Pool Operator Primer

The "Pool Operator Handbook" is a concise guide for maintaining swimming pools, covering water chemistry, filtration, and routine maintenance.

Managing swimming pools and spas requires skilled staff due to the investment and hazards involved. Staff must be trained in proper facility and water management, with a certified professional responsible, even when using external services Larger facilities often have inhouse staff, while smaller ones may rely on third-party services. Facilities can range from infant swim instruction to competitive swimming, and can include diving programs, slides, and interactive elements They can be part of communities like condos, apartments, hotels, or campgrounds, with no restrictions on program additions.

Management varies widely. As facilities grow, staff specialization and diversity increase. Understanding systems, operational limits, hazards, and maintenance is crucial, even with third-party services. External services do not absolve facility management from their responsibilities State codes often require that delegated staff responsible for water quality and maintenance be properly trained. The Swimming Pool and Spa Association, Inc offers training programs designed to enhance facility operations, minimize risks, and ensure compliance with government regulations through its Pool Operator (PO) certification.

1. As facilities become larger and more complex, the requirements of the staff become equaly more diverse and specialised.

Pool classifications are regularly reviewed, with some variations in local regulations

Certified Pool/Spa Operators must understand relevant regulations and definitions.

Recreational facilities are categorized as either public or private, with further classifications:

Class A: Pools for competitive events, not public.

Class B: Public recreation pools

Class C: Pools for hotels, motels, apartments, and similar lodgings.

Class D: Specialty pools with unique features like vortex pools.

Class E: Therapy pools above 86°F (30°C).

Class F: Wading pools for children.

Health inspectors focus on the health and safety of pool users. They review operational standards, approve designs, and enforce regulations Initial enforcement starts with design approval and continues with regular inspections using specific certification checklists.

Certified operators follow detailed checklists to maintain optimal conditions, ensuring the facility complies with health standards. Key operational criteria include:

Pool area free of floating material, visible dirt, and algae

Deck with a minimum four-foot clearance

Pool/spa finish intact and in good repair.

Collaborate with health inspectors to ensure a safe and healthy pool environment.

Health inspectors performing a routine pool safety check.

Depth markings are intact and in proper locations.

Handrails, grab-rails, and ladders are secure.

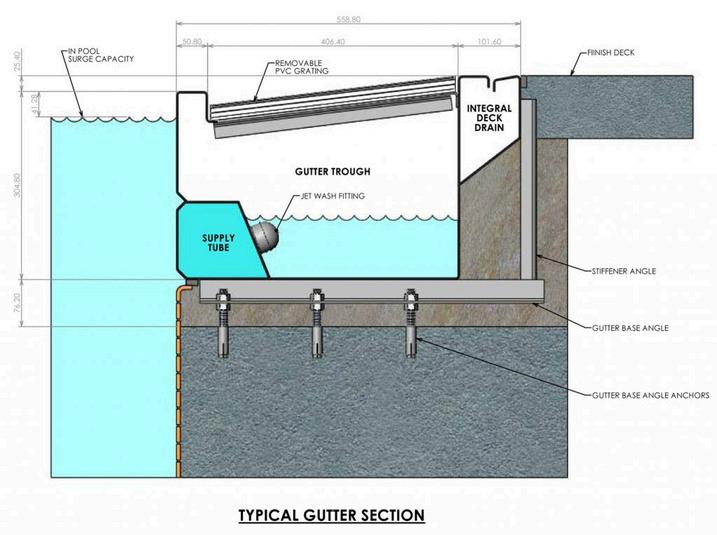

Gutter drains are covered with a fully intact grate, and no protrusions are present.

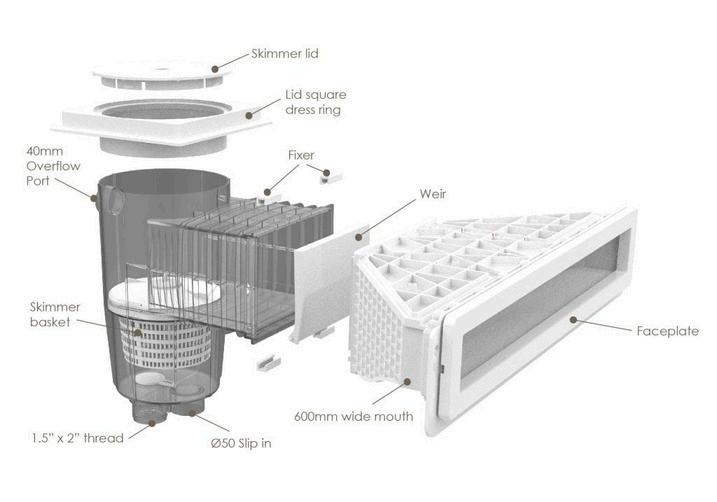

Skimmers have an intact weir in place. Deck covers are in place and properly secured

Underwater lights are in a working order and properly in place with no crevices between the niche and light cover.

Diving boards are secure and slipresistant

The shepherd’s hook(s) attached to a 16-foot (4.88 m) non-conductive pole is fully accessible and easily seen. The 18-inch (45 72 cm) diameter lifesaving ring with sufficient rope attached to reach all parts of the pool is fully accessible and easily seen. A floating safety line is in place 2 feet (61 cm) toward the shallow end before the slope break

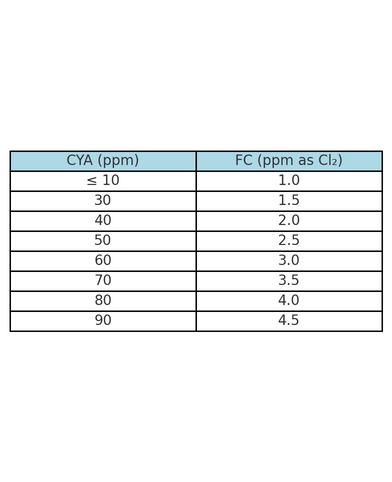

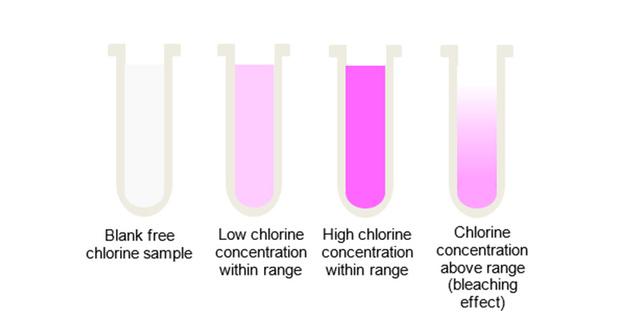

The required pool/spa rules are posted in the mandatory locations. Sanitary facilities have the appropriate supplies and are properly maintained. There is an approved test kit at the site, capable of testing chlorine or bromine, pH, calcium hardness, and total alkalinity. If necessary, other testing capacity should be available, such as cyanuric acid tests, salt tests, and tests for metals such as copper Cyanuric acid, if used, shall not exceed levels required by the local health code. In many cases the limit is 100 ppm In some cases, lower, higher, or no limits exist, although most codes prohibit the use of cyanuric acid at indoor facilities.

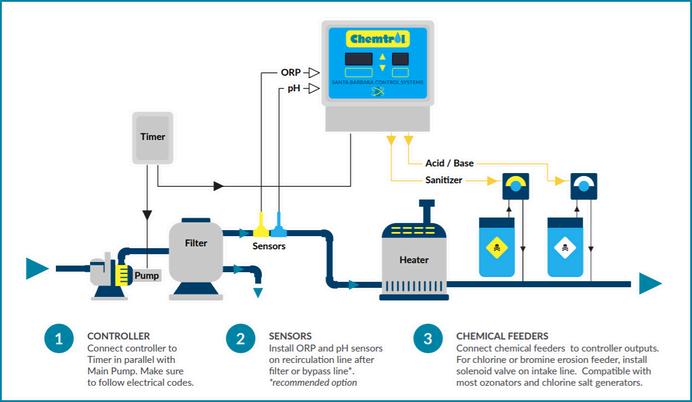

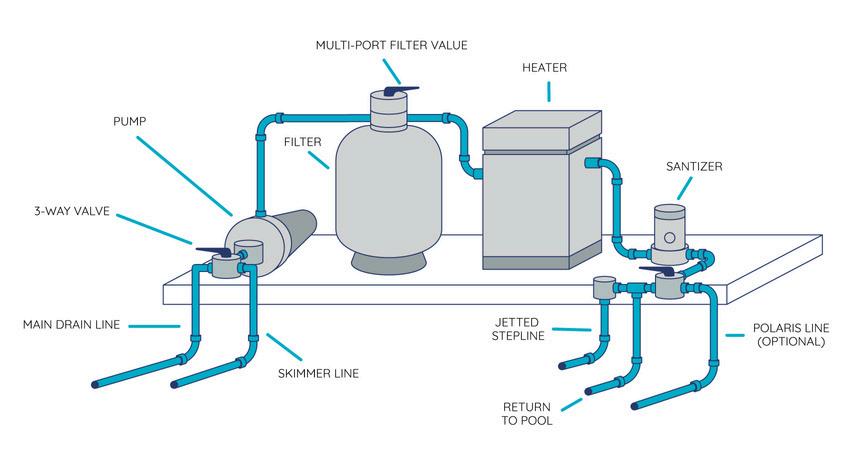

Disinfection feeders are in place and are properly operational. If electrical feed pumps are used, they are electrically interlocked with the circulation pump.

