TABLE OF CONTENTS

ENVIRONMENTAL RESOURCE GUIDE 0

TABLE OF CONTENTS ................................................................................................................... 1

ENVIRONMENTAL DESIGN I ........................................................................................................... 4 module 1: foundations 5 module 2: principles .................................................................................................................. 8 module 3: climate 12 module 4: solar ........................................................................................................................ 15 module 5: energy ..................................................................................................................... 17 module 6: wind 20 module 7: envelope ................................................................................................................. 24 module 8: lighting .................................................................................................................... 26 module 9: materials ................................................................................................................. 30 module 10: site ......................................................................................................................... 37 module 11: water 41 module 12: synergies ............................................................................................................... 48 module 13: tools ....................................................................................................................... 50 module 14: assessments 55

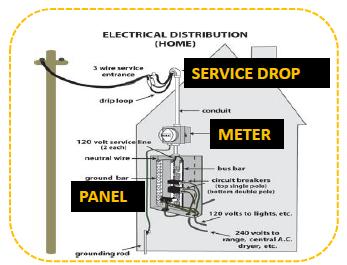

ENVIRONMENTAL DESIGN II ........................................................................................................ 57 module 1: synergies ................................................................................................................. 58 module 2: hvac 64 module 3: lighting .................................................................................................................. 112 module 4: electricity 118 module 5: acoustics .............................................................................................................. 130 module 6: conveyance .......................................................................................................... 133 closing: design process 147 appendix: resources ................................................................................................................. 147

“As architects, we have an obligation to integrate ETHICS and METRICS symbiotically into a holistic sustainable design process. Understanding the principles of environmental science creates a solid basis for employi ng sustainable design”

- patricia andrasik

ENVIRONMENTAL DESIGN I

module 1: foundations

Review Definitions

Carbon Footprint: A measure of direct emission of gases that cause climate change – (for simplicity) the amount of carbon dioxide which is emitted.

Green House Gas: Any type of emission of gas which leads to the entrapment of infrared radiation which warms the planet. When there is more ‘greenhouse’ gas in the air, it holds more heat, which leads to global warming.

Global Warming: A gradual increase in the overall temperature of the earth's atmosphere generally attributed to the greenhouse effect caused by increased levels of carbon dioxide, chlorofluorocarbons, and other pollutants.

Up-cycling: To reuse, discard or otherwise recycle a material in order to create a higher quality product.

Integrated Design Process: A method of design in which multiple disciplines and seemingly unrelated aspects of design are integrated in a manner that permits synergistic benefits to be realized.

Net Zero Design: A building which produces as much energy as it uses over the course of a year, combining (1) exemplary (passive) building design to minimize energy requirements and (2) Renewable energy systems that meet these reduced energy needs.

Greenwashing: Greenwashing is mostly used as a term to describe the deceptive use of green PR or green appurtenances to promote a misleading perception that a building is environmentally friendly.

Rapidification: The continued acceleration of changes affecting humanity and the planet is coupled today with a more intensified pace of life and work.

Throwaway culture: human society strongly influenced by overconsumption of goods. The term describes a critical view of excessive production and items that are cradle-to-grave or disposable.

Down-cycling: When waste materials or useless products are converted into new materials or products of reduced functionality.

Environmental refugees: A society displaced by global warming impacts which directly affect their living environments.

Cradle to Cradle: C2C, cradle 2 cradle is an approach to the design of products and systems that models human industrial processes on nature ‘s. It assumes that materials circulate in healthy cycles and believes that industry must protect and enrich its ecosystems.

Theories:

History of Sustainability

-Sustainability isn’t a trend, or a cult, or a form of hysteria.

-It is rooted in American philosophy and being at once innovative and practical, idealistic and active, one could easily define modern environmentalism as quintessentially American.

Brundtland Report

Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs. It contains within it two key concepts: The concept of 'needs‘, in particular the essential needs of the world's poor, to which overriding priority should be given; and the idea of limitations imposed by the state of technology and social organization on the environment's ability to meet present and future needs.

Integrated Design process is a partnership of Ethics and Metrics

-According to an ongoing temperature analysis conducted by scientists at NASA’s Goddard Institute for Space Studies (GISS), the average global temperature on Earth has increased by about 0.8° Celsius (1.4° Fahrenheit) since 1880.

-Two-thirds of the warming has occurred since 1975, at a rate of roughly 0.15-0.20°C per decade.

-Environmental Responsiveness is Net Zero Design; 1) Exemplary (passive) building design to minimize energy requirements, 2) Renewable energy systems (renewable) that meet these reduced energy needs.

-Solar Responsive Design is a major sustainability strategy.

MERGING ETHICS AND METRICS

Environmental benefits:

Enhance and protect ecosystems and biodiversity

Improve air and water quality

Reduce solid waste

Conserve natural resources

Economic benefits: Reduce operating costs

Enhance asset value and profits

Improve employee productivity and satisfaction

Optimize life-cycle economic performance

Social benefits: Improve air, thermal, and acoustic environments

Enhance occupant comfort and health

Minimize strain on local infrastructure

Contribute to overall quality of life

Many building forms aspire to their respective climate.

-What should an architect know as a key player in the IDP to implement environmentally responsive design.

-Basic principles of environmental science critical to selecting the right sustainable strategies for your architecture!

There are 7 principles of Catholic Social Teaching which are paramount to describing the human condition within sustainable design. Many of these are referred to in the Laudato Si encyclical and certainly relate to each other. Respect the Human Person, Promote the Family, Protect Property Rights, Work for the Common Good, Observe the Principle of Subsidiarity, Respect Work and the Worker, Pursue Peace and Care for the Poor

module 2: principles

Review Definitions:

R Value: A measure of the insulating quality of a material. A higher R-value indicates a greater ability to insulate a space, preventing heat transfer through the material.

U value: An indicator of how well a window resists conduction. The rate of heat conductivity is indicated by the U-value of a window assembly. The lower the U-value, the greater a window’s resistance to conductive heat flow and the better its insulating value.

Conduction: The process by which heat, or electricity is directly transmitted through a material when there is a difference of temperature

between two regions without movement of the material.

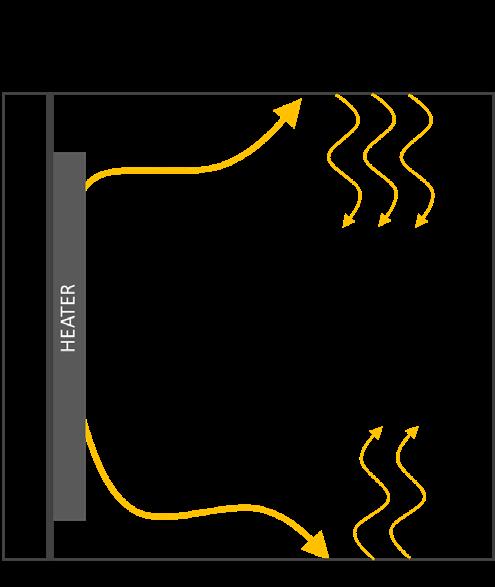

Convection: The transfer of heat by the movement of fluids such as air or water.

Radiation: Energy transmitted directly through space which requires a lineof-sight connection between the objects.

Sensible Heat: The heat energy stored in a substance or a fluid because of an increase in temperature, can be measured with a thermometer.

Latent Heat: The heat energy required to change the state of substance from solid to liquid, liquid to gas, energy that is not stored as the internal energy of an object but in its phase state.

Theories:

How can sustainable architectural design be implemented?

By understanding the basic principles of environmental science which are critical to selecting the right sustainable strategies for your architecture!

Forms of Heat Energy + Flow

Basic principles of environmental science

BTU: is the amount of heat energy needed to raise the temperature of one pound of water by one degree F.

-The human body is a good example of energy efficiency. Your body is like a machine, and the fuel for your machine is food. But your body isn’t very efficient at converting food into useful work. Your body is less than five percent efficient most of the time. The rest of the energy is lost as heat. More specifically, BTU’s.

Radiant heat

-Long and short-wave radiation

-Four possible interactions of materials and bodies:

Equilibrium Temperature = the balance between absorptance and emittance

Heat Island Effect Cool Roof Concrete Paving Mean Radiant Temperature

-Weighted average radiant temperature for one point in space!

-It is simply the area weighted mean temperature of all the objects surrounding the body.

Time Lag: The Delay of Heat Flow

-Most beneficial in areas with relatively large temperature swings.

Thermal Storage

-Some materials can store heat and the effect on thermal properties is that these materials take longer to heat or cool.

Specific Heat: the amount of heat energy (Btu) required to raise the temperature of 1lb of a material 1 ⁰F (Btu/lb. ⁰F)

-A measure of the ability of a material to store heat

-Water has a specific heat = 1 BTU/lb. ⁰F)

-Energy per weight

Heat Capacity: the amount of heat energy (BTU) required to raise the temperature of a 1ft3 of a material 1 ⁰F (Btu/ft3 ⁰F)

-Energy per volume

-Heat Capacity = Specific Heat * Density

Some architects use the term specific heat to refer to the ratio of the specific heat capacity of a substance at any given temperature to the specific heat capacity of another substance at a reference temperature

Thermal Transmittance (U-value) – measure how effective a material is an insulator. The lower the U-valueis, the better the material is as a heat insulator.

