Industry guide

AmbaFlex is active in 4 main industries and 10 sub industries, as mentioned below. For each of these industries we have specific solutions combining the experiences we built up over 25 years with more than 32,000 machines installed. These solutions per industry are explained on the next pages.

In this industry guide you can find more information about the solutions we offer for each industry and how we can support your business.

Logistics Packaging Bottling and canning Print • Logistics single item • Logistics shipping cases • Logistics SKU cases • Primary packing • Secondary packing • Liquid container packing • Filling single file • Filling mass flow • Print finishing AmbaFlex.com Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics Portal Sortation/ merging accumulation y Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics

Logistics

It can be either totes, polybags, cartons, luggage, and many more. We will always have the best solution possible.

Portal Sortati on/ m erging Dynam ic accum ul ation Tim e del ay Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics

Speed, reliability and safety

In the logistics sector, you encounter a broad range of product types and various kinds of product flows. This can be a train of single items or a neverending bulk flow. Also, depending on the process it can be either totes, polybags, cartons, luggage, and many more.

However, regardless of the situation, in logistics there are 3 points truly relevant: Speed, reliability, and safety.

Whether you need to elevate, accumulate or convey, with our solutions for the logistics markets you will always have the best solution possible.

Watch a compilation of various logistic solutions (Video 1.1)

