February/March 2023

NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING

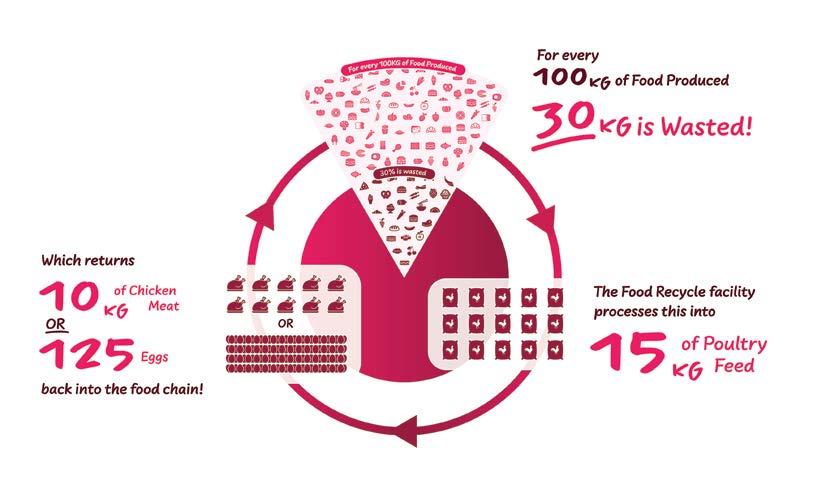

TRANSFORMING FOOD WASTE INTO ANIMAL FEED

Laboratory Suppliers – instruments, equipment, consumables

Lawson Williams’ National Staff Turnover and Employment Survey

THE OFFICIAL JOURNAL OF THE NEW ZEALAND INSTITUTE OF FOOD SCIENCE AND TECHNOLOGY INC.

FEBRUARY/MARCH 2023 | VOLUME 23, NO.1

ISSN 2744-7308 (ONLINE) ISSN 1175-4621 (PRINT)

Copyright © 2023 Peppermint Press

No part of this publication may be reproduced or copied in any form by any means (graphic, electronic, or mechanical, including photocopying, recording, taping information retrieval systems, or otherwise) without the written permission of Peppermint Press. The views expressed in this journal are those of the writers and do not necessarily represent the view of the Publisher, the Scientific Review Board or NZIFST

Director and Editor

Anne Scott, Peppermint Press Limited anne@foodnz.co.nz

Director and Writer

Dave Pooch, Peppermint Press Limited davep@me.com

Advertising

Anne Scott, anne@foodnz.co.nz 021 901 884

Design and Layout

Johanna Paynter, Pix Design

Regular Contributors

Phil Bremer, John D Brooks, Laurence Eyres, Ben Sutherland, Dave Pooch, John Lawson

Published by Peppermint Press Limited

Notice to Contributors

When submitting editorial for Food New Zealand please observe the following, Editorial to be submitted as plain text files, NO FORMATTING please. Images should be sent as high resolution .jpg or .tiff files. Do not embed images in word documents, send separate files. Any images smaller than 500 kb may not be printed as the clarity of the print may be compromised.

Advertisers

Material specification sheet and rate card on website, www.foodnz.co.nz

Food New Zealand 2 NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING Contents 17 4 EDIT ORIAL 5 NEW SBITES 8 OVERVIEW Laboratory instruments, equipment and consumables 17 PACKAGING 2022 AIP Career & Salary Report 18 SLIDING ON Gloves don’t make you bulletproof 19 FOOD SAFETY Summer of food safety Vincent Arbuckle, Deputy Director General, New Zealand Food Safety 20 FOOD SAFETY FSANZ and your food safety enquiries Ben Sutherland, Principal Food Technologist | Standards & Surveillance, FSANZ

Press Ltd 5 Rupi Court,

Auckland

New

Phone

www.foodnz.co.nz

NZ is distributed online to all members of the

tute of Food Science and Technology. An online edition is shared internationally. Visit www.foodnz.co.nz to subscribe.

Contacts Peppermint

Mt Wellington

1072,

Zealand

64 21 901 884

Food

New Zealand Insti-

5 8

Executive Manager, Wendy Bayliss

PO Box 44322

Pt Chevalier Auckland 1022

New Zealand

Phone: 022 549 8483, Email: wendy@nzifst.org.nz

Website: www.nzifst.org.nz

JOIN NZIFST NOW for Professional Development Networking – connecting with your peers

Regular information about your industry

Recognition through awards, scholarships, travel grants www.nzifst.org.nz/join/

21 NZFSSRC

Vibrio – the barometer of climate change

Graham Fletcher, Nicola King, Tim Harwood

24 ENGINEERING

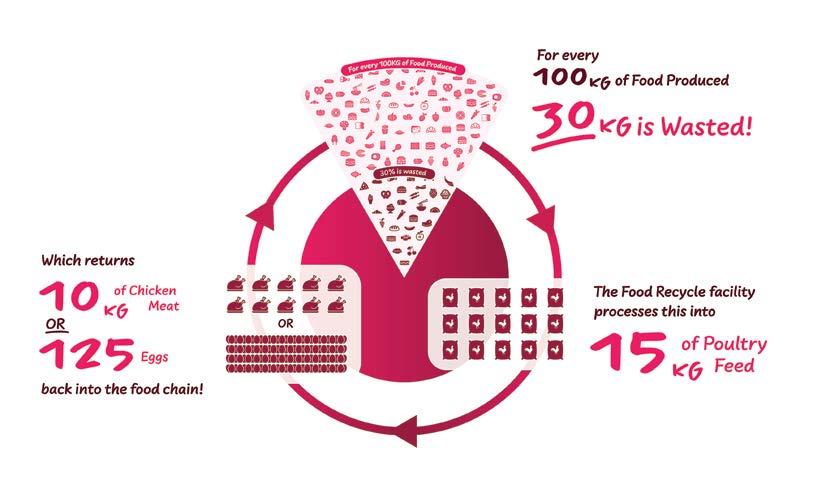

Transforming food waste into animal feed

26 OIL & FATS

News from the world of lipids

Laurence Eyres FNZIFST

28 CAREERS

Staff turnover survey results released

John Lawson, Lawson Williams Recruitment

30 NZIF ST N EWS INCLUDING Conference Update

EHEDG New Zealand

Spotlight on Torben Sorensen Branch News

NZIFST New Members

On the cover

A strong wrist and a pestle and mortar are seldom used in analytical labs nowadays. See pg. 9 for our Laboratory Supplies Overview.

Next editorial and advertising deadline: March 20th, 2023

Features for April/May 2023

Overview: Food Ingredients – flavours, colours, functional ingredients, core ingredients, clean label

February / March 2023 3

20 34 24

It’s been an interesting start to 2023.

Personally I started the New Year out at Kawau Island in the Waitemata Gulf, a trip that was shortened by weather (a trip home in face of a building easterly wind) and a family member having a fall that necessitated a visit to the emergency Doctor (all good now!).

So we started 2023 with a “hang in there” and “things can only get better” mantra.

The dark clouds of Covid are lifting in many areas but for all businesses the shortage of willing and able staff is biting hard. And of course for our food industry, burgeoning costs of shipping, fuel and compliance are digging deep into profits – necessitating price increases which always are a balancing act between re-building cash-flow and loss of sales. Supply chain issues are much in evidence, although I doubt many consumers realise just why supermarket shelves are no longer the cornucopia of everything you want.

I know that things will get better.

Pandemic disruptions are affecting the whole world, reminding us that our society is fragile – at all levels, from struggling low-wage earners to international corporates and governments.

As a food producing nation we export food commodities (and high value products) that support the New Zealand economy far more strongly than many Kiwis recognise. Without our (food) industry we are a third world nation, with a huge gap in our ability to support ourselves through trading in the world economy. Commodity meat and dairy demand and prices are supporting us more strongly than ever in the face of disruptive changes in commerce and trade. On the other side of the coin, labour shortages and supply chain disruptions are compromising the viability of labour-intensive and smaller operations that cannot invest in automated solutions. We are all aware that labour shortages are compounded by Covid restrictions on work attendance.

We cannot deny the effects of climate change, although the myriad points of view, with supporting data and modelling (which must always contain an element of crystal-ball-gazing), merely point the way: there is no one pathway out of this.

It is not all bad. The human race is astonishingly resilient and over millennia has overcome challenges to its survival countless, unknowable times and will do so again. In the face of the doomsayers regarding the effect of human activity on climate I suggest we remember that in spite of our ubiquity, the human race are passengers on a rock that circles the sun every year that has survived for a very long time and recovered from major disasters: we are powerless to change that. Human society will adapt to the changing climate, our home planet will continue to go its own way.

Where does that leave us? Recognising that humankind’s future will be far different than was imagined even as recently as 10 or 20 years ago. The lives we live in 2023 are unimaginably different than those lived even 30 years ago.

Can you imagine a world without your smartphone? The first smartphone was the IBM Simon, dating back to 1994. It was an analogue cellular phone but had email, calendar and fax functions. The touch screen user interface even included predictive text. Not a pocket phone by any means. The “smartphone” Wikipedia page, https://en.wikipedia.org/wiki/ Smartphone makes very interesting reading.

The first iPhone was launched as recently as 2007 – barely 15 years ago!