-A U-value is typically a low number because it is a rating of how much heat energy is lost or gained.

-The unit measure of heat transferred through a building ASSEMBLY per unit of time per unit of area and unit temperature difference and equal to the reciprocal of the total R-value.

-Usually for window systems with many materials

Calculations: Calculating R Value

Step 1: Find current ASHRAE CODE for the climate zone you’re studying.

Step 2: Sketch the assembly (wall) composition and identify the specific assembly requirements.

Step 3: Find the R value for the materials you’re considering in your building Table from ANSI/ASHRAE Standard 90.1 Appendix A

Step 4: Calculate the R and U values

module 3: climate

Review Definitions:

Carbon Neutral: A measure of design that ensures construction and operation of buildings will no longer require the consumption of fossil fuel energy or the emission of greenhouse gases.

Heat Island effect: The temperature differential between a natural environment and manmade as exceedingly high. Too hot = killing off species indigenous to the ecological area.

Microclimate: A very local set of climatic conditions. Near water, in mountains – this is where they exist in a very tangible way. Also, via heat island effect. Such as when the ground is made of tar or concrete; because these are man-made objects, they do not take in much heat, but mainly reradiate it. The term may refer to small sf areas or square mile areas.

Climate: A variability of relevant quantities over a period of time ranging from months to thousands of years. The classical period is 3 decades, as defined by the World Meteorological Organization (WMO). These quantities are most often surface variables such as temperature, precipitation, and wind. Climate in a wider sense is the state, including a statistical description, of the climate system. http://www.grida.no/publications/other/ipcc_tar/?src=/climate/ipcc_tar/wg1/518.htm

Emissions: The release of a substance (usually a gas when referring to the subject of climate change) into the atmosphere.

Climate System: The five physical components (atmosphere, hydrosphere, cryosphere, lithosphere, and biosphere) that are responsible for the climate and its variations.

Psychrometric Chart: The psychometric chart is an AMAZING TOOL for understanding the combination of how temperature and humidity affect comfort.

Degree Days: Heating degree days and cooling degree days are a quantitative measure of the heating and cooling needs of buildings based upon daily temperatures.

HeatingDegreeDays=A measure of how much degrees, and for how many days, the outside air temperature was below 65°F.HDD is used to calculate the energy used to HEAT buildings.

CoolingDegreeDays=A measure of how much degrees, and for how many days, the outside air temperature was above 65°F.DDD is used to calculate the energy used to COOL buildings.

Balance point temperature indicates when the outdoor temperatures equal indoor temperatures, the outdoor temperature below which heating is required.

Theories:

Climate Change: Climate becomes a significant factor in the building design – yet may not be THE ONLY factor to affect the final form of the building.

Psychometric Chart:

The most important aspect to understand is the idea of cooling and heating using latent and sensible heat. The wet bulb temperature reflects how much moisture is in the air using a moistened thermometer. The wet bulb limit in terms of the comfort zone shows the limit for what would be comfortable (being 68°).

The saturation temperature occurs when the wet bulb temperature and dry bulb temperatures are equal, and at this point the air is fully saturated and can’t hold any more moisture –in this case any cooling beyond this point would cause condensation.

Since condensation occurs when air is additionally cooled beyond the point at which the wet bulb temperature and dry bulb temperature are the same, it is the opposite for evaporation. The greater the difference is between the wet bulb and dry bulb temperature, the more likely it is for evaporation to occur.

Evaporative Cooling: When water evaporates, it requires a large amount of energy.

-If the amount of energy in the air (enthalpy) is constant, sensible heat is reduced, thus cooling occurs.

-Rate of evaporation depends on the amount of moisture already existing in the air.

Enthalpy: The sum of sensible and latent heat in the air (Btu/lb of dry air) Enthalpy Scale

Internally dominated buildings are densely populated buildings (high activity)

Externally dominated buildings are sparsely dominated

Factors of Macro/Microclimate:

ELEVATION above sea level FORM of land

WATER Size, Shape, Proximity SOIL types

VEGATATION

MAN-MADE STRUCTURES

Three Basics that dictate Earth’s climate, and our environment: solar heating of the planet balanced by energy loss to space; atmosphere, ocean, land, and ice responses to heating which provide feedbacks that either mitigate or accentuate planetary temperature changes; and regional environmental systems which have innate patterns of climate variability dictated by their unique physical-chemical-biological conditions.

module 4: solar

Review Definitions:

Insolation: Incident solar radiation refers to the amount of solar energy striking a surface.

Daylighting: Illumination of the interior of a building using natural solar luminance.

Illuminance: Generally clean waste from lavatories, baths, sinks, washing machines and has not come in contact with fecal matter.

Solar envelope: It is the greatest volume you can build on a site that will not shade nearby sites during a given time period.

Solar Access: The site's exposure to the sun during a given period. This exposure enables the utilization of solar radiation mainly for radiation, but also for daylighting

Azimuth: Angle of sun running around the edge of the stereographic or solar diagram. This is also the horizontal position of the sun.

Altitude: Concentric circular dotted lines that run from the center of the diagram out. This is also the elevation of the sun.

Date lines: Date lines start on the eastern side of the graph and run to the western side and represent the path of the sun on one day of the year.

Analemma: Hour lines are shown as figure-eight-type lines that intersect the date lines and represent the position of the sun at a specific hour of the day. The intersection points between date and hour lines give the position of the sun.

Solar Heat Gain is the amount of energy via radiation and conduction absorbed into a space. Glazing is the most common method that heat gain occurs, thus, the Solar Heat Gain Coefficient is the unit which measures that material ‘s ability of thermal transmittance.

Solar Heat Gain Coefficient (SHGC) –SHGC represents the ability of glazing assembly (including both the glass and frame) to resist heat gain from solar radiation. The lower the SHGC, the less heat energy enters the building through the window.

Theories:

In 2021, winter begins with the solstice at 10:58 AM on Tuesday, December 21

The start of winter the winter solstice is the darkest day of the year when the Sun reaches its most southern point in the sky at local noon.

After this date, the days start getting "longer," i.e., the amount of daylight begins to increase.

Spring begins with the vernal equinox at 5:37 A.M. on March 20, 2021, in the Northern Hemisphere.

On the first day of spring the vernal equinox day and night are each approximately 12 hours long. The Sun crosses the celestial equator going northward; it rises exactly due east and sets exactly due west.

Summer will begin on Sunday, June 20 for places in North America west of the Central Time Zone. This is the summer solstice.

On the first day of summer the summer solstice we have the most daylight of the calendar year.

The Sun reaches its most northern point in the sky at local noon.

After this date, the days start getting "shorter," i.e., the length of daylight starts to decrease. The autumnal equinox begins Wed, September 22, 2021, at 4:02 P.M

Incident Solar Radiation = InSOLATION

Incident solar radiation refers to the amount of energy striking a surface.

On the first day of fall the autumnal equinox day and night are each about 12 hours long. The Sun crosses the celestial equator going southward; it rises exactly due east and sets exactly due west.

Solar Heat Gain is the Amount of energy via radiation and conduction absorbed into a space

Glazing the most common method that heat gain occurs thus the Solar Heat Gain Coefficient is the unit which measures that materials ability of thermal transmittance

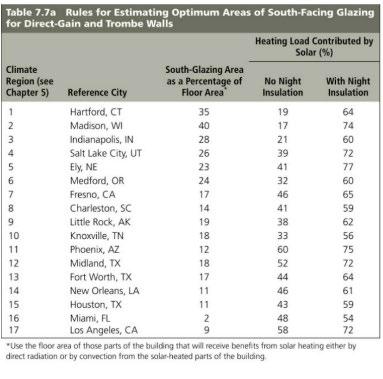

Resources: HCL Table 9.5c Overheated and Underheated Periods

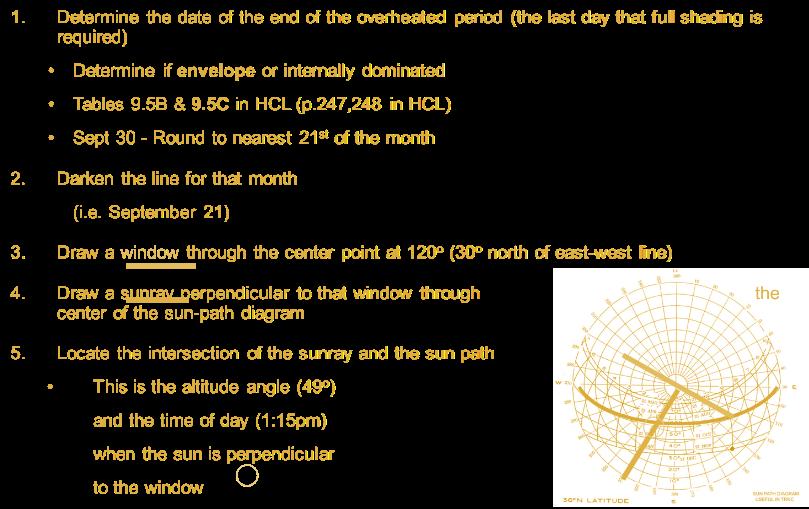

Calculations (Sun Beam Diagrams):

module 5: energy

Review Definitions:

Carbon Neutral: A measure of design that ensures construction and operation of buildings will no longer require the consumption of fossil fuel energy or the emission of greenhouse gases.

