ANCIENT GRAINS, MODERN APPLICATIONS

Discover how Puratos can help!

In our “new normal” more than ever, you can rely on Puratos to continue to provide a full range of innovative products, solutions and services in bakery, patisserie and chocolate. We have the expertise and understanding of consumers and food trends and have developed new online tools to help assist with business opportunities. For more information on our online services, visit www.puratos.ca or contact a Puratos Sales Representative.

BACK TO BASICS

What a summer it has been! We’ve come through a lot in the last three months. Bakeries managed to pull through in ways that some cafés and restaurants could not. What is the secret to their success? It may involve the code of every baker and patissier: Getting back to the basics. It might mean revisiting their core values to provide their house speciality, the baked good that was the reason they wanted open a bakery, and not following social-media-driven trends.

“Back to the basics” could mean providing a service of basic necessities their neighbourhood. Once upon a time, bread was the staple of every house, and during the pandemic, bakeries thrived bringing freshly baked bread, or the ingredients to make the same, for home bakers.

Many have gone back to the basics by providing clients services that were not a part of their original business plan. While some bakeries provided pantry staples, like flour, sugar and yeast, others helped out their neighbourhood by providing sanitizers, paper towel and other sundries.

The real test to business’s resilience lay in how they could promote their bakeries, provide much-needed supplies, or find their niche online. Take Khaos Artisan Bakery, for instance. This bakery was not threatened by the surge in home-baking that some companies would see as competition to their craft.

Kymm Moore, the owner, provides advice for first-time sourdough bakers. She turned her garage into a impromptu farmer’s market, where she sold her cookies, whole grain breads and even sourdough starter to her customers.

However, her dedication to customer service doesn’t end there. Where some bakeries would provide sourdour starters or poolish, Moore went the extra mile for the fledgling home bakers, by providing online lessons and advice.

True Grain’s owners are working with farmers to create cookies that are so delicious you’ll forget they are high in fibre and are “better-for-you.”

The spirit of community was strong this summer, and we saw this in numerous ways, from helping neighbours and neighbourhood companies. “Back to Basics” may be about all natural or plantbased, but it can also be about getting back to your core talents as a chef.

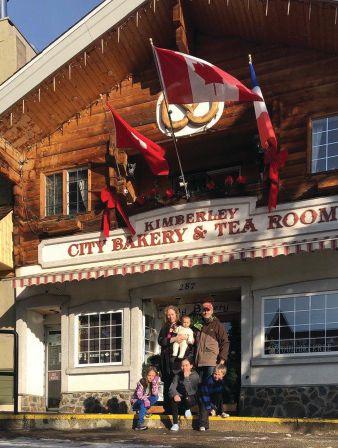

The owner of the hundred-years old institution, Kimberley City Bakery has decided to downsize, but not quit. Instead of creating several hundred varieties of breads an pastries, Eric Forbes decided to get back to basics and spend more time with his family. He’s not quitting the bakery business, just reinventing it: KCB now lives on as a food truck in Alberta that provides freshly baked bread. For the Forbes family, “Back to Basics” meant focusing on his speciality and thinking outside the confines of the bricks-and-mortar bakery.

For True Grain, “Back to Basics” means working with the world’s oldest grains. Normally, when a baker starts talking about whole grains and sustainable farming practices, eyes glaze over and attention spans diminish. However, True Grain’s owners are working with farmers to create cookies that are so delicious you’ll forget they are high in fibre and fall into the “better-for-you” category of treats.

In this issue you’ll read about two different issues that are driving change in the way we see Canada, and how our food industry is evolving. We are slowly on the path to better inclusion of other cultures, but that change has to come from the top on down. Whether our industry is speaking of crisis management during a pandemic, or working through creating a diverse and equitable food industry, Bakers Journal is eager to hear your story. BJ

AUGUST/SEPTEMBER 2020 | VOL. 80, NO. 7

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com 416-510-6753

MEDIA DESIGNER | Mark Ryan

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson sjamieson@annexbusinessmedia.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION bolechnowicz@annexbusinessmedia. com Tel: 416-510-5182

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 32.00

USA — 1 Year $73.50

Foreign - 1 Year $84.50

All prices in CAD funds.

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2020 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

Let us help keep you fresh too...

Welcome to The Baker’s Take, your 24/7 baking industry resource.

In the ever-changing baking business, you need answers and ideas at the tips of your fingers. With The Baker’s Take, you can have access to industry-focused content anytime you want it:

• Video news briefs to keep you in the know

• Market trends and insights in infographic form

• Audio and video podcasts offering our take on baking and food trends

• On-the-go troubleshooting tools

• Technical instruction videos from Corbion experts

• An ever-expanding catalog of recipes and variations Don’t go it alone. Visit thebakerstake.com and subscribe.

thebakerstake.com thebakerstake@corbion.com

Briefly | Lantic Sugar names a new COO; IREKS announces a new managing director and Master-Bilt closes its manufacturing facility | for more news in the baking world, check out our website, www.bakersjournal.com

Bundy Baking Solutions

Mike Walton named COO of Lantic Sugar

Rogers Sugar Inc. announced the appointment of Mike Walton, vice president, sales and marketing, to the position of Chief Operating Officer of Lantic Inc. and president of The Maple Treat Corporation.

This newly created role, reporting to the president and CEO of Lantic, aims to reinforce their succession plans, help improve the efficiency of decision making, and address important strategic decisions. John Holliday, president and CEO of Lantic stated in a press release: “Mike’s experience at Lantic makes him the perfect fit for this important and strategic role for the future of our business. Mike’s excellent leadership skills will certainly be instrumental in helping the highly skilled maple and sugar teams in our journey of becoming the leading North American natural sweetener supplier”.

Rogers Sugar also announces that after twelve years with the corporation and seven years as vice-president, Finance, CFO and secretary, Manon Lacroix has decided to move on to the next chapter of her career. Lacroix will be staying on board until August 15th to ensure a smooth transition during which a search to find her replacement will be taking place.

“During her tenure, Manon has helped orchestrate our critical transition from a sugar refining company to a multi-platform natural sweetener supplier through the acquisitions and related financing of two Maple syrup bottling companies” added Holliday. “We would like to thank Manon for her contribution over the years and wish her much success in the future”.

New Managing Director of IREKS GmbH.

Stephan Bergler was appointed as a Managing Director of IREKS GmbH. Bergler, who holds a Diploma as a Master Brewer as well as a Diploma in Business Administration, joined IREKS GmbH in the summer of 2017 after many years as managing director and owner of a malt factory in Middle Franconia.

Bergler will be responsible as Managing Director for the whole malt business “from farm to brewery” as a press release from IREKS stated.

Master-Bilt closes manufacturing facility

Refrigerated Solutions Group announced that after a full review of its business opportunities, market conditions and other options, it reached the difficult but necessary decision to begin the process of permanently closing its manufacturing facility located in New Albany, Mississippi.

Unfortunately, the COVID-19 pandemic has caused sudden, dramatic, and unexpected conditions outside of the company’s control. The unprecedented and major economic downturn and the governmental-forced closures of many of RSG’s customers have contributed to these unforeseeable business conditions. As a result, product manufacturing will be consolidated to RSG’s Hudson, WI facility by October 31, 2020. The RSG warehouse facility in Guntown, MS will remain an ongoing warehouse and distribution operation.

New VP of Sales for Ardent Mills

Ardent Mills, the flour-milling and ingredient company, announced that Angie Miller has joined the company as vice president of sales. In this role, Miller will be part of the company’s senior leadership team and will lead sales strategies, create consistent value and continue to deliver exceptional customer experience. Miller comes to Ardent Mills from Bayer Crop Science (formerly Monsanto), where she spent more than seven years, most recently as the global sales effectiveness lead. Previously, Miller spent more than 16 years in pharmaceutical sales management for companies such as Pfizer.

Miller’s addition to the team is part of the organization’s plan for long-term growth and focus on delivering an outstanding customer experience.“During this critical time, working with our customers to get flour and grain on people’s tables has never been more important,” shared Angie Miller, VP of sales at Ardent Mills.

