MAJOR PROJECT REVIEW

WHERE DESIGN, NATURE, AND LIFESTYLE CONVERGE

GLOBAL AND WESTBOURNE’S

POLY

THIS ISSUE : CATHERINE MCAULEY CATHOLIC COLLEGE North Construction & Building NOVELLO TQM Group MAYNARD GARDENS BOWRAL Novati Constructions NAUTILUS - SHELL COVE Parkview Constructions IVES TP Dynamics SHIRLEY SMITH HIGH SCHOOL Icon Construction ACT UniSC MORETON BAY CAMPUS University of the Sunshine Coast WARREEN PRIMARY SCHOOL Hutchinson Builders SPRING SQUARE Poly Global and Westbourne

SPRING SQUARE

AUSTRALIAN NATIONAL

ICON CONSTRUCTION SUSTAINABILITY IN EDUCATION HUTCHINSON BUILDERS WORLD CLASS EDUCATION IN MELBOURNE'S WEST ALSO INSIDE

CONSTRUC TION

Find out more about how Cordell Connect and Cordell Estimator Platinum can help your business grow

Nautilus – Shell Cove, New South Wales 4 U ni SC MORETON BAY CAMPUS – University of the Sunshine Coast 74 QUEENSLAND 20 32 38 46 52 NEW SOUTH WALES IVES – TP Dynamics SHIRLEY SMITH HIGH SCHOOL ( previously EAST GUNGAHLIN HIGH SCHOOL – Icon Construction ACT 60 66 AUSTRALIAN CAPITAL TERRITORY WARREEN PRIMARY SCHOOL ( previously TRUGANINA NORTH PRIMARY SCHOOL – Hutchinson Builders 82 VICTORIA NEWS AND INDUSTRY COMMENTARY MAKE A STATEMENT WITH 250MM COMMERCIAL FRAMING – Darley Aluminium UNDERSTANDING ACOUSTIC GLAZING – Oceania Glass PIONEERING CANTILEVER SHADE STRUCTURES – Sydney Shade Sails DELIVERING CONFIDENCE FOR 30+ YEARS IN VERTICAL ACCESS SOLUTIONS – Standard Access 4 14 16 17 18 FEATURES SPRING SQUARE – Poly Global and Westbourne CATHERINE MCAULEY CATHOLIC COLLEGE – North Construction & Building NOVELLO – TQM Group MAYNARD GARDENS BOWRAL – Novati Constructions NAUTILUS - SHELL COVE – Parkview Constructions

LEADING BUILDER FDC COMPLETES RESTORATION AND REBUILDING WORKS OF SYDNEY'S WHITE BAY POWER STATION

Award-winning builder FDC has completed its restoration and rebuilding works of New South Wales State heritage-listed White Bay Power Station (WBPS).

The landmark site located in Sydney’s inner western suburb of Rozelle, will open its doors for the first time in 40 years to visitors, as it makes its debut as a cornerstone location for the upcoming 24th Biennale of Sydney.

The rejuvenation of the expansive 30,000m2 site was awarded by Placemaking NSW to FDC, who commenced work on the project in 2022.

The vision was to create a versatile arts, cultural and community hub - bringing new energy to Sydney’s cultural offering. WBPS adds to FDC’s expanding portfolio of significant arts and culture projects in Sydney.

“We have increasingly become trusted partners in preserving and reimagining several of Sydney’s iconic arts and culture sites including Chau Chak Wing Museum, Phoenix Central Park and Artspace – The Gunnery.

“It is testament to the team’s skill and extensive experience to deliver on complex projects which is especially crucial on sites with heritage elements,” says FDC Managing Director Russell Grady.

“White Bay Power Station has been a once-in-a-lifetime project for many on our

team. With any heritage-site, and without that vital building blueprint to guide us, it required a high level of agility and creative problem-solving skills to address the many challenges in bringing the massive site to life.

“I believe the quality of the project speaks volumes of our team’s dedication to the revitalised site, and we look forward to having visitors rediscover this significant Sydney landmark.”

Constructed in 1917, WBPS is Sydney’s longest serving metropolitan power station and was built to power the city’s tram system, later the train system, and then the electricity grid in 1958. Forty years ago in 1984, the site was decommissioned and has laid dormant since with its status as heritage-listed cemented in 1999.

enquire@skyviewaerial.com.au | 0431 931 910 www.skyviewaerialphotography.com.au We offer unique, cost effective and high quality professional aerial and site time lapse photography, along with video from drone, plane and helicopter for the construction and property industry. SKYview has been in business for nearly 20 years servicing the construction industry, with over 25 years of onsite construction experience. We can service everything from small residential projects to the largest of government projects, throughout NSW and ACT. We are unconditionally certified, insured and operate from planes, helicopters and drones as required.

SKYview

PLANE HELICOPTER DRONE TIME LAPSE CAMERA SYSTEMS

DISCOVER THE DIFFERENCE with

Aerial Photography

Scan to read the full article.

INDUSTRY COMMENT

EMPOWERING WOMEN IN SPORTS AND CONSTRUCTION: BMD'S ATHLETE EMPLOYMENT PROGRAM

Paving the way in our approach to collaboration, BMD’s philosophy is relationship-orientated and we engage people, partners and the community as a way to leave a lasting skills legacy beyond the delivery of infrastructure. After 44 years of operation, BMD continues to invest in the development of long-term partnerships with organisations which align with our values.

A significant part of our sponsorship portfolio lies with sporting organisations and most recently, we have specifically been supporting women’s leagues across various codes such as AFL, soccer, QRL, surf lifesaving and netball. It is because of the support we provide these partners that we created a formalised Athlete Employment Program to provide job opportunities for women to combine their sporting commitments with a career offfield through flexible employment in the construction sector.

We have established this program because of the pressing need for increased female representation within the construction industry. Research tells us that women in flexible roles are among the most productive members of a workforce and we want to ensure we are embracing this together with the positive alignment between sport and construction – the importance of collaboration and teamwork, thinking fast to solve problems and unique working hours.

Gender diversity not only enhances creativity and problem-solving skills but also fosters innovation, which is imperative for addressing our industry's major challenges. At BMD, our broad geographical reach and diverse business operations allow us to offer flexibility and an array of employment opportunities. Whether it’s remote work or roles in metropolitan areas, across various sectors of work including water and wastewater, defence, transport, or any of the myriad of other segments we work, we have lots to offer.

At our core, we are a company that values our people. Believing in their potential and nurturing their growth is what emboldens us to create new avenues for development. I am particularly excited about this initiative and the tremendous opportunities it presents for women and for our sector.

$100M PHARMACEUTICAL MANUFACTURING FACILITY IN SOUTH AUSTRALIA’S NORTHERN SUBURBS

Terre Property Partners (Terre) announce that construction has officially commenced on an $100 million purpose-built facility for pharmaceutical company, Noumed Pharmaceuticals, based within their Nexus North Industrial Estate.

Noumed’s state-of-the-art pharmaceutical manufacturing plant, will be the most modern of its kind in Australia.

Ultimately, the project will enhance Australia’s sovereign supply into the pharmacy and health networks, by manufacturing certain OTC pharmaceutical products here in South Australia rather than being manufactured overseas.

The manufacturing plant, which is being built on a 43,000m2 site and has a floor area of 26,000m2, will join several other prominent national and international companies in Terre Property Partners’ Nexus North Industrial Estate, including Asahi, Telstra, Haighs Chocolates, and FJT Logistics.

Terre is an integrated property development and investment management company who represent a diverse range of institutional and wholesale capital partners, with projects spanning premium industrial precincts in South Australia and Victoria.

Terre Property Partners CEO, Mark Brammy, is excited to be the development and ongoing partner for the modern pharmaceutical manufacturing facility.

“We are thrilled to continue our relationship with Noumed Pharmaceuticals within the Nexus North Industrial Estate.

“The location is an ideal place for hightech industries and we’re looking forward to Noumed leading the way in Australian pharmaceutical manufacturing, right here in South Australia,” Mr Brammy said.

The new manufacturing plant will receive up to $20million in Australian Government funding and is a key part of the state’s 10-year health and medical industries strategy.

The project is expected to create 250 jobs during construction and Noumed will employ more than 180 people when local production begins in 2026.

WWW.ANCR.COM.AU ANCR CONSTRUCTION NEWS 7

SCOTT POWER Chief Executive Officer BMD

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW ANCR CONSTRUCTION NEWS 8

INDUSTRY COMMENT

A HOLISTIC APPROACH TO BUILDING DESIGN - WHY BUILDING PRODUCT MANUFACTURERS SHOULD DEEPLY CONSIDER ENVIRONMENT AND CONTEXT

As multidisciplinary designers, we provide expert advice to major Australian building product manufacturers, informed by decades of industry experience and insights from our in-house interior designers, who specify products for a wide range of clients.

With a deep understanding of the needs and preferences of architects, designers and specifiers, we work to ensure the products manufactured are practical, desirable and will stand the test of time.

When our studio was first founded in the 1960s, the Australian construction market was reliant on products designed and produced for the European market.

Fifty years on and things have changed dramatically. With a landscape and natural light like nowhere else on earth, it has been critical for the Australian architecture and design

industry to develop high quality products that work for the landscapes we live in.

Nexus Designs has been at the forefront of this movement, which sees manufacturers work hard to understand the needs of local specifiers to ensure their products are designed accordingly.

At the heart of this is a holistic approach to materiality. Working with Australian building product manufacturers we ensure that they design and develop their products to work harmoniously with both the environment and the other components on the market that they will sit alongside.

Whilst performance is of course the top priority, considering the aesthetics – finish, colour, tonal range, and tactility of the products together is critical to the final outcome.

With our building products now being exported to countries across the globe, the Australian construction industry continues to pioneer this considered and holistic approach to design.

