PORTFOLIO

HELLO! I’M ANNA CHIARA

ABOUT ME

I’m a design student, currently enrolled in the second year of a Master of Science in Product and Service Design. When I applied for the first year of my Bachelor’s degree in Design my idea was to arrange the spaces and furnish the environments in which man lives. Eventually I discoverd through my studies and personal insights that design is all around us and I’m willind to start my career as a designer.

INTERESTS

LANGUAGES

English: written and spoken, C1

Spanish: written and spoken, B2

French: written and spoken, B1

SOFTWARE SKILLS

RACKS URBAN MOBILITY

ABOUT THE PROJECT

How to integrate a bike rack into the city environment?

The Urban Sustainable Mobility Plan of Rome (PUMS) is a strategic plan aimed at encouraging the movement of people and goods in a perspective of widespread sustainability. Urban mobility and micromobility require tools as parking spots that facilitate movement for people and integrate with the urban context.

CONCEPT

Preliminry studies and sketches helped develop the final project. The bike rack should indeed secure the frame, save city space being the leanest possible and be a serial system. The result is a single piece rack made of a Cor-Ten steel slab. The rack also has spacers from the ground to ensure stability even if placed on uneven ground.

MATERIAL AND MANIFACTURING

Cor-Ten steel is a weather resistant steel which could more accurately be termed as an “Atmospheric Corrosion Resistant Steel”. The protective layer of Cor-Ten constantly develops and regenerates over time, reacting to the pollutants in the atmosphere. The benefits of a self–protecting steel are that it is economic, long lasting and easily recyclable. Some material’s properties incude:

WEATHER RESISTANCE

WELDABILITY

WORKABILITY

APPEARENCE

RECYCLABILITY

To produce this kind of bike rack there are only three steps required, namely cutting the bar, bending and laser cutting for the holes that will host the spacers.This means that the solution is efficent in terms of production and does not require high production costs non encreasing the overall cost.

CONNECTION TO THE GROUND

The bike rack is secured to the groung through anchor bolts which are embedded to the ground and trough spacers that separate the structure from the ground. This helps the structure to be more stable also when placed on uneven grounds.