Angie Miller

Stephan-Bergler

new products ¦

From the latest in protective face masks that match your chef’s uniform to the newest sanitary ball valves, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Robotray offers hygienic loading system

Miami-based Robotray Industrial Automation helps wholesale, commercial and industrial bakeries: In light of the current pandemic, issues such as labour, food and employee safety, efficiency, sanitation and hygiene are some of the key industryrelated concerns.

Robotray offers an automated rack loading and unloading system which can load, unload, or do both, and can handle various size trays, pans, boards and even strap pans, from single or double racks, without each being handled by employees. Speeds can be up to 14 trays per minute with a single head unit or up to 24 per minute with the dual head unit, so this is a very fast, efficient and compact system for high output industrial requirements.

The standard features include touchscreen controls, with self diagnostics, and recording of cycling performance. The system is very quiet, reliable and the open frame design can be easily cleaned and sanitized, and even power washed, to assure complete hygiene and food safety.

For the latest in new products visit www.bakersjournal.com.

BPS offers latest bulk bag discharger

Bulk bag dischargers from Best Process Solutions, Inc. (BPS) provide dust-free product discharge from bulk bags. These bulk bag dischargers are expandable and flexible to meet discharging and bulk bag requirements.

They are available in three reliable models: BPS’s Model MTD-2.5K for unloading large bulk bags up to 2,500 lb. capacity; Model MTD-4K for very large bulk bags up to 4,000 lb. capacity; and heavy-duty Model BBD-4K discharger with vibratory motor agitation to assist in unloading hard-to-remove products. Many options are available.

BPS manufactures a complete line of custom-engineered, bulk-processing equipment and systems. With more than 100 years’ combined experience, the company serves a wide variety of dry processing industries from chemicals and food to aggregates and recycling.

CLEANING FOR COVID-19

COVID-19 is now a reality for all Canadians and the “new normal” is slowly setting in. With bakeries, grocery stores and cafes being declared essential services, you are one of the industries bravely working “the front lines,” making it crucial that you effectively protect both your customers and yourself. As you plan for the weeks and months ahead, this is also an ideal time to look at best practices for ensuring food safety with your refrigeration equipment.

AN OUNCE OF PREVENTION IS TRULY WORTH A POUND OF CURE

Besides preventing the spread of COVID-19, keeping a clean, well-maintained refrigerated merchandiser will also help to prevent product spoiling, avoid costly repairs and even replacement. While COVID-19 is top of mind, you cannot lose sight of food safety, because commercial refrigerators and freezers can quickly become bacterial carriers if they are not adequately maintained and cleaned or if their temperature is not stabilized. Given the right conditions, bacteria found in food can double every ten minutes, which means that 1,000 bacteria can grow to 1/2 million in just over an hour and a half!

}COVID-19 can survive up to nine days on metal, glass and plastic surgaces if they are not properly disinfected.

SOAP AND WATER: STILL EFFECTIVE WEAPONS IN THE SANITARY BATTLE

COVID-19 can survive up to nine days on metal, glass and plastic surfaces if they are not properly disinfected.1 While strong cleaners like bleach or ammonia are fine for floors and countertops, they are actually not recommended for your refrigerated units since they can compromise the quality of the food, possibly contaminate it, and likely make

it unfit to eat. (Plus, no one wants to eat a bleach or ammonia scented sandwich.) Soap and water, used properly, will do the job, and effectively at that, just like when you wash your hands to prevent the virus spread. That’s because soap interferes with the fats in COVID-19’s virus shell, which lifts the virus from surfaces and is then rinsed off with water.2

CLEAN THE “HIGH TRAFFIC AREAS” OFTEN

We recommend deep cleaning your refrigeration units monthly. However, exterior door handles and doors are “high traffic” areas and should be wiped down several times daily as part of your COVID-19 cleaning routine. You probably have hand sanitizer available for customers at the checkout counter, but having hand sanitizer or sanitizing hand wipes (with at least 70 per cent

alcohol content) next to your refrigeration units is another way to help keep your customers clean and safe.

GETTING DOWN TO THE NITTYGRITTY DETAILS

Before deep cleaning your unit’s interior or exterior, always unplug it first. Be sure to use a soft cloth with a non-abrasive liquid detergent cleaner mixed with water. Since excessive liquid can seep into the electrical connections and cause a malfunction or electrical hazard, you should never apply or “spray” any undiluted cleaner directly to the unit. To avoid any contamination, all cleaning materials should also be clean themselves (such as using a fresh cloth each time) and stored between jobs, so bacteria isn’t transferred from one surface to another. You should also keep cleaning equipment for refrigeration units separate from those used for floors or other equipment in the store.

Cleaning also gives you a chance to

inspect the unit for any damage. For example, when wiping down the door gaskets and glass, check for gaps or tears in the gaskets, which can cause air leakage or a build-up of dirt or grease. If you’re not able to snap them back into place, they need to be replaced.

Most units are self-defrosting, but if you have manual defrost units, follow the manufacturer’s instructions and do not neglect regular defrosting, as this can aid in avoiding severe damage to compressors.

If your unit has a conventional condenser, it should also be cleaned monthly, to avoid breakdowns caused by an overworked motor. To clean it, remove the front grill, switch off on the control panel and unplug it, then use a small, hand-held duster to clean inside, and, if necessary, a vacuum cleaner to clean up any additional debris. Don’t forget to reattach the front grill, which helps to protect the condenser from debris and damage. Some units, like those we manufacture at Minus Forty, are built with low maintenance condensers, which require regular visual inspections and much less frequent cleaning than conventional condensers.

YOU’LL NEED TO TAKE YOUR EQUIPMENT’S TEMPERATURE, TOO Just like increased temperatures mean illness in humans, the same could be said for a refrigeration unit. Temperature variations are a serious threat to food safety, potentially contributing to bacteria growth, pathogens and cross-

contamination. In bakeries and cafes where doors are being opened and closed all day, maintaining optimal temperatures within the unit is crucial. For example, chilled foods like sandwiches and microwavable meals should be kept within the 3°C to 5°C range. Short spikes, not exceeding 30 minutes, above 3°C are acceptable. If you do not have a temperature malfunctioning safeguard you should aim to monitor temperatures frequently each hour to make sure they

are within the healthy range. Since you will need to sanitize the handles on merchandizer doors often, you can do both cleaning and temperature monitoring tasks at once.

YOUR EQUIPMENT NEEDS TO “BREATHE” AS WELL.

If your refrigeration equipment doesn’t have optimal airflow, or the ability to “breathe,” this can cause a blocked condenser, leading to possible equipment failure, overheating, spoiled product, higher electrical costs and even a void on your warranty. To ensure they are operating under optimal conditions, all refrigeration units should be kept away from the surrounding walls as per the installation instructions, each with their own dedicated electrical outlet and away from other equipment that radiates heat or produces a lot of airborne oil and grime. Regular inspections to check for blockages should also be routine. Be sure to distribute the product evenly inside the unit as well, since overloading blocks interior airflow, which can lead which can lead to spoiled food and irreparable equipment damage. Cabinets are also better able to maintain a stable temperature if they’re stocked with products (but not overstocked) versus empty, since the thermal mass of the refrigerated or frozen products helps to maintain the interior temperature.

To help remember the musts for food safety, you can use the ACT (Airflow, Cleaning and Temperature) acronym. (Although we explained them all in a different order here for the current circumstances.) All of us at Minus Forty would like to say “thank you” for keeping our essential services going during this challenging time. / BJ

Randy Skyba is the Vice-President of Sales and Marketing at Minus Forty Technologies. He helps retailers merchandise their frozen and refrigerated products.

Sources:

1 https://www.bbc.com/future/ article/20200317-covid-19-how-long-doesthe-coronavirus-last-on-surfaces

2 https://www.sciencealert.com/here-s-theexpert-advice-on-which-cleaning-productsto-use-against-coronavirus

Randy Skyba is the VP of Sales and Marketing for Minus Forty

¦ bakers formula ¦

BY DAWN FOODS

HERO COOKIES WHAT YOU’LL NEED

• 1 lb. - Baker’s Request White Cake Mix

• 6 oz. - Water

• 1 oz. - Oil

• 4 oz. - Sprinkles

• As Desired - Colored Buttercreme

DIRECTIONS

Working Method

1. Mix the cake batter, Water, and Oil on low until it comes together. Mix on 2nd speed for 2 minutes. 2. Stir in sprinkles by hand.