AmbaFlex.com

Logistics Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics

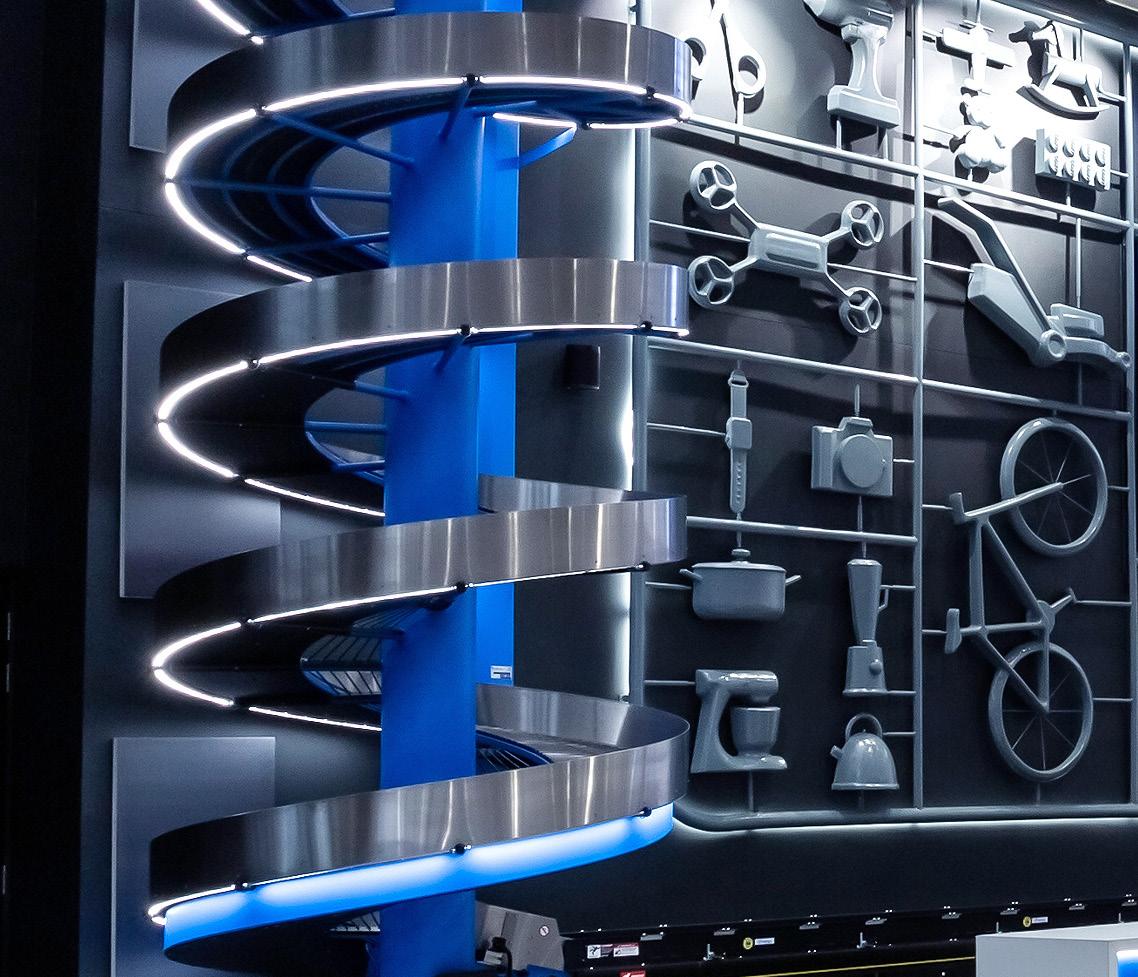

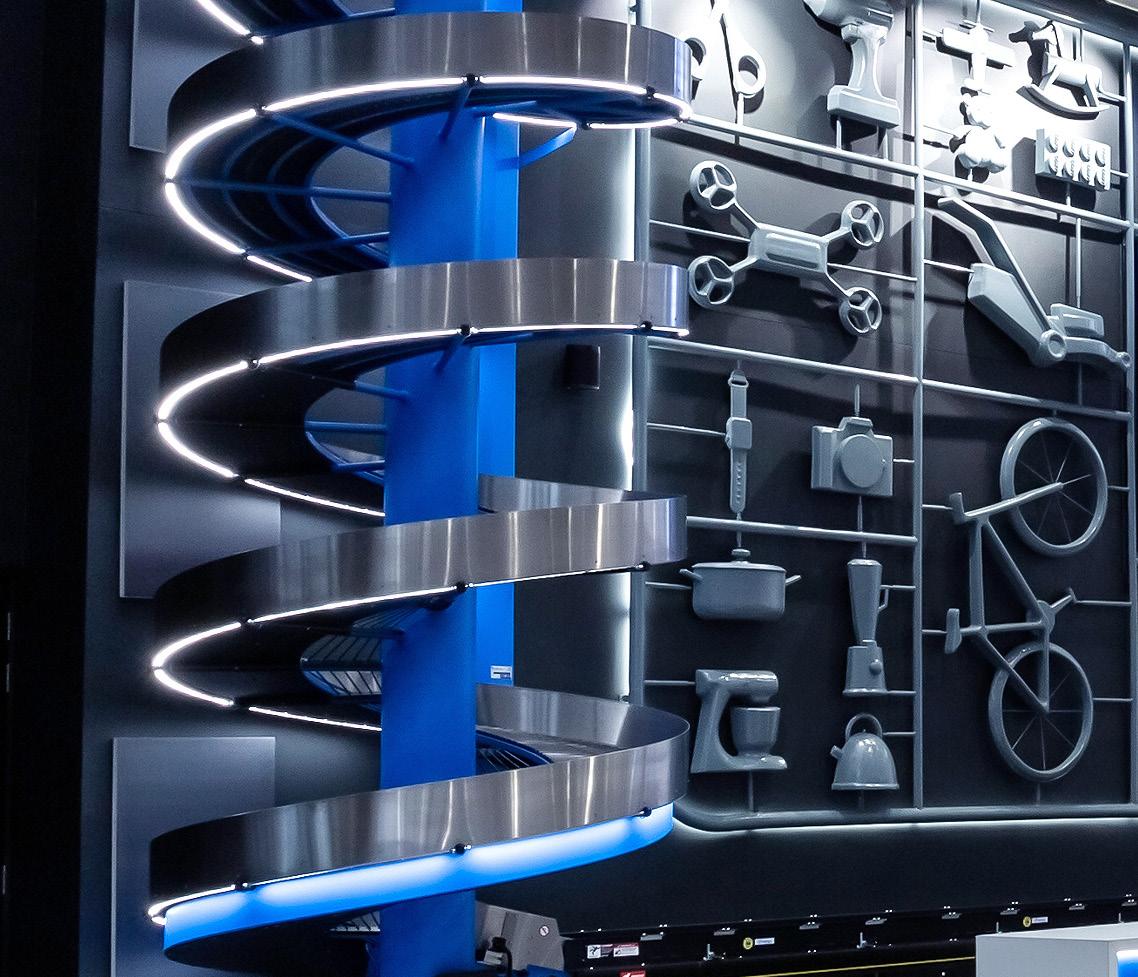

Logistics single items

The explosive growth of e-commerce is causing a real stir within the logistics chain. The chain of delivery, storage, single-item order picking, and overnightexpress delivery is leading to a considerable upscaling of capacity. E-commerce is characterized by a huge product variety, short lead time, and high speeds. That’s why we focus on handling high-speed, large and small product flows.

