NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING THE OFFICIAL JOURNAL OF THE NEW ZEALAND INSTITUTE OF FOOD SCIENCE AND TECHNOLOGY INC. Foodtech Packtech Exhibition preview EQI, an assay for measuring bioactivity of bovine whey proteins NZFSSRC – Annual Symposium Report NZIFST Strategy Refresh NZIFST CONFERENCE 2023 AWARDS August/September 2023 FEATURED IN THIS ISSUE:

AUGUST/SEPTEMBER 2023 | VOLUME 23, NO.4 ISSN 2744-7308 (ONLINE) ISSN 1175-4621 (PRINT)

John D Brooks

Director and Editor

Anne Scott, Peppermint Press Limited anne@foodnz.co.nz

Director and Writer

Dave Pooch, Peppermint Press Limited davep@me.com

Advertising

Anne Scott, anne@foodnz.co.nz 021 901 884

Design and Layout

Johanna Paynter, Pix Design

Published by Peppermint Press Limited

Notice to Contributors

When submitting editorial for Food New Zealand please observe the following, Editorial to be submitted as plain text files, NO FORMATTING please. Images should be sent as high resolution .jpg or .tiff files. Do not embed images in word documents, send separate files. Any images smaller than 500 kb may not be printed as the clarity of the print may be compromised.

Advertisers

Material specification sheet and rate card on website, www.foodnz.co.nz

Copyright © 2023 Peppermint Press

No part of this publication may be reproduced or copied in any form by any means (graphic, electronic, or mechanical, including photocopying, recording, taping information retrieval systems, or otherwise) without the written permission of Peppermint Press. The views expressed in this journal are those of the writers and do not necessarily represent the view of the Publisher, the Scientific Review Board or NZIFST

Regular Contributors

Phil Bremer, John D Brooks, Laurence Eyres, Ben Sutherland, Dave Pooch, John Lawson

Food New Zealand 2 NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING Contents 4 EDIT ORIAL 5 NEW SBITES 10 FSANZ

International Symposium on cell-based fFood ingredients Ben Sutherland, Principal Food Technologist, Standards & Surveillance, FSANZ 11 NZ FOOD SAFETY Celebrating New Zealand’s success at Codex: 60 years and beyond 12 OILS & FATS Oils and Fats update Laurence Eyres FNZIFST 14 CAREERS

NZIFST Salary Survey

Recruitment 15 J C ANDREWS AWARD

2023

2023

John Lawson, Lawson Williams

J C Andrews Address 2023

Contacts

Press Ltd 5 Rupi Court, Mt Wellington Auckland

is distributed

to

members

the

tute of

Science and Technology. An online edition is shared internationally. Visit www.foodnz.co.nz to subscribe.

Peppermint

1072, New Zealand Phone 64 21 901 884 www.foodnz.co.nz Food NZ

online

all

of

New Zealand Insti-

Food

15 11 5

Executive Manager, Wendy Bayliss

PO Box 44322

Pt Chevalier Auckland 1022

New Zealand

Phone: 022 549 8483, Email: wendy@nzifst.org.nz

Website: www.nzifst.org.nz

22 FTPT

Foodtech Packtech 2023: Unveiling the Future of Food Innovation

29 PACKAGING

AIP will offer a packaging forum and a training course alongside Foodtech PackTech 2023

30 NZFSSRC

NZFSSRC Food Safety Symposium Wrap

33 RESEARCH

EQI, an assay for measuring bioactivity of bovine whey proteins

Katharine Adam, Grant Smolenski, Colin Ogle, Rodney Claycomb

36 NZIF ST N EWS INCLUDING

Strategy Refresh NZIFST AGM 2023

Awards Branch News

50 STUDENT ESSAY

Precision Fermentation: Cultivating the future of dairy

Erin Lau, Student, The University of Auckland, Food Science Programme

JOIN NZIFST NOW for Professional Development Networking – connecting with your peers

Regular information about your industry

Recognition through awards, scholarships, travel grants www.nzifst.org.nz/join/

On the cover

Cover image: The culmination of the NZIFST year – a conference in Dunedin and an awards dinner in the imposing Dunedin Town Hall.

Next editorial and advertising deadline: September 20th, 2023

Features for October/November 2023

Cloud-based monitoring and management

Food ingredients overview

Packaging update

June / July 2023 3

36 30 12 50 14 22

Finding your tribe – your network

For millennia mankind has lived within tribes. In prehistory a family, or tribe provided security, both physical and nutritional. As time passed members of a tribe adopted individual roles which supported those around them and tribes grew beyond direct family ties.

We still need our tribe. In our miraculously interconnected world we still need to be connected, personally, with people we like to be around, who are socially congenial, with whom we share a common link.

In the case of NZIFST we are all connected by our knowledge and relationship with food, whether in production of food products, ensuring the safety of our food products, in research into food structure, digestion, flavour –and many more aspects of the food system that sustains our society.

Outside our technical focus, we have interractions with colleagues whose roles connect with ours. We couldn’t develop and market a new formulation without ingredient suppliers, without our costing and production personnel.

Our recent Conference in Dunedin reinforced the interconnectedness amongst members of our industry. One degree of separation is the norm, admittedly enhanced by our small nation.

Many members are connected internationally, through postings and early studies overseas, and they maintain those links to support the New Zealand industry.

As a member of NZIFST I treasure the tribe I joined when I arrived at Massey University in Palmerston North in 1971. Our Institute was incorporated at Massey in 1965 and has developed into a dynasty of networked, supported individuals.

Over the years I have benefited from the networks of my teachers, supervisors, colleagues and peers. I have been able to support others in their own endeavours. In early days I was amazed and somewhat intimidated by Mary Earle’s network. “Ask Mary (Earle) anything and if she doesn’t know she will know who to recommend.” I now realise that Mary’s network was the product of many active years working with her tribe. So here’s my point.

NZIFST is a network of people who will help you build your career. They will help you achieve your goals. But remember, it’s not a one-way road. A network is just that, connections travel in both directions, just like a thriving friendship.