My point is that society and technology are now changing faster than ever before. The added element of climate change is one factor driving change: Homo Sapien’s ability to adapt and create solutions is also a driver of change. So, 2023, onwards and upwards. Have a good one.

Anne Scott FNZIFST, Editor

Food New Zealand 4 EDITORIAL

Editorial

Anne Scott FNZIFST, Editor

Newsbites

Newsbites is Food New Zealand’s pick of the news stories about NZIFST members, about companies with relationships with NZIFST plus items that catch our interest.

Healthy vegan diets, costed

Authors: Dr Michael C. Morris, Royal Agricultural University, Auckland, Dr John H. Livesey, Independent Scientist, Christchurch, Roger J.H. Welsh, Independent Researcher, Christchurch

A study published last year by Bruce Kidd and others from the University of Auckland (1) concludes that healthy vegan diets are more expensive than the current omnivorous diet practiced in New Zealand. The authors state that there must be a trade off in terms of expense versus health and environmental effects.

The authors provide no costing from externalities, such as the higher health and environmental clean-up costs of the current diet (2). However, even under their own terms, the cost to the consumer for a healthy whole-foods plant-based diet as advocated by the EAT Lancet recommendations (3) is actually cheaper than the current omnivorous New Zealand diet.

In 2020 we conducted a survey of animal-based and plant-based protein foods in Auckland and Christchurch, New Zealand's two biggest cities, which was published in this journal (4). We checked prices in supermarkets and Asian food stores and we calculated cost per gram of digestible protein. Our findings were that the cheapest six sources of protein in Auckland were plant-based. The relative paucity of Asian stores in Christchurch meant that plant protein sources were slightly more expensive, but food such as red lentils and oats were still cheaper than animal products.

This survey was conducted before the price rises caused by the COVID-19 pandemic and the war in Ukraine. An updated survey in Christchurch during 2022 revealed that although all prices had gone up, red lentils were the cheapest form of protein at NZD0.75 per 100g protein, and the cheapest 5 protein sources were plant based.

Of course, if one substitutes meat products with highly processed plant-based processed burgers as in the scenario proposed by Kidd (1), then the cost of protein goes up, but this is not a realistic scenario for health-conscious vegans on a budget.

Kidd also assumed that vegans would substitute plant-based dairy substitutes for dairy milk, another questionable choice. There are several cultures, including the very long lived Japanese, who traditionally use few dairy products. It is not necessary to include these (expensive) dairy substitutes (3) – especially almond milk, which is pretty much nutritionally useless.

We congratulate Bruce Kidd’s team (1) for raising awareness of the need for a transformation of eating habits in Aotearoa, for reasons of personal, public and planetary health. If this is to be achieved, we need to put to rest the fallacy that eating a nutritious and tasty wholefoods plant-based diet is more expensive.

References

1.Kidd B, Mackay S, Vandevijvere S, et al. Cost and greenhouse gas emissions of current, healthy, flexitarian and vegan diets in Aotearoa (New Zealand). BMJ

Nutrition, Prevention & Health 2021;4:doi: 10.1136/bmjnph-2021-000262.

2.Drew J, Cleghorn C, Macmillan A, et al Healthy and climate-friendly eating patterns in the New Zealand context. Environmental Health Perspectives 2020;128:17007. doi:10.1289/EHP5996 pmid:http://www.ncbi.nlm.nih.gov/ pubmed/31967488.

3. Willett W, Rockström J, Loken B, et al Food in the Anthropocene: the EAT-Lancet Commission on healthy diets from sustainable food systems. Lancet 2019;393:447–92. doi:10.1016/S0140-6736(18)31788-4 pmid:http://www.ncbi.nlm.nih.gov/pubmed /30660336

4. (Authors) Plant-based protein cost survey. Food New Zealand Oct/Nov 2020: 4244.

Research funding paves way for advanced milk products

Consumers will benefit from new research at the Riddet Institute in Palmerston North that hopes to improve the digestion properties of milk-based products.

The Riddet Institute has been awarded $476,000 by Fonterra Limited for a twoyear project looking at the particulars of nutrient digestion in cow and non-cow milk components, with an emphasis on new formulations for specific age groups.

The new project builds upon the Riddet Institute’s CoRE-funded work on the development and validation of in-vitro digestion simulator technology, and fundamental knowledge on milk digestion.

Project leader Dr Alejandra Acevedo-Fani says the project will investigate different milk protein-based formulations and research what happens in the stomach with the release of macronutrients and micronutrients. A gastric simulator machine that replicates the human digestive system will be used in the research.

“The information will help us learn about the importance of gastric structure on digestion,” Dr Acevedo-Fani says. “The project will generate new knowledge about the contribution milk components such as proteins and lipids have on digestion and nutrient absorption.”

She says this knowledge can then be used to design structurally advanced milk prototypes or formulations with superior nutritional outcomes to meet specific consumer needs. New milk products with enhanced digestibility are expected to follow.

It is expected the work will generate new knowledge and identify opportunities for delivering foods that will grow the New Zealand economy.

The industry-funded project has led to the creation of a new Postdoctoral Fellow position at the Riddet Institute to undertake research on dairy foods digestion. Dr Faith Bernadette Descallar joined the team in September.

February / March 2023 5 Newsbites

Project Leader, Dr Alejandra Acevedo-Fani

Industry faces UPF challenge – and a ‘real food’ opportunity

Consumers’ expectations that convenient, packaged foods should be simpler and less processed are set to become more important over the rest of this decade, predicts food industry expert Julian Mellentin. He says there’s growing evidence that consumers are increasingly shunning ultra-processed foods (UPFs) and looking for more ‘real foods’. In a recent survey of consumers1 by New Nutrition Business, of which Mellentin is director, 20% of Americans and 40% of Spanish consumers said they were trying to avoid UPFs2, the highest numbers since the consultancy began asking this question.

“The growing consumer interest in ‘less processed’ has grown out of the clean label trend of identifying something undesirable in our food and avoiding it,” says Mellentin. “What’s different is that we are entering a new phase. Brands will have to do more to reinvent “ultraprocessed foods” and to deliver products that get closer to consumers’ expectations of ‘real food’.”

Avoiding UPFs means, to a growing number of consumers, choosing fresh and natural foods. When the International Food Information Council (IFIC) asked Americans about the most common attributes of a healthy food, the top answer, given by 37% of people, was ‘fresh’, while 20% of consumers said ‘minimal or no processing’3.

“The opportunity over the next 3-5 years is for packaged food companies – gradually, step-by-step – to renovate products,” says Mellentin. “That will require a focus on ingredients and processing technologies which deliver the safety, convenience and palatability people seek while doing so with as little processing as possible – or at least with a type of processing that people accept.”

Companies do not need to renovate their entire product line, says Mellentin: “A significant percentage of mainstream consumers want to continue enjoying their favourite foods just as they are. The result may be that companies will have some products within their portfolio that meet consumer expectations for less processed and real food –just as today they have free-from or gluten-free lines in their portfolio.”

In his recent report, 10 Key Trends in Food, Nutrition & Health 2023 4, Mellentin notes that there are many companies for whom ‘simply processed’ and ‘real’ are already part of strategy:

Technology has an important role to perform in enabling packaged products to deliver on consumer expectations. US-based plant milk marketer Elmhurst has developed a technology called HydroRelease, which enables it to create a two-ingredient, nutritionally-dense plant milk which delivers on consumer expectations of simple processing and few ingredients, in marked contrast to most plant milks on the market.

References and notes to text

1. New Nutrition Business 5-country Survey 2022. Available January 2023.

2. There is no one agreed definition of UPF and no scientific, legal or regulatory definition. However, university researchers and the media mostly use a definition of UPF which originated with researchers at Sao Paolo University in Brazil. They created the NOVA system, which classifies foods into four categories. The UPF category is used to describe foods:

a. “With little to no whole foods”

b. “Use many ingredients including food additives that improve palatability, processed raw materials and ingredients that are not used in home kitchens such as protein isolate, flavours, colours, emulsifiers...”

c. “Processing involves multiple steps – examples: packaged snacks, cookies, ready-to-eat meals, candy, soft drinks.”

“Real food”, on the other hand, is defined in the minds of consumers, not by university researchers or regulation. Broadly it means fewer ingredients, simpler ingredients, less processed.

3. International Food Information Council (IFIC), 2022 Food & Health Survey.

4. 10 Key Trends in Food, Nutrition & Health 2023 is available here: https://www.new-nutrition.com/keytrend?id=261

Newsbites

“There is also a very high level of engagement with a broad range of stakeholders across New Zealand and internationally which is ensuring their results are being used for policy design and monitoring.”

