ANDALE CONSTRUCTION INC IS A NATIONWIDE, INNOVATIVE, AND AWARD-WINNING CONSTRUCTION COMPANY WITH DEEP ROOTS IN THE COMMERCIAL AND INDUSTRIAL FIELDS.

To provide quality solutions and services through industry-leading technology and service.

To design, manufacture, and build quality safe projects with amazing customers and employees.

FAMILY OWNED

200+ TEAM MEMBERS

Jim and Cindy Molitor founded Andale Ready Mix Inc. in the small town of Andale, KS, in 1972. In the year 2000, the two sons, Pete and Bill Molitor, took over as the next generation of Andale Ready Mix and worked together towards robust business growth. In 2002, the brothers brought Andale Ready Mix to Wichita, KS. The two brothers realized the need for quality paving contractors and founded the company Andale Construction in 2005.

Today, Andale Construction is a recognized nationwide, award-winning contractor specializing in Roller Compacted Concrete (RCC), Cement Soil Stabilization, Earthwork, and Concrete Resurfacing.

100+ YEARS OF COMBINED MANAGEMENT EXPERIENCE

Rail Yards

Lumber Yards

Trucking Centers

Distribution Centers

Large Construction

Shipping Ports

Intermodal

Food Processing Facilities

Wind Farms

Oil and Gas

Building big things takes some know-how, and we are proud to say we have built with some of the biggest clients in the world

Amazon

AMAZON

Andale Construction was chosen as a sub contractor for earthwork, cement soil stabilization, paving, and parking blocks for this mammoth project.

WORK PERFORMED

Earthwork | Cement Soil Stabilization | Curb and Gutter | Conventional Concrete

GAP INC.

Gap Inc builds new distribution center in Longview, Texas to meet rising demand for digital shopping The new $140 million dollart state of the art facility will provide over 1,000 jobs

WORK PERFORMED

Earthwork | Cement Soil Stabilization | Curb and Gutter | Conventional Concrete

GAF

GAF

GAF, a Standard Industries company, is the leading roofing and waterproofing manufacturer in North America for more than 135 years. The new expansion in Ennis, Texas will allow for the company to have much-needed shipping lanes.

WORK PERFORMED

Earthwork | Cement Soil Stabilization | Curb and Gutter | Conventional Concrete

A FEW MORE OF OUR CLIENTS

Ennis, TX

Completion Date: March 2022

Earthwork | Cement Soil Stabilization | Curb and Gutter

Conventional Concrete | Roller Compacted Concrete (RCC)

GAF Materials Corp. has kicked off a multi-year expansion in Ennis, TX. The American-owned and operated company produces roofing materials and finishing shingles for more than 100,000 homes annually. Andale Construction was chosen for its Roller Compacted Concrete (RCC). Fast turnaround, cost savings, and longevity made using RCC a no-brainer. Andale Construction's RCC is strong, versatile, and in most cases, looks like conventional concrete paving.

Description of Work:

Cement Slurry Stabilization

RCC: 400,000 SF 8” RCC

Quantity: 850 Tons of Cement

PARK CITY, KS

Completion Date: June 2022

Earthwork | Cement Soil Stabilization | Curb and Gutter

| Conventional Concrete

Construction for the one-million-square-foot facility began in early September 2021 with 460,000 cubic yards of earthwork fully completed by mid-December. Over 4,220 tons of Andale Slurry™ was used to provide a stable pavement base for the fulfillment center. The concrete paving for the surrounding roads and parking area is well over 1,300,000 square feet.

AMAZON

Description of Work:

Earthwork: 450,000 CY Cut and Fill

Cement Slurry Stabilization: 4,220 Tons

Conventional Paving: 1,300,000 SF

Ft. Liberty, NC

Completion Date: August 2021

Andale Slurry™ was chosen for its superior method of soil stabilization. Our slurry provided accuracy and consistency in delivering the material which translated into reduced overall construction costs and a safer and more accurate alternative to standard cement soil stabilization. The Roller Compacted Drainable Base will provide the needed strength for the 20-inch thick concrete that will make up this crucial military airfield.