Kilowatt kW: is a unit of energy equivalent to one kilowatt (1 kW) of power sustained for one hour.

British Thermal Unit (Btu): a unit used to measure heat. One Btu is about equal to the heat released from burning one kitchen match.

Thermal Mass: material that stores energy, although mass will also retain coolness, The thermal storage capacity of a material is a measure of the material's ability to absorb and store heat.

Thermal mass in passive solar buildings is usually dense material such as brick or concrete masonry, but can also be tile, water, phase change materials, etc.

Indirect Gain: a passive solar system in which the sunlight falls onto thermal mass which is positioned between the glazing and the space to be heated such as a trombe wall.

Passive Solar: design and construction techniques which help a building make use of solar energy by non-mechanical means, as opposed to active solar techniques which use equipment such as roof-top collectors.

Renewable Energy: Power sources that are replenished in a short time. Day after day, the sun shines, the wind blows, and the rivers flow. We use renewable energy sources mainly to make electricity.

Embodied Energy: Power consumed by all of the processes associated with the production of a building, from the mining and processing of natural resources to manufacturing, transport and product delivery.

Benchmarking: Tracking a building’s energy and water use and using a standard metric to compare the building’s performance against past performance and to its peers nationwide.

Non-Renewable Energy: These energy sources are called nonrenewable because their supplies are limited. Petroleum, for example, was formed millions of years ago from the remains of ancient sea plants and animals.

Potential Energy: The power possessed by a body by virtue of its position relative to others, stresses within itself, electric charge, and other factors.

Kinetic Energy: The power that a body possesses when it is brought into motion.

Theories:

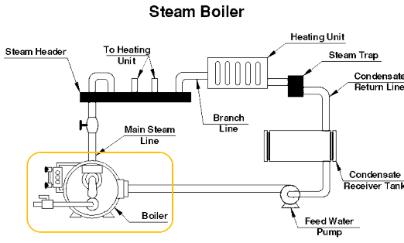

Passive Heating Systems

Direct gain

Sunspace

Indirect gain (Trombe walls)

Convective loop (thermosiphon)

Roof pond

Roof radiation Trap

Direct gain clerestory

Direct gain water wall

Controllable passive Isolated gain

Influences of Direct Gain Orientation Color

Window placement (south facing glazing) Window size & R-value Shading

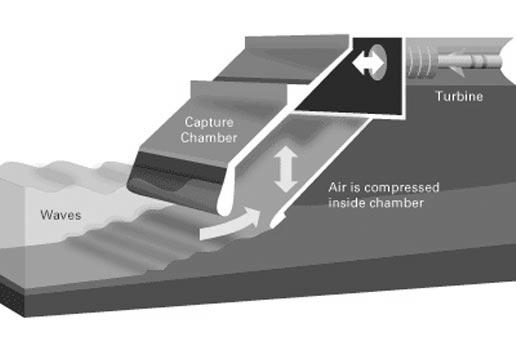

Passive solar –direct access to solar exposure Potential energy is stored energy and the energy of position gravitational energy. Chemical Stored mechanical Gravitational Nuclear Kinetic energy is motion of waves, electrons, atoms, molecules, substances, and objects. Electrical Radiant Thermal Motion Sound Types of Energy Systems Earth Geothermal Heat pump Biomoass Biofuel Uses kinetic energy Wind Turbines Uses kinetic energy Sun Photovoltaic

Solar thermal Uses kinetic energy Water Hydro-electric Ocean Uses potential energy

Calculations: Heat Loss

Heat Loss by Transmission

Units: Btu (HLT) is a function of:

•Area (A)

•Temperature difference between indoors (Ti) and outdoors (To)

•Thermal resistance of the skin (RT); function of time (ft2 Fo / Btu/h)

Formula: HLT = A x (Ti-To) / RT

***OR: HLT = A x U x (Ti-To)****

Heat Loss by Infiltration

(HLI) is a function of:

•Rate of cold air entering building (ACH)

▪Air Changes per Hour

▪Dependent on Construction & Season

▪Winter (0.5, 0.85 or 1.3 – tight, medium, loose modern construction)

▪Summer 70% of the winter values

•Volume (V)

•Temperature difference between indoors (Ti) and outdoors (To)

•The heat capacity of air is a physical constant and is .018 Btu per (°F) (cu. ft.).

Formula = .018 x ACH x V x (Ti-To)

Transmission Heat Loss+ Infiltration Heat Loss = Total Heat Loss

Heat Gain

Solar Heat Gain through Glazing (HGG solar) is a function of: Glazing Area (A), note: subtract frame area as req’d

Unit Solar Heat Gain Factor (SHGF), ASHRAE Handbook of Fundamentals has charts, need date, time, orientation, latitude

Solar Heat Gain Coefficient (SHGC), need glazing type, shading information, table in HCL Formula = AG x SHGF x SHGC

Solar Heat Gain through Wall / Roof Structure (HGO solar) is a function of:

•Area (A)

•Design-Equivalent Temperature Difference (DETD)

•Total Resistance of the wall / roof structure (RT)

Formula = A x U x DETD

**SAME FOR HEAT LOSS**

Total Heat Gain

Formula = 1.3 x (Total Heat Gain from Transmission + Total Heat Gain from Infiltration + (Total Internal Heat Gain x ft²) + Total Solar Heat Gain (includes thermal mass)

Surface Area = lw+2lh+2hw

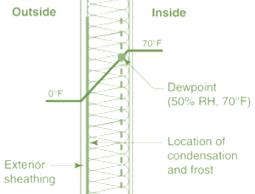

Thermal Gradient

Used to determine if/where the temperature inside the envelope drops below the dew point temperature!

Step 1: Step 2:

Step 3: Step 4: Dew Point:

module 6: wind

Review Definitions:

Photochromics: Materials that can change their transparency in response to light intensity.

Thermochromics: materials that change their transparency in response to temperature

Liquid-crystal glazing: electric charge applied to transparent liquid crystals, making them translucent

Dispersed particle glazing: same as liquid-crystal glazing but can change the transmittance of the material from clear to very dark, excellent for solar control

Electrochromic glazing: most promising material for shading – can change transparency (not translucency) over a wide range

Heat sink: a substance or device that dissipates or absorbs heat, especially unwanted heat

Laminar: Laminar flow tends to occur at lower velocities, below a threshold at which it becomes turbulent.

Turbulent: unsteady vortices appear on many scales and interact with each other. Drag due to boundary layer skin friction increases.

Eddy: swirling of a fluid and the reverse current created when the fluid flows past an obstacle.

Venturi Effect: reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe.

Bernoulli Principle: a principle in hydrodynamics: the pressure in a stream of fluid is reduced as the speed of the flow is increased.

Turbine: A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

Theories

1. Cooling with Ventilation

2. Radiant Cooling

3. Evaporative Cooling

Recall sensible heat / latent heat!!!

When water evaporates, it draws sensible heat from surroundings and converts it into latent heat in the form of water vapor

Conversion causes temperature to drop

4. Earth Cooling

Thermal properties of soil

Wet earth is a good conductor and storer of heat.

Beneath it becomes cooler

5. Dehumidification with a Desiccant

Dehumidification Cooling – 2 methods

a. Cool the air below dew point, water condenses out b. Use a desiccant (drying agent) i.e. silica gel, calcium chloride

Passive cooling is much more dependent on climate than passive heating

Shading is the intentional blockage of solar radiation in order to remove the potential for heat absorption into the building.

-Critical in summer when passive solar heating has potential for overheating

-Reduce demand for energy- intensive air conditioning

Wind is the flow of gases on a large scale. Often it is studied as a fluid (fluid dynamics). On the surface of the Earth, wind consists of the bulk movement of air.

Wind is caused by air currents moving from high to low pressure.

Wind is produced due to uneven heating of the atmosphere by the sun, the rotation, and irregularities of the earth.

-Faster moving air > Less pressure

-Slower moving air > More pressure

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe.

The Bernoulli Principle describes that as the speed of a moving fluid increases, the pressure within the fluid decreases.

the faster air moves, the lower its pressure

Airflow Principles

Inertia: Air tends to move in a straight line. When forced, air streams can follow curves but will not move in right angles

Conservation of air: Air is not created or destroyed on site, and Same amount of air that enters site, leaves site

Stack effect: Exhausts air from a building by natural convection only if indoor temperature difference between the two vertical openings is GREATER than those outside, maximize effect by making openings as large and as far apart as possible Air should flow freely (+) Not dependent on wind (-) Weaker than Bernoulli effect

Best when combined with the Venturi effect (shape of the roof) and the Bernoulli effect (increased wind velocity at roof level)

Ventilation

The introduction of controlled wind from outdoor to indoor space is used to decrease energy consumption, and to improve air quality contributing to mold reduction, particulate/voc decrease, and health.