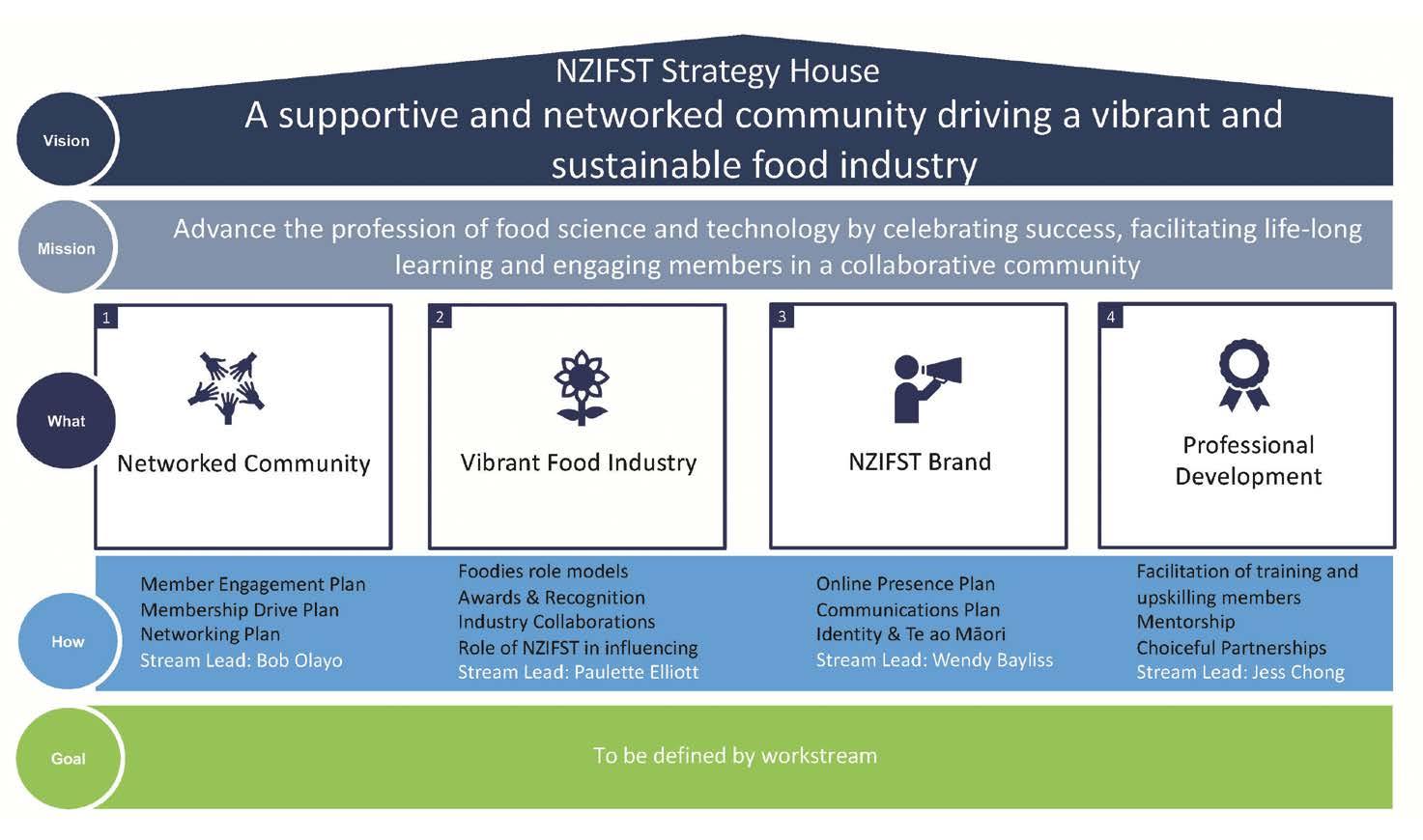

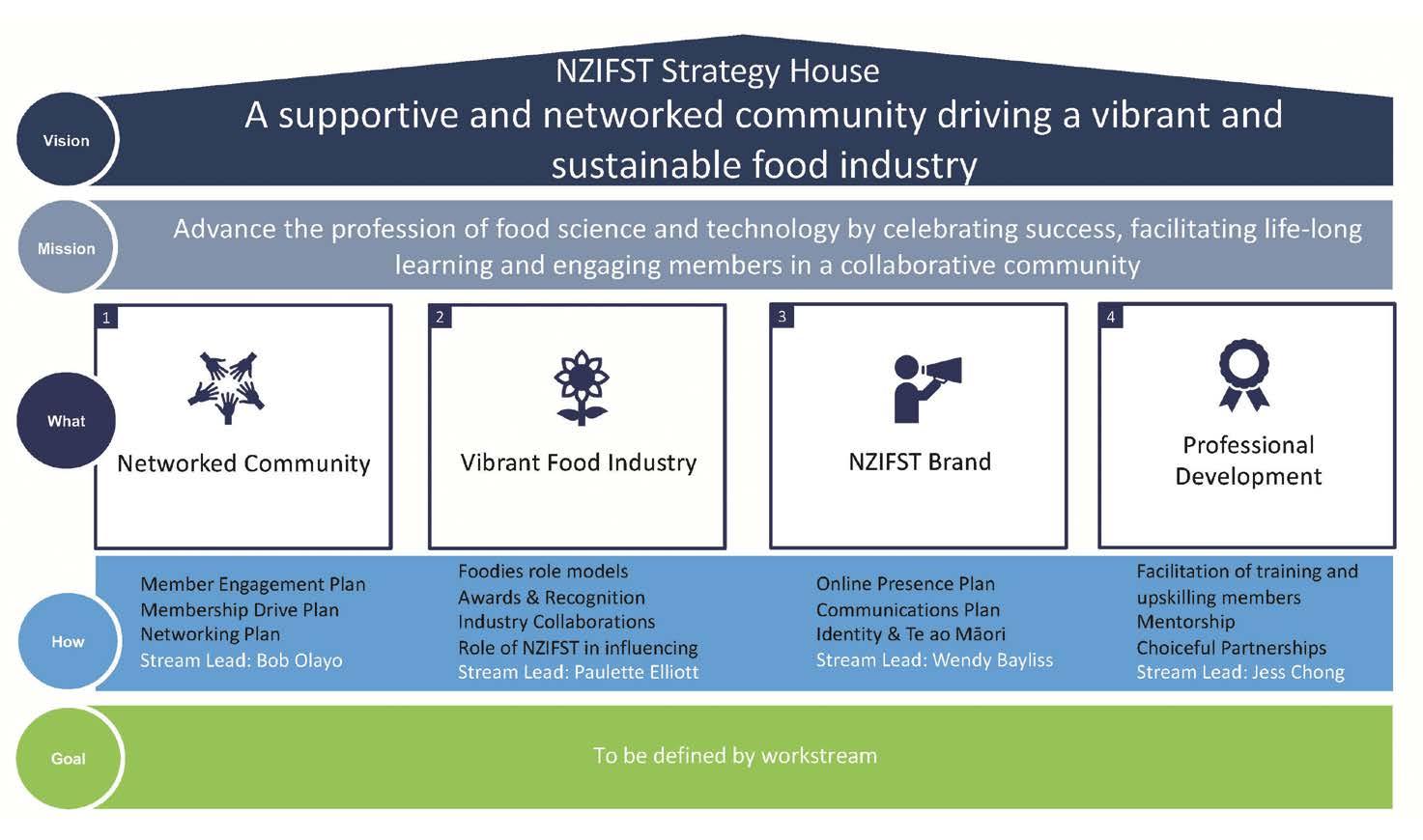

Our Board and Exec are working on an extensive project to refresh the NZIFST brand. Their areas of study are

• Membership: How do we engage with our current membership base?

• Financial: How do we ensure real benefits for our members?

• Partnerships: How do we have strategic partnerships that bring benefits to our members?

• Image: How do we remain relevant in our branding and communications?

• Growth: How do we grow our membership base?

Our President, Esraa Ell Shall and the team are looking for volunteers. If you want to join the NZIFST network you will be making an excellent start if you participate in this project. You will find more about the Strategy Refresh on page 36.

Anne Scott FNZIFST, Editor

Food New Zealand 4 EDITORIAL Editorial

Anne Scott FNZIFST, Editor

Newsbites

Food New Zealand’s round up of news about NZIFST members, associated companies and other items of interest.

Meat still on menu despite challenges

More than nine out of ten New Zealanders are meat-eaters, a survey has found; although almost half of Kiwis have reduced their meat consumption in response to issues such as cost and health.

The results of the online survey carried out in December 2021 – along with an associated review led by crown research institute AgResearch – shows high awareness of meat alternatives, but a “very low” level of consumption of those alternative products.

The study concludes that overall, the outlook for meat consumption and the meat industry in New Zealand is positive and is likely to remain so for the foreseeable future. The study was conducted by AgResearch scientists and Lincoln University researchers.

The online survey of 1061 New Zealand consumers found that for meat-eaters “the taste of meat is the king decider for purchase and consumption”; with 71% rating taste a “very important” attribute when purchasing, followed by price (55%) and use-by date (51%). Results showed that chicken was the main type of meat consumed regularly, accounting for about 33% of the meals within an average week, followed by beef (22%), fish (13%), pork (10%), lamb (8%), and processed meat (7%). Plant-based meat products, venison, game/ hunted meat, and other meat types only make up a minor portion in participants' weekly diets (less than 2%).

Over the past year, nearly half of survey respondents (47%) lowered their meat consumption; most of them (69%) had consumed less meat overall while the rest of meat reducers (31%) only lowered the consumption of particular meat products.

When it came to motivations for reducing meat consumption, “lack of affordability and health concerns” are their key drivers.

Survey participants were also asked to indicate the top 3 factors or words that they considered important to define sustainability for meat production. The most frequent terms include animal welfare, environmental impact and grass-fed closely followed by carbon/ GHG emissions, “free range” and “farming methods”.

Although the respondents' awareness of alternative proteins or meat alternatives was high, their consumption of these products was rated as very low compared to what is reported in other countries.

AgResearch senior scientist Cameron Craigie says the headline survey result on omnivorous diets is not surprising given the value and tradition of meat eating in New Zealand.

“The survey is a snapshot in time, but for us as researchers, it does help us focus on the research that addresses the issues that people

care most about. Clearly taste is a key factor for meat eaters and that’s why we are doing research to help producers maximise that.”

The value or impacts of meat in a diet has recently been the subject of several reports internationally, including the Food and Agriculture Organization of the United Nations (FAO) stating that “meat, eggs and milk offer crucial sources of much-needed nutrients which cannot easily be obtained from plant-based foods”.

The full published research, including the survey findings and information, can be viewed here.

Newsbites

Cameron Craigie, AgResearch Scientist, was a member of the group studying New Zealanders' meat eating habits

Export opportunities in Asia

New research finds Asia’s growing demand for alternative proteins is an opportunity for Australian and New Zealand manufacturers to harness a new market.

China’s increasing interest in alternative proteins makes it the most favourable market prospect in Asia for exporters of plant-based meat and cellular agriculture products such as cultivated meat. The research is available in a new report called Alternative Proteins and Asia published by independent alternative proteins think tank, Food Frontier, which partnered with researchers Mintel and New Zealand’s food and fibre sector think tank Te Puna Whakaaronui to identify new export opportunities for manufacturers.

Alternative Proteins and Asia

Insights for Australian and New Zealand exporters on China, Singapore, South Korea, Japan and Thailand.

Researchers assessed 11 countries across Asia. The top five countries with the greatest market potential were identified as follows, listed in order of opportunity: China, Singapore, South Korea, Thailand and Japan. The report includes primary research from 5,000 consumers across these markets.

Food Frontier Executive Director, Dr Simon Eassom, says Australia and New Zealand have long traded with Asia, occupying a privileged position as close neighbours and reliable trading partners of safe and quality goods.

He says, “With an expanding alternative proteins market in Asia, Australia and New Zealand have the potential to build a major new food export industry that complements our existing ones.”

“Health, environmental and food security concerns are behind the growing demand for alternative proteins. Global demand for meat is likely to double by 2050, driven by population growth and prosperity, particularly in Asia.

“Consumer interest in healthy and environmentally sustainable protein options is increasing, leading to more people becoming

Factors driving the expansion of the Alternative Protein Ecosystem

ADM has released its outlook on what's driving the advancement of the protein ecosystem. The report details four factors driving the expansion of protein choices to feed the world’s growing population while keeping the planet’s best interest in mind.

“Creating a sustainable and secure food system that addresses the sensory experience, nutrition and accessibility is vital to supporting the needs of people around the world,” said Leticia Gonçalves, president, Global Foods, ADM. “We’re excited to share what we believe is needed to expand the protein ecosystem and encourage additional consumer acceptance and adoption.”

ADM has outlined what it will take to expand the alternative protein landscape while addressing concerns, demands, and gaps now and for generations to come:

• Anticipating the next wave of advancements

• Championing consumer adoption

• Bridging the gap to better nutrition

• Solving accessibility with a tailored approach

Learn more about the four driving factors and find a breakdown of consumer and market insights here.

interested in a flexitarian diet – one where they regularly swap conventional animal meat for new options like plant-based meat, which provides a familiar eating experience without compromising on nutritional value.

“Flexitarians are driving demand for alternative proteins in Australia – our latest research shows this is also the case in Asia. A quarter of Chinese identify as flexitarian and one third plan to reduce at least one type of meat. Similarly, twenty-six percent of South Koreans want to reduce meat consumption”

Food Frontier is the independent think tank on alternative proteins in Australia and New Zealand. Funded by grants and donations, our work is growing our region’s protein supply with new, sustainable and nutritious options that create value for businesses, farmers and consumers.

You can download the full report HERE.

Inaugural Grocery Commissioner appointed

“The appointment of the Grocery Commissioner is a momentous day for the sector as well as the wider retail environment,” says NZFGC Chief Executive Raewyn Bleakley, “By holding supermarkets to account, the Commissioner will help make a meaningful difference to competition and behaviour that shoppers and the sector so desperately want to see.”

“As a former long-time executive in the FMCG sector, including leading Sanitarium Health and Wellbeing and other companies, and being Chair of the New Zealand Food and Grocery Council, Pierre van Heerden will bring a deep understanding of the sector to this vital role.”

The New Zealand Food and Grocery Council welcomes the appointment of former grocery sector leader Pierre van Heerden as New Zealand’s inaugural Grocery Commissioner

We are looking forward to the Commissioner issuing guidance on aspects such as application of the good faith provisions, operation of the grace period provisions during transition, and arrangements around the grocery supply agreements supported by a strong and comprehensive Grocery Code of Conduct.

“The Food and Grocery Council looks forward to working with Mr van Heerden and his team, and retailers, to help deliver consumers optimum choice and price.”

Food New Zealand 6 Newsbites

v

Vertical farming systems build traction

A mechanised growing system with the potential to improve New Zealand’s food production security will be set up in Ashburton by the end of August, with planting to commence early September. It will be the first opportunity for New Zealand horticulturalists to see a full-sized Vertical Farm Systems XA Series (VFS) growing system in operation, courtesy of the New Zealand supplier, Landlogic.

The Ashburton set-up is a Landlogic initiative to showcase what a vertical food production system can do. VFS is a modular system designed for warehouse installation with plants grown in multilevel trays contained in climate and light-controlled cells.

Landlogic CEO, Alan Cottington, says the fully automated vertical growing system offers an important alternative to producing commercial levels of leafy greens in the horticultural industry, where traditional outdoor growing systems have taken such a huge hit in recent floods and storms.

“The increasing unpredictability and frequency of severe weather events, attributed to global warming, along with the rising costs impacting traditional open-field farming, mean it's more important than ever to consider new approaches to sustainable agriculture,” Cottington says. “Our food security is vulnerable when we rely on traditional farming methods or importation for leafy greens, which are a basic and healthy food essential.”

In agribusiness the commercial production of leafy greens, herbs or plant seedlings using multi-level growing systems is rapidly expanding around the world.

