BY KRISTY NUDDS

Ireceived an alarming phone call from an Edmonton man calling himself a “concerned consumer” in mid-February. He was quite angry over an episode of Marketplace, the Canadian Broadcasting Corp.’s so-called consumer watchdog television program.

The episode, entitled “Superbugs in the Supermarket,” focused on the relationship between the use of antibiotics in broiler chicken production and antibiotic resistance in humans. It aired on CBC Feb. 11.

Although the caller had quite a bit to say about many facets of agriculture, particularly with respect to chicken production (among other views, he voiced his disbelief in supply management and his refusal to pay “outrageous” prices for chicken) he said one thing that was distressing: “I knew Canadian chicken was bad, but not that bad.”

He was referring to damning evidence presented in the Marketplace episode. Producers of the show purchased various types of raw chicken products (including those labelled organic and raised without the use of antibiotics) from several supermarket chains in Toronto, Vancouver and Montreal. All chicken samples were tested for the presence of bacteria that are resistant to several classes of antibiotics used in human health care. Their results showed that two-thirds of the samples contained bacterial species and that, of these, at least one species of bacteria was resistant to at least one antibiotic. Almost half of the samples contained salmonella resistant to the drug ceftiofur.

Ceftiofur was the focus of a July 2009 article in the Canadian Medical Association Journal (CMAJ), entitled “The Perils of Poultry,” which revealed a link between the off-label use of cephalosporin antibiotics (such as ceftiofur) in hatcheries and human resistance to this class of drugs. The link was made from surveillance data collected by the Public Health Agency of Canada’s Canadian

The link between the use of cephalosporin and other classes of antibiotics on-farm and antibiotic resistance is not conclusive, but the opinion that exists among many human health professionals and scientists studying antibiotic resistance in humans is that overuse of antibiotics on farm animals is one of the major reasons some antibiotics no longer seem to be working as effectively as they once did.

There are many other factors contributing to resistance; however, we don’t want consumers to lose confidence in poultry products because resistance has been found. Nor do we want to follow the European model and ban the use of certain antibiotics (Europe has banned those that have little or no use in human medicine). This measure has not reduced antibiotic usage, as intended, and has actually led to an increase in the use of antibiotics, particularly those associated with human medicine.

We are stuck between a rock and a hard place, said David Fuller, chair of the Chicken Farmers of Canada (CFC), to delegates at the Alberta Chicken Producers meeting in early March. Assumptions are being made, and we can’t sit and wait, he said. “We need to know if we are contributing to the problem.”

That’s why the CFC is “opening its doors” to the Public Health Agency of Canada via CIPARS, he said. The CFC has recently finalized a new protocol to monitor antibiotic usage on-farm and antibiotic resistance levels at the farm level, and has started a pilot project. Since 2002, CIPARS has been performing surveillance at the retail and processing plant level only.

CFC is asking for producer assistance with the project, and I encourage producers to get involved. As Mr. Fuller said, “we all have a role to play in our industry’s success.”

April 2011

Vol. 98, No. 4

Editor Kristy Nudds – knudds@annexweb.com

888-599-2228 ext. 266

Associate Editor

Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com

519-429-5193

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Production Artist

Krista Misener

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

e-mail: cnowe@annexweb.com.

Printed in Canada ISSN 1703-2911

Circulation e-mail: cnowe@annexweb.com

Tel: 866-790-6070 ext 207 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $ 25.20 (includes GST – #867172652RT0001)

$27.12 (includes QST/HST)

USA – 1 Year $ 60.00

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2011 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

[ spek-tak-yuh-ler ] Of the nature of a spectacle; impressive or sensational.

Nothing says specktacular like OptiGROW!

Lubing's all-new Opti GROW Nipple is designed to work in today's challenging broiler environment. Because the nipple has been optimized for growth, you will be amazed by the first-week performance and explosive bird growth. OptiGROW offers:

Large body and pin

Acid resistant design

Easy triggering for day-old birds

Low mortality

Increased side-action flow

Larger flow range for jumbo birds

Increased weight gains

Improved feed conversions

To find out more about this specktacular new product, please contact your local Lubing representative.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Les Equipments Avipor

Cowansville , Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

The local media are calling it the New Brunswick “chicken war.”

It is a war over chicken processing between Nadeau Poultry (owned by Maple Lodge Farms), which operates the only processing plant in the province, and Groupe Westco, which controls much of the province’s broiler production and is proposing to build a new processing plant with its partner Olymel. Sunnymel, the partnership formed by Olymel and Groupe Westco, recently held information sessions for residents near the location of their proposed plant (Village of Clair) to make public an environmental impact study conducted in accordance with the requirements of the New Brunswick Department of Environment.

In the meantime, Westco has been bypassing the Nadeau

plant and shipping its birds to Olymel’s plant in Quebec for processing while Nadeau has been bringing in birds from Nova Scotia, a situation that could end when a new processing plant is built in Nova Scotia next year.

Nadeau has called on the provincial government to intervene and establish an independent agency to allocate the birds among processors but Westco wants the government to keep its hands off.

The provincial government has rejected the calls for a new agency, but has offered to act as a mediator to end the dispute.

Agriculture Minister Mike Olscamp says, “What I’m trying to do is get these two groups together.”

Nadeau disagrees. Maple Lodge Farms CEO Michael Burrows says the government is ducking its responsibility when it describes the breakdown of the system as simply a “commercial dispute.”

If the government proceeded properly, as other provinces have done, it has the tools legislate a fair solution.

“New Brunswick has failed in its legislative role as part of the Canada-wide system of supply management for chicken,” Burrows says.

Meanwhile, Groupe Westco says producers should not be obligated by provincial legislation or regulation to ship to a certain processor.

“From the beginning, this issue with chicken supply in New Brunswick has been between two companies that, for the past several years, have been at odds. The provincial government has done everything in its power to help these companies resolve the issue. All attempts by the provincial government have been legally challenged and struck down by the courts. We must respect those legal decisions,” he says.

was harmed.

Farm labourers returning home just before 9 a.m. on February 9 from catching chickens all night were involved in a head-on impact with a school bus carrying 13 high school students. Five of the labourers were killed, and three were injured in the crash. None of the students

In mid-February, two incidents of illegal poultry sales and smuggling occurred.

The Ontario Provincial Police (OPP) and Canada Border Services Agency (CBSA) seized approximately 1,800 pounds of frozen poultry product that was smuggled into Canada from the U.S. at Cornwall. The chicken was destined for the Chinese market in Montreal.

The boxes containing the illicit poultry were marked “unfit for human consumption” by the U.S. authorities.

In Toronto, an investigation conducted by Toronto Public Health and the Ministry of Natural Resources (MNR) discovered tens of thousands of ungraded eggs. Records show that over the past year, Toronto health inspectors have found at least 15 small grocery stores, food depots and restaurants selling or serving eggs that were never checked for possible contamination.

The collision occurred in Quebec’s Lanaudière region, and it is believed the van’s driver may have fallen asleep at the wheel after working all night.

The United Food and Commercial Workers Canada said the accident raises questions about vehicle safety and inspection involving the

transport of farm workers. In a statement, the union called the accident “just the latest tragedy involving farm workers injured or killed while being trucked to or from Canadian agriculture operations.”

The company involved in the crash, Pigeon 2006 Inc., is one of about 10 brokers that act as middlemen between chicken farmers and slaughterhouses in Quebec. It is not known whether its van was licensed as a transport vehicle.

Source: The Globe and Mail

According to the Toronto Star, charges are pending against nine companies and at least six food establishments within the city.

B.C. health officials have

traced an outbreak of about 650 salmonella cases over the past three years — a 300 per cent increase since 2007 — to egg consumption, including ungraded eggs.

Ontario’s turkey producers and processors have agreed to share changes in the cost of feed until the end of the quota year April 30 and avoid an Ontario Agriculture, Food and Rural Affairs (OMAFRA) Appeal Tribunal hearing.

Processors had been

concerned that rapidly rising costs for corn and soybeans would be quickly pushed into the cost of live birds.

If those costs couldn’t be passed through to retailers and then on to consumers it would hit processors’ margins.

The agreement is retroactive to Jan. 10.

Danny Williams has been named the new Poultry Products Manager for KMG Chemicals Inc. Williams recently served as Sales Manager for PVP – Poultry Division, and has worked nearly 30 years in poultry sales and service with WYNCO (now IVESCO), holding positions as Territory Manager, Sales Manager and Vice President of Sales during his tenure.