RESTORING A 135-YEAR-OLD MELBOURNE ICON

Melbourne’s iconic Princes Bridge is undergoing a major facelift – with restoration works to protect and enhance its distinctive historic features.

The bridge is one of the city’s busiest and most prominent gateways, linking the CBD with a range of popular cultural, historic, sporting and entertainment attractions.

Restoration works are being carried out in sections, including cleaning, repairing and replacing bluestone blocks and restoring heritage features.

Princes Bridge was built in 1888 to accommodate Melbourne’s booming population following the gold rush period. It replaced a single-span bluestone and granite arch bridge (1850-1884) and the wooden trestle bridge (1844-1852) that came before it.

Over the years, the bridge has evolved with the city – accommodating electric trams after being reinforced in 1924, removing lead-based paint from the ironwork in 2006 and becoming more pedestrian-friendly with the introduction of single lanes in each direction in 2013.

It is one of the oldest river crossings in the CBD and has undergone minimal repairs in its 135-year lifetime – until now.

Detailed restoration work has begun on site and will be completed in stages over the next three years.

The restoration project is one of the first to display artwork around the site as part of Council’s Creative Hoardings project – with a thought-provoking work to be installed,

titled Remembering by Yorta Yorta and man, historian, cultural educator and artist John Patten.

Access under and along the bridge will be maintained throughout most of the works. Melburnians and visitors will be notified of any short-term closures and diversions.

For more information about the Princes Bridge Restoration project contact City of Melbourne.

WWW.ANCR.COM.AU ANCR CONSTRUCTION NEWS 9

SALLY EVANS Director Product Development and Graphic Design Nexus Designs

MCNAB WINS NATIONAL GONG FOR ICONIC CITY HALL

McNab, one of Queensland’s largest privately-owned companies, has taken home a coveted national award for the landmark Sunshine Coast City Hall project at the Master Builders National Excellence in Building and Construction Awards hosted at Crown Towers in Perth [25 November, 2023].

After winning the Queensland Project of the Year for its work on Sunshine Coast Council’s City Hall located in the Maroochydore CBD, the construction company was awarded the National Commercial/Industrial Construction Award ($50M to $100M) at the national awards ceremony.

McNab Founder and Managing Director Michael McNab said he was immensely proud of the team honoured with this prestigious national award, presented annually in recognition of the country’s best builders in housing and construction.

“Sunshine Coast City Hall has established a new benchmark in innovation and sustainability for commercial developments – not only across the Sunshine Coast but throughout Queensland and Australia at large,” said Mr McNab. “The unique building design meant each floor was configured

INDUSTRY COMMENT

differently so our team and expert partners worked together to create everything onsite, resulting in exceptional quality that you have to see in person to truly appreciate.

“To meet the Council’s requirements for 5 Star Green Star and NABERS accreditation required innovative building solutions, procurement and assembling a highly skilled delivery team.

BENEFITS OF CONSTRUCTION CLOUD TECHNOLOGY

The Australian construction industry has a great opportunity to embrace the productivity benefits of construction cloud technology.

By implementing cloud and mobile technology in construction, firms can enjoy successful project and business outcomes, including:

• Increased scalability by subscribing to a flexible, cloud-based solution that can grow with your firm’s needs and objectives.

• Access to real-time performance metrics, such as plans, budgets and schedules that allow for more efficient collaboration and decision making.

• Enhanced security that is typically managed by experienced IT professionals, stored on secure servers and protected by advanced security protocols.

• Improved collaboration and information sharing, thanks to streamlined workflows shared between internal and external stakeholders.

• Reduced errors since manual data entry and validation processes can be automated, and since project schedules can be created and managed to ensure timelines are followed.

The Australian construction industry is historically known for its slow uptake of technology and limited productivity, but it doesn’t have to be this way.

When implemented correctly, construction cloud technology can help businesses reach their project management goals, increase productivity and reduce costs.

Construction leaders willing to invest in cloud-based technology will be well-

“In addition to this, when it came to the 2,000-plus workers who contributed to this project, we heavily targeted local market engagement and procurement. McNab's local presence, valued long-term partnerships and ongoing engagement with the Sunshine Coast community was incredibly beneficial in the delivery of this project.”

Sunshine Coast City Hall was designed by award-winning Cottee Parker Architects with the iconic façade of the building inspired by the forms and colours of the Glass House Mountains, one of the most defining natural landmarks of the Sunshine Coast region.

The building is among the earliest projects to be delivered as part of the Sunshine Coast Council, Walker Corporation and SunCentral Maroochydore Pty Ltd’s historic agreement to deliver Australia’s first ‘greenfield’ CBD in Maroochydore over the next 15 to 20 years.

“Sunshine Coast City Hall forms part of the collective vision to create a first-of-its-kind regional civic, business and commercial heart and McNab is delighted to be part of this promising future for the Sunshine Coast,” Mr McNab said.

ANDREW TUCKER Product Manager APAC Trimble Viewpoint

ANDREW TUCKER Product Manager APAC Trimble Viewpoint

positioned to drive their firms to greater success in the years ahead.

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW ANCR CONSTRUCTION NEWS 10

Scan to read the full article.

Photo credit - Willem-Dirk Du Toit

CHARTER HALL COMMENCES MAIN WORKS CONSTRUCTION AT CHIFLEY SOUTH DEVELOPMENT

The construction contract has been awarded to Built, following completion of an early works contract. Built have completed numerous similar-sized projects for Charter Hall recently, including the 43,000m2 , 60 King William Street in Adelaide, as well as the 40,000m2 Australia Post HQ complex in Melbourne, both completed in 2023.

This major construction milestone comes following the City of Sydney granting development approval for Chifley South in December 2023.

“Cinchy.me” is a digital ‘tradie’ database and recruitment platform with Applicant Tracking System (‘ATS’), for the Construction Industry.

“Cinchy.me”helps hiring businesses find and recruit their most important asset, ‘tradie’, via an interactive ‘ATS’. Finding the right tradie for a company and a project offers significant value.

“Cinchy.me” enables this concept via our search and invite feature, which allows job adverts to be targeted to specific individuals, who meet your mobilisation requirements.

For the tradie, we remove the repetitive process they face with every new role, by providing a downloadable app to securely store and share their tradie profile and apply for open positions. While retaining

SUBSCRIBE NOW

Your Subscription to the Australian National Construction Review ensures you receive our premium hard copy publication, featuring stunning Project Showcases, Case Studies, Product Information and Commentary from within the industry and associated disciplines.

OR if digital is more your speed, subscribe to our e-newsletter, released monthly for a snapshot of new products, innovations and services that can benefit your next project. Scan

full control of their privacy in a best-in-class secure ecosystem.

By bringing the digitised tradie and hiring businesses together in an integrated platform, we reduce the lead time to mobilise and improve the efficiency of the recruiting team.

Further downstream, “Cinchy.me” offers an end-to-end workflow, to remove re-work and improve efficiency as candidates (and their data) move from the recruitment process into the operational functions of a business.

It’s not just about broadcasting a job to a tradie database!

To find out more or sign up for free trial visit website www.will-cro.com/cinchyme or email team@cinchy.me.

ANCR JOINS SYDNEY BUILD 2024 AS BRONZE MEDIA PARTNER! MATES IN CONSTRUCTION AND

We are delighted to announce we will once again be supporting Sydney Build 2024.

The Australian National Construction Review publication has dedicated 20 years to fostering collaboration and promoting excellence in the construction industry, and renewing our partnership with Sydney Build this year continues our commitment to finding new ways to support, connect, and inspire growth and innovation within the sector

MATES in Construction (MATES), the champion of suicide prevention and mental health in the construction sector, is thrilled to announce a partnership with EML Group (EML), a specialist in personal injury claims management in Australia.

This pioneering collaboration, enabled by EML’s investment through the Mutual Benefits Program, is set to significantly strengthen mental health support and

education for construction workers.

EML’s funding will enable MATES to boost its on-site support and training in New South Wales by deploying two new Field Officers which will bolster the wellbeing of an estimated 2,300 construction workers each year. These officers will specialise in delivering bespoke training and on-site sessions, with a concentrated focus on mental health and the prevention of suicide.

WWW.ANCR.COM.AU ANCR CONSTRUCTION NEWS 11

CINCHY.ME

EML GROUP JOIN FORCES TO TRANSFORM MENTAL HEALTH IN THE CONSTRUCTION INDUSTRY

to Subscribe

the QR code

INDUSTRY COMMENT LIVE MUSIC & ENTERTAINMENT FUTURE CONSTRUCTION FUTURE AUSTRALIA THE MAIN STAGE STAGE future tech, ai & robotics CONSTRUCTION WELLBEING CONSTRUCTION MARKETING STAGE WORKSHOP hvacR SUSTAINABILITY STAGE DIGITAL CONSTRUCTION STAGE WORKSHOP DIGITAL CONSTRUCTION WORKSHOP building solutions & materials ARCHITECTURE & DESIGN STAGE ARCHITECTURE & DESIGN WORKSHOP DIVERSITY, INCLUSION & RECONCILIATION STAGE AN UNMISSABLE 2 DAYS AUSTRALIA'S LARGEST CONSTRUCTION & DESIGN SHOW REGISTER FREE TICKETS TODAY AT WWW.SYDNEYBUILDEXPO.COM THOUSANDS OF ATTENDEES CPD SESSIONS NETWORKING PARTIES 500+ SPEAKERS 500+ EXHIBITORS MEET THE BUYERS WOMEN IN CONSTRUCTION 12 CPD STAGES MAY 1-2 ICC SYDNEY 9AM - 5PM STAGE Arup | AECOM | 3XN | Arcadis | Aurecon | Autodesk | Architectus | ACO Australia | Acciona | BESIX Watpac | Bryden Wood | BVN | Building Commission NSW | Cundall |CPB Contractors | Freyssinet | Gensler | GHD | Hansen Yuncken | i2C Architects | Jacobs | John Holland | Landcom | Laing O’Rourke | Lendlease | Mace Group| McGregor Coxall | Mott MacDonald | NSW Public Works | Richard Crookes Constructions | RICS | RSHP | Sydney Water | Turner & Townsend | Woods Bagot | WSP | WT Australia and many more. 20,000+ VISITORS FROM LEADING COMPANIES INCLUDING:

MULTIPLEX AWARDED MELBOURNE STUDENT HOUSING CONTRACT

Global contractor Multiplex has been appointed by Brookfield Asset Management to deliver its first-ever student housing project in Australia in a joint venture with Citiplan and Journal Student Living.

