EmailAddress

water@watermanaustraliacom

EmailAddress

water@watermanaustraliacom

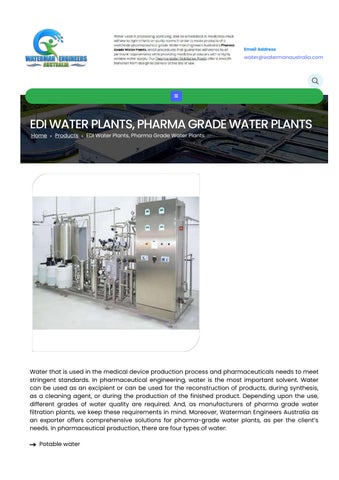

Waterthatisusedinthemedicaldeviceproductionprocessandpharmaceuticalsneedstomeet stringentstandards.Inpharmaceuticalengineering,wateristhemostimportantsolvent.Water canbeusedasanexcipientorcanbeusedforthereconstructionofproducts,duringsynthesis, asacleaningagent,orduringtheproductionofthefinishedproduct.Dependingupontheuse, different grades of water quality are required And, as manufacturers of pharma grade water filtrationplants,wekeeptheserequirementsinmind Moreover,WatermanEngineersAustraliaas anexporterofferscomprehensivesolutionsforpharma-gradewaterplants,aspertheclient’s needs.Inpharmaceuticalproduction,therearefourtypesofwater:

Purifiedwater

Highlypurified

WaterForInjection(WFI)

Threetypesofwaterfiltrationsystemsareusedinpharmaceuticalindustries

In this system the undesirable water-soluble ions and exchanging with desirable ones In this watertreatmenttechnology,theioniccompositionisalteredinadesirabledirection

Amicroporousexchangeresinisthemaincomponentforionexchangesystems Thisresinis suspendedinalooselyheldsolution.Sulfonatedpolystyrenebedssupersaturatedwithsodiumto coverthebedsurfaceareusedforwatersoftening.Whenwaterispassedthroughtheresinbed, theionsattachtotheresinbeadsandreleasethelooselyheldsolutioninwater.

Theresinmustberegeneratedorexchangedwhenitbecomessaturated Theexchangeresinis flushedwithbrinetoregenerateit Sodiumionspresentinthesaltbrinesolutionareexchanged withtheionsandflushedoutwithwastewater.

IONEXCHANGEWATERFILTRATIONSYSTEMADVANTAGES:

Easytooperate

Minimalmaintenance

Extremelyeffectiveforremovinginorganicionsfromwater.

Theresinusedcanberegenerated

In this process, natural osmotic flow is disrupted by applying pressure to the concentration solutioninanosmosisprocess Thisresultsintheflowofwaterfromamoreconcentratedtoaless concentratedsolution

Reverseosmosisplantshavemultimediaprefilter,watersoftenerorantiscalantdosingsystem, dichlorination dosing system, reverse osmosis unit with semi-permeable membranes, andultravioletsterilizersorpostchlorinationasapost-treatment.

ThereverseosmosistechniqueisappliedinROplantsinwhichparticleslargerthan10micronsare removed from feed water by passing it through a multimedia prefilter Then an antiscalant chemicalisinjectedtopreventhardnessfoulingthatcandamagetheROmembrane Hardness, chlorine, odors, color, ion, and sulfur are removed through these pretreatment options The minerals, impurities, and salts that weren’t removed by the pre-filter are removed by passing waterthroughareverseosmosisunitinwhichahigh-pressurepumpappliesextremepressureto the highly concentrated solution and removes impurities From the low-pressure end of the membrane, fresh, potable water comes out whereas, the salts, minerals, and impurities are dischargedintoadrainontheotherend Lastly,tokillbacteriaandothermicroorganisms,wateris passedthroughaUVsterilizer.

Cost-effective.

Safefortheenvironment.

Maintenance-friendly

Inpharmaceuticalpractice,distillationisawidelyusedtechnique.Asthefeedwatercontains innumerableviolentsubstances,thefirsttentotwentypercentofdistillateshouldbediscarded. Moreover,thelasttwentypercentshouldalsobediscardedtopreventexcessivedrynesswhich can result in the contamination of previous distillate by solid impurities A liquid mixture containingvolatilecomponentsisboiledbyheatandcondensationisusedtorecoverthevapor. Additionally,assupplierweprovidethebestavailablesolutionstoreliablyandaffordablyfulfilthe performancerequirementsofthesepharmagradewaterpurifyingsystems.