AIR QUALITY + VENTILATION = ach (air changes per hour)

Ventilation Worksheet

Single-Sided

Stack

Solar heat gain warms a column of air, which then rises, pulling new outside air through the building.

Solar Chimney

Application of the stack effect, solar powered Heat the indoor air above the occupied area of the building to increase air flow

Creates negative air pressure that pulls out warm indoor air and pulls in cooler air at lower levels Night Night cooling refers to the operation of natural ventilation at night in order to purge excess heat and cool the envelope.

Window Orientations and Wind Direction

Winds exert maximum pressure when perpendicular to a surface 50% pressure when 45o to surface, but works well because generate greater wind motion indoors

Winds typically vary in direction (wind rose)

Best orientation for building is along E-W axis (solar) If prevailing winds are E-W, still easier to reroute wind than sun

Inlets and Outlets

Inlets and outlets should be the same size

If not possible, make inlet size smaller to maximize velocity of incoming air

Inlet location determines airflow pattern

module 7: envelope

Review Definitions:

Infiltration: heat loss through joints in the construction, cracks around windows and doors, normal door operation

Transmission: The flow of heat or cold through a building surface.

ACH: ACH is a measure of the air volume added to or removed from a space (normally a room or house) divided by the volume of the space.

Ventilation: Controlled and purposeful form of air exchange.

Summer Heat Gain: similar to heat loss, transmission through walls or windows in winter, except uses summer temperatures, does not take solar radiation into account

Solar Heat Gain: (HGsolar) takes solar radiation into account when calculating skin factors.

Perm: The unit of permeability of a porous material. The mass of water vapor transmitted through a unit area in a unit time under a specified condition of temperature and humidity.

Theories: Envelope ethics

Everything we will go over this week has a foundation from the previous weeks’ worth of passive cooling and heating lessons, CLIMATE lessons, AND the first lesson of R VALUES!!!

-The AIA Research Corporation has identified 17 climate regions (in HCL)

-ASHRAE has also identified several…as you know.

-Each climate region identifies and prioritizes the strategies for greatest conservation of energy, efficiency

Conservation – typically interpreted as a reduction in energy use, a sacrifice, uncomfortable conditions.

Efficiency - thermal comfort can be INCREASED when energy is used efficiently

One of the main ways to achieve this is by tightening the THERMAL ENVELOPE

Four Strategies of Thermal Envelope Design

Winter Defensive – reduce heat loss, reduce temperature swings

Winter Offensive – increase solar heat gain

Summer Defensive – reduce solar heat gain, reduce temperature swings

Summer Offensive – increase cooling strategies, ventilation, evaporative cooling Heat Loss

Three main forms of heat loss from a building

-Transmission

-Infiltration

-Ventilation

Building Shape

Shape – the footprint, the size, the height, the number of floors, the overall configuration of a building; the floor area and surface area

Floor Area – the area inside the thermal envelope

Surface Area – the exterior surfaces that meet the outdoors

Volume – height x width x depth

Thermal Planning of Building Shape

Spaces that require/tolerate cooler temperatures should be located on the north side of a building (bedrooms)

Buffer spaces (garages) should also be on north to block cold wind or on west to protect against heat Occupied spaces in the morning on the east (kitchens, school classrooms)

Area of Building Shape

Reduce Surface Area/Volume Ratio

▪

This idea is correct, but be careful – it assumes the entire envelope (Sa) has the same R-value

▪ Let’s look at examples related to heat loss of walls and roof with different R-values

Recall: HLT = A x U x (Ti-To)

▪ Also referred to as Q = UAΔT, we will use this formula for simplicity

▪ We will consider only transmission heat loss to keep this evaluation as simple as possible…

Calculations for Volume Ratio:

Intents:

Calculations show there are a lot of variables to consider (floor area, surface area, volume, climate, thermal comfort, envelope design, etc.)

In addition, there are also other SIGNIFICANT impacts from building form decisions (shared walls, footprint complexity, ceiling height, roof form, material selection, etc.)

VolumeRatioisjustONEtoolindesign

Note: other factors have a SIGNIFICANT role: Density of occupants (having more efficient ratio or heat loss), consider number of occupants serving

Ratio can affect daylighting, views

Economical trade-offs – i.e. taller buildings require additional structure to resist wind loads, gravity loads, etc.

Sustainable design “tools” at a designer’s disposal – i.e. stack effect, roof area for PVs, etc.

Insulation - Types

1. Batts and Blankets

2. Loose Fill

3. Foamed in Place

4. Boards

5. Air Spaces and Radiant Barriers

Moisture Control

1. Bulk Moisture – liquid water that enters through holes, cracks or gaps; usually rainwater driven by gravity or wind

2. Capillary Action – moves liquid water through porous materials and tiny holes by the surface tension of the water

3. Air Leakage – air carries water vapor through holes and cracks in the building envelope, caused by wind, fans or stack effect

4. Vapor Diffusion – water vapor enters the building envelope driven by a difference in vapor pressure (high to low)

Thermal Gradients

A physical quantity that describes in which direction and at what rate the temperature changes the most rapidly around a particular location.

In architecture, this means the temperatures across a wall, roof, floor are graphed on top of a drawing of the wall, roof, floor, the rate of change of temperature in a given direction A

module 8: lighting

Review Definitions

Luminance = EMITTING light

Illuminance = ARRIVING light

Lumen = amount of ENERGY

Candela = amount of INTENSITY

Daylight Autonomy (symbol DA): Daylight Autonomy (DA) was the first of a string of annual daylight metrics, now commonly referred to as ‘dynamic daylight metrics. It is represented as a percentage of annual daytime hours that a given point in a space is above a specified illumination level.

Ambient Light: general illumination that comes from all directions in a room that has no visible source

The color rendering index (CRI): CRI is an international numbering system from 1 to 100, which is a measure of how well the bulb will render the actual colors of the objects lighted by the lamp.

Sunlight at noon has a CRI of 100, so the higher the CRI the closer it is to natural light. You must use a lamp that has a CRI value of 80 or higher to meet Energy Star requirements.

Light: that portion of the electromagnetic spectrum to which our eyes are visually sensitive

Photometry: measurement of the properties of light (especially luminous intensity)

IESNA: Illuminating Engineering Society of North America, recommended practices and defines light levels and quality of illumination by task and application Task: The work performed

Theories: Solar Studies

Solar Envelope + Solar Access can predict how the sun is acting upon a city, a block, a cluster of buildings, or a building.

Solar access is the site's exposure to the sun during a given period. This exposure enables the utilization of solar properties mainly for radiation, but also for daylighting

The solar path can explain how daylighting and radiation is displaced on the site and building…

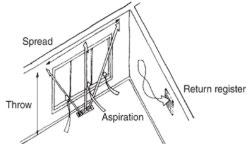

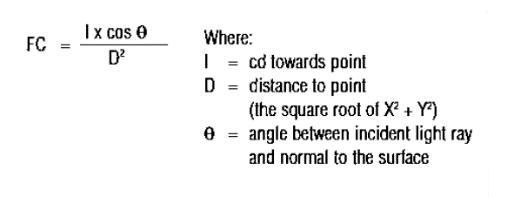

Illumination: FC Footcandles Measure of brightness

Heat: BTU or KWh Measure of energy

Daylighting is the accomplishment of illumination of buildings using natural solar optimization. Daylighting is the controlled admission of natural light; direct sunlight and diffuse skylight into a building to reduce electric lighting and saving energy.

Psychological Impacts

Gender, Age, Mood, Cognitive Performance, Spirituality, Emotion Color temperature of lighting affects participants' mood.

Younger + older adults interpreted different emotional meanings from different lighting colors. Participants in a study by Knez and Kers preserved their negative mood better in the cool light than did the younger participants; Younger participants preserved their negative mood better in warm light than did er participants.

Discomfort Glare is the annoyance or pain caused by high luminance’s in a worker's field of view. Instinctive desire to look away from a bright light source or difficulty in seeing a task. The degree of discomfort glare depends on the size, luminance and number and position of glare sources. The most common causes are windows and luminaires. Increasing Application luminance’s decreases discomfort glare.

Veiling Reflection is the reflection of a large luminance area on a task. This results in a loss of contrast between the task and the Application. Veiling reflections are usually caused by windows or luminaires placed above or in front of the task.

