Andrew Craig

Architectural

Technologist

Technologist

Easton Bevins

Architectural Technologist

August 2023 - Present

Sheerin Bettle Architecture

Architectural Technologist

June 2019 - November 2022

Hollington Architects &

Design Team

Architectural Designer and Technician

January 2014 - May 2019

GoDo Design

Building Services Engineering Assistant

June 2014 - February 2015

Atlas Elektronik UK

Mechanical Engineering Design Assistant

January 2013 - November 2013

AC Building Services

Skilled Labourer

June 2011 - January 2013

Building

Solent University

September 2020 - June 2022 (part-time)

Distinction

Solent University

September 2016 - June 2019 (part-time)

First class

Arts University College Bournemouth

September 2007 - June 2011

As an Architectural Technologist, I integrate architecture, science, technology and engineering with design and creativity.

Within compliance of regulatory, statutory and legal requirements, the core of Architectural Technology is:

Technology

Buildability

Functionality

Performance of the design

Materials selection and consideration

Innovative processes

Production techniques

Sustainability

Inclusivity

Health and safety

As a BREEAM AP, I have specialist skills in sustainability and environmental design combined with a high level of competence and understanding in BREEAM and its assessment process.

A BREEAM AP is one type of ‘sustainability champion’ defined and recognised in BREEAM The BREEAM AP uses their expertise to assist clients and project teams by facilitating cross-project consideration and collaboration on solutions to scheme compliance, target setting and performance monitoring.