In a prominent location in Carlton opposite the University of Melbourne’s Parkville campus, the upcoming development sits on an amalgamated block on the corner of Bouverie and Grattan Streets. It also sits within walking distance of the CBD, Lygon Street, Queen Victoria Market and Melbourne Central, making it a prized location for students.

Multiplex has been awarded the contract after early contractor involvement, collaboratively working with Brookfield, Citiplan and Journal Student Living to develop the design, pricing, and construction methodology for the project.

“This is a wonderful opportunity for us to leverage our robust credentials, successfully delivering residential apartment projects, and combine them with our specialist expertise in the education sector,” said Ross Snowball, Regional Managing Director at Multiplex.

INDUSTRY COMMENT

“It builds upon our strong track record in delivering student housing in Victoria, with projects recently undertaken for both La Trobe and Monash Universities.”

Designed by award-winning firm Jackson Clement Burrows Architects, the new building spans a total area of 13,632m2 , featuring 464 beds across 15-storeys as well as three retail tenancies.

FUTURE-PROOFING YOUR WORKFORCE WITH INSTITUTIONAL MEMORY

Skilled labour shortage, aging workforces and growth in demand for infrastructure can create a concerning need for fresh talent to execute quickly and efficiently on complex projects. To compete and comply with rapidly changing standards, it’s crucial to facilitate intergenerational knowledge transfer, and train new talent at speed, while minimising risks and raising the bar on accurate project delivery.

We’re familiar with the challenges. Talent retention is a constant struggle and new generations enter the workforce short of skills. When employees leave, they leach institutional knowledge and trade secrets to competitors. Teams vary from project to project and there is a wealth of tangible knowledge (legal and technical documents) and intangible knowledge (techniques and skills) that aren’t formally retained or made accessible. This is your institutional memory.

So, how do you capture this valuable IP?

The key is to transform that goldmine of organisational data into a live reference bank that current and future generations can upload and download for enhanced project delivery - centralised solutions that capture documents, drawings, models and estimating and planning solutions with structures for project data that can be used for comparison and benchmarking.

Often, we see veterans in the industry grappling with innovation, yet they are fundamental to driving innovation. With institutional memory systems in place, their knowledge can be captured and processed. Integrated with new project data, AI and advanced digital tools, this will drive up the pace of innovation and demonstrate an attractive vision and culture of successful project delivery.

Brookfield Head of Real Estate Investments for Australia Ruban Kaneshamoorthy said: “There are significant tailwinds for student accommodation in Australia. We see this as a highly favourable environment to develop sites, with international students returning to study and existing accommodation almost at capacity. The winning combination of location, amenity and design will make this site a highly sought-after space for students.”

BOB BRYANT

Executive Vice Presidenr, Asia Pacific & Japan

InEight

BOB BRYANT

Executive Vice Presidenr, Asia Pacific & Japan

InEight

WWW.ANCR.COM.AU ANCR CONSTRUCTION NEWS 13

BIG OPPORTUNITY TO REDUCE GREENHOUSE GAS EMISSIONS OF INFRASTRUCTURE

The Victorian Government has a big opportunity to reduce the climate impacts of the infrastructure it builds and operates, the state’s independent infrastructure advisor finds.

Infrastructure Victoria’s latest advice to the Victorian Government, Opportunities to reduce greenhouse gas emissions of infrastructure makes 10 recommendations to limit carbon emissions across Victorian government schools, hospitals, transport projects and other infrastructure.

Chief Executive Officer Dr Jonathan Spear says planning and delivering infrastructure to support emissions reduction goals can save money, improve productivity and create new jobs.

“There are many ways to reduce the climate impacts of the infrastructure government

builds and operates, such as getting better use from existing assets and prioritising low carbon design and materials,” Dr Spear said.

“Our advice outlines a path for government to make reducing emissions of infrastructure the new business-as-usual.”

The report recommends the Victorian Government adopt a dollar value per tonne of carbon to inform infrastructure planning and business cases. This is the approach that New South Wales and other governments have adopted, so that infrastructure project decisions are consistent with emission reduction targets and policies.

“We can’t manage what we don’t measure. Valuing emissions in business cases ensures that climate change impacts are considered alongside other costs and benefits of a project.”

INFRASTRUCTURE VICTORIA’S 10 RECOMMENDATIONS TO THE VICTORIAN GOVERNMENT TO REDUCE GREENHOUSE EMISSIONS (CARBON) FROM PUBLIC INFRASTRUCTURE ARE:

• Develop a comprehensive approach to measure and manage carbon emissions modelled on the UK’s PAS 2080:2023 Carbon management in buildings and infrastructure standard.

• Identify and adopt carbon measurement tools and deliver training across the Victorian Government.

• Value carbon using a target consistent approach and calculate required values to achieve Victorian emissions reduction targets.

• Update business case guidelines and templates to integrate emissions reduction.

• Measure carbon in infrastructure cost benefit analysis.

• Update procurement frameworks and guidance to promote carbon reduction in tenders.

• Update standard form contracts to include minimum carbon reduction requirements and incentives for further reductions.

• Establish carbon management pre-qualification requirements for government contracts.

• Support industry to develop zero or low emissions solutions by testing alternative materials and adopting performance-based standards.

• Update assurance processes to include carbon emissions.

Dr Spear said swift action now can offer new opportunities for Victoria as the world transitions to a low carbon economy.

“Other regions, including the USA and Europe, are introducing restrictions on high emissions materials and sustainability requirements for businesses,” Dr Spear said. “Reducing emissions of infrastructure means Victoria is better positioned as the global economy shifts.”

The advice recommends the government adopt a consistent and comprehensive approach to measure and manage carbon emissions across the lifecycle of new infrastructure projects, modelled on the UK’s PAS 2080:2023 Carbon management in buildings and infrastructure standard.

Other recommendations include training for staff across the public sector and support for industry to test low carbon materials (see recommendations summary below).

“Industry told us they are ready and willing to respond to clear direction from the Victorian Government about the level and pace of infrastructure decarbonisation,” he said.

“With its multi-billion dollar pipeline of new build infrastructure, the Victorian Government has a big opportunity to influence how infrastructure is designed, what materials are used in construction and the jobs for Victorians in a low carbon economy.”

3 OVERARCHING PRINCIPLES TO GUIDE INFRASTRUCTURE DECARBONISATION EFFORTS IN VIC:

• Prioritise non-build or low build solutions. Aim to get better use from existing infrastructure or modify it to meet changing needs before considering a new build.

• Align approaches with other governments and industry best practices in order to rapidly adopt proven approaches.

• Clarify the scale and pace of infrastructure emissions reduction to give confidence to industry to propose or take up options to reduce carbon in the significant pipeline of infrastructure projects underway.

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW ANCR CONSTRUCTION NEWS 14

INFRASTRUCTURE PARTNERSHIPS AUSTRALIA WELCOMES INFRASTRUCTURE VICTORIA’S ADVICE ON DECARBONISATION

Industry welcomes Infrastructure Victoria’s advice as a significant milestone towards accounting for, and reducing, greenhouse gas emissions in infrastructure delivery.

As a longstanding advocate for sensible reform, it is pleasing to see our advocacy for using a ‘carbon base case’ as a key metric in major project decisions adopted. This includes what should be built, how this can be done, and who delivers it.

Right now, when governments decide where to allocate hundreds of billions of dollars taxpayers’ money to infrastructure programmes, they are flying blind on

NEW 100% RECYCLABLE MANHOLE & STORMWATER PIT FORMWORK

Plastic Formwork Hire has reimagined the production of conventional steel manhole and stormwater pit formwork and introduced a 100% recyclable HDPE plastic version, removing costly management and maintenance issues previously associated with the development of stormwater pits and manholes.

Manufactured from a lightweight and durable High-Density Polyethylene (HDPE) material, the HDPE Formwork is designed to be portable and easy to assemble. It removes the need for heavy transport haulage and machine installation for heavy steel forms, amongst other efficiencies.

carbon. That’s not an exaggeration – they have no visibility of the carbon implications in the decisions they make.

For Australia to reach net zero, we must transform how we build.

Infrastructure Victoria’s recommendations made today have the capacity to limit emissions over the life cycle of a project and save infrastructure providers potentially billions of dollars in capital costs –particularly by creating the right incentives to use less of the highest emitting materials like concrete and steel.

NEXTDC BREAKS GROUND ON $80 MILLION DATA CENTRE, D1 DARWIN

NEXTDC Limited (ASX: NXT), Australia’s leading data centre services provider, officially begins development on its $80 million D1 Darwin data centre facility with a targeted completion and launch in June 2024. Built in collaboration with long-standing partners Kapitol Group, the construction of D1 Darwin will create more than 200 jobs in the region throughout the life of the project and into the daily operation of the facility.

The first-of-its-kind for Darwin, this data centre will enable the Northern Territory economy with world class digital infrastructure, combined with secure, low-latency access to global cloud platforms to fully maximise the benefits of technology innovation such as Gen A.I, automation and robotics.

“As our flagship data centre in NT, D1 Darwin forms part of NEXTDC’s strategy to leverage the next frontier of Edge computing and for the region, it is a big step towards

national digital equity,” says NEXTDC CEO Craig Scroggie.