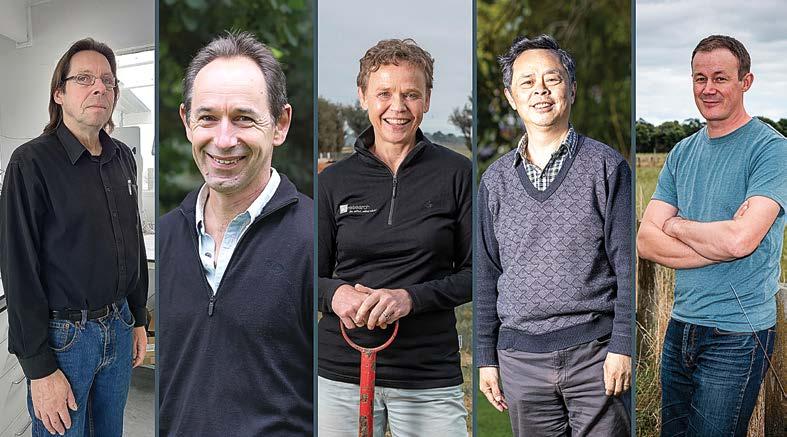

The team - led by senior scientists Cecile de Klein, Tony van der Weerden, Jiafa Luo, Stefan Muetzel and Arjan Jonker - has been able to show through its work that estimates of nitrous oxide and methane emissions should be significantly adjusted, compared to previous calculations using former standard methods from the Intergovernmental Panel on Climate Change (IPCC).

With support of partners, the AgResearch scientists guided the development of what is known as country-specific “emission factors” to improve the accuracy of calculating New Zealand’s agricultural greenhouse gas emissions estimates. Emission factors relate the quantity of an emitted greenhouse gas to a specific activity, such as fertiliser application.

This is critical for New Zealand given methane and nitrous oxide from agriculture make up approximately half of the country’s greenhouse gas emissions, compared to about only 10% in other developed countries. The IPCC prepared guidelines in 2006 for assessing national greenhouse gas emissions, however many of the IPCC’s default values were based on Northern Hemisphere research, where farming systems are different to those in New Zealand. The NZ-specific emission factors developed by the team were incorporated into the Ministry for Primary Industries’ national agricultural inventory, which is now considered one of the best in the world. And with every new update, the accuracy of the estimates has been improved by the research from the team.

“It is fantastic to have the work of the team recognised like this,” says AgResearch senior scientist Tony van der Weerden. “But the biggest thrill of all for us is knowing that the research is making a real difference for New Zealand. We all know the challenge of climate change, and that agriculture is New Zealand’s single biggest contributor, so we all need to act. By better understanding the challenge and the extent of these greenhouse gases, we can not only better understand how we are tracking as a country, but also what tools and approaches could be most effective in reducing emissions.”

“This award is truly the result of a team effort from people across AgResearch, supported by our collaborators at Manaaki Whenua –Landcare Research, Plant & Food Research, Lincoln University, the New Zealand Agricultural Greenhouse Gas Research Centre and the Ministry for Primary Industries.”

This is the second consecutive year that AgResearch has won the Supreme Award in the Science New Zealand Awards. Last year AgResearch’s low methane sheep breeding team won the award. The full list of Science New Zealand Award winners for 2022 can be found at: https://sciencenewzealand.org/news-and-events/ awards-2022/

Newsbites

The winning team: Stefan Muetzel, Tony van der Weerden, Cecile de Klein, Jiafa Luo and Arjan Jonker

Overview: Laboratory instruments, equipment and consumables

Food New Zealand's annual roundup of new products for laboratories working in the food space – from QC labs on site, to product testing for reformulation and compliance, to testing for process management and within research facilities

Alphatech Systems

Alphatech Systems, 100% New Zealand owned and operated, is now celebrating 40 years in the food science community.

Testing of chemicals is essential to understanding their fate and potential environmental impact.

Alphatech brings you quality brands:

• Biochrom/WPA’s range of Libra Scanning UV/Vis spectros, including double beam and variable bandwidth.

• Cooper-Atkins’ thermometry, including their outstanding meters and probe/sensor customisations for use in the food and beverage sectors.

• Eutech Instruments’ renowned food and water analysis instruments including pH/mV/Ion-specific, temperature, conductivity/resistivity/TDS and salinity, DO, turbidity and colorimeter meters.

• Horiba’s high-quality equipment for water and food testing. They will also create applications to use these meters with your sample (pH, ORP, EC, TDS, DO).

• Human Corporation’s laboratory and high-capacity RO water systems, from Type 1 Ultra-Pure to high capacity RO systems for research, general lab and industrial applications.

• Laboratoires Dujardin-Salleron’s traditional range of wine analysis apparatus including ebulliometers, sulfilysers, hydrometers and titrators.

• Multisensor Systems’ water and air analysers specialising in hydrocarbon analysis, oil-in-water detection, THM and ammonia analysis, for use in protecting potable and wastewater.

• Optika’s specialty instruments for refractometry, sugar purity, optical rotation, and polarimetry.

• Pratt Safety’s UN-certified DG cabinets from 30L-425L. The range covers Classes 3, flammable liquids, 4, flammable solids, 5, oxidizing agents, 5.1, organic peroxides, 6, toxic substances, and 8, corrosives.

• Precisa’s Balances with capacity/resolutions ranging from 125g (0.01mg) to 12.2kg (0.1g). The range extends to industrial scales, moisture balances and automatic ashing. The new 390

and 520 Series Balances with Tablet Style Touch Screens are so intuitive you hardly need a manual!

• VICAM offers a complete line of qualitative and quantitative rapid diagnostic test kits, strips, and instruments for testing mycotoxins in food, feed, and grain products.

….and also, talk to us for Waters Corporation chromatographic solutions (HPLC, mass spectrometry, HPLC columns, vials, filters, etc), and OnQ LIMS solutions. Web: www.alphatech.co.nz

Food New Zealand 8

Laboratory Suppliers

The Precisa 390 Series Balance

ATA Scientific

Easy-to-use tools to optimise additives and their interaction with food products.

The Phenom Desktop Scanning Electron Microscope (SEM) is an essential tool used to study the relationship between food processing conditions and morphological changes in food components, given the structure of foods can influence nutritional value.

The new Phenom XL G2 desktop SEM is easy-to-use and offers superfast imaging with fully integrated X-ray analysis to enable both food structures to be examined and their elemental composition determined. With the fastest time to image (less than 40 sec from sample loading) up to 200,000 times magnification and <10nm resolution, the Phenom SEM is an essential tool for any laboratory.

New automation solutions for quality control (QC) replace manual, repetitive tasks, allowing a high volume of samples to be quickly processed. Particles, pores, fibres or large SEM images up to 100 by 100 millimetres can be characterised and foreign contaminants identified and evaluated for chemical composition.

The Malvern Mastersizer particle size analyser is used to determine particle size and size distribution for foods and additives. Particle size defines mouth feel and is important for controlling manufacturing costs.

The Mastersizer 3000 is the premier instrument for performance and software user experience. With a dynamic range spanning 0.01 to 3500 microns, the Mastersizer 3000 delivers precise, robust, wet and dry particle size measurements tailored to the operator’s application needs.

The Malvern Zetasizer Ultra is used for the measurement of particle and molecular size, particle charge and particle concentration. Determine optimal concentrations of food additives for desired taste and smell performance or improve emulsion stabilisation of flavourings.

The new Zetasizer Ultra delivers enhanced speed and ease of use, accelerating sample throughput. Multi-Angle Dynamic Light Scattering (MADLS) technology provides higher resolution and calibration-free particle concentration analysis to enable even greater insight into your samples.

For further details contact ATA Scientific Pty Ltd.

John Morris Group

Food, feed and beverage solutions.

We supply, install and service quality scientific and specialised equipment from trusted brands, helping you discover solutions and achieve reliable results.

• CEM provides new technologies that transform how compositional food testing is carried out for fat (Oracle), protein (Sprint), moisture (Smart) and ash (Phoenix). Simple rapid and direct methods that eliminate extensive calibration and replace outdated wet chemistry techniques. CEM pioneered microwave chemistry and have microwave instruments (MARS) to acid-digest samples for elemental analysis.

• Fritsch instruments have been used for decades worldwide for sample preparation and particle sizing in industry and research laboratories. Fritsch offer laboratory tools for cutting, milling, sieving and sizing solid materials.

• Ankom are helping to feed the world with their dietary fibre, solvent fat extractors, vitamin and cholesterol analyte extractors. Ankom’s crude fibre analyser studies the digestibility of feed, and gas production monitoring modules measure the degradation and fermentation kinetics of soluble and insoluble factions of feed or food.

• Bruker’s solutions optimise food quality and food safety throughout the whole supply chain from field to fork. FoodScreener tests honey, wine and juice for origin authenticity, species purity and fraud. The MiniSpec determines total fat and droplet size of dairy products like margarine or mayonnaise and analyses oil and moisture in seeds and nuts with no sample preparation, independent of sample texture or colour.

• The YSI 2900 makes it practical to measure glucose, sucrose, lactose, ethanol and many more analytes, compared to traditional methods such as HPLC and GC/MS. Results are obtained in about one-minute with little or no sample preparation making the YSI 2900 ideal for process monitoring.

• Atago manufactures hand-held refractometers used in analysis of fruit, salt, brix, coffee and acidity.

Contact John Morris Group via our website or LinkedIn and let us help you succeed with technology.

February / March 2023 9 Laboratory Suppliers

Leaders United in Food Safety: 3M and Neogen Merge

Neogen Australasia, a subsidiary of Neogen Corporation, based in Queensland, is leading the way in food safety solutions for businesses in the food processing, animal protein and agriculture industries.

Recently, Neogen Corporation completed a merger with 3M’s Food Safety business, creating a comprehensive product portfolio, and an enhanced global footprint. This has allowed Neogen to expand its presence in allergen, indicator testing and pathogen detection areas, complementing its existing microbiology lines.