The VFS system is best suited to fast-growing crops, including leafy greens such as loose-leaf lettuce, baby spinach, arugula, mizuna, tatsoi, endive, pak choy, bok choy, beet chard, and herbs such as coriander, parsley, and basil.

There are no ‘seasonal crops’ and no crop losses. “Harvest times and end product quality are consistent and reliable, allowing commercial growers to confidently commit to delivery schedules and quantity agreements.”

In addition to helping with local food security, Cottington says the VFS system is better for the environment especially in such areas as water quality, fertiliser use and pest control chemicals.

Landlogic is the importer and distributor of Vertical Farm Systems for New Zealand and the Pacific, as well as sales agent for the rest of the world – except Canada, Scandinavia, Philippines and USA– and Cottington says vertical farming is a big opportunity for Pacific Island countries to combat growing concerns of food security and access to nutritional foods.

Newsbites

Vertical farming systems are increasingly important for food production security

Investigating nutritional properties of Microalgae

Cawthron Institute has teamed up with biotechnology nutrition startup, NewFish, and Nelson-based marine engineering firm, Kernohan Engineering to explore the nutritional properties of microalgae. The project will see around 100 strains of microalgae from Cawthron’s globally significant Culture Collection investigated for nutritional properties and ease of production that could open up new sustainable protein industries across Aotearoa New Zealand.

“The aim of this project is to identify the best microalgae strains, and then produce them at scale so they can be processed into alternative protein and other ingredients for functional foods,” said Cawthron Science Impact Manager, Dr Johan Svenson.

Cawthron Institute is home to a treasure trove of more than 600 species in their microalgae Culture Collection, so is potentially sitting on a lot of untapped opportunity.

“Cawthron has more than 30 years of algae research expertise, and during that time we have developed a cultivation method that can increase certain algae production, enabling efficient production and development here in Aotearoa New Zealand,” said Dr Svenson. NewFish CEO, Toby Lane, said that certain microalgae were known

Successful Fine Food New Zealand 2023

The recently concluded Fine Food New Zealand event attracted record numbers of exhibitors and delegates, contributing to an event that was not only a stunning success, but a litmus test for a resurgent hospitality industry determined to make the most of every available opportunity.

The three-day trade-only event took place in late June at the ASB Showgrounds in Auckland, drawing 6,405 unique attendees – an increase of 6.5% over the number of delegates who attended 2021’s event. In response to those numbers, event manager Deb Haimes says, “Fantastic result, we had 288 exhibitors offering the widest range of products, services, produce, innovations, and a ton more. The number of vendors was well up on the last event, and the combination of more to see delivered an amazing experience for every delegate.”

Exhibitors have expressed their satisfaction with Fine Food New Zealand 2023, too. Early feedback is universally positive, with vendors experiencing keen interest and strong demand for their products and services.

With any exhibition, the quality of delegates matters to exhibitors. Fine Food New Zealand is ‘trade-only’ by design, so only those in food service, hospitality, beverage, and related industries are in attendance. This consistently delivers the results vendors seek:

to be rich and complete nutrition sources for people, and are a sustainable, high-quality protein source that could signal the start of whole new protein sector.

“The nutritional credentials of some microalgae strains are on par with animal alternatives, yet the environmental impact is microscopic in comparison. The next step is to show the world how delicious microalgae is, so we’re working on a range of applications, starting with bars and drinks targeting active and sports nutrition markets.”

The advantage of microalgae is that it can be grown in bioreactors using a fraction of the resources that traditional food sources use without taking up natural or arable farmland. That’s where Kernohan Engineering expertise comes in, helping to develop production systems that enable the flexible and sustainable production of green protein for the future.

The Government is investing $750,000 in the $1.5 million project through the Ministry for Primary Industries’ Sustainable Food and Fibre Futures fund (SFF Futures), with NewFish and Kernohan contributing the balance.

Minister for Oceans and Fisheries, Rachel Brooking, announced the funding at Cawthron’s Algal Centre and said the Government is backing investigations into a potential new food industry for New Zealand.

expanding market reach, opening new avenues to market, and above all, driving sales of great products and services.

Haimes says the response to the event has surpassed expectations and the litmus test has come back with the right result. “It’s been a tough and truly unprecedented time for the industry. But Kiwi hospitality has shown its resilience once again, with the indomitable Kiwi spirit shining through. We’re looking forward to some productive years before we return in 2025.”

The next Fine Food New Zealand is scheduled for 29 June - 1 July 2025.

Food New Zealand 8 Newsbites

The Microalgae R&D team with Minister Rachel Brooking, third from right in front row

Rhodiola rosea raw material permits

Spain’s authorities have certified the entirety of Nektium’s Rhodiolife® Rhodiola rosea inventory as CITES-compliant.

The approval means the Las Palmas-based company now has permits in place to commercialise large volumes of Rhodiolife® for customers within the EU and worldwide, both directly and via its network of global distributors.

In February, CITES incorporated Rhodiola spp. into Appendix II, its list of endangered species that are subject to international trade controls. On 20 May, the EU added Rhodiola spp. to Annex B, its equivalent list of species subject to restrictions. Subsequent to this, Nektium applied for trade permits for its existing Rhodiolife® stocks. These were granted on 16 June.

CITES is the Convention on International Trade in Endangered Species of Flora and Fauna. Although a voluntary organisation, its decisions are considered binding for the 184 countries that are members.

Rhodiola rosea is one of nature’s most potent adaptogens, offering a range of scientifically proven cognitive health and sports performance benefits. The popularity of the plant, which grows wild in the remote Altai mountains in south and central Asia, has put pressure on supplies, leading to over-harvesting. Historically, Nektium has relied on wild Rhodiola rosea roots harvested using sustainable practices.

But the company recently pioneered the large-scale cultivation of Rhodiola rosea at levels sufficient to satisfy market demand. Based on the island of Gran Canaria, Spain, Nektium specialises in the supply of branded and generic botanical ingredients of the highest quality. In 1997, little was known about many of these botanical extracts, but the team at Nektium made it their mission to explore and unleash their potential health benefits.

Newsbites

Nektium has secured new CITES trade permits for Rhodiola rosea raw material

2023 International Symposium on cell-based food ingredients

Ben Sutherland, Principal Food Technologist | Standards & Surveillance, FSANZ

I recently attended an international symposium on cell-based food ingredients in Seoul, organised by the Korean Ministry of Food and Drug Safety (MFDS). The MFDS has been strengthening international cooperation and food safety dialogue in the Asia Pacific region to facilitate management of novel foods in line with global standards and extend support for industry exports through collaborative efforts.

I was joined by 5 regulators from other regions and it soon became clear there is general agreement amongst all of us that cell-based foods will be considered novel foods. All have a clear, established regulatory pathway for the approval of novel foods which can accommodate cell-based foods. Like a number of other food standards bodies, Food Standards Australia New Zealand may be setting standards for a number of these foods in the future so this commonality in approach is welcome.

William Hallman from Rutgers University gave a fascinating talk on risk communication strategies for safety management of novel foods. William noted that as cell-cultured meat, poultry and seafood products moved closer to markets in the USA and elsewhere, it is critical for stakeholders, including government, industry, academia, consumer organisations and the media, to adopt common nomenclature and risk communication strategies to help consumers understand these products and the technologies involved. William discussed key criteria for assessing appropriate labelling of these products, particularly the attributes and technologies that will influence perceptions of their risks, best practises for engaging with consumers, policymakers and other stakeholders, and the skillset required for communicating the risks.

Not surprisingly there was a call for harmonisation in risk assessment on a global level as each region requests the same data in assessing the safety of cell-based foods. The Godfather of cell-based foods, Professor Mark Post, noted we’re all looking at the same stuff, so how about some harmonisation in risk assessment? Clearly risk management strategies will be different across various regions, but there are synergies within risk assessment which could quite easily be shared.

Mark spoke on developmental strategies for cultivated meat in the EU, listing challenges as being technical, logistical and regulatory in nature. These included the use of “food-alien” proteins to replace serum, use of the cheapest possible food grade ingredients as opposed to pharmaceutical grade, and the reliance on cell division to create astronomical numbers of mammalian cells. Mark mentioned the need for “animal-component-free” culture of cells and tissues, abstinence from antibiotic use, and use of genetic modification as solutions available to developers of cultivated foods. Mark also noted that there are several initiatives being taken, such as work by the FAO and some NGOs and trade organisations to harmonise regulatory approval processes across the world. He said this is exactly what is needed as consumers are increasingly willing to accept alternative sources of meat, giving the sector an appreciable tailwind. The huge potential

for improvement and extension of applied tissue engineering for food makes this an exciting scientific and regulatory endeavour for the next couple of decades.

Watch this space!

In the Republic of Korea itself, several universities acknowledged the demand for alternative protein sources due to population growth, climate change, farmland shortages, declining biodiversity and an increase in informed consumers. Areas of research recognise the usefulness of microbial amino acids for supplementation of plant proteins and animal feed and a view that single cell derived novel food ingredients and haem could enhance the value of alternative proteins, provided their production is safely regulated. Recent advances in adaptive laboratory evolution in synthetic biology have enabled the development of new cell types as sources of novel food ingredients offering unique nutritional profiles and features such as colour flavour and textures. The development of novel foods from Korean native plants was also being investigated. I gathered there are around 10 start up cell-based meat companies in the Republic of Korea, many of which were present at the symposium.

While all of this is fascinating, it's our role as regulators to enable a clear regulatory pathway for the sector, one in which global food regulatory harmonisation should play a significant role.

Food New Zealand 10

Food Safety

Local delegates and international speakers in Seoul with Ben Sutherland, FSANZ, back right

NZ Food Safety News

Celebrating New Zealand’s Success at Codex: 60 years and beyond

In mid-June, New Zealand Food Safety and our wider organisation, the Ministry for Primary Industries (MPI), celebrated a significant milestone – the 60th anniversary of Codex, and 60 years of New Zealand’s successful engagement at the largest global forum for food standards.

Established in 1963, the Codex Alimentarius Commission (Codex –Latin for ‘food code’) is a joint food standards programme of the Food and Agriculture Organization of the United Nations and the World Health Organisation. The mission is simple: “safe, good food for everyone, everywhere”. With 189 member nations, and one member organisation (the European Union), Codex is the main global forum for international food standards, an important area for economic and health diplomacy for our country.

The celebratory event at Parliament on 20 June included speeches from Minister for Food Safety, Hon Rachel Brooking and Minister for Agriculture and for Trade and Export Growth, Hon Damien O’Connor, underscoring the importance New Zealand places on its engagement at Codex and highlighting our successes. Several organisations that have made a significant contribution to New Zealand’s Codex footprint were represented on the night, including Fonterra, the Meat Industry Association, Horticulture New Zealand, Zespri, the New Zealand Food & Grocery Council, Seafood NZ Ltd, and Olives New Zealand.

