ENVIRONMENTAL/ECOLOGICAL: ENERGY/HEATING/COOLING/AQUAPONIC SYSTEM

MCDONALD, JENSEN, THOMPSON | REWE+EC

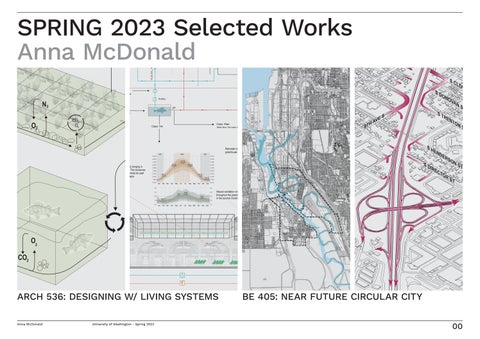

This project features a sustainable building-integrated aquaponic system that exchanges 100 percent green electricty, rainwater collected on the rooftops, fresh produce/fish and their byproducts. The marketplace and atrium is a climate-controlled volume that uses intelligent cooling and heating technology with the stored energy from photovolatic solar panels. The rooftop greenhouse volume uses natural ventilation during the summer months. During the night and winter months stored energy is used for LED lighting for growing plants. This circular system reduces the overall use of rain water and electricity.

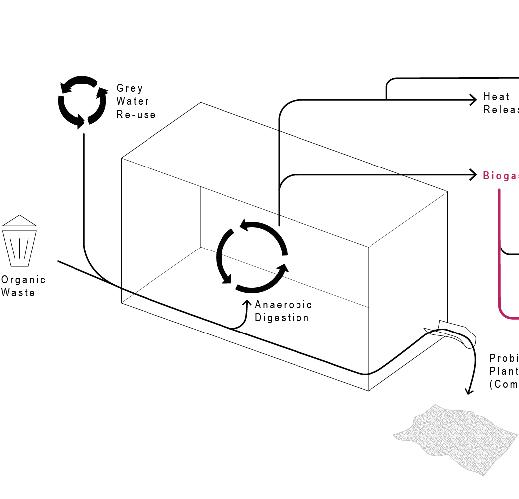

Biodigester

Chomp HORSE AD25 Series

Footprint: 160 sq ft

Biowaste Input: 960 – 6,700 lbs/week

Liquid Plant Food produced: 100 – 730 gallons/wk

Max energy production: 15,000 - 105,000 BTU/hr

Organic Waste

Heat Released

Anaerobic Digestion Process

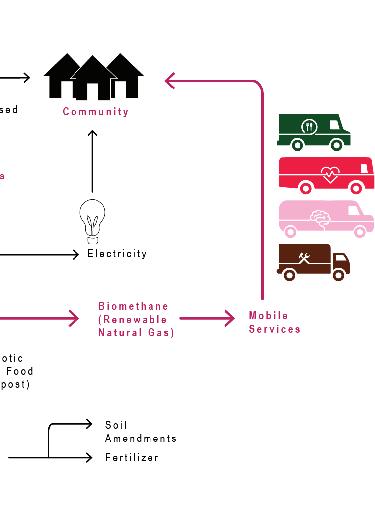

BIO-DIGESTOR & AQUAPONIC SYSTEMS

JENSEN, MCDONALD, THOMPSON | OPTIMIZING AQUAPONICS

An aquaponic system produces significant amounts of sludge that could potentially be used and optimized by a bio-digestor. Sludge from the aquaponics can be used along with organic waste. Bio-gas and compost are produced and used for electricity and growing new produce. A circular system is created, supplying the community with clean energy and fresh produce.

Chomp Nautilus: Vashon Island

Footprint: 620 6,400 sq ft

Biowaste Input: 1,000 - 8,200 lbs/day

Liquid Plant Food produced: 815 - 6,600 gallons/wk

Max energy production: 111,000 - 910,000 BTU/hr

Anaerobic Digestion Process

Complex Organic Matter (carbs, pro tein, fats)

1

Hydrolosis Acidogenisis Acedogenisis Methanogenisis

Organic Molecules (sugars,amino acids, fatty acids)

Volatile Fatty Acids Community Electricity Biogas

Acetic Acids

Chomp HORSE AD25 Series

Footprint: 160 sq ft

Biowaste Input: 960 – 6,700 lbs/week

Liquid Plant Food produced: 100 – 730 gallons/wk

Max energy production: 15,000 - 105,000 BTU/hr

BIO-DIGESTOR & AQUAPONIC SYSTEMS

JENSEN, MCDONALD, THOMPSON | OPTIMIZING AQUAPONICS

An aquaponic system produces significant amounts of sludge that could potentially be used and optimized by a bio-digestor. Sludge from the aquaponics can be used along with organic waste. Bio-gas and compost are produced and used for electricity and growing new produce. A circular system is created, supplying the community with clean energy and fresh produce.

