We Care

ANGULUS partnership with The Footprint Firm

This report is based on analysis, data and counselling from ANGULUS’ collaboration with The Footprint Firm (TFF). We have chosen to collaborate with TFF because they – in our opinion – represent some of the most ambitious, competent and demanding sustainability consultants in the field. We made this choice not to take the easy route. We chose TFF to ensure that our sustainability efforts build on ambitious and solid analysis and universally recognized methods as well as an authentic dedication to create change.

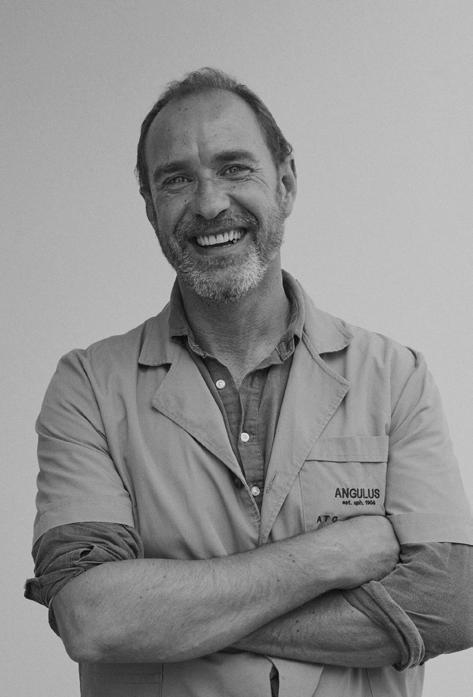

“With their own production facility ANGULUS has a unique insight into their chain of production as well as a high degree of control and opportunity to leverage impact in their value chain. Working with them on their Scope 1-3 GHG baseline and ESG strategy has been very rewarding and given us new insights on sustainability challenges and opportunities in the industry.”

Mikkel Skytte Hejbøl, director, Footprint Firm

Introduction

We firmly believe that sustainability, accountability, and a continuous aspiration to improve our impact in the world is the only way to do business. This is a moral obligation – not something that changes due to fleeting political winds.

In a rapidly changing world, we believe that we need to stand firm in our values. Our commitment to sustainability remains steadfast as well as our willingness to improve. We are definitely not there yet – but we are proud to share in this report the improvements we have made in the past year, the valuable learnings we have gained and our new aspirations.

Our 2024 GHG inventory tells us that we are on the right track with our material strategy. We have managed to reduce the emission-intensity of the leather we use in our production by 8%. We now know enough about our key reduction levers to set emission reduction targets. Our targets are based on what we realistically think we can do – but also ambitious enough to push ourselves.

Much more knowledgeable than we were a year ago, we are optimistic and eager to continue our path to decarbonization with a clear focus on choosing high quality materials from the best suppliers and working closely with both suppliers and customers who share our ambition of a more sustainable shoe industry.

We will continue to do our very best to ensure that when you choose a pair of ANGULUS you are not only making the best choice for your feet but also a responsible choice for people and planet.

Sebastian Dawe, CEO Clara Dawe, Chair of the Board

Highlights 2024

Reduce the emission-intensity of the leather we use by 8 %

Fully transition to only using chrome-free lining in all shoes with leather lining

Increase the share of our leather from LWG certified tanneries from 35 % to 68 %

Launch ANGULUS repair service to support our customers in prolonging the life of their shoes

Have 35 % of our energy use on our production facility come from our own solar panels

30%

Total reduction in GHG emissions of 7 %

ANGULUS at a glance

At ANGULUS we design, produce and sell shoes. Our chain of production is a system of people, machines and technology that enable the transformation of designs and materials into shoes and distribute them throughout the world.

The main concept is this:

Shoes are designed by our designers in Denmark and produced on our factory in Portugal, with natural materials sourced as locally as possible. 97 % of our material suppliers are based in Portugal, Spain and Italy. For us, closer is better.

Product development, Quality assurance Logistics, Design/Product Development, Management, Sales, Quality assurance

Crepe, Rubber etc.

ANGULUS value chain

ATC PORTUGAL Lda.

At ANGULUS, we have one thing in our value chain that makes us stand out from 99% of our industry. Even though we are a small business, we own and manage our own factory in Portugal. ANGULUS shoes are made in one place, by skilled shoecrafters who are proud to work for ANGULUS with working conditions that we are proud of. No sweatshops, only fair and proper treatment of our valued colleagues that we are proud to pay a fair salary every month.