Distillation is a commonly utilised method in the profession of pharmacy. The first 10 to 20 percentageofthecondensateshouldberemovedsincethesupplywatercomprisesaplethoraof aggressive chemicals Furthermore, the final 20% should be eliminated as well to avoid an inappropriatedrynessthatcouldcausesolidcontaminantstoinfiltratethepriordistillate Inorder toreclaimthevapor,condensationisemployedtoboilanaqueouscombinationholdingvolatile components.

Effectivelyremovesinorganiccompounds. Microorganismsarealsokilled

Beneficialmineralsareleftbehindwhileimpuritiesareremoved.

A water treatment technology that is electrically driven and used, ion exchange membranes, electricity,andresinstopurifywaterbyremovingionizedspecies

EDI Reverse Osmosis Plant consists of chambers that contain ion exchange resins and are separatedbyion-exchangemembranes Whenwaterentersthemodules,anelectricalfieldat rightanglesisappliedtotheflowthatforcesionstomovethroughresinsandacrossmembranes Theimpuritiesarenotboundtoamediaandarecollectedinaconcentratedstreamwhichis eitherdirectedtothedrainrrecycled.

Ionexchangebedsareregeneratedcontinuously. Theimpuritiesdon’tbuildupandexhausttheresin Candelivermoreconsistentpurity

1.Whatispharmagradewater?

Inpharmaceuticalproduction,thewaterusedinprocessing,sanitizingandasafeedstockinmedicines(IVFLUIDS) mustmeetthestrictcriteriaonpuritystandards.Thatwatertypicallyknownaspharmagradewater,witharound0 to1ppmTDS Differentgradesofwaterqualityareusedwhichdependsupontheenduseeitherwaterisusedasa medium or can be used in the manufacturing process during synthesis, as a cleaning agent or during the productionoffinishedproduct Asperclient’srequest,twotypesofwaterareusedinpharmaceuticalproduction:

Highly Purified Water for Injection

2.Majortechniquestoproducepharmagradewater

InpharmaceuticalIndustries,threetypesoftechniquesareusedintheformoffiltrationsystemstoproducepharma gradewater:

IONExchangeWaterFiltrationSystems:Thedeplorablewater-solubleionsareexchangingwiththedesirableones inthissystemandioniccompositionofwaterisadjustinadesirabledirection.

Reverse Osmosis Plant Process: In this technique, the natural osmotic flow of water is disturbed by applying pressure to the concentration solution in an osmosis process This results in the flow of water from a more concentratedtoalessconcentratedsolution

DistillationTechnique:Thisistheextensivelyusedtechniqueinpharmaceuticalpractice.

ButthemostusedtechniqueforbiggerquantityisROfollowedbyEDI.

3.Howpharmagradewaterwasbeingproducedthroughwaterdistillationprocess?

Inordertoproducepharmagradewaterthroughdistillationprocess,atfirst10to20percentofthecondensate shouldberemovedsincethesupplywatercomprisesalargeamountofharmfulchemicals,lateron,thefinal20% shouldbeeliminatedaswelltoavoidextraamountofdrynesswhichcanresultinthecontaminationofprevious distillatebysolidimpurities Aliquidmixturecontainingvolatilecomponentsisboiledbyheatandthenvaporis recoveredwiththehelpofcondensation

4.WhatisELECTRODEIONIZATION,EDI?

Itisatreatmenttechnologythatisdrivenbyelectricityandusedionexchangemembranes,electricity,andresinsto purifywaterbyremovingionizedspeciesfromwater

5.HOWELECTRODEIONIZATIONEDIISusefultoproducepharmagradewater?

Itisusefultoproducepharmagradewaterbecauseofthefollowingadvantages:

In this technique, ion exchange beds are regenerated continuously The impurities do not build up and deteriorate the resin. It delivers more consistent purity.

EDIplantconsistsofchambersthatcontainionexchangeresinsandareseparatedbyion-exchangemembranes. Whenwaterentersthemodules,anelectricalfieldatrightanglesisappliedtotheflowthatforcesionstomove through resins and across membranes The impurities are not bound to a media and are collected in a concentratedstreamwhichiseitherdirectedtothedrainorrecycled

7.LATESTTRENDtoproducepharmagradewaterRO+EDI

ReverseOsmosissystem,EDIisthelatesttrendtoproducepharmaceuticalgradewatersystem Thepurifiedwater and water for injection can be used for Oral liquid, finished medicine, biological preparation, etc The GMP, FDA required water systems have activated carbon pasteurization, CIP cleaning system, distribution system ozone sterilization,distributionsystempasteurizationasapartofsystemwiththemostimportantistheEDIasapolisherto achieveTDSlessthan1ppmapproximately

8.Whatshouldbeconductivityforpharmagradewater?

