CONSTRUC TION

Find out more about how Cordell Connect and Cordell Estimator Platinum can help your business grow

QUEENSLAND LIV ALBERT – Mirvac

WOOL STORE – Perri Group

GLASSKOTE FLOAT GLASS INDUSTRIES ANNOUNCES OVER AUD

1.2 BILLION IN SECURED CAPITAL COMMITMENTS FOR TWO NEXT-GENERATION GLASS MANUFACTURING PLANTS

In a game-changing leap for the global glass industry, GlassKote FGI Pty Ltd (GK) has confirmed funding exceeding AUD1.2 billion to build two of the most advanced low-iron float glass plants in the world — the first commencing in Queensland, Australia in early 2026, with the second in the United Arab Emirates to follow in the ensuing months. These plants will not only restore sovereign glass production where it’s needed most — they will set new global benchmarks for innovation, sustainability, and AI-driven performance in the built environment, renewable energy, defence, and consumer technology sectors.

Project One — 700 Tpd Low-Iron Float Glass + 400 Ton Per Day Wte Mega-Plant In Queensland, Australia

Launching in early 2026, GK’s Queensland project will feature:

• 700 tonnes per day of low-iron glass for architectural, solar, and specialty applications.

• 400 tonnes per day Waste-to-Energy facility using proprietary Cyrion technology to generate green hydrogen and renewable electricity with zero emissions.

• Integrated strengthened glass production for domestic and export markets.

• Silicon nanotube integration and DNA AI ‘Living Glass’ technology — enabling

self-healing, seismic-resilient, and energyoptimising glass products.

• Integrated solar glass manufacturing for building-integrated photovoltaics (BIPV) and smart glazing.

• Advanced coating and value-add lines for laminated, toughened, ballistic, Low-E, and solar-control glass.

This facility will close Australia’s glass supply gap, generate its own renewable energy, and export surplus power — making it one of the most sustainable glass plants ever built. The year following the Queensland megaplant launch, GK will commence construction of a second 700 TPD standard float glass plant in Australia.

The Queensland facility proudly delivers 100% Australian-made glass, produced entirely from locally sourced materials and components. This commitment supports Australian jobs, strengthens national manufacturing sovereignty, and drives a truly circular, homegrown economy.

Groundbreaking Refractory Innovation

In a parallel development, SDH Australia and Cyrion Technologies have introduced a world-first refractory material engineered to last the full operational life of a float glass plant. This breakthrough eliminates the need for costly shutdowns and tank rebuilds

— a game-changing advancement that transforms plant economics, uptime, and environmental performance. It represents a decisive leap forward in industrial sustainability and reliability.

Coupled with near-zero energy costs, the collaboration has achieved what many in the industry thought impossible — the most energy-efficient and costeffective glass manufacturing facility on Earth. This nextgeneration platform combines advanced materials science, AI-driven optimisation, and clean-energy integration to deliver unparalleled output with minimal operating costs.

The result is not just a better plant — it’s a new benchmark for global glass production and a model for the future of sustainable manufacturing.

Economic Impact & Global Reach

Together, the projects represent:

• AUD $1.2+ billion total investment

• Projected AU$1B combined annual EBITDA by Year 4

• Creation of a thousand + skilled jobs across manufacturing, R&D, and hightech engineering

SEA-ING IS BELIEVING: CONSTRUCTION COMPLETE AT THE NEW SYDNEY FISH MARKET

One of the most complex and ambitious projects ever undertaken on Sydney Harbour has reached a major milestone, with construction of the new Sydney Fish Market now complete and the keys officially handed over to Sydney Fish Market Pty Ltd for completion of fit-outs.

The Sydney Fish Market is the latest iconic addition to Sydney Harbour. Reaching out over water it follows in the footsteps of the Sydney Harbour Bridge and the Opera House as one of Sydney’s most technically complex projects, showcasing world-class engineering and innovation. The new Sydney Fish Market

is anticipated to attract more than 6 million domestic and international visitors, with the new glass façade giving visitors a front-row seat to the energy of live fish auctions.

The new structure stands proudly on 481 marine piles, 6,000 tonnes of steel reinforcement, with over 400 roof cassettes and 594 glulam timber beams delivered by barge from Glebe Island, it also sets a new benchmark for sustainability removing over 5,650 truck movements on local roads.

The roof’s design allows sunlight during the day to illuminate upper levels, collect

rainwater for recycling, and generate energy via solar panels to offset the building’s energy consumption. The roof can also be lit up with multi-coloured LED lights for special events.

Additionally, there will be over 6,000m2 of accessible public domain and the site’s cultural and historical storytelling is integrated throughout the Civic Plaza with five creative installations that honour the area’s First Nations heritage and its industrial past.

Underneath the building, the project installed seawall tiles, coral panels and hanging fish habitats to support marine life in Blackwattle Bay into the future.

Construction of the new Sydney Fish Market created more than 700 jobs, and the new facility will sustain 700 ongoing roles. In addition, approximately $670 million in contracts were awarded to Australian businesses. Retail space will double compared to the current fish market, and the new building will offer a mix of local seafood traders, specialty food retailers, and diverse dining options, from casual takeaway to premium waterfront restaurants, for all to enjoy.

EQUAL GENDER WINS A TENDER – WOMEN IN CONSTRUCTION TO BUILD NEW WATERFRONT PARK AT BLACKWATTLE BAY

The Minns Labor Government will aim to achieve a first for the State, with a stretch target of 50% women contracted to deliver the new Bank Street Park in Pyrmont.

The new 1.1-hectare waterfront park on Bank Street will surround the southern pylon of the iconic Anzac Bridge and is the first project in NSW to proactively target a goal of 50% women in construction, light-years ahead of the 12% average.

The Women in Construction pilot project aims to address the underrepresentation of women in the NSW construction industry, challenge perceptions and support a long-term increase in women’s participation across the sector - an imbalance that limits diversity, reduces the available talent pool, and makes it harder to meet the state’s infrastructure needs.

Infrastructure NSW is working closely with head contractor BESIX Watpac to achieve a

minimum target of 40% and a stretch target of 50% women working on the project.

The public park will be the first green space delivered in the revitalisation of Blackwattle Bay, an exciting urban renewal opportunity that will transform over 10 hectares of industrial land into a sustainable a world-class

harbourfront destination.

The new waterfront park will be a key connecting piece along the soon-to-be 15-kilometre continuous harbourfront walk from Woolloomooloo to Rozelle Bay and is positioned on the doorstep of the new Sydney Fish Market.

Photo credit - Artist impression - Bank Street Park

Photo credit - Sydney fish Market © Simon Anders

THREE YEARS OF

PROGRESS:

WOMEN IN CONSTRUCTION INDUSTRY SURVEY TRACKS POSITIVE TRENDS AND ONGOING CHALLENGES

The NSW Government has today released the Year 3 Women in Construction Industry Survey Report, marking the third year of survey results across the NSW construction sector.

The report provides a comprehensive view of workforce trends, gender equity progress and the lived experiences of women and men in the construction industry.

The findings from the survey, together with results from previous years, offer a robust evidence base and valuable long-term view of trends and sentiment across the construction industry.

Insights from the survey will inform strategic decision-making and help shape future initiatives aimed at supporting and retaining women in the sector.

Key findings from the survey and detailed in the report include:

• Female workforce growth continues with a 3% increase in women in construction roles over the past year, however, this growth has slowed compared to previous years (+12.5% in 2024 and +13.8% in 2023).

• Introduction of gender-inclusive policies by businesses are on the rise, yet workers reported little change in how these policies are felt or implemented— highlighting a gap between policy adoption and real-world impact.

• Workforce retention is driven by respect and opportunity. Women are more likely to stay in construction roles when they experience career progression, job flexibility, and a respectful workplace culture.

• Discrimination and harassment remain widespread with 32% of workers

experiencing gender-based discrimination or sexual harassment in the past year. Among women, this figure rises to 70%, with site-based female workers reporting even higher rates at 76%.

• Perception gap among potential entrants. Women interested in joining the industry anticipate significantly more challenges than current workers report facing—suggesting that perception may be deterring new talent from entering the sector.

Other trends included alignment between men and women in terms of the key challenges facing the sector: a lack of work/ life balance (59%), lack of flexible working hours (48%), unequal pay for similar roles (44%) and a lack of mentoring and leadership training (43%).

Top challenges identified by businesses included project uncertainty (60%), attracting and retaining appropriately skilled staff (50%), and financial concerns (47%).

Overall satisfaction in the sector remained positive with 72% of women and 76% of men likely to remain in the industry over the next five years.