DEVELOPMENT

DEVELOPMENT

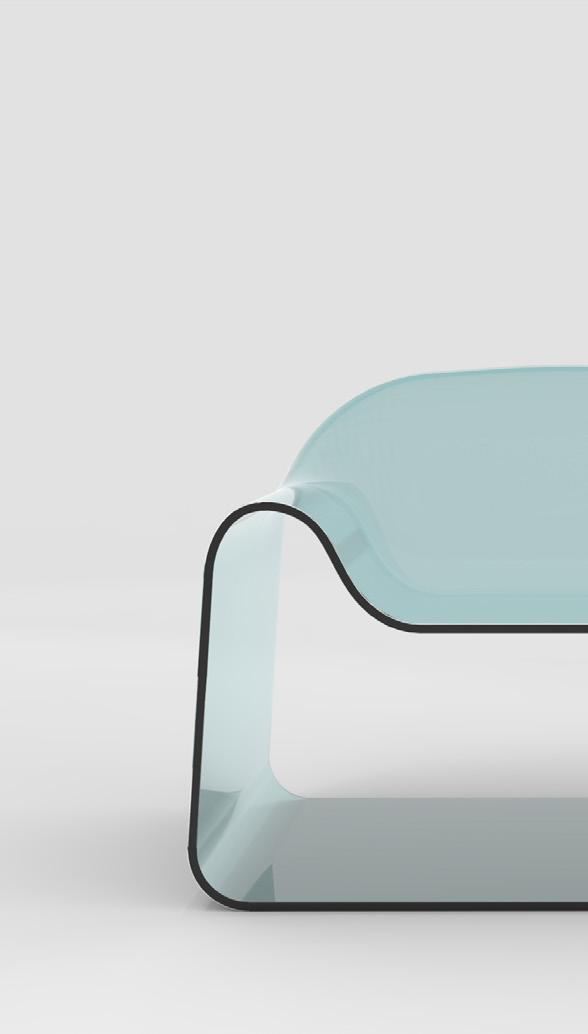

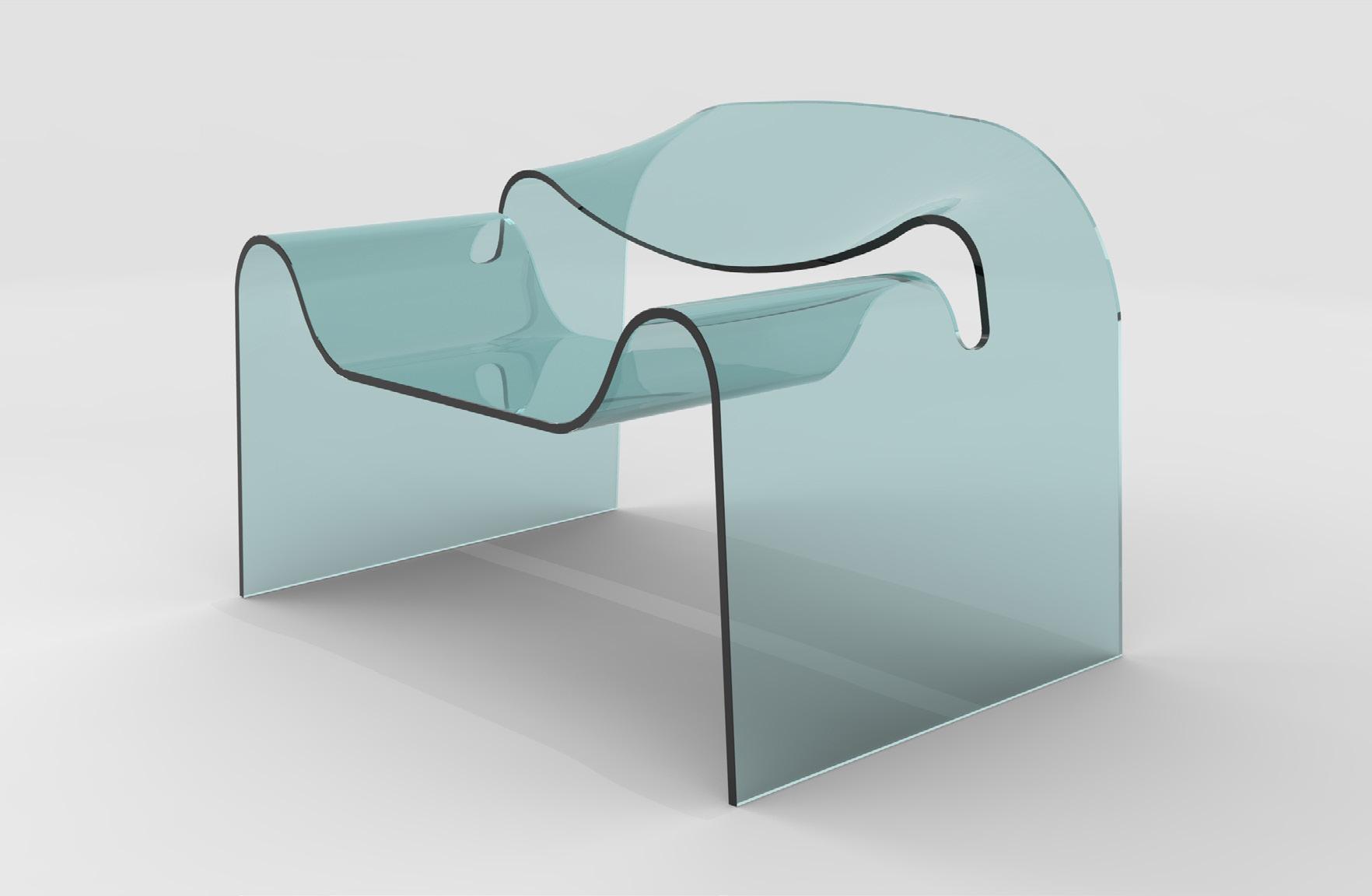

GHOST CHAIR A RE-EDITION

ABOUT THE PROJECT

Is it possible to give a new look to the iconic Ghost Chair?