Dr. John Halley has accepted the position of Global Head of Nutrition Services at Aviagen. John and his team of poultry nutritionists will provide innovative nutrition technical support to Aviagen’s internal production operations and clients, and conduct innovative research to keep its nutrition technical advice current and consistent.

David Beavers has joined Cobb as technical processing specialist. Beavers has 38 years’ experience in poultry processing, most recently with Tyson Foods, at the company’s research, development and technology plant in Springdale, first as plant manager, then as facilities manager.

The National Chicken Council, U.S. Poultry & Egg Association, and several state poultry federations in the U.S. are among a vast coalition of 90 organizations opposing extension of the blenders’ credit that subsidizes the production of ethanol. The groups sent letters to the leaders of Congress March 2 calling on them to let the tax credit expire on schedule at the end of 2011. The ethanol industry is lobbying Congress

for an extension.

“Congress has the opportunity to end the $6 billion a year subsidy to gasoline refiners who blend corn ethanol into gasoline,” the letter said. “At a time of spiraling deficits, we do not believe Congress should continue subsidizing gasoline refiners for something that they are already required to do by the Renewable Fuels Standard.”

The coalition comprises 90 associations.

An attempt by some EU Member States to delay a ban on “battery cages” for laying hens was thwarted by Defra Secretary of State Caroline Spelman’s attack on the proposals during a February meeting of Agriculture and Fisheries Ministers in Brussels. Several other countries, including Germany, France, Spain and the Netherlands, backed her calls to ensure the ban was implemented on time.

Back in 1999, the European Commission announced the use of battery cages for laying hens would

APRIL

April 19-20, 2011

Poultry Industry Conference and Exhibition (London Poultry Show), Progress Building, Western Fairgrounds, London, Ont. For exhibitor and registration information, please visit: www.western fair.com or tel: (800) 619-4629.

MAY

May 10, 2011

PIC Research Day, Victoria East Golf Club, Guelph, Ont. For more information, visit: www.poultryindustrycouncil.ca or tel: (519) 837-0284

JUNE

June 12-14, 2011

CPEPC Convention, Delta Hotel, St. John’s, NL. For more information, visit: www.cpepc.ca or tel: (613) 724-6605

JULY

July 16-19, 2011

be banned from Jan. 1, 2012 (Directive 1999/74/EC). At that time member states were advised that only enriched cages - which include a perch, scratching area and nest box – would be permitted after that date.

Over the last decade, producers in some European countries such as Germany and the U.K. have invested heavily in order to meet the new standards, but other countries have been less attentive and have been pressuring their politicians to get an extension on the deadline.

Poultry Science Association Annual Meeting, America’s Center, St. Louis, Missouri. For more information, visit: www.poultryscience.org/ psa11

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Publishing, P.O. Box 530, 105 Donly Dr. S., Simcoe, Ont. N3Y 4N5; e-mail knudds@annexweb.com; or fax 519-429-3094.

Health Canada says new labelling rules will give consumers more detailed information about the presence of allergens, gluten and sulphites in food and drink.

The department says the new labels will require manu-

facturers to clearly list the presence of such substances. The rules will require a listing of allergens in smaller components of the product. For example, if a product includes spices, the label must declare if the spices contain

According to new nutrition data from the United States Department of Agriculture’s Agricultural Research Service (USDA-ARS), eggs are lower in cholesterol than previously thought.

sition of standard large eggs, and results show the average

amount of cholesterol in one large egg is 185 mg, 14 per cent lower than previously recorded. The analysis also revealed that large eggs now contain 41 IU of vitamin D, an increase of 64 per cent.

“We collected a random sample of regular large shell eggs from 12 locations across the country to analyse the nutrient content of eggs,” says Dr. Jacob Exler, Nutritionist with the Agricultural Research Service’s Nutrient Data Laboratory. “This testing procedure was last completed with eggs in 2002, and while most nutrients remained similar to those values, cholesterol decreased by 14 per cent and vitamin D increased by 64 per cent from 2002 values.”

The collected eggs were

allergens or gluten. Milk, egg or fish products used to purify wines or spirits must also be listed on the label.

The new requirements will be phased in over 18 months to give manufacturers time to comply.

sent to a laboratory at Virginia Tech University to be prepared for nutrient analysis at certified nutrient analysis laboratories. The samples were randomly paired for the testing procedure, and the analysis laboratories tested samples to determine composition of a variety of nutrients including protein, fat, vitamins and minerals. Accuracy and precision were monitored using quality control samples.

This information is available on the nutrient data lab website at www.ars.usda.gov/ nutrientdata . The new nutrient information will also be updated on nutrition labels to reflect these changes wherever eggs are sold, from egg cartons in supermarkets to school and restaurant menus.

The Pullet Growers of Canada (PGC), formerly the National Pullet Growers Association, is seeking Part 2 Agency status under the Farm Products Agencies Act.

“Repositioning PGC within the supply management system as a Part 2 Agency will give Canadian pullet growers the legal voice to address the many issues affecting the pullet industry,” Andy DeWeerd, the chair of the PGC said in a release.

To date, pullet growers have relied on their representation through egg producer organizations; this has been due to the fact that many pullet growers are also egg producers and both commodities are closely connected. However, egg organizations are mandated to represent only their egg producers and not the pullet growers.

“Pullet producers have an excellent relationship with the egg organizations; however,

as an industry, we cannot rely on the good graces of the egg organizations to represent us,” said Mr. DeWeerd. “The time has come for pullet growers to have their own voice on such issues as cost of production, disease control, HACCP programs and housing standards, among many others. Being an autonomous agency will give PGC the required legal powers to make decisions on these issues, on behalf of pullet producers across the country.”

Dosatron International, Inc. is celebrating 25 years of providing waterpowered chemical dosing technology.

The company began in Clearwater, Fla., in 1986. Dosatron president Eddy Kelly said in a release that that the company will continue its focus on listening to customers and resolving any problems they may have.

Since 1974, when the first Dosatron was manufactured, superior engineering has been a common goal. Over the

last 25 years, there have been innovative changes such as simplified motors, materials

that are more chemical resistant, and diaphragm technology. The future will continue to bring state-of-the-art technological advancements.

Today, Dosatron manufactures and sells a wide variety of chemical injectors in over 20 countries worldwide. Its full-service operation has an injector to meet virtually any chemical management need in applications ranging from horticulture, vehicle wash, livestock, printing, hygiene, plant sanitation, water treatment, and many more.

Three major reports released in early March point to healthy prospects for the agricultural industry, according to a federal government news release.

The reports give a clear snapshot of the state of the sector, portraying a highly complex, integrated and globally-competitive value chain that is an expanding and vibrant part of the Canadian economy.

Farm incomes in 2010 are expected to surpass the record set two years ago, with 2011 also anticipated to be a good year for Canadian farmers. Farm income is expected to

peak to more than $50,000, a five per cent jump over 2009 and 31 per cent above the 2005-09 average.

The “Medium Term Outlook” for the next 10 years points to continued high prices for grains and oilseeds leading to dynamic growth in production and exports. Prices for cattle and hogs are expected to increase slightly, offsetting higher feed costs. This will allow for moderate growth in production and exports for the livestock sector.

Both the Farm Income Forecast and the Medium Term Outlook reinforce findings in the 2011 edition of

the Overview, which indicates a younger generation of farmers on the horizon. The Overview reports that farm operations that are managed solely by farmers between the ages of 18 and 39 tend to be well distributed across farm types, size and province and are likely to have higher profit margins, a higher share of onfarm family income and earn higher gross farm revenues.

The three reports produced by AAFC’s Research and Analysis Directorate can be accessed online at: http://www.agr. gc.ca/cb/index_e.php?s1 =n&s2=2011&page=n110228

Pfizer Poultry Health has introduced a broader, diversified portfolio of products and services with the acquisition of Alpharma LLC as part of Pfizer’s acquisition of King Pharmaceuticals.

José Francisco Ortiz C., Vice President, Pfizer Poultry Health & New Established Brands, says the integration has expanded Pfizer’s product portfolio, allowing the company to enter new therapeutic fields.

Pfizer Poultry Health has gained a portfolio of medicated feed additives, watersoluble therapeutics and probiotics and enters the poultry nutrition sector with the acquisition.

The research and development platform established by Pfizer, integrated with the research-laden history of Alpharma, will lead to further advances in poultry health management for poultry producers worldwide, the company said in a release.

Federal, provincial and territorial Ministers of Agriculture met recently to discuss ways to better foster sustainable market opportunities. They are preparing to launch 19 pilot projects across Canada, to expand interprovincial trade in meat.