Neogen Australasia has a strong presence in the region and offers a wide range of solutions for the food processing, animal protein and agriculture industries. The company has long-standing relationships with these industries and serves the Australian and New Zealand markets through both distributors and directly.

Our Food Safety product range includes solutions for the Agribusiness sector such as rapid diagnostic kits to detect foodborne bacteria, food allergens, and hygiene indicators. Additionally, our food quality

range, which was expanded through the acquisition of Megazyme, includes high-quality assay kits and enzyme substrate products for use in analytical and research laboratories.

Neogen Australasia also offers solutions in animal safety and genomics. The company’s animal safety range includes biosecurity products, pest control solutions and more. The genomics division is the region’s largest genomic testing facility in Queensland, offering advanced comprehensive genomic testing solutions including sequencing, for livestock, companion animals and plants and even humans.

At Neogen Australasia, we closely with you to create custom packages that suit your needs, creating more value for your business. With a strong presence in New Zealand, Neogen Australasia is dedicated to ensuring that its products and services meet the specific needs of the market and can be reached directly or through their distributor partners.

Metrohm

Founded in 1943 by engineer Bertold Suhner in Herisau, Switzerland, Metrohm is one of the world’s most trusted manufacturers of high-precision instruments for chemical analysis. Metrohm ANZ offers a full portfolio of analytical instrumentation and services. Metrohm’s solutions comprise methods and instrumentation for modern titration, ion chromatography, pH and conductivity measurement, NIR and Raman spectroscopy, spectroscopy, material testing, research instruments and more. The company is also the exclusive distributor for Retsch and Retsch Technology solutions such as milling, sieving, assisting and dynamic image analysis. Food quality and enology solutions (reagents and analysers) from BioSystems S.A. are also provided and supported exclusively in the region.

Metrohm ANZ is present in all major cities with offices and application laboratories across Australia (NSW, VIC, QLD, SA, and WA) and New Zealand (Auckland and Christchurch).

Food New Zealand 10

Laboratory Suppliers

Onelab: Results Matter

Onelab offers a range of products for food manufacturers, from the laboratory through to process optimisation and finished product testing.

Onelab’s market position is to support the New Zealand market with high quality products that are imperative to your success.

Key to our food testing product range is R-Biopharm. R-Biopharm’s speciality is competence in food and feed analysis, offering innovative products and user-friendly solutions for the analysis of allergens, mycotoxins, microbiological contaminants and more. Technologies include Lateral flow, ELISA, Enzymatic, purification columns and Real-Time PCR.

Key products in our wide range include:

• R-Biopharm – Allergens, mycotoxins, microbiological contaminants, constituents, GMO’s, vitamins

• BUCHI – Kjeldahl, NIR, Evaporation, Freeze Dryers, Fat Extraction etc

• Mettler Toledo laboratory range – balances, electrochemistry, spectrophotometers, titrators, density, refractometers etc

• Gerber Instruments – dairy testing equipment

• NEW! Nasco : Whirl Pak sample bags

• NEW! Masterflex – pumps and tubing

• NEW! Air Samplers and accessories

• Integra – Media Preparators, plate pourers, dispensing pumps, vacuum aspirators

• Omni International – homogenisers and bead mills

• SSI Bio and Technoplas – Plastic laboratory consumables

• Brand – consumables including volumetric glass, digital burettes, bottle top dispensers

• IKA – mixing, shaking, stirring, viscometers, ovens etc

• Grant Instruments – water baths, bench top equipment, dataloggers etc

MiTech for Witt Gas analysers

Witt gas analysers are fast, precise and multifunctional. They can be used as stationary or portable units for sample or continuous gas analysis for many applications in fruit and vegetable production. Intuitive and easy handling of Witt gas analysers is provided by intelligent operating controls. Stateof-the-art sensors and intelligent software solutions guarantee accurate measurement results and secure the quality of your processes. To suit your applications, the gas analysers can be delivered as stand-alone units or integrated in gas mixing systems. Retain control when using carbon dioxide in your storage, control the ripeness of your fruit using ethylene and ensure the quality of your products by sample testing of your modified atmosphere packages with WITT gas analysers. More information at https://www.mitech.nz/gas-analysis-gasmixers/

• Labconco – Class II and Laminar Flow hoods, dry block evaporators, vacuum concentrators

• Interscience – blenders, diluters, pourers, colony counters, dispensing pumps etc

• Milestone – Sample prep for metal analysis, mercury, fat extraction, fragrances and flavours

• Seal Analytical – discrete and segmented flow analysers, robotic sample prep automation – food and beverage analysers

• Hettich – centrifuges and incubators

• Cole-Parmer – everything laboratory!

• Rainin – liquid handling – pipettors, tips

• Tecan and Tecan Genomics – liquid handling and NGS Library prep kits and automation

• Service – Onelab Service all brands we sell – Nationwide!

Onelab believe Results Matter. Contact us for your Laboratory requirements.

Laboratory Suppliers

Laboratory Suppliers

• Priorclave: Wide range of autoclaves for all your sterilisation needs.

• Hamilton Company: Sensors for process analytics in the food and beverage industries. Their optical DO and pH process sensors offer lower operating costs, tighter process control; seamless calibration, troubleshooting and connectivity; quick recovery from SIP, CIP or autoclaving.

• Esco: Ovens and incubators from 32L to 240L as well as a wide range of Laminar Airflow Cabinets in either horizontal or vertical airflow formats providing ULPA filtered clean air.

• BioEcho Life Sciences- nucleic acid extraction solutions for animal breeding and veterinary research that are simple, scalable, affordable, and for a wide range of animal species and sample types.

Bio-Strategy

Multiple solutions for the New Zealand food and dairy industry.

• Jasco – FTIR Application in Food Analysis; FT/IR-4X for maintenance-free design – self-diagnosis function, base isolation structure, optional detectors. For component analysis of dairy product and identification testing of food additives.

• Rad Source – Rad Source’s patented Quastar® Photonic Decontamination technology provides the cannabis industry with the only technology to safely inactivate mould, powdery mildew, Aspergillus, BTGN, yeast, Salmonella, E. coli, Coliforms and other challenging microbes. The roomtemperature process maintains flower integrity with nominal to no effect on terpenes, potency or moisture.

• Molecular Devices: Absorbance microplate readers to streamline your beer, wine and food safety analyses using industry-standard approved methods. Including: Gluten level testing, yeast metabolism, colour and bitterness (IBU's); L-Malic acid and phenolic compounds and Endotoxin testing and melamine detection in GLP/GMP environments.

• Hamilton Robotics – Hamilton® foodInspect™ NIMBUS® for superior precision, accuracy, and reproducibility. A powerful, personalised automation solution for quality pipetting.

• PHCbi – temperature-controlled incubators, designed for precision and accuracy to facilitate the stringent demands of perishable food quality testing.

• IKA – IKA mixing techniques give products exclusive organoleptic qualities and an especially appetising appearance. IKA has extensive expertise in the diverse mixing processes used in the food industry.

• Ohaus – a wide range of high-performance instruments, including balances/scales, benchtop/portable pH meters, shakers, and moisture analysers designed to deliver in harsh packaging, processing, or laboratory environments.

• Miele Professional: Under-bench and stand-alone laboratory washers/disinfectors with a large range of accessories for both wide neck and narrow neck glassware. Available in passive drying or active HEPA filtered drying models.

In addition, Bio-Strategy offer a wide range of quality consumables. www.bio-strategy.com

LabwareHouse

LabwareHouse has been supplying laboratory equipment for more than 15 years to all sectors throughout New Zealand: Industrial, dairy, food, education and individuals. Glassware is available in certified options where accuracy is vital and economy options for budget conscious schools and industrial labs. There is also a wide variety of plastic labware and measuring equipment available to ensure the testing and production of all your products goes smoothly.

We import and stock a range of quality products, ready to ship within 24 hours. This ensures you receive your purchases promptly, often overnight.

With over 2000 products in stock LabwareHouse can supply all your laboratory basics and consumables including:

Beakers Measuring cylinders Flasks Pipettes and tips

Balances, scales and centrifuges by Ohaus

Filtration and testing papers

Thermometers Porcelain basins, crucibles and funnels

Test tubes Forceps Spoons and spatulas pH meters

If you need one or one hundred, we can help keep you supplied and we offer discounts for bulk orders.

As a proudly 100% New Zealand owned company, our goal is to reduce our carbon footprint, by recycling, and importing by sea where possible. We give back to our community by supporting Science based events and contributing to conservation projects.

Our comprehensive website makes selecting and purchasing your items straightforward and the friendly and helpful people at LabwareHouse are waiting to assist you with all your queries and purchases.

Ngaio Diagnostics

Ngaio Diagnostics is an established, New Zealand- owned supply company specialising in market leading hygiene, microbiology, allergen, food and drink testing solutions, plus general laboratory products. Our vast range of products allows us to offer complete solutions to fulfil every customer need.

Our range includes, but is not limited to:

• Hygiena ATP systems – the gold standard solution for ATP testing, with added capabilities for same-day microbiology testing, pasteurisation verification, water testing and cooking efficiency testing (raw meat).

• CertaBlue – real-time microbiology testing, ready-to-use vials and simplified testing procedures.

• MicroFast – a full range of affordable and easy-to-use sheet media.

• Hygiena BAX – a leading molecular system, providing rapid and reproducible results.