Our solutions can deal with all kinds of single items and parcels, whether they are large boxes, polybags, blisters or any item you can think of that’s homedelivered. With bandwidths of up to 1200 mm and a wholly sealed conveyor belt surface, it is suitable for almost any item imaginable.

The transportation of a large variation in parcels, polybags and flats needs to be carried out safely, economically and efficiently. The ParcelLift is used for transportation around the loading dock, around sorter inducts and sorter exits, and for pickto-belt warehouse solutions.

Distinctive features:

Slimline design

Endless stainless guide plate

• Tip support

Multi chain option

Multi track option

Logistics ELEVATE CONVEY SORTATION/ MERGING Click on a functionality to see all related solutions Choose your solution

solution for single

SpiralVeyor ParcelLift Watch video > Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Print Bottling Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Print Logistics

Example

items:

Logistics shipping cases

Warehousing and order picking systems are constantly being developed to become more efficient. This is because of an increase in the number of SKU’s and the variety of their sizes, coupled with a growing number of customers that demand even shorter delivery times and 365 days a year service. Automated high bay storage solutions and multi-level pick stations have one thing in common; the products need to be delivered at workstations, sorters or docking doors quickly and within the given space constraints.

A demanding task but one which AmbaFlex provides numerous solutions for: elevation and using heights, shuttle feeding, retrieval systems or connecting picking modules.

Example solution for shipping cases: SpiralVeyor LogiLift Watch

The SpiralVeyor LogiLift is a special configuration used in distribution centres. The transportation of shipping cartons and plastic (bin) containers needs to be carried out economically and efficiently. The LogiLift is used for transportation around the loading dock, in (multilevel) order picking modules, around sorting systems, and in goods-to-man solutions.

Distinctive features:

• Super grip spiral belt

• Stackable configuration

• Slimline design

• Endless stainless guide plate

AmbaFlex.com

Logistics ELEVATE PORTAL CONVEY SORTATION/ MERGING Choose your solution Click on a functionality to see all related

solutions

video > Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Print Bottling Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Print Logistics Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics

Logistics SKU cases

New trends in retail, such as a fast-growing number of SKU’s and reduced in-shop storage, combined with an increased need for automation to keep costs down, require smart solutions in distribution centers.

All these new systems in mixed case handling and palletization have one thing in common - the need for vertical merging and sortation. The speed of orderrelease modules and other high-end picking solutions requires a quick way to replete and deliver. After inventing the spiral-merge solution and the spiral sorter shortly after that, AmbaFlex became a household name in this industry. We have mastered the skills required for complicated vertical sequencing and the elevation of high-speed streams. Clever Designed Solutions were rewarded with multiple patents and many loyal integrators

Example solution for SKU cases: SpiralVeyor MultiLevel Watch video >

The SpiralVeyor ML-configuration is a Multi-Level Spiral elevator. It offers greater flexibility when designing your layout in 3 dimensions. Products can be merged onto, or be diverted from, the SpiralVeyor on different levels.

Distinctive features:

• Multi-Level Spiral Elevator

• Spiral Merge and/or Divert

• Vertical Sorter

• High Speed

• High Capacity

AmbaFlex.com

Logistics

Click on a functionality to see all related solutions ELEVATE SORTATION/ MERGING Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print Logistics Packaging Print Bottling Logistics

your solution

Choose

Packaging

Safe

accessibility,

ti on/ ing m ic m ul ation del ay Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling

and easy

combining lines and heights and buffering

Making versus moving

In the packaging market it’s critical that products stay in pristine condition while keeping a high throughput. This means there is a great emphasis on well-engineered machines with low MTBF and lightning-fast maintenance options.

AmbaFlex spirals are known for their longevity and careful handling of goods while maintaining blazing speeds, even when handling multiple rows. Or our portal functions for creating accessibility to various parts in the line in a safe and controlled manner. And not to forget our patented technology offers unique solutions for cooling and touchless accumulation.

Watch a compilation of primary packing solutions (Video 1.1)

Watch a compilation of secondary packing solutions (Video 1.2)

AmbaFlex.com

Packaging

Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics

Choose your solution

Primary packing

Primary packages come in many shapes and sizes; this variation in product characteristics coupled with (often) sensitive packaging makes them prone to damage. Because AmbaFlex spiral conveyors are known for the level of quality they deliver and their versatile functionality, they are widely used in primary packing.