Lessthan4μS/cm

9.Whatshouldbeconductivityofinjectiongradewater?

Lessthan1μS/cm

10.Howispharmaceuticalgradewaterproduced?

Pharmaceutical grade water is produced through a multi-step process that includes filtration, reverse osmosis, distillation,anddeionization Thewateristhensterilizedtoremoveanyremainingmicroorganisms Theprocessis carefullymonitoredandcontrolledtoensurethewatermeetstherequiredpuritystandards

11.Howisthequalityofpharmaceuticalgradewatertested?

The quality of pharmaceutical grade water is tested by analysing it for various parameters such as bacteria, endotoxins,conductivity,pH,andtotalorganiccarbon(TOC) Thesetestsareconductedatvariousstagesduringthe productionprocesstoensurethatthewatermeetstherequiredstandards

12.Whyisitimportanttousepharmaceuticalgradewaterinthemanufacturingofpharmaceutical products?

Theuseofpharmaceuticalgradewaterensuresthatthefinalproductisfreefromcontaminantsandimpuritiesthat couldpotentiallyharmpatients Itisessentialtousewaterofthehighestpurityintheproductionofpharmaceutical productstoensurethatthefinalproductissafeandeffectiveforpatients.

13.Whatisinjectablewater?

Injectable water is water that has been purified to a high degree of purity and is suitable for injection into the bloodstream Itisoftenusedasadiluentformedicationsandotherinjectablesolutions

14.Whatissalinewater?

Salinewaterisasterilesolutionmadeupofwaterandsalt(sodiumchloride)inaspecificconcentration Saline solutions are used for a variety of medical purposes such as hydration, electrolyte replacement, and cleaning wounds

15.WhatareIVfluids?

IVfluidsaresolutionsthatareadministeredintravenously,meaningtheyaredelivereddirectlyintothebloodstream throughavein IVfluidscanbemadeupofavarietyofsubstancessuchaswater,electrolytes,andmedications They are used for a variety of medical purposes such as hydration, electrolyte replacement, and medication delivery.

16.Whataresomecommonusesofinjectablewater,salinewater,andIVfluids?

Somecommonusesofinjectablewater,salinewater,andIVfluidsinclude:

Hydration:Thesesolutionsareusedtorehydratepatientswhoaredehydratedorhavelostfluidsduetoillnessor injury

Electrolytereplacement:SalinesolutionsandotherIVfluidscontainingelectrolytesareusedtoreplaceelectrolytes thathavebeenlostduetoillnessorinjury

Medicationdelivery:Injectablewater,salinewater,andIVfluidsareoftenusedasadiluentformedicationsthatare givenintravenously.

Woundcleaning:Salinesolutionsareoftenusedtocleanwoundsandhelppreventinfection

17.Howareinjectablewater,salinewater,andIVfluidspreparedforuse?

Injectablewater,salinewater,andIVfluidsarepreparedinasterileenvironmenttoensurethattheyarefreefrom contaminantsandimpurities Theyarepackagedinsterilecontainersandareusedwithinaspecifictimeframeto ensuretheirsterility

18.Whatarethesideeffectsofinjectablewater,salinewater,andIVfluids?

Thesideeffectsofinjectablewater,salinewater,andIVfluidsaregenerallymildandmayincludediscomfortorpain attheinjectionsite,swelling,orredness However,inrarecases,anallergicreactionorotherserioussideeffectsmay occur It is important to consult with a healthcare professional if you experience any side effects or have any concernsabouttheuseofthesesolutions

19.WhatistheUSPharmacopeia(USP)?

Drugs and other healthcare goods sold in the United States must meet the criteria established by the US Pharmacopeia(USP),anon-profitorganisation TheUnitedStatesPharmacopeia(USP)establishesguidelinesfor pharmaceutical formulations, including components, dosage forms, packaging, and testing and manufacturing procedures Thesestandardsareusedbymanufacturers,regulators,andhealthcareprofessionalstoensurethe safetyandefficacyofpharmaceuticalproducts.

20.WhatistheBritishPharmacopoeia(BP)?

TheBritishPharmacopoeia(BP)isacollectionofstandardsforthequalityandpurityofdrugsandotherhealthcare productsintheUnitedKingdom TheBPsetsstandardsforingredients,dosageforms,andpackaging,aswellasfor methodsoftestingandmanufacturing.Thesestandardsareusedbymanufacturers,regulators,andhealthcare professionalstoensurethesafetyandefficacyofpharmaceuticalproducts

21.HowdotheUSPandBPstandardscompare?