3. Using a #70 or plum disher, scoop .5oz. scoops onto sheet tray lined with parchment paper.

4. Bake at 375*F for 10-12 minutes.

5. Once cooled, using a straight tip, pipe a swirl of buttercream in the center of half the cake circles, top each with another half.

ARE YOU READY FOR SANDWICH DAY? CANADA TAKE OUT WANTS TO PROMOTE YOUR BAKERY

Heads up: August 15 is Sandwich Day, sponsored by Campbell’s: Post your sweet (and savoury) treats on your social media platform of choice, and use the hashtags #SandwichDay or #CanadaTakeOut.

To get your bakery literally on the map, Canada Take Out will help boost your social media and post your restaurant, cafe or bakery on their online, interactive map.

Simply go to www.canadatakeout. com, and click on “Add Establishment.” Once you’ve added your address and added some photos, more people near and far from your neighbourhood will come by for a visit.

This free initiative aims to help small food industries in Canada. Who doesn’t want to know there’s a bakery nearby that has lunch ready to go?

TRUE GRAIN

Baking with whole grains isn’t a new trend, but True Grain Bakery is putting a modern spin on ancient grain. Summerland business owner Todd Laidlaw says his clients are as equally interested in luxurious treats as they are about reduced sugar, gut health and environmentally sustainable grains.

The bakery is located in the Okanagan Valley, and Laidlaw

uses wine country analogies to describe the range of flavours and mouth feel each grain brings to their brownies and cookies, as a sommelier would describe vintages. The original owners, Bruce and Leslie Stewart are the original founders of the three-store bakery chain, with Laidlaw picking up the reins when Bruce took up farming in New Hazelton. Laidlaw’s business background was just

what the whole-grain bakery needed to hit the ground running.

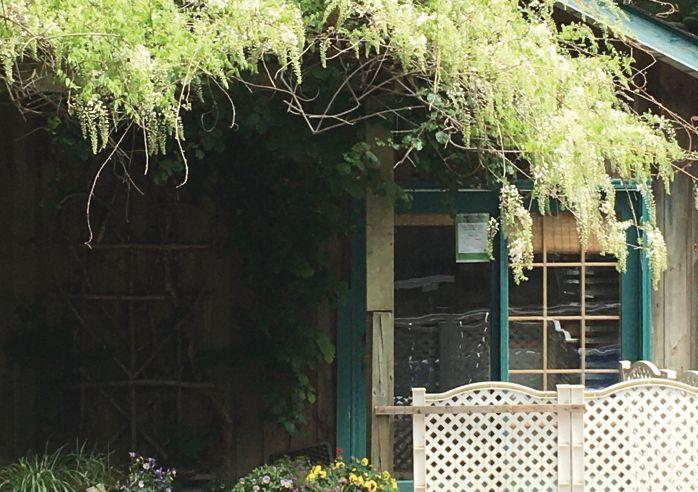

“We were really impressed with what we saw; this little organic and handcrafted bakery, which at the time had just the one location in Cowichan Bay, British Columbia, right out by the ocean. It was charming, had lots of character and we could feel the warmth when we walked in to that little bakery. We

knew that we had found something that our business school backgrounds could help grow.”

The bakery grew into three chains from the original Cowichan Bay location, to another in Summerland in 2012 and Courtenay in 2017. “It was never about growing it into a Starbucks. It’s not really about the number of locations; it’s more about how the values of our business are

True Grain in Cowichan Bay: The shop where it all began.

kept alive with fresh, local, organic handcrafted product.”

The choice to keep the grains sourced locally started in either 2016 or 2017, according to Laidlaw. The bakery was previously bringing in Canadian grains from the Prairies. Becoming aware of the bakeries’ carbon footprint, True Grain’s owners decided to find farmers within B.C. They selected organic white flour from the Okanagan, along with their einkorn, Khorasan, rye, spelt and heritage sweet red fife heritage wheat flour.

“So we really reduced our overall carbon footprint as a business. But it’s more than that. It’s building that sustainable food system. You know, think of all the farming jobs, all the cleaning, milling, baking and transportation jobs involved. We’re really building an infrastructure and creating a vibrancy in our local communities through the creation of these jobs. So we’re really pleased about that. That’s a big success of the last five years,” states Laidlaw.

Part of that success lies with getting back to the basics of what customers want and love. The locals respect and love the idea of supporting local business and farmers, to say nothing of the reward of getting a sweet treat from the bakery through their patronage. The question then remains as to how to get clients hooked on a different kind of grain, instead of making chocolate chip cookies from the well known AP flour?

In response, Laidlaw holds up their legendary chocolate roasted almond cookie. “The customers feel this connection because everything’s done within a tight circle. We like to say we’re connecting the farmer with the miller with the baker, and then back out to the community.”

To make customers’ selection easier, the bakery colour-codes their products with labels that correspond to a specific grain. Spelt products have blue tags, Red Fife has a red tag, oats a brown tag, cream coloured labels contain rye products and orange tags belong to einkorn baked goods.

“If someone learns that they can digest spelt without any issue, then they know that they can then purchase ours. We offer handcrafted pasta online so they could purchase spelt pasta, spelt cookies, spelt flour, spelt bread, and the same color coding continues throughout the store.”

The variety of flour brings a range of flavours that most bakeries might not experience with a single type of available material. “For the longest time it’s been white bread and

}Laidlaw. “The benefit is for people that want to or maybe have a hard time digesting the modern wheat. They have an alternative, but with a grain that hasn’t been hybridized.” Laidlaw also features cookies for a wide range of activities as well as dietary concerns. The Carrot, Raisin and Pumpkin Seed Cookie, made with Emmer flour, is popular for cookie fans with an active lifestyle.

“I call it my ‘hiking and mountain biking’ cookie. But it has the texture of a muffin. It’s very soft. A lot of our demographic really liked this cookie. It’s wholesome. With carrots, raisins, and the pumpkin seeds as ingredients, it’s almost a healthy indulgence, it’s not an explosion of sugar. It’s not a big insulin spike.”

While there are still customers who shop by

“It’s like reversing the clock. These are grains from 10, 000 years ago and to be able to bake with them today is a real pleasure.”

brown bread. It’s boring if all you could buy is white wine and red wine. You want to buy a Cabernet Sauvignon; you want to buy a Merlot…you want to buy varietals, and that’s what True Grain does. They all taste different. They all look different. They’re all on display in the store so people can actually see the ears of the grain. We end up educating our clients all about grain.”

Laidlaw laughs about how he could ‘talk about cookies for days.’ “We sell a lot of cookies. We sell them in cookie packs. And they’re not cheap: They’re adult indulgences. They fly right out of the store.” The shop’s most popular choice is the Fresh Ginger cookie, made of heritage wheat.

“It’s just a delicious, delicious cookie,” says

colour for ease of digestion, there are many indulgent treats that can still be savoured by those with and without dietary restrictions. With True Grain’s interest in ancient grains, bridging the gap between healthy grains and indulgent treats became a mission. The result? The Purist Einkorn Cookie.

“We set out to make a cookie that is wholesome; Not overly sweet, but one that brings out the natural flavour of this wonderful grain.” The company uses organic butter, farm-fresh eggs and what Laidlaw lists as very simple ingredients that really accentuates the natural flavour of Einkorn. “We don’t use a lot of butter and a lot of sugar. We really want the taste experience to be the grain. And it’s a phenomenal

flavor. People swear that it has macadamia nuts in it, despite there not being any such nuts. That’s that true taste of the Einkorn grain coming through.” Laidlaw says the Einkorn cookies were a true success story for both the bakery and the farm. “It’s like turning back the clock. These are grains from 1000 years ago and to be able to bake with them today is a real pleasure.”

Laidlaw says that going contrary to popular choices found in any grocery store, artisanal whole grain choices makes consumer better connect with their food and their health. While Laidlaw attributes a lot of his success to educating his customers about the wide array of grains and their origins, he is not against the idea of expanding the bakeries. That said, he doesn’t see them growing outside of British Columbia, where he can link the farmer to the miller and then directly to his bakeries.

