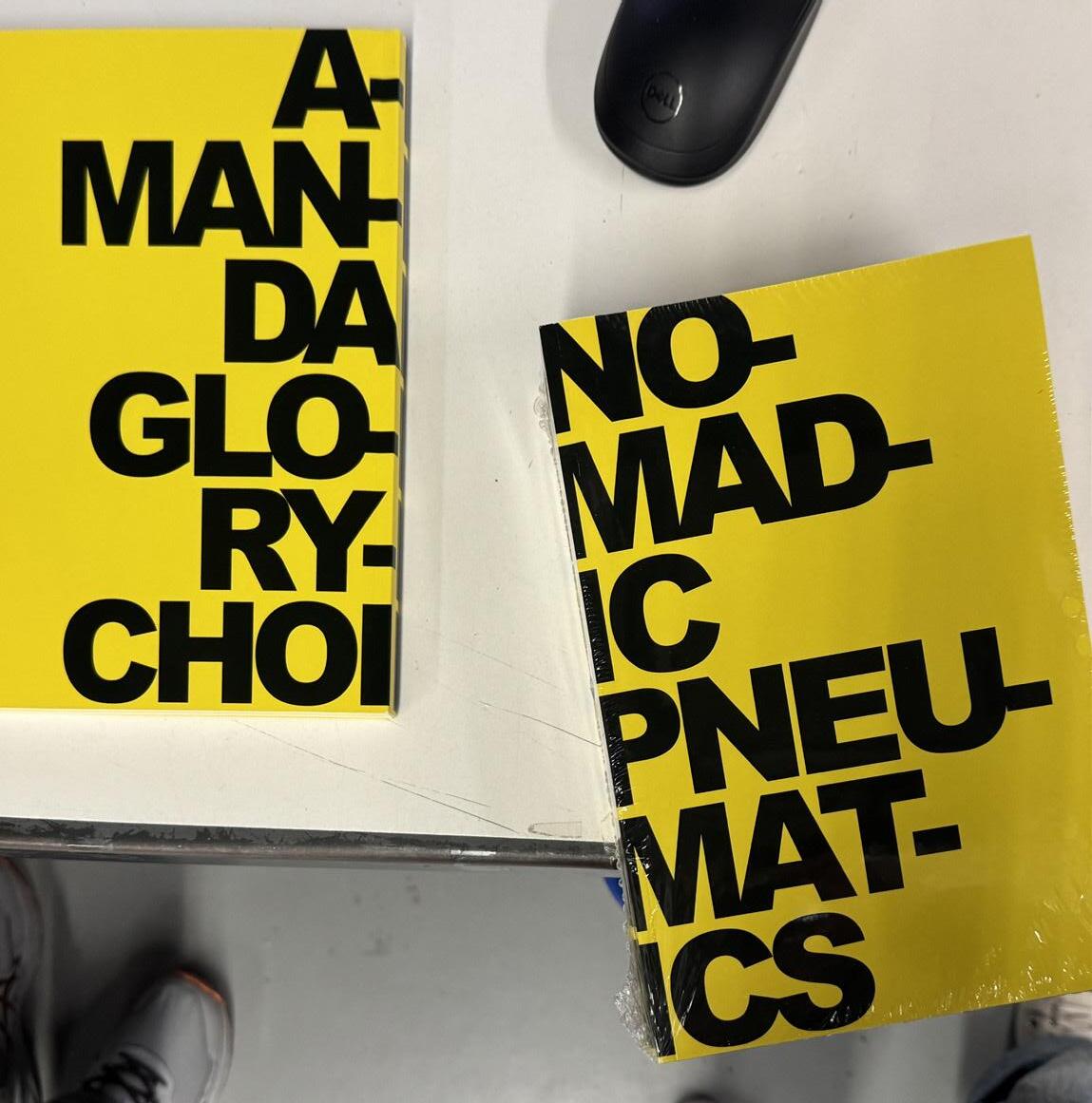

NOMADIC PNEUMATICS

Architecture that moves with you

Amanda Choi

Nomadic Pneumatics

B.Arch Thesis Spring 2025

Amanda Choi

Advisors: Ekin Erar + Martin Miller

Cornell University

May 2025

© 2025 by Amanda Choi

All Rights Reserved.

Printed in the United States of America.

No part of this publication may be reproduced, stored, or transmitted without permission, except for brief excerpts used for academic or critical purposes.

Acknowledgements:

To the ones who made room for my wild ideas, and stayed long enough to see them take shape—thank you.

To my brilliant and inspiring advisors, Ekin and Martin, who pushed me to think harder, design better, and stay grounded through it all—thank you. It has been an honor to learn from you. Your intelligence, insight, and belief in my work gave it structure and strength.