“Its proximity to Darwin’s CBD and direct access to the major submarine cable infrastructure, means legacy industries such as mining and resources alongside the emerging defence sector can have real-time responsiveness to operational and mission-critical needs, fully capturing the value of emerging technologies.”

NEXTDC is partnering with the Northern Territory Government to accelerate the economic development of the region through investment in technological infrastructure and advancements. D1 Darwin, with a projected 8MW capacity, will propel Northern Territory’s (NT) Digital Territory Action Plan by providing the crucial digital infrastructure to unlock new opportunities for NT’s growing digital industry – and more broadly, contributing to its $40bn 2030 economic outlook.

Do you have a project, media release, product or news item you would like to feature with the Australian National Construction Review?

Get in touch with our submissions team by scanning the code or at submissions@ancr.com.au to find out more.

WWW.ANCR.COM.AU ANCR CONSTRUCTION NEWS 15

INDUSTRY

ADRIAN DWYER Chief Executive Infrastructure Partnerships Australia

COMMENT

Scan to read the full article.

MAKE A STATEMENT WITH 250MM COMMERCIAL FRAMING

With over 27 years of dedicated service in the aluminium industry, Darley Aluminium stands as a respected Australian-owned family business and one of the nation's premier distributors of aluminium extrusions. Far more than a supplier, Darley provides tailored solutions to fabricators across the country, and have added the 250mm commercial framing system to their suite of cutting-edge solutions.

Darley Aluminium introduced their new CityView 250mm front double glazed commercial framing system to the market to cater to large spans, high wind loads and applications where design and visual appeal are a top priority.

The system is perfect for commercial spaces where light and visibility are premium realestate including car dealerships, showrooms, hotels, exhibition halls, and commercial lobby spaces.

Design Flexibility and Versatility

The sleek and modern aesthetic of the 250mm system can be customised to suit the buildings’ colour and style. As this framing system is front-glazed, its glazing pockets are in a forward position, making it flush with the external finishes. This gives the façade of the building a clean, sleek, and minimalist look

from the outside while allowing an abundance of light and creating bright open spaces.

The 250mm system is compatible with Darley’s CityView 45mm commercial doors and CityView Awning and casement windows making this system versatile and customisable to your design wants and needs.

Compliance with Australian Standards

The new 250mm commercial framing system has been tested to and exceeds AS2047 Windows and external glazed doors in buildings and AS/NZ 4284 testing of building facades offering superior quality.

Structural Integrity

With dedicated mullion stiffeners for additional strength when required, the 250mm system provides robust structural support and is perfect for projects featuring large spans of distance between two supports.

A 250mm system can provide the necessary structural support and can be load bearing when required, able to reach an overall height of 6,000mm. The system also features a dedicated sub-framing system for optimal installation and weatherproofing.

ANCR SPECIAL FOCUS AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 16

High Wind Loads

The strength, structural integrity and ability to withstand strong weather forces of the 250mm system makes it the ideal choice for installation in areas with high wind and extreme weather conditions.

Energy efficiency and Sustainability

Many commercial projects now have energy efficiency and sustainability goals and the 250mm framing system can help achieve those goals.

The 250mm framing suite with a wide 50mm pocket is able to accommodate highperformance insulated glass up to 44mm thick while the system is made from aluminium which is highly recyclable and only uses a fraction of the energy used to produce other metal framing.

The unique attributes of the 250mm commercial framing system perfectly meet the functional, structural and aesthetic requirements of many commercial applications. Whether you are a builder, property developer, architect, or anyone else involved in commercial construction projects, you should consider Darley’s new 250mm system – for something that will make an impression, grab attention and is high-performing.

With many more superior-performance aluminium window and door solutions to suit

a range of specifications and designs, Darley prides itself on being a one-stop solution for all your aluminium window and door needs. From window frames to security screen doors to glazed windows and more, Darley has exactly what you need to fit the unique aesthetic, performance and size specifications of your project.

DARLEY ALUMINIUM

NSW (02) 8887 2888

VIC (03) 9238 3888

QLD (07) 3287 1888

WA (08) 9437 2999

darleyaluminium.com.au

ANCR SPECIAL FOCUS WWW.ANCR.COM.AU 17

Scan the QR code to learn more about Darley Aluminium’s 250mm Commercial Framing Solution

Understanding Acoustic Glazing

Specifying the best glass for noise reduction

The ability to control external sounds in our homes, workplaces, hospitals and schools has gained importance due to modern lifestyles and the close proximity of these buildings to highways, airports, construction sites and industry. Among the many building materials and products that make up a structure, windows and doors have a big impact on how well the home or building is insulated from outside noise. With the wide range of glazing solutions available, understanding the differences between singleglazing, multi-layered glazing, laminated glass and high-performance acoustic glazing is essential.

Understanding Acoustic Glazing: Specifying the best glass for noise reduction explores the role of glazing in acoustic design and how different types of glazing products compare in terms of sound reduction performance. We highlight what makes acoustic glass a high-performance solution distinct from other forms of glazing. We also look at common misconceptions surrounding acoustic glass.

Australia’s leading brand of acoustic glass, Genuine Hush™ is highly specified and made exclusively by Oceania Glass™. Genuine Hush™ offers a range of quality performance acoustic glass that has been tested and certified. The Genuine Hush™ acoustic performance range comprises of QLam Hush™ and ComfortHush™ –two distinct yet complementary products suited to a wide range of applications and available in a choice of colours.

Download this whitepaper and learn why acoustic glass stands above the rest when it comes to sound reduction.

www.oceaniaglass.com.au/resources/white-papers/

Australia’s Architectural Glass Maker

oceaniaglass.com.au TM are trademarks of Oceania Glass Pty Ltd I ANCR 2024

Our Range of Acoustic Glass is Made In Australia by Oceania Glass

PIONEERING CANTILEVER SHADE STRUCTURES

Case Study : Stockland Wetherill Park Kitchin Lane Shade Structure

In the heart of Wetherill Park's foodie hub, Stockland Shopping Centre’s Kinchin Lane, Sydney Shade Sails has once again demonstrated its commitment to innovation and excellence with the creation of a butterfly-style cantilever shade structure to enhance the outdoor experience in this bustling culinary enclave.

The client’s request was ambitious – a butterfly-style cantilever shade structure with canopies manufactured from a fiberglass fabric coated in PTFE (trade name Teflon®) coating (Skytop FGT-800). This product is not manufactured in Australia; outsourcing to an overseas company marked a change in practice for Sydney Shade Sails, who usually manufactures everything themselves.

Skytop FGT-800 is an architectural fabric developed in Japan for membrane structures. It is a composite material produced by heating and compacting fluoroplastic (a class of plastics

using fluorine instead of hydrogen in it’s carbon chain composition) and glass filament yarn. The fluoroplastic membrane FGT series is a combination of Teflon® PTFE with self-extinguishing properties and glass cloth fiber with heat resistance.

For Sydney Shade Sails the challenge lay in working with a fabric never used before. The material, lacking the stretch of regular PVC, initially caused apprehension. However, once the first canopy was in place, the pieces fell into perfect alignment.

The project’s sheer size, in terms of steelwork, made it the most significant undertaking for Sydney Shade Sails to date. With specifications including a 6m width, two structures measuring 6m x 9m and 6m x 30m, and a towering height of 5530mm, the project demanded precision and creativity.

Operating in a busy shopping center, the team faced the additional challenge of working

amidst operational shops. The meticulous planning, fabrication of the canopy’s framing, and three weeks of on-site work, including adjustments and modifications, highlighted the company’s versatility and dedication to delivering beyond expectations.

For more information contact Sydney Shade Sails (NSW) Pty Ltd, phone 02 9592 0401, email enquiries@shadesailsydney.net.au, website www.shadesailsydney.net.au

43 DUNMORE DRIVE, TRUGANINA, VICTORIA, 3029, AUSTRALIA e sales@standardaccess.com.au | w standardaccess.com.au

+61 3 9116 4090

Scan the QR Code to learn more about our construction industry hoisting solutions or speak with our team. tel.

DELIVERING CONFIDENCE FOR 30+ YEARS IN VERTICAL ACCESS SOLUTIONS

As today’s distinctive building architecture pushes design boundaries, Standard Access provides the expert stewardship needed to deliver safe, efficient and effective outcomes, from beginning to end.

Servicing Australia and south east Asia for more than 30 years

Temporary hire and sales

Global supply chain partnerships with leading OEM manufacturers

Top-down/bottom-up solutions to meet almost every project requirement

SWING STAGES

SUSPENDED ACCESS

Perfect for top-down applications where facia fixing is not an option or ground access is unsuitable. Commonly used for façade remediation and where 360˚ access is required.

MAST CLIMBER WORK PLATFORMS

Operable at heights up to 200 meters and loads up to 10,000kg, mast climbers are the ideal solution for safe and efficient access to expansive facades, and can be integrated with monorails.

In-house engineers and custom fabricators

State of the art service and testing facility

Highly accredited trainers

Specialists in addressing complex vertical access requirements such as detailed facade profiling and overhangs

MONORAIL SYSTEMS

Fixed directly to a building façade or integrated with a mast climber, monorails are integral where heavy elements require hoisting into place such as glass panels/ curtain walls, cladding and signage.

HOISTS

Safely and effortlessly transport personnel and materials to any height with frequency control and stop/ start comfort. Full operator induction. Customise with various door sizes and locations, manual or automated opening.

NSW PROJECT FEATURE SPRING SQUARE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 22 SPRING SQUARE DEVELOPER : Poly Global MAIN CONSTRUCTION COMPANY : Westbourne ARCHITECT : Scott Carver CONSTRUCTION VALUE : $364 million

NSW PROJECT FEATURE SPRING SQUARE WWW.ANCR.COM.AU 23

WHERE DESIGN, NATURE, AND LIFESTYLE CONVERGE

Spring Square stands as a meticulously crafted mixed-use master-planned development valued at $364 million. It encompasses 516 elegantly designed studios, along with one, two, and three-bedroom apartments distributed across five towers spanning 10 to 14 stories. The development features a twostory podium, 6,500m2 of retail and commercial spaces, communal open areas, an integrated childcare facility, and extensive landscaping.