“First and foremost, it’s just an amazing taste experience and so unlike any other cookie. It’s very unique. And I think that attracts people. But I think the history behind the grain is equally attracting. In a lot in a lot of ways, craft baking is becoming a lost art in the Americas. Just being aware that this is a grain that first grew in the Fertile Crescent about 1000 years ago, is quite appealing to foodies.”

Laidlaw’s advice for bakers to get customers to try new grain-based products, is to continue experimenting with flavour, textures and a wider array of grains. “Be creative. It’s a craft…I think a number of the most wonderful things we discovered were happy accidental mistakes. You never know when you’re going to stumble across that next thing that customers really come to love. “ / BJ

ACRYLAMIDES AND ORGANIC LABELS

With COVID-19, consumers are changing their lifestyles more than ever, driven by concerns about their health, and they increasingly consider organic foods beneficial to their health. In France, for example, 49 per cent of consumers agree that organic food is healthier than non-organic. The organic market continues to see strong sales growth, with the European organic sector recording expansion of 11 per cent — from €33.5bn to €37.3bn — from 2016 to 2017. With 17 per cent of food and drink products launched in Europe carrying organic claims (Aug 2018–July 2019, Mintel Insights), this category needed a suitable and effective solution for acrylamide reduction.

Kerry, a food ingredients company, announced that its Acryleast™ acrylamide-reducing yeast has received “organic suitable” status in the European Union. This means that yeast is an organic-suitable acrylamide-reducing processing aid available in either the EU or Canada, allowing it to be used as an ingredient in the production of organic foods such as children’s cookies, baked goods, crackers, bread and others. Acryleast, which was launched in 2019 was already considered to have “organic suitable” status in the United States as a non-GMO, clean-label yeast.

“These are challenging times for food manufacturers as they work to adapt to the emerging demands of today’s marketplace. One of these evolutions is that consumers are now more focused than ever on protecting their health and that of their children,” said Mike Woulfe, VP of Enzymes at Kerry. “Acryleast enables food manufacturers — now including organic producers — to vastly reduce acrylamide levels in their products. The ability to apply a clean-label, organic suitable, non-GMO yeast solution is a significant milestone that will be of great interest to food producers focused on acrylamide reduction strategies, in preparation for the impending update of European regulations and to meet consumer demand.”

EU TIGHTENS ACRYLAMIDE AND GENERAL ORGANIC FOOD AND BEVERAGE REGULATIONS

This new designation for Acryleast — “organic suitable” — comes at a time when the EU Commission and member states have agreed to soon set maximum allowable levels of acrylamide in young children’s food categories (cookies processed cereal-based foods, etc.). The EU Commission will also begin discussions with member states on the possible setting of maximum levels for foodstuffs for other age groups as they conduct a review of existing benchmark levels.

Mike Woulfe adds: “The EU continues to both expand and

tighten its ongoing regulatory control of acrylamide’s presence in a wide variety of foodstuffs, especially with regard to the exposure faced by children, where rulings on maximum allowable limits are expected shortly. The November 2019 EU announcement requires member states to monitor an expanded list of bakery and potato products beyond those previously designated.”

These regulatory developments occur against a backdrop of updated EU-wide regulations for organic foods and beverages (set to take effect January 1, 2021). The new law, published May 2018 (2018/848), presents a substantial challenge for food and beverage manufacturers who wish to maintain their organic claims and designations. It also means a significant enhancement in the “naturalness” of organic foods and beverages offered for sale across the EU. Acryleast’s new status will enable organic producers to improve the healthfulness of their products by reducing the amount of acrylamide in children’s and adult organic biscuits, rusks, crackers, breads and many other items. / BJ

Steve Campbell is the president of Campbell & Company Strategies Inc.

Deep fried doughnuts are an example of a baked good that can contain a high amount of acrylamides.

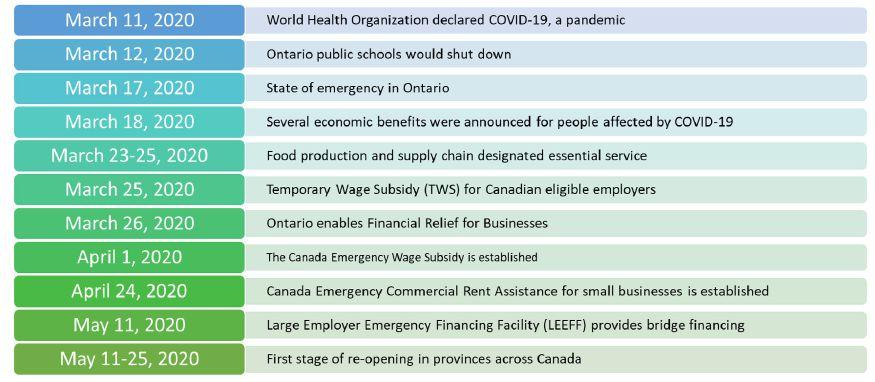

May 25, Canadian provinces proceeded carefully and slowly to their first stage of reopening. As of June 29, Canada counted 103,918 cases of COVID-19, one thousand times more than 3 months ago.

Timelines

When the World Health Organization made that declaration of a COVID-19 pandemic on March 11, 2020 there were only around 128,000 confirmed cases worldwide. Canada had only reported 103 cases.

On March 12, Ontario Premier Doug Ford announced that public schools in the province would shut down for three weeks. This order was later extended with the announcement on March 17 of a state of emergency in Ontario and ordered many businesses, including bars, cinemas, and private schools to close. Gatherings of more than 50 people were also prohibited. These restrictions would only grow over the coming weeks.

Prime Minister Justin Trudeau announced on March

18 several economic benefits for people affected by COVID-19, or the economic problems it caused. Over the next few weeks, these programs were expanded and began accepting applicants. Between March 23-25, all the provinces in Canada designated food and beverage manufacturing sector and its supply chain as essential services; they were to remain open and follow Health and Safety protocols to keep the workforce safe. Between May 11 and

Regulatory timelines delayed COVID-19 provided a slowing down of the regulatory timelines. As government and industry focused on the new normal of living with COVID-19, many of the inspection and regulatory activities were delayed while industry is dealing with the burden of increased cost, absenteeism, and delays in the supply chain.

Why your plans might go sideways

by Dave Fuller

A) Safe Food for Canadian Regulations (SFCR)

July 15, 2020 was the deadline for the baking industry to comply with the three elements of the SFCR: holding a valid licence, having written Preventative Control Plans and Traceability documents. Early in April 2020, the Canadian Food Inspection Agency (CFIA) published a notice that they will not prioritize compliance activities associated with the July 15, 2020 coming into force of the SFCR for the manufactured food sector.

However, all businesses are encouraged to apply for a licence under the Safe Food for Canadians Act (SFCA). Importers of manufactured food will generally not encounter delays or disruptions in their imports simply because of not having a Safe Food for Canadians licence yet and domestic manufacturers can

continue to operate while they apply for a licence. Industry is reminded that it is responsible for ensuring the safety of their food products at all times.

B) Food Labelling Modernization (FLM)

The objective of the FLM regulatory initiative is to develop a more modern food labelling system that responds to current and future challenges in the area of food labelling, for all foods including: imported, domestic, retail; consumer packaged or bulk, and food for further manufacturing. This proposal would amend labelling requirements in the Safe Food for Canadians Regulations and Food and Drugs Regulations in key areas, such as, date marking, food company information, and origin of imported food.

In September 2019, BAC submitted their comments to the proposed FLM

legislation which was published in Canada’s Gazette Part I. Earlier this year, CFIA confirmed to BAC that the publication of the final regulations in Canada’s Gazette Part II was being written and would be published later this year. CFIA published a notice on their website “Due to the impact of the COVID-19 pandemic on stakeholders and government, timelines for all regulatory initiatives will be delayed. The dates in the 2019-21 Forward Regulatory Plan are no longer applicable. CFIA will assess these timelines over the coming months.”

CFIA also announced that they are suspending certain labelling requirements for foodservice products due to COVID-19. Foodservice products are those intended for hotels, restaurants, and institutions. The temporary changes apply to the labelling of Canadian foodservice products for sale at retail

and those re-imported from the U.S.