Failuretocomplywiththefollowing itemsmayresultinimmediatepoolor spaclosure:

Self-closing, self-latching gates and doors that prevent access to unsupervised children.

Free available chlorine levels should not fall below 1.0 ppm (mg/L). Ideal levels in pools range from 2-4 ppm (mg/L) and in spas should range from 3-4 ppm (mg/L). Total bromine should fall between 4-6 ppm (mg/L) for pools and spas.

The pH shall be between 7 2 and 7 8

The water circulation/filtration system must be operating and circulating water at the proper rate

Pools or spas with single drains must be VGB compliant and have an additional system of protection against entrapment

Water temperature should not exceed 104°F (40°C)

The certified pool operator must always ensure safe water conditions.

A pool operator may have management responsibilities over the facility or staff members. A manager’s primary responsibility is to make sure that the team understands what is expected of them and that they have the tools they need to get their jobs done. Therefore, everyone’s roles and responsibilities need to be defined. For example, some activities involve two, such as backwashing the filter Other activities involve management, such as planning when to backwash a filter. The manager specifies who is responsible for performing each of these tasks Successful managers must continue to develop their communication skills since many of the activities they carry out involve communication.

Management involves:

Planning: Deciding the course of action before the work is started

Organizing: Defining and connecting the work to be done so it can be executed efficiently.

Leading: Encouraging people to take proper action

Controlling: Measuring and regulating all work in progress and evaluating the results.

Many of the manager’s work functions rely on keeping records documenting that these management tasks were, in fact, carried out. See the Keeping Records chapter for more information on this subject.

Planning involves setting and organizing goals to meet the facility’s objectives. This process includes several key activities:

Forecasting: Predicting future conditions and needs

Programming: Setting designated results and outcomes.

Scheduling: Planning action steps and timelines.

Budgeting: Allocating resources effectively

Policy setting: Establishing standing decisions to guide actions.

Developing procedures: Standardizing repetitive work to ensure consistency

Records like chemical usage and patron numbers are important management tools. They help identify new objectives, schedule maintenance, and revise preventative measures.

Organizing ensures that work is assigned and carried out with clear objectives. Good organization prevents conflict and duplication, helping staff understand their roles and responsibilities. Key aspects include:

Defining tasks and responsibilities. Assigning roles to ensure all work is covered

Preventing duplication of efforts.

Ensuring clear communication among team members.

Coordinating activities for smooth operation

Effective organizing enhances operational efficiency and helps in achieving the facility's goals. A well-structured system reduces wasted time and resources, allowing staff to focus on core tasks Clear organization also improves communication and collaboration among team members, leading to a more cohesive workflow. It enables better tracking of progress and ensures that deadlines are met consistently.

The pool/spa facility manager has a significant impact on staff, influencing their ability to take effective actions. A competent manager makes sound decisions, delegates tasks appropriately, and encourages necessary actions within the team This is achieved through effective communication and active participation in the selection and hiring processes. Managers must also exemplify the behavior they wish to see in their staff. Additionally, they should understand the strengths and areas for improvement within their team, providing training as needed. Key areas of leading include:

Making informed decisions

Communicating clearly

Hiring the right people

Developing staff skills

Maintaining detailed records

Proper control requires timely measurement and reporting of performance, comparing actual performance to established standards, and addressing any deviations.

Continuous monitoring ensures that any necessary corrective actions are documented and resolved promptly

The existence of plans, objectives, and organizational documents ensures that all personnel know what needs to be accomplished. Performance tracking and evaluation are essential for maintaining standards. Managers should regularly review performance metrics and document any necessary actions to ensure continuous improvement.

Setting Clear Objectives: Objectives should be specific, measurable, achievable, relevant, and time-bound (SMART)

Monitoring and Evaluation: Regularly review performance metrics and document necessary actions for improvement.

Documenting Procedures: Maintain transparency and accountability with detailed records of activities and incidents.

Implementing Corrective Actions: Address performance issues promptly through additional training, updated procedures, or repairs.

Communication: Maintain open communication channels for feedback and improvement

Staff Training: Ensure continuous staff development through ongoing training and skill-building sessions.

Preventative Maintenance: Schedule regular maintenance checks to minimize equipment downtime and prevent unexpected failures. Develop standardized procedures and guidelines to ensure consistency in operations and quality across all areas of the facility.

"Measure the free chlorine reading using a commercial DPD test kit (specified at 9:00 am, 12:00 noon, 2:00 pm, and 4:00 pm every day) and record the readings in the daily log book. This ensures the proper operation of the pump room and compliance with safety standards "

Aquatic facility management involves ensuring the safety of both the users and the staff. This is achieved through risk management, which includes preventing injuries, managing liabilities, and maintaining facility assets Key factors to consider in risk management are: Negligence Standard of Care Record Keeping

Negligence involves failing to take reasonable care, resulting in potential harm. Standard of care sets the benchmark for expected conduct, and record keeping ensures compliance with safety standards and regulations

Negligence in aquatic facilities can lead to serious injuries or even fatalities. Proper training and adherence to safety protocols are essential to minimize these risks Regular reviews and updates to safety measures are necessary to ensure ongoing compliance and protection for facility users. Failure to maintain equipment, such as lifeguard gear and pool machinery, can significantly increase the risk of accidents. Consistent monitoring and prompt reporting of hazards, such as slippery surfaces or broken tiles, are crucial for preventing incidents Engaging staff in continuous safety education can enhance their ability to respond effectively in emergencies.

The standard of care involves adhering to established safety and operational guidelines to prevent harm Operators must understand and implement these standards consistently to avoid negligence and ensure the safety of all facility users. Regular training sessions and certifications for staff are essential to maintain a high standard of care Clear documentation of safety procedures and incident reports can help track compliance and identify areas for improvement.

Accurate record keeping is vital for demonstrating compliance with safety standards and legal requirements. Records should include detailed logs of maintenance, safety checks, and any incidents, ensuring that the facility meets all necessary regulations and standards. When developing a risk management plan, operators should consider the following key factors: Negligence Standard of Care Record Keeping

Negligence refers to the failure to take reasonable steps to prevent harm The standard of care involves adhering to a consistent level of safety and operational practices, while record keeping ensures compliance and accountability.

Risk management in aquatic facilities is essential for the safety of both users and staff By understanding and implementing effective risk management strategies, operators can minimize potential hazards and ensure a safe environment for everyone. Regular training, adherence to safety standards, and diligent record keeping are crucial components of a successful risk management plan.

A certified individual must oversee the operation of each pool facility to maintain high standards of safety and efficiency. Typically, a third-party service or an external professional ensures the presence of a certified Pool Operator, providing unbiased evaluations of service quality

Pool owners or managers should prioritize safety, making certification crucial not just for compliance but also for the well-being of pool users Certified Pool Operators are knowledgeable about regulations, standards, and common practices, providing essential education for maintaining pool systems. They undergo rigorous training to stay updated with the latest safety protocols and technological advancements in pool management. These operators play a key role in ensuring the safety and proper functioning of the pool, creating a safe and enjoyable environment for all users By having certified professionals on board, pool facilities can significantly enhance their operational standards and provide a better experience for visitors.

In facilities with smaller Class C pools, a single person can manage the upkeep. The maintenance head should occasionally oversee pool operation to ensure everything runs smoothly. The part-time operator should hold a Pool Operator certification and have hands-on experience, allowing them to handle various tasks efficiently

The manager of a small Class C pool must be knowledgeable about pool safety and operations, with a good understanding of maintenance requirements to prevent any potential issues For larger Class C pools, a full-time operator may be necessary due to the increased complexity and usage. These pools might remain open for extended hours, often up to 24 hours a day, requiring constant supervision. To maintain high standards, the department head and any individuals responsible for evaluating and adjusting pool chemistry should also hold Pool Operator certification. This is particularly important during weekends when the pool is crowded, as this is when the risk of incidents is higher.

Class E pools, used for therapy and special purposes, require specialized staff Daily operations are typically managed by a certified Pool Operator technician. This ensures that the facility is maintained by someone with the necessary training.

Class F pools follow the same certification standards as other classifications Ensuring that these pools are managed by certified operators helps maintain safety and hygiene.

Classes A, B, and D pools employ highly trained staff with several management layers. A facility director oversees coordinators, coaches, lifeguards, and supervisors Each level of management ensures the safety and proper supervision of the facility.

Facility descriptions should specify the required certification and training for each role, from maintenance personnel to head lifeguards This ensures that all staff members are well-prepared to handle their responsibilities.