These projects will enhance processors’ ability to sell their product to more Canadian consumers, in turn increasing market opportunities at the farm gate.

In addition to growing the domestic market, collaborative efforts continue to expand export opportunities while maintaining support for supply management. Ministers were pleased that the $20 million Livestock Auction Traceability Initiative is now accepting applications to help strengthen Canada’s national trace ability system by modernizing the identification and tracing of animals at auction marts, assembly yards, feedlots, and other high-volume commingling sites.

Ministers acknowledged the more than 100 cost-shared and federal programs delivering results in innovation, environmental management, food safety, food processing and marketing. Governments will continue to seek input from Canadians to help set priorities for the next policy framework, Growing Forward 2, which will drive the economy, help the industry maximize its resources, and reduce input costs. Ministers also agreed that young and beginning farmers will be key to the future of the sector and will be full partners in discussions on Growing Forward 2.

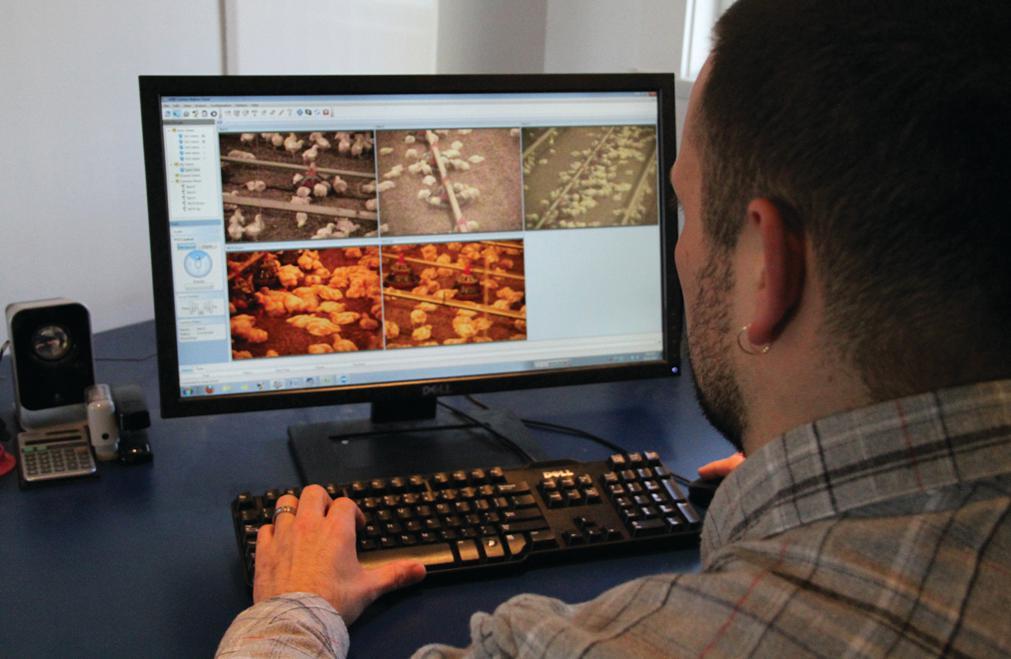

Scott Salter makes in-barn cameras work, allowing for “real-time” observation of birds anywhere, anytime

BY KRISTY NUDDS

Broiler farm manager Scott Salter has given new meaning to “bringing technology to the farm.”

He has successfully introduced an in-barn network of cameras that have the ability to record and stream live video in the barn 24 hours a day, seven days a week. The 360-degree PTZ cameras can pan, tilt, and zoom, offering continuous live viewing of a poultry operation with just one click from anywhere in the world over an IP network.

As the manager of two broiler farms in the Fraser Valley, Salter has utilized his background in computer networking to explore new ways of using modern technology on-farm. Murray Hamm, who owns one of the farms that Salter manages, says that the “in-barn cameras are the most useful tool I’ve come across since starting farming more than 20 years ago.”

With the cameras, Salter can keep an eye on 130,000 birds at two different locations using a computer or any smartphone device. “The cameras are not designed to replace us as farmers, but it’s an additional real-time tool that allows you to see the inside of your operation instantly,” he says.

As both a poultry veterinarian and a broiler grower, Dr. Neil Ambrose agrees that no technology ever replaces sound husbandry practices, and he is interested in implementing the live camera system in his own barns.

Broiler manager Scott Salter has utilized his background in computer science to set up a live, in-barn camera system that allows viewing of birds from anywhere using a computer or smartphone device.

“Throughout the production cycle it is critical that there is no equipment failure or environmental mismanagement that could negatively impact the health and welfare of the birds,” he says. “Consideration to utilize the technology available to us all these days only makes sense in order to enhance our ability to care for our birds to the best of our abilities.”

The camera system allows a grower to view the birds’ behaviour, their eating and drinking patterns, whether they are huddling in a particular location (indicating a draft), the up and down time of

the lighting program, the available feed in the feed pans, water leaks, as well as fan and inlet operation.

“When you are offsite and there has been a sudden in-barn alarm due to temperature, feed and water changes, you can actually view the details of the alarm and decide the appropriate action to take,” says Salter.

This has come in handy for pinpointing

Continued from page 12

the cause of a problem in its earliest stages, before the situation becomes worse. Salter says that there have been occasions where he has been able to react more quickly than he would have prior to the camera system, such as when a water leak in one of the barns occurred due to a faulty nipple, and when there has been an issue with the feed line auger, resulting in no feed in the feed pans.

According to Salter, the cameras require an Internet connection at the farm and can be installed and configured in one day. Each camera can be controlled and viewed from any type of computer, an iPad, an iPhone or any other smartphone device or tablet. Because security will be a worry for most users, Salter says network security can be enhanced by employing options such as multi-level password protection, IP address filtering, and HTTPS encryption. To help obtain the necessary bandwidth required for streaming video and control commands

over the network, the cameras support Quality of Service (QoS), a network control mechanism that guarantees a certain level of performance to the flow of data.

The system is running smoothly now, but it took Salter a year to work out the kinks. Networking wasn’t the biggest obstacle; it was finding the right camera for the job.

Working with a budget in mind, the challenge was to find a camera that could meet the various demands of viewing the interior of a poultry barn, says Salter. He spent many trial hours narrowing the choices down to a few cameras that could actually meet these demands.

The chosen cameras had to have the ability to pan 360 degrees, tilt up and down and zoom in a 500-foot barn – all over a standard Internet connection. It also had to be functional when the lights

are dimmed, providing a clear picture when the light intensity is as low as 0.5 foot-candles, he says.

Size also was a consideration. “The last thing I wanted was a massive device that restricted airflow,” he says. The camera also had to have several mounting options available. “With so many types of poultry barns with various ceiling heights and types of equipment, this was a must.”

Protecting the camera from dust was another requirement, and to solve this, a translucent dome was fitted over the camera. Salter says dust on the dome doesn’t really become a problem until the last week of a cycle. To remove it, he says he cuts a Swiffer duster pad into a small piece to remove any dust on the dome.

The camera system also allows for enhanced biosecurity. Conditions in the

barn can be checked more often, without having to physically be in the barn and always having to change in and out of coveralls and boots.

What Murray Hamm likes most about the system is its ability to record what the birds are doing, especially at night. “Never before have I been able to see what the birds are doing or where they feel the most comfortable throughout the night,” he says. “Because of this, we are able to see and make changes that we would never have known about before. It’s a small investment that will continue to make positive changes in the way we farm.”

Salter says he has used the live camera system in multiple broiler barns, but there is no limit as to where and what type of operation it can work in. “From broilers to

layers, turkeys, dairy, hogs, you name it, these controllable, recordable, live compact cameras will work,” he says.

Currently, he has helped with the installation of in-barn camera systems on three broiler and one layer operation in the Fraser Valley, involving a total of 10 cameras (one per barn floor).

He says that interest in the in-barn camera system among growers continues to climb, and that many have expressed an interest in using exterior barn cameras for security as well. He has five additional broiler growers wanting both indoor and outdoor cameras for their operations. “I am getting calls almost daily from word of mouth alone.”

Another type of technology Salter has implemented is BinMaster’s Smartbob

TS-1 sensor to measure feed inventory in real time. The Smartbob is designed for smaller feed bins. As it travels down the bin, when it hits the top of the feed, it stops and retracts back to the top of the bin, allowing Salter to determine the level of feed in the bin. It comes with software that allows him to take manual measurements at any given time, and he can log in remotely from anywhere. “It’s fully customizable,” he says.