Food Tech Solutions A Focus to Food Safety!

Food Tech Solutions is a niche supplier of quality testing solutions to the New Zealand food and dairy industry. Our long history of working closely with leading milk processors has helped position New Zealand as a global leader in the dairy industry,

Since 1998 we have fulfilled demands within the food industry for a superb source of products contributing to Food Safety and quality programmes monitoring manufacturing cleanliness, ensuring our food industry produces only quality products with a maximum shelflife, whilst minimising recalls!

Our Product Range Includes:

• Air Monitoring – Bacterial air monitoring instrumentation –TRIO.BAS™

• Product Sterility Testing (EPIC) – UHT, ESL (soft dairy, personal care) – Charm Sciences.

• ATP Detection Systems – Superior science for advanced hygiene control – Charm Sciences.

• Texture Analysis – Food profiling and packaging testing –Stable Micro Systems.

• Enzymatic Test kits and Enzymes – Wine, beverage, food and research – Megazyme.

• Instruments – Automation – Rapid wine component analysis –Awareness Technology Inc.

• Allergens – Wide range of ELISA and rapid tests for testing food and environments.

• Pasteurisation Confirmation – Milk (cow, goat, sheep), soft cheeses – Charm Sciences.

• Rapid Antibiotic Residue Testing – Raw milk and other food matrices – Charm Sciences.

We work closely with our clients, delivering solutions, ongoing relevant training, providing rapid essential technical support, loan instruments, educational seminars, focus groups, and regular instrument demonstrations.

• Allergen kits – for all requirements, lateral flow tests and ELISA kits.

• Microbium MPN Analyser – automated detection and quantification of E. coli and coliform bacteria in water.

• Solus Pathogen Detection System – one day Listeria and Salmonella testing, offering cost, time and performance benefits over molecular systems.

Ngaio also assists with specialised systems for constituent, mycotoxin, dairy, industrial contaminant, pesticide, toxin and drug analysis.

Proud to supply top customer service, trusted solutions and great pricing to all customers.

Contact Ngaio (www.ngaio.co.nz) with any enquires or technical assistance.

Please Contact: Jo Kelly-Tuckey, General Manager, for inquiries. Tell us how we can facilitate making the most out of your quality control!

February / March 2023 13 Laboratory Suppliers

Merck RQflex® 20: Testing on the go at Mataura Valley Milk

For food and beverage production facilities, a reliable, precise system to perform critical analyses at any stage of the production process, directly on-site, is invaluable. That’s where the RQflex® 20 comes in.

Strip – Dip – Read – Record – Action

Designed by Merck, the RQflex® 20 provides an inexpensive, mobile laboratory for performing analyses of chemical parameters in water, food & beverage samples, and environmental samples in the laboratory, on the production line or in the field.

The RQflex® 20 reflectometer combines the simplicity of test strips and test kits with the accuracy of mobile on-site instrumental analysis—for more than 20 parameters in various fields of application. Examples include rapid quantitative detection of hydroxymethylfurfural in honey, testing Vitamin C in food & beverages, monitoring acrylamide formation, analysing chemical disinfectant parameters after disinfection of production lines, and more.

The full range consists of test strips, reflectometer, and accessories, combining ease-of-use with the accuracy of instrumental analysis.

Creating tomorrow’s nutrition with Mataura Valley Milk

Mataura Valley Milk sources milk from one of the finest grassproducing regions in the world – Southland, New Zealand – to produce exceptional nutrition for a growing world.

For Mataura Valley Milk, it’s all about quality, reliability, and expertise

– with milk sourced from a select group of suppliers, processed in the most up-to-date nutritional plant in the world, and used by well-known international brands in the manufacture of nutritional products.

RQflex® 20 in action – CIP cycles

As a food, dairy, or beverage processor, the importance of maintaining a hygienic process environment with a robust Clean-in-Place (CIP) system is vital. Mataura, like many dairy production plants, uses an acid wash cycle on process equipment and tankers used for milk collection.

CIP Acid is a low foaming heavy duty acid-based cleaning fluid that is particularly suited for dissolving mineral scale from hard water deposits and protein residue build up from stainless steel surfaces. Nitric acid is the most commonly utilised wash for scale removal and pH stabilisation after a caustic wash.

The RQflex® 20 is used after the rinse step of the CIP cycle, with rinse water samples tested to determine if nitric acid residue has been flushed from the plant equipment. On the Reflectoquant® nitrate test strip, nitrate ions are reduced to nitrite ions by a reducing agent. In the presence of an acidic buffer, these nitrite ions react with an aromatic amine to form a diazonium salt, which in turn reacts with N-(1naphthyl)-ethylene-diamine to form a red-violet azo dye that is determined reflectometrically on the RQflex. Quick, easy, and precise!

Lab Supply – supporting science and discovery across Aotearoa

Lab Supply is a privately held, family-owned and operated distributor of scientific equipment and consumables, with offices and warehouses in Dunedin and Auckland. Established in 2010, the company is known for its personalised approach and commitment to quality, integrity, and service.

Their expansive product range is sourced from over 75 global brands, like Eppendorf, Memmert, Greiner Bio-One and Technoplas, with more than 5000 SKUs available for customers to order from. Lab Supply is also an authorised distributor for the Merck and Sigma range of products, giving customers access to industry-leading laboratory products.

Food New Zealand 14 Case Study

Mataura Valley Lab Technician tests rinse water samples

RQflex® 20 in action: Strip – Dip – Read – Record – Action

Lab Supply

Supporting science and discovery across Aotearoa

Who we are

We are a family-owned and operated New Zealand laboratory distribution company, with offices and warehouses in Dunedin and Auckland.

We work behind the scenes, enabling scientists across New Zealand to take their work the extra mile, helping translate it into tangible benefits for society. We support our food and beverage customers with the right solutions to help grow their production capacity and lead the way in food safety and quality.

We partner with over 75 global brands, including Eppendorf, Memmert, Greiner Bio-One, Technoplas, GVS Filtration, and Ahlstrom (Munktell), to bring you industry-leading scientific tech.

We have also recently announced an enhanced partnership with Merck, to increase coverage in the F&B market and offer customers better access to the Merck and Sigma product range.

What we do

We supply what the F&B industry needs to successfully innovate, process, and manufacture their products. Our portfolio includes a range of products for media and sample preparation, rapid chemical

testing, bioburden and pathogen testing, environmental monitoring, analytical technologies, product testing, and more.

We also support what we sell with in-house servicing, calibration, and repair capabilities for a wide range of laboratory equipment, including liquid handling instruments.

With our expertise in the setup of labs, we can install your equipment, ensure it works within the necessary parameters, and upskill staff on usage.

Why partner with us

We understand the importance of accuracy and rigour and are committed to helping you maintain the integrity of your work through:

• Supplying reliable and best-in-class products.

• Knowledgeable, responsive customer service and infield support.

• Online customer portal and 24/7 ordering capability.

• Maintaining optimum stock levels of our most popular products for quick delivery.

We are a supplier of choice for the scientific community across New Zealand and look forward to being of service to you. Talk to our team today!

Laboratory Suppliers

NZMS Scientific

Rapid tests for ensuring food quality help producers to stay agile in a changing world.

The world has changed in the 40 years since Richard Plowright founded New Zealand Medical and Scientific (NZMS) from his home in Auckland. But some things never change.

“We pride ourselves on the expertise of our staff…That’s always had a lot of emphasis, so the expertise can then be provided in the marketplace” says Richard.

Despite rising costs and shifting economic conditions, New Zealand’s food manufacturers continue to maintain high standards for food safety. The friendly team of microbiologists at NZMS Scientific are here to support producers with finding the right products to stay nimble without sacrificing quality.

According to Stephanie Lavill, the Division manager at NZMS Scientific, “We’ve hand-picked testing solutions utilising innovative methods that are intuitive to use and produce faster, more accurate, actionable results. In this current environment, businesses cannot afford to be waiting 7 days for results from traditional testing methods.”

Mätt Solutions

Proper process control could double your profits

It’s estimated that improper measurement, lack of control during production and a “guess and check” attitude, costs some businesses as much as 43% of their annual profit. Proper control of inputs and monitoring of the process can save the expense of “reworks”, dramatically reduce wasted product, get you closer to quality control checkpoints and save everybody a lot of time. They key to this success and increased profitability, is measurement at line. By having a quality metric for each input or stage of production and then measuring and ensuring that metric is met you can have confidence in the final product. At the same time, you will be able to address problems in a more timely manner –fixing out of spec readings before the next stage of production.

Bob Olayo, manager at Mätt Solutions, specialists in food quality measurement tools, notes, “If you’re not measuring it then you

NZMS Scientific offers a range of products to support all facets of in-house testing, giving local manufacturers a clearer picture of the issues affecting their products; detecting problems earlier and responding faster.

“Our favourite is the MVP Icon,” says Stephanie. “It’s a smart system keeping records of ATP and HACCP parameters so it’s all in one place – it’s a really simple way to track cleanliness.”

Pathogen and hygiene testing

Regular monitoring of the final product and the facility environment can help ensure a high standard of food safety. A range of products are available for rapidly detecting foodborne pathogens, spoilage organisms, and environmental hygiene monitoring.