ATC FOOTWEAR A/S

Our operations in DK where all products are designed and developed all the way from ideas to shoes. This is also where we service all of our customers and consumers around the world through our logistics and costumers service operations, making sure that all the shoes we produce reach their final destination, in the warehouse of a retailer or the front door at the home of the final user. Located in Herlev, outside of Copenhagen, Denmark our HQ is where all back-office tasks are taken care of. Logistics, IT-services, management and much more all take place here.

Production of rubber boots, thermo boots and wool slippers

Our facility in Portugal are experts on crafting leather shoes. But we know that our customers want to put ANGULUS rubber and thermo-boots on their feet for a rainy day. For this we collaborate with the Danish company LUXKIDS on selecting the best production facilities for this type of shoes as well as our wool-slippers. The production of these products take place in China. LUXKIDS are committed to transparency, fair working conditions and human rights in their supply chain and report on this in their yearly CSR report.

ANGULUS ESG strategy

Our overall strategic ambition is to get more people to buy less, but better shoes. And we genuinely believe that ANGULUS is better. But we also believe that we need to raise the bar and continuously work to make ANGULUS even better.

We aspire to contribute to the movement towards more circular shoe production by creating high-quality, long-lasting, repairable shoes – handcrafted with love, care and the finest materials.

But, how do we go from strategic ambition to actionable initiatives and efforts? What is important and what is not? How do we distinguish between what sounds right and what is right? To help us answer these questions, we have gone through the rigorous process of a double materiality assessment on the basis of these insights formulated our ESG Strategy.

Material strategy

We make choices about what materials to use in our production based on a material hiarachy that balances upfront emissions with the quality and longevity of the materials. We are dedicated to transparency, traceability and chosing low emission leather types.

Transparency

Increasing transparency throughout our value chain has been a key priority in 2023 and 2024 and will be in the coming years. We are committed to report on our progress yearly and will focus on improving data for our GHG inventory and set meaningful reduction targets.

Circularity

We work to extend the lifetime of our products through our principle of constant care. This applies in all stages of a shoe-life cycle: design, material choices, construction and assembly methods as well as promoting a culture of care, reuse and repair among our customers.

Social Responsibility

Our social responsibility covers all parts of Angulus’ value chain. We ensure a safe and fair working environment in both Denmark and Portugal. We prioritize upskilling and training and health insurance for all our employees. And we engage with our customers to support them on their journey towards becoming more responsible consumers.

Greening operations

Greening operations through renewable energy sources and better transport solutions are key priorities.

Environmental impact

2024 GHG INVENTORY

We are proud to present our updated 2024 GHG inventory conducted in accordance with The Greenhouse Gas (GHG) Protocol - the world’s most widely used greenhouse gas accounting standard.

When we set out to create our GHG baseline for 2023, our ambition was not to cut corners but to dig deep in our value chain and create a baseline that could tell us where we can actually make a difference in the choices we make. In our opinion this requires a baseline that covers scope 1-3 calculated on the basis of activities, where possible.

In our 2024 updated inventory we can see that this was the right decision. Emissions reduction is all in the detail. The developments from 2023 to 2024 has given us extremely valuable knowledge and thus direction as to where we need to focus our emission reduction efforts.

Methodology GHG inventory

ANGULUS CO2 inventory is based on The Greenhouse Gas (GHG) Protocol - the world’s most widely used greenhouse gas accounting standard. Specifically, our inventory follows “The GHG Protocol Corporate Accounting and Reporting Standard” and “The Corporate Value Chain (Scope 3) Accounting and Reporting Standard”.

A combination of spend-based and activity-based approach has been used to calculate GHG-emissions in scope 1.2 and 3. Specifically, a great accuracy was paid to the raw materials used for the shoe production at our factory in Portugal. For these raw materials granular data was collected and combined with best available GHG-emission factors from various databases (such as DEFRA3) and specific Life-Cycle-Assessments (on e.g., leather types). This gave clear insights into emission drivers, as well as potential reduction levers to be further assessed.

Key take-aways from the GHG inventory

• Total decrease in emissions by 7%

• 99% of our emissions come from scope 3

• Reduction in the emission intensity of leather by 8%

Scope 1

• Emissions at 2023 level – scope 1 remains at 0,3% of our total emissions.