Lifeguards primarily prevent and respond to emergencies, ensuring compliance with safety policies and regulations They inspect the pool, identify unsafe conditions, and report concerns to the appropriate authorities. Their duties include administering first aid and CPR, and conducting water quality tests Professional rescuers often require advanced training in emergency response and aquatic safety. Lifeguards' main duty is surveillance, ensuring swimmer safety and responding promptly to emergencies, especially during peak hours when risks are higher.

Lifeguards also educate swimmers about safety rules and promote adherence to these guidelines Facility owners and managers should never expect lifeguards to double as operators while on duty. If a lifeguard must cease surveillance and no certified replacement is available, the pool should be closed to bathers Response Planning is crucial, and all staff should be trained in emergency procedures to ensure swift action during incidents. Regular emergency drills help reinforce response protocols and keep the team prepared for real-life situations

facility is kept clean, with informational signs and safety equipment in place, functional, and easily visible.

have a Pool Operator certification as a minimum training requirement Operators seeking contractor licensure will need pre-licensure certification. Operators servicing residential pools and spas should consider the Certified Service Technician certification, a comprehensive pre-licensure program for pool and spa service professionals. Operators should be familiar with pertinent legislation, regulations, codes of practice, standards of design and operation, and safety protocols It is the operator's responsibility to have a copy of the relevant information on file.

The operator should consult industry publications for current information on facility design, equipment, legislative changes, liability concerns, and management practices. Many publications are free or inexpensive. Operators who are service professionals join servicefocused associations that provide professional benefits and growth opportunities.

The operator has a good understanding of the facility's mechanical system and all its components The pool operator understands how to troubleshoot system components to ensure minimum downtime. Pool operators with certification are responsible for maintaining water quality and are

knowledgeable about providing proper disinfection and water balance. Operators who graduate from the certification program minimize hazards to bathers by understanding proper chemical storage, usage, and handling. The facility will be maintained cleanly with informational signs and safety equipment in place, functional, and easily seen. Risk management is part of the operator's responsibilities, including identifying and evaluating risks and determining strategies to minimize them.

The manager and operator never stop learning, emphasizing continued education and staying up-to-date with industry standards and technology. The pool operator attends training, reads industry publications, and networks with other professionals to share knowledge and experiences, ensuring they are always improving their skills.

The pool operator must be familiar with all aspects of pool operations, including first aid, CPR, lifeguarding, and chemical handling They should also have management skills, which may include budgeting, personnel decisions, record keeping, and equipment procurement. The operator understands the need for proper insurance at all levels, both individual and facility coverage, to ensure comprehensive protection for everyone involved.

Risk management involves identifying and evaluating hazards and developing strategies to reduce or eliminate the risk of exposure.

A pool operator might be a maintenance person with part-time pool responsibilities. They could also be part of the engineering staff, with full-time pool operations responsibility The pool operator could be a manager without hands-on responsibility or someone with management authority over other operators in staff positions.

The pool operator could be an outside service technician who provides periodic support to a pool. Regardless of the background, all pool operators must meet the required standards of the facility. Whether owner or technician, manager, or lifeguard, the pool operator embodies an Aquatic Facility Professional.

The pool operator might be a lifeguard, providing pool operations management when not surveilling They must ensure that all equipment is in place, functional, and easily seen. This includes ensuring that safety and informational signs are prominently displayed and that all safety equipment is regularly checked and maintained

Risk management is a key part of the pool operator’s responsibilities. They must identify, evaluate, and implement strategies to minimize or eliminate hazards This proactive approach ensures a safe environment for all pool users, with regular assessments and updates to address new risks.

The pool operator’s role is multifaceted, requiring a deep understanding of operational and management aspects This includes daily maintenance, emergency preparedness, and resource allocation. Continuous education and staying updated with industry best practices are crucial Attending workshops, participating in professional organizations, and pursuing advanced certifications help maintain and enhance their expertise

By adhering to these standards, pool operators maintain the safety and efficiency of aquatic facilities. Their commitment ensures the well-being of pool users and enhances the facility's reputation

A pool or spa involves multiple trades, including mechanical elements, electricity, water, staff, bathers, and more Due to this complexity, many agencies regulate these facilities to ensure safety. Regulations and guidelines minimize risk, shutdowns, and injuries. An aquaticrelated death or injury can cause significant emotional and financial hardship for a facility and its stakeholders. Management/ownership must ensure staff understands the importance of compliance This chapter reviews mainly U S organizations and some international bodies. Aquatic facilities must understand local regulations and guidelines. These examples illustrate the roles of various agencies

Basic matters for the health, safety, and welfare of public pool or spa users include:

Human and environmental contamination of the water

Facility design and construction

Facility operation and management Hazards include physical situations which could result in fatal or non-fatal drowning, entrapment, or spinal injuries. Hazards could also be microbiological, hydraulic, chemical, or physical

Any of these factors could become a risk to health. For this reason, many different regulations and guidelines for proper pools/spa operations have been developed.

There are several public regulatory agencies at the local level of government in the U S At the federal level there are: Environmental Protection Agency (EPA)

Occupational Safety & Health

Administration (OSHA)

Consumer Product Safety Commission (CPSC)

Department of Transportation (DOT) Department of Justice (DOJ)

Centers for Disease Control & Prevention (CDC)

The CDC is also a U S federal agency; however, its role is advisory and investigative rather than regulatory. Besides regulations, there are also standards that have been developed by various national and international organizations. These standards serve as guidelines. Organizations that create standards and guidelines include: American National Standards Institute (ANSI)

Improper chemical storage could result in fatal chemical reactions

ASTM International (ASTM)

Chlorine Institute (CI)

Council for the Model Aquatic Health Code (CMAHC)

International Code Council (ICC)

NSF International (NSF)

National Fire Protection Agency (NFPA)

Underwriters Laboratories (UL) World Health Organization (WHO) Other organizations, like the YMCA and the American Red Cross, also set standards.

Many states, provinces, counties, and cities have regulations for public and private pools, leading to administrative codes enforced by relevant departments, such as health departments or Bureaus of Recreation. Local laws often cover barriers, accessibility, and hours of operation, and facilities must consider compliance with the Americans with Disabilities Act

The Environmental Protection Agency (EPA)

The U.S. Environmental Protection Agency's mission is to protect human health and safeguard the natural environment The EPA aims to shield Americans from significant health and environmental risks where they live, learn, and work. It achieves this through numerous regulations that guide and affect pool operators, ensuring safe and healthy swimming environments These regulations cover various aspects, including water quality standards, chemical use, and safety protocols, all designed to minimize potential hazards and protect public health The EPA's efforts are crucial in maintaining the overall well-being of communities and preserving the natural environment for future generations.

The EPA controls pesticide registration and labeling under the Federal Insecticide, Fungicide, Rodenticide Act (Title 7, Chapter 6). Pesticides are chemicals used to prevent, destroy, repel, or mitigate pests, including algae, fungi, bacteria, and viruses in aquatic facilities. Most pesticides contain chemicals harmful to people Labels use signal words—Caution, Warning, and Danger to indicate a product's toxicity or safety. Proper storage and handling of these chemicals are essential to minimize health risks for both staff and facility users

Danger is the strongest signal word If a label has the word Danger on it, the operator must be extremely careful handling the product. If it is used the wrong way, medical problems or injury such as blindness or death could occur Danger is also used on products that could explode if they become overheated.

Warning is less strong than Danger, but it still means that the bather could become very ill or badly injured by exposure. Warning is also used to identify products that can easily catch on fire.

Caution shows that the product could be harmful, but less harmful than products with a Danger or Warning signal word Caution is used for products that could cause skin irritation, illness if the fumes are breathed, or trauma if the product contacts the eyes These products require careful handling, including the use of protective gloves and eye protection. Proper ventilation is also crucial when using products labeled with Caution to reduce inhalation risks

Store in original container in areas inaccessible to children Do not reuse empty container Wrap container and put in trash

(DANGER) Corrosive. Causes irreversible eye damage and skin burns. May be fatal if swallowed. Avoid contact with eyes, skin or clothing. Wear safety glasses, rubber gloves and protective clothing. Wash thoroughly with soap and water after handling and before eating, drinking, or using tobacco Remove contaminated clothing and wash clothing before reuse

The signal word on this label is Danger Provided by BioLab, Inc. – A KIK Company

Store in original container in areas inaccessible to children. Do not reuse empty container. Wrap container and put in trash This algaecide is compatible with most chemicals normally used in swimming pool maintenance; however, in concentrated form, this chemical should not be mixed with high concentrations of chlorine DO NOT MIX THIS ALGAECIDE AND CHLORINE TOGETHER IN THE SAME CONTAINER. Each chemical should be handled separately.

DIRECTIONS FOR USE: It is a violation of Federal Law to use this product in a manner inconsistent with its labeling. For initial application when pool water is clear, use one quart per 25,000 gallons of water.

2

1. For maintenance, use one cup per 25,000 gallons of water. Add maintenance dose once a week after the initial treatment.

Labels give instructions for proper use and dosage amounts Provided by BioLab, Inc – A KIK Company.