Short remarks made by Mike Cronin, Managing Director, Corporative Affairs, Fonterra, and Emma Glover, Executive Officer of Olives NZ noted the benefits of Codex standards to their businesses and industries, particularly in terms of market development and reduction of technical barriers to trade.

This video, launched at the event, highlights New Zealand’s contributions at Codex to date, and acknowledges Codex’s important role in protecting consumers and ensuring fair practices in food trade.

What does it mean for industry?

Led by MPI, New Zealand’s work with Codex (both at the headquarters in Rome, Italy, and at regional committees) has a material and positive impact on the whole food sector – from food businesses, manufacturers and importers, to the hospitality industry. We all know that food standards are vital for the health, wellbeing and prosperity of our people. Food standards mean safer food for consumers who can trust the food they are buying and eating – at home and internationally. New Zealand is a strong trading nation and food standards are good news for our exporters, meaning importers around the world can trust in the quality and safety of food they’re buying from New Zealand and that global markets trust New Zealand’s assurances.

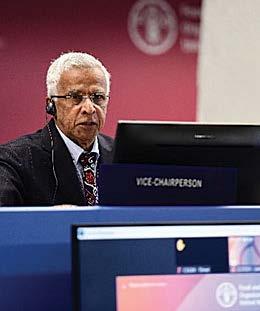

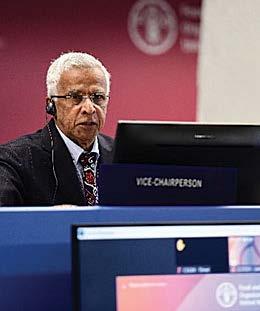

New Zealand has played a leading role in Codex since its inception, with Kiwi, H. Doyle being one of three Vice-Chairs of the inaugural Commission. Now history has repeated itself as MPI’s Raj Rajasekar sits as one of the current three Vice-Chairs.

Through Codex, New Zealand has led the development of international standards around meat hygiene and milk and milk products. It has also served as host country for Codex Committees on these important areas and has played a leading role in the development of other international standards. This includes food hygiene, food additives,

pesticides and veterinary drug residues, food labelling, nutrition, food inspection and certification systems, fresh fruits and vegetables, and methods of analysis and sampling.

All of this directly benefits New Zealand producers, growers, manufacturers and the primary sector. A stronger food standards environment translates to stronger and more prosperous economic conditions, and safer food for all.

Looking ahead

Celebrations at Parliament closed with the launch of New Zealand’s Strategic Objectives in Codex 2022-2026, an outline for New Zealand’s continued role and work there. The objectives are to:

• Influence standards relevant to New Zealand’s food safety, human health protection, nutrition, and trade interests by actively participating in Codex.

• Ensure New Zealand’s regulatory systems are informed by and aligned with Codex.

• Promote a strong Codex system and advocate for global uptake and use of Codex standards, guidelines, and recommendations. A key area of the strategy relates to partnering with Māori/Iwi to understand their aspirations for international trade in food products and how this can be supported through Codex. MPI will also be looking to strengthen ties with key stakeholders and Codex members, including those in the South West Pacific region, to support development of standards, guidelines, and recommendations in areas of mutual interest.

New Zealand places considerable importance on our relationships, membership and active leadership and participation at Codex. As a country, we are well positioned to contribute new thinking and promote the development of international standards essential to advancing our trade and market access interests.

Sixty years on, Codex has demonstrated its immense value to international organisations, member-countries and global citizens alike, and we look forward to continuing our robust engagement on behalf of New Zealand exporters, food businesses, those in the primary sector, and our consumers – indeed all New Zealanders.

August / September 2023 11 Food Safety

MPI’s Raj Rajasekar has been appointed one of three ViceChairs of the Codex Commission. A New Zealander, H. Doyle, held the same position in the inaugural commission in 1963

Oils and Fats News

Laurence Eyres FNZIFST

A regular roundup of news and opinion from the Oils and Fats Group of the New Zealand Institute of Chemistry.

AAOCS Conference Newcastle

The 2023 Australasian section of the American Oil Chemists’ Society (AAOCS) conference is at Noah’s on the Beach in Newcastle Australia, Nov 13-15th 2023.

Extra benefits on offer

1. The first 50 people to register will receive an Omega-3 Index test kit valued at $59.95 each. Thanks to OmegaQuant, who are suppling 50 kits which measure levels of Omega-3 in your blood. Get in quick to get one HERE

2. For Students we are offering 2 x $500 travel bursaries to get to the conferences for people doing their PhD or MSc. Fantastic opportunity to display your work in a great environment and we will foot the bill. How to apply is HERE

3. The agendas for the two workshops are now available so please check them out at the links below.

a. Sustainable Ingredients for Food and Feeds HERE

b. Lipids in the health of our futures HERE

Contact Dr. Matt Miller: Matt.Miller@cawthron.org.nz

Shark Liver Oil (squalene)

Squalene and its hydrogenated product (squalane) are long chain hydrocarbons. Shark liver oil is the generic term to describe a mixture of squalene, diacylglyceryl (DAGE) ethers and triacylglycerol (TAG) derived from the livers of certain deep-water dogfish species. Squalene is the purified distillate from shark liver oil, having 99.85% active ingredient. Squalane is the fully hydrogenated product (no trans).

They are both used as dietary supplements and in skin products. For many years there have been cheap substitutes of low quality on the market which has ruined the businesses who focus on quality natural products.

Now Australian Standard (AS) 5380:2023 which has taken several years, has finally been published. It specifies requirements for the responsible harvesting of sustainable sources of squalene and shark

liver oil, quality parameters and methods for testing and analysis, and requirements for packaging and labelling consumer products, especially when claiming provenance.

Australian Standards are voluntary. They do not include contractual, legal or statutory requirements. This document does not replace the provisions of the Australian Fisheries Management Authority, Australia New Zealand Food Standards Code, Therapeutic Goods Administration or applicable Commonwealth, State and Territory laws and regulations.

Our well-known colleague and expert on marine oils, the main author on the standard, Dr Peter Nichols, has also just published a paper. Using Compound-Specific Carbon Stable Isotope Analysis of Squalene to Establish Provenance and Ensure Sustainability for the Deep-Water Shark Liver Oil Industry, Sustainability (July 2022)14(15):9228,DOI: 10.3390/su14159228

Squalene in Olive Oil

Modern Olives (Australia) have also looked at the provenance of olive oil and squalene content. We received a quotation from Claudia Guillaume as follows.

We have been testing squalene for several years at our groves (Australia and USA) and the range is quite maintained. I would say that the variation is more driven by Maturity index and variety than origin. In our main varieties the range of squalene is quite consistent over the years in both countries, as per below:

• Arbequina – 2600 – 3400 mg/kg

• Coratina – 4000 – 4500 mg/kg

• Picual – 6000 – 7000 mg/kg

Reference: Determination of fatty acid methyl esters (cis and trans) and squalene in olive oil and other vegetable oils by gas chromatography (2023): International Standard ISO 24363 For historical interest, an early reference to work done: Eyres, Laurence, et al. "Potential of squalene as a functional lipid in foods and cosmetics." Lipid Technology 12 (2002): 104-107.

Food New Zealand 12

Oils & Fats

Brain Lipids

“Loss of myelin sheaths occurs during the normal ageing process and in neurological diseases, such as multiple sclerosis and Alzheimer’s disease," said Sengottuvel Vetrivel, senior research fellow with DukeNUS’ Cardiovascular & Metabolic Disorders (CVMD) Programme and lead investigator of the study. "Developing therapies to improve myelination – the formation of the myelin sheath – in ageing and disease is of great importance to ease any difficulties caused by declining myelination."

Lipid Transporter

To pave the way for developing such therapies, the researchers sought to understand the role of Mfsd2a, a protein that transports Lysophosphatidylcholine (LPC) – a lipid that has an omega-3 fatty acid – into the brain as part of the myelination process. From what is known, genetic defects in the Mfsd2a gene leads to significantly reduced myelination and a birth defect called microcephaly, which causes the baby’s head to be much smaller than it should be.

In preclinical models, the team showed that removing Mfsd2a from precursor cells that mature into myelin-producing cells – known as oligodendrocytes – in the brain led to deficient myelination after birth. Further investigations, including single-cell RNA sequencing, showed that Mfsd2a’s absence caused the pool of fatty acid molecules – particularly omega-3 fats – to be reduced in the precursor cells, preventing these cells from maturing into oligodendrocytes.

"Our study indicates that LPC omega-3 lipids function as factors within the brain to direct oligodendrocyte development, a process that is critical for brain myelination," explained David Silver, senior author of the study and deputy director of the CVMD Programme. "This opens up potential avenues to develop therapies and dietary supplements based on LPC omega-3 lipids that might help.

Pentadecanoic acid-C15:0-A healthy saturate?

There are claims that dietary, odd-chain saturated fatty acids (OCFAs), especially C15:0, are active fatty acids, having cell-based activities and in vivo efficacy that align with health benefits, including lower risk of inflammation, cardiometabolic diseases, and NASH, to which they have been associated with some epidemiological studies in humans. Chronic low-grade inflammation, driven by proinflammatory chemokines and cytokines, contributes to cardiometabolic comorbidities and the ageing process 48–50. Saturated fatty acids have few health benefits compared to unsaturated fatty acids. Despite bold claims, the jury is still out. The company pushing dietary supplement called C15 make all sorts of health claims based on a zoologist’s work with dolphins. It is an expensive supplement.

A bottle costs $USD 119.95 for 90 days’ supply, NZD $2.20 per day.

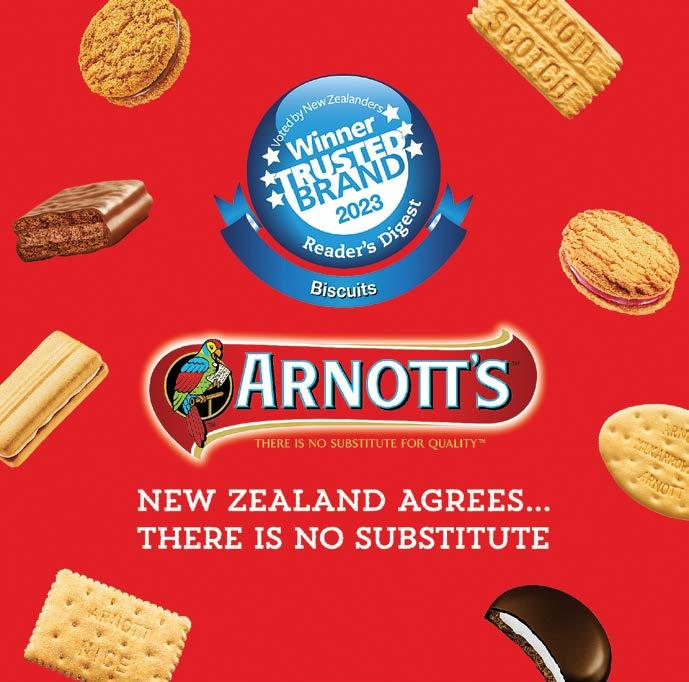

Arnott’s biscuits reopening production in NZ

Arnott’s has opened a new factory in Avondale which it says will help it create biscuits designed for local palates “for the first time … in a long time”. For the first time in 25 years, Arnott’s will be producing in New Zealand again, after taking over Kiwi cracker business 180 Degrees and launching a new multi-million-dollar 4000sqm manufacturing facility and innovation hub.