Probiotic Plant Food: Vashon Island

BIO-DIGESTOR & AQUAPONIC SYSTEMS

JENSEN, MCDONALD, THOMPSON | OPTIMIZING AQUAPONICS

An aquaponic system produces significant amounts of sludge that could potentially be used and optimized by a bio-digestor. Sludge from the aquaponics can be used along with organic waste. Bio-gas and compost are produced and used for electricity and growing new produce. A circular system is created, supplying the community with clean energy and fresh produce.

Chomp Nautilus: Vashon Island

Footprint: 620 - 6,400 sq ft

Biowaste Input: 1,000 - 8,200 lbs/day

Liquid Plant Food produced: 815 - 6,600 gallons/wk

Max energy production: 111,000 - 910,000 BTU/hr

Probiotic Plant Food: Vashon Island

ECONOMIC MODEL

ECONOMIC MODEL

Cost Savings for Aquaponic Farms Using

Cost Savings for Aquaponic Farms Using

In general, for the financial side of the aquaponics about the economic advantageousness of cent of aquaponic operations make less than Waste Savings for aquaponic Cost Structure Hydroculture

In general, for the financial side of the aquaponics about the economic advantageousness of cent of aquaponic operations make less than teer labor. By using an anaerobic digester, Waste Savings for aquaponic Cost Structure Hydroculture

Environmental: Green Hause

Ecological: Farming

REWE+EC: OVERVIEW OF BUILDING INTEGRATION

MCDONALD, JENSEN, THOMPSON | REWE+EC

Summer Solstice

Rainwater collects in crevases of greenhouse roof

Winter Solstice

Photovoltaic panels collect sunlight and operable windows allow for ventilation

A central atrium juts out, bringing in lots of natural daylight. This conserves energy that would otherwise be used on lighting the marketplace

Natural ventilation circulates throughout the greenhouse volumes in the summer months

ENVIRONMENTAL/ECOLOGICAL: ENERGY/HEATING/COOLING/AQUAPONIC SYSTEM

MCDONALD, JENSEN, THOMPSON | REWE+EC

The REWE green farming market is designed as a marketplace typology, emphasizing sustainable construction and on-site farming practices. As the pilot store in a planned series of stores, this market showcases adaptability in size and layout to its local site and is comprised of three elements (1) a ground floor marketplace, filled with regional produce and produce grown on-site; (2) simple and sustainable timber construction and energy use design; (3) produce grown in rooftop greenhouses using aquaponic systems. STAGE 1: Planting

This project features a sustainable building-integrated aquaponic system that exchanges 100 percent green electricty, rainwater collected on the rooftops, fresh produce/fish and their byproducts. The marketplace and atrium is a climate-controlled volume that uses intelligent cooling and heating technology with the stored energy from photovolatic solar panels. The rooftop greenhouse volume uses natural ventilation during the summer months. During the night and winter months stored energy is used for LED lighting for growing plants. This circular system reduces the overall use of rain water and electricity.

CONSTRUCTION/BUILDING INTEGRATION: MODULAR MASS TIMBER CONSTRUCTION

MCDONALD, JENSEN, THOMPSON | REWE + EC

The building construction consists of an important timber element, which is part of REWE’s future market strategy. The column itself consists of 12 layers. The elements are designed to be recognizable and easily built, with a simple timber construction that are scalable for all future REWE markets. The timber elements consist of locally produced wood and can be assembled with few screws. The stacked timber construction is designed to be modular, from market to market. The Construction function is a unifying element for all REWE markets. The building below the timber roof is supposed to house the specific REWE markets context.

ECONOMIC: MARKETPLACE TYPOLOGY

MCDONALD, JENSEN, THOMPSON | REWE + EC Regional

The REWE Green Farming Market is a protoype for a ”new adaptable and sustainable market concept, able to fit any site typology”. The long-term goal of the market chain is to connect shoppers to local produce and products in every market, including produce and fish grown on site and products from local farms. On a regional scale, branches will increase the variety of local produce offered by sharing rooftop-grown produce with each other. This strategy creates a series of regional zones: closed-loop networks that bring this movement to a national scale.

Anna McDonald

University of Washington - Spring 2023

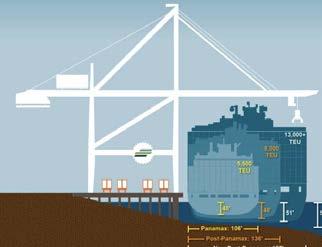

West Waterway Authorized Depth 34 Ft

East Waterway North End Authorized Depth 51 Ft

East Waterway South End Authorized Depth 34 Ft

LDW Reach 1 River Mile 0 to First Ave South Bridge Authorized Depth 30 Ft

First Ave South Bridge to Fourteen Ave South Bridge Authorized Depth 20 Ft

LDW Reach 3 Fourteenth Ave South Bridge to Turning Basin 3 Authorized Depth 15 Ft

East & West Waterway Dredge Depths and Ship Seattle District, U.S. Army Corps of Engineers. Accessed April 14, 2023. https://www.nws.usace.army.mil/.