Evidence in this report indicates that issues surrounding attraction, retention, work-life balance, and gender-based discrimination are complex and require ongoing, coordinated efforts from both government and industry.

This year the NSW Government Women in Construction Program has officially reached the initial three-year program timeline. While significant progress has been made, the program has received an extension to continue delivering key initiatives designed to build a diverse and sustainable workforce.

Key achievements delivered through the Program in the past 12-months have included:

• Completion of the Industry Innovation Program. Over 2 years, the program awarded $5.9 million in grant funding across 34 industry initiatives to encourage the participation and retention of women.

• Completion of the Pilot Program, which embedded 19 Project Officers across 23 NSW Government major infrastructure projects to drive increased targets for women in trades and non-traditional roles.

• Roll out of the ‘Hard Work Knows No Gender’ campaign across the state to promote awareness around gender diversity and inclusivity in the sector.

• Sponsorship of the $30,000 National Association of Women in Construction (NAWIC) NSW 2025 Executive Leadership scholarship to support executive-level further education.

Photo credit - NSW Government Women in Construction Program

Photo credit - NSW Government Women in Construction Program

Construction delays often start at the last mile. In tightly scheduled projects, materials need to arrive just in time – if bricklayers are starting at 8am, deliveries must hit the site by 6am. Late arrivals create idle crews, eating into razor-thin margins in an industry where insolvencies surged nearly 21% last financial year. These hidden inefficiencies drain finances and erode customer trust.

Many construction companies still rely on static schedules and limited visibility, leading to idle trucks, wasted fuel, and site managers scrambling to adjust timelines.

AI-powered delivery orchestration can change this. NowGo by Shippit is a powerful new last-mile delivery orchestration solution that dynamically re-optimises deliveries in real-time, accounting for unplanned disruptions and delivery priorities. This cuts downtime and keeps projects on schedule.

Trade suppliers using this advanced solution, including Mitre 10, have improved fleet utilisation by up to 15% and reduced fuel consumption and driver downtime.

These gains provide a competitive edge. By offering Uber-like tracking and robust delivered-on-time adherence, NowGo reduces inbound queries and redeliveries, directly impacting profitability.

As Julian Yule from Mitre 10 noted, with NowGo powering their Truck Tracker, they “know exactly when materials will hit the siteno more downtime waiting around and fewer contacts to our busy store customer service teams.” This ensures on-site teams can work productively and projects stay on track, which is paramount to building consumer trust.

If the sector wants to lift productivity, it must recognise that the last mile is the starting

point for on-site efficiency. Effective delivery management is a lever for boosting efficiency across construction projects.

WHY REPAIRING CONCRETE SHOULD COME BEFORE RECYCLING

As Australia prepares for National Recycling Week (10–16 November), Building Chemical Supplies says the path to sustainability starts with repair, not replacement.

Australia’s construction and demolition sector has made great progress in recycling concrete waste, but Building Chemical Supplies (BCS) says it’s time to take the conversation a step further. Before concrete reaches a recycling facility, many structures could be repaired and restored — saving materials, energy and emissions along the way.

With construction and demolition waste making up around 26.8 million tonnes of material every year, repair is a major opportunity to keep concrete in use for longer and reduce the need for new materials altogether.

In Queensland, it was reported about 83.3% of construction and demolition waste was diverted from landfill in 2023–24, already exceeding the state’s 2025 recovery target of 75%. Around 1.6 million tonnes of concrete were recycled that year, a strong sign that the industry is heading in the right direction.

But recycling still happens at the end of a structure’s life. Repairing concrete gives it another decade, or several, before it ever becomes waste. Every tonne of concrete repaired means less raw material mined, less energy used in production and fewer emissions from cement manufacturing, one of the most carbon-intensive industries on the planet.

Repairing concrete isn’t a quick fix. It’s a trusted and effective way to restore strength, safety and performance. Techniques like crack injection, spalling repair, waterproofing and carbon-fibre strengthening are proven to bring ageing structures back to life across commercial and civil projects.

Demolition and rebuilds use huge amounts of energy and materials. Repair focuses on restoring what’s already there, using a fraction of the resources. It’s a practical, lower-impact way to maintain Australia’s built environment and reduce embodied carbon, which currently accounts for around 10% of national emissions.

A call to rethink during National Recycling Week

“This National Recycling Week, we want the industry to think one step earlier,” said Blair Edmonds, Director at Building Chemical Supplies. “Recycling is valuable, but before concrete becomes waste, there’s an opportunity to repair and reuse what already exists. That’s the real foundation of sustainable construction.”

Repairing before replacing helps builders, engineers and asset managers reduce waste, extend the life of their structures and take pressure off recycling facilities. It’s a practical shift that cuts costs, saves time and delivers real environmental impact.

Australia’s recycling efforts show great progress, but true circular construction starts well before the skip bin. Repairing what already stands keeps materials in use for longer, reduces landfill and moves the industry closer to a lower-carbon, more sustainable future.

ROB HANGO-ZADA

Co-Founder and Joint CEO Shippit

HOW

CAPRAL BACKS AUSSIE SMELTERS AND CONFIRMS SUPPLY CHAIN STRENGTH

Recent reports about the future of the Tomago Aluminium Smelter have drawn national attention to the challenges facing Australia’s aluminium industry. Capral recognises the significance of this facility to the nation’s aluminium manufacturing strength and reaffirms its support for the continuation of local smelting operations.

“As a business that proudly sources Australian aluminium for our local extrusion operations, we understand the importance of maintaining a strong domestic smelting capability,” said Tony Dragicevich, Capral CEO. “While our billet supply chain remains secure and diverse, sustaining local production is essential to preserving Australia’s industrial capability and manufacturing independence.”

Australia’s aluminium industry is one of the nation’s most strategically significant sectors, operating as a vertically integrated value chain, from bauxite mining and alumina refining through to aluminium smelting,

extrusion and downstream manufacturing. This integrated system generates around $18 billion in annual economic value, supports more than 75,000 Australian jobs, and underpins regional economies across the country

Capral believes coordinated action between government, industry, and energy providers will be critical to ensuring the long-term viability of Australia’s aluminium sector and the thousands of local jobs it supports

ADELAIDE AND PARAFIELD FIRST AUSTRALIAN AIRPORTS TO REACH HIGHEST LEVEL OF AIRPORT

Adelaide and Parafield Airports have become the first airports in Australia to be recognised by the global Airport Carbon Accreditation program for reaching the highest level of accreditation on the path to Net Zero.

Both airports are now certified as Airport Carbon Accredited at Level 5, which requires maintaining a Net Zero carbon balance on Scopes 1 and 2, and actively addressing Scope 3 emissions sources that it can significantly influence on the pathway to Net Zero. Only four other airports in the AsiaPacific and Middle East regions have reached this level.

Airport Carbon Accreditation is the only institutionally endorsed global carbon management certification programme that independently assesses and recognises airports for their efforts to measure, manage, and reduce carbon emissions.

Adelaide Airport Managing Director, Brenton Cox, said Adelaide and Parafield Airports had reinforced their credentials as the benchmark for environmentally friendly

CARBON ACCREDITATION

airports in Australia. In December 2024, Adelaide Airport became the first major airport in Australia to reach carbon neutrality.

“Our participation in this programme is recognition of the importance of long term sustainability to aviation sector and the value of collaboration to achieve our industry goals,” Mr Cox said.

“Achievement of Level 5 accreditation validates that we have transitioned from carbon management to decarbonisation, with credible evidence of emissions reduction and long-term planning.

“Our sustainability and decarbonisation efforts aim to create long-term value for our shareholders and our customers who represent the broader community.

Stefano Baronci, Director General of ACI Asia-Pacific & Middle East, said Adelaide and Parafield Airports have demonstrated strong leadership in advancing environmental sustainability. “Achieving Level 5 of the Airport Carbon Accreditation

Programme reflects their sustained effort and collaboration with stakeholders to reduce emissions and this accomplishment aligns perfectly with airport industry’s shared vision of achieving net zero goals by 2050,” Mr Baronci said.

Recent achievements across Adelaide and Parafield Airports include:

• Generating more than 15% of the domestic and international terminal’s electricity needs via onsite solar installations;

• Reducing electricity consumption through a major LED lighting upgrade and by choosing energy efficient options for major equipment upgrades;

• Purchasing all remaining electricity consumption through a renewable purchase power agreement via a South Australian wind farm; and

• Offsetting residual emissions by purchasing carbon credits from a land regeneration project in South Australia.

