Official magazine of the 2020 International Congress of Food Science and Technology F ebruary /M arch 2020

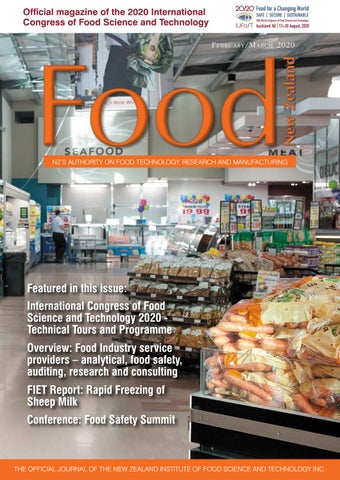

NZ’s Authority on Food Technology, Research and Manufacturing

Featured in this issue: International Congress of Food Science and Technology 2020 Technical Tours and Programme Overview: Food Industry service providers – analytical, food safety, auditing, research and consulting FIET Report: Rapid Freezing of Sheep Milk Conference: Food Safety Summit

The official Journal of The New zealand institute of food science and technology inc.