The landscape of Bankstown is set to transform with the unveiling of Spring Square, a groundbreaking $364 million mixed-use development poised to redefine urban living in the heart of the region.

Developed by leading international developer Poly Global, in collaboration with awardwinning design firm Scott Carver and boutique building company Westbourne, Spring Square promises to be a vibrant, integrated community hub that caters to every aspect of modern life.

Comprising five towers spanning 10 to 14 stories, Spring Square boasts a total of 516 beautifully designed studios, one, two and three-bedroom apartments. These residences are complemented by a two-storey podium featuring 6,500sqm of retail and commercial spaces, ensuring residents have convenient access to essential amenities right at their doorstep. Additionally, the development includes communal open spaces, an integrated childcare facility, lush green lawns, native trees, outdoor BBQ and kitchen spaces, al fresco-style leisure areas, seating nooks and expansive district views, creating an enriched urban vertical village.

According to Poly Global, Spring Square is more than just a residential development; it's a transformative project aimed at revitalizing Bankstown and fostering a sense of community and connectivity among its residents. Inspired by vertical communities around the globe, Spring Square is designed to uplift the area, offering a new way to live, work and play in this vibrant precinct.

Bankstown's central location within Sydney, coupled with its elevation, makes it one of the highest vantage points in the region. Residents of Spring Square can enjoy expansive district Sydney CBD and Olympic Park views from their homes, a unique feature that sets the development apart.

Poly Global, known for its commitment to creating socially sustainable communities, has brought its global expertise to Spring Square, ensuring that the development meets the highest standards of design, functionality and livability. Collaborating with Scott Carver, an award-winning design firm renowned for its innovative and emotive design approach, and Westbourne, a boutique building company with a track record of delivering high-quality residential projects, Poly Global aims to set a new benchmark for integrated living in Bankstown.

Poly (Australia) Real Estate Development

is the Australian division of international property development company, Poly Global. The company entered the Australian market in 2015 with acquisitions in Melbourne and Sydney. Poly Australia made its first acquisition in Brisbane in 2019, and now operates across the eastern seaboard of Australia.

Westbourne is a proud wholly owned Australian company who have just celebrated their 21st anniversary, specialising in the home unit construction industry.

They have a reputation for producing high quality apartments, together with a comprehensive after sales service delivering a seamless transition to the new owner and/or occupier.

The recipient of multiple awards, Westbourne’s most recent MBA Award was the Excellence in Construction – Adaptive Re-Use Division for their 127 apartment Milsons Point development which also won the Urban Taskforce Development Excellence Award for Adaptive Re-Use.

Westbourne have regularly been recognised for their construction professionalism not only through awards but via feedback from purchasers, clients, agents and various industry professionals.

Spring Square is poised to become a landmark destination in Bankstown, offering residents a true sense of place and community. As the project nears completion, anticipation is building for the unveiling of this transformative development that promises to shape the future of urban living in Bankstown for years to come.

For more information contact Poly Global, Poly Centre, Level 16, 210 George Street, Sydney NSW 2000 phone 02 9336 8899, email info@polyglobal.com, website www.polyglobal.com

For more information conatct Westbourne, Suite 23, 12 Tryon Road, Lindfield NSW 2070, phone 02 9413 8442, email info@westbourne.net.au, website www.westbourne.net.au

NSW PROJECT FEATURE SPRING SQUARE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 24