DESIGN, ADVISORY

AND ENGINEERING CONSULTING BUSINESSES SHOW RESILIENCE THROUGH UNCERTAINTY

Project uncertainty, business risk and cost pressures continue to weigh on Australia’s consulting and engineering sector – but signs of optimism are emerging, according to Consult Australia’s 2025 Market conditions report.

The 2025 report, based on a survey completed by 41 member businesses representing 29,000-plus employees, shows a continuation of last year’s subdued market conditions. Almost all respondents (97%) report current or near-term capacity.

Consult Australia Chief Executive Officer

Jonathan Cartledge said the results underline the need for pipeline clarity and government coordination.

“Our members continue to face the pressures of uncertain project pipelines, escalating business costs and heightened risk,” Mr Cartledge says. “But they’re also

demonstrating remarkable resilience. The fact that 49% of respondents are optimistic about the year ahead suggests the market is stabilising and confidence is returning.”

Among the key findings from respondent member businesses:

• 97% report current or near-term capacity, with ‘not enough work’ the dominant response across most sectors.

• 51% have redeployed staff to other projects; 43% have made additional resource cuts due to delayed or cancelled projects.

• 43% say they are operating in a higher-risk environment than a year ago.

• Salaries are the fastest-rising business cost, outpacing insurance and compliance costs.

• 57% continue to face rising professional indemnity insurance premiums despite marginally improved availability.

• 62% cite digital, data and AI as critical skill gaps for the next three years.

SUBSCRIBE NOW

Get the ANCR Construction Insights e-newsletter, featuring Case Studies, Product Information and Commentary from within the industry, straight to your inbox every month. Scan the QR code to Subscribe

The release of the market conditions report coincides with the launch of Consult Australia’s 2025-2028 Strategic Plan, unveiled at the Annual General Meeting, Thursday 30 October 2025.

“Our new strategy is built on three clear commitments to maintain, enhance and innovate. It reflects the breadth of our membership, from micro-firms to multinationals, and sets a confident course for how we represent, support and elevate every part of our industry,” Mr Cartledge concludes.

Scan to access Consults 2025 Market Conditions Report

Scan to access the 2025-2028 Strategic Plan

DICE (AUST) WINS 2025 TELSTRA BEST OF BUSINESS AWARD FOR

INDIGENOUS EXCELLENCE

DICE (Aust), an NT-based construction enterprise, has been announced as the Indigenous Excellence National Winner at the 2025 Telstra Best of Business Awards.

DICE (Aust) provides commercial building, electrical and smart energy solutions across the country. Through these infrastructure services, it empowers First Nations employees and communities, becoming a successful enterprise.

The judging panel was unanimous in their praise of DICE (Aust)’s entrepreneurial spirit, leadership, and commitment to research and innovation. opperating in one of Australia’s toughest logistical environments in the NT.

After years of advocacy, Master Builders welcomes the state government’s decision to scrap Best Practice Industry Conditions (BPIC) – a move that will help restore productivity and reduce costs across Queensland’s construction industry.

With a once-in-a-generation pipeline of housing and community projects ahead, Master Builders CEO Paul Bidwell said the policy had long hindered progress.

Photo credit - DICE Founder Ray Pratt

RICHARD CROOKES CONSTRUCTIONS & ESR COLLABORATES WITH MORSL TO DELIVER FIRST MOBILE MICRO-MARKET SOLUTION FOR CONSTRUCTION TEAMS

ESR Australia & NZ has partnered with Morsl, Australia’s leading provider of unattended micro-markets, to launch the country’s first mobile micro-market solution on a Richard Crookes Constructions’ (RCC) site at Moorebank Intermodal Precinct.

This pioneering initiative replaces traditional vending machines with a fresh, nutritious, and better-for-you food solution designed to support the health and wellbeing of construction teams throughout the project.

A Healthier Alternative for Construction Workers

Construction workers often face long shifts and limited access to healthy food, with vending machines typically offering only high-sugar, high-salt options. Morsl’s mobile micro-market provides round-the-clock access to fresh meals, snacks, and drinks — from protein-rich salads and wraps to low-sugar beverages and wholesome snacks — ensuring workers have convenient access to fuel that sustains energy and focus on the job.

Mitchell Kay, Senior Project Manager at RCC said, “Morsl’s healthy food options have been a gamechanger for our team. Fresh and nutritious food plays a pivotal role in overall wellbeing – we’ve noticed an increase in energy and focus since consuming these healthier alternatives.”

Collaboration Driving Innovation

By joining forces, ESR Australia & NZ and Morsl are delivering more than food: they’re introducing an industry-first innovation in workplace wellbeing.

The mobile micro-market is designed to be flexible, fully self-service, and tailored to the unique demands of a construction site environment, as seen on the RCC site

Simon Sayers, Head of Development, ESR Australia & New Zealand said: “At ESR, we’re always looking for practical ways to support the wellbeing of the people who bring our projects to life. Partnering with Morsl to deliver healthier food choices on site is a simple but powerful initiative to help

construction teams stay energised, focused, and safe throughout the day.”

Why It Matters

• Health & Wellbeing – Better food choices help reduce fatigue, improve focus, and support long-term health.

• Productivity & Safety – Access to quality nutrition reduces the risk of accidents linked to fatigue or poor diet.

• Innovation in Industry – This collaboration sets a new benchmark for how the construction sector can support frontline teams.

“Construction workers deserve the same level of nutritious choice and convenience as those working in offices or hospitals. By bringing our micro-market technology into a mobile solution, we’re closing that gap and supporting a healthier, safer, and more productive workforce,” said Karla Borland, Morsl CEO

Looking Ahead

The launch is the first step in exploring how mobile micro-markets can be deployed across construction, infrastructure, and industrial projects nationwide, where worker wellbeing is essential and food options are often limited.

Do you have a project, media release, product or news item you would like to feature with the Australian National Construction Review?

Get in touch with our submissions team by scanning the code or at submissions@ancr.com.au to find out more.

PRECISION REFURBISHMENT RESTORES FORM AND FUNCTION

When a delivery vehicle damaged one of the major car park shade sails at Kellyville Shopping Centre, Sydney Shade Sails was called in to take on the complex refurbishment, after another contractor was unable to complete the job.

“The structure had been left half-finished,” explained Leonard Collins, Managing Director of Sydney Shade Sails. “We came in, surveyed, patterned, and fabricated a completely new sail to restore both function and appearance.”

Measuring 36m by 12m, the replacement shade required precision design, custom fabrication, and meticulous installation. With the site located in the busiest part of the shopping centre, right outside major supermarkets, and multiple fast-food outlets, the Sydney Shade Sails team worked exclusively overnight between 10 pm and 8 am, ensuring minimal disruption to the public.

“It was a tough job,” Leonard said. “The sail weighed around 250kg and had to be lifted and tensioned 3m off the ground using scissor lifts, winches, and a ute for leverage. It took several nights to remove,

position, and tension the fabric perfectly, but when it was finished, it fit like a glove.”

The project also marked one of the first Australian applications of Fluo²Max, a next-generation architectural fabric supplied by Ricky Richards. “It’s a premium European product with an advanced titanium dioxide and PVDF coating that helps it self-clean reflect UV rays, and resist dirt,” Leonard explained. “It’s stronger, stays cleaner longer, and carries an extended warranty compared to traditional membranes.”

Beyond restoring the structure, the project demonstrates Sydney Shade Sails’ capability in asset renewal and lifecycle management, critical for facilities and project managers maintaining high-traffic commercial environments. The company’s ability to integrate seamlessly with live operations, deliver durable solutions, and minimise downtime sets it apart in the maintenance and refurbishment market.

For more information contact Sydney Shade Sails (NSW) Pty Ltd, 10/8 Jindalee Place, Riverwood NSW 2210, phone 02 9592 0401, email enquiries@shadesailsydney.net.au, website shadesailsydney.net.au

REVOLUTIONISING SUSTAINABLE CLIMATE CONTROL

THE KXZ3 VRF SYSTEM BY MHIAA

As sustainability, efficiency and design integration become increasingly critical in commercial projects, mechanical solutions must go beyond temperature control — they must enhance building performance, help achieve environmental ratings, and fit seamlessly into architectural intent.

Mitsubishi Heavy Industries AirConditioners Australia (MHIAA) has achieved exactly that with the KXZ3 series of R32 VRF system — a next-generation air conditioning solution designed for future-focused developments.

What is the KXZ3 VRF System?

The KXZ3 series VRF (Variable Refrigerant Flow) Systems is Mitsubishi Heavy Industries’ most advanced commercial air conditioning platform solution to date. Built on cuttingedge engineering, it utilises R32 refrigerant, making it one of the first large-scale VRF systems in Australia to adopt this more sustainable refrigerant alternative.