Allergen detection

When food is around, the risk of cross-contamination of food allergens abounds. Romer Labs’ AgraStrip tests provide instant results for action, while AgraQuant can detect more sensitive trace allergens in less than 2 hours. While it takes an hour to incubate, by utilising the modern ELISA method, the results are highly sensitive and accurate.

can’t control it. The way to avoid unwelcome surprises is by testing and checking at each stage of the process”.

Specialists in the field, Mätt Solutions have a wide array of testing solutions available that can help monitor and manage the production process. This includes robust, at line tools for use by production line managers and highly accurate lab-grade instruments for final product verification and release, which can include 21 CFR part 11 and GMP compliance.

If you are looking for measurement solution that is proving challenging or uncommon, Mätt Solutions may be able to help, they have been in the industry for more than 20 years and have built a valuable store of knowledge on how to achieve usable results, even with the most challenging of measurements. For the more common of solutions, such as brix, salinity, pH, water activity, gas analysis, DO, EC, fat, protein, moisture, viscosity and more, you should also call Mätt Solutions, the team will listen to you and tailor a solution to your specific needs.

Food New Zealand 16

Laboratory Suppliers

RomerLabs | AgraStrip Rapid Allergen Test Kits

Merck | MVP Icon ATP & HACCP Management

Dimanco | Dipslide Rapid Bacterial Test Kits

Nissui | Compact Dry Rapid Bacterial Tests Kits

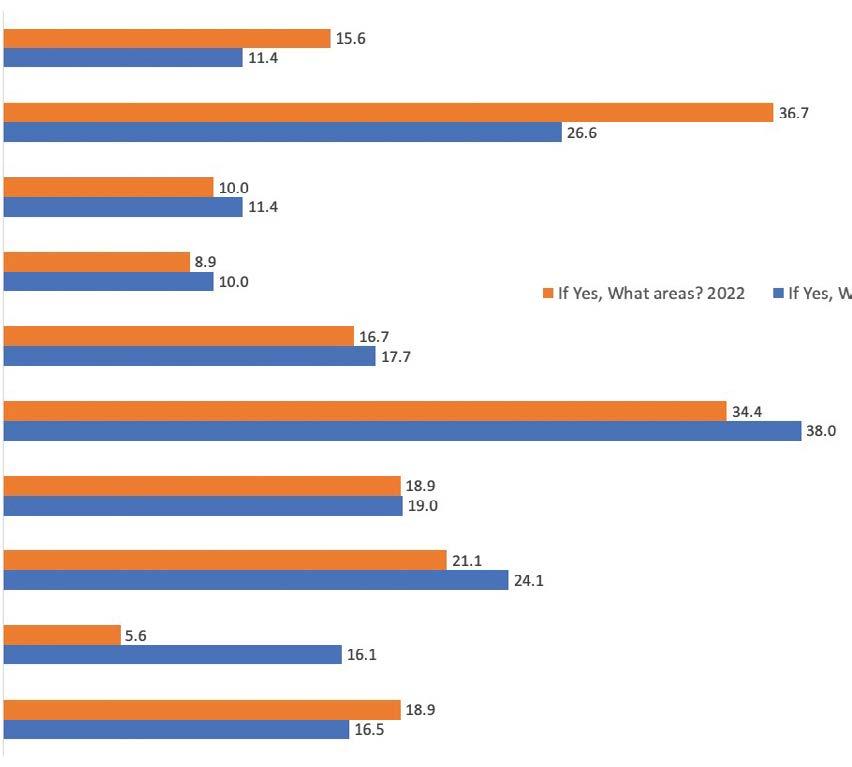

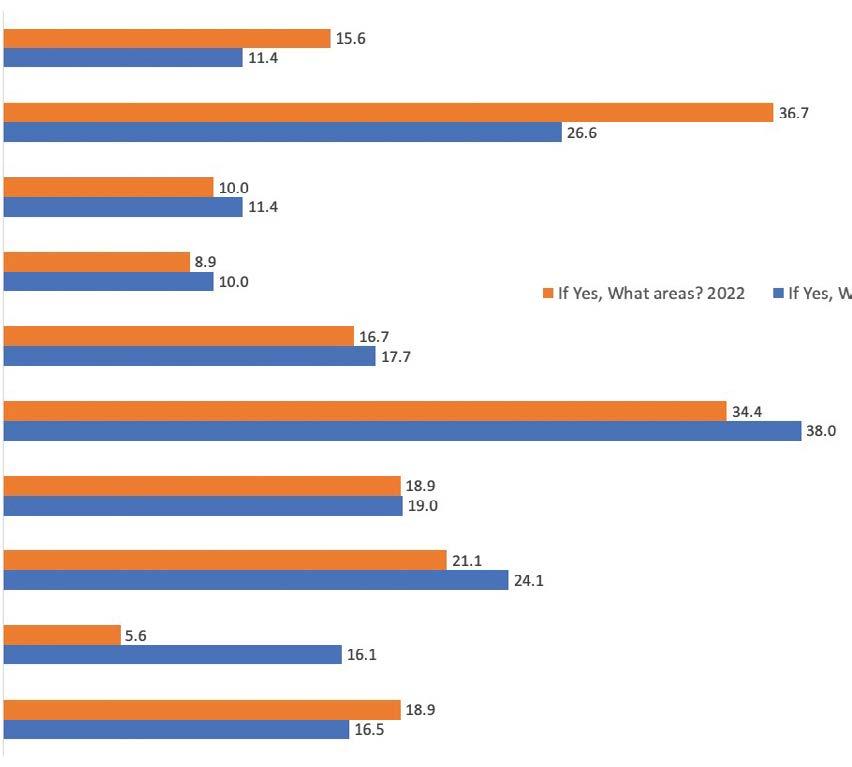

News from the Australian Institute of Packaging

2022 AIP Career & Salary Report now available

For the second consecutive year the AIP has released the key findings from the 2022 Career & Salary Survey for the Food & Beverage industries.

According to AIP Executive Director, Nerida Kelton MAIP, the AIP 2022 Career & Salary Survey report was developed in partnership with the IoPP, to provide a more detailed breakdown of the people who make up the industry, including their roles, education, experience, career satisfaction, concerns and salaries. The survey covers Australia and New Zealand and also all roles within the industries. The Australia and New Zealand report aligns with the same offering developed by the IoPP for the rest of the world.

“The 2022 Career & Salary report has some interesting findings and certainly highlights one of the key challenges that the industry has right now which is upskilling industry professionals in the science and technical side of all materials and pack formats,” Mrs Kelton said.

AIP Education Director, Prof. Pierre Pienaar FAIP, CPP added, “The Report provides a summary of salary levels for packaging technologists, but also gives a general indication of the qualifications of those who are currently working in the packaging industry. The data indicates that although well qualified, i.e., post graduate degrees, they may not be qualified in the science, engineering and/or technology of packaging.”

“We need to see more of those working in the packaging industry, undertaking courses such as the Certificate in Packaging Technology, Diploma in Packaging Technology, the Fundamentals of Packaging Technology and the Master of Food & Packaging Innovation degree. Attaining these qualifications will go a long way towards improving the overall knowledge and skillset in the industry and ensuring that the technical knowledge void is filled with suitably qualified people. We need more packaging professionals. Education helps us get exposure to new ideas and concepts that we can use to appreciate and improve the world around us, and the world within us,” Prof. Pienaar said.

Some of the key findings:

Industry/Products

• 46% of the total respondents work in food

• 13% work in the beverage industry.

• 11% indicated that they work in packaging materials.

Job Function

30% of the total respondents indicated that they work in Packaging Technology/Design. This was followed by Marketing/Sales at 15.90% and 11.20% in Research & Development.

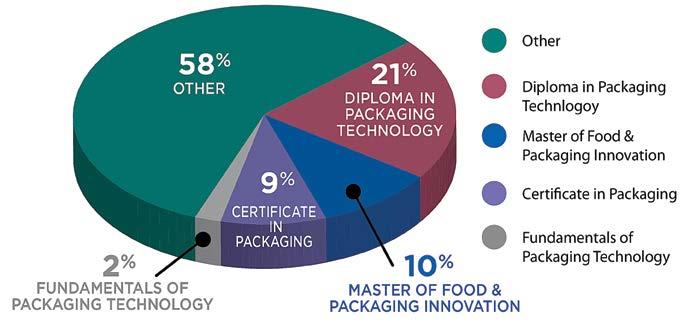

Qualifications of respondents working in packaging in Australia and NZ

What is your highest level of education?

46% of the total respondents have a Graduate Degree and 23% have an Undergraduate Degree. This is a continued indication that the industry is highly educated at degree level qualifications.

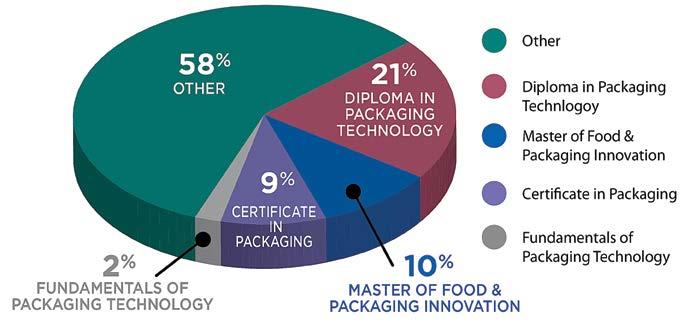

Do you have any of the following packaging-related degrees?