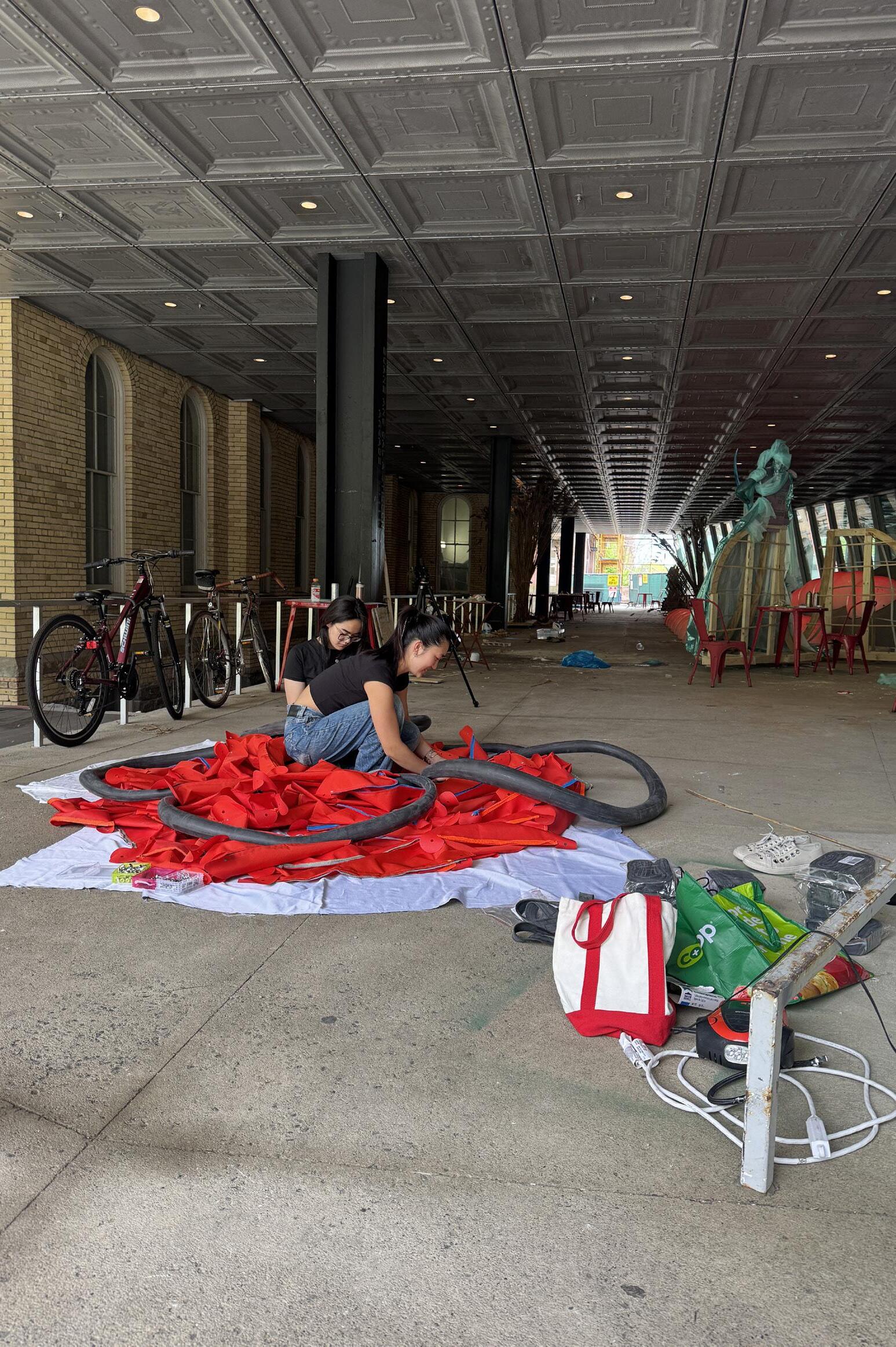

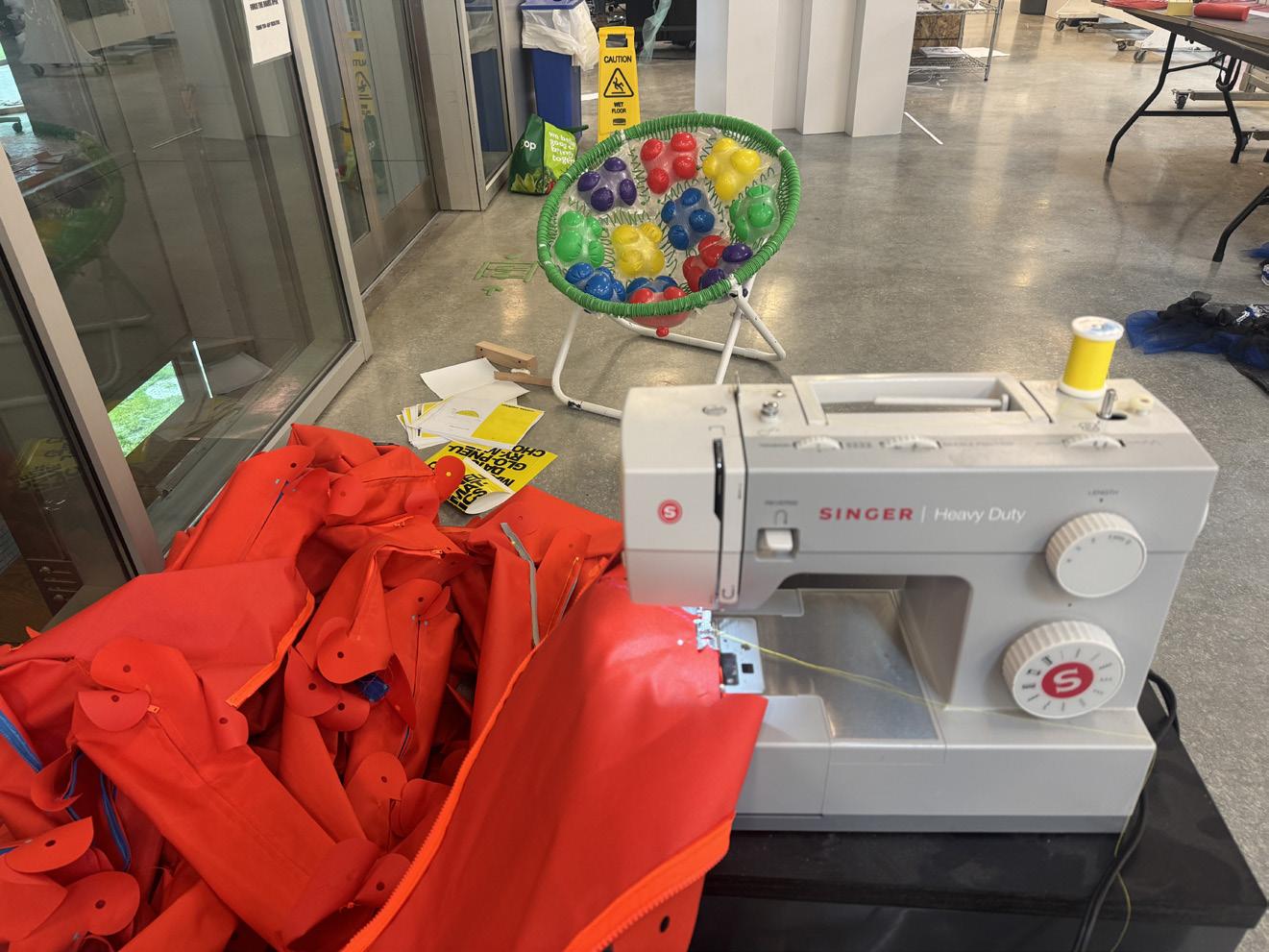

To my incredible thesis helper, Lillian Casazza, who cared for every seam as if it were her own and matched my passion at every turn—your presence, skill, and energy made all the difference.

Pressure is a privilege, and I’m proud to have been challenged and uplifted by a community of architects, educators, students, friends, and family who continue to shape the way I see, think, design, and build.

chapter one-

PROBLEM + OPPORTUNITY

Inflatable architecture has long been dismissed as temporary, inefficient, and wasteful, often requiring continuous air input to maintain form.

Nomadic Pneumatics challenges these limitations by proposing a shift toward pneumatic architecture — a system where pressurized inner tubes create durable, mobile, and reusable structures without constant inflation.

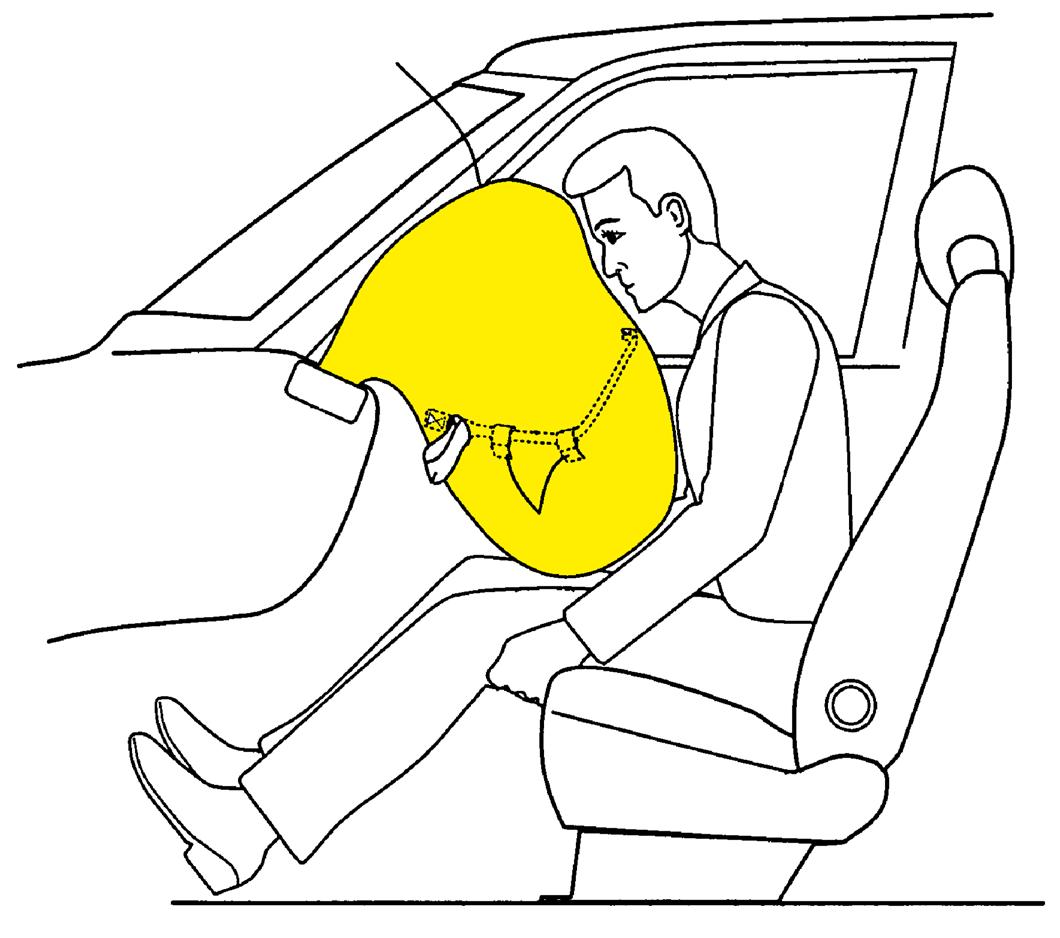

By drawing from industrial pneumatics in transportation, aerospace, and safety systems, this research investigates how pneumatic structures can store and redistribute pressure to form self-supporting, lightweight, and deployable architectural solutions.

By exploring air pressure as a structural force, this thesis examines how pneumatic systems— capable of holding high PSI, like tires, airbags, and hydraulic bladders—can be reconfigured to create scalable, adaptable enclosures.

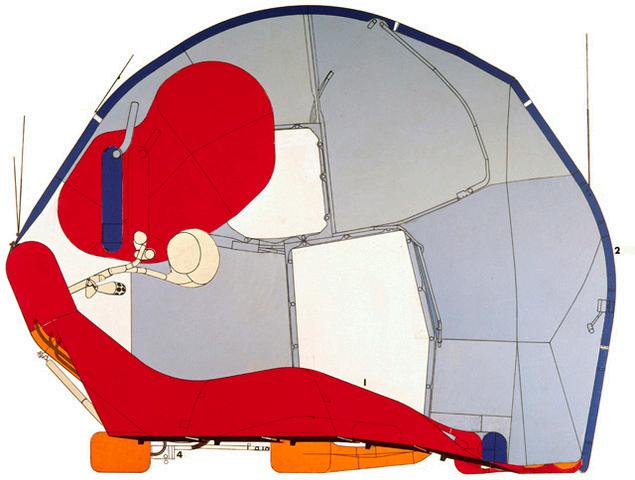

Author: Michael Webb | Archigram

Year: 1967

Function: Individual Housing

Unlike site-specific, rigid materials such as concrete or timber, pneumatics offer ease of transportation, rapid deployment, and dynamic flexibility, making them ideal for mobile and nomadic architecture.