The system is designed to serve diverse commercial applications—from mid to highrise offices to multi-residential developments, healthcare, retail and education projects— offering high performance with minimal environmental impact.

Key Features and Benefits

Low GWP R32 Refrigerant R32 refrigerant offers a Global Warming Potential (GWP) of 675, which is approximately two-thirds lower than R410A, positioning it as a future-proof choice ahead of evolving refrigerant regulations.

Optimised Coefficient of Performance (COP)

The KXZ3 series delivers outstanding COP values across a wide operating range, contributing to lower energy consumption.

Wider Operating Range

Suitable for any climate, it delivers reliable performance in temperatures from -25°C up to 52°C.

Energy-Saving Inverter Technology

Advanced inverter compressor technology dynamically adjusts performance to match demand, reducing operational costs.

Quiet and Compact

Ideal for urban developments with acoustic limitations, the KXZ3 series is engineered for quiet operation and optimised space efficiency.

Understanding NABERS – Why Ratings Matter

The NABERS (National Australian Built Environment Rating System) is a government-backed initiative that measures the environmental impact of buildings based on energy, water, waste and indoor environment quality.

As mandatory energy performance disclosure (CBD program) is expanding to more buildings, NABERS is becoming an increasingly important benchmark for developers, asset owners, and tenants, supporting compliance frameworks and informing lease negotiations.

Higher NABERS ratings not only improve a building’s marketability but also support ESG reporting and green financing opportunities.

How KXZ3 Helps Improve NABERS Performance

By combining R32 refrigerant, new compressor technology and high COP outputs, the KXZ3 series helps reduce total building energy consumption — a key driver for achieving higher NABERS ratings.

KXZ3 supports NABERS-driven outcomes through:

• Lower emissions from high-efficiency operation.

• Improved part-load performance, better aligning with real-world usage.

• VTCC+ : A precise capacity control system that optimises the system output based on indoor load and pre-selected eco level (Low, Medium, High, U-high).

• Integration with centralised building management systems for optimisation.

In short, the KXZ3 sereis is not just cooling air — it’s directly contributing to measurable sustainability outcomes.

Compact, Modern Design

Modern developments demand mechanical solutions that support the architectural narrative rather than disrupt it.

The KXZ3 series features a sleek, compact unit profile designed to blend seamlessly into rooftops and plant areas without visual bulk. Its space-saving footprint enables more creative freedom for designers and reduces construction complexity.

Award-Winning Engineering Excellence

Only months after its Australian launch, the KXZ3 series was honoured with the Australian Good Design Award for Engineering Design, recognising its innovation across sustainability, performance and technical refinement.

This accolade reinforces the system’s industry leadership and builds confidence for specifiers seeking proven, future-ready solutions.

A VRF System Built for the Future of Construction

With the KXZ3 series, MHIAA has set a new benchmark for climate control in commercial developments, combining sustainability credentials, engineering intelligence and architectural versatility.

Whether the goal is compliance, carbon reduction or premium building performance, the KXZ3 series is designed to take projects further — from the design stage to operational excellence.

To learn more or explore how the KXZ3 can help future projects meet performance and NABERS targets, visit: www.mhiaa.com.au

NEXT GENERATION OF VRF AIR-CONDITIONING SYSTEMS

Improved Energy Efficiency

Advanced compressor technology, optimised airflow and utilisation of R32 refrigerant deliver superior energy efficiency and performance.

Compact Design

Compact single-fan, vertical discharge design simplifies installation, saves space and integrates seamlessly into tight layouts without compromising performance or efficiency.

Wider Operation Range

Wide operating range delivers reliable year-round comfort, with efficient heating down to -25°C and cooling up to 52°C, ideal for diverse climates and demanding conditions*.

The KXZ3 series of VRF air-conditioning systems combines high performance, exceptional energy efficiency, and an expanded operating range to meet the demands of modern commercial projects.

The KXZ3 delivers around 70% lower CO2-equivalent emissions than R410A systems, In addition, the superior energy efficiency of KXZ3 systems combined with its precise capacity control system and its new saving mode, make it the perfect choice for developments aiming to achieve high NABERS and Green Star ratings.. Its compact footprint, flexible design, and superior efficiency provide precise comfort, reliable year-round performance, and strong environmental credentials offering a sustainable, future-ready solution without compromising performance or control.

Easier Serviceability

Engineered for easy access and smart diagnostics, enabling faster maintenance, reduced downtime, and reliable peak performance.

Blue Fin Corrosion Protection

A specially formulated, multilayered coating protects the heat exchanger from salt, moisture and harsh elements, extending lifespan, preserving efficiency and ensuring reliable performance in demanding environments.

Variable Temperature Capacity Control

Advanced variable temperature and capacity control precisely adjusts output to match demand, enhancing comfort, improving efficiency, and ensuring year-round performance.

DRIVING CONSTRUCTION PERFORMANCE THROUGH INTEGRATED REINFORCEMENT AND POST-TENSIONING

Goldenlight REO Fix & PT is redefining structural delivery in Australia through its fully integrated reinforcement and post-tensioning model. By managing every stage, from planning and installation to precision tensioning, the company delivers stronger, lighter, and more sustainable concrete structures while simplifying coordination across trades. Their work on projects such as Raya Gungahlin demonstrates how smarter integration is driving the next generation of construction performance.

Building upon their proven success in delivering integrated reinforcement (REO) and post-tensioning (PT) systems, Goldenlight REO Fix & PT continues to advance how reinforced concrete structures are designed and delivered.

At Raya Gungahlin, a landmark collaboration with Core Development Group, Goldenlight showcased how this integrated approach translates to measurable results on site.

“We manage the entire process, from reinforcement planning through to post-tensioning, ensuring everything is perfectly aligned. It means less downtime between trades, better structural consistency, and a safer, more efficient work environment,” Del explained.

Goldenlight’s comprehensive REO packaging services have already become an industry benchmark in Canberra, delivering streamlined scheduling, reduced material waste, and simplified project management.

The addition of in-house post-tensioning extends these benefits even further. “Post-tensioning lets us create lighter, stronger slabs and beams while using less concrete and steel,” said Del. “It’s about smarter design that improves strength, durability, and sustainability.”

The Raya Gungahlin project exemplifies these advantages in realworld application. “By managing both the reinforcement and tensioning, we’ve reduced duplication, simplified communication, and accelerated delivery. Our integrated system ensures that the structure performs at the highest level, it’s strong, flexible, and built to last,” Del added.

Goldenlight’s team approach has also been key to their success. “Every project is a collaboration,” Del noted. “At Raya Gungahlin, our coordination with Core Development Group and other trades ensured that every pour, every cable, and every tensioning sequence ran smoothly. That’s the standard we set, excellence through teamwork.”

Their commitment to innovation extends beyond Canberra. Following the successful completion of projects such as Narrabundah High School, Goldenlight has expanded operations into Queensland and New South Wales, positioning the company as a national leader in integrated REO and PT systems.

“We’re proud to bring our expertise to more builders and developers across Australia,” Del said. “Our goal is to deliver the same quality and reliability we’re known for in the ACT to every project we undertake.”

The company’s approach is guided by five core benefits for contractors;

• Simplified coordination

• Consistent quality

• Faster delivery

• Improved site safety

• Clear communication

“When you have one subcontractor managing both trades, there’s no disconnect, everyone’s on the same page from design to completion,” Del explained.

As the construction landscape continues to evolve, Goldenlight remains focused on performance, precision, and partnership. “We’re not just installing steel and cables, we’re building confidence,” Del

concluded. “Whether it’s a school, a commercial tower, or a major residential development like Raya Gungahlin, we ensure that every structure we touch is stronger, smarter, and safer.”

As construction projects increase in scale and complexity, integration and collaboration are becoming central to improving efficiency and sustainability. Goldenlight’s combined reinforcement and posttensioning delivery model reflects this shift, consolidating design coordination and structural execution to support quality control, site safety, and reduced environmental impact.

For more information contact Goldenlight Pty Ltd, 490 Northbourne Avenue, Dickson ACT 2602, phone 0421 548 469, email alex@goldenlightcivil.com.au, website www.goldenlightstructure.com.au

MULTIPLEX COMPLETES SYDNEY’S FIRST MAJOR AIRPORT TERMINAL BUILD IN MORE THAN 50 YEARS

Premier global contractor Multiplex has completed construction of the Western Sydney International (Nancy-Bird Walton) Airport (WSI) terminal in Badgerys Creek. It represents the first major airport to be built in Sydney in more than 50 years, and will be the city’s only 24-hour airport.