This project investigates how, by utilizing 3D modeling software and combining different commands or changing their order, it is possible to alter and give a new appearance to an iconic Ghost Chair designed by Cini Boeri. The Product was first reproduced using modeling software, and then studied to identify where it would be possible to intervene to change its look without drastically altering its aesthetic through simple commands.

SINGLE PROJECT

DEVELOPMENT

DEVELOPMENT

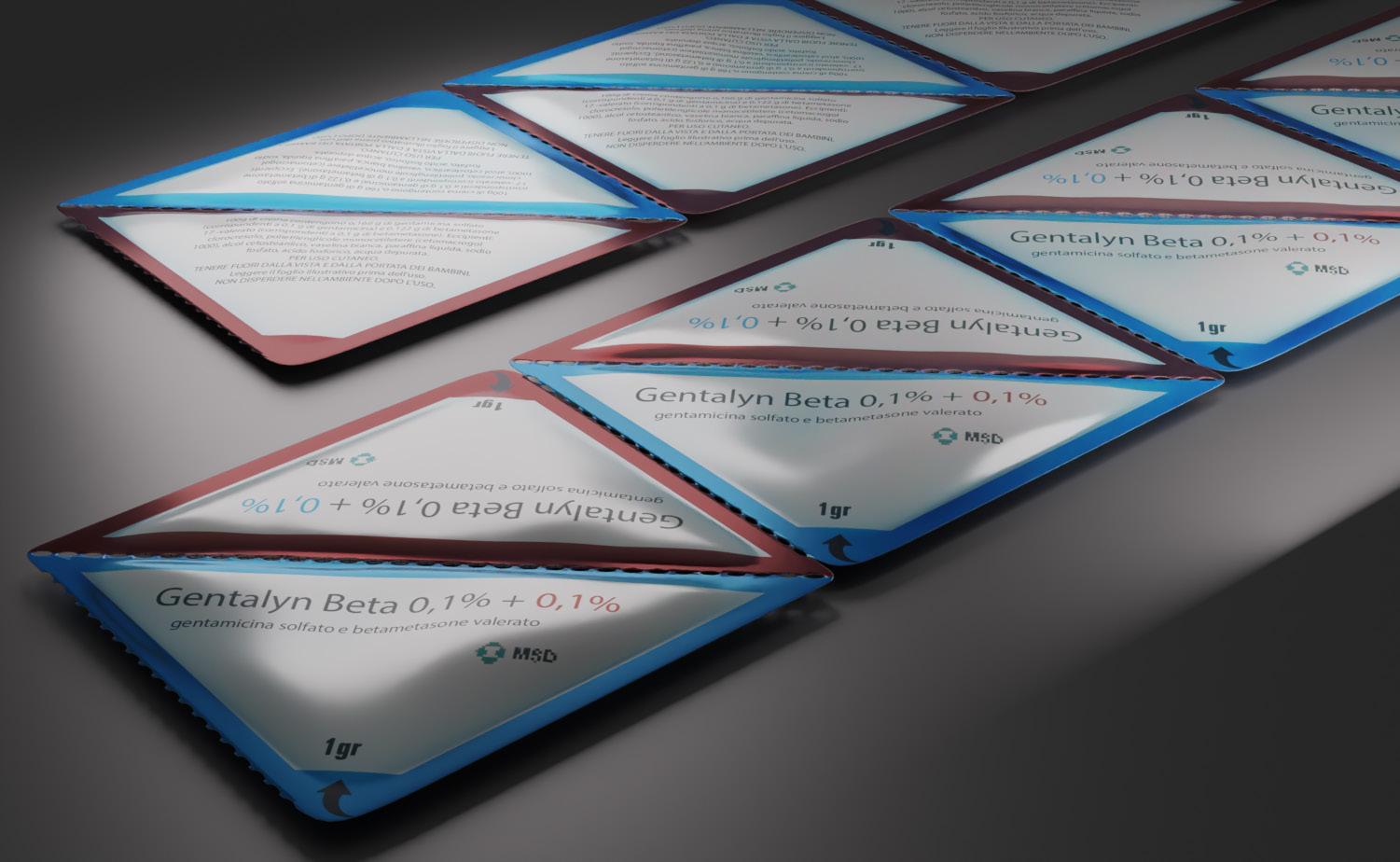

TOPICAL ANTIBIOTICS

ABOUT THE PROJECT

Can a pharmaceutical packaging solve a social issue?