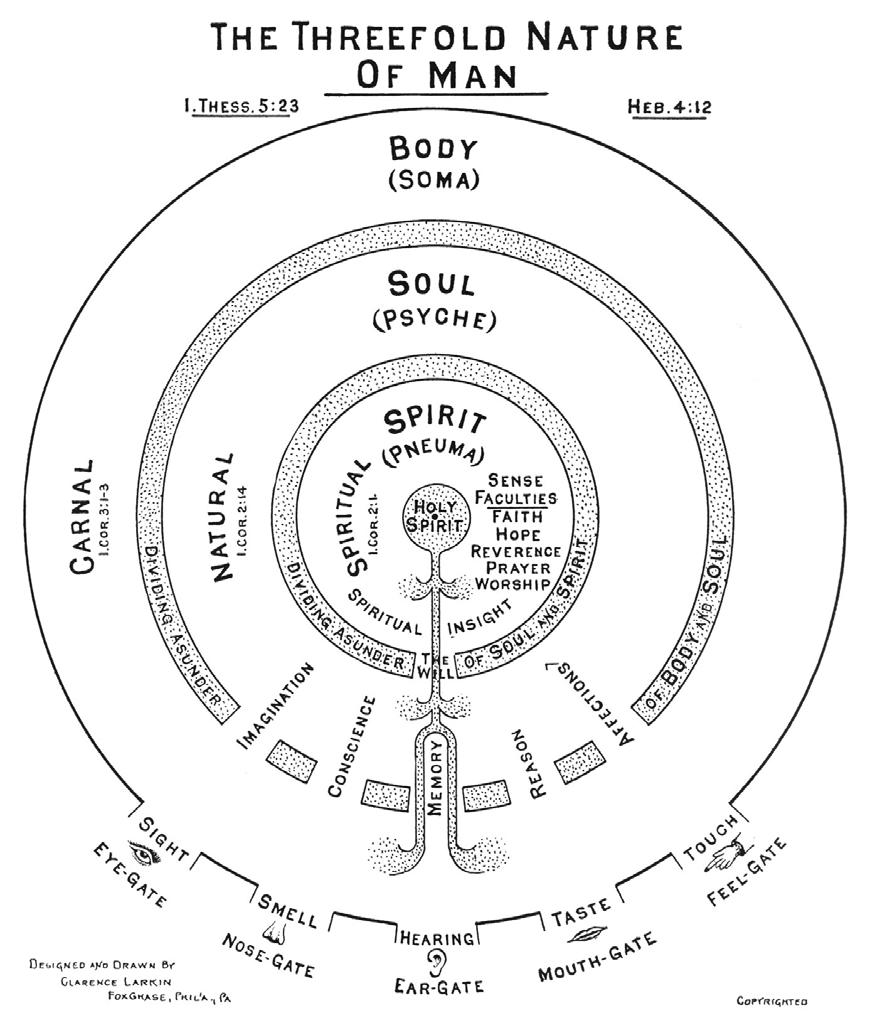

The word pneumatic is derived from Greek word “pneuma” meaning “breath” or “air in motion”. It can also be translated as “spirit” in a religious context.

Pneumatic Architecture

a building design that uses compressed air to support a flexible membrane. This creates lightweight, energy-efficient structures.

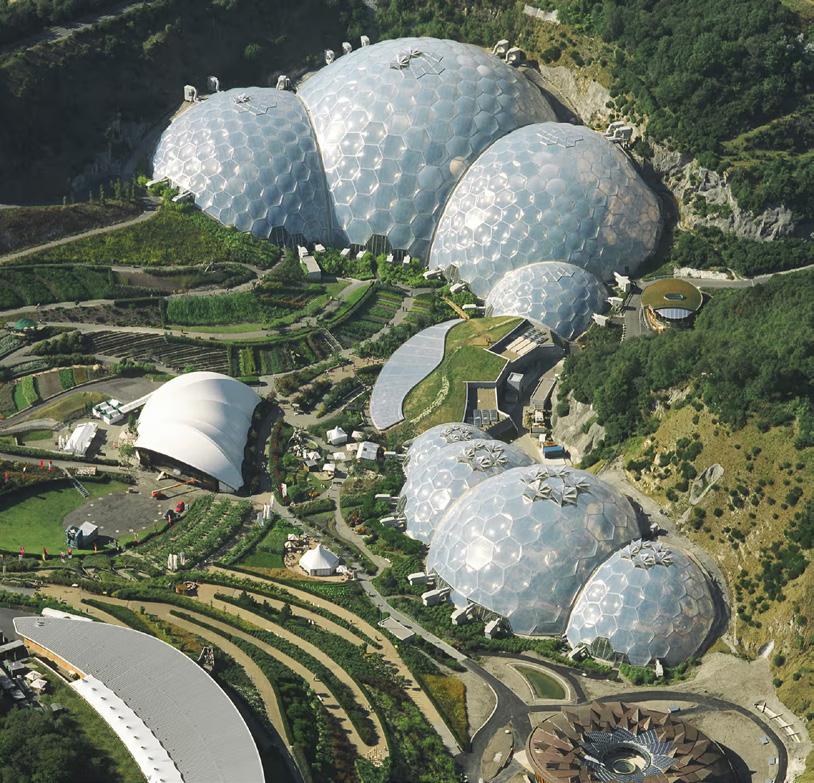

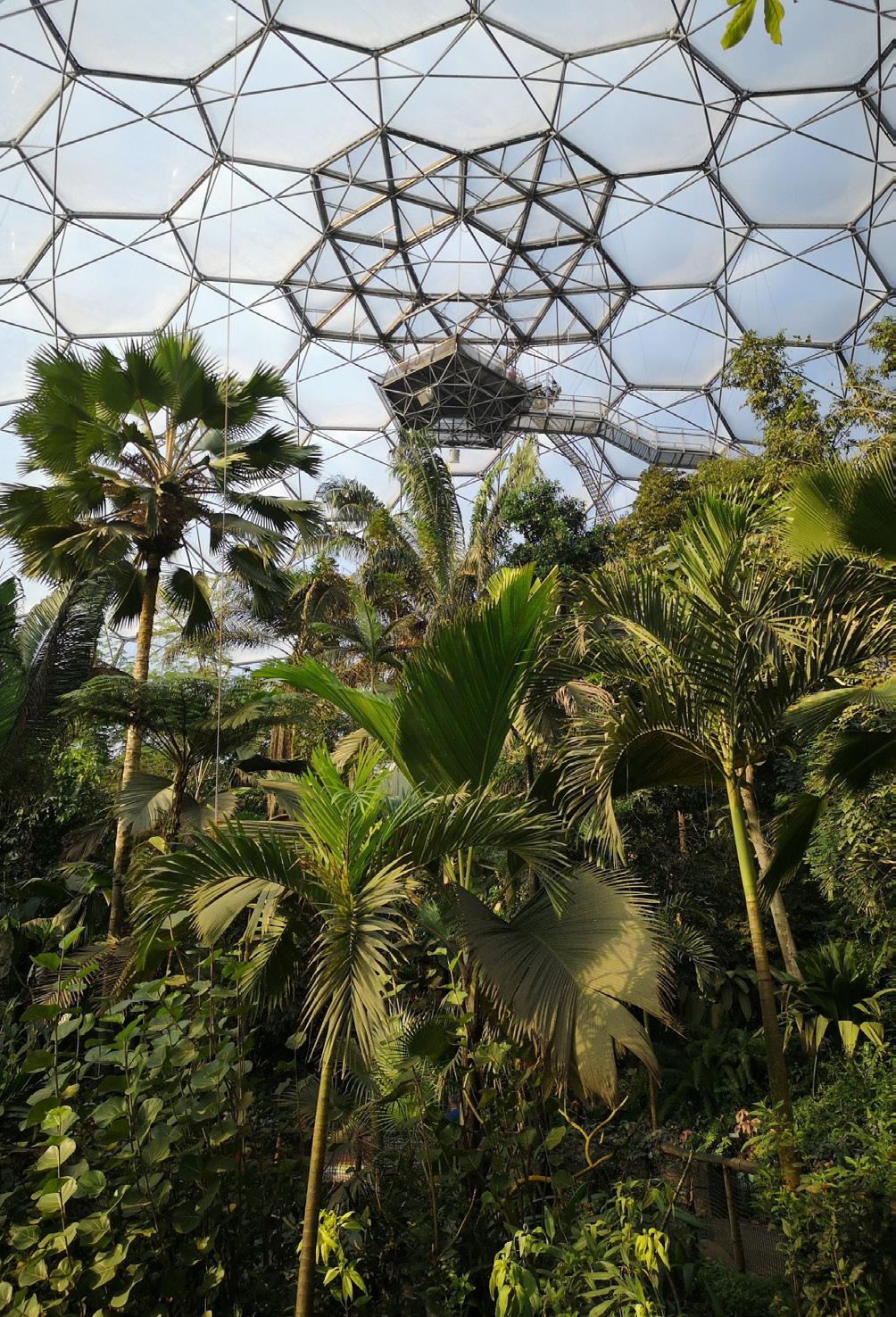

The Eden Project: supposedly the air inside is actually heavier than the structure itself

tire they are not that much different.