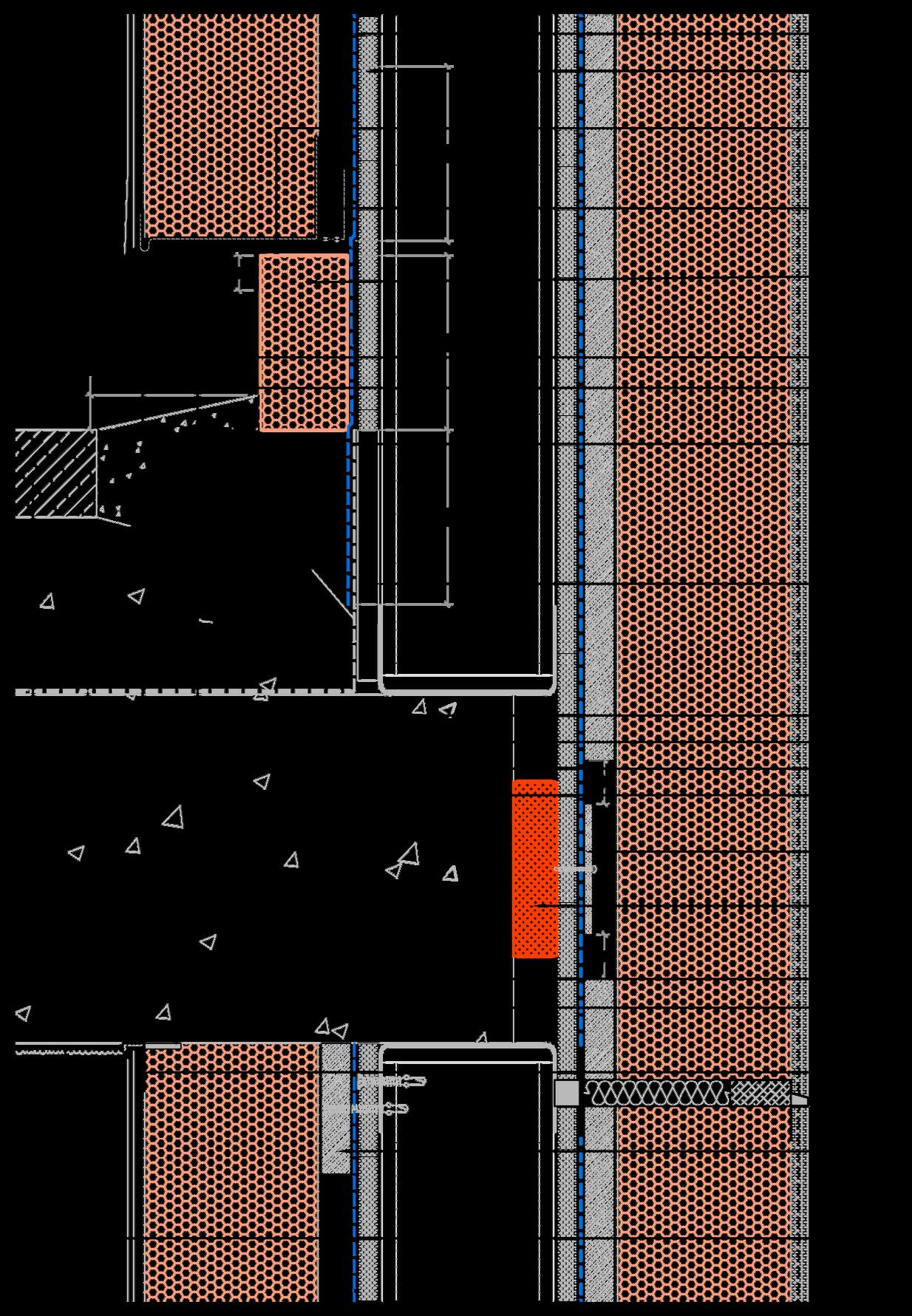

This project is for the remediation of the external wall insulation of a high rise residential tower block (18 storeys) in the heart of London through the EWS1 process. Removal of existing external wall insulation and sheathing board which are considered dangerous and replaced with suitable materials.

The project started before I joined Easton Bevins and was tendered under a JCT Minor Works contract As such, Easton Bevins are the Principle Designers and I have taken a key role with providing technical details and construction solutions

The project has provided many challenges Standard details provided by the suppliers of the external insulation and render system do not cover all design details that are uncovered during demolition. For example, the curved wall required the alteration of the insulation layout and fixing pattern as well as providing further segments. This was crucial to allow the render to be within tolerance of the base and top coat render thickness stipulated by the manufactures providing warranties for the system. The details to right have been agreed by Manufacturers, Fire Engineer, Building Control and Contractor.

Far Left - Site photo of contractors timber template/ formwork for external wall insulation and rendering applied to curved section

Left - Curved wall detail

Below - Site photo of concrete upstand/ parapet

Right - Concrete upstand/ parapet coping detail

Upon removal of the existing external insulation and sheathing board, rainwater down pipes were found encased close to the corner of the balcony return wall and double glazed doors.

It was decided to encase the rainwater pipes as existing but this providing unique design constraint with supporting the cases work whilst not jeopardising fire containment, airtightness of windows, etc.

The rainwater pipe penetrates through the concrete deck of 5 floors. Although externally located, the proximity to the existing wall construction required fire collars to be installed at the base and head. These designs (and all other produced for this scheme to date) have been approved by fire engineers, manufactures and build control.

Above - Balcony window/ door and wall return junction detail (with RWDP encasement)

Right - Balcony upstand and soffit detail (with horizontal PVC pipe)

Far Right - Site photo of existing exposed rainwater drainage pipes

2 5

TYVEK Breather Membrane Y-wal sheath ng board

EPDM to face down 20mm below top of BauderGLAS upstand and lap up 100mm beh nd dra nage bead

Drainage bead w th minimum 5mm free air gap be ow (10mm preferred)

BauderGLAS Inverted Upstand Insu at on

Concrete to fall to exist ng s abs DPM

EPDM to face down 100mm be ow top of ex sting waterproof ng membrane and lap up 100mm behind Tyvek breathable membrane

Exist ng partic e board to be cut nline with ba cony waterproof upstand

Exist ng PVC pipe

Exist ng concrete

Exist ng waterproof ng membrane

Exist ng pav ng slabs

Tenmat FF102/50 Intumescent Str p expanding cavity fire strip with Stainless stee f xing

Tenmat NVFB Non Venti ated Fire Barr er mechan cally f xed to slab edge in accordance w th manufacturer's instruct ons

Low Modu us s l cone sealant

Seal ng Tape compressed by 2/3rds

Surface mounted stop bead

Hor zontal CS1 Fillet - A1 F re Rated Packing Str p to be embedded/sealed with f re rated mastic to close cav ty

Exist ng texture render to ba cony soffit to be made good at abutment l ne with new external render

Damp discolouration was present in localised areas around downlights, extractor fans and the base of the ceilings of recently completed (2020) 5No houses terraced housing. Further defects included screw heads ‘punched’ through the ceiling plasterboard in the centre of the rooms.