C) Nutrition Labelling

Health Canada new Nutrition Facts Table and Ingredient List final regulations were published December 14, 2016, with a compliance date of December 14, 2021. The intent of giving industry five years to comply was to align compliance dates of all other upcoming labelling initiatives such as Front of Package Labelling and the CFIA FLM to help industry manage the additional cost of updating their packaging.

Front of package labelling is a Health Canada mandatory initiative to place a symbol in front of packages that are high in sugar, sodium, and/or saturated fat. BAC opposed this initiative from the start and has been challenging Health Canada on its validity and relevance in official responses to face to face and

written consultations including in Canada Gazette Part I in 2018. The initiative has generated many discussions and meetings among industry, Health Canada, and the Treasury Board of Canada. As of today, Health Canada is still investigating the validity of this initiative.

Although we have no official confirmation on the compliance date for Nutrition Labelling other than CFIA website notice of regulatory timelines delay, there is expectation of another extension to the Nutrition Facts Table labelling compliance until at least December 14, 2022 and potentially beyond. Health Canada will also not be moving forward with Front of Package Labelling within this current environment of COVID-19. BAC continues to watch for official communication and will share with the membership once released.

D) Prohibition of Marketing to Children

Since 2017, BAC has been engaged in the proposed prohibition of Marketing to Children. The proposition introduced a strict nutrition criteria to define unhealthy foods making 99% of all breads unhealthy for children, only based on the sodium content, not taking into account the nutritional contribution of bread to iron, fibre and folic acid which are nutrients of concern for children in North America.

For the past two years BAC continued to defend the goodness of bread for children in collaboration with allied industry who are developing a new Code for Responsible Advertising of Food and Beverage to Children. The “New Code” proposed and developed by industry includes a nutrition criterion that has been proposed by BAC members and also include an exemption from the restriction on advertising for all packaging, in-store displays, point of sale material etc.

This initiative, like all other regulatory projects, is on hold.

E) Voluntary Sodium Reduction Initiative

The Voluntary Sodium Reduction Strategy has been a collaborative strategy of Health Canada and industry. It started in 2009 and ended in 2016. The goal was to reduce the population sodium intake from 3400 mg per day to 2300 mg per

day. The results of Canada Community Health Study of 2015 showed that Canadian’s sodium intake is at 2760 mg which is a reduction of almost 20%. Furthermore, when looking at the details of the population intake, most Canadians are at 2300 mg per day except for men 18-40 years old, who because they eat larger amount of food also ingest larger amount of sodium.

At the time of the announcement of the pandemic, Health Canada has put on hold their next steps on the Voluntary Sodium Reduction Strategy including the following priorities: sodium reduction targets for restaurants and foodservice industry; gaining a better understanding of industry opportunities and challenges in sodium reduction; refining sodium reduction targets for processed foods and monitoring progress in sodium reduction.

What to expect post COVID-19 Without a crystal ball to see the future, we can only speculate on what the regulatory environment will look like once the country recovers from COVID-19.

1. Canada’s Gazette Part II for the Food Labelling Modernization including an extension on the compliance date for the Nutrition Labelling until December 14, 2022

2. Resuming discussion on the Front of Package Labelling – leading to the publication of a second Canada Gazette Part I and Canada Gazette Part II. Industry will continue to suggest that the Nutrition Labelling compliance date be further delayed, past 2022, to harmonize all labelling changes together.

3. Health Canada will resume its work on the prohibition of Marketing to Children. Industry will be ready to be part of the discussion.

4. CFIA will publish a date of enforcement for The Safe Food for Canadians Regulations. Industry is encouraged to register for a licence and to work of the elements of Preventative Control Plan and Traceability to be ready.

5. Health Canada will resume their focus regarding next steps for the Voluntary Sodium reduction.

The balance on regulatory policy between public good and costs to industry is going to be paramount as we move forward in this new COVID world.

© RAULBACHILLER / ADOBE STOCK

Dave Fuller MBA is an Award-Winning Professional Business Coach with the firm Pivotleader.com and the author of the book Profit Yourself Healthy. Need Plans? Email dave@profityourselfhealthy.com

WHY YOUR PLANS MIGHT GO SIDEWAYS

Aprofessional came from the big city to a small town to build a cabin so he could escape the hustle and bustle of life and set down roots where he could return to revive his spirits. His plan was to build a tiny house from the ground up. He asked around for help building his dream and found a couple of guys willing to give him a day’s work in exchange for his professional services.

Things started to go sideways when it was discovered that there were no plans for the tiny house. This might not have been a problem if the professional had hired a carpenter to draw up the plans and help supervise the job, however in an attempt to save money, the professional opted to leave his dream in the hands of the free help. It’s true that one of the two helpers had some experience in construction, but what the professional didn’t know was that that helper was prone to make mistakes.

As the day of construction neared, one of the guys asked if the lumber was going to be ready. “Tell me what I need” said the professional. The helper drew up a list and on the day of the build, the two boys showed up and went to work building the tiny house. Down went the floor, as they were about to lift the first wall up, the professional asked where the door was. Because there were no plans, the helpers had thought they were building a back wall while the professional thought they were building the front wall. There was mass confusion.

Unfortunately, this is how most people and businesses operate. We start with a vision in our mind of what we want to achieve but we don’t apply the time and effort necessary to draw up plans of the final product. We don’t write down and share our vision with our partners and staff. When this happens, everyone gets busy building something that they envision as the final

product but usually each version differs from the original concept.

Just as carpenters need plans to follow, your employees need clear and concise directions to follow in order for them to be truly successful. If they don’t have clarity about what is expected of them, they will imagine what they think you are looking for. Sometimes they will get it right but most times you, as their leader, will be frustrated. Developing systems that provide direction, checks and balances for accountability and feedback, help to ensure that everyone is on the same page. This leads to less stress and better outcomes.

If you are tired of tearing down walls

because someone built them wrong, frustrated because you are floundering, disillusioned, or not achieving results in your personal or professional life, you can change that! I love this quote from Jim Rohnor:

“If you don’t design your own life plan, chances are you’ll fall into someone else’s plan. And guess what they have planned for you? Not much”

If you want better outcomes, starts by creating a written plan for your life and your business, and coming up with specific actions on how to achieve it. Failure to do so will result in plans that go sideways and outcomes you do not want.

BY DIANE CHIASSON

ADJUSTING YOUR BUSINESS

Changing your bakery services during a pandemic

This pandemic has hit lives and livelihoods around the world. It has also changed customers’ shopping habits, and bakery operations are trying to adapt.

Every day, more consumers buy online. They are looking for curbside pickup, and delivery for products they would have typically bought in-store. You are perhaps wondering if this is the end of your bakery: Not a chance. Based on consumer research, more than 95 per cent of Canadians still prefer to buy at a physical location, particularly when it comes to bakery items. Canadian consumers still prefer to go to their local bakery store to see fresh products, buy “baked on the same day” items, and experience personal service.

There is no known evidence that the coronavirus is transmitted through foods such as baked goods. Make sure to tell your customers about this fact.

1. SELL DURING PEAK HOURS

Selling more during peak hours is a must for any bakery operation. Allow yourself and your team members plenty of time to follow up on new hygiene guidelines, restock and keep your customers and team members healthy at all times.

Your bakery operation is probably operating at some level of reduced hours. Ensure that your hours of operation coincide with peak sales times. Start by evaluating the volume of people in your bakery and when they are most likely to purchase. Mornings are often hectic at bakery stores when customers like to buy fresh-from-the-oven baked goods. It’s an opportunity to cross-sell and upsell breakfast items and coffee. Afternoons give customers the chance to pick up a sweet treat for their afternoon break.

2. ANALYSE, ADJUST, AND ADAPT

You should take a thorough look at your product range and pricing.

As a small bakery business owner, one of your most important decisions is how

to price your bakery items accurately. If your prices are too high, you will lose buyers to your competitors, but if your prices are too low, you will lose money. Consider bundle pricing to offer a group of related products, features or services all for one price. Bundle pricing simplifies marketing and selling strategies, so you don’t have to create promotions for individual products.