Description of Work:

1,684,333 SF Andale Slurry

Roller Compacted Drainage: 16,567 SF

Cement Powder: 110,411 Tons

Cement Soil Stabilization | Roller Compacted Drainable Base

POPE AIRFIELD

Cement Soil Stabilization | Roller Compacted Drainable Base

POPE AIRFIELD

Bel Aire FDR RCC

Bel Aire, KS

Completion Date: May 2022

WORK PERFORMED

Full Depth Reclamation | Cement Soil Stabilization | Roller Compacted Concrete

Utilizing Full Depth Reclamation allowed a cost-effective strategy to integrate the existing asphalt into the base. Andale Slurry™, a dustless form of cement soil stabilization, was the ideal choice for its speed, accuracy, and strength. The cement slurry was directly injected into the main roads to provide a strong base for the 4,205 SY of 6” RCC that will serve residents for years to come.

Bel Aire, KS

Description of Work:

Full Depth Reclamation: 4,510 SY

Andale Slurry: 90 Tons

Roller Compacted Concrete: 4,205 SY 6" RCC

Garden City, KS

Completion Date: In progress

Concrete Paving

Empirical Foods has broken ground on a new ground beef facility in Garden City, KS. The planned facility is the most significant single investment in the company’s 40-year history and will bring 250 new jobs and more than $250 million in capital investment to Garden City and Finney County. Utilizing over 25,000 CY of concrete ranging from 8 to 12 in most areas, this concrete will be able to handle the heavy and constant traffic for years to come.

Description of Work: Concrete Paving: 500,000 SQFT

Grapevine, TX

Completion Date: June 2022

OXCON Systems was chosen to come in with a time-tested product and provide the city with a new road surface that is quiet, environmentally friendly, cooler, and the best cost-effective strategy to resurface and preserve the original concrete. Saving taxpayers nearly $78,000 dollars was a win for the City of Grapevine and, most of all, the taxpayers. City officials allowed for two weeks on this busy street that turns onto the freeway using OXCON Systems Resurfacer; the project was completed in two days with only minor traffic delays.

GRAPEVINE, TX

Description of Work: Concrete Resurfacing

Concrete Resurfacing

Concrete Resurfacing

The basic ingredients are the same as conventional concrete: sand, aggregates, cement, and water. However, the quantities are different.

Requires less cement

Lower cost

Greater durability

Lower overall maintenance cost

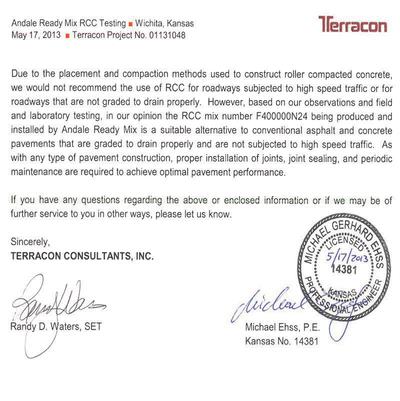

Our RCC mix is commonly produced using a twin-shaft mobile concrete batch plant capable of thoroughly mixing zero-slump concrete in high volumes.

Today’s RCC is nothing like the past: rough, unfinished, and inconsistent. RCC of today is economical and can even be broom finished creating an improved look in most cases over conventional concrete at a fraction of the cost.