Scope 2

• 25% decrease in emissions in scope 2 due to lower energy usage and more renewable energy sources.

Scope 3

• Decrease in scope 3 emissions by 6,5%

• Emissions from leather accounted for 96% of all material emissions

• We have reduced the emissions intensity from the leather we buy by 8%

• 5% of leather procured was SPOOR leather, traceable back to the farm, with 7 times lower emission-intensity

Note: The 2023 baseline result has been updated due to better data quality, explaining the difference in 2023 baseline result communicated here and in our 2023 report.

Scope 1 21,26 tons Co2 (0,3%)

Scope 2 26 tons Co2 (0,4%)

2024

Total baseline

6.389 tons Co2 (100%)

Scope 3 6.342 tons C02 (99,3%)

Scope 1 21 tonnes CO2 (0,3%)

Scope 2 35 tons Co2 (0,5%)

2023

Total baseline

6.836 tons Co2 (100%)

Scope 3 6.836 tons C02 (99,2%)

2023

112 kg Co2/M2

121 kg Co2/M2

98,3

tCO2e / mio DKK

62,6

tCO2e / FTE

94

tCO2e / mio DKK

59

tCO2e / FTE

44,1

tCO2e/ 1000 shoes sold

45

tCO2e/ 1000 shoes sold

Deep dive Leather emissions

tCO2e from material use, per. material type (Comparison)

Total emissions from leather

Total m2 of leather

Chrome-tanned leather

Chrome-free / vegetable tanned

Average leather

Scan-Hide leather (SPOOR)

Intensity (KgCO2 emissions /m2)

2.658 (44% of leather, 50% of emissions) 2.904 (50% of leather, 52% of emissions)

1.938 (36% of leather, 36% of emissions) 1.392 (27% of leather, 25% of emissions)

725 (15% of leather, 14% of emissions) 1.303 (23% of leather, 23% of emissions)

41 (5% of leather, 0,8% of emissions) 0

Emission factors for different material types

Chrome-tanned Non- chrometanned SPOOR Leather

/ m2

/ m2

/ m2

Reduction target

35%

By 2030 we will reduce the emission intensity of the leather we procure by 35%.

30%

All things equal, this will mean an absolute reduction in emissions by 30%.

Our approach to setting reduction targets has been to carefully analyze our value chain, map the main drivers of our emissions, and identify the most effectful reduction levers.

84 % of our total emissions come from leather used for shoe production. And we know that emission factors for different types of leather and tanneries vary significantly. So, procuring the right type of leather and working closely with our suppliers is where we will put our efforts.

On this basis we have set a reduction target for the emissions intensity of the leather we procure. Our baseline is 121 kg Co2 pr. m2 leather. The target is a reduction in intensity of 35% by 2030. All things equal, this will mean an absolute reduction in our emissions of 30% in 2030. For us, this is an ambitious and still realistic goal.

In our material strategy, we lay out how we will reach that goal.

Our big job, when it comes to reducing emissions, is to find materials which meet our quality standards and have the lowest emissions possible. This is the core of our material strategy.

Sebastian Dawe, CEO

Material strategy

The purpose of our material strategy is to strike the right balance between reducing the upfront emissions of the materials we use and securing that we make long lasting quality shoes. This is a process where our designers, shoe-crafters and suppliers work together to make the right material choices and continuously aspire to improve.

When it comes to robustness and durability, our assessment is that there is no real alternative to natural leather at the moment. But C02 emissions and other environmental impact from leather vary significantly depending on farming of the cattle, different tanning methods and the concrete procedures at different tanneries.

Why leather is the right choice for shoes, if you do it right

At ANGULUS, we firmly believe that leather is a superior material for crafting responsible footwear. We acknowledge that natural leather production has a higher initial CO2 emission compared to synthetic alternatives. But for us, the most critical perspective is the lifetime impact of our products.

With thoughtful design focused on durability and proper care and repair opportunities, leather shoes have a significantly lower CO2 impact over their lifespan. A well-made leather-shoe lasts 4 years, whereas a synthetic shoe lasts 1 year. These numbers are average and should be understood as such.

This extended durability not only provides better value for our customers but also ensures that the initial higher emissions associated with leather are more than compensated for by its longer life.