The 4000 square-metre plant employs 40 people across manufacturing, three research and development staff and a health and safety team,

Arnott’s announced the decision to build the factory 12 months ago. It’s the first time it has brought manufacturing back to New Zealand in 25 years.

The plant has transferred staff and equipment from Kiwi cracker manufacturer, 180 Degrees' Glendene factory. “It will also further strengthen the century-long affection we know Kiwis have had for the Arnott’s brand, which recently saw us recognised as New Zealand’s most trusted biscuit brand in the 2023 Reader's Digest Annual Trusted Brand Awards.”

Many years ago, this author worked for the major oil company in New Zealand, Abels who supplied it with their range of fat products.

August / September 2023 13 Oils & Fats

Made in New Zealand again. Arnott’s have opened a 4000 square-metre factory in Avondale which it says will help it create biscuits designed for local palates for the first time in 25 years

2023 NZIFST Salary Survey

John Lawson, Lawson Williams Recruitment

Employer and employee salary expectations are misaligned

In my 30 years in the employment sector, I have never experienced a time like now where employers and employees have such varied expectations around what salaries can or should be paid in the Food Industry.

The 2023 Lawson Williams, NZIFST and NZFGC employer Salary Survey has been released and shows some interesting trends around salaries and benefits.

It is no surprise that we report significant increases in salaries since our last survey in 2021, well beyond the more typical 3% annual CPI increase.

(You can find out more by visiting www.lawsonwilliams.co.nz/ surveys)

We have all heard about the pressure on salaries over the past two years. Recent reports have suggested that 72% of employees are currently feeling underpaid in New Zealand with 42% saying they will actively negotiate their salary in 2023. Over 52% believe they will benefit from changing jobs. (Hays)

Yet we have also read recently that many organisations are attempting to budget only a 3% increase in salaries in 2023 and 2024 – despite the high level of inflation and increasing cost of living and despite the continuing and increasing demand for skills. (Mercer)

How can this be?

Well, it is true that the New Zealand economy is slowing and as a result many companies are becoming more cautious. The numbers of job adverts on job boards have decreased but surprisingly, they remain at higher levels than 2019 and the persistent low unemployment rate underpins the ongoing shortage of skills.

Immigration levels are up. Are companies expecting that this will alleviate the pressure on skills and salary increases?

The immigration data however shows that most of the current migrants are filling roles in the tourism, hospitality, construction and logistics sectors, not the highly skilled roles that the New Zealand Food Industry needs.

We are seeing significantly lower interest in New Zealand from skilled migrants than expected. It appears they have all gone somewhere else!

The 2023 Food Industry Salary Survey provides some interesting

insight.

Our survey has now grown to the size that we can show detailed data across location and company size among other variables.

When we look at the salary increases that have occurred against company size, the 2023 survey results present very clearly that the smaller the company the higher the percentage of salary increases since 2021.

Larger companies have more easily moderated the impact of the increases in salaries we have seen in 2021 and 2022.

Smaller companies have had to respond and increase salaries to higher levels to ensure attraction and retention of the skills they need. In future articles we will investigate these differences in more detail. What are large companies doing to respond to the changes in the employment market. What can employers regardless of size do to attract and retain staff.

Is it all about the money? The answer is no, but beware, it’s never been more important!

Food New Zealand 14 Careers

Specialist Recruitment - Permanent and Contract www.lawsonwilliams.co.nz

John Lawson is founder of Lawson Williams Consulting Group. He initially studied Biotechnology at Massey and is a professional member of NZIFST. He now enjoys leading a team of recruitment consultants, helping people like you develop satisfying careers.

Employees have their eyes on remuneration as never before!

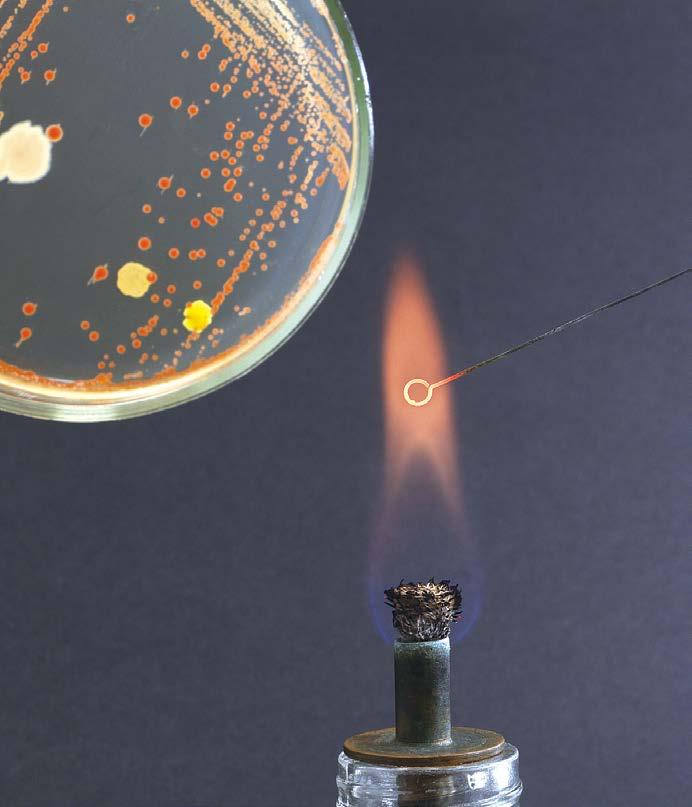

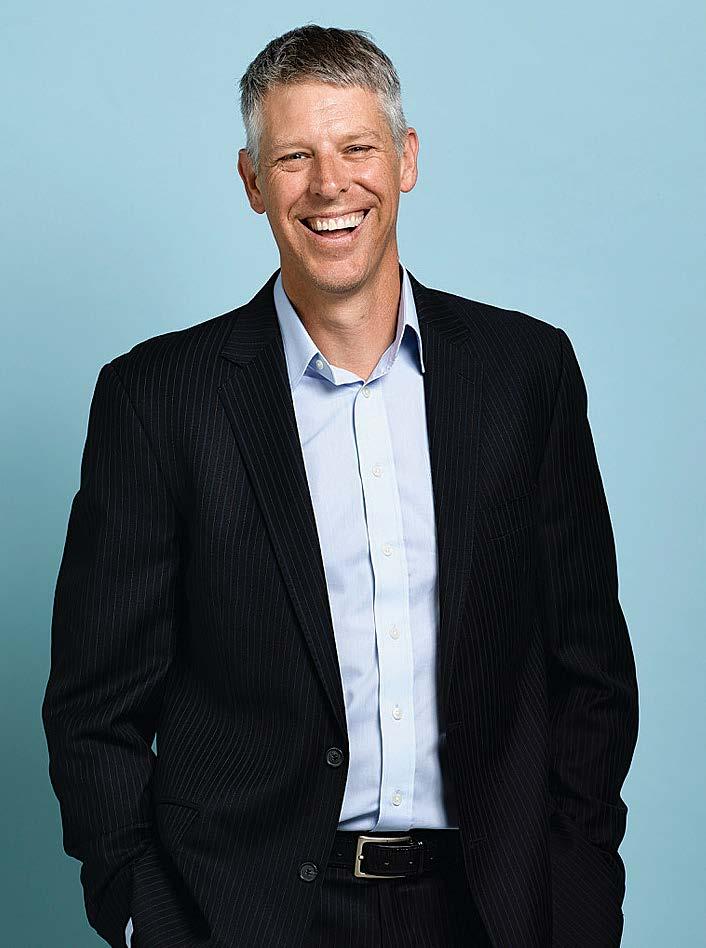

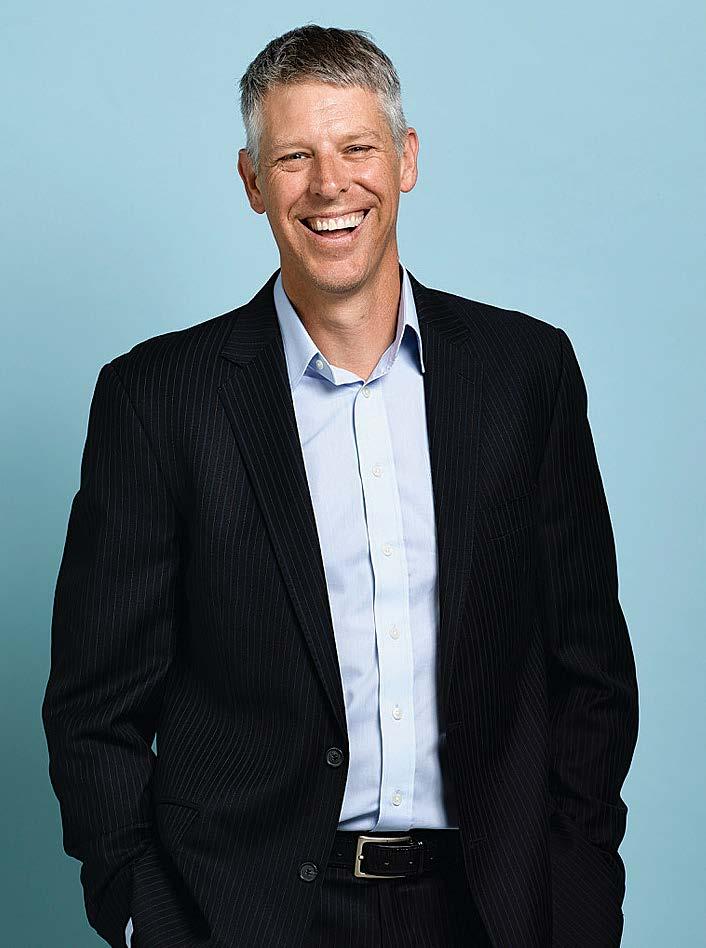

J C Andrews Address 2023: John D Brooks

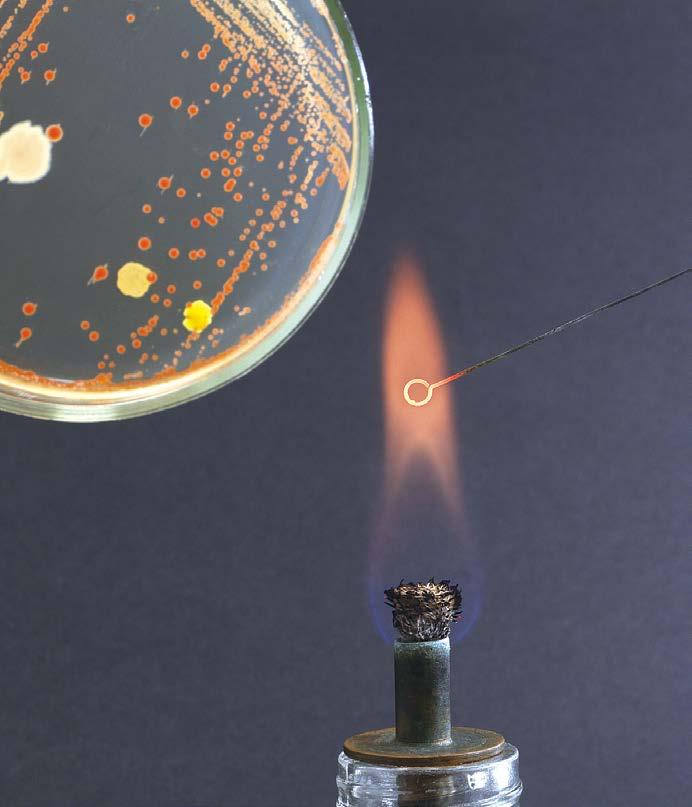

Keep flaming the loop

This award is in memory of Dr John Clark "Jack" Andrews who proposed the establishment of the Chair in Food Technology at the University of New Zealand in the 1960s. It is largely through him that we are all gathered here today.