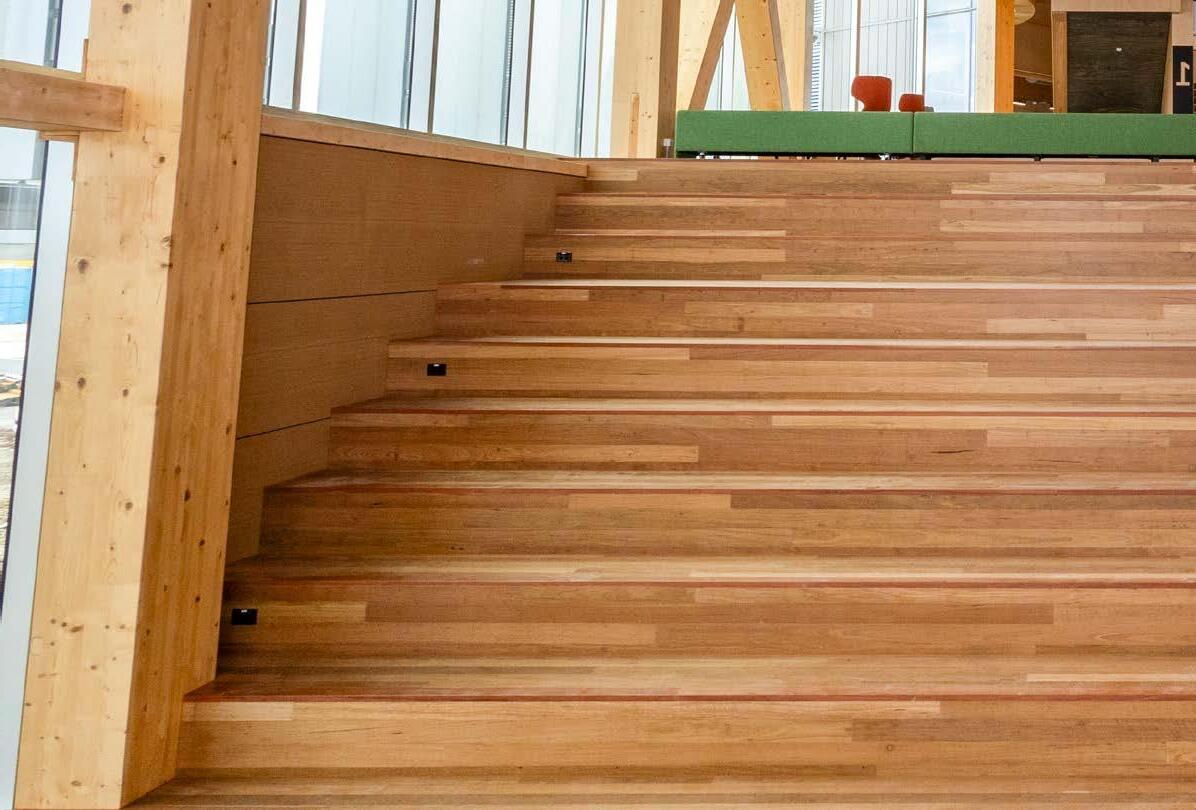

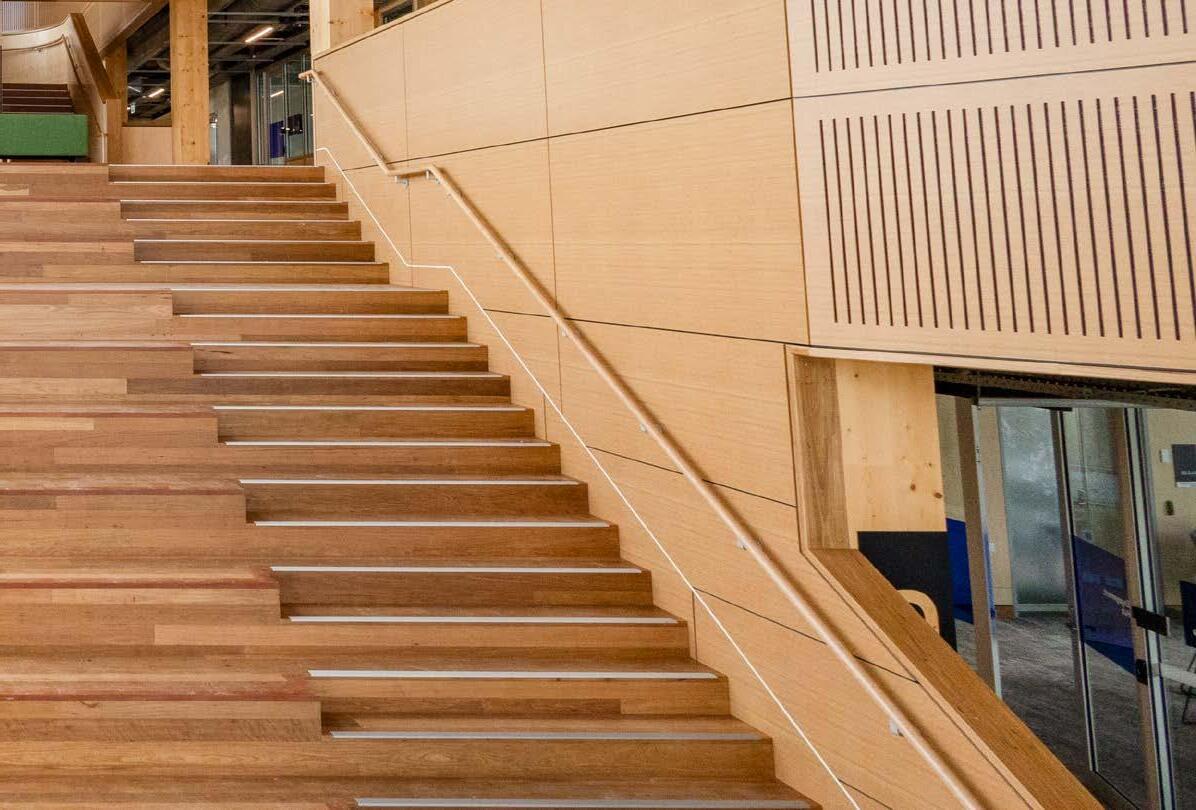

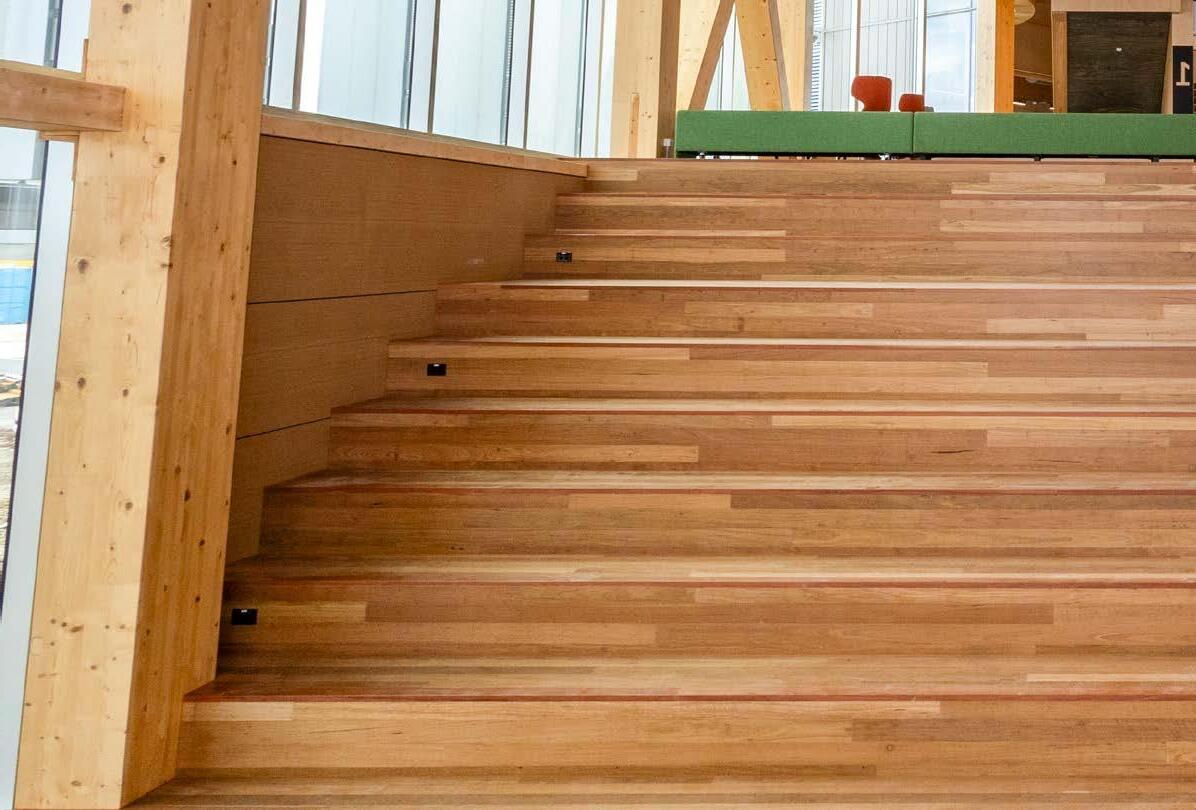

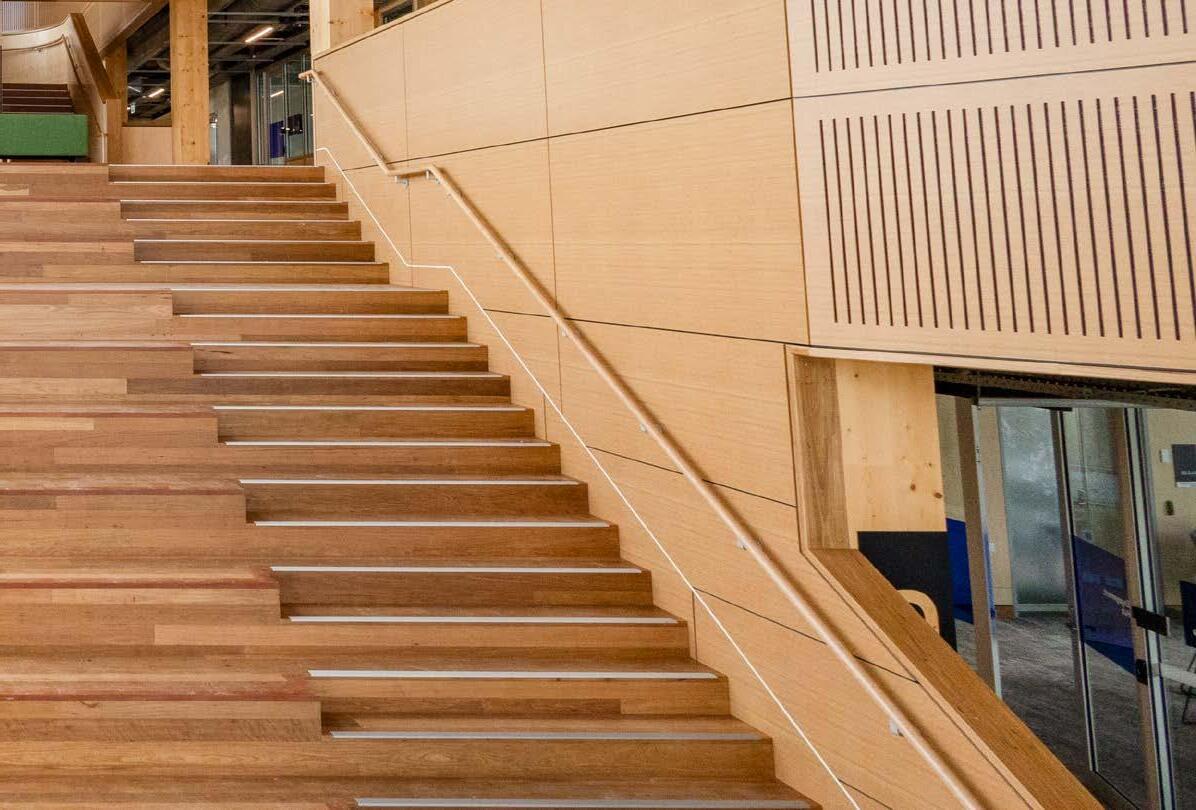

Established in 2003, Topdeck Flooring is Australia’s leading importer and supplier of luxury engineered timber, hybrid flooring, solid timber, and laminate flooring. Topdeck Flooring also offers project-based solutions to support major residential and commercial developments across the country.

“We supplied over 22,000m2 of custom-made European oak engineered flooring to 516 apartments in the Spring Square development located in Bankstown, News South Wales. In the process, we partnered with developer and builder to provide project customisation based on architect requests,” said General Manager of Topdeck Flooring, Jerry Ji.

“Engineered flooring is highly durable, economical and satisfies the 5-star acoustic rating requirements for apartments whilst retaining the texture and characteristics of solid timber and retains a high-end look and feel.”

There are several key advantages of engineered oak flooring over solid oak. One of which is the multi-layered construction and its durability which offers superior strength allowing the floors to be more resistant to warping, buckling and moisture damage. These planks withstand decades of wear, making them versatile for high traffic commercial and residential spaces with minimal maintenance.

Cost-effectiveness and sustainability is another advantage of this product type. “We recognise a major challenge of development projects is around the management of budgeting and cost. Engineered flooring provides a friendly, cost-effective solution compared to solid oak, tiles and carpet,” said Jerry.

“Not only is Engineered oak cost-friendly, it is also environmentally friendly by using only a thickness of 2mm-6mm oak wood per plank as a top layer veneer. We only use a small portion of the tree, unlike solid oak wood, which uses the majority. The compressed core of engineered flooring utilises waste wood and pulp, using fewer materials during the construction process,” emphasised Jerry.

Aesthetics are synonymous with engineered flooring as it is available in a range of styles, finishes and widths allowing our clients more flexibility and choice. Engineered oak is also

designed to be incredibly long-lasting; it is intended to last longer than the lifespan of you home, with limited maintenance required.

“We also custom make stair nosing locally for 612 steps using the corresponding European oak engineered flooring featured in the apartments. This ensures a minimum P3 slip rating in accordance with the Australian Standard AS4586, as well as creating flooring consistency throughout the building,” said Jerry.

“The Spring Square build is one of the major projects over the past year where we have supplied engineered timber flooring and stair nosing in stages over 12 months to satisfy building schedule requirements.”

“The forestry industry is still impacted by the effects of COVID, which means there is a global shortage of European oak logs used for the veneer of engineered flooring solutions. In order to combat this, my team and I carefully planned and worked closely with timber suppliers and manufacturers and ensured our company held sufficient supply in our 10,000m2 warehouse in Sydney to meet the demands of ongoing projects. Innovating and creating solutions is core to who we are as a company.”

Current projects include supplying laminate flooring to the Parade West Ryde and Lidcombe Rise and engineered flooring to the Aurora Terrace townhouse developments in Rose Hill.

For more information contact Topdeck Flooring, 16 Salisbury Street, Silverwater NSW 2128, phone 02 9748 2288, email info@topdeckflooring.com.au, website www.topdeckflooring.com.au

NSW PROJECT FEATURE SPRING SQUARE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 26

Below Topdeck Flooring supplied 22,000m2 of European oak engineered flooring for the 516 Spring Square apartments.

NSW PROJECT FEATURE SPRING SQUARE WWW.ANCR.COM.AU 27

Innovation in Every Pane: Redefining Skyline Aesthetics

Spring Square is a versatile development comprising 516 apartments across 5 buildings, alongside a blend of commercial and retail spaces.

Yan Xie, Director of Logikal Façade, expressed pride in being chosen to collaborate on this Project with the renowned builder Westbourne Construction and global developer Poly.

Logikal Façade is actively involved in a current project: 45-level residential tower in Macquarie Park. Glazed facade spanning more than 25,000m2

Logikal Façade operates manufacturing bases in both China and Australia, manage projects across Canberra, Sydney, and Brisbane, solidifying its role as an increasingly vital facade supplier to the Australian industry.