After opening up the ceiling, it showed the construction to be a cold roof which is not suitable for standing seam construction as well as potentially undersized rafters. Upon access the roof, it became apparent the contractors solution to fixing the leaks greatly exacerbated the problems with the interstitial damp as over boarding and asphalt roof finish had been applied over the existing standing seam. This is preventing necessary airflow from dissipating moist air from within the cavity. I further believe the ‘punched’ screw heads will have resulted from the weight of the new roof materials and dynamic forces of the workers on the roof.

The proposed roof is a hybrid warm roof with ventilation. Remediation requires a complete replacement due to rafter members being sized correctly by an engineer. The proposal has not increased the roof height and thus not require planning permission which was a important constraint.

I joined Sheerin Bettle Architecture after planning permission had been granted and my role was to aid with technical design and contract administration

The challenge of this project was providing all the necessary consultation spaces, surgical suites, offices space, etc in a relatively small building with strict planning requirements.

Situated in the Western Escarpment Conservation Area of New Forest National Park, the planning authority required the building façade to provide the appearance of a rustic, barn like structure.

The project won New Forest National Park Building Design Award for Best Nonresidential Scheme in April 2023.

Left - Corner view of reception entrance from the front car park

Below - Theatre #2 (Orthopaedic)

Right - Reception and waiting area (hall leading to consultation)