The Federal Food, Drug, and Cosmetic Act (FFDCA) of 1996 governs the use of chlorine gas in swimming pools (7 U.S.C. Sec 136w-5, "Minimum Requirements for Training of Maintenance Applicators and Service Technicians"). Each state may have additional training requirements for this. To reduce the risks of chlorine's high toxicity, the EPA requires that nonresidential pools use chlorine gas under stricter controls, limiting access to certified applicators. California tracks pesticide illnesses and accidents, which mainly occur in swimming pools and food processing plants Issues arise from inadequate training or maintenance.

Aquatic facility staff and others nearby can be exposed to chlorine gas during leaks.EPA mandates nonresidential swimming pools to switch from General Use to Restricted Use Pesticide for chlorine gas, limiting who can apply it. This change aims to enhance safety by ensuring only trained professionals handle chlorine gas.

Handling chlorine gas requires proper training Cylinders must be anchored and regulators regularly inspected

The Emergency Planning & Community Right-To-Know Act (EPCRA) was enacted to encourage emergency planning for hazardous chemicals. Aquatic facilities should be aware that SARA Title III requires a comprehensive plan for handling hazardous chemicals Compliance ensures safer chemical storage and usage. Specific chemicals covered under SARA Title III include:

Aluminum sulfate

Ammonium sulfate

Calcium hypochlorite

Chlorine gas

Hydrogen peroxide

Muriatic acid

Sodium bisulfate

Sodium hypochlorite

By adhering to SARA Title III, aquatic facilities can effectively manage chemical risks and enhance overall safety

In some instances, the storage limit for certain chemicals on site may be as low as 100 pounds (45 kg). Facility managers should consult with legal counsel and the facility's insurance provider to ensure the aquatic facility is in compliance, or needs to comply, with SARA Title III.

Incompatible chemicals can cause dangerous reactions Emergency response plans are essential

OSHA's mission is to prevent workplace injuries and illnesses and to protect American workers across various industries. With over 32 million workers exposed to hazardous chemicals, OSHA enforces regulations to mitigate these risks Key regulations include the Hazard Communication Program and the provision of Safety Data Sheets (SDS). These critical documents inform workers about the chemical hazards they might encounter, detailing necessary safety measures and handling procedures. Employers are mandated to ensure that SDS are easily accessible to all employees and must retain these documents for 30 years after the chemical has been used. This long-term accessibility helps protect workers and provides valuable information for future safety audits and compliance checks. By maintaining stringent standards and promoting continuous education,

OSHA aims to create a safer and healthier work environment for everyone

The Consumer Product Safety Commission (CPSC) protects the public from unreasonable risks of injury or death associated with consumer products, including pool chemicals. This vital agency oversees the regulation of over 15,000 products, aiming to minimize injuries and fatalities, with a particular focus on protecting children. In recent years, the CPSC has launched initiatives to educate staff about the dangers of chemical exposure and the importance of proper storage practices These efforts include comprehensive training programs, informational resources, and guidelines to ensure that all personnel handling chemicals are well-informed and equipped to maintain a safe environment By promoting awareness and adherence to safety standards, the CPSC strives to reduce accidents and enhance overall consumer safety.

Hazardous substances that may endanger public safety or the environment during transit are regulated by the Department of Transportation (DOT) due to their physical, chemical, or nuclear properties. The DOT provides classifications for these materials, which operators need to be familiar with to adhere to transportation laws

The main categories of hazardous materials according to the DOT are:

Class 1: Explosives

Class 2: Gases (compressed, flammable, poison)

Class 3: Flammable Liquids

Class 4: Flammable Solids

Class 5: Oxidizers and Organic Peroxides

Class 6: Toxic and Infectious Substances

Class 8: Corrosives

Class 9: Miscellaneous Hazardous Materials

Operators must ensure compliance with DOT regulations, particularly when outsourcing transportation to third-party providers. This includes verifying that the third-party carriers are properly licensed and trained in handling hazardous materials

Sample of a Typical SDS (Safety Data Sheet):

Date:July 16, 2024

1.Identification

Product: Sodium Carbonate Anhydrous

Use: Industrial manufacturing, pH adjustment

Supplier: Example Chemical Co , 123 Industrial Way, Anytown, USA

Emergency: (555) 987-6543

2.HazardIdentification

Hazard Class: Eye irritant

Precautions:Avoid eye contact, wear protective gear.

3.First-AidMeasures

Eyes: Rinse with water for 15 minutes, seek medical help if irritation persists.

Skin: Wash off with water, seek help if irritation continues.

Ingestion: Rinse mouth, drink water, do not induce vomiting

4. HandlingandStorage

Handling: Minimize dust, ensure ventilation.

Storage: Keep in cool, dry place in closed containers

5.ExposureControls/PersonalProtection

Ventilation: Use exhaust to reduce dust.

Protection: Safety goggles, gloves.

6.PhysicalandChemicalProperties

Appearance: White powder

Solubility: Soluble in water

7.StabilityandReactivity

Stability: Stable under normal conditions.

8.DisposalConsiderations

Disposal: Dispose of following local regulations

9.TransportInformation

DOT: Not regulated.

10. Regulatory Information

Regulations: Listed in TSCA inventory

This document example outlines safety guidelines for handling a white, watersoluble powder classified as an eye irritant

Precautions include wearing safety goggles and gloves to avoid contact. In case of exposure, rinse eyes or skin with water, and seek medical help if irritation persists The product should be handled with proper ventilation to minimize dust and stored in a cool, dry, sealed container. Disposal must comply with local regulations, and it is not regulated for transportation It is listed in the TSCA inventory.

The DOJ enforces the Americans with Disabilities Act (ADA), ensuring equal opportunity and accessibility for individuals with disabilities in various settings, including public pools

Accessibility Compliance: The DOJ mandates that public pools adhere to specific ADA standards to ensure accessibility for all. This includes requirements such as accessible entry and exit methods (e g , pool lifts, sloped entries), handrails, and clearly marked pool edges to assist those with visual impairments.

Inspections and Enforcement: Public facilities undergo regular DOJ inspections to verify ADA compliance These inspections can lead to recommendations for necessary modifications or penalties for non-compliance. The DOJ also offers a grievance mechanism for reporting noncompliant facilities

Education and Outreach: The DOJ provides educational resources and conducts workshops to inform pool operators and the public about ADA requirements These initiatives aim to enhance understanding of legal obligations and promote widespread compliance and awareness of disability rights.

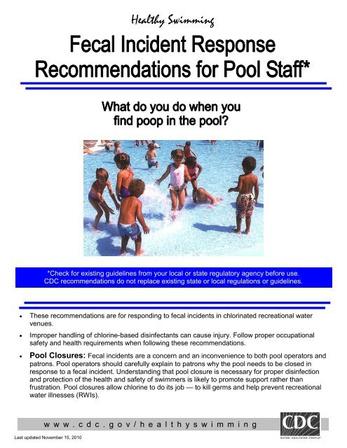

The CDC plays a key role in promoting safety and preventing illness in public pools through guidelines, research, and public education initiatives.

Water Quality and Disease Prevention: The CDC develops and disseminates guidelines for maintaining the chemical balance of pool water, which is essential for disinfecting pools and preventing the spread of waterborne diseases. They provide protocols for routine water testing and managing chemical levels effectively.

Model Aquatic Health Code (MAHC): The MAHC provides comprehensive, evidencebased guidelines that address pool and spa design, operation, and maintenance. It is a resource for local health departments and pool operators to ensure best practices are followed for safety and health.

Public Health Campaigns: Through the Healthy Swimming program, the CDC educates the public on preventing illness transmission in swimming venues Key messages include showering before swimming and not swimming when sick with diarrhea.

International Code Council (ICC) The ICC has been integral since 1994 in developing global standards for the design, construction, and sustainability of swimming pools, spas, and related facilities to ensure safety, efficiency, and affordability. These guidelines are widely adopted in the U.S. and many global regions. As of the latest update in 2021, the ICC continues to enhance these standards through extensive research and community engagement.

The World Health Organization (WHO) has developed comprehensive Guidelines for Safe Recreational Water Environments, which are designed to safeguard public health in aquatic facilities around the globe The primary aim of these guidelines is to significantly reduce health hazards associated with swimming pools, spas, and similar environments.

Guidelines for Managing Fecal Incidents by the Centers for Disease Control

By establishing rigorous standards for water quality, the WHO seeks to mitigate risks stemming from physical, chemical, and microbial contaminants. These guidelines underscore the critical importance of maintaining optimal water conditions to prevent infections and illnesses that can arise from improperly managed water facilities. The WHO's recommendations focus on a multi-barrier approach that includes proper water filtration, regular monitoring of chemical disinfectant levels, and systematic microbial testing to detect and address pathogens promptly

NSF International is known for its contribution to pool and spa equipment safety through its voluntary standardization program, which is encapsulated in NSF/ANSI Standard 50 This standard is a comprehensive benchmark for evaluating pool and spa equipment, ensuring they meet rigorous public health standards and operational efficiencies

The organization provides a pamphlet that is particularly useful for pool operators, highlighting critical areas of maintenance and safety. This resource offers detailed guidance on several key aspects:

Proper chemical feeding equipment and processes ensure continuous compliance and effective water treatment.