NSW PROJECT FEATURE SPRING SQUARE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 28

Mesh & Bar are the reinforcing specialists tasked with manufacturing and supply of cut and bent reinforcing bar, reinforcing mesh and accessories for the Spring Square project.

“We manufactured and supplied in excess of 3,100 tonnes of cut and bent reinforcing bar and over 230 tonnes of reinforcing mesh as well as a variety of specialised ancillary products to the Spring Square project. We had assigned two schedulers on the project to ensure that we were providing the right material and delivering it to the site according to the specific needs of the program,” said a Mesh & Bar spokesperson.

“Spring Square was a large scale, multifaceted project. Our production team worked tirelessly to ensure that we could meet the time sensitive pressures that came from managing and servicing the projects five buildings. The schedulers were constantly reviewing multiple drawings and engineer’s requirements, as well as liaising with multiple site team members to coordinate the scheduling of reinforcing steel for our manufacturing and dispatch of those materials.”

Mesh & Bar began work on Spring Square in November 2020 and faced national supply and demand issues of reinforcing steel; they were able to mitigate some of the impacts this had on the project.

Mesh & Bar Pty Ltd is one of Australia’s leading manufacturers of reinforcing steel and mesh products. Since being established in 1998, Mesh & Bar has enjoyed significant growth throughout eastern Australia, which includes their head office in Sydney & associated manufacturing facilities in Melbourne and Brisbane. They also have regional branches located in Newcastle, Wollongong, Coolum and Ballarat.

“At Mesh & Bar, we believe our success comes from the success of our clients. We take great pride in fostering and maintaining long-term customer relationships as well as helping new clients wherever we can along the way,” said a Mesh & Bar spokesperson.

Current projects include multiple large-scale projects across Sydney, Melbourne & Brisbane.

For more information contact Mesh & Bar, 15 Owen Street, Glendenning NSW 2761, phone 02 9832 2000, email sales@ meshbar.com.au, website www.meshbar.com.au

NSW PROJECT FEATURE SPRING SQUARE WWW.ANCR.COM.AU 29

Below Mesh & Bar supplied over 3,100 tonnes of reinforcing bar, and over 230 tonnes of mesh, and ancillary products to the Spring Square development.

Metromix has a 25-year history of providing construction materials involved in building communities for Sydney and surrounding regions. Projects of architectural complexity like the Spring Square build, require the expertise and quality products of industry specialists like Metromix who were contracted onto the Spring Square project to fulfil this foundational need.

Metromix offers a range of high-quality products to suit the commercial, civil and domestic sectors, supplying ready-mixed concrete, quarry products and transport services. With eight concrete plants spread across Sydney and two quarries located in Lithgow and Newcastle, Metromix supplies a wide circle of suburban areas and rapidly developing regional centres.

With a product and service offering that spans multiple types and standards of concrete, aggregates, sand, road base, fill materials, rocks and decorative pebbles, Metromix is amongst the leaders in quarry products and materials for commercial, industrial and residential projects.

Underpinned by their ethos, “Big Enough To Deliver, Small Enough To Care”, Metromix are dedicated to offering quality products,

providing exceptional customer service and safely fulfilling any product supply requirements.

The team can deliver to meet the concrete and quarry requirements of a range of diverse project types and sizes, having developed a fleet able to adequately supply sprawling multi-million dollar developments as well as small confined locations.

Metromix is committed to reducing energy and water consumption and improving the utilisation of resources. Their active participation in the Department of Environment, Climate Change and Water (DECCW) Sustainability Advantage program further emphasises their commitment to environmental sustainability.

For more information contact Metromix, phone 029849 7400, email info@metromix.com.au, website www.metromix.com.au

NSW PROJECT FEATURE SPRING SQUARE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 30

Below Metromix, supplied top-quality concrete construction materials for Spring Square, to ensure a premium finish on the project.

Just Skip Bins is a 100% Australian-owned company based in Camellia New South Wales that has unrivalled experience in the environmental services industry. The Just Skip Bins team were contracted on the Spring Square project to safely and efficiently handle the construction waste created during the project.

“We specialise in providing skip bin hire and construction and demolition waste removal and management services. Just Skip Bins provides safe, sustainable waste management solutions with a focus on recycling, sustainability, and the environment,” said a Just Skip Bins spokesperson.

“We understand that each job is different and will tailor all services to suit your needs, to ensure the smooth running of your project, however large or small.”

Just Skip Bins is accredited in sustainable waste management and has developed its business over the years focusing on the core values of efficiency, reliability and sustainability. The team have a range of bins that are designed to handle the disposal of construction and demolition waste, brick and concrete, asphalt, soils, paper and cardboard, and all metals.

From mini skip bins of around 2-3 tonnes to large skip bins of up to 12-14 tonnes, the Just Skip Bin team have the perfect skip bin size and shape for all commercial and residential waste disposal needs. The team services Sydney, the western suburbs and surrounds their wide range of waste solutions.

For more information contact Just Skip Bins, 39 Grand Avenue, Camellia NSW 2142, phone 1800 736 343, email info@justskipbins.com.au, website www.justskipbins.com.au

NSW PROJECT FEATURE SPRING SQUARE WWW.ANCR.COM.AU 31

Below Just Skip Bins provided eco waste managing solutions to ensure effective recycling, and sustainability options for Spring Square's construction.

For over 40 years, family-owned and operated Moits has been a leading civil and construction contractor delivering projects across New South Wales. Moits’ experience and expertise were contracted to deliver the excavation and piling packages for the Spring Square project.

With over 300 employees, Moits provide a range of services including demolition, excavation, remediation, shoring and site retention, underpinning, shotcrete, culverts, stormwater, sub-soil drainage, landscaping, relocation and diversion of services, pavements, kerbs and gutters, and electrical and communication works. Also via Moits’ wholly-owned subsidiary – Rock and Dirt, Moits provide a range of material-recycling services.

Moits’ track record for exceptional project delivery has resulted in strong industry relationships and repeat client work. With an experienced team and privately owned fleet, Moits specialises in helping partners and stakeholders achieve their construction ambitions while safely delivering quality materials, products, solutions and services.

With more than 100 years of combined industry experience, brothers Michael, George and Tony have been hands-on in establishing a

company based on their values-first ethos of Family, Safety, Respect, Integrity and Commitment.

Coupled with 100+ of the company’s dedicated fleet of trucks and plant, Moits’ highly experienced team is recognised across the industry for delivering complex projects that ensure client satisfaction and quality outcomes. From private residential developments to public infrastructure, roads, bridges and stadiums, Moits’ expertise and capabilities have seen this family-owned company support some of Australia’s most iconic construction projects.

For more information contact Moits, 142 Wicks Road, Macquarie Park NSW 2113, phone 02 8026 1700, email info@moits.com.au, website www.moits.com.au

NSW PROJECT FEATURE SPRING SQUARE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 32

Below Moits offers diverse services, including demolition, excavation, remediation, civil and materials recycling.

Recently, CCYE has established its own cladding manufacturer factory, allowing them to supply, design and install external claddings for residential and commercial projects, public schools, and aged care centers.

CCYE was contracted to supply and install the internal and external lightweight framing and sheeting and undertake extensive cladding installations. The team conducted detailed design and engineering planning to ensure the successful installation of the cost-efficient and streamlined installation of Easy Lap cladding, and CFC claddings for Buildings 1, 2 and 3.

“This is a multifaceted venture encompassing five distinct buildings, making it one of our more complex undertakings,” said a CCYE spokesperson. “It was essential to have a well-structured plan and a dedicated project management team to oversee the entire endeavor.”

“Work on-site commenced in late 2021 and was completed in late 2023. At the peak of operations, we had between 60-80 of our personnel actively working on the site,” said a CCYE spokesperson. “Despite the nationwide shortage in supply and labour and the rising costs, we have been able to complete this project on schedule.”

CCYE has 20 years of industry experience in fit-outs for residential apartments, commercial developments, and luxury residences.

The company also works across the education, aged care and community sectors and offers project management services. CCYE also provides all different types of claddings design and installation services for residential and commercial projects.

Current projects include installing the internal framing, sheeting, and external cladding at the Verset in Rouse Hill, the Opal Care facility in Marsden Park, and the Trinity Grammar School.

For more information contact Cathay Chung Yue Estate, 1/3 Sutherland Street, Clyde NSW 2194, phone 02 9682 6888, email info@ccye.com.au, website www.ccye.com.au

NSW PROJECT FEATURE SPRING SQUARE WWW.ANCR.COM.AU 33

Below Cathay Chung Yue Estate (CCYE) successfully completed streamlined cladding installations across the Spring Square project.

Cathay Chung Yue Estate (CCYE) is an interior and exterior design and construction company that specialises in the installation of plasterboard walls, ceilings, and façade systems.

EMPOWERING THE NEXT GENERATION

CLIENT : Catholic Schools Office, Diocese Maitland-Newcastle

MAIN CONSTRUCTION COMPANY : North Construction & Building

ARCHITECT : Webber Architects

CONSTRUCTION VALUE : $46.5 million

The Catherine McAuley Catholic College involved the completion of multiple stages, including the construction of Blocks E, F, G and H; a multi-purpose hall, and refurbishing works to existing staff rooms, science rooms and hospitality spaces. The overall design incorporated linkways, car parking, services infrastructure works, exterior break out spaces and landscaping.

Catherine McAuley Catholic College, located in Medowie, New South Wales, is a brand new educational institution that aims to provide state-of-the-art learning facilities for its students.

North Construction & Building (North), an experienced regional construction company, was initially engaged as an Early Contractor Involvement partner, along with Webber Architects, to develop a masterplan for the entire school and deliver Stage 1 works. North was then awarded Stage 2 from a competitive tender process and then Stages 3 and 4.