Below Right - Preparation Ward

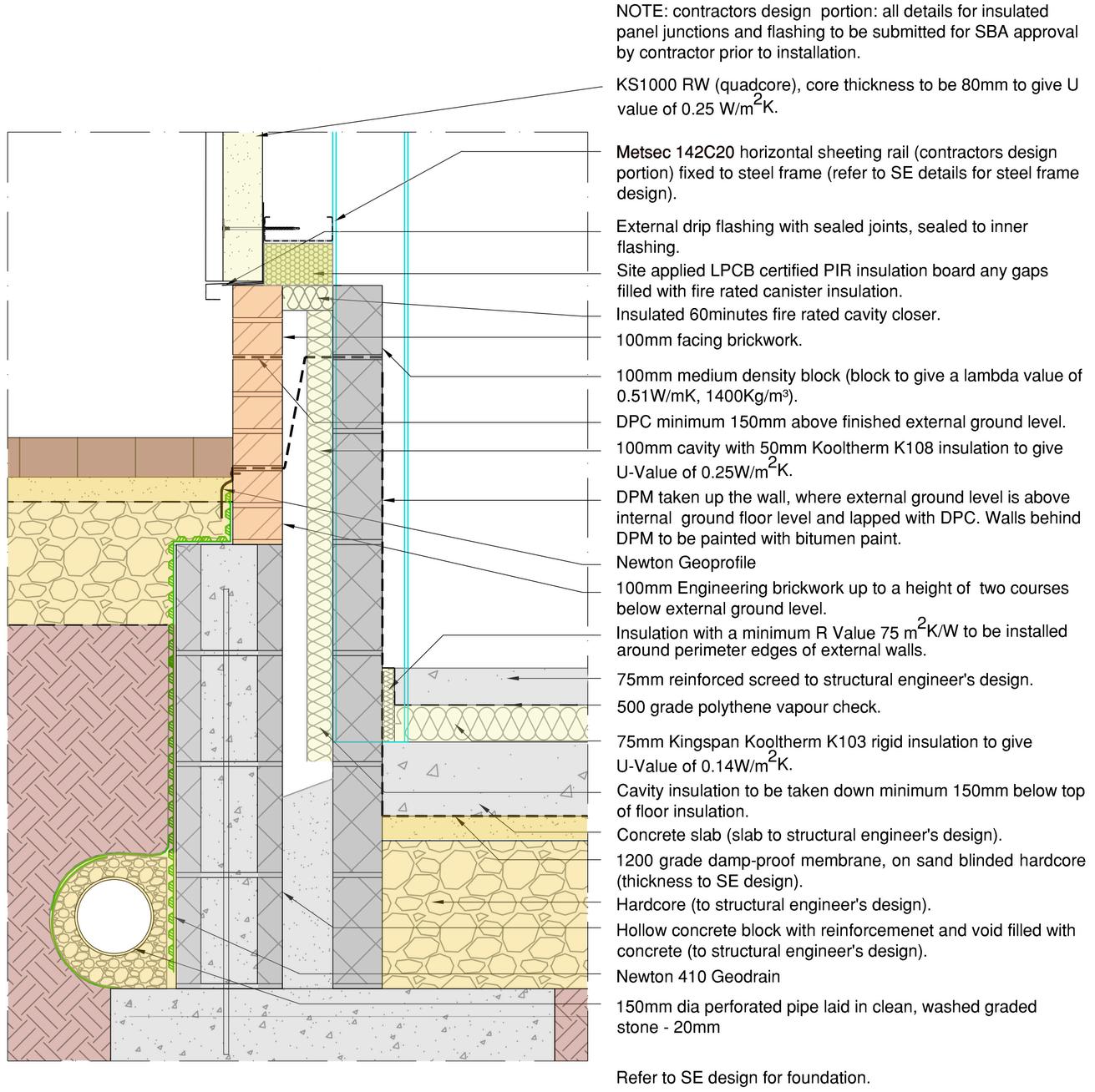

A challenge that occurred during construction was the incorrect placement of the steel bracing by the steel manufacturer within the web of the steel structure. I noticed the error during a site visit. After discussion with the structural engineer, contractor and steel manufacture; The solution to the placement of the bracing on the flange of the steel saved the most time for contractors on site and at no cost to the client

A further challenge that had to be overcome and detailed was the excess amount of ground water and the flow onsite. It became necessary to add drainage to the rear of Unit 1 as the internal floor level was significantly lower than the ground level as shown in the technical detail opposite.