Combined with existing forms of remote software to control in-barn computers, having a controllable, live, inbarn view of the birds is one more tool in the toolbox, he says. “The technology is there, let’s use it!” n

If you would like to know more about how to implement an in-barn camera system on your farm, Scott Salter may be contacted by e-mail at premierpoultry@gmail. com, or by telephone at 604-835-3163.

BY DR. JOHN R. GLISSON, UNIVERSITY OF GEORGIA

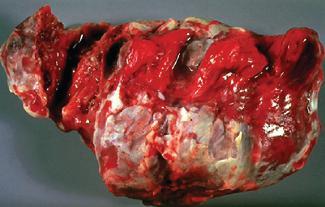

Fowl cholera, caused by Pasteurella multocida, continues to be a nagging problem for many breeding companies. The disease that is primarily seen today is chronic fowl cholera, characterized by swollen joints and wattles. Some cases of fowl cholera result from exposure of susceptible flocks to wild, virulent P. multocida Other cases are induced by live fowl cholera vaccines.

There are two recommended approaches for protecting broiler breeders against fowl cholera: reduce the P. multocida field challenge and properly vaccinate the replacement birds against P. multocida

Unlike E. coli or Staphylococcus sp., Pasteurella multocida is not usually found in chicken litter, feed, or water. P. multocida is found as a normal inhabitant of the oral and nasal cavities of many animals such as dogs, cats, rodents, and other mammals. These animals are the reservoir for wild P. multocida and serve as the source of challenge organism for broiler breeders. Rodents and cats are the primary vectors.

Therefore, the most important way of reducing P. multocida challenge in a broiler breeder house is to eliminate the exposure of the birds to these mammals which carry the organism. This is certainly not a new concept but it is an idea which many companies fail to take seriously.

A typical rodent control program for broiler breeders often consists of

Fowl cholera continues to be a nagging problem for many breeding companies. The disease that is primarily seen today is chronic fowl cholera, characterized by swollen joints and wattles.

nothing more than providing the grower with rodent bait. Partially slatted broiler breeder houses provide a nearly perfect environment for rodents, so a focused professional approach to control is required to effectively reduce rodent numbers in a breeder operation. If a company has flocks suffering from fowl cholera which is not live vaccineinduced but caused by wild P. multocida, rodent control is generally more important for preventing the disease in future flocks than are various manipulations of the vaccination program.

Fowl cholera in broiler breeders can be caused by wild P. multocida or live fowl

cholera vaccines. Fowl cholera caused by wild organism may be any serotype but is most commonly serotype 1, 3, or 3, 4. Vaccine-induced fowl cholera is always serotype 3, 4 because all of the live vaccines are serotype 3, 4. Fowl cholera caused by wild organism can occur at any time in a flock’s life but vaccine induced fowl cholera typically occurs within a few days or weeks of vaccination, regresses for a few weeks, and then may reoccur in a long-term pattern of chronic fowl cholera soon after moving to the laying house or near peak egg production.

In some instances, the early postvaccinal cholera may not be noticed and only the chronic fowl cholera near peak egg production is reported. Live fowl cholera vaccines are used because they very effectively induce protective

immunity against a broad range of P. multocida serotypes.

The Clemson University (CU) strain is the most virulent of the three vaccines. M-9 is the least virulent and PM-l is intermediate in virulence between CU and M-9. All of these products have the potential to cause vaccine-induced fowl cholera in certain circumstances. For instance, live fowl cholera vaccine with a high titer is more likely to cause disease than one with a low titer. Birds are more likely to develop vaccine-induced cholera when injected in the wing muscle rather than the wing web. Flocks have a greater risk of vaccine-induced cholera when they are moved to the laying house at the same time they are vaccinated. Male broiler breeders, in general, appear to be more susceptible to vaccine-induced cholera than females.

There are a number of things that can be done to minimize the incidence of live fowl cholera vaccineinduced disease:

1. Use the milder vaccines PM-l and M-9; both induce less disease than the more virulent CU strain.

2. Do not use high titer serials of CU or PM-l vaccine. High titer vaccines have the potential to induce a high incidence of fowl cholera.

3. Do not use live fowl cholera vaccines intended for oral use in turkeys. Dilution of these products is required for use in broiler breeders.

4. Vaccinate pullets and cockerels 1-2 weeks before moving to the laying house.

5. Add a treatment level of oxy-

Sommers has been a trusted name for standby and PTO power systems in rural Canada for almost 75 years. Over the generations, we’ve been there to keep your lights on and your equipment running with reliable generator systems personally tailored to your family and business needs.

Times have changed, but Sommers is still leading the next generation of power solutions with advanced features like Sentinel remote monitoring and our new easy-to-buy series of packaged systems.

For now and for your future, count on Sommers for “the power to live better.”

tetracycline or chlortetracycline to the feed during the first week in the laying house (1-2 weeks after vaccination).

6. Males may be vaccinated with a milder vaccine than the females. For instance, if the females are vaccinated with PM-1, vaccinate the males with M-9. In prac-

tice, this may be difficult to accomplish if males and females are reared together. If males are stressed by severe feed restriction, vaccine-induced fowl cholera is more likely to develop. The most severely restricted males within the flock are most likely to develop the disease. In this

THE

As poultry farms become larger and more land-based with farmers growing grains on their operations, the savings from making feed on the farm has increased signi cantly.

Recent advances in technology have resulted in the development of automated systems, designed speci cally for the manufacture of feeds on farm. The combination of on-farm milling and Grand Valley Forti ers poultry premixes have shown to increase pro ts by 19%.

Ask us how incorporating your own grains and mixing on-farm will add to your net pro ts

Call us today at 1-877-625-4400 and speak to one of our Poultry Specialists.

case, it is very important to use a mild vaccine and not move the birds to the laying house at the time of vaccination. Also, rough handling of males, such as catching and holding by one leg also increases the likelihood of vaccine-induced fowl cholera.

7. Give a fowl cholera bacterin at 8-12 weeks of age followed by the live vaccine at 16-18 weeks of age. The single dose of bacterin induces a level of immunity capable of reducing the negative side effects of the live vaccine.

8. Ensure that the vaccine is not injected into the wing muscle. This increases the dosage of vaccine received by the bird and increases the likelihood of postvaccinal fowl cholera.

9. Prevent contamination of live fowl cholera vaccine during use. Staphylococcus easily contaminates needles and open vaccine bottles. Injection of contaminated vaccine often leads to swollen joints and lameness.

10. Use fowl cholera bacterins in your vaccination program. Bacterins do not cause fowl cholera, they only induce immunity to the serotypes contained within.

Fowl cholera is still a major problem in broiler breeders. The key factor for reducing the incidence of fowl cholera caused

Continued on page 54

Your business needs are unique. Your livelihood depends on weather conditions, market changes and production cycles.

Managing and expanding your agricultural business requires the expertise of a business advisor intimately familiar with your challenges and opportunities.

You need the trusted, one-on-one relationship of a CIBC business advisor, backed by a team of dedicated CIBC Agricultural Banking Specialists.

You need solutions that are as unique as you are.

To speak to a CIBC business advisor, visit any CIBC branch, go to cibc.com/agriculture or call 1-888-493-2422.

BY TREENA HEIN

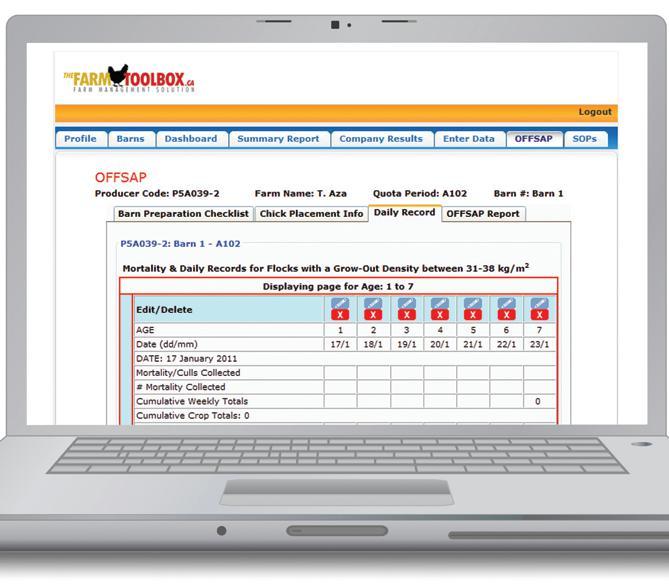

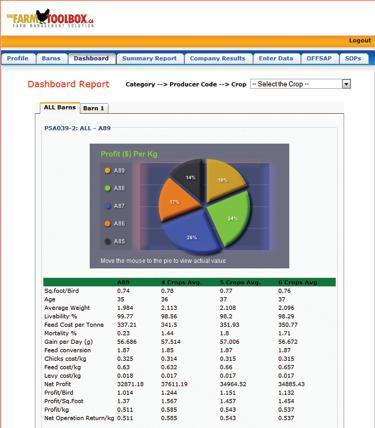

Farmers are becoming more computer and technology savvy than ever, and are on the lookout for programs and hardware that make production easier. They want record-keeping to be streamlined and show more clearly how costs might be cut. That’s why two years ago Costa Aza, a second-generation poultry farmer in West Lincoln, Ont., began developing The Farm Toolbox, an online software farm management program. It keeps track of profits, makes sure you are in compliance with on-farm food safety protocols, allows you to compare production cycles and much more.