Premier global contractor Multiplex has completed construction of the Western Sydney International (Nancy-Bird Walton) Airport (WSI) terminal in Badgerys Creek. It represents the first major airport to be built in Sydney in over 100 years, and will be the city’s only 24-hour airport.

Built on behalf of the Western Sydney Airport Corporation (WSA Co), the concept design of WSI’s state-of-the-art terminal was created by renowned architects Zaha Hadid and COX Architecture. Spanning four levels, it has capacity to service 10 million annual passengers.

Building on this, Multiplex delivered an optimised design for WSI’s terminal and surrounding infrastructure, working in collaboration with leading consultants including Airbiz and architects, Woods Bagot. This optimised blueprint enhanced the project’s performance within a refined, more efficient space – supporting the passenger experience that WSI envisaged.

Multiplex initiated construction planning in tandem with site works, working to a strict programme that ensured the new airport terminal was delivered on time and within budget.

“Western Sydney International Airport is a once-in-a-lifetime project. It has created a new world-class gateway to Sydney for domestic and international travellers. The completion of this highly technical build is also a significant milestone for Multiplex, as the largest project we have delivered in NSW in Multiplex’s 60-plus-year history,” said Multiplex’s NSW Regional Managing Director, David Ghannoum.

“The delivery of this complex project is testament to our diverse capabilities and ability to collaborate, unlocking insights from other sectors to achieve outstanding outcomes. WSI is a highly impactful piece of infrastructure that will leave a legacy for years to come,” he added.

“We are on the precipice of launching a seamless and stress-free airport experience unlike any other in Australia,” said Western Sydney International Airport’s CEO Simon Hickey. “WSI will give our global city a 24-hour international gateway that will continue to create significant economic opportunities for all of Greater Sydney.”

WSI’s terminal construction spanned almost four years and delivered a major employment boost to Western Sydney, generating thousands of construction jobs as well as permanent roles within the airport itself. Over 2,000 workers were on site at the terminal project’s peak, and importantly, over 50% were local Western Sydney residents.

According to Multiplex, the highly technical WSI build presented challenges that were overcome using innovative construction methodologies.

“Significant challenges were presented by the scale of the terminal building and the volume of conventional concrete and specialised labour required to build it,” said Mr. Ghannoum.

To maintain the project’s delivery schedule, Multiplex opted to construct Levels 2 and 3 of the terminal using a ‘Slimdek 210’ flooring solution – a locally-made composite steel frame developed by BlueScope Steel.

This reduced the amount of labour and concrete required to build the terminal and enabled the fit-out of WSI’s baggage handling system to commence several months ahead of schedule.

Another innovation in Multiplex’s methodology was a prefabricated service riser system, used within the main terminal building and allowing each core to be installed in a single day.

Beyond completing the iconic new WSI terminal, Multiplex has delivered tangible social and economic impacts for the broader community. More than 60 local subcontractors, consultants, and suppliers from Western Sydney, whose combined contract value exceeded $400 million, worked on the project.

Multiplex also launched the Western Sydney Airport Connectivity Centre in partnership with Penrith TAFE, aimed at generating sustainable, long-term employment opportunities for local jobseekers.

A variety of initiatives were rolled out, including Construction Pathways to Certificate II and vocational training for trade and flight-related careers, particularly for First Nations women. Since its inception, the Connectivity Centre has facilitated 381 work placements for First Nations people.

The project also saw Multiplex roll out its Jump Start, Jump Start Trades and Jump Start Juniors programs, which promote construction careers amongst female high school students and primary school students, respectively. Over 550 students from 21 Western Sydney high schools and 11 primary schools participated in Jump Start programs over the course of the project.

Media information: The PR Partnership

Images - Multiplex & Aran Anderson Photography

Experimental studies have demonstrated HPC’s capability to enhance structural capacity with minimal additional thickness. For example, tests on fullscale reinforced concrete columns jacketed with thin layers of HPC have shown significant increases in axial load capacity and ductility. Likewise, overlaying deteriorated floor systems with lowthickness HPC screeds has led to notable improvements in flexural stiffness and cracking resistance, even without the use of shear connectors.

ADVANTAGES

Very high flexural and compressive strength

Excellent adhesion

Fibre reinforced

High resistance to abrasion and impact

High resistance to cyclical loads

Impermeable to water

STANDING TALL ON SUSTAINABLE DESIGN

DEVELOPER : Mulpha

MAIN CONSTRUCTION COMPANY : Parkview

ARCHITECTS : Bates Smart Architects (Banksia), Smart Design Studios (Lacebark), and Aspect Studios (Wild Greens)

A commitment to sustainability and style have been the guiding principles for construction delivered on of the first stage of Mulpha’s Norwest Quarter precinct in Sydney’s Hills District.

Stage 1 of Mulpha’s $1 billion master planned community is realised in Banksia and Lacebark.

Stage 1 of the precinct combines residential, community and retail amenity overlooking the landscaped public domain and interactive communal area known as the Wild Greens. Banksia and Lacebark have been architecturally designed with distinctive but complementary identities by Bates Smart Architects, Smart Design Studios, and Aspect Studios.

The carefully considered modernist designs feature premium materials, optimise light, and create integrated, shared amenity spaces with residents set to enjoy access to dining rooms, a pool, community gardens, workshops and playgrounds. Importantly, the buildings are also entirely powered by renewable energy.

For builders, Parkview Constructions – who have delivered the first stage – the opportunity to demonstrate a commitment to innovation, sustainability, high-quality communityfocused design at this scale has been second to none. The construction contract exceeded $200 million and has resulted in 184 muchneeded homes in a thriving area of Sydney.

“Parkview undertook an early contractor involvement (ECI) process to help Mulpha develop the design at all stages, from DA approval through to a fixed lump-sum design and construct contract,” explained Glenn Moran, Head of Construction at Parkview. “Being engaged with our client from inception to delivery has allowed us to plan carefully and collaboratively from the start with the assembly of the right, experienced team including our most-trusted subcontractors and suppliers.

What was incredibly beneficial was the crystal-clear brief and vision from Mulpha,” said Moran. “Our client’s philosophy around sustainability, community and nature shaped every decision we made.

“We understood from the outset that the delivery of the first two towers of the precinct was a defining moment for Mulpha, for the design team, and for the community,” Moran said.

“It was critical that our construction delivered the level of quality, materials and workmanship to set a new benchmark for integrated, sustainable design and I believe we’ve achieved that. It’s one of the finest mixed-use apartment developments in New South Wales, and we are proud to be a part of the team behind Banksia and Lacebark.”

How green

does your development grow

The sustainability ambitions for Norwest Quarter were to ensure the buildings were powered on 100% renewable energy, built with zero waste to landfill, and water resilience.

To contribute to the achievement of these goals, Parkview Constructions implemented a suite of measures including:

• Water-efficient fixtures and fittings.

• Apartment layouts designed for zerowaste living.

• 100% electric residences, with induction cooking and no gas connections.

• Electrical Vehicle (EV)-ready parking with fast-charge infrastructure.

• Rooftop solar power providing renewable energy.

• Double-glazed windows for superior thermal and acoustic efficiency.

• Urban heat-reduction landscaping, with layered canopies and native species planting.

“These integration of sustainable design features and energy efficiency are part of the building’s DNA, they’re not bolt ons,” said Moran. “The goal was to create a community where residents and businesses can live and work in a carbon-neutral environment without sacrificing comfort or quality.”

Partnerships that Build Excellence

Parkview Constructions drove productivity and consistency by strategically splitting key trade packages between the two towers, including brickwork, stone benchtops, and tiling. The approach meant there was a balance of resource allocation, while ensuring uncompromised attention to detail.

“The biggest challenge wasn’t the site itself – It was the defining design elements and commitment to quality finish at a large scale, and to achieve that, consistency, communication and care was needed at every step,” Moran said. “When you’re building something of this quality, every junction,

every line, every material has to be perfect and we committed to meeting that challenge.

“There are so many standout features including the Banksia façade with its precast form and GRC planter boxes, while the Lacebark façade uses custom-made Lohas Spanish bricks with curved balconies, blades and soffits. There are also the hit-and-miss black brick drums that house a communal dining room and future restaurant.”

The Parkview Construction team were equally invested in the internal spaces, including the Banksia lobby featuring a library and greenery, and the Lacebark entry, which both set the tone for luxury living.

“Although the project was complicated, the commitment to collaboration, attention to detail and quality across the client team, architects and contractors never wavered,” Moran explained.