We are diligent in selecting the right type of leather for each application, as environmental impact varies with different leather types.

It’s essential to note that the longevity of our leather shoes, like all shoes, requires care from the user. Leather shoes offer a much higher potential for care and maintenance, and it is our dream at Angulus that our shoes last centuries, not just years. This vision drives our commitment to quality and sustainability, aiming to create footwear that stands the test of time both in style and in function. While we take pride in the durability and longevity of our footwear, we recognize specific considerations with children’s shoes. Children often outgrow their shoes before they are worn out, which suggests the potential for reuse. This poses a specific challenge that you can read more about on page 18.

ANGULUS x SPOOR

In 2023, we started a corporation with the Danish leather tannery, Scan-Hide, leveraging their SPOOR technology and traceability. The goal of this collaboration is to implement fully traceable hides from SPOOR as the base for the leather used in our shoes. SPOOR hides are sourced directly from Nordic abattoirs and no middlemen are in between. The leather is pre-tanned at Scan-Hide and finish-tanned at our Portuguese partner Topfinish Lda. in Portugal.

Through a unique, laserprinted reference, SPOOR leather is fully traceable from shoe all the way back to the cattle. This enables full transparency in the value chain, through data and documentation from both farmers, abattoirs and tanneries and provides a guarantee of responsible sourcing.

Furthermore, SPOOR provides data on the actual emissions associated with leather production all the way through the value chain. In 2024, the emission factor on SPOOR leather was 17,5 kg C02 pr. m2 leather –approximately 7 times less than the standard emission factor for comparable leather. Approximately 90% of emissions from leather come from farming, and emissions vary significantly with different farming methods and the utilization rate of the animal.

FSC – Certified Natural Rubber

In our ongoing efforts to promote environmental sustainability and ethical sourcing, we have committed to exclusively using FSC-certified natural rubber for all our crepe soles. The Forest Stewardship Council (FSC) certification ensures that the rubber is harvested in a manner that is environmentally responsible, socially beneficial and economically viable. Natural rubber, as a renewable resource, offers considerable environmental advantages over synthetic or oil-based alternatives, including lower carbon emissions and reduced reliance on fossil fuels. By choosing FSC-certified sources, we not only support sustainable agriculture and forest management but also contribute to protecting biodiversity and the rights of workers and local communities in our value chain.

Material strategy

2024 highlights

Transitioning to fully traceable leather

In 2024, 5% of the leather we procured came from Scan Hide, and 8,5% of all ANGULUS shoes sold in 2024 were made from traceable leather. Our goal is to increase the share of fully traceable leather to 35% by 2030. This is going to be the main driver in our C02 reduction strategy. This requires close collaboration with our suppliers and a clear focus on traceability all the way through our value chain.

Chrome-free

leather linings

We are in the process of phasing out chrome in the leather lining of all our women’s and men’s shoes. In the production of SS25 collection (in stores spring 2025), approximately 90% of the leather lining in our women’s and men’s shoes is chrome-free and in our AW2025 collection 100% of lining in all ANGULUS shoes will be chrome-free.

This is a rather extensive process, and as both our retailers and we ourselves have stock of ANGULUS shoes from previous seasons, you may still find ANGULUS women’s and men’s shoes with chrome in the lining for some time.

Vegetable tanned upper leather

In our Women’s Collection we have introduced a new material for uppers: vegetable-tanned hand-braided leather. This type of material gets its robustness from the braiding making it suitable for uppers without using the chrome-tanning, which is often necessary to make the leather suitable for outdoor shoes.

Working with tanneries to improve methods and transparency

Working with certified tanneries is an important tool for us to secure transparency and the best possible tanning procedures. 68% of the leather we used in 2024 came from Leather Working Group certified tanneries – in 2023 the share was 35%. The certification by Leather Working Group means that the tanneries have high standards on a broad range of criteria covering energy consumption, water usage, air-emissions, chemical management and health & safety preparedness.

We will continue to use certification as one of the parameters that we evaluate our suppliers through. However, we don’t believe that excluding non-certified tanneries from our supplychain is the right approach at the moment, because this would mean excluding some of the local small businesses that rely on us for their business. We believe in impacting our supplychain by collaboration, dialogue and involvement, and we are happy to see that this approach is working and that an increasing number of local tanneries obtain certifications.