The misuse or overuse of topical antibiotics in dermatology is one of the causes leading to the phenomenon of Antimicrobial Resistance (AMR).

AMR occours when bacteria, viruses or fungi no longer respond to the antimicrobial medicines, becoming ineffective. As a result, some infections may be difficult to treat, or even impossible, causing a real global emergency.

GROUP PROJECT

2023

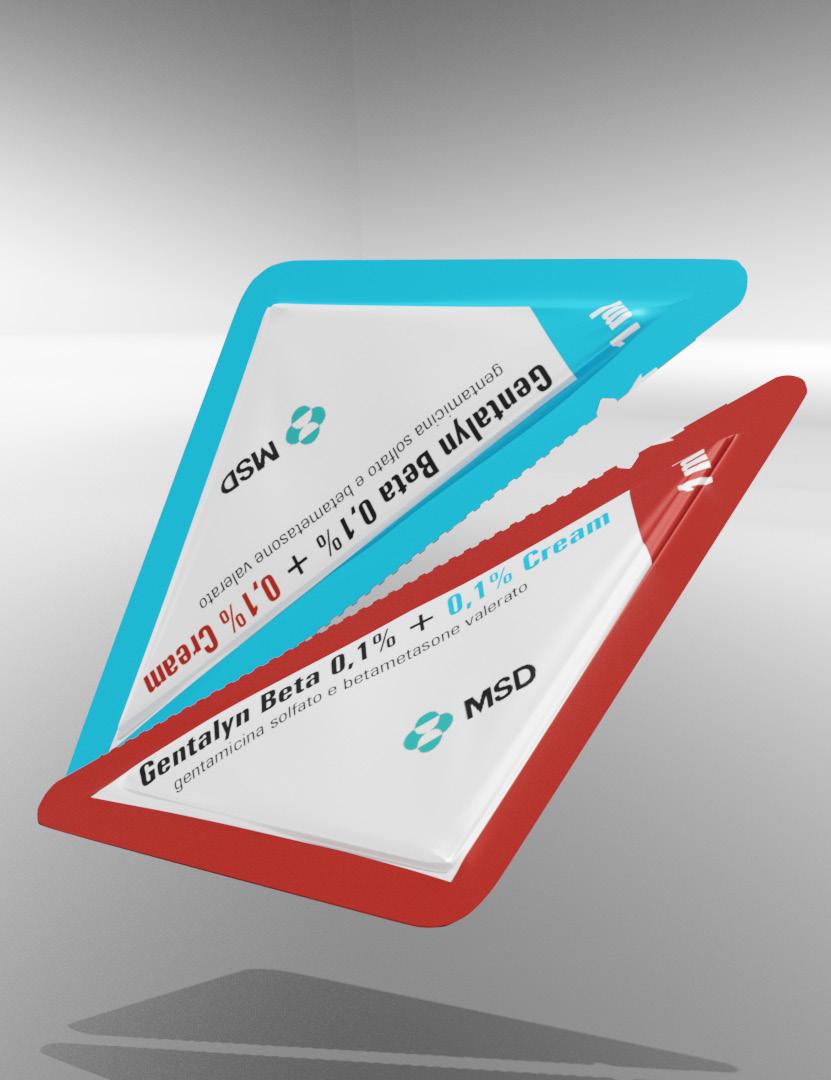

CONCEPT

The packaging primarily serves three functions: protecting the contents from external agents, containing the product, and communicating to the user how to use it properly. Especially in the pharmaceutical field, it is important to ensure that the internal product is not damaged and to guarantee user safety. To solve the problem, therefore, the shape of the packaging should suggest to the user how to use it, with the aim of better understanding the most suitable use of the medication as well.