“We believe this project is one of the highestquality apartment buildings ever constructed in the state and it proves that when developers, designers, and builders share a vision, they can create something truly extraordinary.”

For more information contact Parkview, 02 9506 1500, enquiries@parkview.com.au, website www.parkview.com.au

Below Renyi guided Norwest Quarter’s sustainability, ensuring energy efficiency, regulatory compliance, and practical, high-performance building outcomes.

SUSTAINABLE BY DESIGN: BALANCING AMBITION, BUDGET, AND COMPLIANCE

Renyi, a building performance and energy efficiency consultancy, played a key role in the Norwest Quarter development, one of Sydney’s most ambitious sustainable mixed-use precincts.

Engaged early in the pre-construction phase, Renyi provided technical guidance to ensure the project met and exceeded Australia’s minimum compliance standards, aligning sustainability targets with practical construction constraints.

“We got involved before construction began,” explained Allan Ang, Director at Renyi. “Our scope included providing NatHERS/BASIX certification, NCC Section J and ESD design implementation advice for 181 dwellings over two buildings within the precinct at construction stage, all mandatory energy efficiency requirements under the National Construction Code. We set the performance criteria for the building envelope and service equipment to ensure compliance and efficiency.”

This involved detailed technical calculations to establish benchmarks for everything from air-conditioning systems to tapware efficiency.

“This project had ambitious sustainability targets that went beyond minimum national requirements,” said Allan. “Our job was to align those aspirations with the builder’s practical and financial constraints, helping to achieve the best possible outcomes within budget.”

Striking that balance required careful co-ordination between the developer, builder, and Renyi’s team. “It was a juggling act,” Allan admitted. “There were some areas where we couldn’t compromise, like the building fabric’s thermal performance, but in others, we found smart substitutions, sourcing more cost-effective, water-efficient fixtures that still met high sustainability ratings.”

Renyi’s involvement continued throughout construction, ensuring every trade aligned with the project’s sustainability matrix. “Once the performance parameters were established, our role was to follow through with the builder to make sure all subcontractor works complied,” Allan said. “When unexpected challenges arose, such as availability of materials or system conflicts, we worked closely with the design and construction teams to find compliant, efficient alternatives that didn’t compromise on quality or aesthetics.”

The result is a benchmark in sustainable mixed-use development, demonstrating how collaboration, technical precision, and adaptability can translate lofty sustainability goals into real-world outcomes. “We’re proud of how we managed to balance the expectations of both developer and builder,” said Allan. “Norwest Quarter showcases our ability to go above and beyond minimum standards to help deliver a building that’s genuinely sustainable.”

With Renyi’s guidance, the project not only achieved compliance, it helped redefined it.

“It wasn’t a straightforward process,” Allan reflected. “But through true expertise and teamwork, we helped the builder resolve complex service issues and ensure the project met its high-performance aspirations.”

The outcome resulted in 7.8 Star NatHERS/ BASIX certification for the project with cost-effective advice to revise the glazing thermal targets.

Renyi partners with clients to achieve Green Star accreditation through the Green Building Council of Australia, as well as NABERS and BASIX certification with NSW Planning—further reinforcing each project’s commitment to sustainability and energy efficiency.

With a focus on collaboration and transparency, Renyi supports clients at every stage of development, helping them achieve superior environmental performance without compromising on quality or functionality. The dedicated Renyi team takes pride in providing personalised service, technical excellence, and ongoing guidance—building strong, lasting partnerships that deliver smarter, greener outcomes.

For Renyi, Norwest Quarter stands as a testament to their philosophy: building smarter, greener, and better.

For more information contact Renyi, Level 23, 520 Oxford Street, Bondi Junction NSW 2022, phone 02 9316 8882, email info@renyi. com.au, website www.renyi.com.au

Below Vergola® delivered over 30 bespoke louvre systems at Norwest Quarter, enhancing sustainability, comfort, and architectural integration across diverse spaces.

ADAPTIVE DESIGN MEETS SUSTAINABLE LIVING AT NORWEST QUARTER

At Sydney’s Norwest Quarter, Vergola® transformed architectural vision into climate-responsive living. Delivering over 50 bespoke opening-and-closing louvre roof systems, the company showcased how intelligent, adaptable design enhances both building performance and everyday resident comfort.

Bespoke Louvre Roof Systems Across Four Distinct Settings

The project spanned four unique environments: penthouse apartments, mid-level residences, retail dining areas, and a technically complex trapezium-shaped structure. Each posed its own challenges, but all were united by Vergola’s trademark ability to combine functionality with architectural harmony.

On Building C’s crown level, two luxury penthouses required a seamless integration of 12 panels each, forming a continuous roofline over expansive wraparound balconies. Initially, alternative shading options had been considered, but only Vergola® could deliver the year-round usability demanded of these premium residences.

Finished in custom colour Hamptons White, the installations give residents fingertip control of light and shade, whether for a sunlit breakfast or a shaded evening gathering.

Level 4 presented a different challenge: six adjoining systems had to be installed within existing concrete beams and piers, yet function and appear as one continuous structure. Through precise engineering and meticulous planning, Vergola® achieved a solution that preserved architectural integrity while providing consistent aesthetic and functional outcomes.

Vergola’s role extended beyond residential spaces to the retail heart of Norwest Quarter, where six restaurant tenancies were fitted with systems set within steel frames clad in timber.

Finished in COLORBOND® Paperbark, these louvres enhance outdoor dining by enabling operators to adapt their spaces to any weather condition. The result is vibrant, all-weather hospitality venues that strengthen the precinct’s community appeal and offer residents and visitors a lively, connected place to gather.

Perhaps the most innovative aspect was the trapezium-shaped structure in Building B, featuring a glass roof framed by two COLORBOND® Monument-coloured louvre roof systems. This bespoke design required customisation to accommodate the geometry while maintaining weatherproofing and operational performance, exemplifying Vergola’s capacity for engineering excellence.

Collaborative Delivery, Lasting Results

Delivering across such varied applications demanded seamless teamwork. Vergola’s design consultant, operations team, and installers worked closely with architects, builders, and multiple trades, including lighting, plumbing, glazing, and fire systems.

This collaborative approach ensured each system integrated smoothly with surrounding structures and services. It was this alignment of expertise and vision that enabled Vergola® to transform ambitious design concepts into fully realised lifestyle features, all while meeting strict programme requirements.

Since its invention in 1984, Vergola® has remained the benchmark for opening and closing louvre roof systems. The Norwest Quarter installation demonstrates why. Their systems offer 99% weatherproofing with tight louvre closure, 89% light transmission when fully open, outperforming competitors, and automated rain sensors that provide immediate responses to weather changes. They also contribute to energy-efficient regulation by reducing HVAC demand and enhance property values by creating premium outdoor living spaces.

For Norwest Quarter, Vergola® didn’t just provide shade structures, they created spaces

that enrich everyday life. From penthouse balconies to buzzing restaurant terraces, the installations elevate both design and usability. The project demonstrates how functional innovation can support long-term sustainability while enhancing the human experience.

By delivering solutions that respond to climate, maximise comfort, and contribute to architectural identity, Vergola® has reinforced its reputation as a trusted partner on landmark developments.

As a multi-building project with diverse challenges, Norwest Quarter stands as a

showcase of Vergola’s unmatched ability to blend innovation, durability, and beauty. The end result is not only an architectural success but also a community enriched by thoughtful, adaptable outdoor spaces that will be enjoyed for generations.

Vergola® continues to prove why it is the original and still the best in the market, transforming challenging architectural spaces into premium lifestyle experiences.

For more information contact Vergola, 7 Tepko Road, Terrey Hills NSW 2084, phone 02 9160 0338, website www.vergolansw.com.au

Below Radiant North provided façade structural support for Norwest Quarter’s façades, ensuring stability, adaptability, and on-time delivery.

HOLDING IT TOGETHER: THE HIDDEN ENGINEERING BEHIND EVERY FAÇADE

As one of the most ambitious mixed-use developments in NSW, Norwest Quarter demanded engineering partners who could adapt swiftly, communicate clearly and solve complex challenges with confidence. Radiant North Engineers stepped into this role as the project’s structural façade engineering consultant, applying deep expertise to ensure structural adequacy across key components of the development.

“We were engaged specifically to ensure the structural adequacy of the façade components,” explains Principal Engineer and Director, Zebei Jiang. “That included facade lightweight steel wall and opening framing and cladding sub-framing, supporting systems for sliding doors, cladding elements like CFC panels, brick slip systems, and the structural steel columns for the commercial areas in Buildings B and C.”