“During my first eight years of farming – seeing firsthand the importance of overall farm management as well as attention to daily operations – I was looking for a time management solution to help reduce the number of hours that I spent completing paperwork,” says Aza. Two years ago, he began creating the initial concept for the program, and once he found the appropriate support team (mainly Bruce Leung, a programmer with previous background in information technology development for the poultry industry), the development of the website moved ahead quickly. It was introduced in April 2010 at the London Poultry Show in Ontario.

After registering on the website, users can log on and access the program

After registering on The Farm Toolbox website, users can log on and access the program whenever they choose. They can enter or view information on crop results for each flock/production cycle, OFFSAP checklists, SOPs and other operational details.

whenever they choose. They can enter or view information on crop results for each flock/production cycle, OFFSAP checklists, SOPs and other operational details. Flock data recorded in the program includes feed consumed, medications used, supplier information, mortality rates, water consumption and more. One of the most useful aspects of the program is the way users are able to go back and look at data from previous production cycles. “The ‘Dashboard’ application compiles and analyzes crop results automatically to provide you with barn-

to-barn and crop-to-crop comparisons,” says Aza.

In Abbotsford, British Columbia, on a farm with 22,000 broilers, Ron Faber started using The Farm Toolbox in December 2010. “I have only entered data on one flock so far, but I’m very impressed,” he says. “It’s got everything you need, and you can look back and it’s all right there and very convenient. You don’t have to go through sheets of paper to find the information you’re looking for. It simply works like a computer program should.”

The OFFSAP and SOP information can be printed or e-mailed to the marketing boards when required by the auditing process. “It’s all in one secure location, organized and easily accessible, which makes the audit process a lot less stressful and more efficient,” notes Aza. “It allows producers to concentrate on their farming operations.” All the information is stored on a remote server that is backed up daily. “We have the highest level of security and follow the Canadian Privacy Act, which means the only person who sees a producer’s information is the producer,” Aza explains.

The program can be used on a daily, weekly or flock/production cycle basis. “For the average-sized farm using all the functionalities, it would take a producer no more than five minutes every day to enter data, but you can also log on once a week and get

all the information entered in about 10 minutes,” says Aza. “Or, you can choose to enter in all the results for a flock once it’s shipped, and that takes about 30 minutes.” In terms of recordkeeping efficiency, he estimates that by using The Farm Toolbox, customers are saving an average of an hour per barn per quota period.

Generally, the first crop is the most work for a producer because they need to enter all their farm details into the program, Aza notes. “During the second crop, the producer learns the copy function of the program which copies common items from your previous crop,” he says, “and by the third crop, producers are comfortable with this process and easily interact with the program to quickly enter new data.” It takes about three crops for users to feel completely comfortable and fluid with the website. “This is why I felt it was very important to provide a free 90-day trial,” Aza says. “We also provide customers with help during this time.” Aza is in the process of hiring people to provide demonstrations and hands-on support to new users, with the province of B.C. first in line.

As an added bonus to using the software, Aza says he has partnered with other select farm service providers in order to give discounts for products and services such as barn cleaning, shavings and disinfection. Ivan DeVries, who farms 60,000 roasters in Smithville, Ont., says “The discount I have with a supplier helped pay for the program.” He has been using The Farm Toolbox for six months. “It’s very user-friendly,” he notes. “You’re able to get on the program and right away, everything’s in front of you. I also like the way you can bring things forward to the new crop record that are similar to the last one.”

Chris Rose has been using The Farm Toolbox for about a year to manage the broiler barns and one turkey barn at Vassilakos, Apostolakos and Sigma Farms near Smithville. “We find it’s a nice service because you can access things online,” he says. “It’s also helping to solve paperwork issues, especially in our situation, when there are several barns to oversee.”

DeVries is also happy the way Aza is willing to make changes to the program so that almost everyone in the poultry industry can use it. Aza continually receives feedback from customers on ways to improve the site and to adapt to changes in the OFFSAP/SOP process, such as the recent inclusion of animal welfare requirements. “The program will continue to expand and add new features based on customer feedback and board requirements,” he says.

For more information, visit www.thefarmtoolbox.ca. n

Pathogens can enter a barn without one in place

BY DANIELLE JULIEN, BIOSECURITY PROGRAM SPECIALIST, AND SARAH THOMSON, EDUCATION PROGRAMS MANAGER

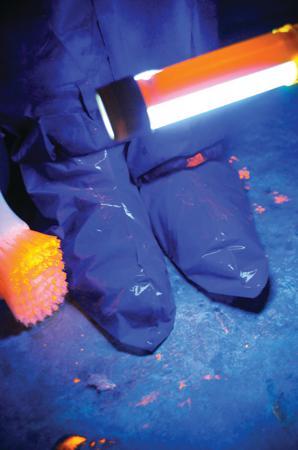

After they’ve been contaminated with pathogens (bacteria, viruses, etc.), poultry facilities are extremely difficult and expensive to clean, sanitize and disinfect.1 Demonstrating the importance of having a biosecurity plan in place to prevent pathogens from entering poultry facilities was the focus of a workshop held by the PIC for producers. Using GlogermTM, a chemical that is luminescent under UV light, participants were shown how improper washing of boots and hands can provide an opportunity for diseases to get into poultry facilities from outside sources.

Wearing designated boots in the barn is by no means a new concept. Pictures 1 and 2 show that bacteria and viruses can get tracked into your facility without you knowing it if a proper biosecurity program is not in place. Effective cleaning and disinfection of designated barn boots or wearing disposable boot covers is just as important in ensuring disease stays out of your barn.

Foot baths have historically been used to keep barn boots clean; however, maintenance of these on most facilities is poor, and frequently they are

GlogermTM, a chemical that is luminescent under UV light, was used to show workshop participants the importance of dedicated barn footwear and proper hand washing.

overly contaminated with organic matter. Picture 3 shows what a foot bath can look like after a single use! People commonly avoid stepping into foot baths or simply step through the bath without

stopping to clean their boots. Improper boot cleaning methods waste time and money, and may place the flock at risk of pathogen spread.2

1. Ensure that your barn is equipped with boot covers that allow for easy disinfection and

At the beginning of 2010, Chicken Farmers of Ontario (CFO) set a goal to lead and facilitate the growth of a world-class Ontario chicken industry that can profitably grow locally, across Canada and internationally.

In 2010, CFO implemented a disciplined, team-based business model designed to be more responsive to farmer and processor-customer needs; one which takes a longterm perspective on generating growth in Ontario industry value and sustainability.

What did we achieve in 2010? Following are some of our successes:

● Enhanced relationships with the processing sector through Team Ontario, our business framework for collaboration between farmers and processors to advance strategies and manage issues.

● Continued efforts to champion action and accountability at national allocation-setting meetings including working with Les Éleveurs de volailles du Québec. Through consultation, CFO established fact-based volume allocation recommendations that led to a 2010 allocation growth, from A-96 to A-101, of 2.1 per cent and +8.3 million live kilograms versus 2009.

● Audited our biosecurity and animal care protocols as part of CFO’s commitment to ensuring safe, smart farming practices.

● Worked with our industry partners to develop and implement the Broiler Chicken Industry Safe Work Practices document for handling chickens on-farm.

● Hosted three national forums, bringing together representatives from provincial chicken boards across the country to collaborate on policy and discuss important issues facing the industry.

● Educational opportunities for Ontario chicken farmers and industry partners at Farm Insight and Industry Insight Meetings.