This ranges from vertical transport between floors to creating portal passages, as well as the cooling and dynamic accumulating of products. Compared to the usual modular plastic conveyor belts, the AmbaFlex conveyor belt is much stronger due to its steel base chain which can be extended to over 100 meters of belt.

The AmbaFlex belt has fewer transitions, fewer motors, better product handling and offers some unique solutions.This fits in perfectly with the demands of a smart and efficient enhancing solution in packaging lines.

Example solution for primary packing: AccuVeyor AccuPack

Watch video >

The AccuVeyor AccuPack is a spiral accumulator used to accumulate flows of primary packed items of all kinds. For example horizontal pouches and cartonbriks, flowpaks, cups, jars and (food)trays.

Distinctive features:

• Ultra flat,high friction

• Compact transfer

• Non-touching

• One belt system

• Integrated side guide

solutions

Packaging ELEVATE PORTAL ACCUMULATE TIME DELAY

functionality

on/ ing Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics

Click on a

to see all related

Secondary packing

In end-of-line packaging, there are two critical aspects for keeping the whole process running smoothly.

First is the line availability; because if the end of the line stops, the complete upstream packaging and processing needs to stop. The second is a clever layout; as most palletizers need to be closer to the dispatch area than to the packing line, creative three-dimensional solutions are required.

AmbaFlex offers solutions that include both these critical aspects, high performance and low cost of ownership. For multi-row handling, AmbaFlex was the first company that invented and implemented the multi-belt, dual lanes or even triple lane spirals, thus allowing multiple independent flows of items to run parallel between a packer and a palletizer. And now the SpiralVeyor SVe is also available. The “e” stands for extended belt width which allows for even wider multiple flows in different configurations.

Example solution for Secondary packing: SpiralVeyor CartonLift

Watch video >

The SpiralVeyor CartonLift is a special configuration of a spiral conveyor used on a secondary packing line. Suitable for goods like wrapped around cartons, shrinkwrapped trays, cartons, sixpacks and bags.

Distinctive features:

• Super grip spiral belt

• Endless stainless guide plate

• Stainless steel chain

• Continuous flow

AmbaFlex.com

ELEVATE CONVEY SORTATION/ MERGING ACCUMULATE PORTAL

Packaging

Click on a functionality to see all related solutions Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Print Bottling Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Print Logistics Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics Choose