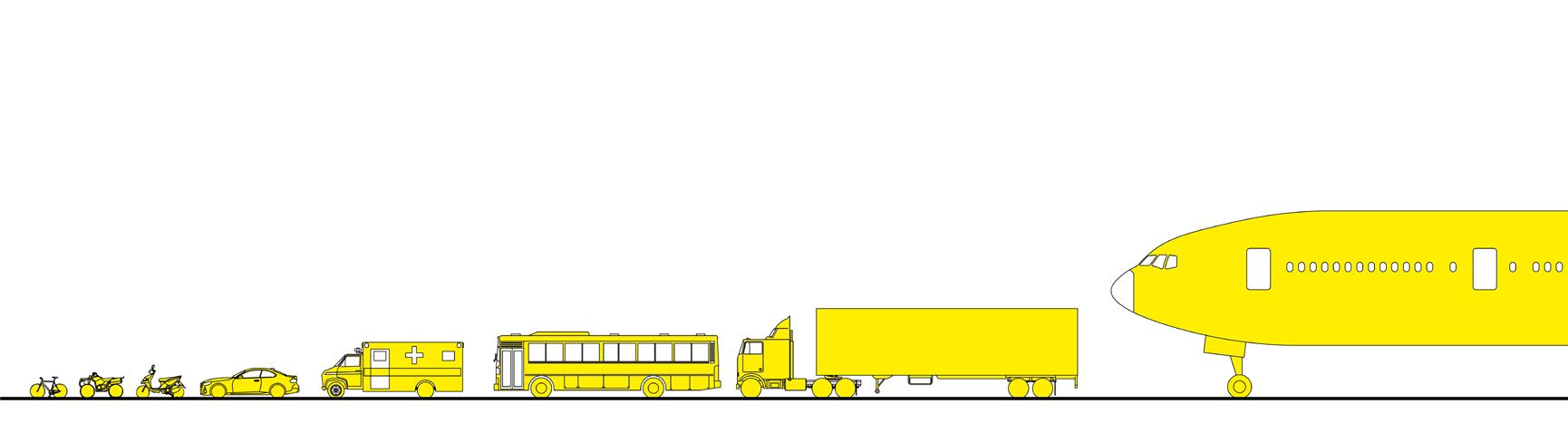

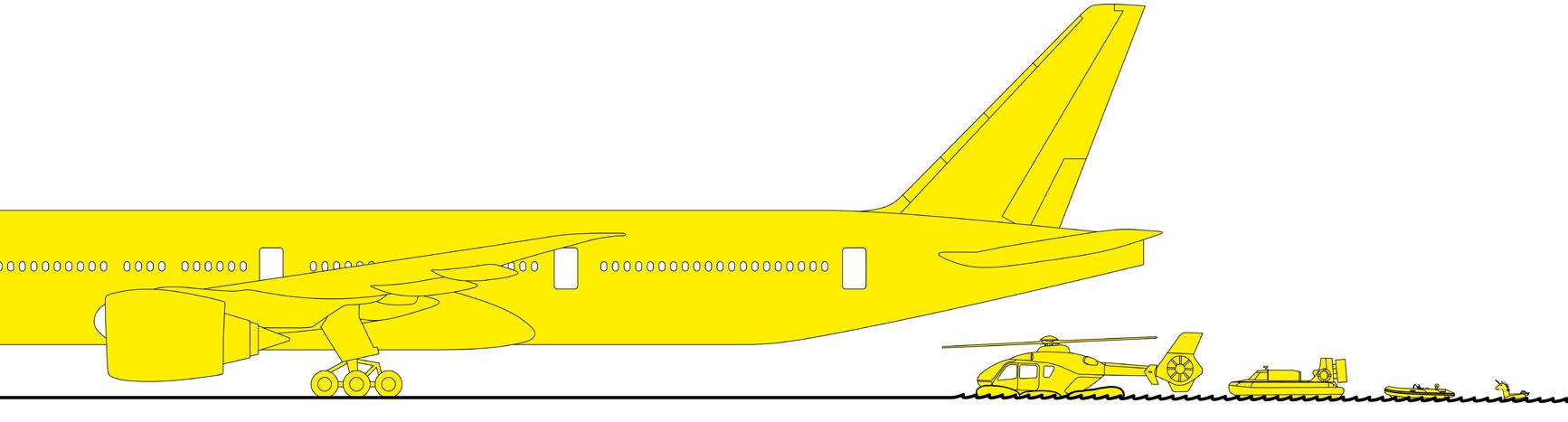

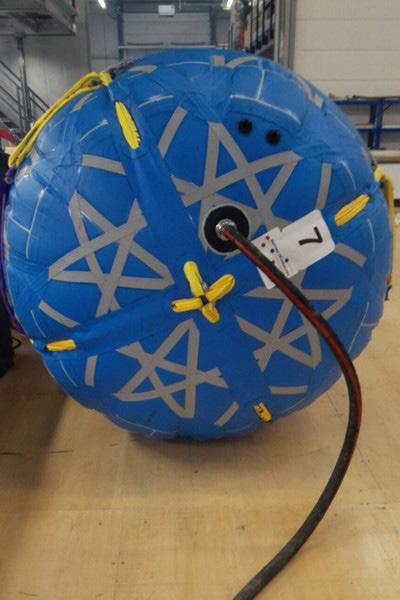

Pneumatics quietly power many of the ways we move through the world.

a range of vehicles and devices—across land, sea, and air—that rely on pneumatic systems to operate, stabilize, or transport.

Pneumatics are all around us, intently built into the ways we move and stay safe

Their ability to store, release, and shape air on demand makes pneumatics an essential, invisible layer of safety we trust with our lives every day

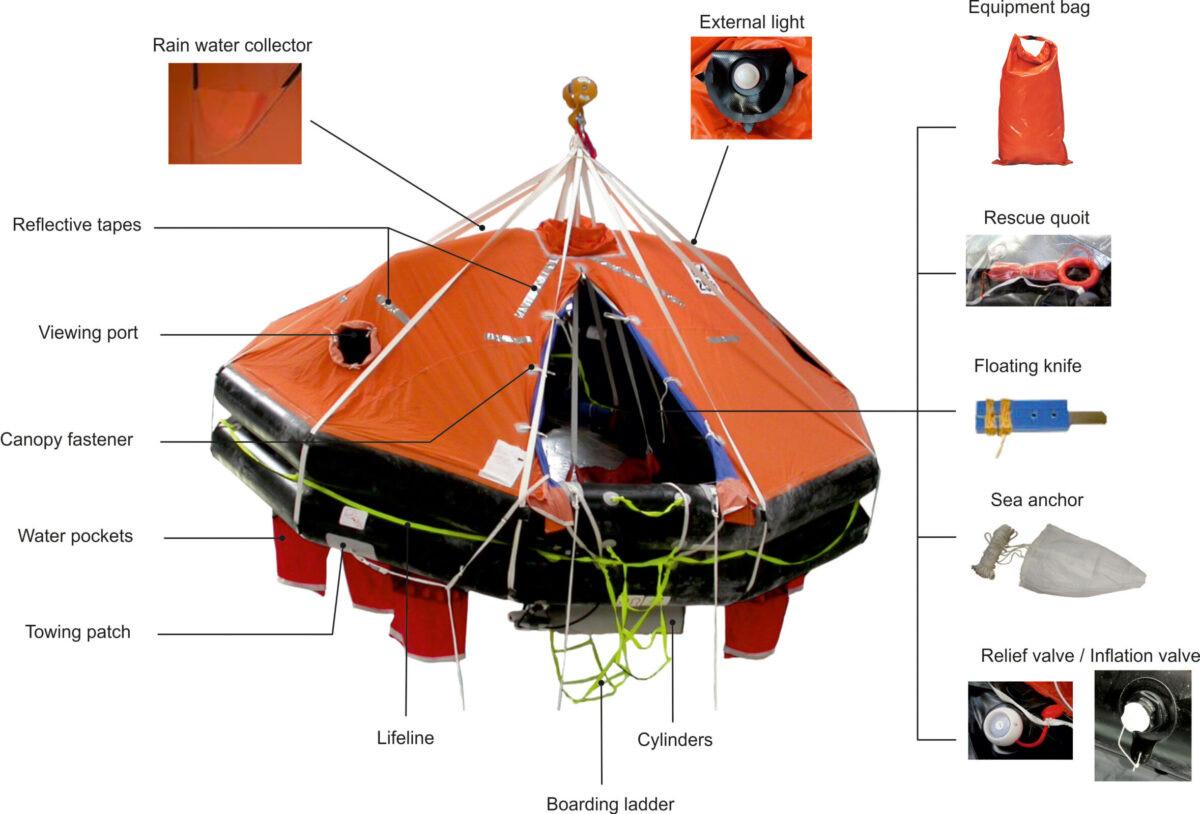

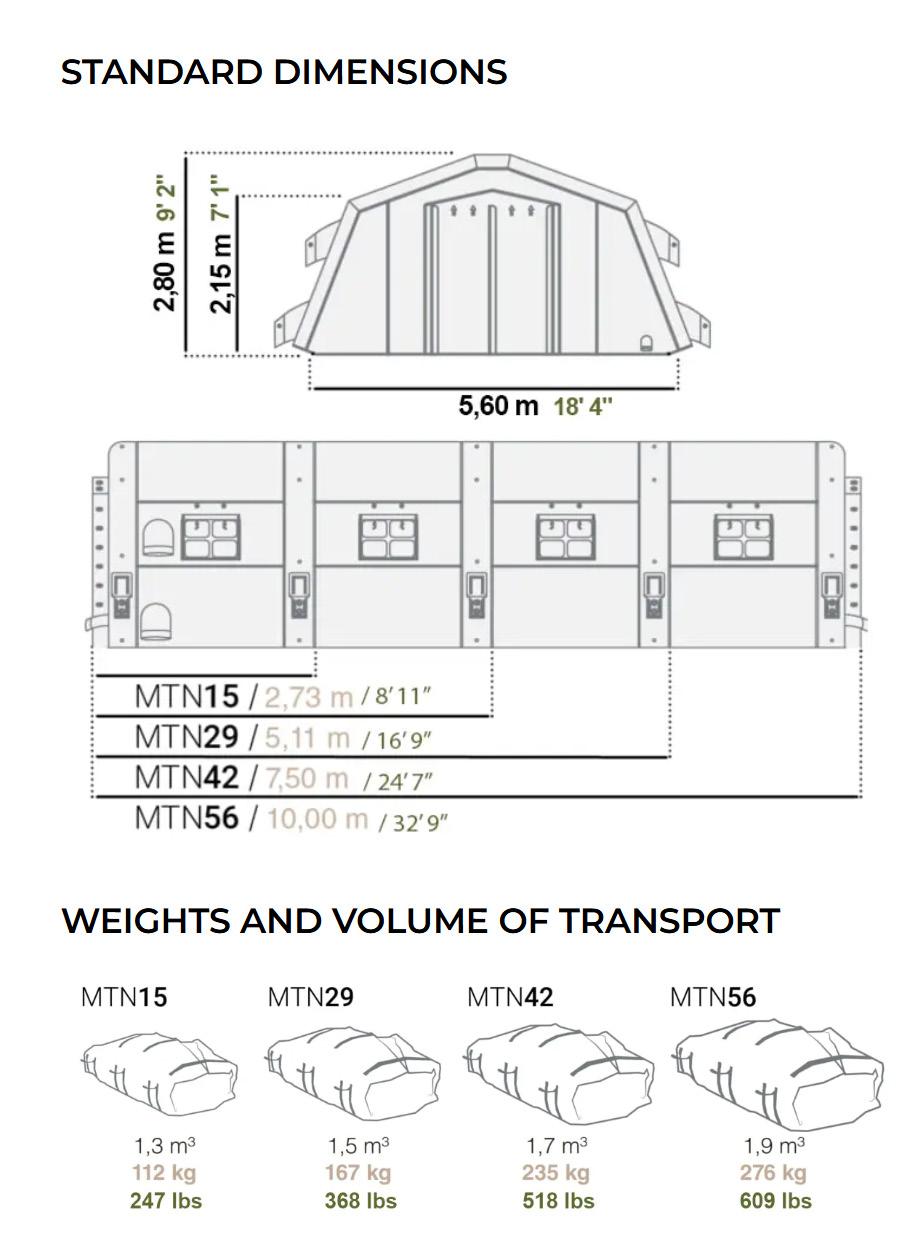

Pneumatic structures offer unique advantages for temporary and mobile applications.