● Reconnected with consumers through the "Savour some local flavour" campaign which included print advertising in marquee food publications.

Having built a foundation for better performance, our work will continue in 2011. Our priorities include:

● Implementation of the new processor allocation system.

● Evolving models for industry collaboration through the Team Ontario business framework.

● Working with the new Chicken Industry Advisory Committee (CIAC) to develop and implement activities that deliver profitable volume growth, enhance quality, lower costs, strengthen competitiveness and support sustainability

● Working with the Chicken Farmers of Canada to develop, audit and enforce the evolving On-Farm Food Safety Assurance Program and Animal Care Program. We are also working with the industry on traceability strategies through the entire industry value chain.

● Moving away from paper-based towards inter net-enabled business operations or "CFO Online".

CFO will continue to be a strong and progressive leader in the Ontario and Canadian chicken industry. On behalf of Ontario’s 1,026 licensed chicken farmers, we look forward to the future and to many more successes in the year to come.

Murray Booy

Rob Dougans Chair Chief Executive Officer

CFO held its 2011 Annual General Meeting on March 7, 2011. Further information about CFO’s 2010 activities and priorities for 2011 can be found in the 2010 Performance Report. The 2010 Performance Report and the presentations from the AGM can be found at www.ontariochicken.ca

THE MAINTENANCE OF FOOT BATHS AT MOST FACILITIES IS POOR AND THEY ARE OVERLY CONTAMINATED WITH ORGANIC MATTER. THE PHOTO ABOVE SHOWS WHAT A FOOT BATH CAN LOOK LIKE AFTER A SINGLE USE.

don’t collect organic debris.3 Pictures 4 and 5 show less residue is left on cleaned boot covers versus rubber boots

2. Remove built up shavings, manure or dirt from your boots as soon as possible, focusing on the boot treads and crevices. Use a dedicated brush for boot cleaning.

3. Keep disinfectant, wash pails and a plastic/non-porous boot brush specifically for scrubbing boots readily available.3

4. Step into a disinfectant foot bath and scrub boots clean; research has found that bacteria counts were significantly less when boots were scrubbed for 30 seconds in a bath compared to not using a bath or standing in a bath that had been used 10 times.2

5. Clean scrub brushes and pails of water. Once scrubbed, spray with disinfectant or sanitizer soap.3

Among the various hand-cleaning products available (soaps, scrubs, antibacterial formulas, and alcohol hand rubs), alcohol-based products have the most rapid bactericidal action (tested without organic material present on hands).4

Studies have shown that increased hand hygiene due to the presence of alcoholbased products can be attributed to the availability of product dispensers and the minimal time required to use them.4 Studies have also shown that the use of alcohol products was overall less costly than traditional hand washing because of the longer time required for hand washing as well as the added costs of paper towels and water.4

Alcohol-based sanitizer –Application time: 20 – 30 seconds

1. Apply a palmful of alcohol-based hand-rub and cover all surfaces of the hands.

2. Rub hands until dry.

Soap and water wash – Application time: 40 – 60 seconds

1. Wet hands with water and apply enough product to cover all surfaces.

2. Rinse hands with water and dry thoroughly with a single-use towel. Use clean, running water whenever possible. Avoid using hot water, as repeated exposure to hot water may increase the risk of dermatitis.

3. Dry hands thoroughly using a

RESIDUE CAN BE LEFT ON CLEANED RUBBER BOOTS. IT IS BEST TO USE BOOT COVERS.

PROPER HAND WASHING INVOLVES WETTING HANDS WITH WATER AND APPLYING ENOUGH PRODUCT TO COVER ALL SURFACES; HANDS SHOULD BE WASHED FOR 40-60 SECONDS.

method that does not recontaminate hands. Make sure towels are not used multiple times or by multiple people.

4. Liquid, bar, leaf or powdered forms of soap are acceptable. When bar soap is used, use small bars of soap in racks that allow the bars to dry in between uses.

1. Poultry Facility Biosecurity, John B. Carrey. http://repository.tamu.edu/bitstream/handle/1969.1/87791/pdf_823. pdf?equence=1

ENSURE THAT YOUR BARN IS EQUIPPED WITH BOOT COVERS THAT ALLOW FOR EASY DISINFECTION AND DON’T COLLECT ORGANIC DEBRIS

2. Evaluating the efficacy of boot baths in biosecurity protocols, Sandra F. Amass, DVM, PhD, Dipl. ABVP et al., http://www. aasv.org/shap/issues/v8n4/ v8n4p169.html

3. Ontario Veterinary Biosecurity Initiative Protocol OnFarm Veterinary Biosecurity, Ontario Veterinary Medical Association (OVMA), http:// www.ontariopork.on.ca/User/ Docs/Research/Biosecurity/ biosecurity_protocol_onfarm_ may09.pdf

4. National Institute of Health “Effect of Guideline Implementation on Costs of Hand Hygiene.” Patricia W. Stone, PhD, RN, Associate Professor, Sumya Hasan, Student Intern, Dave Quiros, MD, Project Director, and Elaine L. Larson, PhD, RN,Professor. The information presented here is also available in two factsheets, “Bootwashing” and “Handwashing”. You can obtain these factsheets by visiting www.poultryindustrycouncil.ca or by telephoning (519) 837-0284. n

Continued on page 32

Immucox®. Coccidiosis vaccine via a patented gel spray.

As a producer, you know that coccidiosis is endemic in your flock; birds are being challenged and that has a cost—lower feed efficiencies. Expensive medications lose effectiveness as coccidia strains become more resistant, and may not be the answer. Vaccination is an alternative method of coccidiosis protection that can perform as well as medication without losing sensitivity in disease control. The Immucox gel droplet delivery system provides vaccine to the poults and sees immediate uptake— *we routinely find over 90% beak and tongue coloration within 3 minutes. Because the droplets sit on top of the down, the birds remain dry, stay warm and active, and recover immediately. (Canadian patent pending)

The Canadian Poultry Research Council (CPRC) is currently accepting applications for its annual research grant competition. This competition is open to all poultry researchers in Canada. The competition process starts with a “Call for Letters of Intent” (LOI). These LOI are short proposals that highlight the details of a research project: objectives, methodology, expected outcomes and budget. Completed LOI are due June 1. The LOI are reviewed by CPRC’s Scientific Advisory Committee (plus external reviewers where appropriate) for scientific merit and by the CPRC’s directors for relevance to national priorities. The CPRC members then decide which proposals they wish to support and invite each successful applicant to prepare a full, more detailed application to be submitted to a funding partner (e.g., the Natural Sciences and Engineering Research Council (NSERC)). Funding from CPRC is contingent on securing matching funds from one or more of these partners.

Any given Call usually pertains to two priority research areas. These priorities are set during regular national workshops, with participants representing industry, government and academe. These workshops provide participants with the opportunity to collectively decide where major research efforts should be directed. Provisions have also been made within CPRC to support research that addresses acute or emerging needs for the industry. This year, CPRC is calling for research proposals pertaining to “Poultry Welfare and Behaviour” and “Food Safety and

Quality – The Impact of Poultry Health and Disease.” These areas cover a wide range of research topics that are often interrelated. Such a broad Call is aimed at fostering collaborations among different researchers and institutions. Collaborative approaches to research are encouraged and will be a major component of the National Poultry Science Strategy, which is under development in consultation with stakeholders across the country.

The CPRC also directly promotes succession in our poultry research community through its scholarship program. The purpose of the program is to entice students to consider a career in poultry science. Specific program objectives are:

• to encourage and support graduate students to carry out research in an aspect of poultry science

• to build Canada’s intellectual capacity in poultry science

• to promote graduate research in poultry science at Canadian universities

The CPRC offers a “Postgraduate Scholarship Supplement.” The Supplement is $7,500 per year. To be eligible, a student must be studying (or planning to study) some aspect of poultry science and must also hold a Natural Sciences and Engineering Research Council (NSERC) scholarship at the masters (eligible for one year) or doctoral level (eligible for up to two years). Several

excellent students have received supplements to their scholarships through this program. Details on past winners are available at the “Scholarship” section of the CPRC website (www.cp-rc. ca), where there is also a link to the NSERC website, which details eligibility criteria and application procedures.

In order to attract students from a wider pool, CPRC will now also accept applications from non-NSERC scholars. Applications to the CPRC Postgraduate Scholarship, also set at $7,500 per year, will be assessed using the same criteria as the Supplement above, but applicants will not be required to hold a NSERC scholarship.