I never met Jack, but I had tea with him every morning, as his portrait hung in the staff common room in the Riddett Building. It’s a great honour to be joining the previous recipients of this award. Dr. Garth Wallace was the first recipient – he helped me when I joined the Food Technology Department at Massey in 1977. Professor Mary Earle, who became my mentor, was also an awardee. “Come

on Brooks, get that PhD written.” Without her, I would never have completed the PhD write-up. My supervisor at Sydney University had abandoned five PhD students and I found it difficult to write up my work without supervision while writing lectures at Massey. When Wendy informed me of this award, she said the winner presents a keynote address on a topic of their choice at the NZIFST annual conference. Not an easy choice – Flying Gliders? Flying UAVs in Antarctica? Perhaps a lecture on food microbiology? Many of you will have already suffered my Food Micro lectures. Spoiler alert – you don’t get off scot-free. So, I’m going to pick out some aspects of my career – I have never worked in the food industry, but thinking back, it has always featured.

August / September 2023 15 J C Andrews

John Brooks, 2023 J C Andrews awardee, as many know him, seated at a microscope

Continuous change

First I’d like to discuss briefly the changes that have occurred in the food industry over the last 70 years. Initially, it was very simple, most production was exported. Now our food has a much greater variety, comes from many sources and the storage, packaging, transportation and distribution have become much more complex. Who would have thought that oats grown in New Zealand would be exported and processed into oak milk overseas and then imported back here? Even food produced and sold here is considerably more complex, and central distribution hubs mean that supply chains are longer. Our diet has changed – 70 years ago, meat might have been eaten three times a day, particularly in rural areas, but now much less meat is consumed and some of us rely largely on plant-based foods.

Consumer expectations have also changed dramatically – they want a wide variety of foods, either fresh or processed and, with perfect reason, they want the food to be safe. This has led to increased legislation and regulation, such as the requirement for HACCPbased food safety plans. This is a worldwide phenomenon. In some cases, it leads to strange consequences. In Arkansas farmers’ markets, you can buy Non-TCS Foods, defined as “food that does not require time or temperature control for safety to limit pathogenic microorganism growth or toxin production and as defined in the rules of the Department of Health”. “Uncut fresh fruits and vegetables” are explicitly named as falling under the non-TCS foods category. The rules named “Ready-to-eat foods” as foods that are covered under the non-TCS foods. “Any ready–to-eat food that is prepared on-site or any food that is provided to the consumer in a non-prepackaged form can only be sold or served from an ADH-permitted and inspected facility. Any establishment preparing, selling, or serving any of these food items must fully comply with the Arkansas Department of Health’s

Food New Zealand 16 J C Andrews

“Keep flaming the loop”, refers to one of earliest things a practical microbiologist learns. The inoculating loop is used to transfer microbial cultures from one medium to another. The loop is sterilised between transfers by passing it through a flame

Taking social distancing to extremes? In Antarctica in 2014

Rules and Regulations.” Therefore, a tomato is a non-TCS food, however, a cut tomato may be considered a ready-to-eat food, so if the seller shows traditional southern generosity and cuts the tomato and offers a taste to the consumer, they are in contravention of the regulations. A similar situation arose here some years ago with the shelling of walnuts in the orchard or under a simple shelter, which was required to comply with the rules for a processing facility. The requirements of our trading partners have also become more stringent.

Lately, gene editing, ‘lab-grown meat’, and insect consumption have become hot topics. I’m going to leave it there as these ideas potentially open up new cans of worms if you will.

Finally, I think that we need to take more notice of our food consumers. The questions I receive from readers of my food safety blog and my own observations suggest that many people still don’t understand how to avoid food poisoning, and we don’t teach young people the basics of food safety.

Connections

It occurred to me that my career was a reflection of James Burke’s TV series “Connections”. He demonstrated how various discoveries, scientific achievements, and historical world events were built from one another successively in an interconnected but unpredictable way to bring about particular aspects of modern technology. Of course, the inventor of an accurate escapement mechanism for a clock probably didn’t realise that this would lead to more precise ship navigation. Some of the material I was taught as an undergraduate seemed to

have no relevance for me, but 50 years later, I find myself applying it. I don’t believe in fate, but it does seem that stuff just comes together in unexpected ways.

Student days

My journey started at Queen Elizabeth College, University of London, with a so-called Special Microbiology Degree. The Head of Department was S. John Pirt and there were 24 undergraduates. There were courses in Physical Optics, Surface Chemistry, Organic and Inorganic Chemistry, Maths, Calculus, and Electronic Circuit Theory. Somewhere, there was one course on Introductory Microbiology, and two years later, one on food microbiology, which didn’t particularly impress me.

Pirt had been a microbiologist at Porton Down, a science and defence technology campus in England, and had written a seminal text, Principles of Microbe and Cell Cultivation. He introduced us to a controlled environment culture apparatus of his own design and we conducted an experiment to measure a growth curve and set up a steady state.

We attended Intercol, a short series of lectures at various London colleges, on thermophiles and their enzymes, Again, this became relevant only much later when we studied thermophiles in the New Zealand dairy industry.

John Norris, author of “Methods in Microbiology” from Shell Sittingbourne, Kent came in to give lectures and run practical classes, introducing the concept of Single Cell Protein (SCP). (Remember, this was in the 1960s.) He encouraged me to spend a summer holiday at Sandoz in Switzerland, working on tissue culture.