Lightweight and compact when deflated, they can be easily transported, rapidly deployed, and quickly adapted to different needs.

Standard Dimensions

Weights and Volume of Transport

In disaster relief, pneumatic shelters provide immediate, life-saving protection. In refugee camps, they offer flexible housing solutions that can move and grow with shifting populations.

Though they may seem ordinary, these materials are the products of highly engineered, industrial fabrication processes.

Containing air, nonetheless, is not easy.

“How can pneumatics reframe inflatable architecture as a scalable,serious,and deployable design system?”

chapter two-

WHY MATICS?PNEU-

there is no maximum span as determined by strength, elasticity, specific weight as with other materials

they can span great lengths

Pneumatics use significantly less material than traditional construction,

The amount of CO2 emissions from steel manufacturing is almost double the amount of steel created: 1.85 tonnes of carbon per 1 tonne of steel. If steel were a nation, it would be the 5th largest producer of carbon emissions in the world!

ultimately lowering construction time and cost

pneumatic structures can be constructed faster and at a lower cost than traditional buildings

they are lighter than traditional building materials so less energy needed to transport

and they require less material to make which means reduced costs

inflatable elements can be disassembled, transported, and repurposed.

PSI

“pounds per square inch,” which is a unit of pressure measurement, indicating the force applied per square inch of area

Atmospheric pressure is measured in absolute terms, whereas the other pressures are relative to atmospheric pressure. Therefore the absolute pressure in a car tire is around 350,000 Pa/50 psi/3.5 atm (relative pressure of car tire, plus absolute atmospheric pressure) 6,900 Pa

51,700 - 58,600 Pa 7.5 - 8.5 psi 0.5 - 0.6 atm

- 262,000 Pa

Negative pressure domes use air-blowers to create a vacuum between the inner and outer layers of a dome. This vacuum, or negative pressure, holds a projection screen in place and gives it its shape.

Solid structures can buckle or fracture under pressure, even if the material itself resists compression—especially when forces are applied directly without flexibility.

With pneumatic constructions, internal pressure distributes evenly across the membrane, creating pure tensile forces that prevent buckling.

The construction has a specific fluidity and reverts to its natural form the moment that any pressure is removed.

Homogeneous: looks the same at all locations

Not Isotropic

Isotropic: looks the same in all directions

Not homogeneous

inflatable structures do not work well with objects created by flat surfaces, however with spherical objects, the air pressure distributes evenly to each point on the surface, allowing the object to maintain its integrity across.

The inner pressure automatically seeks to find its own form, the outer surface assuming the minimum surface area by maximum volume.

This is the principle of the sphere. If the membrane differs considerably from the spherical form this results in differing pressures causing a cushion effect.

chapter three-

SOFT STARTS

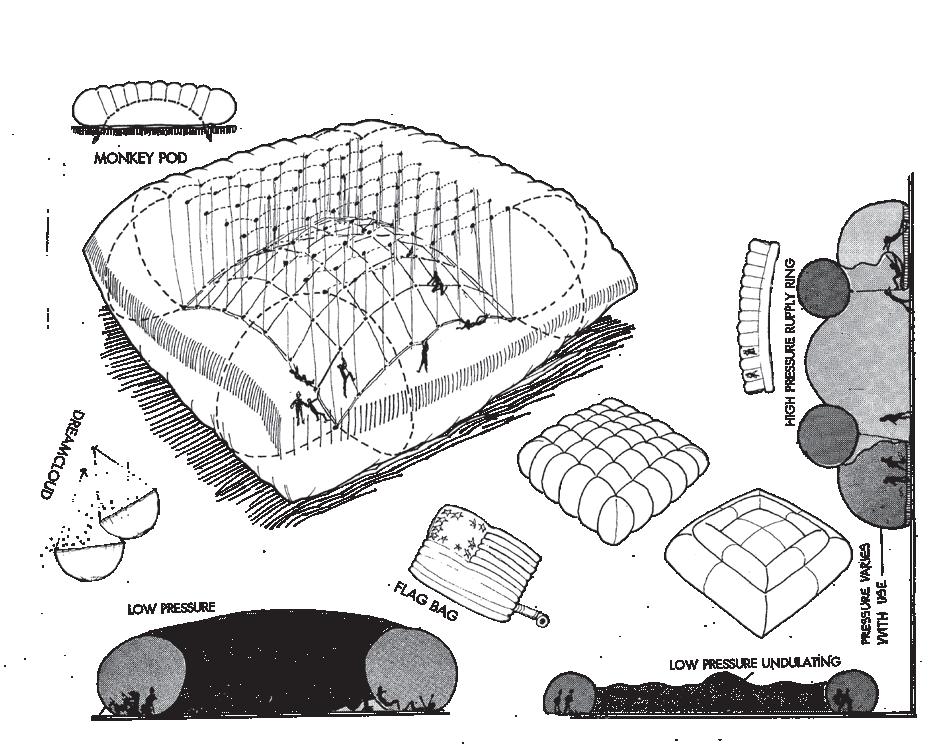

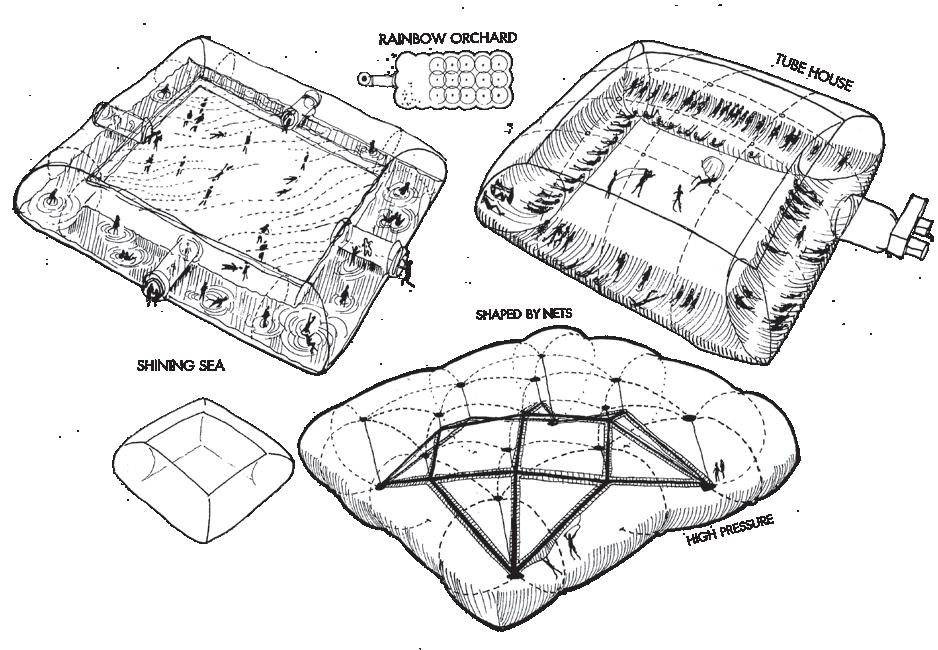

Air Supported - the entire internal volume of the structure is pressurized

Air Inflated - only the space between dual membranes is pressurized. the interior functional space remains at atmospheic pressure atmospheric pressure

internal air pressure keeps membranes taut, shedding snow and preventing buildup

Tension in Cables

Foundation Reactions

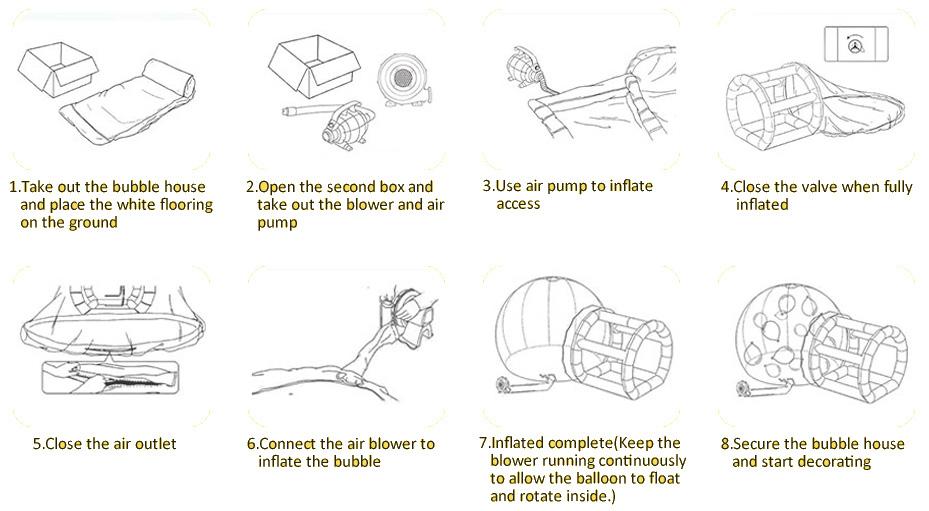

INFLATOCOOKBOOK

Author: Ant Farm

Year: 1971

Function: practical guide to creating inflatable structures

9 x 12 ft plastic drop cloth

.7 mil

Polyethylene

10 x 25 ft clear plastic sheeting

6 mil

Recycled polyethylene

20m x 50mm clear, gloss finish

0.23mm

Polyethylene fabric

INFLATOPIA

18 x 32 ft Inflatable Bubble

Milstein Hall Visions of Utopia Exhibition

In collaboration with Jack Miezskalski and Raihaan Bose

Exhibition Threshold exterior interior

walls conforming the space

constant source of energy

BUBBLE BUTT

Lounge Chair

system of modular, bladder cushions suspended by tensioned cords

constant use of energy

balloons were so easy to use because they maintain their pressure no energy needed

chapter four-

BURSTING THE BUBBLE

Why InflatablesCurrentFail

Inflatables today are unsustainable. They are often single-use and wasteful. Puncture prone.