LOW COST

EASY PREPARATION

ABILITY TO PUT STRUCTURAL FIBER IN THE MIX

HIGH-VOLUME PRODUCTION WITH MINIMAL LABOR

HIGH STRENGTH & DURABILITY

PROVEN PERFORMANCE

Proper consolidation, or in this case, density, is critical for strength and durability. Because compaction is so critical, real-time Quality Control (QC) plays a large role in the placement of RCC At Andale Construction, we use a combination of internal and external QC to ensure the highest quality possible QC tests performed before, during, and after placement include:

Cylinders cast for compressive strength testing and historical data

The major difference in construction is that RCC:

Requires less compactive effort

Longer workable period

Trowled surface

Textured surface

Using our specialized finishing process along with the ACEiT admix and finishing aid, we can now construct a textured surface on the pavement that is indistinguishable from conventional concrete.

In 2015 The University of North Carolina-Charlotte performed testing using ASTM C-944. The tests verified that ACEiT and troweling had positive effects on the surface of the pavement. RCC with the ACEiT additive increases the surface durability and resists abrasion by a factor of over 200% and is comparable to or better than conventional concrete mixes.

KRMCA Sedgwick County AYSO Parking Lot

KRMCA State Award & National Award 45th Street , Bel Aire, KS

American Concrete Institute Award Chapel Landing, Bel Aire, KS

KRMCA State Chapel Landing Phase I, Bel Aire, KS

Municipal Concrete Award Harper, KS

ACPA National Award Brickhaven Ash Unloading Facility, Moncure, NC

ACPA National Award Charrah Inc, Brickhaven, NC

ACPA National Award NCDOT Ramp Replacement, Randolph, NC

ACPA National Award NCDOT Inner Shoulder, Gilford, NC

Andale Construction Inc. and its sister companies have been a leader in the concrete paving industry for the past 40 years. We strive to continually develop new concrete paving methods by using ingenuity and innovation that are generations in the making. We have a wide variety of concrete paving equipment that can handle any application. We use cutting-edge technology coupled with a good old-fashioned work ethic.

If concrete is your paving material of choice, our experienced professionals can help. If you’re looking for a brand-new concrete installation, we can gladly help you pave:

Streets

Parking Lots

Distribution Centers

Driveways

Emergency Lanes

Airport Aprons

Curb and Gutter

Large Concrete Parking Lots

Schools

Oil and Gas

To help maintain the highest quality control, our full in-house laboratory will test our concrete and form a records database for all our mixes.

Certified lab personnel

Custom design any concrete mix for your job specifications

Cylinder casting for compressive strength testing and historical data

With a meticulously maintained front-discharge fleet, our concrete trucks have helped put us on the map.

Drivers approach jobs head-on, control the chute, and ultimately take control of concrete placement

The central mixer features a series of paddles along two rotating shafts, mixing the concrete vigorously, creating an unrivaled product in our market

Andale Slurry™ is a soil stabilization product and application process used as an alternative to standard soil stabilization practices. Our technology takes cement and catapults it into the construction world of the future. Andale Slurry™ has many technical, economic, and environmental advantages over commonly used soil treatment substitutes.

Andale Slurry™ is a liquefied Portland cement

Material is 100% pre-hydrated by water

Hydration of cement doesn’t begin until the mixing operation starts

The slurry mixture is a suspension of cementitious proportions with admixtures to enhance it's physical properties.

Andale Slurry is 60% solid additives and 40% H2O 8-hour transport time without segregation

Dust free application

Metered application based on engineer's recommended rate Can be blended with Fly Ash, CKD, or ABD

Cement Stabilized Soil has a layer coefficient number of 0.20 - 0.24

Low permeability

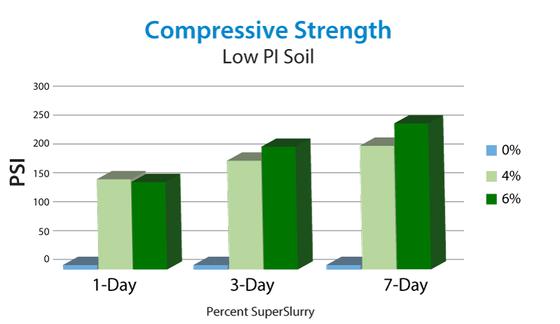

Increases compressive strengths of soil

Increases the durability of the pavement

Increases pavement substrate

Optimizes the performance of the upper layer

Decreases plasticity index to meet job specifications

Eliminates the need for additional base materials

Liquid form eliminates dust, causing air pollution

Less waste

More efficient

Better engineering properties

Reduced mixing time to achieve engineered gradation

Cement factor of 2-8% (3-5% common)