August / September 2023 17 J C Andrews

John’s happy place

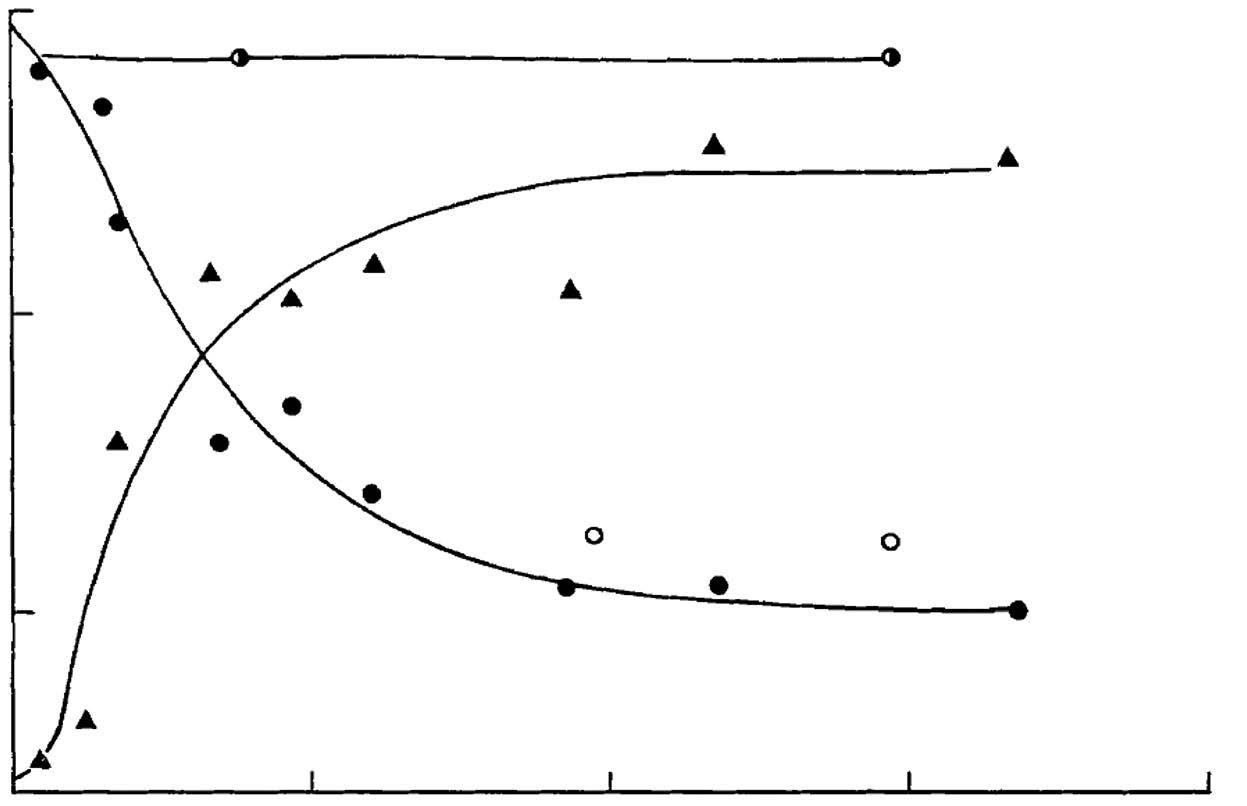

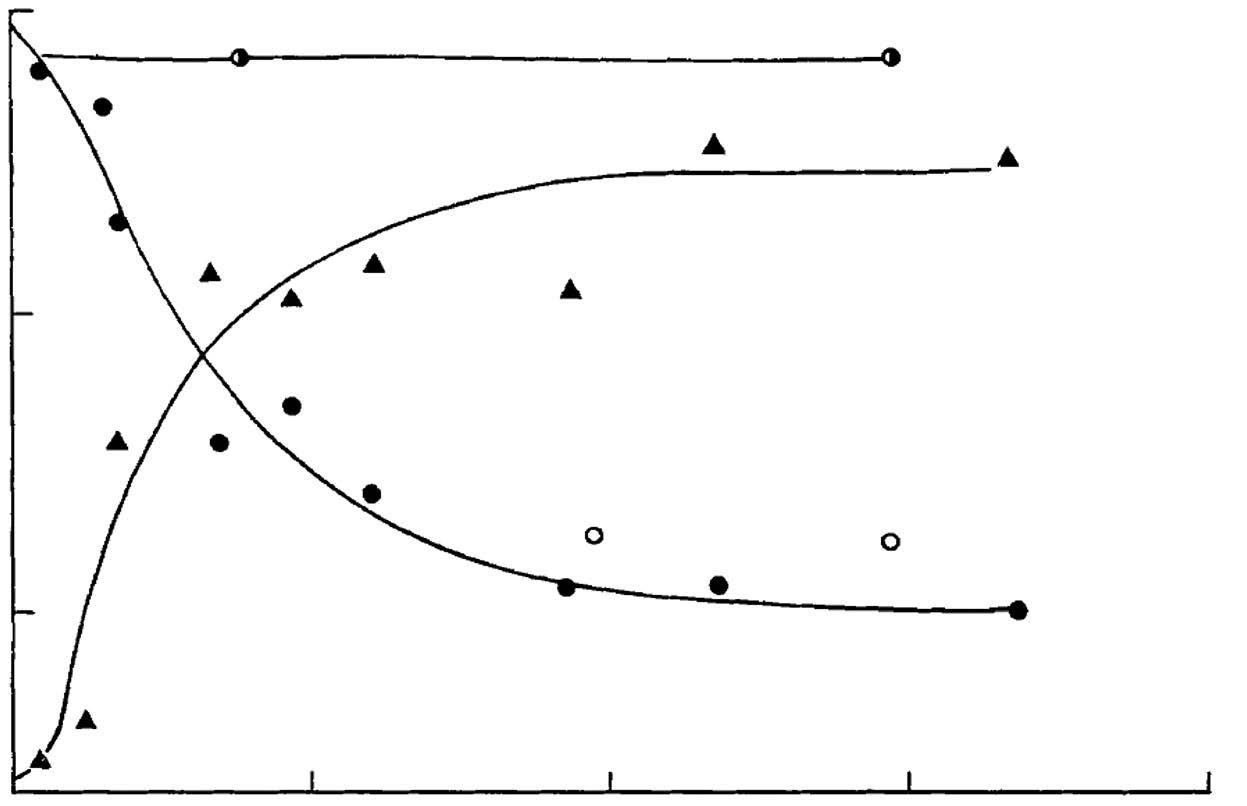

Discontinuous growth of a pseudomonad

Unexpectedly, the cells in the fermenter were alternately in carbon excess and then starved, over a period of 170 seconds.

Commercial SCP production

Immediately on graduation, encouraged by Pirt, (I don’t think he wanted me in his PhD student programme) I went to ICI to work on the SCP process. The initial substrate was methane, but that can be exciting, as it is explosive with oxygen, so methanol was substituted. ICI had ready access to methane and owned the low-pressure catalytic process to make methanol. Because of the huge energy requirements to stir a culture vessel capable of making 50,000 tonne/yr of SCP, it was decided to use an air-lift fermenter. Because of some concerns with the “pressure cycle fermenter”, I was tasked with modelling this device, so developed a modification of a lab fermenter. (The pressure in the culture fluid varied from 1 to 6.5 atm over the circulation period).

What we didn’t expect was that the cells would alternately be in carbon excess and then starved, over a period of 170 seconds. I found that with increasing cycle time, the cell yield dropped dramatically and carbon dioxide production increased proportionally. (See Fig. 1) I showed that this was caused by the energy-wasteful shuttling of glutamine and glutamate in an attempt to readjust their enzyme and key intermediate levels. The end result was that the process was modified by injection of methanol and air in the downcomer to prevent cyclic starvation.

A PhD in Sydney

After being told that I had reached my career maximum at age 24, I left ICI and went to Sydney to do a PhD, still working on C1

Food New Zealand 18 J C Andrews

0 50 100 150 200

Yield (g/g methanol) 0.45 0.40 0.35

time (s)

Fig. 1 The yeilds of bacteria (l) and carbon dioxide (s) when both methanol and nutrient salts were added intermittently to continuosly growing Pseudomonas mythylotropha

Cycle

The enormous ICI production fermenter being installed. The fermenter was 60m tall with a capacity of 3,000m3

metabolism, with a grant from ICI. I studied the determinants of yield and attempted to find a predictive measure. This turned out to be the number of electrons available for oxidation in the substrate molecule. I wanted to find the number of sites of oxidative phosphorylation in the cells and grew them on methanol, formaldehyde and formic acid, the sequence of oxidation in the cell. Thus, I have the dubious honour of being the first person in the world successfully to grow bacteria in steady-state on formaldehyde. The basis for this came from a study of Pirt’s book – in steady-state, the residual concentration of substrate is practically zero. This study can’t be done in shake flask culture.

…and on to New Zealand

After the PhD, I couldn’t get a job in Australia – nobody wanted a fermentation engineer at that time, and the prospect of making paper bags or canning kangaroos for pet food didn’t appeal. I applied for and got the job of Lecturer in Food Microbiology at Massey University. I arrived in New Zealand on a Wednesday and gave my first lecture on the following Tuesday. I was terrified. I had 13 students in my class and they were only six years younger than I.

I stayed there for 30 years and perhaps my greatest achievement was to teach food microbiology to 940 undergraduates and some hundreds of Dairy Diploma students. I get great satisfaction from seeing those graduates in senior positions in the New Zealand and overseas food industries. Later, I spent a year teaching at Hong Kong University, where I had 360 undergraduates, and eventually was appointed Professor of Food Microbiology at AUT, where I developed and taught a course “Frontiers of Food Microbiology to 180 postgraduates.

At Massey, I was greatly influenced by a paper by A.N. Sharpe “Germ of a New Food Microbiology” in which he claimed that the true tragedy of agar is that it stimulated the development of a whole science around a unique type of analysis – The Plate Count. By its nature, it provides data so unique that they can be related to no other analytical data than those from other plate counts. Problems include whether the bacteria clumped, how vigorously the dilutions are prepared, whether they are viable but non-culturable or sublethally injured and whether they can grow on selective media. I studied many different automated analytical techniques that could speed up analysis and potentially provide more information on the microbiological safety and stability of foods, predominantly based on activity, but to this day, our microbiological specifications for food are still given in terms of plate counts. The number of specific bacterial cells in the food at point of production takes no account of handling in the supermarket or home. Will the numbers increase to hazardous levels or will they produce toxins? What we really need is to be able to show whether the food will spoil or become hazardous to the consumer and this requires dose-response data. Of course, we have no simple laboratory method of determining viruses in foods.

The biofilm project

Another major event occurred when Steve Flint came into my office in 1996 and asked if I knew anyone who could supervise a PhD on biofilms. I suggested that we could learn together He was at that time employed by the Dairy Research Institute and this gave us access to the industry. We joined with Dr. Phil Bremer and spent about 15 years studying thermophilic biofilms in dairy plants.

Sitting in a meeting of people from NZ Dairy Board, I heard that

“Thermophilic bacilli do not form biofilms in milk evaporation and drying plant.” I didn’t believe this, as the residence time in the plant is too short for growth to occur in the flowing milk to the level seen in the finished powder. A calculation on the back of an airline ticket showed that thermophilic bacilli must form biofilms in the plant, growing and shedding both cells and spores into the flowing milk. Very quickly, we were able to show that vegetative cells and even spores can attach to 316 stainless steel in less than 60 seconds and become very difficult to remove fairly soon afterwards. Attachment is a multivariate process and depends on the suspending medium, the substrate's physical characteristics, whether it is clean or dirty, and the bacterial cells' surface. Lifschits-van der Waals forces, hydrogen bonds and electrostatic charge and the production of extracellular polymeric materials are all involved.

Steve and I were able to establish a biofilm research unit at Massey, with support from the “Plant Availability Project” of NZDB. We studied the attachment and growth of thermophiles and thermodurics and also the use of temperature cycling suggested by Geoff Knight in Australia. Our post-doctoral fellow, Shanthi Parkar studied cleaning methods specifically with respect to the materials of construction. We were ultimately able to work for a short time in a brand-new milk powder plant at Clandeboye and suggest minor modifications to the process.

Old microbiologists never stop working

Of course, all good things come to an end and I decided to retire. Initially, I panicked – “What am I going to do all day?” However, I have been a consultant to about 50 companies having problems with microbial contamination here and in Australia and I continue this work. Most recently, I went back to first principles (Thanks Pirt) to show that a shipment of frozen product to China must have been temperature-abused for 145 to 180 hours at one of two different temperatures prior to shipping. There is no software app that can do that. I am lucky to remain in contact with Steve Flint and am called upon to assess Food Technology student HACCP projects. Eventually, I began to wonder how I ever found time to go to work.

I guess old microbiologists never stop working, they just become more cultured.

August / September 2023 19 J C Andrews

Biofilm of Streptococcus on 316 stainless steel

Food New Zealand 20

August / September 2023 21

Foodtech Packtech 2023: Unveiling the Future of Food Innovation

Mark your calendars for Foodtech Packtech featuring the Materials Handling & Logistics Expo, the ultimate trade showcase for the food and beverage manufacturing and logistics industries. From packaging and food processing equipment to ingredients, food safety, and sustainability, this event promises to be a game-changer for your business. Held at the Auckland Showgrounds, the floorplan is almost full to capacity, making this the largest trade show for over a decade and an unmissable event for the entire industry.

A notable highlight is the return of international exhibitors for the first time since the pandemic, bringing with them cutting-edge technologies and advancements from around the globe. With over 225 exhibitors participating, attendees will have ample opportunities to explore new technologies and meet new suppliers. Industry giants like Vemag, Oji Fibre Solutions, Motion NZ, TNA, Heat & Control, Food Processing Equipment (FPE) and Mettler Toledo will be present, unveiling their latest breakthroughs, including meat processing equipment, food-grade hydraulic presses, flexible packaging options, food processing equipment and precision weighing instruments –and that's just the tip of the iceberg.

One of the most exciting features of this year's event is "The Pantry," a new food ingredients area. Developed based on valuable visitor feedback, it promises to be a unique experience that delves into the latest trends in the industry, including plant-based food ingredient alternatives. Exhibitors such as ICMD, Formula Foods, and Carmi Flavours will be on hand to showcase their innovations, while Reward Hospitality will create a sensory experience by using these ingredients in their onsite commercial kitchen, allowing attendees to see, taste, and smell the featured ingredients.

Beyond the exhibition of new technologies and products, the event aims to foster learning and collaboration among industry peers. The three jam-packed days of seminars will cover all categories represented at the show, providing an immersive platform for attendees to stay up-to-date with the latest advancements in food technology and to collaborate on solutions that will shape the future of the industry. The event offers an excellent opportunity for professionals to come together, network, and develop ideas that will future-proof their businesses. The presence of strategic partners further cements the

importance of innovation in the industry. Callaghan Innovation will be on hand to offer various services, including funding, research and development, and innovation expertise. The New Zealand Institute of Food Science and Technology will again host dedicated seminars, supporting the education and development of the food industry.

Packaging is a critical aspect of the food and manufacturing industries, and this event doesn't fall short in that regard. Exhibitors like Sealed Air, Prime Pac, Packtech Moulding and Forbes Packaging will display cutting-edge packaging solutions designed to enhance the shelf life of various food products. Add to this more automation and robotics on display than ever before. You are guaranteed to find something new! Foodtech Packtech featuring the Materials Handling & Logistics Expo is scheduled for 19-21 September at the Auckland Showgrounds. With the support of strategic partners and being the largest trade show in over a decade, it is an event not to be missed.