Left - Ground/ wall junction detail illustrating steel bracing placement

Right - Ground/ wall junction detail illustrating foundation and land drain

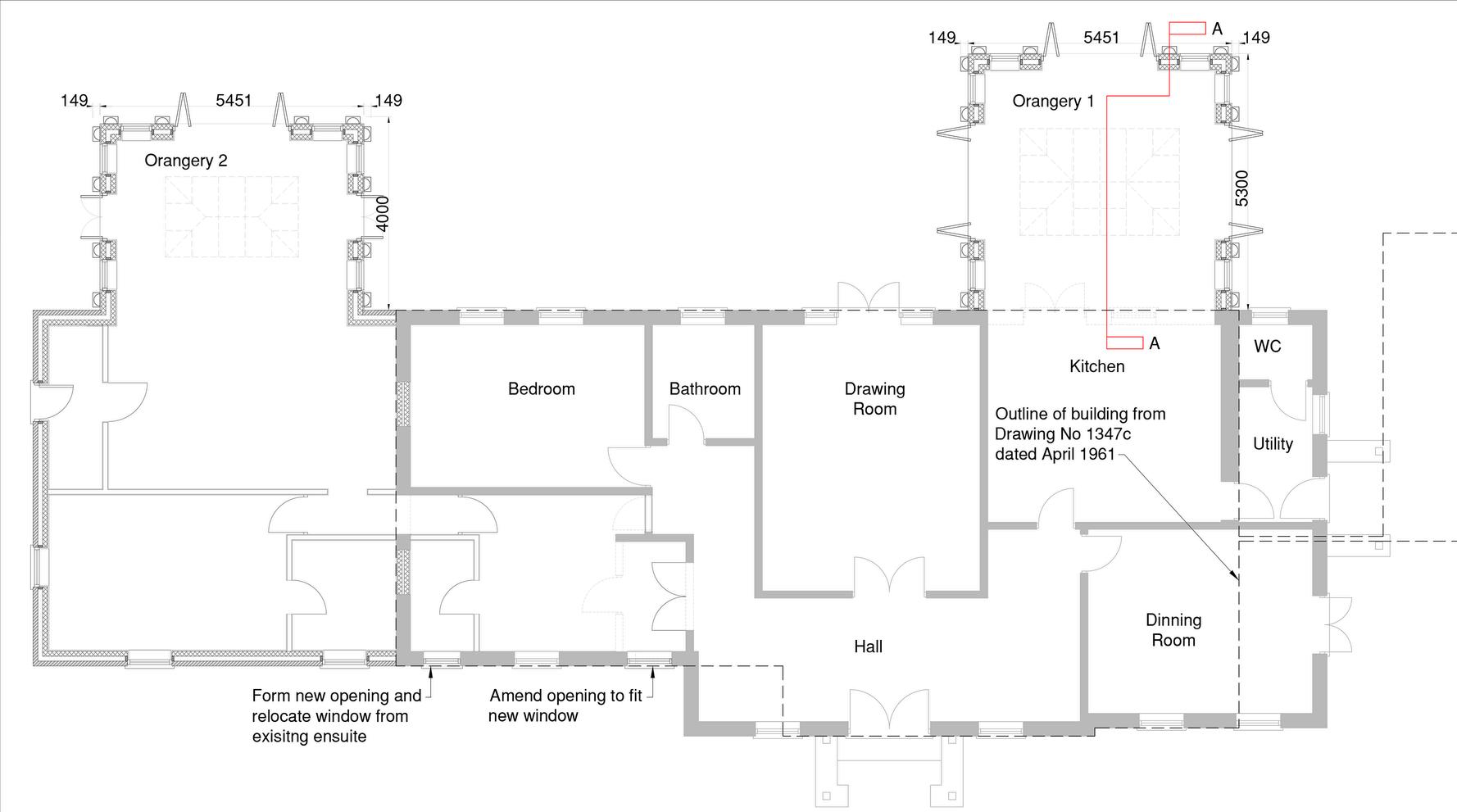

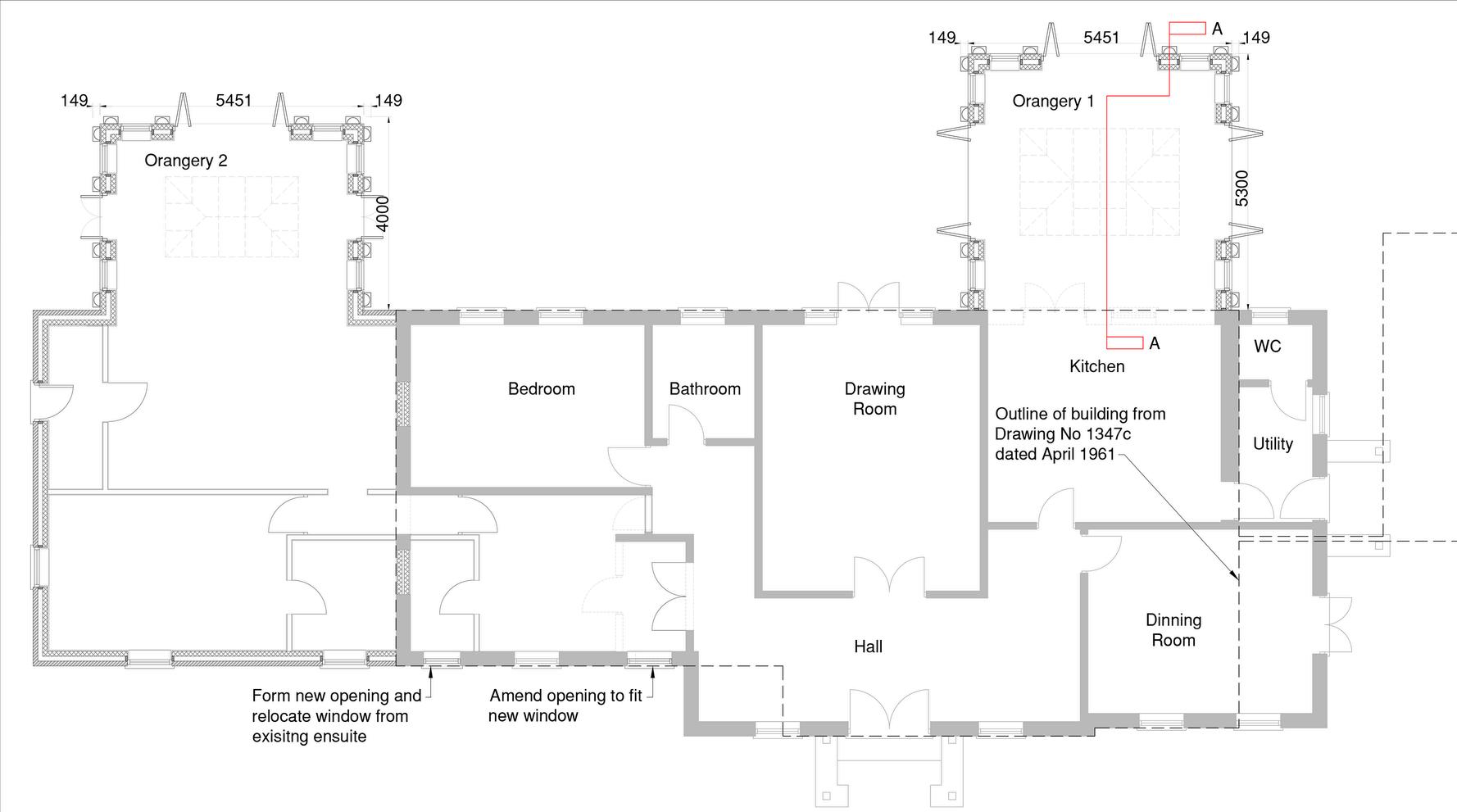

During my time at Sheerin Bettle Architecture I was involved in the extension and additions to this property. This proved to be difficult due to technical detailing that was restricted by planning authority’s stipulations, technical building constraints and client demands The client provided their own design for the extension and 2no Orangeries in the NeoClassical style with Portland stone decoration. I explained how Neo-Classical additions to the rear of a ‘rustic’ styled dwelling would clash architecturally and the extents of the solid stonework for single storey additions would require significant structural support. The client understood this consultation but chose to progress with their designs.

A technical/ planning issue was encountered with regards to the orangery on the rear of the dwelling, which was required to connect to the existing structure no higher than the height of the eaves of the original property.

The client also required all rainwater drainage be hidden. The only option was to utilise the lowered bulkhead that connect the orangeries to the original dwelling height as a box gutter and hide the RWP within a hollow stone decorative column. It was at my insistence that the box gutter be accessible via a removable stone as the build-up of leaves and other debris could cause water to collect and sit within the hidden box gutter. This would cause leaks into the building envelope and interior.

Left - Section A-A

Below - Parapet detail

Right - Flat roof detail illustrating connection to existing wall and roof

The brief for this group student project was to create a multipurpose unit with accommodation, retail and parking with the focus on sustainability and community within the heart of Southampton. The project provided self enclosed living spaces, office space, commercial units, gym, café, shared space, required utilities and electric car parking.