Usage and maintenance of UV and ozone generators to enhance water quality.

Routine inspection protocols for filtration systems, aimed at preventing operational failures and maintaining system integrity

NSF International's pamphlets are a cornerstone resource, aiding operators in maintaining NSF/ANSI Standard 50 compliance

These guidelines not only support operational excellence but also promote a safer swimming environment by ensuring all equipment meets established safety standards

Guidelines for Managing Fecal Incidents by the Centers for Disease Control

The Chlorine Institute (CI) supports the chlorine and chlor-alkali industry by promoting safe and sustainable operational practices It focuses on enhancing public safety and environmental stewardship through various initiatives.

Key Functions and Offerings: Safety and Best Practices: CI provides extensive resources, including guidelines, training materials, and technical publications to promote safety in handling and using chlorine.

Emergency Response: The Institute offers robust support for chlorinerelated emergencies, providing expertise and coordinating with emergency services.

Environmental and Regulatory Engagement: CI works closely with regulatory bodies to advocate for responsible policies that align industry practices with environmental safety standards.

Outreach and Education: Through seminars and workshops, CI educates stakeholders on chlorine safety and emergency preparedness

ASTM International ASTM International sets globally recognized voluntary consensus standards for materials, products, systems, and services used across various industries, including recreational water facilities. These standards form the basis of manufacturing, procurement, and regulatory activities, ensuring quality and safety in pool operations

ASTMPublications:

F2209-03: Standard Specification for Fence/Barrier Safety for Commercial and Multi-Family Residential Use

Outdoor Play Areas

F1346-91: Standard Specification for Safety Covers and Labeling

Requirements for All Covers for Swimming Pools, Spas, and Hot Tubs

F2815-10: Standard Guide for the Safe Use of Fully Automated Swimming Pool, Spa, and Hot Tub Equipment

F2387-04: Standard Specification for Manufactured Safety Vacuum Release Systems (SVRS) for Residential and Commercial Swimming Pools, Spas, and Hot Tubs

F2461-09: Standard Practice for Manufacture, Construction, Operation, and Maintenance of Aquatic Play Equipment

ASTM International offers a range of significant publications, which can be accessed at www.astm.org. These materials are derived from the copyrighted standard.

Underwriters Laboratories (UL) UL, an independent organization, conducts safety and quality testing for diverse products, including pool equipment. Products that meet UL's stringent safety criteria are granted a UL certification, a mark of safety recognized universally. Products and equipment that pass UL's evaluations are listed as UL certified, ensuring their reliability and safety.

National Fire Protection Association (NFPA) NFPA works globally to mitigate fire and other hazards by setting standards and advocating for safety and prevention They focus on guidelines that manage risks like liquid and solid oxidizers and flammable solids. Their NFPA 704 system categorizes chemicals based on their health and instability hazards, informing both the public and emergency services about potential dangers.

The American Red Cross has long been pivotal in enhancing community safety and preparedness, with a significant focus on water safety. They provide comprehensive training in CPR and First Aid, specifically designed to handle aquatic emergencies. Their water safety programs emphasize crucial skills like swimming proficiency and emergency response, aiming to reduce drowning risks and improve safety in aquatic environments

Through educational initiatives and partnerships, the Red Cross reaches out to various community groups, fostering a culture of vigilance and safety around water activities Their commitment extends to advocating for consistent supervision and the use of life-saving devices to further safeguard individuals in water settings. Additionally, they engage in public awareness campaigns that highlight the importance of water safety norms and procedures. By collaborating with local communities, the Red Cross helps to implement effective water safety policies and practices that can save lives Furthermore, they offer specialized training for disaster response teams, enhancing their capabilities to manage water-related emergencies effectively. This training includes advanced rescue techniques and strategies for handling floods and other water crises, ensuring preparedness across a broad spectrum of potential scenarios.

Water Safety USA is committed to improving water safety through education, resource sharing, and public initiatives. These efforts are aimed at increasing awareness of safe water practices among the public. Additionally, the organization actively develops and distributes educational materials that serve as guidelines for safe swimming and water recreation.

Workshops and training sessions are also part of their strategy, providing hands-on learning experiences for individuals of all ages. The goal is to foster a culture of water safety that includes every community and demographic By ensuring access to safety information and resources across diverse populations, Water Safety USA endeavors to reduce water-related incidents and promote a nationwide commitment to water competence.

Member organizations include:

American Academy of Pediatrics

American Red Cross

Boys Scouts of America

Centers for Disease Control & Prevention

National Park Service

National Safe Boating Council

Pool & Hot Tub Alliance

Safe Kids Worldwide

U.S. Coast Guard Product Safety Commission

United States Lifesaving Association

YMCA of the USA

Water Safety USA advocates for critical safety practices to keep your pool safe and enjoyable.

Resource Contact List

Aquatic facilities with specific programming should ensure that their operations meet national and local regulations by utilizing the services of the accredited organizations listed below. The following is a compiled list of information providers for your aquatic facility, listed in alphabetical order to guide you. Visit each organization's website at the provided URLs for more comprehensive details and resources:

American Academy of Pediatrics (AAP)

American Alliance for Health, Physical Education, Recreation, and Dance (AAHPERD)

American Chemistry Council (ACC)

American National Standards Institute (ANSI)

American Red Cross American Swimming Coaches Association (ASCA)

Aquatic Therapy & Rehab Institute (ATRI)

ASTM International (ASTM) Boy Scouts of America (BSA) Centers for Disease Control & Prevention (CDC)

The Chlorine Institute, Inc. Consumer Product Safety Commission (CPSC)

College Swimming Coaches Association of America (CSCAA) Department of Justice (DOJ) Department of Transportation (DOT)

Environmental Protection Agency (EPA)

Federation Internationale de Natation (FINA)

International Academy of Aquatic Art (IAAA)

International Association of Amusement Parks and Attractions (IAAPA)

International Association of Plumbing and Mechanical Officials (IAPMO)

International Code Council (ICC)

Jeff Ellis & Associates

Jewish Community Center Association (JCCA)

National Drowning Prevention Alliance (NDPA)

National Fire Protection Association (NFPA)

National Institute of Standards and Technology (NIST)

National Parks Service (NPS)

National Recreation and Park Association (NRPA)

National Safe Boating Council (NSBC)

National Spa & Pool Foundation (NSPF)

Occupational Health & Safety

Administration (OSHA)

Safe Kids Worldwide (SKW)

U.S. Army Corps of Engineers

U S Coast Guard

U S Consumer Product Safety Commission

U.S. Diving

U.S. Lifesaving Association

U.S. Masters Swimming (USMS)

U S Swim School Association (USSSA)

U.S. Synchronized Swimming (USSS)

U.S. Water Polo

Underwriters Laboratories (UL)

Water Safety USA

Water Safety USA

World Health Organization (WHO)

World Waterpark Association (WWA)

YMCA/YWCA of the USA

A thorough grasp of basic mathematical operations is crucial for anyone managing a swimming facility This includes being adept at volume calculations, chemical dosage estimations, and maintaining appropriate pool dimensions, which are vital for the effective management and operation of a pool Precise calculations ensure the safety and efficacy of the pool for patrons and staff alike. Additionally, accurate record-keeping of chemical levels and adjustments helps in monitoring pool conditions and preventing potential hazards

It is necessary for pool operators to be proficient in basic math skills, as they must routinely calculate chemical dosages and manage water quality parameters Accuracy in these calculations helps maintain the pool's health and safety. Regular tasks include conversions between different measurement units, which are essential for ensuring consistent application of treatment protocols

Example3-1: (Amount Conversion)

You determine from the results of your pool water test that you need to add 42 ounces of soda ash to your pool. How many pounds is this?

Conversion: (Ounces÷16=pounds)

42ounces÷16ounces/pound=2.625 pounds

Example3-2: Distance Conversion

Your pool is 30 metres long and 30 yards wide What are the dimensions in feet?

(Note: 1 metre is actually 3.28084 feet. Rounding to 3.28 is done to simplify the calculations.)

Yardsx3=feet

Metresx3.28=feet

30yardsx3=90feet

30metresx3.28=98.4feet 98feetlongand90feetwide

Example3-1:Metric

You determine from the results of your water test that you need to add 3200 grams of soda ash to your pool. How many kilograms is this?

Conversion:Grams÷1000=kilograms 3200÷1000=3.2kilograms

Example 3-3: Distance Conversion

Your pool is 55 metres long and 35 metres wide What are the dimensions in feet?

Conversion:Metresx3.28=feet

55metresx3.28=180.4feet

35metresx3.28=114.8feet 180feetlongand115feetwide

Example3-3:Metric

Thepoolis50metersinlengthand 30metersinwidth.Keepthe measurementsinmeters.

Example3-4:FilterSurfaceArea

Your D.E. filter has 8 grids measuring 20 inches by 30 inches each. Each grid filters from both sides. What is the filter area?