Your near-term success will likely depend on maximizing your existing inventory while redefining your pricing strategy to optimize your sales. Identify and focus on high-interest products that represents your brand. Now is the time to keep your costs low and to appeal to a broader audience. Hold off on more complicated recipes and decorating, and start to focus on what you can make quickly, affordably, with minimal waste.

3. START A LOYALTY PROGRAM

A ‘Loyalty Program’ can as simple as a business card that gets stamped or punched with every customer visit. After a certain number of purchases, customers receive a reward. It could be something as simple as “Buy 5 muffins and get the 6th free”. Promoting loyalty cards is a great way to offer your customers a safe way to increase sales and boost revenue. In addition to increasing sales, a loyalty program will yield word-of-mouth marketing.

According to a Nielsen study, over 70 per cent of global consumers would rather purchase from a retailer with a loyalty program than one without. It often costs more to acquire new customers than to keep existing ones. Look for a program works with your budget, your point-ofsale (POS) system and your bakery. Start promoting loyalty cards. Advertise your loyalty program on your website and in your social media campaigns.

4. PROMOTE GIFT CARDS

If your bakery operation has thin margins, gift cards will certainly help you stay afloat until the crisis is over. Gift cards will provide customers with a safe option to make a purchase they can redeem at a later date, which can help free up cash flow for your business. To

help reduce the risk of human contact, you should consider a digital gift card program to include in your social media and email marketing campaigns.

5. FOCUS ON CUSTOMER SERVICE

If you are looking to increase sales, invest in your staff. Instead of trying to sell, they should focus on finding ways of helping your customers. Make sure that every member of your team is passionate and knowledgeable about what you sell. Train your employees to identify a customer’s needs and wants and to create great buying experiences. Empower your sales associates to interact with your customers, and to wow them within the first few seconds. In-store expectations have changed towards a focus on customer and employee safety, and this will require clear and thoughtful communication throughout your bakery store. You might spend some time adjusting visual merchandising and bakery layout to focus on high-interest categories.

6. BE UNIQUE AND CREATIVE

More families are together at home; they could benefit from kid-friendly activities to do around the house. Consider offering “Bake At Home” kits where customers can buy baked goods that they can take home and bake themselves. Or, sell “DIY Baking” kits with pre-measured ingredients, supplies, recipes, instructions and tips from your team. Try selling a dozen of cookies with a “Pre-packaged Decoration” kit for decorating cookies and cakes. Always spread the word about the kits on social media.

© 2020 Chiasson Consultants Inc. All rights reserved. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 35 years by providing innovative and revenue-increasing food service and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns. Call her at 416-9261338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultlants.com , or visit www. chiassonconsultants.com

COVID19 AND CULINARY SCHOOL

In the last twenty years baking and pastry education has changed. Aspiring culinary students are already in the kitchen, at a young age, recreating recipes demonstrated by their favourite Food Network hosts or YouTube channel personalities.

The universal obsession with food has also made it part of the travel and tourism experience. More government money has been given to culinary school, in order the give the students the opportunity, space and equipment they need to succeed in the industry, and ultimately increase regional revenues.

Culinary schools teach the classics but have also expanded the repertoire to encompass a broader scope. While some school stick to the tried and true methodology of teaching, others craft courses to the student’s specific interest.

As schools were applauding the talent of their students, along came Covid-19. This has left both educators and administrator wondering just how to continue. Much discussion and planning has followed. Of course, everyone in the country is on edge about a second wave of the corona virus and the effects it may have, given there is not yet a proven vaccine.

NAIT, a polytechnical college, with four campuses--three in Edmonton and one in

Student chefs at the Culinary Institute of Canada research, plan, and execute the menu for various real-world scenarios.

Grove, is a base for studies to over 40, 000 students. Each September, they offer their 2-year Baking and Pastry Arts Diploma. Plans for these students to start classes on time are already in the making.

“We usually have about 27 students enrolled each year,” says Alan Dumonceaux, chair of the Baking and Pastry Arts program. “This year we will cut the numbers in half to 13 or 14 students only. We will have the workstations set up, so students are working the

required two meters apart, “he explains. “It won’t be a worry though, because we have a 4000 square foot space to work in. Both students and instructors will wear the required personal protective equipment.”

First year students study yeast fermentation and learn to create artisan loaves. The fundamentals of cookie and cakes making is also taught, as well as the production of first classical and then more modern pastries. “We start with the basics, like making

bread by hand and later move on to laminated doughs, plated desserts, ice cream, sorbets and frozen products,” says Dumonceaux. Students also study courses in nutrition, safety, and sanitation. By Year Two more advanced traditional baking, pastry and confectionary continues to be taught. This also incorporates specialty desserts from around the world. Then, it’s time to create the showstoppers, or mixed media showpieces and other edible arts. Dumon-

ceaux is impressed by the talent NAIT continues to nurture. “By the end of the second-year students are working on advanced chocolate work and really stunning showpieces.”

That training is put into good use. In the third and fourth semesters, students work in the school’s much lauded, on-campus dining room called Ernest’s, which has 110 seats. Here students are responsible for making everything from the bread, to all the components of the plated desserts and even specialty items for chefs’ tables.

Across the country, on Canada’s tiniest province, baking and pastry instructor Richard Braunauer has happily been teaching at The Culinary Institute of Canada, at Holland College, in Charlottetown, Prince Edward Island, for 30 years.

“The very first baking and pastry program had only one full-time student,” he remembers with a laugh.

In 2017, the school underwent a six-month, $7.5 million renovation, which included an additional $1.8 million for new and emerging technologies and equipment. The building was essentially taken down and then put back together, with a 3000-squarefoot addition.

Today, each year, 30-35 students enroll and take part in the 1-year Pastry Arts certificate program, with a unique teaching method. “The first five weeks students learn the fundamentals, through theory and hands on classes. They develop a basic understanding, and feel for the ingredients and the work,” Braunauer explains.

During this time, students learn basic dough and batter preparation, advancing to classical French pastries and modern plated desserts. Classes start at 6 am. Every

day at 10:30 am, students take a break from baking to study theory and observe a demonstration by Braunauer, who was classically trained in Europe.

Then, after the five-weeks are completed, students are part of six rotations--- three in the morning and three in the afternoon. Here they are assigned to small teams, in which they will spend three to four weeks on specific assignments. Students must research, plan, and execute the menu for various realworld retail outlets and restaurants, on the campus grounds.

“The students have the ability to be more flexible in what they create, while working in conjunction with the instructors to come up ideas. It’s a more individualize way of teaching.”

For example, the Grab and Go outlet, students prepare all the loaf breads, muffins, and cookies. At the Marche Café, students provide all the quick bread, yeast breads and desserts. In the Fine Dining Room, lunch service includes four to five plated desserts, on the menu each week. And then there is dinner service. The school also hosts a numerous banquets and functions. Chocolates, truffles, and showpieces are always part of these celebrations.

“With every rotation there is a fixed practical mark,” explains Braunauer. He also notes that in the students works on individual assignments, which are self paced, such as planning and building a two or three-tiered wedding cake.

Of course, this year, the biggest hurdle to face is teaching, while managing Covid19. In a bid to keep the beautiful little island safe, Holland College has chosen to delay the start of the school year. On November 2, the

first day of business classes will begin online with classes in business communication, computer essentials and WHIMIS. From January 3-17, 2021, students who do not live on Prince Edward island will be asked to arrive and undergo a period of self isolation. Then, on Jan 18, in

person classes begin again, wrapping up in late June. The pandemic aside, students are still signing up for classes in baking and pastry arts programs. Educational programs provide a valuable base of knowledge for those who are interested in working it the industry. / BJ

Achieve a lasting softness from which bakers’ dreams are made of.

FROM ‘KHAOS’ TO CREATION

Khaos Artisan Kitchen creates order in a time of chaos

Ancient Greek mythology had the goddess Khaos (in English, “Chaos”) create the universe from the void. As the owner of Khaos Artisan Kitchen, Chef Kymm StAmour has also created something from the ground up.

The bakery began as part of an application in a “Win This Space” contest. St-Amour and her wife moved to the charming town of Port Franks, ON, with the intention of getting back to the basics. “One of the conditions I gave her upon moving there from Avra (also in Ontario), was that I would get to open up my own bakery, and do this for myself instead of doing it for somebody else.”