Duwamish Waterway Allowable Ship Sizes Over Time Seattle District, U.S. Army Corps of Engineers. Accessed April 14, 2023. https://www.nws.usace.army. mil/.

Canal Dredged Chanel (Trench) Shallow Water

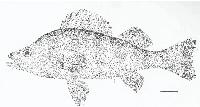

HISTORY, PRESENT, AND FUTURE OF THE DUWAMISH RIVER

DREDGING AND MAINTENANCE OF WATERWAY

In the early 1900s, the lower (northern) section of the river was straightened and dredged for industrial development. By the 1940s, channelization had transformed a 9-mile estuary into the 5-mile Lower Duwamish Waterway (LDW). Some of the dredged material was used to create Harbor Island and some was used to fill in parts of the old channel in Georgetown. Since 1916, the LDW has been regularly dredged by the US Army Corps of Engineers to support ship navigation.

“Site History Washington State Department of Ecology.” Accessed April 7, 2023. https://ecology.wa.gov/Spills-Cleanup/Contamination-cleanup/Cleanup-sites/Lower-Duwamish-Waterway/Site-history.

HISTORY, PRESENT, AND FUTURE OF THE DUWAMISH RIVER

EXISTING SHORELINE CONDITIONS | SOUTH PARK

The present day waterway serves as a major shipping route for containerized and bulk cargo. Common shoreline features include constructed bulkheads, piers, wharves, buildings extending over the waters, and steeply sloped banks armored with fill materials. The Port of Seattle has begun several shoreline restoration efforts, notably at the Terminal 117 site. The intention is to restore natural floodplains and develop resilient landscapes.

“Site History Washington State Department of Ecology.” Accessed April 7, 2023. https://ecology.wa.gov/Spills-Cleanup/Contamination-cleanup/Cleanup-sites/Lower-Duwamish-Waterway/Site-history.

Anna McDonald

University of Washington - Spring 2023

0’

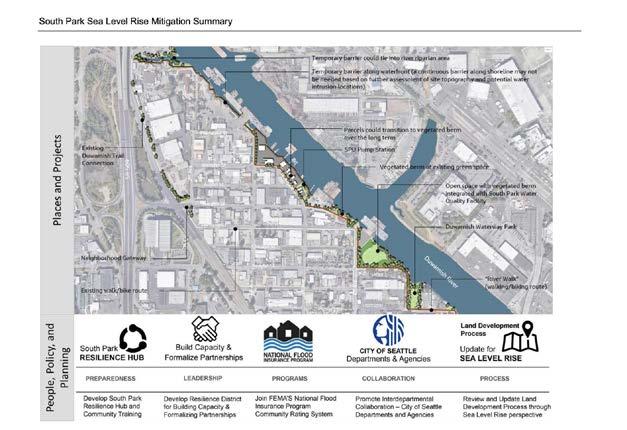

Sea Level Rise Mitigation Plan

“South Park Sea Level Rise Adaptation Vision Summary.” Accessed April 16, 2023. https://seattle.gov/documents/departments/ose/duwamish/south%20 park%20sea%20level%20rise%20adaptation%20strategy%20-%20final%20summary%20(2).pdf.

7,500’ 15,000’

0’ 2’ 0.5’