Conversion: sq.in.÷144sq.in./sq.ft.=sq.ft. 20inchesx30inches=600sq.in. 600sq.in.x2sides=1200sq.in./grid 1200sq.in./gridx8grids=9,600sq.in. 9,600sq.in.÷144sq.in./sq.ft.=66.67 sq.ft.

YourD.E.filterhas10gridsmeasuring 0.6by0.8metreseach.Eachgridfilters frombothsides.Whatisthefilterarea?

0.6mx0.8m=0.48m²

0.48m²x2sides=0.96m²/grid

0.96m²/gridx10grids=9.6m²

You determine from the results of your pool water test that you need to add 24 fluid ounces of muriatic acid to your pool

How many cups is this?

Fluidounces÷8=cups 24fluidounces÷8=3cups

Youdeterminefromtheresultsofyour poolwatertestthatyouneedtoadd750 millilitresofmuriaticacidtoyourpool. Howmanylitresisthis?

Millilitres÷1000=litres

750÷1000=0.75litres

You determine from the results of your pool water test that you need to add 24 fluid ounces of muriatic acid to your pool

How many cups is this?

Fluidounces÷8=cups24fluidounces ÷8=3cups

OuncestoPounds

Ounces ÷ 16 = Pounds

FluidOuncestoGallons

Fluid Ounces ÷ 128 = Gallons

LitrestoGallons

Litres ÷ 3 785 = Gallons

FluidOuncestoCups

Fluid Ounces ÷ 8 = Cups

YardstoFeet

Yards x 3 = Feet

CubicFeettoGallons

Cubic Feet x 7.5 = Gallons

QuartstoGallons

Quarts ÷ 4 = Gallons

PintstoQuarts

Pints ÷ 2 = Quarts

GallonstoPounds

Gallons x 8.33 = Pounds

SquareInchestoSquareFeet

Square Inches ÷ 144 = Square Feet

BritishThermalUnitsvs.TemperatureRise

BTUs = Gallons x 8.33 x °F (Temp Rise)

PoundsperSquareInch(psi)toBar

1 psi = 0.069 Bar

PoundsperSquareInch(psi)toKiloPascals (kPa)

1 psi = 6.89 kPa

GramsorMillilitrestoKilosorLitres

Grams or Millilitres ÷ 1000 = Kilos or Litres

1Micron=1MillionthofaMetre

25 4 microns per 1/1000 inch

MetrestoFeet

Metres x 3 28 = Feet

CubicMetrestoLitres

Cubic Metres x 1000 = Litres

FluidOuncestoMillilitres

Fluid Ounces x 29 57 = Millilitres

PartsperMillionandMilligramsperLitre

1 ppm = 1 mg/L

1ppm=8.33PoundsofChemicalinOne MillionGallonsofWater

Celsius(°C)toFahrenheit(°F)

°F = (9/5 x °C) + 32 Fahrenheit(°F)toCelsius(°C)

°C = (5/9 x (°F - 32)

1PoundperSquareInch(psi)isthepressure createdbyacolumnofwater2.31feethigh

Kilojoulesvs.TemperatureRise

Kilojoules = Litres x 4.18 x °C (Temp. Rise)

BarstoPoundsperSquareInch(psi)

1 Bar = 14.51 psi

KiloPascals(kPa)toPoundsperSquareInch (psi)1kPa=0.145psi

Example3-6:Metric

Youdeterminefromtheresultsofyour poolwatertestthatyouneedtoadd 15,000millilitresofsodiumhypochlorite tobreakpointchlorinateyourpool.How manylitresisthis?

Millilitres÷1000=litres

15,000÷1000=15litres

Understanding the volume (in gallons or litres) of water in any aquatic feature is crucial for the effective management of operating equipment, chemical dosing, and user safety Typically, the design engineer who created the original specifications provides this information on the technical drawings If these specifications are not available, local health officials may have the required technical data The pool operator should always keep a copy of the facility’s technical specifications Design calculations and the actual as-built water volume may differ due to construction variances

Pool floors are rarely perfectly flat Pool walls often have a slight gradient from vertical Walls and floors are typically connected by a radius or blend These variations result in a pool volume that is approximate Therefore, swimming pool volume calculations are considered accurate within a 5% deviation from the actual volume.

To estimate a pool or spa's volume, start by calculating the water’s surface area. The surface area of an aquatic facility is the pool area exposed to the air. This area is also used to determine pool cover sizing, bather load (in some codes), and to calculate water temperature losses. The basic formula for calculating surface area is:

Surface area = length × width

Irregularly shaped pools present a challenge. Figure 3-3 illustrates some common shapes. Other important surface areas include the pool wall and floor (for resurfacing) and the deck (for pool-related activities) Calculating filter area is essential for water quality management Filter surface area is discussed in the Pool & Spa Filtration chapter

Foreverycubicmetreofwaterthereare 1,000literslitresofwater.

ImperialConversions

Foreverycubicfootofwaterthereare 7.5gallonsofwater.

Accurately calculating the surface area of a pool is crucial for various aspects of pool management, from determining water volume to selecting covers and managing bather loads.

Determine the volume of a multi-shaped pool by dividing it into sections and calculating each one separately.

To find the pool volume in gallons, multiply the surface area by the average depth and then by a conversion factor of 7.5. This method requires measurements of length, width, and depth in feet.

Formula:Volume=surfaceareax averagedepthx7.5

The conversion factor of 7 5 is an approximation, as the exact value is 7.48 gallons per cubic foot. In a pool containing 60,000 gallons, this approximation results in a minor error of 160 5 gallons, which is just 0 25% The simplicity of using 7.5 instead of 7.48 outweighs this negligible error. Furthermore, volume calculations are typically rounded up (for example, 49,850 gallons is rounded to 50,000 gallons)

To determine pool volume in litres, use measurements in metres. Multiply the surface area by the average depth in metres. The result is in cubic metres (m³). Multiply this by 1000 to convert to litres, as there are 1000 litres in a cubic metre of water.

Determining the average depth can be challenging. For a simple pool with a constant slope, calculate it as the average of the shallow and deep ends' depths (refer to Figure 3-2)

For more complex shapes, divide the pool into several sections and calculate each section’s volume individually. Sum the volumes of all sections for the total pool volume in gallons See Figure 3-4 for reference.

Gallons=areaxaveragedepthx7.5

Averagedepth= (shallowend+deepend)÷2

Averagedepth= (4feet+9feet)÷2Averagedepth= 6.5feet

Gallons=(55feetx26feet)x6.5 feetx75Gallons=70,125gallons

Litres=AreaxAveragedepthx1000

Averagedepth= (shallowend+deepend)÷2

Averagedepth=(1.2metres+3.8 metres)÷2Averagedepth=25 metres

Litres=(16metresx8metres)x25 metresx1000Litres=320,000litres

To estimate the volume of water in a pool or spa in gallons or litres, start by calculating the surface area Then multiply the surface area by the average depth and use the conversion factor of 7 5 for gallons or 1000 for litres For irregularly shaped pools, divide the shape into simpler sections, calculate the volume for each section, and then sum them up In circular pools, R represents the radius

OBLONG

Area=RadiusxRadiusx314-(Lengthx Width)

Gallons=AreaxAverageDepthx75

Litres=AreaxAverageDepthx1000

RECTANGULAR

Area=LengthxWidth

Gallons=AreaxAverageDepthx75

Litres=AreaxAverageDepthx1000

CIRCULAR

Area=RadiusxRadiusx314

Gallons=AreaxAverageDepthx75

Litres=AreaxAverageDepthx1000

OVAL

Area=MajorAxisxMinorAxisx3.14

Gallons=AreaxAverageDepthx75

Litres=AreaxAverageDepthx1000

The volume of a kidney-shaped pool is determined by multiplying the area by the average depth and then by 7.5.

KIDNEY-SHAPED

Area(approximate)=(MajorAxis+Minor Axis)xLengthx0.45

Gallons=AreaxAverageDepthx75

Litres=AreaxAverageDepthx1000

SectionA

Your pool is 60 feet long and 20 feet wide. The shallow end varies in depth from 4 feet to 6 feet deep. The main drain is at a depth of 12 feet, and the deep end wall is 9 feet deep. How many gallons are in your pool?

SectionA - Section A is 35 feet long, with a width of 20 feet The depth varies from 4 feet to 6 feet deep.

SectionB - Section B is 15 feet long, with a width of 20 feet. The depth varies from 6 feet to 12 feet deep.

SectionC - Section C is 10 feet long, with a width of 20 feet The depth varies from 12 feet to 9 feet deep

Gallons = area x average depth x 7.5

Area = length x width

Average depth = (4 feet + 6 feet) ÷ 2 = 10 feet ÷ 2 = 5 feet

Gallons = (35 feet x 20 feet) x 5 feet x 7 5

Gallons = 26,250 gallons

SectionB

Gallons = area x average depth x 7.5

Area = length x width

Average depth = (6 feet + 12 feet) ÷ 2

= 18 feet ÷ 2 = 9 feet

Gallons = (15 feet x 20 feet) x 9 feet x 7 5

Gallons = 20,250 gallons

TotalPoolGallonsA+GallonsB+GallonsC

SectionC

Gallons = area x average depth x 7 5

Area = length x width

Average depth = (12 feet + 9 feet) ÷ 2

= 21 feet ÷ 2 = 10.5 feet

Gallons = (10 feet x 20 feet) x 10.5 feet x 7.5

Gallons = 15,750 gallons

Total Pool = 26,250 gal + 20,250 gal + 15,750 gal

Total Pool = 62,250 gallons or rounded off to 62,500 gallons

SectionA

Your pool is 20 meters long and 12 meters wide. The shallow end varies in depth from 1 meter to 1.5 meters. The main drain is at a depth of 2.5 meters, and the deep end wall is 2 meters deep. How many liters are in your pool?