Block E consists of a TAS workshop and design spaces; Block F consists of both PDHPE and art/multimedia spaces, including outdoor work areas; Block G consists of the senior school library, senior and junior study and general purpose learning areas; and Block H consists of general purpose learning areas.

These stages also encompassed the creation of linkways, car parking, services infrastructure, and landscaping, to ensure a fully-equipped campus was available to support the learning of 1,200 students from years 7 to 12.

“The development of a brand new college comes with its own set of challenges,” said Construction Manager, Darren Wilton. “Coordinating the construction process, adhering to timelines, and ensuring seamless integration of the new buildings with the existing ones requires careful planning and execution.”

North’s extensive experience and commitment to excellence positioned them as the perfect collaborator for the Catherine McAuley Catholic College development. With an award-winning reputation and a sincere commitment to projects, North prioritises relationships and values trust, ensuring that their clients are fully involved throughout the construction process.

NSW PROJECT FEATURE CATHERINE MCAULEY CATHOLIC COLLEGE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 34

North was engaged from the initial phases of design development, enabling the team to offer valuable insights and assist in aligning the project’s schedule, approach, and budget with the desired objectives.

“North’s Early Contractor Involvement (ECI) process is characterised by transparency,” said Darren. “We openly disclose all details, including preliminary work, subcontractor prices, overheads, and margins, adopting an open-book approach. This commitment to transparency builds trust between North and our clients, paving the way for successful collaborations and strong partnerships.”

Catherine McAuley Catholic College’s development in Medowie relied on this expertise and dedication. North navigated the challenges of constructing a new school while ensuring the project aligned with the school’s vision. The ongoing partnership between North and Catherine McAuley Catholic College exemplifies the importance of trust and collaboration in creating outstanding educational facilities.

North Construction & Building was founded in 1987 and has grown to become a trusted regional construction company with an award-winning reputation for excellence. With offices across New South Wales (Tuggerah, Newcastle, Dubbo, Orange, Mudgee and

Tamworth), and most recently Brisbane Queensland, North works across a diverse range of projects within the commercial, education, aged care, health, industrial, infrastructure, retail, and hospitality sectors.

For more information contact North Construction & Building, Level 5, Suite 501, 1 Bryant Drive, Tuggerah NSW 2259, phone 1300 667 840, website www.north.com.au

COLLEGE WWW.ANCR.COM.AU 35

NSW PROJECT FEATURE CATHERINE MCAULEY

CATHOLIC

Centurion Civil were contracted on the Catherine McAuley Catholic College Project to deliver bulk earthworks and detailed excavation work. The package also included construction of the asphalt car parks and the multi-levelled tiered concrete pathways and amphitheatre.

Centurion Civil allocated a small, dedicated team to successfully complete these complex works.

“Part of the work included lime stabilisation in the subgrade of the carpark to expediate the construction and improve the pavement foundation” said Director, Grant Jefferson.

Lime stabilisation was carried out to improve the subgrade to achieve an acceptable standard and can also provide greater long-term stability of the pavement structure.

“There were some tricky elements to this project because of the different levels and heights in the Stage 3 area around the amphitheatre, seating and yarning circle,” said Grant. “A lot of trades had to collaborate to get the work completed. The end result is quite outstanding; it came together really well.”

NSW PROJECT FEATURE CATHERINE MCAULEY CATHOLIC COLLEGE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 36

The family owned and operated company was formed in 2004 by Ray, Chad and Grant Jefferson, however their civil construction experience goes back to the 1970’s. The history of the company is one characterised by controlled growth and expansion.

With nearly 20 years of operation and under the leadership of the Jefferson family, Centurion Civil has become a reputable, genuine and hardworking civil contractor in the Newcastle, Hunter, Central Coast and Mid-coast regions of New South Wales.

“We’ve been around for a couple of decades,” said Grant. “We’re local to the Newcastle area and we just love what we do.”

Centurion Civil’s team is dedicated, eager and passionate about delivering a quality outcome for every client and their project, on time and within budget. They specialise in all aspects of civil construction including water and sewer projects, earthworks, roadworks and subdivisions. Centurion Civil can guide you through the entire process providing expert advice from start to finish.

“We have the knowledge and experience within our current workforce to deliver complex projects across a broad range of civil categories,”

said Grant. Our personnel include civil engineers, project managers, site supervisors, skilled operators, experienced labourers and a fleet of plant and equipment that all work together to deliver a quality outcome for our Clients.

Centurion Civil’s portfolio consists of single stage residential subdivisions to multiple staged industrial subdivisions. They are also accredited to carry out minor and major works for numerous Local Government and Water Authorities.

Current projects include in New South Wales includes Sweetwater Grove Retirement Village in Tomago, roadworks in Weston NSW, as well as water and sewer works in Belmont, Woongarrah and Cessnock.

For more information contact Centurion Civil, 14 Ferry Road, Sandgate NSW 2304, phone 1300 748 970, email mail@cenciv.com.au, website www.centurioncivil.com.au

NSW PROJECT FEATURE CATHERINE MCAULEY CATHOLIC COLLEGE WWW.ANCR.COM.AU 37

Below Centurian Civil completed bulk earthworks and detailed excavation work across the Catherine McAuley Catholic College.

PCW Commercial Windows are very proud to have been associated with North Construction again, this time completing Stage 1 and Stage 2 of the Catherine McAuley Catholic College at Medowie. PCW were contracted to supply and install all of the commercial windows, commercial doors and security screen products.

“We were engaged quite early on in the design process by North Construction,” explained Director, Leigh Spinks. “Webber Architects knew what they wanted and we were involved in the selection of the glass and window suites that would achieve the energy ratings, as well as the desired aesthetic of the building.”

To that end, PCW and their 25 year partnership with Capral were able to provide Capral’s market-leading LocAl (Lower Carbon Emission) aluminium products for this build. The products have been responsibly sourced from mining to end-user with a focus on keeping emissions down. Capral are the only ASI Certified aluminium supplier in Australia, and PCW were excited to showcase this cleaner, greener sourcing of materials.

PCW’s project management expertise was a clear highlight as the team tackled multiple buildings simultaneously to satisfy a time-sensitive

construction program. “We needed to be in multiple buildings at once – finishing off in one while starting in another,” said Leigh.

“We fabricate all the products locally in our factory at Somersby before they go to site, and this requires efficiency from office, to warehouse, to site, to hit each milestone for the builder. It was important that we didn’t lose sight of what was happening ahead of us, which meant thinking months ahead of the construction program.”

Leigh highlighted the efforts of his project team for the project’s success – Dillon Selby (Project Manager), Tim Smith (Site Supervisor) and Luke Bardsley (Factory Manager). “These guys kept the job running efficiently, at a high quality and with such amazing, positive attitudes,” said Leigh.

PCW is a highly respected market leader in the manufacture and installation of all quality commercial, industrial and upmarket residential windows and doors.

For more information contact PCW Commercial Windows, Unit 6/113 Wisemans Ferry Road, Somersby NSW 2250, phone 02 4340 1100, email info@pcw.net.au

NSW PROJECT FEATURE CATHERINE MCAULEY CATHOLIC COLLEGE AUSTRALIAN NATIONAL CONSTRUCTION REVIEW 38

Below PCW Commerical Windows supplied and installed glass and window suites that would achieve the energy ratings, and the right aesthetics.

Having worked on Stages 1 and 2 of the Catherine McAuley Catholic College, SM Concrete Constructions has continued their involvement in the construction of Stage 3.

“Our works involve the Concrete Package Works associated with the construction of Blocks G & H, Blocks E, F, PE Store and Maintenance Shed, Block A Multi-purpose Hall and all associated linkways and also the construction of the extensive concrete landscaping package,” said Managing Director, Sandy Martin.

“The project spans over approximately 13,000m² and every member of our 20-strong team has worked on it,” said Sandy.

SM Concrete Constructions (SMCC) is a rapidly growing company delivering professional formwork, reinforcement and concrete services, across the Central Coast, Newcastle and Hunter regions.

SMCC was founded in 2015 and since that time it has quickly developed a sound client base and demonstrated the ability and capability to deliver numerous projects across the residential, commercial, industrial, civil, health, education and aged care sectors to the highest possible standard and with excellent quality and service.

“We cover all aspects of concreting works including detail excavation, formwork, reinforcement supply and fix and concrete supply, pump, place and finishing,” said Sandy. “Our highly skilled team of workers possess a wide range of experience in all aspects of concrete construction which enables us to take on all types of concrete works.”

SMCC strives to operate in alignment with its company vision which is ‘to be a great company to work for and to be a great company to work with’. This has resulted in the development of ongoing business relationships with several national builders who regularly select SMCC to partner with to deliver quality projects.

Current projects include the ONE Apartments in the Newcastle CBD, St Bede's Catholic College in Chisholm and the Hunter Sports Centre Redevelopment in Glendale.

For more information contact SM Concrete Constructions, phone 0415 932 541, email sales@smconcrete.com.au, website www.smconcrete.com.au

NSW PROJECT FEATURE CATHERINE MCAULEY CATHOLIC COLLEGE WWW.ANCR.COM.AU 39

Below SM Concrete Constructions were instrumental in the extensive Concrete Package Works required for the Catherine McAuley Catholic College.

PRECAST EXCELLENCE IN DESIGN AND URBAN LIVING

DEVELOPER : TQM Group

MAIN CONSTRUCTION COMPANY : TQM Design & Construct ARCHITECT : DWA

ENGINEERING : TQM Consulting Engineers

CONSTRUCTION VALUE : $38 million

Boasting 63 residential units, 1,000m² of commercial space, and three levels of basement parking, Novello stands as an epitome of sophisticated design and construction expertise utilising precast construction methodologies. Featuring one, two and three-bedroom apartments, the project utilises space with open-plan living and dining areas. The project has been designed to capture a harmonious blend of comfort, luxury, and contemporary aesthetics.