LEGEND

Shoreline Restoration Sites Present-Day Waterway

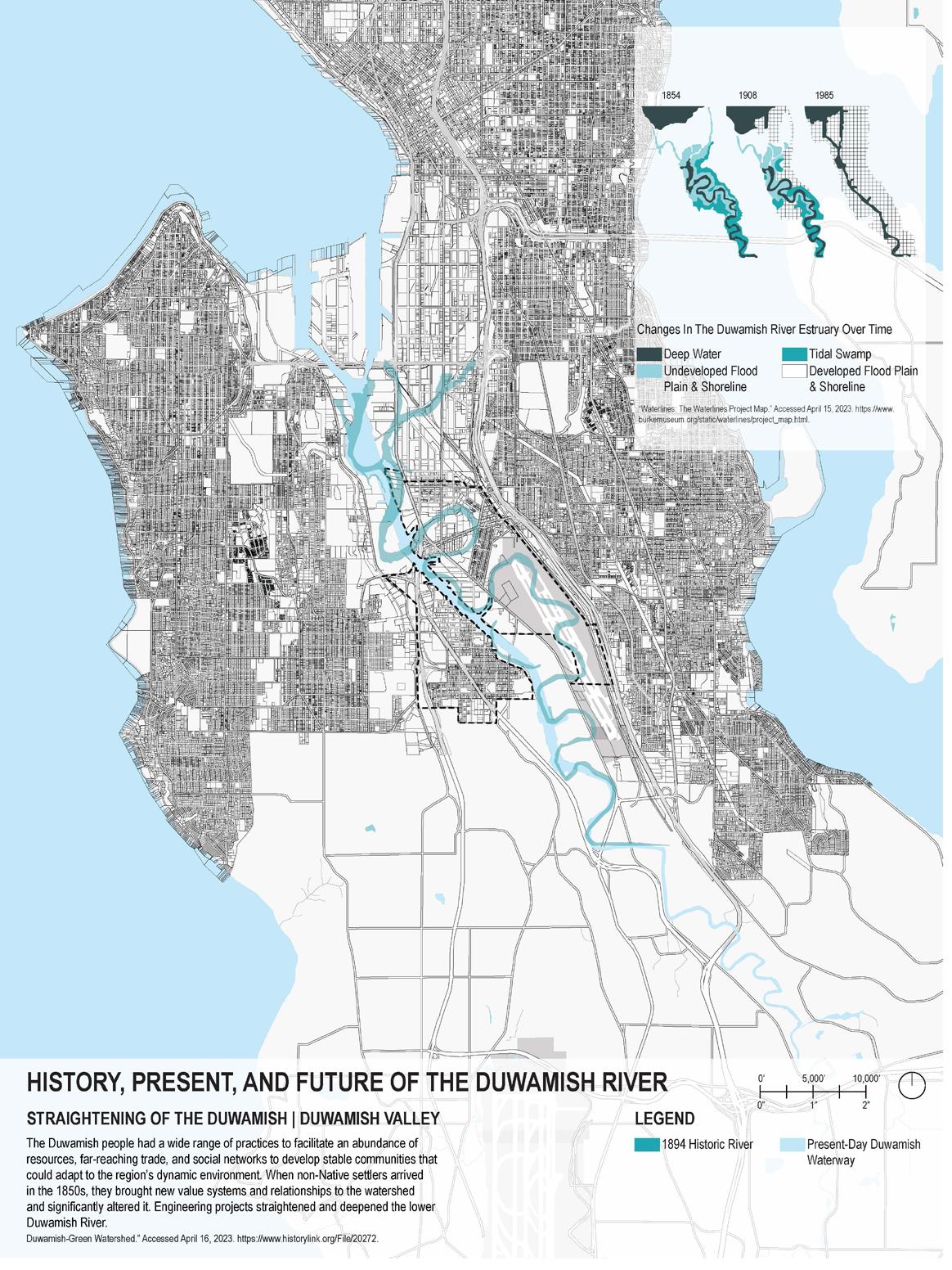

CATALYZING CONNECTIONS

HE, HUANG, LUKE, MCDONALD, SEARLE, SUND, WOOD, YANG

Welcome to Catalyzing Connections! Our comprehensive plan aims to transform South Park into a vibrant and inclusive community. We will reconnect roads to Highway 99, establish a transit corridor, reactivate networks, implement a circular city framework, and introduce a fleet of vehicles delivering essential services.

BIODIGESTER & GREENHOUSE CENTER

MARRA FARMS COMMUNITY MARKET

MARRA FARMS COMMUNITY CENTER

MARRA FARMS

MCDONALD, HUANG | CATALYZING CONNECTIONS

MARKETPLACE

The Marketplace will introduce the opportunity to create a new community gathering space on the southwestern side of South Park. Residents will have access to fresh produce produced by the farm. Produce can be harvested and sold the same day of the week to avoid food waste and provide help addressing food desertification

BIODIGESTER

The Biodigestor drop-off and processing shed is connected to the greenhouse allowing for a direct exchange of input/ output of bio-waste & bio-energy. Trucks powered by South Park’s organic waste return to the tool shed to drop off waste by backing into the stalls. Fresh produce can be grown year round with the help of aquaponics systems housed by the new community space.

COMMUNITY SPACE

Marra Farm’s new community space fosters the connection between indoor and outdoor gathering. We believe that it is equally valuable to have accessible greenspace and fresh produce as it is to have indoor spaces to convene as a community. The farm grid merges with open space under shelter to extend the reach of community resources in this new hub. Agriculture and recreational landscape merge in this center for community members to enjoy. The new hub also features a rain garden, providing respite and restorative atmosphere and echoing restorative landscape design across the neighborhood’s interventions. The features are connected by series of covered walkways, providing access to indoor/outdoor community assets.