Not Scalable or Adaptable:

Designed for temporary use, not for architectural longevity.

The Need for a New Approach: Can we make fun, adaptable, and reusable pneumatic architecture?

The future of inflatables is not in temporary, wasteful structures,

but in deployable, mobile, and scalable pneumatic architecture.

Why does deployability matter?

Allows for mobility and reusability, avoiding single-use waste.

Creates architecture that moves with people—not just stays in one place.

chapter five-

FOUND PRESSURE

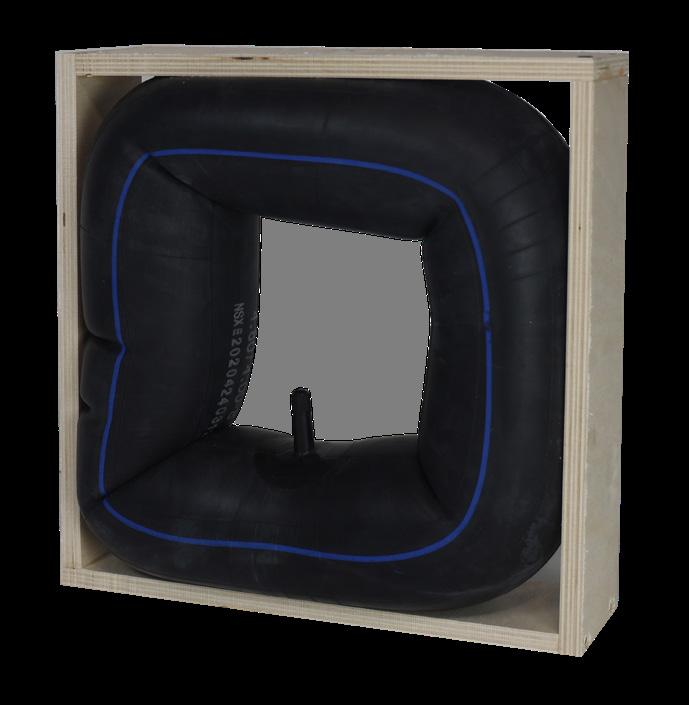

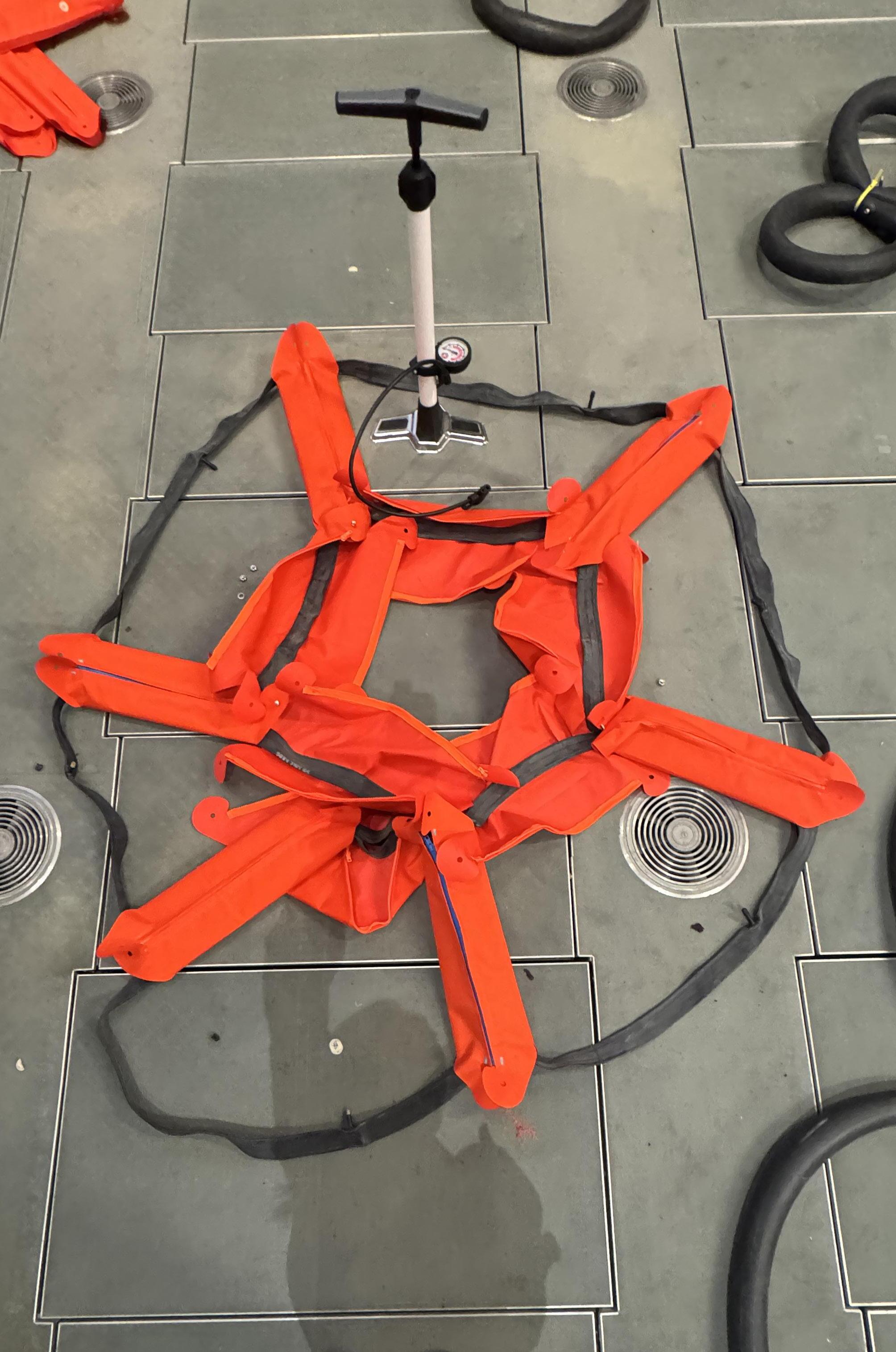

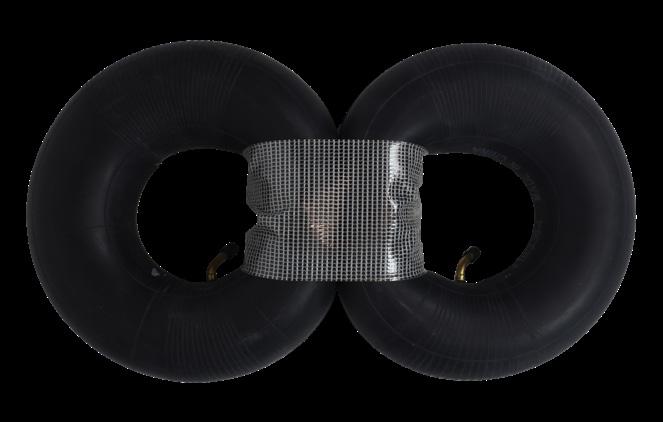

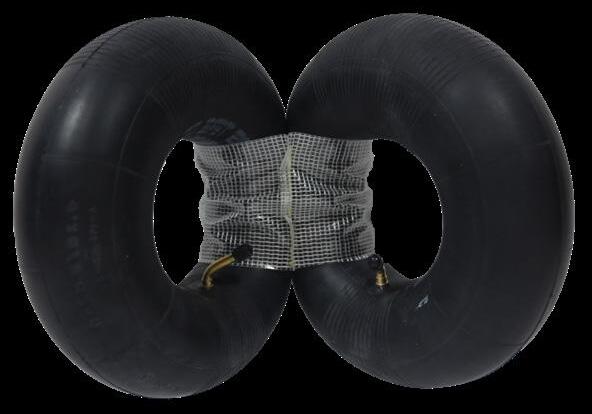

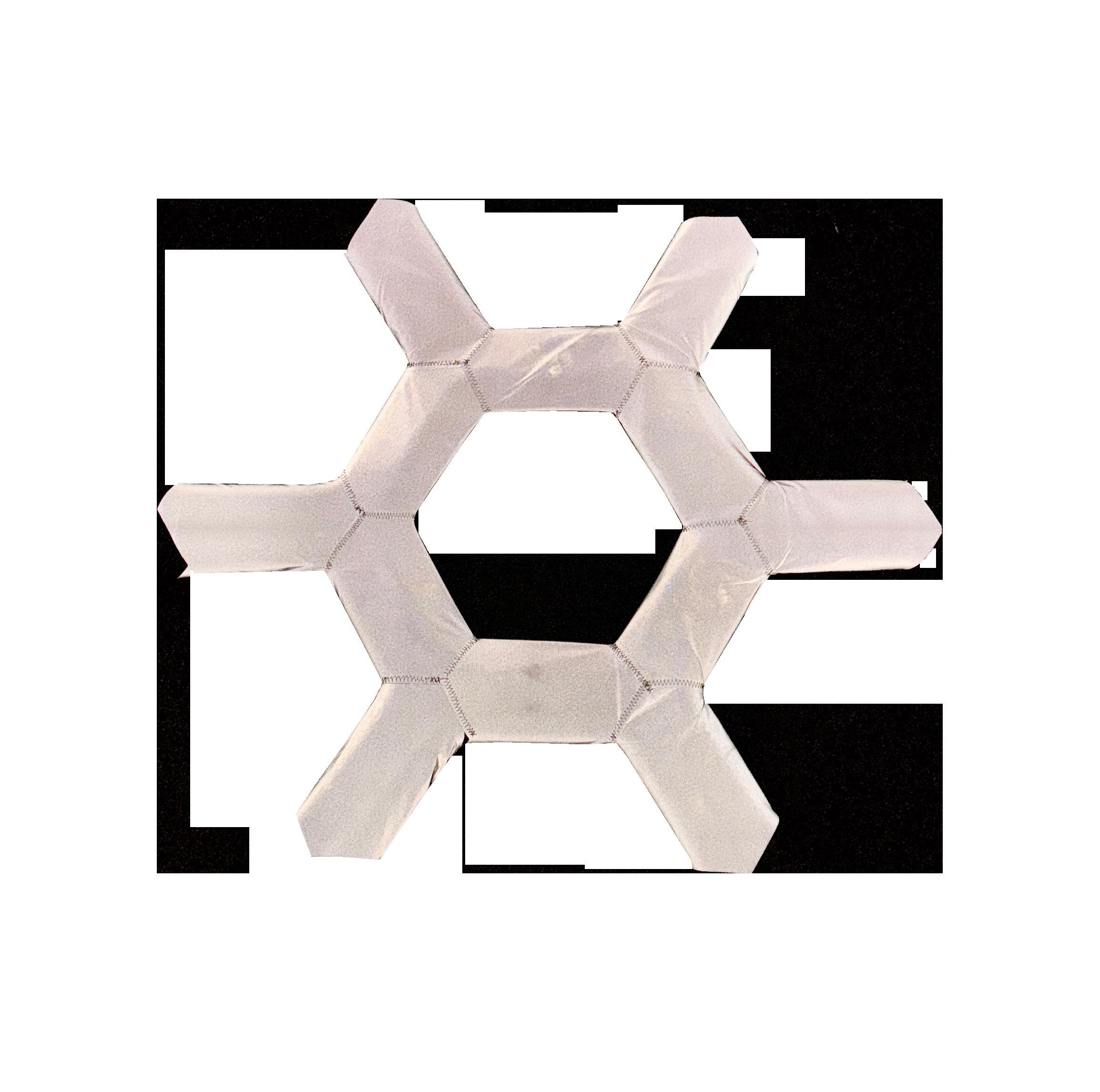

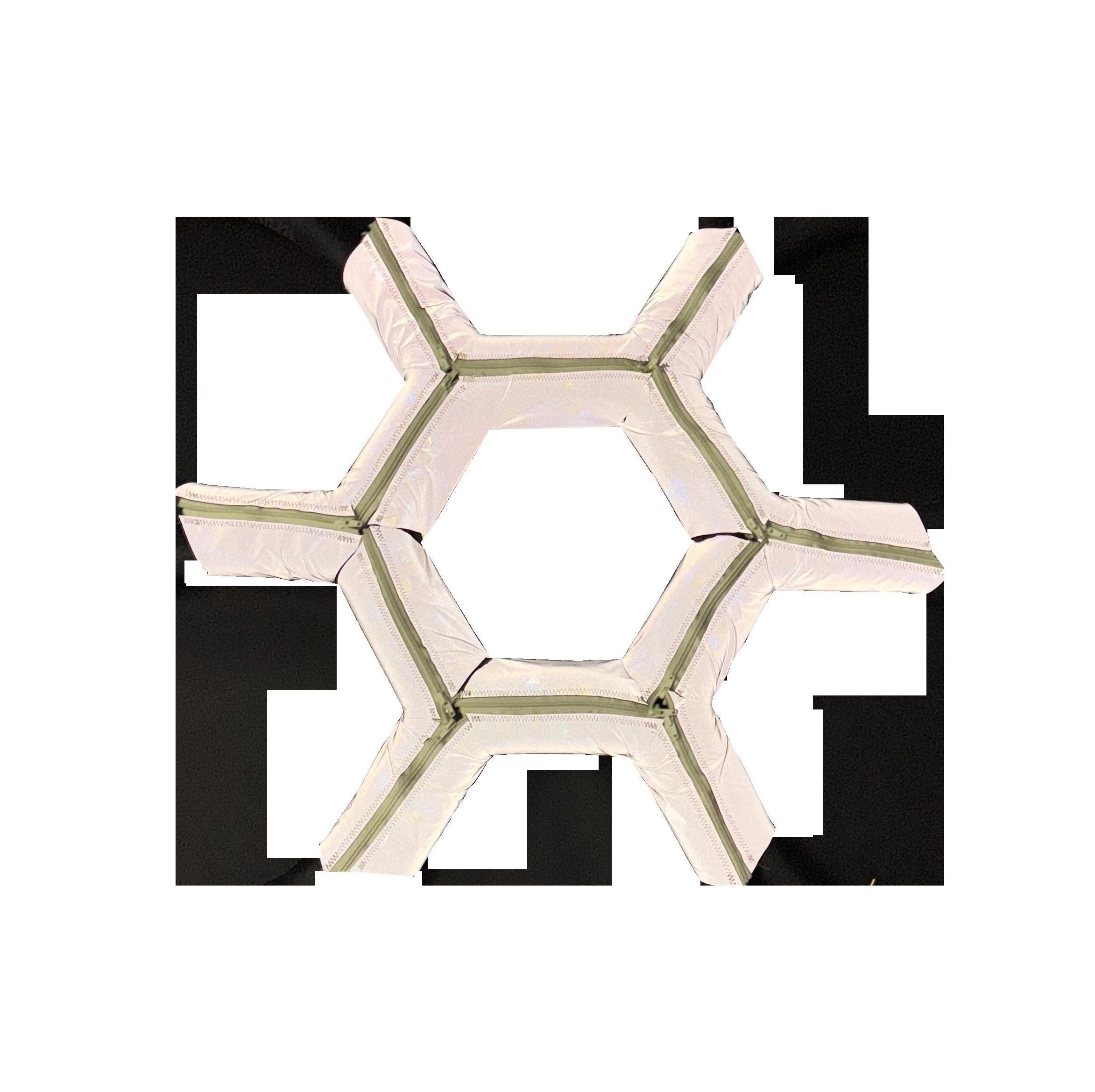

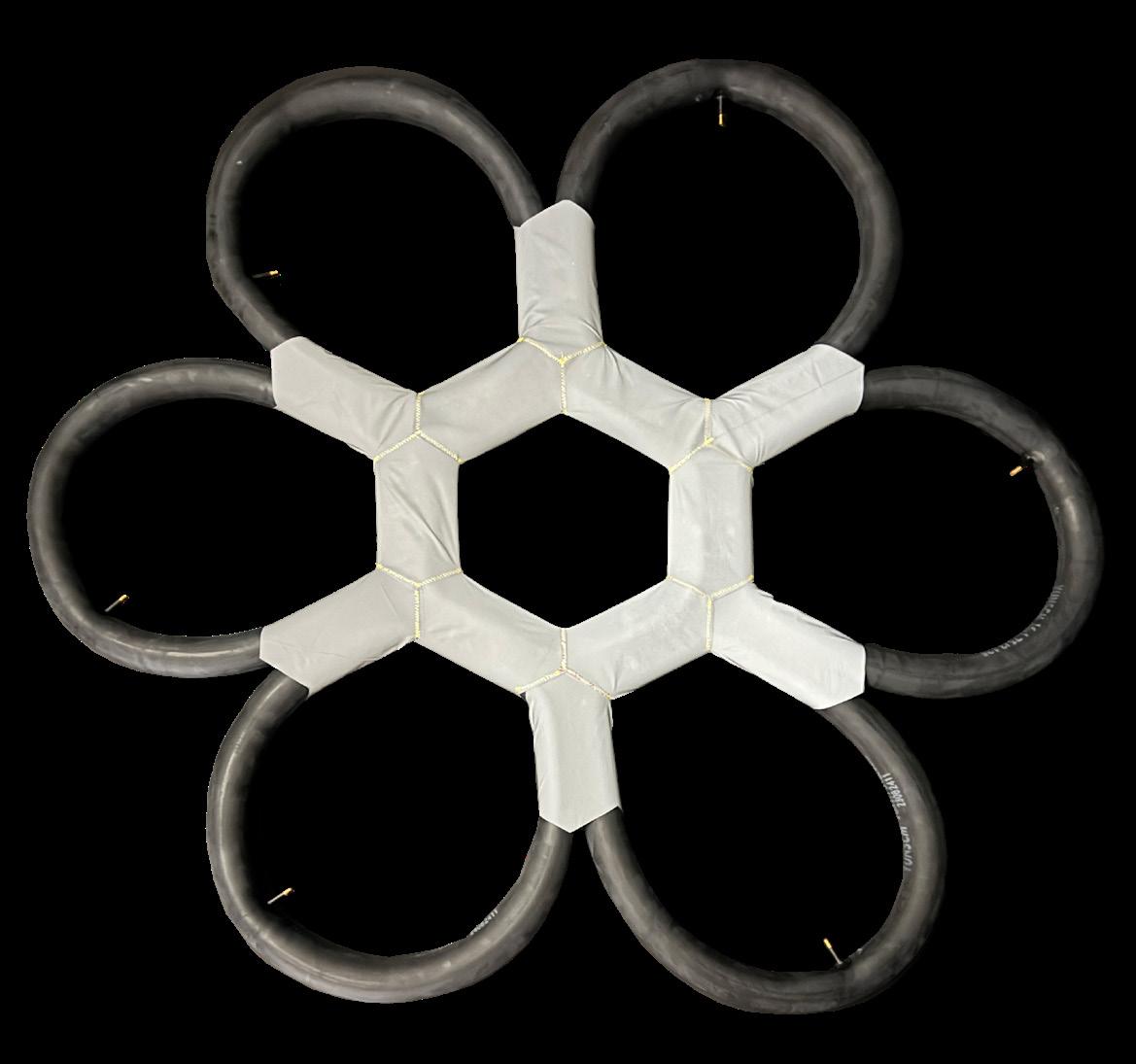

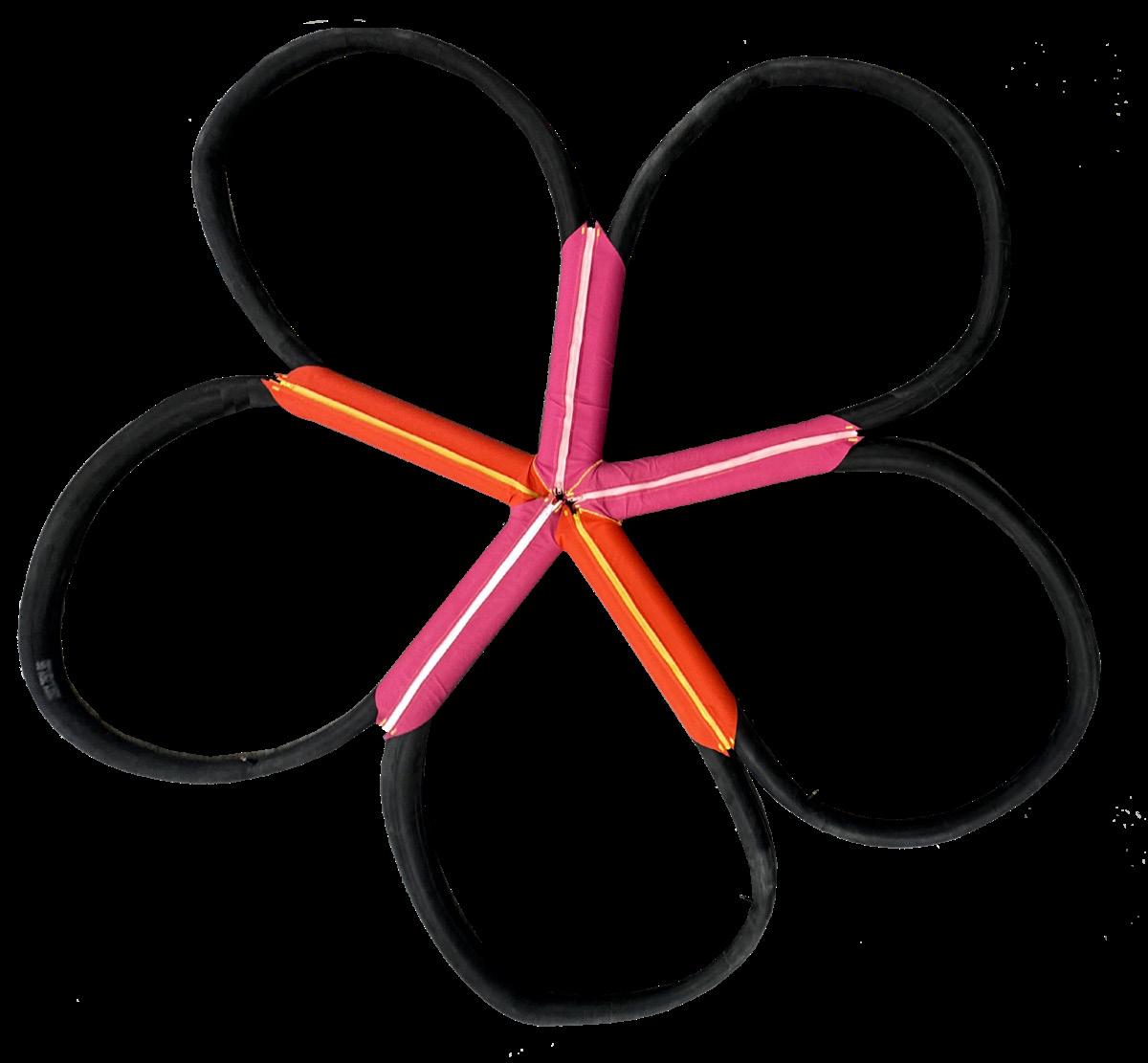