your solution

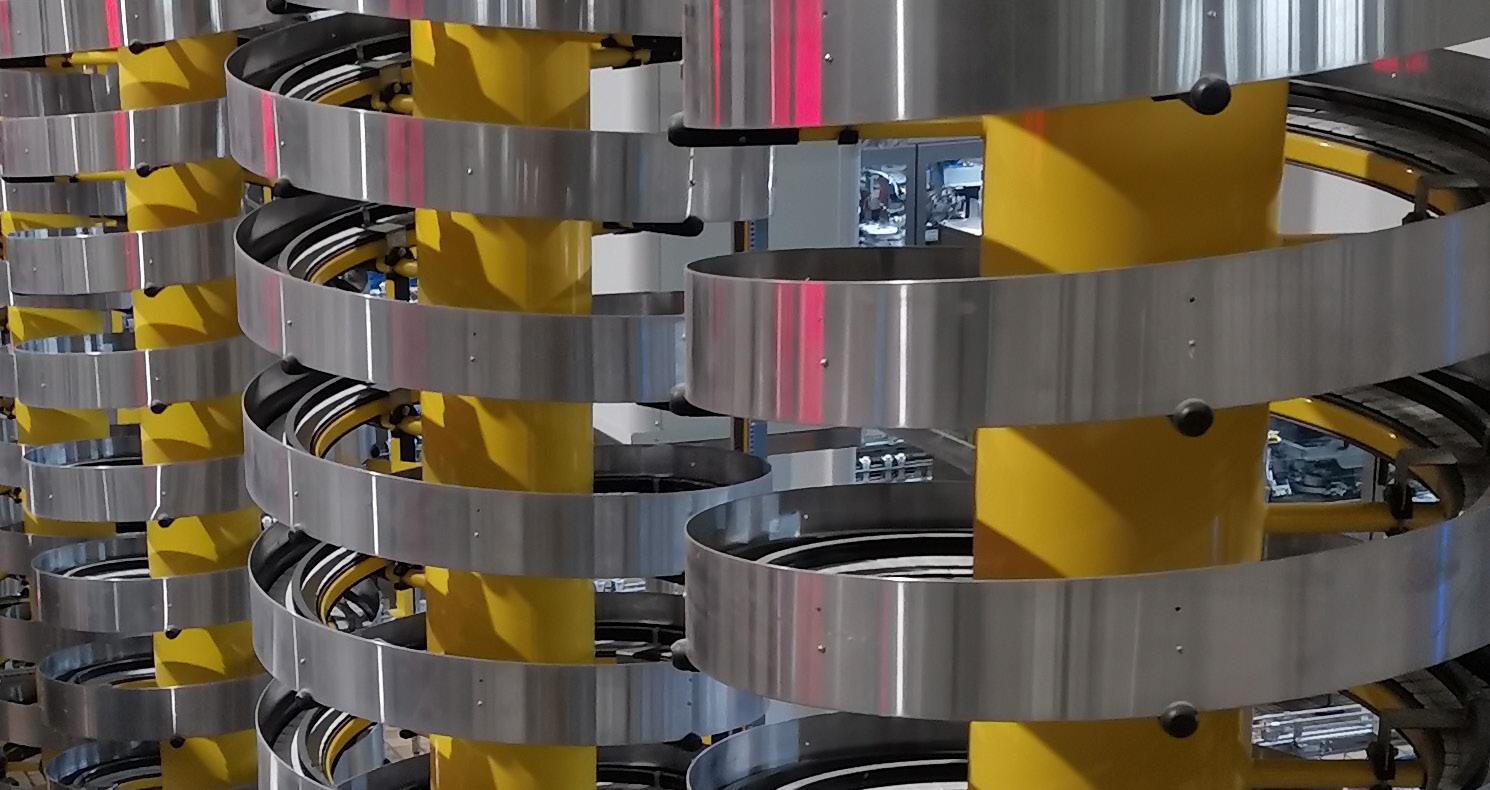

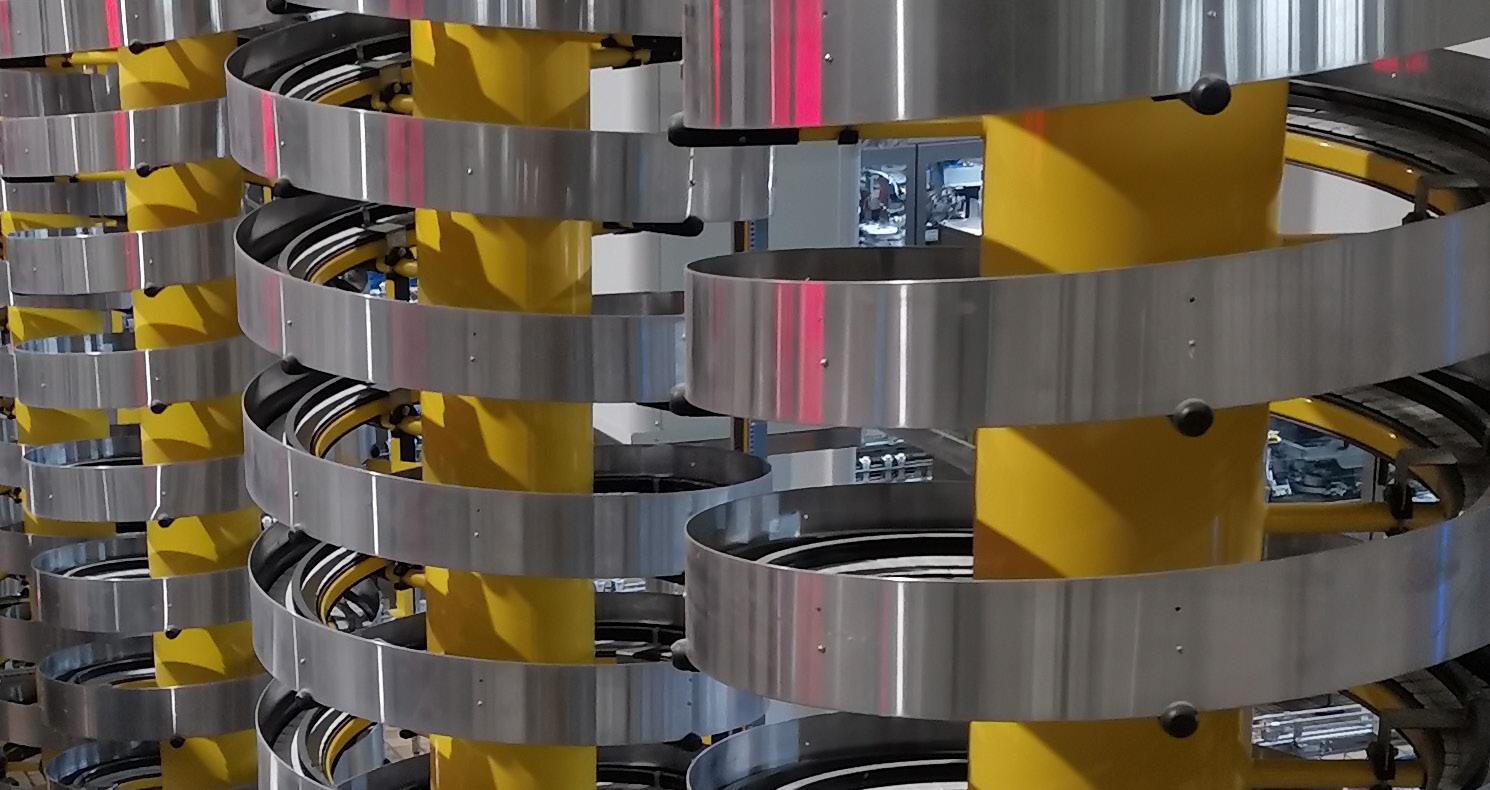

Liquid container packing

One of the most demanding secondary product flows is bottle packs. High speeds, high loads, multiple rows and new eco-packs make these lines a challenge for most elevator suppliers. But not for AmbaFlex. The high loads can be comfortably dealt with thanks to the Triple-E belt guide. This true rolling friction technology reduces driving power to a minimum, allowing extreme elevations and high loads while consuming the least amount of energy.

It’s not just the internal technology, but also the extended range of products and configurations that exactly matches the market’s needs and makes AmbaFlex the preferred choice. In fact, even back in the nineties, AmbaFlex was already THE solution for shrink packs, crates, and trays of liquid containers.

For multi-row handling, AmbaFlex was the first company to invent and implement the multitrack, dual lanes or even triple lane spirals, allowing multiple independent flows of items to run parallel between packer and palletizer.

Example solution: SpiralVeyor ContainerPackLift

Watch video >

The ContainerPackLift is used on a secondary packing line and for end of line high speed liquid container elevation.

Distinctive features:

• Triple-E technology

• Super grip spiral belt

• Tip support

• CR chain

• Multi track option

AmbaFlex.com

Packaging

PORTAL ELEVATE CONVEY Click on a functionality to see all related solutions Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Print Bottling Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics Packaging Logistics

your solution

Choose

Bottling and canning

Ready to handle any type of material, shape or size.

Logistics shipping cases Bagage handling Print nishing Bottling

Cleanability, product stability and speed

Both single file and mass flow transportation of liquids is made easy. Ready to handle any type of material, shape or size. No matter if its PET, HDPE or glass, cylindrical, rectangular, reverse tapered or irregularly curved.

Our solutions offer optimal stability for the products on the belt and through the transfers, ensuring the products come out in pristine condition.

And perhaps just as important, our machines are easy to clean with no bolts or nuts for dust or debris to latch on.

Watch a compilation of single flow solutions (Video 1.1)

Watch a compilation of mass flow solutions (Video 1.2)

AmbaFlex.com

Bottling and canning

Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics

Choose your solution

Filling single file

Liquid containers are usually transported single file, especially in applications such as winemaking, dairy, distilled, sports drinks and sodas. These containers are made from carton packs, PET, HDPE or glass. The shape can be cylindrical, rectangular, reverse tapered or irregularly curved.

Preventing mass flow is a trend, as it requires a great deal of space in the re-single lining of the flow. It is also the preferred method if the right handling solutions are available. Many single file flows remain on ground level. Height differences require long lengths due to instability, but usually there is no floor space available for this.