Circularity

We aspire to contribute to the movement towards more circular shoe production by creating high-quality, long-lasting repairable shoes. The circular economy is a system where materials never become waste and nature is regenerated.

We base our circularity efforts on the ‘REUSE, REPAIR & RECYCLE’-principles, defined by the Ellen MacArthur Foundation and supported by existing and upcoming EU-regulation. This applies to our entire value-chain, where we aim to create as little waste as possible, to extend the lifetime of our products through design, material and construction choices and by actively supporting a care and repair culture and praxis among our customers. To ensure maximum lifetime of our products we depend on our customers to take good care of their shoes and to have them repaired when needed. We guide our customers on shoe care, supply protective cream/spray and facilitate repair of shoes with our vetted repair partners.

We will incorporate more recycled materials in our production as recycled materials, living up to our quality and durability standards, become available.

Reuse – should used shoes be passed on?

In our opinion; some should, some should not.

From a perspective of circularity, reuse is always the preferred option. Passing on products that you are done with and that are still good to use, either by selling or giving, holds great potential for extending the lifetime of products. However, when it comes to shoes, there is a tradeoff between extending the lifetime of products and potential health-related issues from wearing pre-used shoes.

Shoes are shaped after the feet that wear them. In particular if they are made from natural materials. Walking in shoes that have been shaped after someone else is not good for your feet. Moreso, it can also damage knees, hips and back if you wear shoes that have been worn by another person with a different use pattern. This is especially important with children, whose feet and bodies are soft and growing, and therefore in high risk of the health-related consequences of wearing shoes that prohibit natural development and movement of their feet. Also, children will not always be able to express that a shoe doesn’t feel right .

There are no official recommendations on this issue at the moment. At ANGULUS we take the stand that children’s shoes should only be passed on to someone else if they haven’t been shaped by the former user. In effect this means that children’s shoes that have been used on a daily basis should not be passed on. And we always recommend that you let your child try on the shoe before buying.

When it comes to adults, we recommend reuse, but encourage you to examine and try the shoe first and make sure that it fits in both size and shape and that soles (both inner and outer) aren’t crooked.

We acknowledge the inherent dilemma that we face between extended lifetime of our products and costumer safety, and we are committed to exploring how reuse of children’s shoes can be done in a safe way. We don’t have the answers yet, but in the coming years we will invest in gaining more knowledge and experience in this field.

2: Read more here: 5 facts om børnefødder - Danske Fodterapeuter (altomfoden.dk) + Fysioterapeutens

Circularity

2024 highlights

ANGULUS Repair Service

To ensure maximum lifetime of our products we depend on our customers to take good care of their shoes and to have them repaired if needed, should they break in some way. ANGULUS are quality shoes made of natural materials that provide good repair options. In 2024 we launched ANGULUS Repair Service to help customers have their shoes repaired instead of disposing of them. Within the first two years, we offer free repairs. We also pay the shipping back and forth. The repair is done either in our own workshop, at our regular partners, or our customers can use their local shoemaker and have the costs covered by us. We are also happy to supply spare parts that customers can take to their local shoemaker.

We track the number of repairs that we do each year, in 2024 the number was 168.

Repurposing Rubber Waste

In 2023, we embraced a practical approach to waste reduction by implementing a circular economy strategy with our natural rubber waste. In 2024 we redirected approximately 10.555 kilograms of excess material from our sole production. The material was sold to our glue producer, who repurposed it into a key component of the adhesive products used in our shoes.

Greening operations

In September 2023, we made a significant investment in renewable energy at our production facility, by installing a comprehensive array of solar panels. In 2024, 35 % of the energy used on our production facility came from our own solar panels, effectively enhancing our energy efficiency and significantly reducing our reliance on non-renewable energy.

Greening transport

In 2023, we introduced a company policy requiring that all newly purchased company cars must be electric or hybrid vehicles. As part of our ongoing efforts to improve, we recognize the need to eventually transition away from hybrid vehicles to a fully electric fleet. Currently, our company operates 4 electric cars, 2 hybrids, and 3 petrol/diesel cars, with plans to phase out all non-electric vehicles.

Social Responsibility

Our social responsibility covers all parts of ANGULUS value chain.