REQUIREMENTS:

1) WASTE REDUCTION. Due to fast expiration once opened

2) INFORM ABOUT THE CORRECT DOSAGE. Twice per day is correct

3) LIMIT USE. Overtime and for single use

DEVELOPMENT

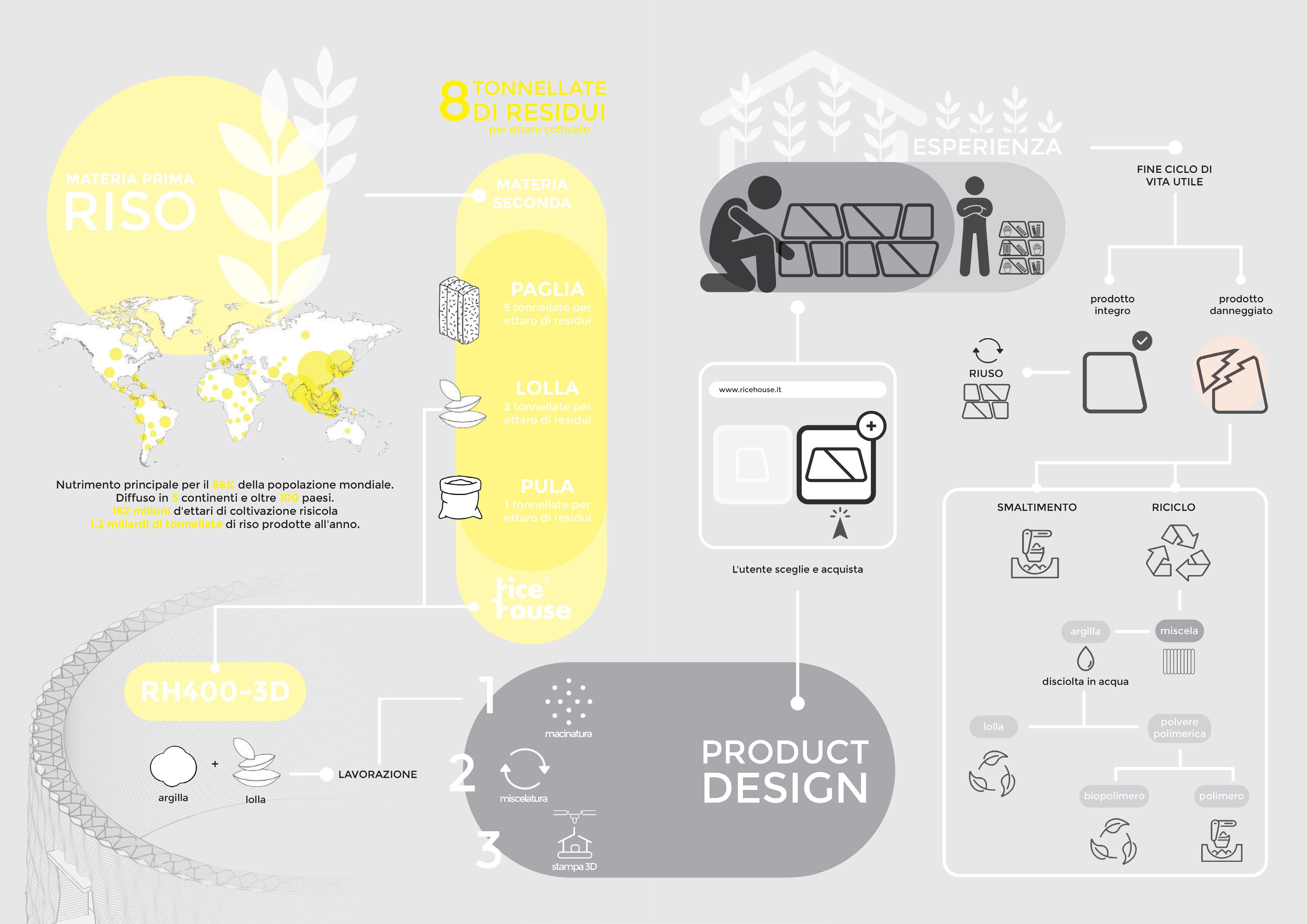

RICE BLOCKS

ABOUT THE PROJECT

Construction material from architecture to design

The thesis investigates the possibility of expanding the potential applications of the clay and rice hull-based 3D printer mixture produced by the Italian company Ricehouse, in order to broaden the material’s value chain.