TheUSPandBPstandardsaresimilarinmanyways.Bothorganizationssetstandardsforthequality,purity,and identity of drugs and other healthcare products. Both organizations also provide guidelines for testing and manufacturingmethods However,theremaybesomedifferencesbetweenthetwosetsofstandards,particularlyin thespecificdetailsoftherequirements

22.HowareUSPandBPstandardsenforced?

The USP and BP standards are not legally binding, but they are widely recognized and respected by the pharmaceutical industry, regulatory bodies, and healthcare professionals Compliance with the standards is typicallyrequiredbyregulatoryauthorities,andproductsthatdonotmeetthestandardsmayberefusedentryinto themarket

23.HowdomanufacturersensurecompliancewithUSPandBPstandards?

Manufacturers can ensure compliance with USP and BP standards by following the guidelines set out by these organizations,includingguidelinesforingredients,dosageforms,packaging,testing,andmanufacturingmethods Theyshouldalsoconductregulartestingoftheirproductstoensurethattheymeetthestandards.

24.Whatisthereverseosmosisprocessformanufacturingpharmaceutical-gradewater?

Duringreverseosmosis,waterispushedacrossasemi-permeablemembraneinordertofilteroutcontaminants anddissolvedsolids Thewaterthatpassesthroughthemembraneisconsideredtobeofhighpurityandissuitable foruseinthemanufactureofpharmaceuticalproducts.

25.Whatisthedistillationprocessformanufacturingpharmaceutical-gradewater?

Distillationisaprocessinwhichwaterisheateduntilitturnsintosteam,whichisthencondensedbackintowater Thecondensedwaterisconsideredtobeofhighpurityandissuitableforuseinthemanufactureofpharmaceutical products.Distillationcanremoveimpuritiessuchasbacteria,dissolvedsolids,anddissolvedgases.

26.Whatisthedeionizationprocessformanufacturingpharmaceutical-gradewater?

Deionizationisaprocessinwhichwaterispassedthroughabedofion-exchangeresin,whichremovesionssuchas sodium,chloride,andotherdissolvedminerals Thewaterthatpassesthroughtheresinisconsideredtobeofhigh purityandissuitableforuseinthemanufactureofpharmaceuticalproducts

27.Arethereanyothermethodsformanufacturingpharmaceutical-gradewater?

Yes,thereareothermethodsformanufacturingpharmaceutical-gradewater,suchasultrafiltration,microfiltration, andultraviolet(UV)treatment Thesemethodscanalsobeusedtopurifywatertoahighdegreeofpurityand suitableforuseinthemanufactureofpharmaceuticalproducts

28.Whataretheadvantagesanddisadvantagesofeachmethod?

Eachmethodhasitsownadvantagesanddisadvantages Reverseosmosis,forinstance,isthoughttobeoneofthe besttechniquesforpurifyingwater,However,itcanbeexpensiveanddemandsalotofpower Distillationisoften regardedasahighlydependableapproachtowaterpurification,despiteitshighupfrontcostandhighenergy demand.Deionizationisconsideredtobeacost-effectivemethodforpurifyingwater,butitmaynotremoveall impurities Othermethodssuchasultrafiltration,microfiltration,andUVtreatmentalsohavetheirownadvantages anddisadvantages

29.Howisthequalityofpharmaceutical-gradewaterensured?

Thequalityofpharmaceutical-gradewaterisensuredthroughregulartestingtoensurethatitmeetsthestandards setbyregulatoryauthoritiessuchasUSPandBP Inaddition,manufacturersshouldconductregulartestingoftheir watertoensurethatitmeetsthestandardsandthatitisfreefromcontaminants

30.Whywasthemethodofproducingpharmaceutical-gradewaterchangedfromdistillationtoRO +EDI?

Themethodofproducingpharmaceutical-gradewaterwaschangedfromdistillationtoRO+EDIbecauseitismore efficientandcost-effective Distillationrequiredasignificantamountofenergyandwasrelativelycostly,whileRO+ EDI is more energy-efficient and cost-effective Additionally, RO + EDI is a more efficient method for removing impuritiesanddissolvedions,whichresultsinahigherpurityofwater.

31.HowdoesRO+EDIproducewaterofhigherpuritycomparedtodistillationandDI+MBDI?