• 21% of the respondents have a Diploma in Packaging Technology.

• 10% have completed the Master of Food & Packaging Innovation.

• 9% have a Certificate in Packaging and 2% the Fundamentals of Packaging Technology.

This is a positive sign that more packaging professionals are coming to the AIP to further their education.

Experience

58% of the total respondents have more than 20 years’ experience in the packaging industry which is an indication of longevity in the industry and stable careers.

Satisfaction with Job Security

38% of the total respondents are very secure with their job, while 33% are ‘somewhat secure’.

The complete 2022 AIP Career & Salary Survey report is available to AIP Members and respondents of the survey.

An executive summary is available to the wider industry upon request. The next AIP Salary Survey will be made available to complete in early 2023 and the AIP encourages all of industry to complete the survey to strengthen the results.

http://aipack.com.au

February / March 2023 17 Packaging

Sliding on

Gloves don’t make you bulletproof

Professor John D Brooks FNZIFST

John Brooks' view of the food world through the lens of a microbiologist.

Have you noticed that now everyone uses disposable gloves for everything? Doctors, nurses, dentists, customs officers, microbiologists and, of course, food handlers are routinely gloved. Have you also observed the way that they are used?

Many years ago, when I first started teaching food microbiology, O.P Snyder used to write regularly about the hazards associated with handling food with bare hands or with gloves. He argued that the use of clean hands was less hazardous than unchanged gloves. The critical words here are “clean hands”. Indeed, New Zealand law does not require gloves to be worn but does require that certain food be prepared and served without bare-hand contact. Wearing disposable sanitary gloves is one of several acceptable ways to comply with this law.

Councils frequently receive complaints from customers that food workers handle food, then take money and operate cash registers or credit card scanners without changing gloves. Surprisingly, investigations have revealed that handling money is not the cause of illness.

A company that started out in New Zealand, but is now based in California, recently presented the findings of a 5-year study on the hazards of contamination in the disposable glove industry. If gloves are to be used to prevent cross-contamination of food by bare hands, then the gloves should be of high quality and not contribute to contamination. Unbelievably, FDA’s current standards for disposable gloves are insufficient because there is no requirement that they are clean or intact and inspection procedures are weak. The study found human faecal indicators on 50% of new and unused, off-theshelf gloves and other microbes, including Bacillus cereus, Bacillus anthracis, Listeria monocytogenes, Clostridiocles difficile, Staphylococcus, Pseudomonas aeruginosa, and Streptococcus pneumoniae on the inside and outside of disposable gloves. These data show that the contamination occurred during manufacture and packaging.

Does the use of disposable gloves engender a false sense of safety?

Gloves become contaminated at the same rate as hands, but there may be a temptation not to change them, as hands don’t feel dirty. Crosscontamination between raw and cooked foods, therefore, becomes an obvious hazard. How often should gloves be changed and how should that be done? If we wear gloves for an hour, our hands become sweaty

and bacteria in the skin are likely to be shed. When we take off the gloves, do we wash our hands again? If not, then there is a strong chance of contaminating the outside of the new gloves. There is no doubt that cross-contamination can occur by manual handling of food. Some regulatory authorities require that food handlers wear gloves and do not permit contact between bare hands and ready-to-eat foods.

Gloves didn’t become common in restaurant kitchens in USA until the ‘90s, when a few high-profile E. coli outbreaks made food safety a major public concern. However, chefs don’t like wearing them and claim that they lose their feeling of contact with food such as sushi. Some also claim that gloves are hazardous while handling hot pans. Simple observations in kitchens and service areas show that chefs often use their fingers to assemble food: counter staff handle food while wearing gloves and then clean the counters before going back to handling food – without changing the gloves. A friend suggested that gloves will be changed between serving every customer in superior food service operations. I highly doubt that this is common practice and the food handler would be washing hands every few minutes. My wife observed a commercial caterer setting up a room for conference meals. One of the girls was setting out plates with her bare hands. She then returned to the room with plastic-wrapped bananas on a pile of plates. She was wearing one plastic glove and contrived to remove the plastic wrap from the bananas with the ungloved hand. She then carefully separated the individual bananas using her gloved hand. But people don't eat banana skins and anyway, how many hands touched the skins during harvesting and transport?

A study to assess the bacterial contamination of the hands of hospital food handlers found that although bacterial loads on gloved hand samples were significantly lower (p<0.05) than ungloved hand samples, these loads were still not within acceptable limits. High levels of S. aureus and E. coli were found on samples taken from bare and gloved hands (1).

Dirty gloves are just as dirty as dirty hands. Wearing gloves does not make you bulletproof. You have to keep your brain engaged when handling food.

Food New Zealand 18 Sliding On

1. Hasan Ayçiçek et al 2004. Assessment of the bacterial contamination on hands of hospital food handlers. https://doi.org/10.1016/S09567135(03)00064-1

Summer of food safety

Presented by Vincent Arbuckle, Deputy Director General, New Zealand Food Safety

Our summer months are synonymous with getting outdoors and sharing good kai with whānau and friends. While we can’t control the sunshine, we can plan to have a safe and healthy summer of eating with a bit of vigilance in the kitchen and on the barbeque.

Foodborne illness is a risk year-round, but every summer, there is a rise in cases and hospitalisations from people getting sick from food. As the temperatures rise we cook and eat more outside, gather and consume more kai moana, and often prepare food for large groups at celebrations and get-togethers.

New Zealand Food Safety (NZFS) wants Kiwis to have an enjoyable summer while helping them develop good habits that will carry over into other seasons.

That’s why we have invested in two key food safety campaigns running over the summer months. We have extended the reach of our messaging in an effort to prevent as many people as possible becoming ill or seriously ill (particularly in the case of those with underlying health conditions, pregnant and older people, and younger children).

We have focused on two leading causes of foodborne illness in the summer months: Vibrio and Campylobacter

Collecting shellfish? Cook it

Vibrio parahaemolyticus (Vibrio) is a bacteria naturally living in the sea, and some strains can make people sick with gastroenteritis when consumed in raw or undercooked shellfish.

New Zealand has started to see more cases of illness from Vibrio, in recent years. In the most recent outbreak, there were 60 cases reported between November 2021 and May 2022, with the concerningly high hospitalisation rate of 42%. This is a notable increase in reported cases from previous years, with 24 cases reported earlier in 2021, 16 cases in 2020 and 23 cases in 2019.

The reason for the increase is unclear at this stage – it could be caused by environmental change, increased testing and reporting, or a combination of these and other factors – but it is clear that cooking shellfish kills the bacteria that makes people sick.

Our campaign educates people about the heightened risk and encourages them to thoroughly cook any shellfish they gather to make it safe for eating. The more people know how to collect, store, prepare and cook shellfish safely, the more they can look out for both themselves and others in their communities who may be more vulnerable.

To help spread this message, we worked with a community chef to develop easy, tasty recipes that make kai moana safe for eating, and we shared them on our website and social media. The recipes include a kina and watercress omelette and pan-fried pāua with kawakawa and lemon. While this campaign has an important message for anyone gathering shellfish, it was also developed to reach Māori and Pasifika communities specifically, as they traditionally gather and eat more kai moana. Focus groups in these communities were very helpful in informing the direction of our campaign.

With a simple tagline, “Collecting shellfish? Cook it”, NZFS hopes to minimise the number of cases of vibriosis this summer.

Chicken Scene Investigators are on the case

The most reported foodborne illness is campylobacteriosis, with our youngest and oldest having the highest rates of infection. The illness is caused by Campylobacter bacteria. While there are several ways to come in contact with the bacteria, the most common source of Campylobacter from food is raw or undercooked chicken.

There were 5729 confirmed cases of campylobacteriosis in 2021, with 846 people needing hospital treatment, up from 718 hospitalisations in 2020. And 2022 looked set to follow a similar trajectory, with more than 5300 cases nationally before the year had reached a close. NZFS is committed to reducing foodborne illness caused by Campylobacter. Our target is a reduction in rates by 20% by the end of 2024. That means a reduction from 88 to 70 cases per 100,000 population in just over two years.

In summer, case numbers go up, possibly due to a more relaxed food preparation and cooking atmosphere, which can lead to increased cross-contamination during food preparation and to chicken being undercooked.

To help spread the message of safe handling and cooking of chicken, we brought in the Chicken Scene Investigators. Our two detectives, created for our latest campaign, are reminding consumers to remain vigilant about food safety in the kitchen, using three common points of contamination (or scenes of the crime) when preparing raw chicken as examples: tongs, tea towels, and knife. The short, punchy videos and still images are light-hearted with a serious message, and we have so far seen rewarding engagement with higher-thanaverage viewership and interaction on social media. We have also shared important tips on safely storing, defrosting, preparing and barbequing chicken on our website.

Early data shows that this serious message, playfully delivered, is sticking with Kiwis, and we hope it will endure throughout the year. Join us in spreading the food safety word – you can find more information about vibriosis and campylobacteriosis, including our campaigns, on our website.