INDIVIDUAL THESIS PROJECT

2023

CONCEPT

The interior space of homes today is more flexible than ever, much like people’s lives, adaptable to the context and changes that occur. Choosing to design within the parameters of modular design, thus allowing the user to proceed with non-binding partial additions in furnishing their space, is what best suits the need for adaptability that postmodern life requires. Visibility and impact are the desirable effects one aims to achieve to give relevance to the material and its texture, also leveraging its characteristics.

MATERIAL AND MANIFACTURING

The material, RH-400 3D has been specifically developed to withstand the load of the upper layers during the printing and laying phases to allow its use in digital manufacturing. The components, clay and rice husk, provide the material with moisture regulation properties and thermal and acoustic insulation due to its porosity. Following is a table with additional data:

Resistance to water vapour diffusion µ 5,9

Mechanical compressive strength class CSI

Apparent density of the dry mortar 950 kg/m³

Rection to fire A1

Granulometry from 0 to 3 mm

The design must take into account that the manufacturing process occurs through additive 3D printing, depositing the mixture layer by layer.

DEVELOPMENT

BIOMATERIAL MADE WITH PEANUTS SHELLS

ABOUT THE PROJECT

Is it possible to create a biomaterial from waste?

This project investigates how ustilising residual peanut biomass not only offers an inventive substitute for conventional materials but also addresses agricultural waste challenges, contributing to circular economy and mitigating environmental impact.

GROUP PROJECT 2024

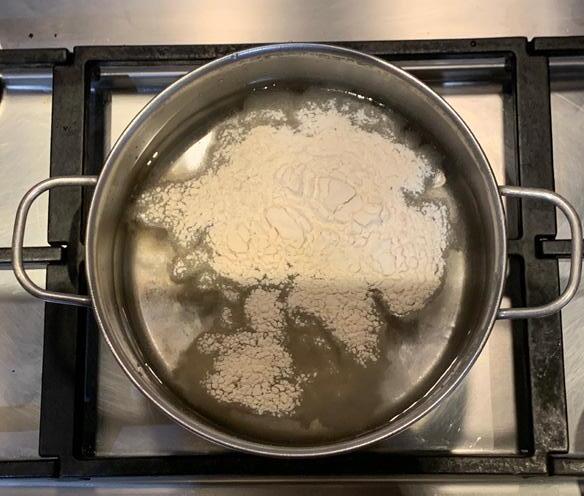

RESEARCH AND PROCESS

At the European level, the biomaterials sector is prioritized, and according to estimates from the European Commission, bio-based products and biofuels generate annual revenues of approximately 57 billion euros and employ 300,000 workers. Investments in this area offer promising prospects for improving climate and environmental conditions, motivating numerous professionals to engage in research.

The material under examination and subject of study can be defined as a particle-reinforced biocomposite, specifically using peanut shell powder. Peanuts are a variety of legumes cultivated for the production of edible oily seeds, making them the sixth most important crop in the world. According to a statement released in March 2023 by the United States Department of Agriculture (USDA) on global agricultural production, the United States estimates that 29.63 million hectares of global land area are dedicated to peanut cultivation, with a total production of 50.11 million metric tons annually, generating a byproduct of 11 million metric tons annually.

RESULT

The material obtained is comparable to cork due to its lightweight, opacity, and porosity. By smoothing the material’s surface, a soft and pleasant tactile finish can be achieved, reminiscent of suede or leather. The material is resistant yet flexible and can undergo slight bending without breaking or creating cracks. Among other properties, it has sound-absorbing capabilities due to its porous structure, does not propagate flames when exposed to heat, and electrically insulates due to its woody component. In conclusion, a material comparable to Medium Density Fibreboard (MDF) panels for soundproofing is obtained, derived from wood fibers, making it suitable for applications such as wall cladding or standalone sound-absorbing panels.