SectionA-is 10 meters long, with a width of 12 meters. The depth varies from 1 meter to 1.5 meters.

SectionB-is 5 meters long, with a width of 12 meters. The depth varies from 1 5 meters to 2 5 meters

SectionC-is 5 meters long, with a width of 12 meters The depth varies from 2.5 meters to 2 meters.

Liters = area x average depth x 1000

Area = length x width

Average depth = (1 meter + 1 5 meters) / 2 = 1 25 meters

Area = 10 meters x 12 meters = 120 square meters

Liters = 120 square meters x 1 25 meters x 1000

Liters = 150,000 liters

SectionB

Liters = area x average depth x 1000

Area = length x width

Average depth = (1 5 meters + 2 5 meters) / 2 = 2 meters

Area = 5 meters x 12 meters = 60 square meters

Liters = 60 square meters x 2 meters x 1000

Liters = 120,000 liters

TotalPoolLitersA+LitersB+LitersC

SectionC

Liters = area x average depth x 1000

Area = length x width

Average depth = (2 5 meters + 2 meters) / 2 = 2 25 meters

Area = 5 meters x 12 meters = 60 square meters

Liters = 60 square meters x 2 25 meters x 1000

Liters = 135,000 liters

Total Pool = 150,000 liters + 120,000 liters + 135,000 liters

Total Pool = 405,000 liters

Use the previous pool for this example. You return to the pool on a Monday and find that the auto-fill failed to operate. Your pool water level is 4 inches too low. Howmanygallonsmustbeadded?

Gallons = area x average depth x 7.5

Area = length x width

Averagedepth1inch = 1 foot ÷ 12 = 0,833

Gallonsfor1inch = (60 feet x 20 feet) x 0,833 feet x 7 5

Gallonsfor1inch=7.497

Gallonsfor4inches = 7.497 gallons x 4 = 2998.8 gallons

Use the previous pool for this example. Your return to the pool and find that the waterlevelis7centimeterstoolow.Howmanylitersmustbeadded?

Liters = area x average depth x 1000

Area = length x width (measured in meters)

Averagedepth(inmeters) = depth / 100

7centimeter = (7÷100) = 0,07

Litersfor7centimeters = 20 metres x 12 metres x 0,07 x 1000

Liters for 7 centimeters = 16.800 litres

Aquatic facilities lose water in a number of ways:

Evaporation

Bather splash-out and drag-out

Plumbing and shell leaks

Planned dilution

For operational and planning purposes, the pool operator needs to understand how much water is lost in one inch of depth. It's the same formula used to calculate the volume for a constant slope pool. The difference is that there is no slope; the depth is constant.

Rather than cover them in the general chapter, they are reviewed in the relevant chapter. For example, the following calculations will be discussed in later chapters:

Chemical dosage: Pool & Spa Water

Issues chapter

Filter area: Pool & Spa Filtration chapter

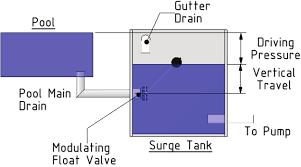

Turnover rate: Water Circulation chapter

Heater sizing: Heating & Air Circulation chapter

Bather loads: Facility Safety chapter

The pool must first be separated into its component parts. Each part must be calculated and then added back together

Radius(R)=Diameter/2

SectionA

Section A is the top of the spa down to the seat. The depth is 10 inches (0.83 feet) and the diameter is 12 feet.

Area = R X R x 3 14

Area = 6 feet x 6 feet x 3.14 = 113.04 square feet

Gallons = average depth (in feet) x area x 7 5

Gallons = 0 83 feet x 113 04 square feet x 7.5 = 702.65 gallons

Section B is the foot well of the spa from the seat down to the main floor. The depth is 2 feet and the diameter is 6 feet.

Area = R X R x 3 14

Area = 3 feet x 3 feet x 3.14 = 28.26

square feet

Gallons = average depth (in feet) x area x 7 5

Gallons = 2 feet x 28 26 square feet x 7.5 = 423.90 gallons TotalPool:GallonsA+GallonsB TotalPool = 702.65 gallons + 423.90 gallons

TotalPool = 1,126 55 gallons or rounded off to 1,127 gallons

Calculating Litres in a Multi-Depth Circular Spa

The pool must first be divided into its component parts Each part must be calculated and then added together

Radius(R)=Diameter/2

SectionA

This section is from the top of the spa down to the seat. The depth is 0.5 meters, and the diameter is 3 meters

Area: R x R x 3.14

Area: 1.5m x 1.5m x 3.14 = 7.07 square metres

Litres: Area x average depth x 1000

Litres: 7.07 square metres x 0.5m x 1000 =3,535

Litres =3,535

SectionB

This section is the footwell of the spa, from the seat down to the main floor. The depth is 1 meter, and the diameter is 1 5 meters

Area: R x R x 3.14

Area:0.75 m x 0.75 m x 3.14 =1.77 square metres

Volume:Area x average depth x 1000

Volume: 1.77m2 x 1m x 1000 =1,770

Litres = 1,770litres

TotalPool:Litres +Litres

TotalPool = 3,535 litres + 1,770

TotalPool = 5,305litres

RoundedVolume: 5,300 litres A B

Swimming has long been associated with exercise and health It provides an excellent way to keep fit and has numerous benefits for public health. The confidence and enjoyment people get from swimming lead to a variety of aquatic-related activities. However, water, and sometimes the air above it, can create unhealthy conditions if water quality is not properly managed. Ensuring people don't get sick from ingesting or coming into contact with pool water is a primary reason pools are continually disinfected Disinfectants kill germs that can cause disease, and poor disinfection is a significant concern. Public health departments require pool operators to be trained and certified, demonstrating competency in handling pool water contamination.

The role of a pool operator is critical in minimizing the spread of Recreational Water Illnesses (RWI) Effective pool management involves maintaining water quality standards and keeping thorough records. The Centers for Disease Control and Prevention (CDC) Model Aquatic Health Code (MAHC) provides guidelines to help pool operators maintain safe and healthy water conditions.

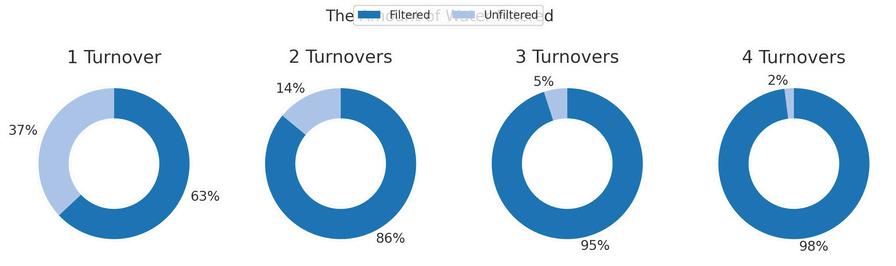

Statistics indicate that about a quarter of disease outbreaks in pools are due to improper disinfection or failure to meet required standards. Reports show that many pools are not adequately treated, which highlights the need for bettertrained pool operators.

Health inspections play a crucial role in identifying and addressing issues in pool facilities. Despite regular inspections, many violations are found each year. These include inadequate chlorine levels and poor maintenance practices

Inspections aim to ensure that pools are safe and comply with health codes.

Pool operators must be vigilant about preventing disease transmission. Regular maintenance, proper disinfection, and adherence to health guidelines are essential. Keeping the water clean and safe not only prevents illnesses but also ensures that people can enjoy swimming without health risks

An essential part of health and safety is preventing the spread of diseases through pool water. Properly maintained pools reduce the risk of infections and contribute to public health.

Swimming offers substantial health benefits, including physical fitness and improved self-confidence. However, poorly managed pool environments can lead to health risks Preventing the ingestion of contaminated water is crucial, as pools are regularly treated with disinfectants to eliminate harmful pathogens. Public health authorities and pool operators undergo training and certification, such as the Certified Pool/Spa Operator (CPO) program, to ensure proper pool management. Despite guidelines from the Centers for Disease Control and Prevention (CDC) and the Model Aquatic Health Code (MAHC), many pools fail to comply with safety standards, leading to outbreaks of Recreational Water Illnesses (RWIs). These illnesses, caused by bacteria, viruses, and protozoa, can result in various symptoms, including gastrointestinal issues and skin infections.

Regular inspections and operator education are essential to maintain pool safety. Ensuring adequate disinfectant levels and adherence to health regulations can significantly reduce the risk of RWIs. Promptly addressing equipment malfunctions and pool hazards can further prevent accidents Consistent staff training on emergency protocols helps prepare for any unexpected incidents.