The EYE

-Light enters through an opening called the pupil

-The iris muscle allows the pupil to change in size to accommodate varying light levels; process takes 1 hour

-Light is focused on the light-sensitive lining at the back of the eye called the retina. The retina has:

Cone cells that are sensitive to colors

Rod cells that respond to motion and dim lighting conditions

Rapid and extreme changes in brightness can cause stress and fatigue Daylighting typically changes gradually Fovea – small area in the retina consisting mainly of cone cells, surrounding the center of vision; where eye receives most of information re: detail and color; central 2o cone of vision

Foveal surround – about 30o Peripheral - 130o in the vertical, 180o in the horizontal

When seated, center of vision is 15o below horizontal Perception – the brain’s interpretation of what the eyes see Designers must understand that what is designed / built may not be perceived as expected

Illumination Level

As light levels increase to 50 fc, significant increase in visual performance

Above 100 fc, limited gains with additional illumination

General “rule” – keep illumination at 30 fc, increase for task specific lighting Design guidelines for the task, energy efficiency, biology, and aesthetics

Illumination Level & the Quantity of Light…

Guidelines published by Illuminating Engineering Society of North America (IESNA), referred to in ASHRAE

Hawthorne effect – a decrease in illumination levels can cause an increase in productivity

Illuminance (symbol E) : total luminous flux incident on a surface, per unit area. Luminousfluxor luminous power (lm)

Luminance (symbol L): The intensity of light emitted from a surface per unit area in a given direction. The lumen (symbol lm): is the SI unit of luminous flux, a measure of overall light emitted by a light source or human eye. A lumen is a way of measuring how much light gets to what you want to light.

One lumen ≈ 1 FC on 1sf / 1 CP equivalent ≈ 12.57 lumens

The lux (symbol lx) (Lumens per m2): is the SI unit of illuminance and luminous emittance. It is used in photometry as a measure of the intensity, as perceived by the human eye, of light that hits or passes through a surface 1 lux = 0.0929030436 footcandles

Footcandle (symbol FC or lm/ft2): a unit of illuminance on a surface that is everywhere 1 foot from a point source of 1 candle. Non-SI-unit of measurement.

One footcandle ≈ 10.764 lux One lumen ≈ 1 FC on 1sf

Candlepower (symbol CP): Is luminating power expressed in candelas or candles. A candlepower as a unit of measure is not the same as a foot-candle. A candlepower is a measurement of the light at the source, not at the object you light up.

1 CP equivalent ≈ 12.57 lumens

Light to Solar Gain (LSG) Ratio = VT / SHGC

Ratio of visible light transmittance expressed as dimensionless fraction

→if greater than 1.0 glass transmits more light then heat

→ determines coolness of transmitted

→higher the ratio, the cooler the light

module 9: materials

Textbook Chapters: LEED Materials and Resources Credits

Review Definitions

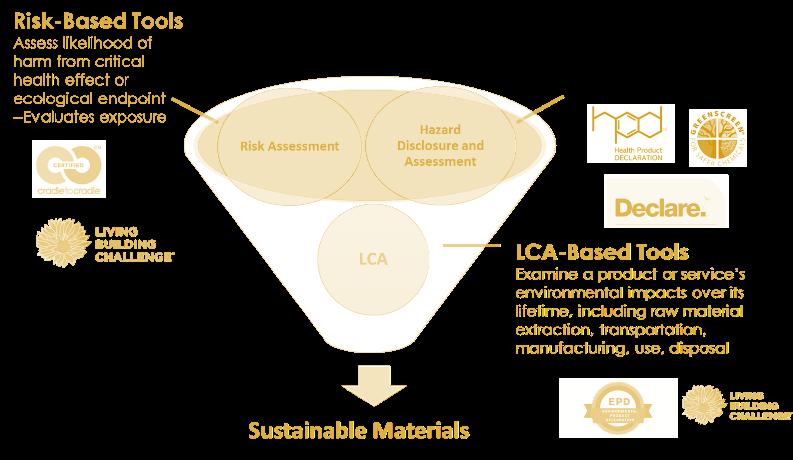

Embodied Energy: Embodied energy = The available energy that was used in the work of making a product. This lifecycle includes raw material extraction, transport, manufacture, assembly, installation, disassembly, deconstruction and/or decomposition.

Life Cycle Assessment: Life Cycle Assessment= 'LCA', also known as 'life cycle analysis‘ is the evaluation of the environmental impacts of a given product caused by its existence. The goal of LCA is to compare the full range of environmental and social damages assignable to products and services.

Life Cycle Cost Analysis: 'LCCA', is used to evaluate the economic performance of a material or building system over the service life of the material or system. Costs associated with purchasing, installing, maintaining and disposing of an item from the time the item is installed in a building through the duration of the LCC study period are analyzed.

Recycling (Post-consumer waste): Waste material generated by households or by commercial, industrial and institutional facilities in their role as end-users of the product, which can no longer be used for its intended purpose.

Recycling (Pre-consumer waste): Material diverted from the waste stream during the manufacturing process. Excluded is reutilization of materials such as rework, regrind or scrap generated in a process and capable of being reclaimed within the same process that generated it.

EPD: A formal document that communicates transparent information about the lifecycle environmental impact of products.

HPD: Formal document that communicates transparent information of the potential chemicals of concern in products by comparing product ingredients to a wide variety of “hazard” lists published by government authorities and scientific associations.

MATERIALS A

CSI Divisions

CSI is the Construction Specifications Institute. This organization is responsible for categorizing building materials into 15 divisions before 2004, and then subsequently 50 divisions of construction information. The platform is called MASTERFORMAT.

Typically, specs are prepared by the architect or designers.

Materials used in the building include items to be recycled, items which are used in the building, and the health and sustainability of those items as they interact with people

Activities indoors and Climate outdoors are a key feature in determining WHERE the building’s THERMAL COMFORT ZONE will appear on a psychrometric chart!

DETAILS ON LCA

Eutrophication potential (EP) is the collective quantification of nutrients (phosphorus and nitrogen) present in the inland waterways through conversion into phosphorus equivalents.

Acidification Potential (AP) is also known as ACID RAIN. soils and waters are contaminated predominantly through the transformation of air pollutants into acids which have the potential to decrease PH values of rainwater and impact both natural and built environments through degradation.

Global Warming Potential – (GWP) is also known as "Greenhouse Effect/ Carbon Footprint".

The mechanism of the greenhouse effect can be observed on a small scale, as the name suggests, in a greenhouse. These effects are also occurring on a global scale.

Embodied energy is the energy consumed by all of the processes associated with the production of a building, from the mining and processing of natural resources to manufacturing, transport and product delivery.

Embodied Energy vs. Carbon

Embodied Carbon is a better measure of how much ‘goes into’ a material than Energy.

It reflects what really matters, environmentally: the amount of carbon being released into the atmosphere. It’s normally expressed as tons of CO2e that is, of CO2 and its equivalents.

Reducing the amount of energy, it takes to operate a finished building is important.

But the energy embodied in a building can be as much as 50% of the energy used to operate a building in its first 50 years. And as the amount of energy needed to operate

buildings decreases, thanks to improvements in materials and systems, the relative importance of embodied energy will only increase.

Material Health

Materials used in the building include items to be recycled, items which are used in the building, and the impact of those items as they interact with people.

Materials

Natural: Clay, Concrete, Cement, Rock, Mineral, Sand, Wood-based materials

Synthetic: Fabric, Foam, Glass, Metal, Plastic, Adhesive, Paint, Caulking, Adhesives, Coatings the aim of the Cradle to CradleTM Certified Material Health Assessment Methodology is to characterize the hazards of chemicals present in a material and generate material assessment ratings based on those hazards and routes of exposure during manufacturing, application, and end-of-use.

Hazard = the inherent property of a substance having the potential to cause adverse effects when an organism, system or (sub) population is exposed.

Risk = the probability of an adverse effect in an organism, system or (sub) population caused under specified circumstances by exposure to a substance.

LCA may overlook Hazard and Risk

• LCA assess different impacts than intrinsic hazard (carbon, acidification, eutrophication)

• Toxicity impacts in LCA are not based on inherent hazard, but rather emissions

An EPD® (EnvironmentalProductDeclaration) is a verified and registered document that communicates transparent and comparable information about the life-cycle environmental impact of products.

MATERIALS B

Standard LEED Material Calcs

The Materials and Resources (MR) credit category focuses on minimizing the embodied energy and other impacts associated with the extraction, processing, transport, maintenance, and disposal of building materials. The requirements are designed to support a life-cycle approach that improves performance and promotes resource efficiency.

Each requirement identifies a specific action that fits into the larger context of a life-cycle approach to embodied impact reduction.

CONSTRUCTION WASTE

Establish waste diversion goals for the project by identifying at least five materials (both structural and nonstructural) targeted for diversion. approximate a percentage of the overall project waste that these materials represent.

Specify whether materials will be separated or commingled and Describe the diversion strategies planned for the project. Describe where the materials will be taken and how the recycling facility will process the material.

Provide a final report detailing all major waste streams generated, including disposal and diversion rates

LIFE CYCLE IMPACT REDUCTION

Demonstrate reduced environmental effects during initial project decision-making by reusing existing building resources or demonstrating a reduction in materials use through life-cycle assessment.

CONSTRUCTION WASTE

LIFE CYCLE IMPACT REDUCTION

Achieve one of the following options: historic building reuse

renovation of abandoned or blighted building building and material reuse whole-building life-cycle assessment

Raw material source and extraction reporting

Use different manufacturers that have publicly released a report from their raw material suppliers which include raw material supplier extraction locations, a commitment to long-term ecologically responsible land use, a commitment to reducing environmental harms from extraction and/or manufacturing processes, and a commitment to meeting applicable standards or programs voluntarily that address responsible sourcing criteria.