Applications to either the Scholarship or the Supplement are due May 1. Only one Scholarship or Supplement will be awarded each year. Details are available on the CPRC website and are being advertised throughout the academic community.

For more details on any CPRC activities, please contact Gord Speksnijder at The Canadian Poultry Research Council, 483 Arkell Road, R.R. #2, Guelph, Ontario, N1H 6H8, phone: 289-2512990, fax: 519-837-3584, e-mail: info@ cp-rc.ca, or visit us at www.cp-rc.ca. n

The membership of the CPRC consists of the Chicken Farmers of Canada, the Canadian Hatching Egg Producers, the Turkey Farmers of Canada, the Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

Continued from page 29

BY TIM NELSON, EXECUTIVE DIRECTOR

I’ve been fortunate to attend a few conferences recently, which have been interesting but at the same time a bit disturbing.

Many of the talks and presentations at these conferences have reflected on the fact that there are now so many external influences impacting our industry that it’s hard to know where to start to address them. The big ones are environmental management, animal welfare, food safety, worker safety and biosecurity.

Some members of the general public have recently started to take an interest in these elements of our farming practice. For the majority of producers, this interest in a few elements of our operations is creating a “skewed” picture of our operations, which is very frustrating because it forces us to wonder whether we are doing the right thing or not. When we hear at conferences that these pressures are being brought to bear and quite vitriolic attacks on the way we farm it’s no wonder farmers become concerned about the future. There are very few farmers who need to worry unduly about these things. Good farmers farm sustainably and safely, producing a wholesome product with no negative environmental impacts. There are some emerging threats that need a scientific investigative response through research and there are some that can be mitigated by simply adhering to what we know of as best practice –particularly when it comes to biosecurity.

As a result, the theme for this year’s PIC Research Day is “Sustainability: Poultry and People, Growing Together.”

It will feature great speakers who will showcase the work they and others are doing to ensure we can live with our neighbours long into the future – with more understanding of why we farm the way we do and less antagonism brought about by ignorance.

Research Day is on May 10 at the Victoria East Golf Club, starting at noon. Contact PIC for more details on our Research Day, as well as for details about the remaining Growing Forward biosecurity workshops. These workshops have been really well attended, with producers wanting to hear more about this important management issue, as well as qualifying for “cost share” funding that will allow them to undertake some biosecurity initiatives on their farm(s).

Finally, the other really terrific thing I can report is the huge upturn in registrations for and attendance at the producer updates. Getting out into the regions discovering what you want and delivering it has proven very successful. We thank all those who have participated in the regional development meetings. See you at the London Poultry Show on April 19 and 20.

Control coccidiosis and eliminate ionophore rotation hassles with Coccivac®-B vaccine.

Nicholas Tremblay a réussi à se lancer en production d’oeufs. Sa détermination et l’esprit d’entraide des producteurs au Québec y sont pour beaucoup. BY ANDRÉ DUMONT

La production d’oeufs est fermée aux nouveaux venus. Le prix du quota et la façon qu’il se transige rendent un démarrage impossible, à moins que la famille soit déjà en production. »

Ces affirmations, les leaders syndicaux des producteurs d’oeufs du Québec les ont tellement entendues, qu’ils ont décidé de changer les choses. Leur programme d’aide au démarrage (prêt de quota à vie de 5000 pondeuses) ne fut que le début.

Deux nouveaux programmes de la Fédération des producteurs d’oeufs de consommation du Québec (FPOCQ) marquent le début d’une nouvelle ère de transparence et d’accessibilité des quotas. Fonctionnent-ils vraiment? « C’est certain! », vous dirait un producteur de 34 ans que Canadian Poultry magazine a rencontré en novembre dernier.

Faites connaissance avec Nicholas Tremblay. Le poulailler qu’il a bâti à partir de rien en 2008 est un bel exemple d’un rêve qui se réalise, grâce à la solidarité entre producteurs, beaucoup de détermination et un peu de chance.

Après avoir obtenu un diplôme en agronomie de l’Université McGill, Nicholas Tremblay a été embauché au

CHERCHEUR D’OCCASION

Amélie Audet, Nicholas Tremblay et leur plus jeune fille Juliette. La petite Meggy est absente.

couvoir de Victoriaville de La Coop fédérée. Un an plus tard, une compagnie pharmaceutique retenait ses services, pour desservir les producteurs de porc et de volaille.

À Sainte-Julie, au sud de Montréal, notre jeune agronome entreprend de monter une modeste production de poulet. Tout est en place pour l’achat de 300 mètres carrés de quota, mais le projet avorte pour une question de distances séparatrices.

En 2006, Nicholas Tremblay devient l’un des quatre finalistes pour l’obtention du tout premier prêt de quota à vie pour 5000 pondeuses de la FPOCQ. Le tirage au sort a favorisé Joanne LaBranche et Patrick Côté, de Kinnear’s Mills.

L’année suivante, la candidature de Nicholas Tremblay s’est hissée parmi les cinq meilleures, sur 26. Cette fois-ci, la chance fut de son côté au moment du

Experience...That’s the Braemar Difference.

tirage au sort parmi les cinq finalistes.

« Le concours est très exigeant. C’est sérieux, insiste le gagnant. La Fédération nous oblige à tellement bien préparer notre candidature qu’une fois qu’on est choisi, on ne panique pas! »

« Je suis un agronome de formation et j’étais destiné à travailler dans le domaine, en pensant que ce serait impossible de devenir producteur », ajoute-t-il.

En mai 2008, Nicholas Tremblay commence à construire le poulailler sur une terre qui avait appartenu à son grand-père à Saint-Ambroise, au Saguenay-Lac-Saint-Jean. Le bâtiment de 20 par 200 pieds sera complété en septembre, avec un poste d’emballage et une pièce réfrigérée. La ferme s’appellera « Les poules à Meggy », du nom de sa première fille.

Les 5000 poules arrivent et les débuts sont difficiles, puisque sa conjointe Amélie Audet doit rester à Saint-Hyacinthe pour terminer un diplôme d’études vétérinaires. Elle visite Nicholas et Meggy à chaque fin de semaine.

Gilles Aurélien Tremblay, le père de Nicholas, vient en renfort. Pour joindre les deux bouts, Nicholas accepte de travailler pour la même compagnie pharmaceutique, à raison de trois jours semaine.

Tous les moyens d’accroître la production sont envisagés. Une productrice qui siégeait au conseil d’administration de la FPOCQ lui témoigne de son enthousiasme en offrant de lui vendre du quota dont elle souhaite se départir.

Nicholas Tremblay achète du quota directement de cette productrice. Il en convainc d’autres de lui louer le quota pour lequel ils n’ont pas de place sur leurs fermes.

« Nous sommes extrêmement contents, mais ça ne s’est pas fait tout seul. Nous avons fait beaucoup de démarches au téléphone. Nous croyons dans notre production et nous sommes prêts à nous endetter. »

Deux nouveaux programmes sont venus lui faciliter la vie, pour accroître la rentabilité de sa ferme. Emboîtant le pas aux producteurs de lait du Québec, la FPOCQ a mis sur pied un système centralisé de vente de quota.

« Nous voyions que c’étaient surtout les grosses exploitations qui étaient favorisées par les transactions de quota de gré à gré », soutient Philippe Olivier, responsable des communications à la FPOCQ.

Le nouveau système centralisé est géré par le Groupe Agéco, une firme de recherche indépendante. Le système se veut transparent, avec des ventes environ quatre fois par année. Les vendeurs établissent leur prix en secret et les acheteurs enregistrent leur mise. Par un système d’« enchère tronquée », ceux qui misent trop haut ou trop bas sont écartés, le quota disponible étant distribué à ceux qui avaient deviné exactement le prix demandé par le ou les vendeurs.

Le prix s’est rapidement stabilisé à 250 $ par pondeuse, ce qui a mis fin au jeu de devinette auquel devaient se livrer les acheteurs. Par contre, l’incertitude est revenue après que le quota se soit échangé à 255 $ lors d’une récente enchère.

« Le système est fait pour trouver un prix d’équilibre, soutient Philippe Olivier. Ce n’est pas celui qui fait la plus

haute mise qui l’emporte. »

Nicholas Tremblay a réussi à acheter un peu de quota avec ce nouveau système. Par contre, il croit qu’un plafond devrait s’appliquer au prix du quota, comme cela se fait déjà pour le lait. Pour un producteur bien établi, il est très facile de payer 325 $ pour acheter un peu de quota, explique-t-il. Mais pour un jeune producteur comme lui, le prix doit être raisonnable et prévisible.