Video Presentation

YouTube title - Multiple purpose living centre https://youtu be/B1o TA xg w

Right - External perspective from courtyard of front entrance

Far Right - Hand drawn parti diagram showing site constraints and opportunities

As a university group project, most of the building form and design work was created by committee with all members of the group However, most works tasks were allocated to people with different backgrounds and specialisms as this unit had many students with varied professional backgrounds and specialisms.

My focus was on the technical detailing, creation and coordination of the 3D Revit model and presentation video.

A key measurement of showing the sustainability of the building included illustration the reduction strategy for operational and embodied carbon. Life Cycle Assessment (LCA) was also undertaken for this project

Below Left - Exploded diagram of the fabric, structure and partition elements

Below - High level aerial street view of front courtyard and entrances

Right Top - Commercial gymnasium

Far Right Top - Cafe

Right Below - Street level view of front courtyard and entrances

Far Right Below - External perspective view

I was awarded the Building Research Establishment (BRE) Academy Award for Best Design for Health & Well-Being in June 2019.

In 2018, there were a number of riots in UK prisons following many severe heatwaves The cause of the riots were due to the vast majority of prisons being outdated Victorian construction that were poorly designed, manged and over populated.

For my final year project for BA (Hons) Architectural Design and Technology, I thoroughly researched this topic. The goal of designing a solution that not only addressed the potential for improved construction methods but also for the betterment of the health and well-being of inmates.

Right - External public congregation area

Below - Personal desk space

Below Right - Common room

Far Right - Technical detail through the wall and roof junction. Produced in AutoCAD and styled with Adobe photoshop for final year presentation