RAW = the basic substance from which products are made, such as concrete, glass, gypsum, masonry, metals, recycled materials (e.g., plastics and metals), oil (petroleum, polylactic acid), stone, agrifiber, bamboo, and wood

Building product disclosure and optimization – sourcing of raw materials

Bio-based materials. Bio-based products must meet the Sustainable Agriculture Network’s Sustainable Agriculture Standard.

Wood products. Wood products must be certified by the Forest Stewardship Council or USGBCapproved equivalent. Products meeting wood products criteria are valued at 100% of their cost for the purposes of credit achievement calculation.

Materials reuse. Reuse includes salvaged, refurbished, or reused products. Products meeting materials reuse criteria are valued at 100% of their cost for the purposes of credit achievement calculation.

Recycled content. Recycled content is the sum of postconsumer recycled content plus onehalf the preconsumer recycled content, based on cost. Products meeting recycled content criteria are valued at 100% of their cost for the purposes of credit achievement calculation.

USGBC approved program. Other USGBC approved programs meeting leadership extraction criteria.

Material ingredient reporting

Use at least 20 different permanently installed products from at least five different manufacturers that use any of the following programs to demonstrate the chemical inventory of the product to at least 0.1% (1000 ppm).

Manufacturer Inventory.

Health Product Declaration.

Cradle to Cradle.

The end use product has been certified at the Cradle to Cradle v2 Basic level or Cradle to Cradle v3 Bronze level.

USGBC approved program

Diversion

Path 1. divert 50% and three material streams

Divert at least 50% of the total construction and demolition material; diverted materials must include at least three material streams.

Path 2. divert 75% and four material streams

Divert at least 75% of the total construction and demolition material; diverted materials must include at least four material streams.

Option 2. reduction of total waste material

Do not generate more than 2.5 pounds of construction waste per square foot (12.2 kilograms of waste per square meter) of the building's floor area.

module 10: site

Textbook Chapters: HCL Ch. 10

Review Definitions

Monoculture: Agricultural practice of producing or growing a single crop, plant, or livestock species, variety, or breed in a field or farming system at a time. Monoculture farming relies heavily on chemical inputs such as synthetic fertilizers and pesticides.

Low Impact Development LID: Construction techniques to manage and conserve stormwater on site. This method – rapidly being adopted in all regions of this country - is helping communities reduce the impact of the constructed environment on the surrounding natural resources.

Greenfield: Land that has never been developed; virgin land but is being developed my commercial or institutional purposes.

Brownfield: Land that is contaminated with hazardous or chemical ingredients.

Xeriscaping: The conservation of water through creative landscaping which also mimics the natural ecosystem.

Albedo: A measure of the ability of a surface material to reflect light. The scale ranges from 1100 typically.

Stormwater: Water that originates during precipitation events and snow/ice melt and will infiltrate the soil. In instances of hardscape, the water will evaporate, pond, run into the existing ecosystem and / or end up in nearby streams, rivers, or other water bodies.

Bioremediation: Using microorganisms or vegetation to remove contaminants from water and soils. This is a form of in-situ remediation.

Low impact, analysis, and the Strategies of site design

Low-Impact Development strives to minimize the human impact on the ecosystem. It begins with a decision on where to develop and continues up to methods of construction.

Pre-developed – Infill – Urban or otherwise; Renovation, Redevelopment, Brownfield

Construct or renovate a building on a site that is located on a previously developed site within a dense neighborhood with pedestrian access.

Greenfield – Virgin Land

A greenfield site is a virgin site with an ecosystem in tact. Other definitions which include legal greenfield site designations: Prime farmland, Flood Plan land, Endangered species land, Wetland, National Park land

Low Impact Development: Transit

Transport systems have significant impacts on the environment, accounting for between 20% and 25% of world energy consumption and carbon dioxide emissions.

Site should include development in locations shown to have multimodal transportation choices or otherwise reduced motor vehicle use, thereby reducing greenhouse gas emissions, air pollution, and other environmental and public health harms associated with motor vehicle use

Low Impact Development: Stormwater

New York State experienced 1,280 beach closure or advisory days in 2006, many due to the combined sewer overflow systems being overwhelmed by stormwater runoff.

Low Impact Development: Landscape

Conserve existing natural areas and restore damaged areas to provide habitat and promote biodiversity. Employ strategies, materials and landscaping techniques that reduce the heat

absorption of exterior materials. Heat Island | Indigenous / adaptive foliage | Reduce hardscape

Certain methods of landscaping can improve the retention of natural ecosystems in the microclimate while creating a natural infiltration – synergizing with stormwater mitigation, habitat preservation and water conservation.

Low Impact Development: Transit, Stormwater, Landscape

Low-Impact Development strives to minimize the human impact on the ecosystem. It begins with a decision on where to develop and continues up to methods of construction.

Prevent loss of soil during construction by stormwater runoff and/or wind erosion, including protecting topsoil by stockpiling for reuse.

Prevent sedimentation of storm sewers or receiving streams.

Prevent pollution of the air with dust and particulate matter.

Research

Research involves two basic ideas: Questioning the site and compiling the relevant information about the site. These are the basic questions one needs to ask when looking at a site, be it in person or otherwise. We ask ’What is There’?

-Site Survey; Topography, Circulation, Boundaries, Utilities-Site Services, Zoning Setbacks & Regulations, Scaled -Tax Map -Street Map

Synthesis

Selective inclusion Unnecessary Findings (don’t use these), Impactful Findings (use these), Constraints, Opportunities

Data: Photo montage of site, Integration of the critical elements of Research and Documentation.

Conclusions: Diagrams of integration of data (Research and Documentation) in a professional manner.

1-Research – Site Visit

2-Documentation – Climate Consultant + Zoning

3- Analysis

4-Synthesis

Low Impact Development: SITE DESIGN

Prioritize; identify and maximize synergies (i.e., south facing glass – daylighting, passive heating, air quality, ventilation, cooling, acoustics, circulation, vegetation…)

SITE SELECTION: Regarding heating and cooling: building type and climate play MAJOR roles in where best to locate a building on a slope

• Internally dominated buildings can be on north sides of the slopes

• Envelope dominated should be placed according to heating/cooling strategies prioritized by climate region

•

Tier 1 – Basic Building / Site Design

• Orientation - Design using solar window analysis, the part of the sky dome through which useful solar energy passes

• Shadow pattern is a composite of all shadows case during winter hours when access is most valuable.

• 9am-3 more than 80% of a winter’s radiation will fall on building.

• Form - The form of the site, including topography, affects wind speed and direction…. …also, solar access, heat gain and shading opportunities, drainage, + acoustics

• SOLAR ACCESS boundary determines how high objects can be before they obstruct the sun. Best when designing single building.

• Vegetation - In areas where wind is desired to foster ventilation, low vegetation, if any, used in airflow path OR use vegetation design to increase air flow. The higher the windbreak, the longer the wind shadow, also dependent on porosity

• Tier 2 – Passive Design Strategies

• Passive Heating & Daylighting

• Passive Cooling module 11: water

Textbook Chapters: GSH Ch. 4 Water & Waste

Review Definitions:

Potable: Water that is drinkable. This type of water requires a high standard of filtration and chemical purification from its source for human consumption.

Stormwater: Water that originates during precipitation and the melting of snow. It infiltrates into the soil or is held on the surface and evaporates or runs off asphalt or hardscape and may end up in nearby streams, rivers, or other water bodies.

Blackwater: Any type of water after kitchen or toilet use. This type of water requires specific filtration processes to achieve a standard of human contact again.

Graywater: Generally clean waste from lavatories, baths, sinks, washing machines and has not come in contact with fecal matter. IT is easy to treat and reuse onsite for toilet flushing, landscape or crop irrigation, and other non-potable uses.

Aquifer: An aquifer is a body of saturated or permeable rock – typically beneath the ground - through which water can easily move. If the amount of water put into the aquifer (recharge) is higher than the amount taken out of the aquifer (discharge), level goes up. If the opposite occurs, water goes down.

Effluent: Treated or untreated wastewater that flows out of a treatment plant, sewer, industrial outfall –commonly referred to as water pollution, it generally refers to waste discharged into surface waters.

Influent: the water that enters the recycling process

Primary: physical process removes some organic matter and suspended solids

Secondary: biological process removes residual organic matter and some suspended solids by microorganisms

Tertiary: physical, biological and/or chemical processes to further remove suspended and dissolved material

Net zero water is like net zero energy; to become self-sufficient as a building. However, without the two parts of passive and renewable.

Through a combination of rainfall harvesting, aggressive conservation, and water recycling, buildings can achieve self-sufficiency from the water “grid.”

Scarcity: Global + Local

1- SURFACE – watershed. - Typically, from surface water sources, such as lakes, rivers, and reservoirs. The watershed is the land area over which water flows into the river, lake, or reservoir.

2- 2- GROUND – aquifers. - In rural areas, people are more likely to drink ground water that was pumped from a well. These wells tap into aquifers the natural reservoirs under the earth's surface that may be only a few miles wide or may span the borders of many states.