We ensure a safe, attractive and fair working environment for our colleagues in both Denmark and Portugal. We recognize the value of having a skilled workforce with possibilities for our employees to learn and grow as part of their job. We believe in continual learning and invest in development opportunities for our team. We offer health insurance for all our employees in both Portugal and Denmark. And we play a positive part in our local community in Portugal by collaborating with the local vocational training center for shoemakers and the local employment agency.

Costumer safety is in our DNA at ANGULUS. Shoes are not just a question of fashion and function. It’s ultimately a question of health and giving people the best conditions to move around freely. Especially when it comes to children, we have a big responsibility to make footwear that gives tiny feet the best conditions to grow and move freely and supported. At ANGULUS we take this responsibility very seriously – and we aspire to be a credible partner for our customers in making the right footwear choices.

We make shoes in different fits – because feet are different. We use natural materials that create the best conditions for free movement and a healthy foot climate. And we advise our customers on how to make the right shoe choices.

We want to enhance these efforts and increase transparency about our products and support our customers in taking good care of their shoes, so they last as long as possible.

Social Responsibility

2024 highlights

Product material labeling

Understanding the composition of the products you choose is essential. That’s why we are committed to improving transparency by labeling all our products with detailed material information. We believe that informed consumers make better decisions, and our straightforward labeling will help customers to know exactly what they are buying, enhancing trust and satisfaction with every purchase. In 2024 we added information about tanning procedures to the product information on our own webshop. Furthermore, we did a pilot-project in collaboration with our wholesale partner Boozt on product labeling gaining valuable experience about how to label products in a meaningful way for customers. Building on these experiences we will continue to add more detailed information on each product.

Governance

ANGULUS has been in the shoe making business for 120 years and has been a family-owned business for over three generations.

Being a family owned business comes with both privilege and responsibility. A privilege to invest in the things that are important to us. And a responsibility to take care of the heritage that we have been entrusted with. Long term, cross-generational thinking is in our DNA. In our products and in the way we do business.

We are committed to fostering a culture of responsibility, transparency and ethical practices throughout the organization. This strategic direction not only aligns with contemporary consumer values but also stems from a steadfast belief that taking care of people and planet is a moral obligation and fundamental for the business’ license to operate.

We believe in the importance of local leadership to effectively align our operations with community needs. The two directors of our Portuguese operations each hold a 5% share of the company. This decision reflects our commitment to integrating local expertise into our decision-making processes, ensuring that our strategies are informed by those most familiar with the context in which we operate.

The history of ANGULUS

The history of ANGULUS starts in 1904 with a small cobblers shop on Nørrebrogade in Copenhagen owned by Johannes Madsen. His son, Willy Madsen, was a schoolteacher and concerned with the pointy children’s shoes at the time, that hindered movement and the natural development of growing feet. In 1928 Willy Madsen turned the Danish footwear industry upside down with his new foot-formed shoes developed in collaboration with doctors and physiotherapists. The new type of shoes quickly gained popularity and soon the ANGULUS factory in Nørrebro became the largest shoe factory in Denmark.

From 1949 and onwards ANGULUS has been owned and led by the Dawe Family. Starting with Roland Dawe who was initially employed as a leather buyer at the ANGULUS Factory, who lead the company until the early 1990, where his son Christian Dawe took over. After a successful generational change in the leadership, ANGULUS is currently managed by Clara Dawe (Chairwoman) and Sebastian Dawe (CEO).

Governance

2024 highlights

B-corp Certification in process

In 2024 we started the proces of B-corp certifcation. It’s a rigorous proces and in 2024 we learned a lot about what it will take for us to achieve the certifiction and we started the relevant processes of data collection and target-setting. However, in spring of 2025 B-corp announced a whole new set of standards for the certification process that will be effective from january 2026. Therefor we have decided to wait for the new standards before we apply for certification.

Improvements in our yearly ESG reporting

We are committed to report on our progress, learnings and shortcomings in a yearly ESG report. In 2024 we have worked on getting more accurate data, eg. in the data we have from our suppliers on their specific tanning methods and incorporating material specific emission factors based on Life-cycle analysis provided by our suppliers.

Take care!

Thank you for reading our 2024 Sustainability Report! We hope that you found the report informative, useful –and maybe even inspiring?

We are committed to continuing our sustainability efforts and look forward to collaborating with suppliers, customers and other stakeholders on our mission to make more people buy fewer, but better shoes.

If you have any questions, please feel free to reach out to us:

Love what you buy –take care of what you have