Effective in granular and clay soils

Significant and immediate reductions in PI

Immediate increases in soil strength

- Next-day traffic and construction (no ‘mellowing’)

- All-weather work platform

Produces workable foundations for both rigid and flexible pavements

Permanent modification

- Strength improves immediately

- Strength increases over the years

- No long-term effects from leaching

Our world requires housing, roads, rails, ports, pipelines, power, and many other critical infrastructures. Andale Construction earthwork crews transform work across the project through:

Sophisticated planning and design

Advanced GPS machine control that offers accuracy down to 1/4”

Top-of-the-line software, such as AGTEC and Viewpoint, create accurate 3D takeoff and estimates for any project

Scrapers

Tractors and Pans

Motor Graders

Excavators

Compactors

Front-end Loaders

Dozers

Mixers/ Tillers

Move Trucks

Belly/ End Dumps

Water Trucks

Hydro-Vac

As an IS Networld contractor, we are a trusted and certified commercial and industrial contractor. We are proud to say that safety is embedded into our daily culture. On-site safety management and monthly training ensures we operate safely, eliminating injuries or time lost.

OXCON Systems is a concrete resurfacer, also known as a PCMO (Polymer Composite Micro Overlay) based material, specifically designed to fix deterioration such as spalling, scaling, and disintegration. In addition, our product provides a new, durable, and wear-resistant surface. Fast installation coupled with over 20 years in case studies ensures this is a proven and effective product to add to your toolbox.

How do we add value, longevity, and strength to a project in today's environment while reducing the customer's construction costs, schedule, and maintenance expenses? The answer is simple ... by adding the engineering benefits with the use of our concrete resurfacer. Unlike traditional methods, we do not require lengthy and costly demolition of your existing surfaces.

Least expensive annualized cost

Effectively seals existing pavement from further deterioration and degradation

Long life expectancy compared to other surface treatments

Adds an additional wearing surface

Freeze thaw and chemical resistant

Environmentally friendly

OXCON Systems was chosen to come in with a time-tested product and provide the city with a new road surface that is quiet, environmentally friendly, cooler, and the best cost-effective strategy to resurface and preserve the original concrete.

DustKut™ is an environmentally friendly, biodegradable dust and mud suppressant proven to encapsulate and keep dust and mud down.

The simple answer is that because it is profitable and responsible.

Increases safety

Reduce maintenance

Saves Water

Reduces operating cost

Reduces site emissions

Reduces loss of aggregate

Environmentally Friendly

No toxic chemicals

Unlike other products, DustKut™ encapsulates the material creating a hardened surface trapping the fines of the material, reducing the loss of aggregate, and the chance of mud on your project. DustKut™ keeps the dust down and conserves water because it is manufactured as a concentrated product.

EASYTOUSE-APPLYWITHYOUREXISTING

EQUIPMENTREDUCESDUSTANDMUD

CONSERVESWATER

ENVIRONMENTALLYFRIENDLY SAFEFORHUMANSANDANIMALS

NOLONGWAITTIMES-READYIN10MINUTES* NON-CORROSIVE-SAFEFORALLEQUIPMENT

GRAVEL ROADS

MINING & QUARRY

ROADS LAYDOWN

YARDS STOCKPILES

AGRICULTURE ROADS

CONSTRUCTION SITES

WIND FARM ACCESS

ROADS

OIL FIELD

BUILDING PADS

LEASE / LEASE TO OWN

CUSTOM OPTIONS

AVAILABLE PARTS/ SERVICE

AMERICAN MADE & OWNED

EQUIPMENT VERSATILITY

RAPID DEPLOYMENT AND SETUP

INDUSTRY KNOWLEDGE

NATIONWIDE CAPABILITIES

Our freestanding silos are engineered for wind-rated at 90 mph empty… any material stored in the silo increases that rating significantly.