February / March 2023 19 Food Safety

The chicken-scene investigators in action

FSANZ and your food safety enquiries

Ben Sutherland, Principal Food Technologist | Standards & Surveillance, FSANZ

Ever wondered where your food safety enquiry to FSANZ ends up? The answer is with a living, breathing human being. We have a dedicated guru – Peter “Kegs” Keegan who has over 20 years’ experience in Code related matters and has assisted thousands of food business to adhere to and understand Code requirements. In addition to Kegs, there’s a network of experts within FSANZ who deal with enquiries on all sorts of food related issues – from cell-based meat one day to Methyl acrylate-divinylbenzene-diethylene glycol divinyl, aminolysed with dimethaminopropylamine and quaternised with methyl chloride the next!

We refer many of our enquirers to our website, which houses over 3000 pages of information relating to food and food safety. But we do occasionally get enquiries which need extra consideration and a more fulsome response!

A recent enquiry to FSANZ asked how a particular Health Star Rating (HSR) is possible on a product that contains an ingredient “banned” in other countries, with a suggestion money must have changed hands. If we break this down, the ingredient in question is a food colour assessed as being safe by The Joint Expert Committee on Food Additives, so this poses no real risk to consumers. Our regulation is mature, risk based and independent from other countries and although we have regard to overseas regulators’ views, we maintain our independence. The algorithm that calculates the HSR provides transparency and was developed in collaboration with technical and nutrition experts from government (including FSANZ), industry, public health and consumer organisations. Interestingly enough, the algorithm doesn’t consider colours in its calculation, so the ingredient could not contribute to the HSR. And to my knowledge the food industry doesn’t pay anyone off to secure a higher HSR!

The old saying “the customer is always right” remains a guiding principle. However with enquiries like these, we are able to provide additional information and guidance to our valued stakeholders. We can also provide suggested reading material and reinforce our commitment to developing and maintaining world-leading food standards. Part of our role, in addition to ensuring the food supply is safe and suitable, is to make sure information is provided so that the consumer is not misled as to the representation of a food via its

label. Labelling certainly provides detailed information on any food additives such as colours and can help assure people that the HSR rating displayed provides a true representation of the food.

In some instances, we are asked to interpret the Australia New Zealand Food Standards Code for compliance or enforcement purposes. While FSANZ develops the standards in the Code, it does not enforce them. In certain instances, we need to hand enquirers over to our jurisdictional colleagues at MPI who are charged with interpreting the Code, for which we thank them.

We also get some more quirky enquiries such as what height a food serving window has to be from the ground, whether dogs (or other animals) are allowed in cafes, or whether using rusty cutlery is hazardous. We get food service workers filling us in on their employer’s poor hygiene practices or letting us know they wear stickon eyelashes. We’re notified when someone comes across research which indicates that chocolate bars on average contain 8 pieces of insect and we are asked what regulation is required on freeze dried human breastmilk. Conversely, there are more serious enquiries, such as the allergen status and labelling requirements for various foods, guidance on micro limits for foods, questions around infant formula products and what they are can and can’t contain, and what foods should be limited during pregnancy.

Then there’s the wonderful consumer comments which really make our day, like this one: “Good day, it is a truly a profound privilege to connect. I greatly appreciate your highly gracious and generous willingness to send over this truly substantive response. I am highly confident in you and your best-in-class team.” Got to take credit where credit’s due!

FSANZ continues to invest in our relationships and is stepping-up engagement with our stakeholders to maintain our focus on achieving excellence in client service delivery. This includes the consumers that take the time to reach out to us. Last year we asked how we can better meet our stakeholder needs via a new satisfaction survey. Our survey results which included feedback from consumers showed FSANZ stakeholder satisfaction rating is 72%. Let’s see if we can beat that figure this year!

Food New Zealand 20 Food Safety

Vibrio – the barometer of climate change

This article was written exclusively for Food NZ magazine by the NZ Food Safety Science & Research Centre

On the 5th of January, RadioNZ announced that the severe marine heatwave the lower South Island was experiencing was expected to peak around 4 degrees above average*. Great news for Southland swimmers, but also a warning to shellfish lovers. Many waterborne pathogens enjoy warmer temperatures too. Shellfish, being filter feeders, absorb and accumulate bacteria in their delicious flesh, with no harm to themselves, but sometimes serious consequences for their human predators.

Just before Christmas and the mass exodus to coastal holiday spots, NZ Food Safety (NZFS) launched a nationwide, targeted campaign to alert shellfish harvesters to the increased risk, in response to a series of outbreaks of gastroenteritis caused by the marine bacterium Vibrio parahaemolyticus. These bacteria live naturally in coastal and estuarine environments.

Graham Fletcher, a microbiologist and award-winning food safety scientist at Plant & Food Research who has studied Vibrio for forty years, was not surprised by the outbreaks. “I’ve just been waiting,” he said.

In a paper on the human pathogen, UK scientists dubbed Vibrio the “microbial barometer of climate change”. Water temperature is the main environmental factor affecting their population growth.

The most recent and largest outbreak in New Zealand, November 2021 to May 2022 (referred to as the 2022 outbreak), affected 60 people, that we know of, and hospitalised 25. Half of those infected were Māori or Pasifika, which could simply be due to the fact that they gather and share more shellfish. Outbreaks in 2019, 2020, and

2021 involved 23, 16, and 24 people and, unusually, two of them occurred in winter.

Enquiries identified undercooked mussels, both wild and commercially sourced, as the common link in all outbreaks, although a wide range of other seafoods were also implicated in the 2022 outbreak. While these Vibrio infections were foodborne, causing gastroenteritis, another species of Vibrio bacteria can also infect people through open skin wounds when wading or swimming in the sea, causing soft tissue infections. Sometimes these infections turn serious, endangering lives.

All identified cases of acute Vibrio parahaemolyticus gastroenteritis must be reported in New Zealand, but these cases are only identified when people have become sick enough to seek medical attention.

As with all cases of gastroenteritis, many people do not go to the doctor, or have faecal samples taken to confirm what is making them sick, so reported cases are likely the tip of the iceberg. In the United States, vibriosis caused by a range of Vibrio species, including Vibrio parahaemolyticus, causes about 80,000 illnesses and 100 deaths every year.

Surveillance data needed

Nicola King of the Institute of Environmental Science and Research (ESR), who has contributed to projects aimed at understanding and managing New Zealand’s Vibrio risks, says, “We really need a reliable baseline of surveillance data so that we can tell if rates of infection are increasing as a result of climate change, to predict and plan for

February / March 2023 21 NZFSSRC

Graham Fletcher, Plant & Food Research

Nicola King, ESR Tim Harwood, Cawthron Institute

Phil Bremer’s not so new position as Chief Scientist of the NZ Food Safety Science & Research Centre (NZFSSRC or the Centre) – he’d been acting in the role for some months – is a pinnacle of his four-decade-long career in microbiology, food science, marine biology, consumer behaviour studies, and his practical knowledge of the food industry, and how the research process works in universities and crown research institutes. Phil is currently the President of the NZIFST and a former president of both the NZ Microbiology Society, and the NZ Association for Food Protection.

The appointment comes on top of his recognition by the University of Otago as an outstanding researcher, teacher and leader, with the title of Distinguished Professor. Phil will now divide his time between his University teaching and research roles, and directing the Centre’s research pipeline. The synergies make the two roles seamless.

Phil grew up in Invercargill, and studied Zoology at the University of Otago, majoring in both Microbiology and Zoology. After an MSc in Marine Microbiology, he embarked on his PhD investigation of how heavy metals in sediments are accumulated by bacteria and passed along the food chain. His research attracted the interest of a group in the US that were looking at how bacteria attach to metal surfaces. And so followed 3 years as a postdoc, first at Long Beach State University in California, and then at the Centre for Biofilm Engineering in Montana State University in Bozeman, Montana, where he investigated how bacteria attach to surfaces, and how

they form biofilms which protect them from environmental stresses, like cleaning agents in food processing facilities.

On the strength of his expertise in understanding how bacteria live and survive on surfaces, and his marine microbiology background, Phil landed a job in the Seafood Research Unit at Plant & Food Research, focusing on controlling Listeria in seafood processing plants. He was ten years there, ultimately as programme manager for seafood and vegetable safety. Phil started to realise that “it’s one thing to make safe food, but it also has to taste good and that can be more challenging.” And so he became more interested in food science and because his wife Louise was at the medical school in Otago – she is now a consultant oncologist – Plant & Food allowed him to spend part of his time in Dunedin, teaching microbiology in Otago University’s food science department. He enjoyed himself so much he eventually became full-time. Initially he taught food microbiology - understanding where and how pathogens enter the food system and how to control them.

Over time, his interest has evolved to encompass other research topics, including new product development, novel processing technologies, and understanding consumer acceptance or otherwise of these.

The role of Chief Scientist is absolutely critical to the Centre. Food safety science is, after all, its raison d’être, and Phil knows how to work with the food industry to identify and frame research projects, and how to put together effective research teams from the national science talent pool. One of the things he’d like to achieve as Chief Scientist is to develop better links between researchers working in food safety research and public health.

future disease burden, and to measure the impact of interventions.” Data on all types of Vibrio infections are not currently collated in New Zealand.

But how can we possibly manage such microbial invaders when they are naturally present in our oceans and have the freedom to come and go as the environment pleases them, and when we have thousands of kilometres of coastline to monitor? Is there any such thing as border control when it comes to water and airborne pathogens? What’s more, mutations in the bacteria keep moving the target.

Public education