Deliberate disposal of waste at point sources such as landfills, septic tanks, injection wells and storm drain wells can have an impact on the quality of ground water in an aquifer.

Pollution: Types + sources

1. DIRECTLY: In developing countries, 70 percent of industrial wastes are dumped untreated into waters, polluting the usable water supply.

2. INDIRECTLY: On average, 99 million pounds (45 million kilograms) of fertilizers and chemicals are used each year.

Consumption: Indoor + Outdoor

There are many types of water. Blackwater, graywater, condensate, rainwater, and potable water. Each has a function in the water cycle, and each one besides POTABLE water may be mitigated to improve the environment and the discharge rate in aquifers or watersheds.

Tiers: Water

As a resource – Tier1

As a passive system component – Tier2

As a generator of electricity – related to Tiers 2 & 3, Tier 2 –includes passive design to avoid use of purchased energy.

Tier 3 includes active designs that use purchased energy, purchased energy can be renewable…

Issues with Water

Unmanaged surface water can have a negative impact on indoor environmental quality Mold –intrusion of water or water vapor; from rainwater, surface water that finds its way into buildings

What designers can do…

Prevent flow of water toward and into the building, provide surfaces that allow water to percolate into the soil rather than flow toward a building -Grade the site away from the building, install foundation drainage system, Install exterior waterproofing system

How do we engage water in design?

OUTDOOR Storm water

Design should protect bodies of water and wetlands, mitigate negative environmental effects of SW runoff, Design should protect inhabitants from negative effects of unwanted water

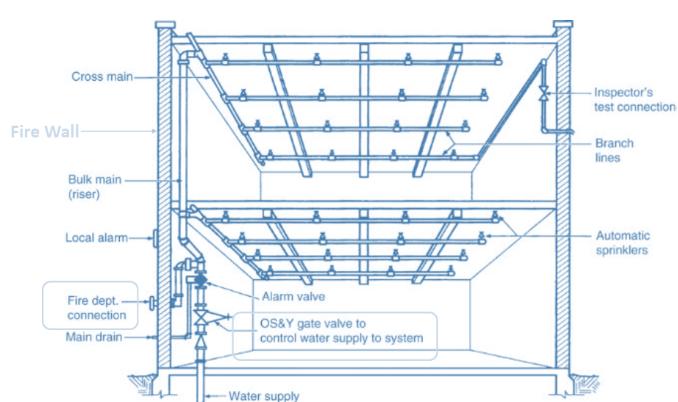

INDOOR Consume

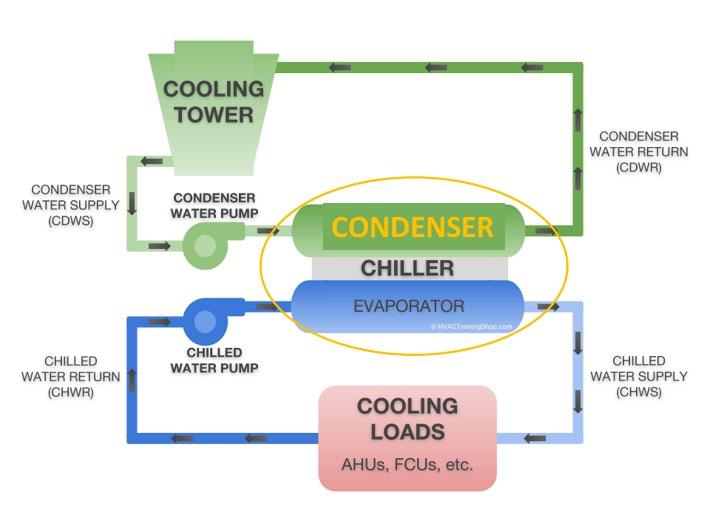

Building - Human consumption (bathing, drinking, elimination), Fire suppression, Active systems heating and cooling

Consideration of where stormwater goes is critical to limit disruption of natural hydrology. Several ways can be implemented in building design….

Reducing impervious cover,

Increasing on-site infiltration,

Reducing or eliminating pollution from stormwater runoff and eliminating contaminants.

Reuse stormwater for non-potable use.

Design the project site to maintain natural stormwater flows by promoting infiltration.

Specify vegetated roofs, pervious paving, indigenous foliage other measures to minimize impervious surfaces.

HOW?

Keep hot water heated inside thermal envelope

Keep distribution piping inside thermal envelope; insulated or will affect thermal cooling

Minimize distribution piping (point of use); innovative technologies discussed in Enviro 2

Three main ways water contributes to passive design:

Used in passive heating and cooling design (review)

Used in building design passive systems to conserve potable water (conserve supply, not using potable water when don’t need to)

Used in site design passive systems for quality and quantity control (protecting the existing potable water supply – quantity and quality)

Composting Toilets - Two types of composting toilet systems:

•

Self-contained toilets ▪

More labor intensive, utilizing relatively small pans or trays for removal of the humus ▪

Minimal smell, area sealed except when needed

• Centralized units with a destination catchment area

▪

Need only infrequent attention, once or twice a year, regular maintenance

▪

Available in Batch or Continuous Systems

• Batch – uses a compost receptacle that is emptied when container reaches capacity, not yet humus

• Continuous – rely on raking and removal of finished humus

Rainwater Harvesting – the collection of rainwater for potable and non-potable uses, irrigation, laundry, and passive cooling

• Smaller systems collect roof runoff for domestic uses; most frequent for watering the landscape (simple) and toilet flushing (more complex)

• Larger systems use landforms as catchment areas (discussed later re: sites) to increase quality and reduce quantity and can provide supplemental irrigation for agriculture.

Water reuse / recycling strategies depend on an evaluation of the degree of potability the water will need to obtain, i.e. toilet flushing water is non-potable; water for cooking is potable

Greywater – wastewater from lavatories, showers, washing machines that does not include food or human waste

Blackwater – wastewater that contains food and/or human waste

▪

Greywater has less nitrogen and fewer pathogens and degrades faster than blackwater, more economical strategy for recycling / reuse ▪

Recycling / Reusing greywater on site: ▪

Reduces load on sewage / septic system ▪

Lower a building’s contribution to energy use ▪

Create new landscaping opportunities ▪

Depends on how much potable water is used on site that can be recycled & how much demand there is for recycled greywater to be reused or recycled

Ecological Sewage Treatment – an engineered waste treatment system designed to process a building’s sanitary drainage on site by using wetlands; The Living Machine is an example

▪

A series of anaerobic and aerobic tanks house bacteria that consume pathogens, carbon and other nutrients in the wastewater, making it safe to use for reuse/recycling

Hydroponic, most common, relies on bacteria, plants and an overflow wetland

Blackwater reused (recycled) as greywater

Site Catchment Systems

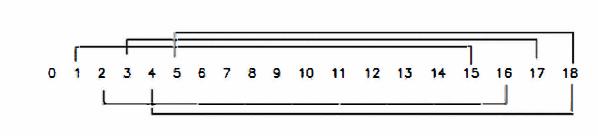

Pervious surfaces – ground covers (softscape or hardscape) that allow rainwater to infiltrate and reach subsurface layers ▪

(+) lessen stormwater runoff ▪

(+) reduce the flow of pollutants from a site ▪

Many systems: ▪

Plastic Grid Systems ▪

Porous (open graded) asphalt pavement ▪

Porous block pavement systems ▪

Porous Portland cement concrete ▪

Bioswales / Biofilters - densely vegetated open channels designed to attenuate and treat stormwater runoff

Swales have gentle slopes at allow runoff to be filtered by vegetation planted on the bottom and sides

Not designed to hold water for an extended period of time

1. Grass Channels - like conventional drainage ditches but with wide flattened sides, providing greater surface area to slow runoff; provides preliminary treatment of water prior to flowing into another stormwater management component

▪

2. Dry Swales - like a detention pond, have water holding capacity and permit water to flow at the bottom of the swale but are designed to have a relatively dry, grassy top; have a fabric wrapped soil base with a perforated pipe to facilitate water movement

3. Wet Swales - essentially long, linear wetlands designed to temporarily store water in a shallow pool; treats water by allowing a slow settling of particles, the infiltration of water and bioremediation of pollutants

Biofilters – like bioswales but in a contained area, box

Retention Ponds - designed to control stormwater runoff on a site and in some cases remove pollutants from the retained water:

Strategies include Ditches, swales, ponds, tanks, vaults- Capture, store, treat and then slowly release stormwater downstream or allow it to infiltrate into the ground

Infiltration Pond – a retention pond that acts as a final storage destination for runoff, water evaporates or infiltrates (no drain)

Detention Pond – a retention pond that is designed to temporarily store the accumulated water before it slowly drains off downstream (has a drain)

Calculations:

Stormwater Reclamation

1. Calculate your daily per capita water consumption for your facility

• How many people will use your building and for how long?

• Are you trying to offset potable water for toilets, lavs and showers? Calculate all of them!

2. Calculate annual water needs by multiplying daily by 365 days per year, or other times/schedules of the operation of the building

3. Determine available rainfall for the building site

• Data available from government source annual summaries http://www.usclimatedata.com/climate/united-states/us

• Assume a dry year (2/3 of average precipitation)

4. Determine required HORIZONTAL catchment area

If you need 50,000 gallons per year and your location provides 30” of rainfall per year (assume a dry year will produce 2/3 of this).