Instability or sensitive handling also requires special options, but good solutions for elevation, accumulation or buffering have not been available in the past. AmbaFlex enjoys taking on special challenges such as belt lubrication, glass breakage and hot filling. We offer an extensive range of elevation and accumulation solutions.

Watch video >

The SpiralVeyor BottleLift is a configuration spiral conveyor that is used to elevate or store flows of Liquid Container items of all kinds. For example filled and empty bottles, cans, cartonbriks, cups and jars.

Distinctive features:

• Ultra flat, high friction

• CR coating

• Stainless steel chain

• Banking

• Slimline design

• Continuous flow

Bottling and canning

solution for Single Flow: SpiralVeyor BottleLift

Example

Click

functionality

ELEVATE PORTAL ACCUMULATE TIME DELAY on/ ing Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics

on a

to see all related solutions

Filling mass flow

Handling the mass flow of bottles and cans presents some well-known challenges in filling line layouts.

Mass flow accumulation tables and single liners take up a lot of space and can become problematic when operators need to move efficiently along multiple filling, labeling and packing stations.

Making use of the 3rd dimension, or using multiple stories in a mass fill line, has been impossible for a very long time. Even lowering empty cans or bottles down from a depalletizer presented a difficult challenge.

However, AmbaFlex’s development of the first spiral conveyor that was able to handle mass flow products opened up many new possibilities in the efficient use of space in liquid container handling.

Example solution for Mass Flow: SpiralVeyor MassFlowLift HD

Watch video >

The SpiralVeyor MassFlowLift HD is used to bring bottles and cans to the desired level. It can cope with particularly high requirements such as extreme loads or height overcoming. It contains all functions for a pressureless product handling.

Distinctive features:

• Tip support

• Ultra flat, high friction

• Stainless steel chain

• Multi chain option

• Glass contamination package

AmbaFlex.com

Bottling and canning

Click on a functionality to see all related solutions ELEVATE PORTAL Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Print Bottling Logistics

Choose your solution

Compact space, plug and play, upscaling. SKU Logistics shipping cases Bagage handling Print nishing Print Bottling

Print

Innovation in print

AmbaFlex has its roots in print finishing. After the invention of the modern spiral conveyor in the late nineties, the first industry to use the SpiralVeyor was the print industry. At the end-of-line newspaper printing (mail room), binding and stitching lines, continuity is essential to success.

Our solutions offer the smallest footprint while offering the highest uptime and ease of maintenance.

Watch a compilation of various print solutions (Video 1.1)

AmbaFlex.com

Print Portal Sortation/ merging Dynamic accumulation Time delay Packaging Print Bottling single Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Logistics Packaging Print Bottling Logistics

Print finishing

AmbaFlex has its roots in print finishing. After the invention of the modern spiral conveyor in the late nineties, the first industry to use the SpiralVeyor was the print industry. At the end-of-line newspaper printing (mail room), binding and stitching lines, continuity is essential to success.

Every link in the chain is crucial and any stoppage or crash will result in a dramatic drop in line efficiency.

Furthermore, since start-ups are arduous and time-consuming work, all machines and conveyors in the line should be 100% reliable. And it is that reliability that made the SpiralVeyor so popular. In fact, at least 25% of the bound magazines and books distributed around the world have been conveyed on an AmbaFlex SpiralVeyor.

Example solution for Print Finishing: SpiralVeyor CoolingTower

Watch

The SpiralVeyor CoolingTower configuration is based on the trusted SpiralVeyor SV-series. It is designed for the cooling of books, magazines and book blocks in print finishing lines. It can be custom configured for up to 80 metres of cooling length and for a speed of up to 90 metres per minute. This suits all modern needs from low to high end.

Distinctive features:

• Flat track

• No flick

• Integrated side guide

• Cool and connect

• Interlocking belt surface

AmbaFlex.com

Print

video > ELEVATE CONVEY PORTAL ACCUMULATE Click on a functionality to see all related solutions Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Logistics Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Print Bottling Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Bagage handling Print nishing Packaging Print Bottling Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics shipping cases Logistics Packaging Print Logistics Portal Sortation/ merging Dynamic accumulation Time del ay Packaging Print Bottling Filling single le Filling mass ow Primary packing Secondary packing Liquid container packing Logistics single items Logistics SKU cases Logistics Packaging Logistics Choose

your solution

For more information you can contact us by phone or email: Contact +1 877 800 1634 info@ambaflex.com