Our specially designed trailer makes setting up and taking down the silo a low-effort 10-minute breeze—no need for expensive cranes and rigging personnel to have your essential silo operational without the hassle.

Engineered steel foundation makes site prep as easy as constructing a flat hard surface with a load-bearing of 18 psi or more.

WELDING AND FABRICATION

From pre-fabrication to finishing, we can keep your fabrication project in house, eliminating the need for subcontracting work out to other companies, putting a strain on your budget and your timelines.

Custom Metal Fabrication

Structural Steel Fabrication

Heavy Fabrication

Custom Welding

CNC Cutting and Forming

Mobile Welding and Fabrication

Carbon Steel

Stainless Steel

Titanium

Cutting

Special Alloys

MOBILE WELDING AND FABRICATION

As an IS Networld contractor, we are a trusted and certified commercial and industrial contractor. We are proud to say that safety is embedded into our daily culture. On-site safety management and monthly training ensures we operate safely, eliminating injuries or time lost.

Checks

The same ingredients are the same as conventional concrete: sand, aggregates, cement and water. RCC requires lower amounts of cementitious materials compared to conventional concrete, allowing for both lower material costs, greater durability, and lower overall maintenance cost.

LOWER COST

FASTER INSTALLATION

LOOK OF CONVENTIONAL CONCRETE

HEAVY DUTY

DURABLE

SHORTER CONSTRUCTION TIME

LOWER COST

FASTER INSTALLATION

SHORTER CONSTRUCTION TIME

INCREASED PAVEMENT SUPPORT

ELIMINATES DUST

AndaleSlurry™ is a liquefied type I/II Portland cement material that has been 100% hydrated by water Hydration of cement doesn’t begin until the mixing operation starts. AndaleSlurry™ is comprised of 60% solid additives and 40% H2O at a low viscosity and can be transported up to 8 hours without segregation. AndaleSlurry™ is a dust free application that capitalizes on cement particle distribution.

Allows for lower material cost due to using on site material. Full depth reclamation saves time and money and works great to provide a strong base when combined with If designed well, a combination of RCC and AndaleSlurry™ in a Full Depth Reclamation process can

SAVE UP TO 30% OF TOTAL CONSTRUCTION COST

proven system that can improve and protect your bridges, roads, parking garages, driveways, and damaged slabs Designed to deliver long-lasting solutions for aging substrates. Our Concrete Resurfacer is PCMO (Polymer Composite Micro Overlay) based material specifically designed to fix deterioration such as spalling, scaling, and disintegration In addition, our product provides a new durable and wear-resistant surface. Fast installation with over 20 years in case studies ensure this is a proven and effective product to add to your toolbox

Cost savings over replacing concrete Preserves pavements

Long Life Cycle

Adds another wearing surface

Fast Installation

Compressive strength 28 days 7,000 psi

UV Resistant

Freeze thaw resistant

Reduces fugitive dust affecting safety, the environment, people and wildlife

Minimizes erosion and deterioration of roads, paths and trails

Sustainable and Environmentally conscious

DustKut™is a proprietary liquid dust suppressant for unpaved roads, parking lots and construction sites. In combination with water, DustKut™binds to the soil particles to a depth of 0 5 inch or potentially more depending upon soil type. It agglomerates soil particles to form larger size and weight particles; mitigating opportunity for fugitive dust particles to become airborne DustKut™ does not undergo any polymerization and will not leave any residue that will run o or form a hard crust on the surface of the soil that will de-laminate.