RO+EDIproduceswaterofhigherpuritycomparedtodistillationandDI+MBDIbecauseitusesacombinationof two processes Reverse osmosis removes impurities and dissolved solids, while electro-deionization removes dissolvedionssuchassodiumandchloride.Thistwo-stepprocessresultsinahigherpurityofwaterthandistillation orDI+MBDIalone

32.ArethereanydisadvantagesofusingRO+EDItoproducepharmaceutical-gradewater?

SomeofthedisadvantagesofusingRO+EDItoproducepharmaceutical-gradewaterincludetheneedforregular maintenanceandreplacementofthemembranes,aswellastheneedforpre-treatmentofthewatertoprotectthe membranesfromfouling Additionally,themethodrequiresasignificantamountofenergy However,thebenefitsof producingwaterofhigherpurityandcost-effectivenessmakeitawidelyusedmethod

EDIstandsforElectro-Deionization Dissolvedionslikesodiumandchloridearefilteredoutofthewaterbypassingit throughanion-exchangemembrane

34.WhataretheadvantagesofusingEDItoproducepharmaceutical-gradewater?

SomeoftheadvantagesofusingEDItoproducepharmaceutical-gradewaterinclude:

High purity water production

Low chemical consumption

Low operation and maintenance cost

No waste liquid or chemical regeneration

No environmental pollution

Compact design

35.WhatarethedisadvantagesofusingEDItoproducepharmaceutical-gradewater?

SomeofthedisadvantagesofusingEDItoproducepharmaceutical-gradewaterinclude:

High initial investment

Requires electricity to run

The need for regular maintenance and replacement of the ionexchange membranes.

36.HowdoesEDIworktoproducepharmaceutical-gradewater?

EDI works by passing water through a series of ion-exchange membranes that are alternately charged with a positiveandnegativevoltage Asthewaterpassesthroughthemembranes,thedissolvedionsinthewaterare attractedtotheoppositechargeonthemembraneandareremovedfromthewater.Theionsarethenreplaced withhydrogenandhydroxylions,whicharegeneratedbyapowersupplyconnectedtotheEDImodule Thewater thatpassesthroughtheEDImoduleisconsideredtobeofhighpurityandissuitableforuseinthemanufactureof pharmaceuticalproducts

37.WhatarethekeycomponentsofanEDIsystem?

ThekeycomponentsofanEDIsysteminclude:

Ionexchange membranes.

Anode and cathode compartments.

A power supply to generate the electrical charge

A water flow control system

A monitoring and control system to monitor and regulate the system's performance.

38.HowdoesEDIcomparetootherwaterpurificationmethods?

EDIisconsideredtobeamoreefficientandcost-effectivemethodforproducinghigh-puritywatercomparedto traditionalmethodssuchasdistillationandmixed-bedion-exchange EDIrequireslessmaintenanceandchemicals comparedtoothermethodsanddoesnotproduceanywasteliquid.However,EDIrequireselectricitytorunandhas ahigherinitialinvestmentcost

WatermanEngineersAustraliaisamanufacturer,exporterandsupplierofwaterwastewatertreatmentplants,ROplants(Reverse OsmosisPlant),Desalinationplants,EffluentrecyclingSystems,Zeroliquiddischargesystems(ZLDSystem),Causticrecoveryplants, Waterfiltrationsystems,Drinkingwaterplants,Arsenicremovalsystemsfordrinkingandindustrialwater,Mineralwaterplant,Sewage treatmentplants,Solid&Liquidwasteincineratorsystems,TextileMiningPharmaceuticaleffluenttreatmentplants,Solarbased waterwastewatersewagetreatmentplantsetc,withdecadesofexperienceinwaterwastewatertreatmentfromconceptto commissioning

ReverseOsmosisPlant

WaterTreatmentPlant

PharmaceuticalWaterPurifyingPlant

ArsenicRemovalSystem

ZLDSystem

Per-andPoly-fluoroalkylSubstances(PFAS)

BiogasUpgradationPlant

PlasmaPyrolysisSystemManufacturer

Solid/LiquidWasteIncinerators

DesalinationPlants

CausticRecoveryPlant

PaddleDryer/ScrewPress/FilterPress

HardWaterSofteners

SoftDrinkManufacturingMachine

VitaminWaterProjects

FruitJuiceandBeveragesMachineries

Solar-poweredROSystem

MineralWaterTreatment&PackagingPlant

SewageTreatmentPlant

MetalRecoveryFromEffluent

HighEnergyVenturiScrubber

HeatExchangers

FlueGasDesulfurization(FGD)Scrubber

FOLLOWUS

MailUs: water@watermanaustralia.com

Copyright©2024,WatermanAustralia,Allrightsreserved