Recreational Water Illnesses (RWIs) are illnesses caused by germs and chemicals found in the water we swim in. These illnesses are spread by swallowing, breathing in mists, or having contact with contaminated water in pools, hot tubs, water playgrounds, lakes, and oceans. Common pathogens causing RWIs include Cryptosporidium, Giardia, Shigella, norovirus, and E. coli. These germs can lead to a variety of symptoms, such as diarrhea, skin rashes, ear pain, cough, congestion, and eye pain.

Gastrointestinal issues, such as diarrhea, are the most frequently reported symptoms and can be severe, especially in vulnerable populations like young children, pregnant women, and those with weakened immune systems. Respiratory infections, eye infections, and skin infections, including hot tub rash and swimmer’s ear, are also common Preventing RWIs involves multiple strategies. Pool operators must maintain proper disinfectant levels and conduct regular water testing Public awareness campaigns emphasize the importance of showering before swimming, not swallowing pool water, and avoiding swimming when experiencing diarrhea. Facilities should ensure that filtration systems are functioning correctly and that the water chemistry is regularly balanced.

Effective management involves not only proper maintenance but also educating swimmers on good hygiene practices and the importance of reporting and managing fecal accidents promptly. With these measures in place, the spread of RWIs can be minimized, ensuring a safer swimming environment for everyone Clear signage about showering before entering the pool and avoiding swimming when ill can reinforce good habits.

Pathogens like Cryptosporidium, Giardia, E. coli O157, and Shigella can cause infections when present in pool water due to fecal contamination These pathogens may enter the water through accidental fecal releases (AFR). People with diarrhea should avoid swimming to prevent spreading these pathogens

Chlorine and other disinfectants do not kill all pathogens instantly. Chlorineresistant organisms have become more prevalent in pools. Proper pool and spa water treatment, along with vigilant hygiene practices, are essential to prevent the spread of these microorganisms.

Protozoa are single-cell organisms transmitted through food and water

Once ingested, they live in the intestines and may cause illness. The most common protozoa in recreational water are Giardia and Cryptosporidium. These organisms can cause severe gastrointestinal symptoms and are resistant to chlorine Cryptosporidium, in particular, can survive in properly chlorinated pools for several days.

Cryptosporidium, often referred to as Crypto, is a chlorine-resistant protozoan parasite that poses significant challenges for pool sanitation This pathogen can survive in properly chlorinated water for up to 10 days, making it particularly problematic. Crypto is one of the most common causes of waterborne illness outbreaks in the United States

When ingested, Crypto causes cryptosporidiosis, which leads to severe gastrointestinal symptoms including diarrhea, stomach cramps, nausea, and vomiting These symptoms can be especially dangerous for young children, pregnant women, and individuals with weakened immune systems. The incubation period for Crypto ranges from 2 to 10 days, and symptoms can last for up to two weeks or longer Preventing the spread of Crypto requires rigorous pool maintenance and hygiene practices. The CDC recommends that individuals diagnosed with Crypto avoid swimming for at least two weeks after symptoms have subsided. This is crucial because Crypto can be shed in feces even after symptoms resolve, continuing to pose a risk of contamination

To combat Crypto, pools should ensure effective filtration systems, such as those using ultraviolet light or ozone, which can help inactivate the parasite. Regular monitoring and maintaining higher than usual chlorine levels can also reduce the risk of Crypto outbreaks. Public education campaigns emphasizing the importance of not swimming when experiencing diarrhea and maintaining good hygiene can help prevent the spread of Crypto in swimming environments.

Giardia can survive in chlorine-treated water and is similar to Crypto in terms of symptoms and transmission. Proper filtration and chlorine levels can help control its spread. It can cause prolonged diarrhea, stomach cramps, and nausea. People infected with Giardia should also avoid swimming until cleared by a healthcare provider. Effective treatment and strict personal hygiene can help manage and prevent further spread.

Bacteria are microscopic organisms that can thrive in various environments, including pool water. Bacteria like E. coli O157 and Shigella can cause severe gastrointestinal illness. Maintaining proper chlorine levels and pool cleanliness can prevent bacterial outbreaks. Regular water testing and immediate response to contamination events are critical in managing bacterial threats

Shigella is a bacterium that spreads through fecal contamination and can cause severe gastrointestinal symptoms. It is highly contagious and can be transmitted through ingestion of contaminated water or direct person-toperson contact.

Symptoms include diarrhea, fever, and stomach cramps, which typically develop one to three days after exposure. In some cases, Shigella can lead to more serious health complications such as severe dehydration and hemolytic uremic syndrome, particularly in young children and those with weakened immune systems. To control its spread, pools should be closed and thoroughly cleaned if contamination is suspected Public health education on proper handwashing and hygiene practices can significantly reduce the risk of Shigella outbreaks.

E. coli O157 can cause severe abdominal cramps, diarrhea (often bloody), and vomiting. It is particularly dangerous for young children and the elderly. Proper chlorination and avoiding swimming after AFR incidents are crucial for preventing its spread

Transmission of E coli O157 in swimming pools usually occurs through accidental ingestion of contaminated water. This contamination can happen if someone with the bacteria has a fecal accident in the pool or if improper hygiene practices are followed, such as not showering before entering the pool. Preventing the spread of E. coli O157 involves maintaining proper pool sanitation through adequate chlorination and filtration. Pools must be regularly tested to ensure disinfectant levels are sufficient to kill harmful pathogens. In the event of a fecal incident, immediate and thorough cleaning and disinfection are necessary to prevent an outbreak. Swimmers should be encouraged to shower before entering the pool, avoid swallowing pool water, and refrain from swimming when experiencing diarrhea It's also important to take regular bathroom breaks, especially for young children, to prevent accidents.

Viruses are smaller than bacteria and can only grow inside living cells They don't respond to antibiotics as bacteria do, though some vaccines are available.

Noroviruses cause gastroenteritis, leading to stomach pain and diarrhea, and can spread through infected individuals Symptoms typically appear within 12-48 hours post-exposure and include nausea, vomiting, diarrhea, and stomach cramps. Severe cases may also include fever, chills, headache, muscle aches, and fatigue The illness generally resolves within a few days, but those with compromised immune systems can experience more severe symptoms. Measures to take:

Proper Chlorination: Ensure the pool is properly chlorinated with adequate levels of disinfection to kill norovirus particles Regularly monitor chlorine levels and adjust as necessary Swimmer Education: Educate swimmers to avoid entering the pool if they are ill, especially if they have symptoms of gastroenteritis Post clear signs around the pool area to remind users of this guideline.

Rigorous Cleaning Protocols: Implement rigorous cleaning protocols for areas around the pool, including locker rooms, showers, and restrooms. Use disinfectants that are effective against norovirus.

Adenoviruses can cause respiratory illnesses, gastroenteritis, conjunctivitis, and rashes. These viruses are particularly problematic for immunocompromised individuals, potentially leading to severe complications

Adenoviruses are resilient outside the body and can spread through direct contact, water, or airborne droplets.

Preventive measures:

Maintain Proper Chlorination: Keep the pool water properly chlorinated to inactivate adenoviruses. Regularly test and adjust chlorine levels.

Regular Cleaning: Ensure regular cleaning and disinfection of the pool area, including common surfaces like handrails and poolside furniture.

Health Screening: Encourage users with symptoms of respiratory or gastrointestinal illness to stay out of the pool Consider implementing health screening procedures for frequent users.

Hepatitis A affects the liver and is usually transmitted through feces Symptoms include fever, jaundice, and fatigue, and can last several weeks. It is crucial to maintain high hygiene standards in and around pools to prevent its spread. Prevention strategies: Increase Chlorine Levels: If contamination is suspected, increase chlorine levels to at least 2 ppm to effectively inactivate the hepatitis A virus

Temperature Maintenance: Ensure water temperature is maintained at or above 77°F (25°C), as this can help inactivate the virus.

Public Education: Educate pool users on the importance of not swimming when experiencing symptoms of hepatitis A or other gastrointestinal illnesses. Distribute informational pamphlets and display signs to raise awareness Host regular workshops or informational sessions to discuss safe swimming practices. Utilize social media platforms to reach a broader audience with water safety tips and guidelines

Properplanningandresponseto accidentalfecalreleases(AFRs)arevital tomaintainingpoolsafety.AFRsintroduce harmfulpathogensintothewater,posing healthrisks.Havingadetailedresponse planensuresswiftandeffective contaminationcontrol,minimizingdisease transmissionandallowingforsafe reopening.Thisincludestrainingstaffon procedures,maintainingdisinfectant supplies,andcommunicatingprotocolsto poolusers.BeingpreparedforAFRs protectspublichealthandkeepsthe swimmingenvironmentsafe.

Raisethechlorineleveltoatleast2ppm andmaintainitfor25minutesbefore allowingswimmersbackin.Ensurethe filtrationsystemisoperationaland monitorchlorinelevelsregularlytoensure thecontaminantisfullyneutralized.