Working across lower levels, ground and Level 1, the team was responsible for designing the structural ‘skeleton’ that supported multiple façade systems. As construction progressed, scope changes and onsite realities required rapid reassessment and redesign.

“The timeframe was definitely the biggest challenge,” says Zebei. “It was a really fast-paced programme with evolving site conditions.

In some cases, designs had to be revised multiple times after surveys revealed discrepancies from the original drawings.”A notable example was the transition from brick slip cladding to conventional brickwork due to logistical constraints. “We had to redesign shelf angles and support systems very quickly to keep the project moving,” he explains.

For Radiant North, responsiveness wasn’t just about speed—it was about understanding the client’s needs immediately and delivering practical, buildable solutions. “When the client called with a problem, we understood what they needed right away,” Zebei says. “That’s where our experience really stood out. We were transparent, direct, and able to meet tight turnaround requirements—even when our work was on the critical path.”

Meticulous documentation, clear communication, and a problem-solving mindset contributed to the firm’s success. “We’re proud that our work speaks for itself,” says Zebei. “Most of our business comes from repeat clients and word of mouth—and projects like this are the reason why.”

For more information contact Radiant North Engineers & Constructors, 22 Ross Street, Windsor NSW 2756, phone 0403 564 772, email zebei@rneng.com.au

Below Ozbrick Masonry showcased precision, innovation, and collaboration, delivering bespoke masonry that elevated Norwest Quarter’s architectural excellence.

FROM VISION TO STRUCTURE: THE ART OF MASONRY AT NORWEST QUARTER

The Norwest Quarter development represents a new benchmark in sustainable, design-led living, and for Ozbrick Masonry, it was an opportunity to demonstrate how expert craftsmanship and innovative problem-solving can elevate complex architectural visions into enduring structures.

Combining technical precision with aesthetic sensitivity, Ozbrick delivered a comprehensice masonry package including bricklaying, stonework, and blockwork that were integral to both the structural framework and also enhanced the projects visual identity and longterm performance.

The project’s use of distinctive LOHAS bricks introduced an exciting technical challenge, as their unique shapes and dimensions required careful planning and precise workmanship. “Additionally, the incorporation of a railing slip brick system required precise integration with conventional brickwork, ensuring a seamless blend of styles and functionality,” said Louay Ahmed, Managing Director.

Among the most distinctive design features were the ‘drums’, a striking hit-and-miss brick element created with smoked LOHAS bricks. “The integration of this feature required precise coordination with

the structural steel that supported the brickwork,” Louay noted. “Thanks to the skill and expertise of the Ozbrick team, these challenges were successfully overcome, ensuring a seamless and visually appealing result.”

“Our team collaborated closely with architects and engineers throughout the design and construction phases,” Louay said. “We employed high-quality materials and skilled tradespeople to achieve superior alignment and finishes. Regular quality checks and adherence to best practices ensured that both the structural integrity and the aesthetic vision were realised.”

The use of durable materials and expert craftsmanship contributes significantly to the long-term resilience and weatherproofing of the Norwest Quarter complex. “The success of the masonry work is a testament to the strong collaboration between all parties. The Norwest Quarter stands out as a benchmark for future developments in the region,” said Louay.

For more information contact Ozbrick Masonry, 3 Holbeche Road, Arndell Park, NSW 2148 Australia, phone 0425 807 705, email admin@ozbrick.com.au, website www.ozbrick.com.au

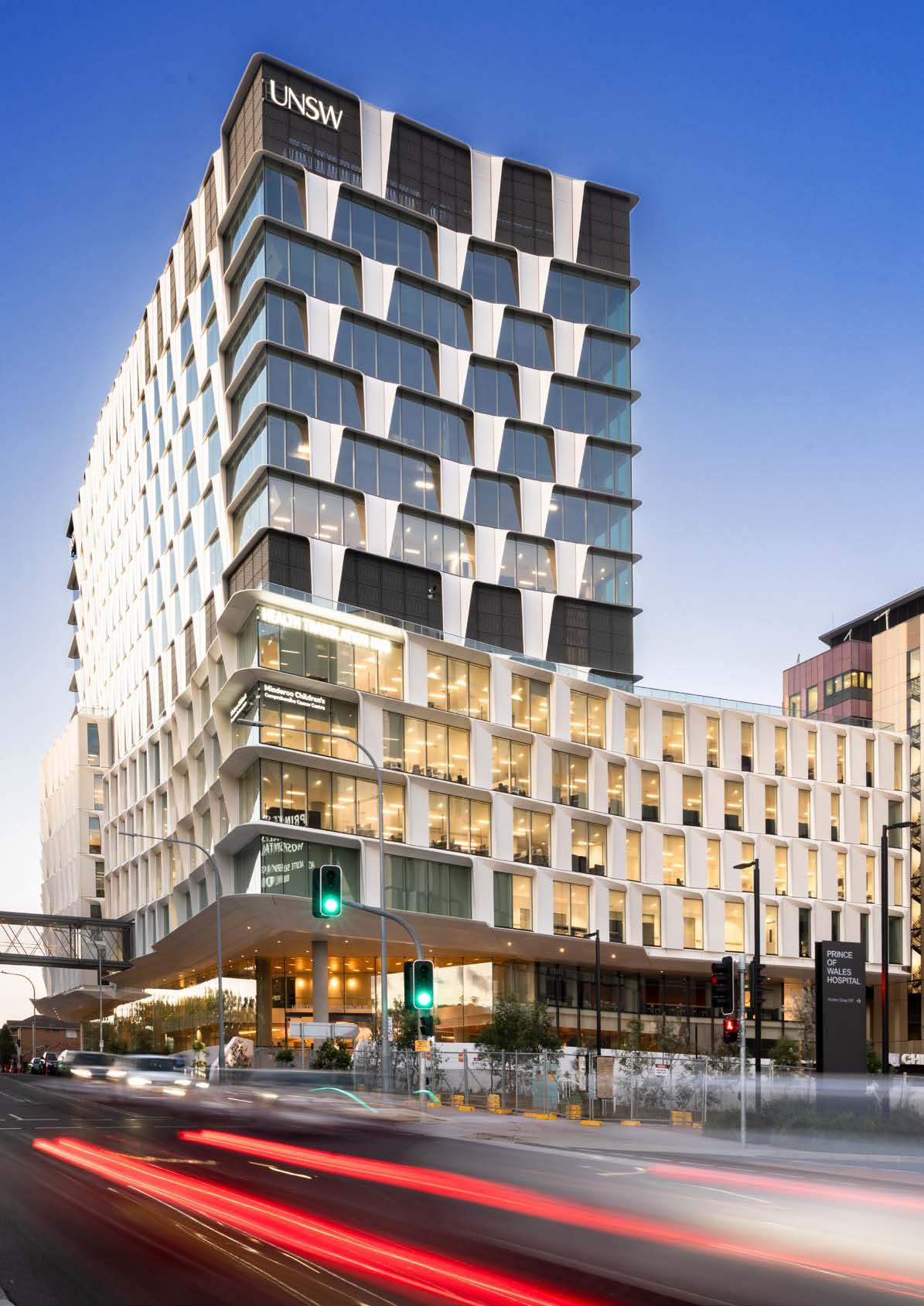

TRANSFORMING HEALTH INFRASTRUCTURE: UNSW HEALTH TRANSLATION HUB

DEVELOPER : Plenary

MAIN CONSTRUCTION COMPANY : Hansen Yuncken

ARCHITECT : Architectus

ESD : Flux

The UNSW Health Translation Hub (HTH) delivers world-leading research, innovation, and education spaces, supporting rapid healthcare translation, sustainable design, and community wellbeing. Featuring 6-Star Green Star buildings, 100% renewable power, 10,900m2 total area with flexible floor plates, and 3,000m2 of public space, the HTH integrates accessibility, purpose-built facilities, and environmental leadership.

The University of New South Wales Health Translation Hub (HTH) represents a new benchmark for integrated health, research, and education facilities. Located in the heart of the Randwick Health & Innovation Precinct, this landmark development combines clinical, academic, and public spaces within a single vertical structure, requiring exceptional planning, innovation, and collaboration.

For Hansen Yuncken, the project was as complex as it was rewarding. “The HTH is one of the most high-value, high-profile projects we’ve delivered,” said Justin Sut, Project Manager. “It brought together diverse stakeholders, ambitious design elements, and highly technical requirements, all while building in the middle of a live hospital and university precinct.”