Look at the 20” diagonal line (2/3 of which is 20”) and see where it intersects with the 50,000 gallons catchment yield line – answer is 5,700 sf of HORIZONTAL area.

Or you may do the reverse and find the yield of catchment area in gallons based upon your annual precip and horizontal catchment area.

5. Calculate the cistern capacity

• Assume a storage capacity equal to ¼ annual water needs.* (1/4) x (50,000 gallons)

• In our example: 50,000 gallons per year x .25 = 12,500 gallons

• Assume a storage capacity equal to ¼ annual water.

6. Calculate the volume

• Assess the volume – use the formula

• So using 12,500 gallons

1ft3 = 7.48 gallons - So, our cistern should be 1,671 ft3

7. Design the cistern! Use your creativity (underground won’t freeze as fast in colder climates)

Design a 1,671 ft3 cistern

module 12: synergies

Textbook Chapters: HCL Ch. 19,22 GSH Ch. 5

What is Catholic Social Teaching?

It is a formula or a set of principles for reflection to evaluate the framework of society and to provide criteria for prudential judgment and direction for current policy and action.

The Church's social teaching is a rich treasure of wisdom about building a just society and living lives of holiness amidst the challenges of modern society.

sustainable design encounters the challenge of modern society.

SUSTAINABLE STRATEGY:

A sustainable strategy is one component of a building design which contributes towards a larger goal of reducing the environmental impact on a building; A method, technique, or technology that is used decrease the environmental impact of a building.

-Tilt up Panels, Solar Shading, Geothermal, etc.

SUSTAINABLE SYNERGY:

Multiple sustainable strategies realize as symbiotic components of a sustainable system (if one strategy were to be removed the strength of the design would be compromised).

BUNDLES – SWL Part IV reading

Charrettes are popular with architects, planners, designers and developers as the intensive nature of the process means results are achieved quickly.

SYMBOLS - Examples of universal symbols designating environmental systems. There are many more….

module 13: tools

Textbook Chapters: HCL Ch. 21 Codes + 24 Digital | HCL Ch. 20 IDP + 23 Assessment

In 2012, 60 buildings or projects were zero energy or were Emerging to that level.

In 2018, 482 buildings or projects are zero energy or Emerging to that level.

Energy Codes are not static documents. They are constantly under revision to improve energy efficiency in buildings….new is the ZERO CODE!

ZERO Code is a national / international building energy standard for new building construction that integrates cost-effective energy efficiency standards with on-site and/or off-site renewable energy and results in zero net carbon buildings.

IECC addresses design of energy-efficient building envelopes

3 options to meet: ASHRAE 90.1, Prescriptive set of requirements and Performance Requirements)

EPA Portfolio Manager (PM) Tracks energy and water consumption and greenhouse gas emissions

40% of commercial buildings in the US use this as benchmarking software.

Comcheck/Rescheck helps check compliance with Sustainability Codes.

Performance and Sustainability Trends

Passive Design will receive increasing focus

• The common thread is a renewed focus on passive design principles among them, efficient envelopes, daylighting, and natural ventilation paired with rigorous analytics to identify the most effective strategies and ensure human comfort as well as low energy use.

Firms will push to implement integrative design

BUILDING PERFORMANCE ANALYTICS

BIM sustainability tools used in an iterative process of evaluating the passive impact of various environmental factors on a building’s performance prior to engaging formal energy modeling.

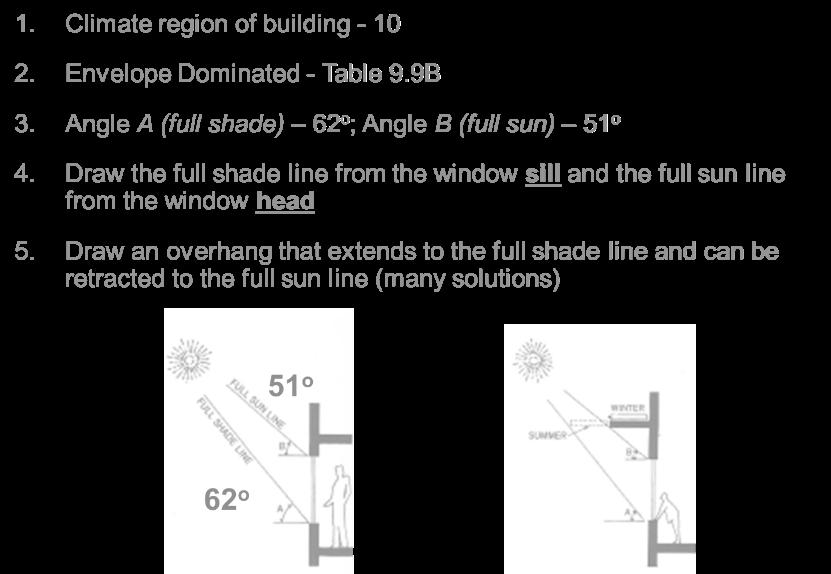

SHADING – BASIC METHOD

DESIGN GUIDELINE METHOD

1. Determine the climate region of building

2. Refer to Table 9.9A or 9.9B to determine angle A (full shade) and Angle B (full sun)

3. Draw the full shade line from the windowsill and the full sun line from the window head

4. Draw an overhang that extends to the full shade line and can be retracted to the full sun line (many solutions)

APPLICATION

Sefaira, IESVE, AUTODESK FORM-IT (SOLAR ANALYSIS), ECOTECT TRANSMISSION HEAT LOSS INFLITRATION HEAT LOSS

TOTAL HEAT LOSS

APPLICATION – FORM- IT (Energy Analysis) THERMAL GRADIENT -

APPLICATION –WUFI® is an acronym for Wärme Und Feuchte Instationär which, translated, means heat and moisture transiency.

RAINWATER HARVESTING

APPLICATION – Sefaira, Sustainable Technologies

PASSIVE COOLING – NATURAL VENTILATION

Autodesk CFD (ventilation contributes to energy reduction), Sefaira (ventilation contributes to energy reduction), Autodesk Form-it (Flow Design), Simulation CFD, WinAir, IESVE – Microflow / Macroflow

DAYLIGHTING

APPLICATION – Sefaira, IESVE, Climate Studio, Ecotect

Using

specificBIMBuildingPerformanceAnalyticalToolsas you design into whole building synergies will help to achieve that goal.

As architects, we have an obligation to integrate ETHICSandMETRICS symbiotically into a holistic sustainable design process.

module 14: assessments

Green assessment systems require an integrated design process to create projects that are environmentally responsible and resource-efficient throughout a building's life-cycle: from siting to design, construction, operation, maintenance, renovation, and demolition.

Green CODE

Green building codes continue to be developed and adopted in the U.S. and abroad that seek to push the standard of building design and construction to new levels of sustainability and performance.

A Prescriptive path is a fast, definitive, and conservative approach to code compliance. Materials and equipment must meet a certain level of stringency, which are quantified in tables.

Performance-based codes are designed to achieve particular results, rather than meeting prescribed requirements for individual building components.

Outcome-based codes for example, establish a target energy use level and provide for measurement and reporting of energy use to assure that the completed building performs at the established level.

What is Assessment?

During a building’s life, there is extensive direct and indirect impact on the environment. During construction, occupancy, renovation, repurposing, and demolition, buildings use energy, water, and raw materials, generate waste, and emit potentially harmful atmospheric e missions.

These facts have prompted the creation of green building standards, certifications, and rating systems (assessments) aimed at mitigating the impact of buildings on the natural environment through sustainable design.

Benefits of Sustainable Design

There are a wide range of economic and environmental benefits to sustainable design, often achieved through the use of standards, rating, and certification systems.

According to a study of LEED certified buildings, the USGBC has found that energy, carbon, water, and waste can be reduced, resulting in savings of 30 to 97% respectively.

Operating costs of green buildings can also be reduced by 8-9% while increasing in value up to 7.5%.

Many sustainable buildings have also seen increases of up to 6.6% on return on investment, 3.5% increases in occupancy, and rent increases of 3%.

Other benefits of green buildings, such as higher productivity and increased occupant health, have been attributed to better indoor environmental quality, increases in natural daylighting, and healthier materials and products within green buildings.

STRATEGY: A sustainable strategy is one component of a building design which contributes towards a larger goal of reducing the environmental impact on a building.

SYNERGY: A synergy is an integration of sustainable strategies which have a positive symbiotic performance to reduce the environmental impact of a building.

-Building Performance Analytics

The process of evaluating the passive impact of various environmental factors on a building’s performance using a sequence of building information modeling (BIM) tools prior to engaging formal energy modeling.

Assessments

WELL measures attributes of buildings that impact occupant health by looking at seven factors, or Concepts. Air, Water, Nourishment, Light, Fitness, Comfort, Mind

Performance Excellence in Electricity Renewal™ (PEER) program. PEER is the nation’s first comprehensive, consumer-centric, data-driven system for evaluating power system performance and is modeled after LEED.