Attendance is entirely free. Register to attend for FREE at www. foodtechpacktech.co.nz or www.mhlexpo.co.nz

Food New Zealand 22 Exhibition

Formula Foods

Innovating natural flavours and ingredients at New Zealand's flavour house company. Formula Foods, the renowned Flavour House company based in Christchurch, continues to make waves in the food industry with their innovative offerings. From spice and herb oleoresins, natural antioxidants to spray-dried flavours, they have established themselves as a go-to supplier for natural, high-quality ingredients. In this article, we'll explore some of their latest developments and how they are meeting the changing demands of consumers.

Expanding expertise

With the recent acquisition of Scios Ltd, Formula Foods has expanded their expertise in the supply of base ingredients and client-specific blends. This move allows them to offer a comprehensive savoury range of natural oleoresin extracts and natural antioxidants, that provide consistent flavour, aroma, colour, and shelf-life enhancement for prepared foods and food ingredients. This acquisition further

solidifies Formula Foods' position as a leading player in the industry. Formula Foods is proud to announce the production of their range of spray-dried powder Flavours in Christchurch. These flavours are natural, high-quality ingredients that can be used in various applications. The advantage of local production allows for greater customisation, ensuring that clients can develop or adjust flavour profiles to meet their customers' evolving preferences, making them a popular choice among food manufacturers.

Introducing Eggxel

One of the company's standout ingredients is Eggxel, a colour-free powder that serves as an excellent part-replacement for eggs in bakery products. By combining milk proteins with eggs, Eggxel offers a cost-effective solution without compromising the finished product's quality. With its ability to bind water and improve shelf life, Eggxel presents an attractive option for bakers looking to reduce costs without sacrificing taste or texture.

Meeting consumer trends

Formula Foods understands the importance of staying ahead of consumer trends. To cater to the desire for unique and exciting flavours, they have developed a wide range of exotic options. Among their favourites are Yuzu, a citrus fruit known for its bitter taste and popularity in beverages; Blood Orange, a bittersweet citrus with raspberry undertones; Lychee, a sweet and delicate flavour often found in desserts and beverages and Taro, which offers a slightly nutty and earthy note, making it a versatile choice for both sweet and savoury dishes.

Formula Foods, New Zealand's Flavour House company, continues to make strides in the food industry with their innovative products. From their extensive range of spice and herb oleoresins and natural antioxidants to their customisable spray-dried powder Flavours, they are committed to meeting the demands of their clients and consumers alike. By staying attuned to market trends and developing unique flavour profiles, Formula Foods remains at the forefront of providing natural, high-quality ingredients to the ever-evolving food industry. See them at Stand 150, The Pantry Food Ingredients Feature

TNA New Zealand

Visitors to stand 3102 at FoodTech PackTech 2023 will have the opportunity to experience the pioneering tna robag® 3e and the tna intelli-flav® OMS 5.1 first hand, as well as to speak with local experts directly about TNA’s customer-centric approach to complete line solutions and how the company is leveraging the very latest VR capabilities.

From potato chips, nuts and seeds and pretzels, to meat based snacks, popcorn and ethnic/traditional products, our experts will be on hand to walk visitors through the process of creating tailor made solutions to individual challenges, and to offer live demonstrations of the latest technical innovations for the snacks market.

The ‘Perfect Pair’ adds significant value to complete integrated lines. This powerful combination features the tna robag® 3e – a high-speed vertical form fill and seal (VFFS) packaging system capable of reaching

Food New Zealand 24 FTPT

speeds of up to 250 bags per minute, along with the tna auto-splice 3, which seamlessly splices packaging film without interrupting the packaging process, maximising throughput and enabling faster and smoother film changeovers. These advances in packaging technology help manufacturers to optimise resource usage, simplify servicing, improve diagnostics and achieve operational efficiencies, resulting in more efficient and sustainable packaging operations.

The tna intelli-flav® OMS 5.1 is the next-generation on-machine seasoning (OMS) system that provides both powder flavouring and liquid oil in a single drum. It ensures consistent and precise seasoning coverage for a variety of snacks, including fried, puffed, and baked products. The system utilises a mass-based gravimetric spraying and dry seasoning control method, weighing the raw materials to apply the exact amount of seasoning or oil required based on a preprogrammed recipe.

TNA provides comprehensive, complete-line solutions designed for the highest output, minimal downtime and reduced total cost of ownership. TNA’s extensive offer covers every aspect of food processing and packaging

FTPT

The pioneering tna robag® 3e

Look out for the

Energy efficient food processing solutions

HRS Heat Exchangers, Stand 2110

HRS Heat Exchangers is set to showcase its market-leading food processing solutions, designed to help manufacturers improve energy efficiency and reduce operating costs, at this year’s Foodtech Packtech. Part of the global EIL Group, HRS Heat Exchangers has more than four decades of experience, helping businesses to reduce energy consumption in all areas of food production such as pasteurisation and sterilisation. Today, as manufacturers continue to face the dual challenge of high energy costs and the need to reduce carbon, it is essential for every business to examine the equipment it uses and identify where immediate savings and longer-term efficiencies can be made.

Chris Little, managing director, HRS Australia & New Zealand said: “Delivering unparalleled energy efficiency, HRS Heat Exchangers solutions provide the shortest possible payback period and rapid return on investment.”

“A difference of 5-10% in thermal efficiency, for instance, will quickly translate into direct savings in energy and operating costs while rising wholesale energy prices could see the payback period reduced further still.

to learn more about their products for the food and drink industry

“HRS equipment includes hygienic corrugated tube and scrapedsurface heat exchanger designs which are ideally suited to highly viscous products, improving heat transfer and operational efficiency. At the same time, options such as heat regeneration provide the highest levels of energy efficiency which cuts costs and reduces carbon. Features such as remote monitoring and telemetry are standard.” Offering stand-alone solutions or complete packaged systems, HRS produces a wide range of equipment as well as bespoke systems, including:

• Corrugated tube and scraped surface heat exchangers

• Pasteurisers and sterilisers

• In-Place Cleaning systems (CIP & SIP)

• Aseptic fillers

• Direct steam injection sterilisers

• Concentration and evaporation systems

• Ice crushers and melters

• Hydraulic piston pumps

• Air removal (deaeration) systems

Food New Zealand 26 FTPT

distinctive orange shoes worn by the HRS team,

Specific solutions for products and packaging

You will find them at Wadding Solutions

When searching for the right packaging components, it always helps to have a solid understanding of your options. This is especially true with closure liners, where their performance is key to preventing leakage and loss of product quality. It can be a challenge to navigate their differences and design details, but at Wadding Solutions our packaging experts will guide you and find the right solutions for your products.

There are many different types of closure liners, along with various types of caps that utilise them. Closure linings are there to provide a hermetic seal, demonstrate product integrity through the use of a tamper-evident seal, and prevent leakage.

We recommend talking through your product’s need for a seal, we also encourage customers to trial and validate various lining options with their products and packaging. At Wadding Solutions we can assist you with testing your products in our food grade certified facility. We have a vast tooling library and range of sealing equipment.

Overall, closure lining enhances product integrity, ensures consumer safety, and presents an opportunity for companies to deliver a higher quality, more reliable product experience.

Our friendly team is here ready to assist you, whether you need help with your packaging design, specific requests or simply want to learn

more about the services our business can offer, reaching out to us is an excellent next step. We are committed to providing exceptional customer service so your enquiry and feedback are invaluable to us.

FTPT

Wadding Solutions supplies specific solutions for products and packaging

Cuddon Freeze Dry’s new ‘green’ commercial conductive batch freeze dryer

Cuddon Freeze Dry

Cuddon Freeze Dry are delighted to announce the launch of our new ‘green’ range of commercial conductive batch freeze dryers. Designed with reduced whole of life costs and reduced environmental footprint from the outset, we are incredibly proud to be leading the field in this technology.

With the global movement to replace synthetic refrigerant gases with more environmentally acceptable alternates (driven by the Montreal Protocol and updated by the Paris Agreement 2015), the new range of Cuddon freeze dryers has been specifically

designed, built and optimized for CO2 refrigerant; there is no compromise on performance often associated with dropin alternate refrigerants. The range matches or exceeds the performance of the previous Cuddon R507 general purpose freeze dryers.

We will also be offering a retro-fit package to enable our current clients to switch to CO2 refrigerant. Released earlier this year, there are 3 options: from a simple switch out of refrigeration machinery through to a full upgrade to the higher capacity shelf area, ice coil and CO2 refrigerant.

Food New Zealand 28 FTPT

AIP events at FTPT

AIP will offer a packaging forum and a training course alongside Foodtech PackTech 2023.

After an extended hiatus due to the pandemic, the AIP will be back in person hosting an extensive range of educational programmes alongside FoodTech PackTech 2023. The AIP educational offerings include a full day of Packaging Sessions, a training course and an AIP stand where you can visit the education team.

Packaging Forum – 19th September

Upstairs seminar room, 10.30 am to 4.30 pm

The sessions will be designed as panel discussions covering a broad range of topics including packaging targets, waste directives, Sustainable & Circular packaging innovations and designs, incorporating recycled content into packaging, the future of soft plastics and flexible packaging, how to embed the 10 Sustainable Packaging Design Principles into your business, the role that packaging plays in minimising food waste, the future of fibre and renewable materials, the important role that the Australasian Recycling Labelling programme plays across ANZ and updates for ANZPAC. The speakers will also include a number of NZ winners of the ANZ PIDA Awards and the WorldStar Packaging Awards. Just some of the speakers confirmed this far…

• Lyn Mayes, Sustainability Lead, NZ Food & Grocery Council

• Liz Butcher, Manager Waste Streams Policy, Ministry for the Environment New Zealand

• Nerida Kelton FAIP, Executive Director – AIP, VP Sustainability & Save Food WPO

• Nikki Withington MAIP, NZ Co-ordinator – ARL & the ANZPAC Plastics Pact, APCO

• Kitty Sandoval MAIP, Senior Packaging Manager, Frucor Suntory Oceania

• Sarah Yanez MAIP, CPP, Director, Totally Wrapt Packaging

• Huzaifa Mohsinally MAIP, Packaging Manager, Goodman Fielder New Zealand

• Ben McCulloch AAIP, Product Manager (rPET), Martogg

• Deanne Holdsworth, General Manager Sales, Pact Packaging NZ, Pact Group

• Alan Adams MAIP, Sustainability Director APAC, SEE

• Joe Foster FAIP, Chief Executive Officer, Close the Loop Group

• Vikas Ahuja, Sustainability Director, Tetra Pak

• Barbara Nebel, Chief Executive Officer, thinkstep-anz

• Chris Thomas, Divisional Manager Packaging, BJ Ball NZ Ltd

• Apoorv Mehrotra AAIP, Business Development Manager, Oji Fibre Solutions