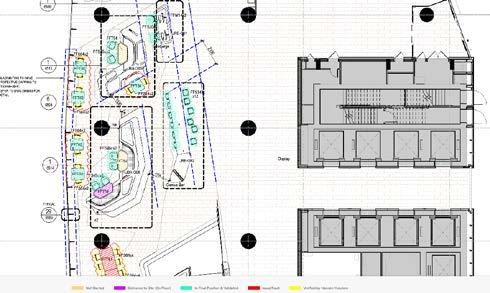

Building within the operational Randwick health precinct required meticulous logistics and stakeholder coordination. Hansen Yuncken managed interfaces with the Sydney Children’s Hospital main contractor, co-ordinated crane strategies and shared access arrangements, and implemented a robust programme of regular interface meetings to mitigate potential conflicts.

“The site posed unique challenges,” Justin explained. “We had to plan around aviation constraints under PANS-OPS, which affected our building height and crane operations for a three-month period. At the same time, we needed to maintain safe access for the hospital, UNSW, and the light rail corridor, supported by dedicated traffic control and logistics management.”

The team also handled complex façade design and installation, the prefabricated Wallace Wurth Link Bridge, and an atrium sequence that required innovative planning to resolve buildability challenges. “Early procurement and close collaboration with specialist subcontractors were key to keeping the programme on track,” Justin said.

With a 6-Star Green Star rating and net-zero carbon target, sustainability was embedded into every decision. Hansen Yuncken engaged a specialist Green Star consultant from the outset and trained its project team to align daily operations with strict sustainability goals.

“Collaboration was critical,” Justin noted. “We worked closely with our subcontractors to ensure material selections, waste reduction initiatives, and energy-efficient construction methods were delivered as planned. Sustainability wasn’t just a checkbox, it drove our approach from design through to handover.”

Digital tools and real-time reporting platforms also supported efficient monitoring, incident management, and project visibility, enhancing both safety and environmental performance.

Given the building’s mix of clinical, simulation, education, and public-use spaces, early stakeholder engagement was essential. Hansen Yuncken coordinated regular design and user group workshops with UNSW, consultants, and end users to ensure

operational flow and spatial relationships were optimised.

The collaboration extended to the project’s architectural partners. “We workshopped the design with Architectus and presented updates to the client throughout each stage,” Justin said. “This process ensured every requirement was captured, feedback was addressed, and the design remained true to the project vision.”

For Hansen Yuncken, the HTH is more than a construction achievement, it is a legacy project for the health and education sectors in New South Wales. “In terms of complexity, innovation, and impact, the HTH raised the bar across all fronts,” Justin explained. “It’s a flagship example of how collaborative delivery, sustainable construction, and technical excellence can come together to transform a precinct and a community.”

With its completion, the UNSW Health Translation Hub not only strengthens the Randwick Health & Innovation Precinct but also sets a new standard for integrated health and research infrastructure.

Beyond its architectural and technical significance, the project delivers a tangible benefit to the community, bringing worldclass research, clinical innovation, and learning spaces into closer connection than ever before.

Hansen Yuncken’s involvement ensures that this state-of-the-art hub will support the next generation of healthcare advancements and educational excellence, leaving a lasting mark on the precinct and the people it serves.

For more information contact Hansen Yuncken, phone 02 9770 7600, email sydney@hansenyuncken.com.au, website www.hansenyuncken.com.au

Below Ausrise Façades delivers precision-engineered, curtain walls and architectural façades, combining innovation, and technical excellence.

PIONEERING COMPLEX CURTAINWALL AND FAÇADE ENGINEERING

For over two decades, Ausrise Façades has been at the forefront of façade innovation and precision, specialising in complex curtainwall systems, highperformance glazing, and architectural cladding solutions across Australia.

With 23 years of experience and a skilled team of 50 professionals, the company has become synonymous with quality, craftsmanship, and collaborative delivery, which were on display in their recent work on the UNSW Health Translation Hub (HTH) project.

Located within the Randwick Health and Innovation Precinct, the HTH project posed a unique opportunity and significant technical challenge: to create a world-class façade system for a facility that brings together education, research, and clinical care under one roof.

“Our scope of work included all external curtain wall façades—glass, GRC (glass reinforced concrete), aluminium feature elements, fixed louvres, and frameless glazing at the podium,” said Kevin Hartin, Director at Ausrise Façades. “Every one of our 50 staff members was involved in this project in some capacity. It was truly an allhands on effort.”

From the outset, the HTH’s architectural ambition was clear, with striking geometric forms and curved aluminium and GRC features shaping the building’s exterior. Ausrise was brought on for their ability to deliver complex façade systems with high technical accuracy and aesthetic precision.

“What made this project really stand out were the scale and shape of the GRC projections,” Kevin explained. “They involved largeformat panels with very tight tolerances and complex curvature that pushed the limits of conventional fabrication and installation.”

Overcoming the engineering challenges of both these curved aluminium and GRC elements required early engagement with structural consultants, iterative 3D modelling, and customised mounting systems. The Ausrise team worked closely with the

builder, architect, and façade engineers to ensure every panel aligned with the architectural vision while maintaining longterm durability and thermal performance.

The podium-level frameless glazing system also presented logistical and sequencing complexities. These were resolved through meticulous staging and real-time coordination with other trades. Despite the scale and technical difficulty, Ausrise delivered their scope on time and to specification.

“The HTH project exemplified what Ausrise does best, bringing engineering, fabrication, and site installation together seamlessly to meet architectural intent,” said Kevin. “We’re proud to have been part of such an important project for UNSW and the broader research community.”

Beyond the HTH, Ausrise continues to push the boundaries of architectural façade delivery. The company is currently working on the Macquarie University Engineering and Astronomy Building, another architecturally ambitious project that showcases their deep capability in technical façade solutions.

With a growing portfolio of major university, commercial, and public infrastructure projects, Ausrise remains committed to its founding values of quality, innovation, and collaboration. Their vertically integrated model (combining in-house design, manufacturing, and installation,) enables them to tackle increasingly complex façades with confidence and precision.

“Over the past 23 years, we’ve built our reputation on consistency and problemsolving,” Kevin noted. “Every project is different, and we pride ourselves on adapting our systems and processes to suit. At the end of the day, it’s about delivering value, performance, and design excellence to our clients.”

For more information contact Ausrise Façades, 6/5 Clerke Place, Kurnell NSW 2231 Kevin Hartin – phone 0422 803 933, email kevin@ausrise.com.au, Paul White – phone 0422 803 932, email paul@ausrise.com.au, website www.ausrise.com.au

Below ASP Access Floors delivered carbonneutral ICON X flooring at UNSW HTH, combining sustainability, precision, and high-performance.

CARBON-NEUTRAL ACCESS FLOORS

As the UNSW Health Translation Hub (HTH) set out to integrate research, education, and healthcare in one cuttingedge precinct, ensuring the building’s infrastructure supported its multi-use demands was key. For the flooring, ASP Access Floors delivered more than just a foundation, they brought performance, precision, and powerful sustainability.

“Our scope involved the installation of over 11,000m² of our ICON X access flooring system across six office levels,” said Angela Zlatar, Marketing & Sustainability at ASP Access Floors. “Given the HTH’s design constraints, we worked with a low-height configuration to meet the spatial requirements without compromising functionality.”

But this project wasn’t just about fit-for-purpose performance. The flooring was also a statement in environmental leadership. “Hansen Yuncken and UNSW opted for a carbon-neutral solution,” Angela said. “100% of the flooring installed through our Walk Carbon Neutral programme was fully offset, making it a ZeroCarbon certified installation.”

The facility’s diverse mix of clinical, research, and teaching spaces demanded a flooring system capable of handling significant load variations and traffic.

“We used the ICON X 3.0kN load-bearing system,” Angela explained. “It’s designed for high-use environments, perfect for supporting not just foot traffic, but also heavy equipment and furniture typical of a health and research precinct.”

ASP’s meticulous attention to detail was critical when it came to integration with mechanical, electrical, and data systems. “Our estimating team conducted comprehensive drawing reviews and services overlays before installation,” said Angela. “This meant we could proactively resolve clashes and ensure seamless coordination with other services.”

That forward-planning was supported by close collaboration. “We worked with architects, consultants, and contractors from the earliest design phase,” Teah said. “We weren’t just there to install, we offered technical guidance, adjusted plans to match service layouts, and helped ensure the project ran smoothly.”

Innovation and sustainability went hand-in-hand throughout the delivery. “With our own logistics team and trucks, we had full control of delivery schedules,” Angela added. “This agility allowed us to align with the construction timeline, often helping accelerate the programme rather than hold it up.”

What truly set this project apart was ASP’s ability to balance innovation, environmental responsibility, and client outcomes without compromise.