers were developed for recovering residues from cut-to-length harvesting systems; however, the Rogbico is truck mounted, designed for producing large energy logs from residues placed at the roadside. Bundling improves the payload, but a comminution stage is still required at a central terminal or energy plant. There are no bundling systems in use in Canada at this time, and the place for bundlers in Canadian supply systems will be discussed in a future Residues to Riches article.

Comminution, which is just a fancy word for particle-size reduction, is the critical stage in the design of an efficient supply chain for harvest residues. It is the chipping, grinding, hogging, or shredding phase done in the woods,

with the purpose of increasing the payload in the van and facilitating the handling of material further down the chain.

As I stated in my previous column, the supply chain begins with the customer, in this case, an energy plant. The comminution method plays an important role in meeting the feedstock quality demands of the conversion facility, and in many cases, it will determine the final product quality, as there may be no further rehogging capacity in the system. Smallerto medium-sized heat plants are more susceptible to variations in feedstock particle size, resulting in a narrow allowance for delivered particle size. Even at large combined heat and power facilities, there may be other physical limitations to the feedstock because of the types of feeding devices that are used, such as augers.

where they are used to process municipal debris. They can treat highly contaminated debris, but they also produce large oversized pieces not readily suitable for burning. Tub grinders are also used in many applications, but again, they are more suitable for municipal debris and for producing mulch from bark. However, they are not suitable for handling long pieces and tops. High-speed shredders

A few years ago, the choices in comminution equipment were somewhat limited, but recent development and refinement of horizontal grinders and the emergence of more drum chippers in North America is opening up more avenues for tailoring the feedstock quality to the needs of the energy plant. With greater choice, however, comes a greater risk of making the wrong choice.

Comminution equipment includes highand low-speed shredders, tub and horizontal grinders, and disc and drum chippers. All have a place for treating woody residues, but some are more suitable to forest conditions and for harvest residues than others.

High-torque, slow-rotation shredders are common, especially in larger communities,

are not common, and their use is limited to specialized applications such as producing mulch. This leaves three main equipment types: disc chippers, drum chippers, and horizontal grinders.

The choice of these tools and their specific configuration will be determined by the customers’ needs, the forest conditions, the nature of the material to be treated, and how well the residues were handled before the comminution stage, i.e., the level of contamination.

This stage is one of the most critical in designing an efficient supply system. I will examine these equipment choices in more detail in my next column, called “To chip or to grind?” •

Mark Ryans is with FPInnovations–Feric Division and can be reached at mark.ryans@fpinnovations.ca.

The future of energy cogeneration lies in the trees.

asthe North American housing market fights to stay alive during these tough economic times, some Canadian loggers are rolling with the punches and taking advantage of environmental incentives from the government to stay ahead of the game.