The “Khaos” that St-Amour lovingly refers to is her wife, a fellow chef who

likes to “throw a monkey wrench” into some recipes. “Certified chefs tend to just kind of ‘do things’ and not plan things out as much as bakers do,” laughs St-Amour.

“So she becomes a little bit of my chaos. And on some days, the chaos is a little too aptly named, because it can really get chaotic around here.”

The chaos that St-Amour speaks of is not your run-of-the-mill tasks that local bakeries experience; the pandemic had

made the already popular bakery a hub for resources beyond bread and pastry. Khaos Artisan Kitchen began selling yeast, offering bread delivery and giving away sourdough starter and advice free of charge.

“When the pandemic put everybody on lockdown, the bread was flying off the shelves. There were empty bread shelves as well as the ones containing flour and yeast supplies. I knew that people would be needing bread, and I could provide that for them. My sales were probably double, if not triple what they would be at that time of year,” reflects St-Amour. “Now, it just levelled out to what my sales would be this time of year which is which is good, because it’s just me.”

It was a friend who worked in Toronto hospitals during the SARS crisis, who tipped off the bakery as to how serious the pandemic would be when the first reported case numbers starting climbing in Canada. “I adjusted the way I served the public very quickly,” recounts St-Amour. “I would make deliveries for them and perform curbside and doorstep drops, and they would gladly come out to pick up the goods.”

When sign of the pandemic first hit, St-Amour was still using cash transactions, but to keep her clientele safe, she opted for an affordable option that didn’t involve using a POS-system that accepted debit or credit. Her bakery opted to accept eTransfers from clients she knew. “Because of the pandemic, the increase of the etransfers has increased by 80 percent…but I wanted it to be as safe for myself as well as my customers. The eTransfers option has certainly been handy for a lot of people and they’ve truly appreciated that alternative.”

An alternate payment method has been the least chaotic element for the bakery. Being a small, family-run space, finding a way to accommodate clients without closing entirely was a challenge many other bakers can relate to.

“What I do is set up a tent and a table, and allow a separate container for clients to put the cash into…it’s like my own personal farmer’s market. I’ve always put out a sandwich board sign to indicate when I’m open. I have another chalkboard sign that I put up, itemizing the sellable goods for that day. One of the big differences is that people would normally be able to come into the bake shop, where I would have things on display,” explains St-Amour. “Now they’re relying

on my reputation and word of mouth vis-à-vis the quality and reliability of my products, because they obviously don’t get to see it ahead of time, due to safety and distancing rules.”

Despite the bakery being unable to cash in on impulse buyers who add an eye-catching item in-store, business is still booming thanks to frequent social media posts. “I will advertise on Facebook so clients can pre-order. Initially, I had a larger menu available for preordering and opted to pare that down, now that things are starting to level out with each new phase of provincial re-opening.”

Despite being located in cottage country, this little bakery provides the same menu items often seen in a bustling metropolis. “I think that’s one of the attractions for people who come here, in that they’ve discovered this little niche bakery in the middle of nowhere… they’re surprised when I have macros, that they can get croissants here.”

And then of course there’s her famous bread. “Customers love that they can get bread that’s low on preservatives and utilizes local ingredients. We’re quite lucky to have the Arva flour mill, just outside of London.”

At a time when people are protective of their recipes and guard their sourdough recipes closely, Khaos Artisan Kitchen donates their starter at no charge. Normally, St-Amour charges for her off-season baking classes, but hasn’t hosted any this year, due to the ongoing pandemic.

“Community is very important to me. Part of the reason I extended my hours at the beginning of the COVID outbreak, was to make sure that people could get bread as needed.” St-Amour recalls an earlier time when yeast and flour were hard to find in Port Franks, but she wasn’t worried since she had sourdough starter. The experienced baker didn’t charge for the starter but insisted that clients name their starter pick, “so they would take better care of it,” she laughs. “But anybody who needed sourdough was gladly obliged and encouraged. I talked them through the process of utilizing it, since it’s something that is easily grown.”

St-Amour’s support also extended to online assistance, answering various e-mail queries ranging from starter issues to sourdough bread baking techniques.

“I’ve also given clients extra recipes of what to do with their cast off starter. I hate throwing it away excess material,” states St-Amour. She recommends people try recipes like sourdough pancakes, which she also supplies.

The Khaos Artisan Kitchen still strives to provide comfort food during a crisis, and new skills for those looking to distract themselves to stave off isolation fatigue. “One of the benefits of having stayed open — besides being able to still provide them with baked goods — was to provide that sense of normalcy for them in this decidedly chaotic time in our lives.”

St-Amour’s bakery may be Khaos in name, but its presence has certainly provided order and stability for the town of Port Franks. / BJ

COVID-19 BUSINESS STRATEGIES

The rules of business have changed overnight, and many are struggling.

The following 5 strategies will help you persevere through any challenge.

1. BE TENACIOUS

If you feel your tenacity wavering, pick a mantra that is powerful and motivating for you and play it on a loop in your mind. Some mantras leaders use are, “never give up,” “tough times don’t last; tough people do,” and “persistence breaks down resistance.”

2. CONSIDER PAST CHALLENGES By working through past setbacks, you

learned some important skills. The skills you’ve honed over the years during other challenges are the same that will get you through the current crisis.

3. GET UNCOMFORTABLE

During times of crisis, you will need to try new things. For example, many business owners are now doing live videos on social media to stay in front of customers and prospects. During any crisis, “business as usual” isn’t enough. Think of things you can do to keep your company in your customers’ minds.

4. REINVENT YOURSELF

Reinvent or reposition your message and your offerings.

The key is to locate your client’s pain. Deliver solutions to meet their needs. This requires only a slight pivot, not a 180-degree change. You already know how; you did it when starting your business.

5. PROTECT YOUR COMPANY’S CULTURE

This requires you to model strength for your employees, and to communicate honestly and often with them. The goal is to keep fear at a minimum and to make your employees feel safe. Listen to their ideas. Ensure they feel part of the team and valued.

EMBRACE CHALLENGES

Often, the best innovations come during crisis. Assess the

California Walnuts add a layer

With their nutty crunch and sweet mild flavour, California Walnuts are the perfect addition to your creations.

situation, determine where your business can add value, and then take action using these outlines strategies. When you do, you’ll find that your company can weather any obstacle and emerge as the marketplace leader.

Shelley Armato is CEO at MySmartPlans, a provider of best-in-class SaaS construction technology that eliminates risk, creates transparency and protects the budget. She provides professional construction services to some of the most prestigious business owners in the healthcare, scholastic, government, and other commercial market sectors. Contact her at www.mysmartplans.com.

KCB KEEPS ON TRUCKIN’

2020 has been a hard year for many so far, and even the 100year Kimberly City Bakery (KCB) has felt the hardship. Their daughter has health issues, the family moved to Alberta and decided to sell their heritage bakery, but wanted to try something new: a food truck.

Then, the COVID-19 pandemic hit worldwide. “It’s stressful. We were trying to get a business up and running and we have a business that can’t run.”

Homeschooling three children during the pandemic, while trying to work the logistics of a bread bakery truck, is not easy. “We ran it on weekends in Cranbrook (BC), and it went well. It’s what we want. Most people go from a food truck concept to brick and mortar, but we’re going the opposite way.”

recalling how potential customers were so excited to see the bakery truck, only to discover it stopped due to engine trouble.

Forbes outlined how clients place their orders at a drive-thru compound: “You park in the line where the truck you want is parked, and pre-order via their Instagram account, and you can get your food from the food trucks. We’re limited as to what we can do, with little staff. It’s a very small truck compared to what I have in the bakery right now. We have learned to work in close proximity to each other,” he concedes.

}Owner Eric Forbes was heartbroken to close the 100-year old bakery that served the Kootenay, BC community. “We have a lot of visitors that come up for a day trip from Calgary to come grab stuff for dinners, especially at Christmas and Easter and that sort of thing,” added his wife, Michelle. KCB was renowned not only on the west coast, but with a devoted following in Europe as well. Michelle adds that they’ve had return customers from across the Atlantic.