La plus grande part de l’augmentation de production chez Les poules à Meggy est réalisée avec du quota loué. Ici aussi, la FPOCQ est intervenue pour améliorer les règles du jeu.

Le quota en location provient principalement des producteurs dont les bâtiments sont remplis à capacité, mais qui reçoivent du nouveau quota à partir des allocations rendues possibles par l’augmentation de la consommation. Très souvent, ce quota aboutissait entre les mains des couvoirs ou des meuneries, qui le louaient à un producteur à condition qu’il leur achète ses poussins ou sa moulée.

Tout le nouveau quota en location est maintenant administré par la FPOCQ, qui le combine à ses propres réserves. Une fois par année, ce quota est rendu disponible à un prix fixe, à tous ceux désirant le louer.

« Il est très intéressant de produire avec ce quota loué, reconnait Nicholas Tremblay. J’ai un petit bâtiment, mais ma génératrice, ma salle de travail, mon système d’alarme et ma facture d’électricité me coûtent la même chose que dans une grande entreprise. »

Trois ans après le démarrage, la production a presque doublé. « Nous sommes très contents de ces programmes, affirme Nicholas Tremblay. Il y a eu une part de chance dans l’obtention du prêt de quota de 5000 pondeuses, mais pour le reste, nous faisons notre propre chance. On travaille très fort pour démontrer que nous sommes des producteurs d’oeufs sérieux et qu’on ne se contente pas de ce prêt de quota à vie. » n

built to survive

Flexible, shock-absorbing stem prevents breakage.

300 Series stainless steel is corrosion resistant.

After years of field research and fine tuning Ziggity has created the robust T-Max turkey drinker using the same proven principles as our poult drinkers. Finishing turkeys requires birds to get ample hygienic water. Turkeys have poor eye-beak coordination, so we created a large target that they can’t miss. With each drinking action T-Max dispenses a small amount of fresh water, while minimizing spillage. Birds grow big. Litter stays dryer, reducing ammonia release for healthier flocks.

Tel: + 1 574.825.5849

www.ziggity.com

Big, healthy male and female turkeys. Self-cleaning. Built-to-survive. T-Max drinkers from Ziggity, the most trusted name in poultry watering.

Visit www.ziggity.com/turkey for a demonstration.

BY FARM CREDIT CANADA

Farm Credit Canada (FCC) is urging producers to think about how financial fitness can advance their own agribusiness.

“Farmers are always busy, so there’s never a good time to reflect. But planning is key to business success and individual success contributes to a vibrant industry,” says FCC Chief Operating Officer Rémi Lemoine. FCC has created a list of 10 considerations to enhance personal financial fitness. The more farmers pay attention to these considerations, the more likely they are to succeed. “These tips apply to everyone, and they’re particularly important for young farmers who are the future of the Canadian industry.” He says that FCC research shows that young farmers are more likely to believe that farm or business will be better off in the next five years if they follow the tips.

1. Plan ahead. Successful farmers take the time to create a business plan. What do you want your operation to look like in five, 10 or 15 years? Write down strengths, weaknesses, opportunities and threats. Then consider how to build on strengths, take advantage of opportunities and mitigate weaknesses/threats. What is your goal? Consult “Prepare Your Business Plan” under Learning Centre/FCC Business Planning Award on the FCC website, www.fcc.ca, to see

Farm Credit Canada has created a list of 10 considerations to enhance personal financial fitness. The tips apply to everyone, and they’re particularly important for young farmers.

a business plan template.

2. Know your financial picture. What is your debt-toequity ratio? What were your equipment costs last year? What did you grow and how do you track what you sell? Did you meet the goals established in your business plan? Knowing these things will help to produce better decisions.

3. Calculate profit. Younger farmers typically have less equity, making it more important to focus on the bottom line. Did you make enough to cover the

cost of living, operating costs and payments?

4. Purchase versus rent/ lease. What impact will a debtfinanced purchase have on the balance sheet or taxes? Given your equity, renting or leasing may be a solution.

5. Gain access to credit. An input purchasing strategy coupled with adequate, ready-touse input financing can help you maximize profits. Consider off-season purchasing to realize overall cost savings and put in place pre-approved credit to let

you hold commodity inventory until the market will pay the most for it. Most producers still don’t have an inventory marketing plan.

6. Learn. The agriculture world is changing fast and requires that you stay abreast of current trends, best practices and marketing solutions. What type of course would enhance your skills? FCC offers several learning opportunities free of charge at www.fcc-fac.ca/ learning.

7. Consider the global economic environment. Since interest rates are very low, the only way they’ll go is up. If rates rose by one per cent, could your business withstand it? What impact will it have on land values and the overall market? What about the strength of the Canadian dollar? For example, a onepenny increase in the Canadian dollar compared to the U.S. dollar decreases the price of a hog by one dollar.

8. Think about your employees. Develop a strategy to attract employees and retain them over the longer term, whether they are family or not.

9. Ask for help. Focus on what you are good at and seek help with the rest. Talk to your accountant. Hire someone to help you market your product. Look at risk mitigation tools with your financial service provider. Ask your lawyer for estate planning advice.

10. Investigate technology. Is there a new way to do something that can save you time and money? Consider keeping field records in one place with software found at www. fccsoftware.ca.

For more information, visit www. fcc.ca. n

BY ROB PATTERSON, CANADIAN BIO-SYSTEMS

There is an increasing interest in the application of yeast-derived nucleotides for livestock nutrition due mainly to the growing body of research that is showing the healthand growth-promoting properties of this group of dietary supplements. Originally the focus of human pediatric and geriatric nutrition, research on nucleotides in all livestock categories is now routinely presented at scientific meetings and published in leading scientific journals. However, the amount of information specific to poultry in general and chickens specifically is still limited. What exactly are nucleotides, what is their mode of action and how they should be applied and incorporated into poultry nutrition so as to maximize performance and reduce antibiotic usage are the questions this article will address.

Similar to how amino acids are the building blocks of protein, nucleotides serve as the building blocks of DNA and RNA, the genetic currency of all living cells. Just as there are many different individual amino acids, so too are there multiple nucleotides. Chemically, nucleotides are one part non-protein nitrogen, one part sugar and one part phosphorus, and are grouped into two categories: purines and pyrimidines. It is the specific base pairing between these two groups that gives DNA and RNA their

As a feed supplement, nucleotides, the building blocks of DNA and RNA, can reduce feed costs and show potential as a replacement for growth-promoting antibiotics.

characteristic double helix structure and the alignment, or “sequence,” of nucleotides within the DNA and RNA molecules that makes up individual genes and the overall genetic code.

Nucleotides can be found in nearly all tissue types and because of their association with DNA and RNA are involved in almost all metabolic processes from protein synthesis and cell division to energy metabolism and immune functioning. Nucleotides participate in this wide array of processes not only by being required

for DNA and RNA synthesis, but also by assisting in cell signalling and acting as enzyme co-factors for multiple pathways.

Nucleotides are components of the non-protein nitrogen fraction of milk, yeast and other ingredients with high cellular density. Yeast and yeast byproducts such as live yeasts and yeast extracts are typically the best nucleotide sources. However, there exists considerable variation between commercial products (see Table 1). When procuring a dietary nucleotide supplement, it is a good idea to obtain a certificate of analysis showing the total level of all nucleotides present in the product.

In mammals, where, as mentioned above, the bulk of dietary nucleotide research has been conducted, there appears to be an evolved requirement for dietary nucleotides, which serves as the rationale for dietary nucleotide supplementation. Although, like mammals, poultry can synthesize nucleotides de novo, it is currently thought that the capacity for nucleotide production, especially in young animals, may not be enough to meet demand. Because of this, nucleotides have been described as being conditionally essential, and will be most beneficial under periods of stress, such as during disease and health challenges, high stocking densities, periods of rapid growth and antibiotic replacement or removal.

Because predicting when birds will become stressed is so difficult, a prudent feeding strategy is to ensure a constant supply of dietary nucleotides during production stages when the birds are at high risk of becoming stressed. That is, starter birds and flocks being raised under specific production conditions such as under “antibiotic-free” feeding

programs should be fed a steady diet of nucleotides.

There are few, if any, published studies that report a minimum level of dietary nucleotides required to elicit a feeding response. This is likely due to the inherent variability of the nucleotide levels within the supplements, the nucleotide source (ingredient), as well as the method

of evaluation and inconsistencies in analytical methods used to measure individual and total nucleotide levels, making it challenging to formulate to a minimum dietary nucleotide level.