–

Most people go from food truck to brick and mortar, we’re going the opposite way.”

Eric Forbes, owner and bakery of Kimberley City Bakery

are built with the purpose of baking. Many are made for quick meals rather than the long, slow baking process that involves wood ovens.

The bakery truck finds its customers through social media and email campaigns. They receive emails from interested clients asking where they will be parked, or where the truck will deliver pre-ordered baked goods, with the location announced shortly thereafter. “I park it somewhere and I start baking in the morning. Come ten, eleven o’clock, you can come pick up your bread,” says Forbes.

The Forbes family made the bakery popular for its traditional European-style pastries and breads, but they didn’t want to give up the industry altogether. “I think it would be better for us to have a smaller market, where we could have more exposure. We can just focus on a few things instead of the bakery where I was doing about 400 items a day.”

Forbes and his family relocated in late August of last year. Between staff changes and many doctors’ appointments for their daughter, they managed to get the bakery food truck project to start from the ground up. No one in the family has had experience with trucks, and few

In searching for answers about his food truck, Forbes was informed that ‘no one does that’. “I was like, ‘Huh, so no one does it, that means I need to do it. So we came back, thought about it. And one day we saw a truck for rent online, and we thought, ‘let’s rent a truck for this summer’. It definitely needed work…I hate to say it, but I’m glad that wasn’t a fixer-upper because it showed us the stuff you need to know to run it.”

“It’s not a kitchen in the way that you might think it is,” explained Forbes. “It runs differently; you’re in a very small space in the galley and you can’t pass each other. At the same time, people recognize the truck. It broke down on the way up to Calgary. I parked on the side of the road, and people were asking, ‘Oh, are you open?’” laughed Forbes,

The family hopes that another baker will buy the legacy that comes with the 100-year old bakery, and provide the community with its European-style baked goods. “We do have recipes that we’ve been using from the 1920s, that we’d like to pass on to people that were there right from the very beginning. We had to modernize them a little bit but it’s basically the same recipe. We’d like to continue with that and offer them to the new owners.”

“We are hoping that someone will see the bakery as an opportunity… and hopefully, if they don’t have the full baking experience necessary to run it, that they’ll run it as a co-op and have different baked goods: This person does doughnuts, this person does cakes and that one does breads, and so forth,” suggests Forbes.

Baker’s Journal wishes the family good health and prosperity, and that they’ll “keep on trucking.” / BJ

Professional Course Guide

for the baker

Are you looking to learn a new skill? Hone a specific craft? Welcome to the Bakers Journal Professional Courses Guide 2020. Continuing education is essential to today’s success. As new trends become mainstream and techniques continue taking tradition up a notch, it’s imperative to maintain a passion for

CHOCOLATE ACADEMY

The Chocolate Academy™ Montreal offers classic, specialized and innovative classes with our skilled technical advisors as well as with talented and renowned guest chefs for pastry chefs or chocolatiers. Courses are both offered in English or French. We also offer a range of digital and virtual courses for all levels.

Visit chocolateacademy.online for a free trial or chocolateacademy.com for the courses located in Montreal. chocolate-academy.com

CANADORE COLLEGE, SCHOOL OF CULINARY ARTS

North Bay, ON Canadore offers quality full-time programs including Culinary Skills – Chef Training and Culinary Management,as well as part-time and apprenticeship options. Our culinary training facility includes classrooms, experimental and production kitchens, and Canadore’s very own casual fine dining restaurant. We have awardwinning chefs de cuisine and experienced professors that will train you hands-on for a

career in this versatile industry.

canadorec.on.ca

CENTENNIAL COLLEGE

Toronto, ON

Correspondence and online courses offered, including nutrition and health, sanitation and safety, kitchen equipment and food preparation, and workplace communication centennialcollege.ca

COLLEGE OF THE NORTH ATLANTIC

Newfoundland and Labrador

• 9-month Baker program (full-time) offered at Bay St. George campus

• 9-month cook program (full-time) offered at several campus locations

• Marine Cook program also available cna.nl.ca

CONESTOGA COLLEGE

Waterloo, ON

Continuing education courses in food processing supervisor and advanced sanitation practices

Distance learning courses in creative cooking and food service worker conestogac.on.ca

DURHAM COLLEGE

Whitby, ON

• Advanced Baking & Pastry Arts

• Culinary Management

learning. What better place to ignite your creativity than back in lab’s lap at school?

The institutions listed in the Bakers Journal Professional Courses Guide 2020 are proud to serve the baking community. Check out what our education system can do for you.

• Hospitality ManagementHotel, Restaurant and Tourism

• Special Events Planning

905.721.3000 durhamcollege.ca/cff

GEORGE BROWN COLLEGE CHEF SCHOOL (LOGO)

Toronto, ON

Continuing education programs and courses in baking arts, baking and pastry management, culinary management and culinary arts.

georgebrown.ca/chefschool

GEORGIAN COLLEGE

Barrie, ON

Continuing education programs and courses in bake theory, patisserie, techniques and baking. georgianc.on.ca

NIAGARA COLLEGE FOOD AND WINE INSTITUTE

Teaching excellence at the Canadian Food and Wine Institute. Located at Niagara College’s

breathtaking Niagara-on-theLake Campus, nestled in the heart of Niagara’s rich wine and culinary country, the Canadian Food and Wine Institute (CFWI) provides students with valuable hands-on experience and academics in all aspects of culinary, baking, food innovation, wine, spirits and beer.

Niagara College is home to Canada’s first teaching brewery, teaching Distillery and commercial teaching winery, along with a worldrenowned full-service teaching restaurant that focuses on local and seasonal cuisine.

Fortified by the teaching vineyards, hop yards, and organic gardens, CFWI delivers an unmatched learning environment.

Niagara College offers the following programs:

• Artisan Distilling

• Beverage Business Management - NEW in Fall 2021!

• Baking and Pastry Arts

• Culinary Skills

• Brewmaster & Brewery Operations Management

• Culinary Management (Co-op)

• Winery & Viticulture Technician

• Culinary Innovation & Food Technology (Co-op)

• Cook Apprenticeship

Please note that both the Culinary Skills/Management and Baking programs are now continual intake. CFWI will be accepting students in September, January and May. canadianfoodandwineinstitute.ca

NORTHERN ALBERTA INSTITUTE OF TECHNOLOGY (NAIT)

Edmonton, AB

NAIT is a leader in culinary education, with full-time, part-time and apprenticeship options:

• Culinary Arts diploma

• Hospitality Management diploma

• Baking certificate

• Retail Meatcutting certificate

• Baker and Cook apprenticeship training

• Numerous evening/weekend courses

1.877.333.6248 nait.ca

NOVA SCOTIA COMMUNITY COLLEGE

Dartmouth, NS

Short-term, on-campus continuing education classes in pies and tarts, croissants and danishes, fondant and cake decorating for beginners and restaurant desserts

nscc.ca

RED RIVER COLLEGE

Winnipeg, MB

Food services management continuing education program (some courses available by distance delivery) rrc.mb.ca

VANCOUVER COMMUNITY COLLEGE

Vancouver, BC

Continuing education/ part-time programs and courses in baking and pastry arts

vcc.ca

VANCOUVER ISLAND UNIVERSITY

Nanaimo, BC

• Professional Baking and Pastry Dept.

• Foundation, Apprentice and Leisure Courses in Artisan Baking, Viennoiserie, Decorating and Wood Fired Baking. 2.viu.ca/baking

List $101,000. Sale $86,000.

¦ classified Ads ¦ Phone 705-826-2254 | 1-888-599-2228, ext. 268 Fax 1-866-810-8111 (secure line)

List $101,000. Sale $86,000.

List $33,400. Sale $29,500.

List $81,800. Sale $69,000.

COOKIE

List $33,400. Sale $29,500.

List $28,500. Sale $24,000.

List $50,200. Sale $39,900.

List $101,000. Sale $86,000.

SPIRAL MIXER

$28,500. $24,000.

List $50,200. Sale $39,900.

List $76,700. Sale $64,900.

List $33,400. Sale $29,500.

List $28,500.

BY JANE DUMMER,

RESISTANT STARCH

What is resistant starch, and how does it contribute to functional wellness?