Tire = Building Component

Textile = Joint

Air = Structure

By reusing these industrially manufactured inner tubes, I tap into their existing material intelligence while giving them new life and purpose.

PVC laminate ripstop

A Movement and rigidity

B C

Excellent compressive strength

Unable to be unassembled without ripping the stitching

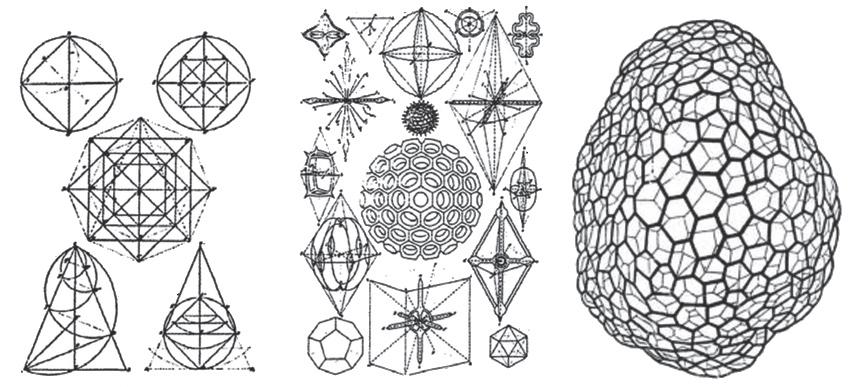

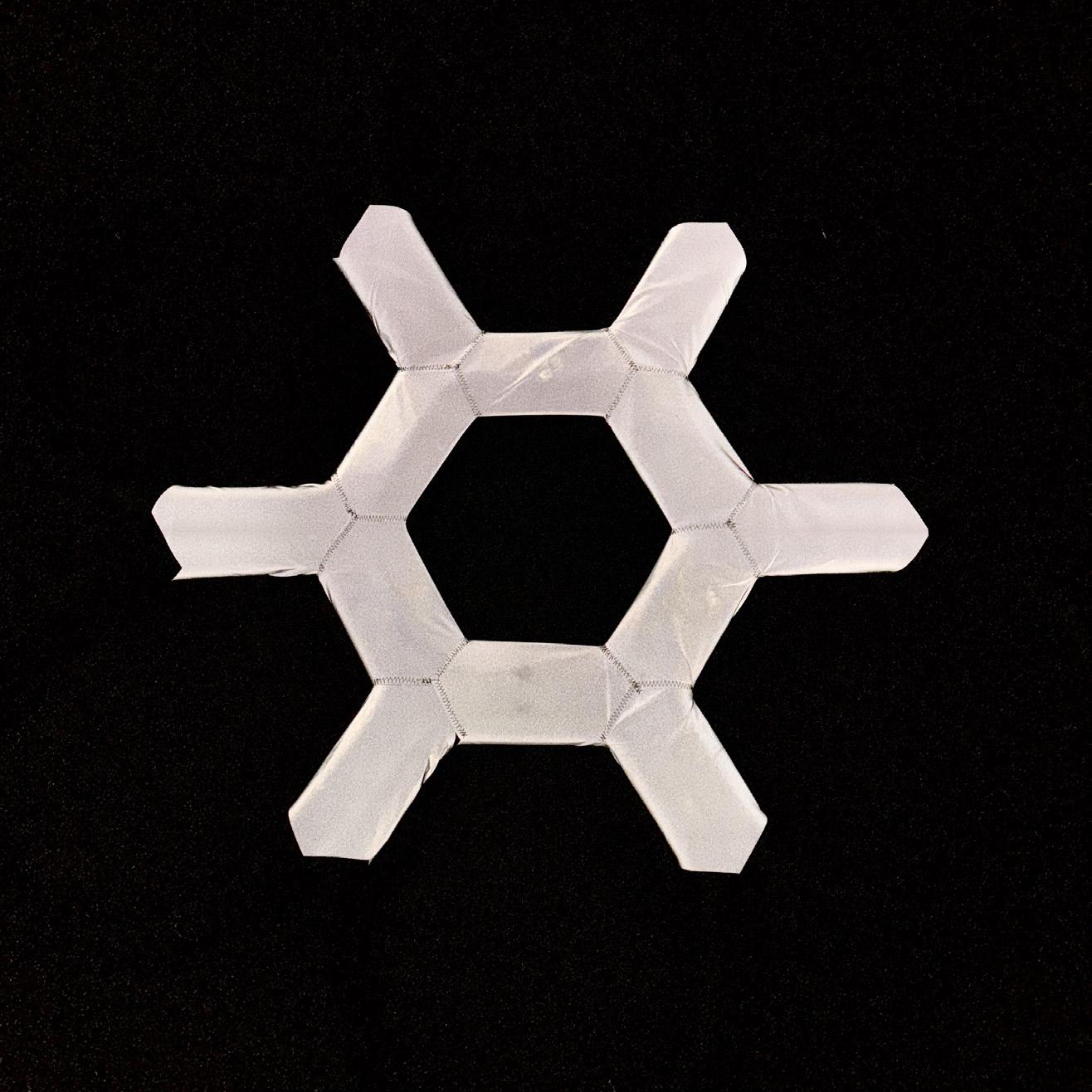

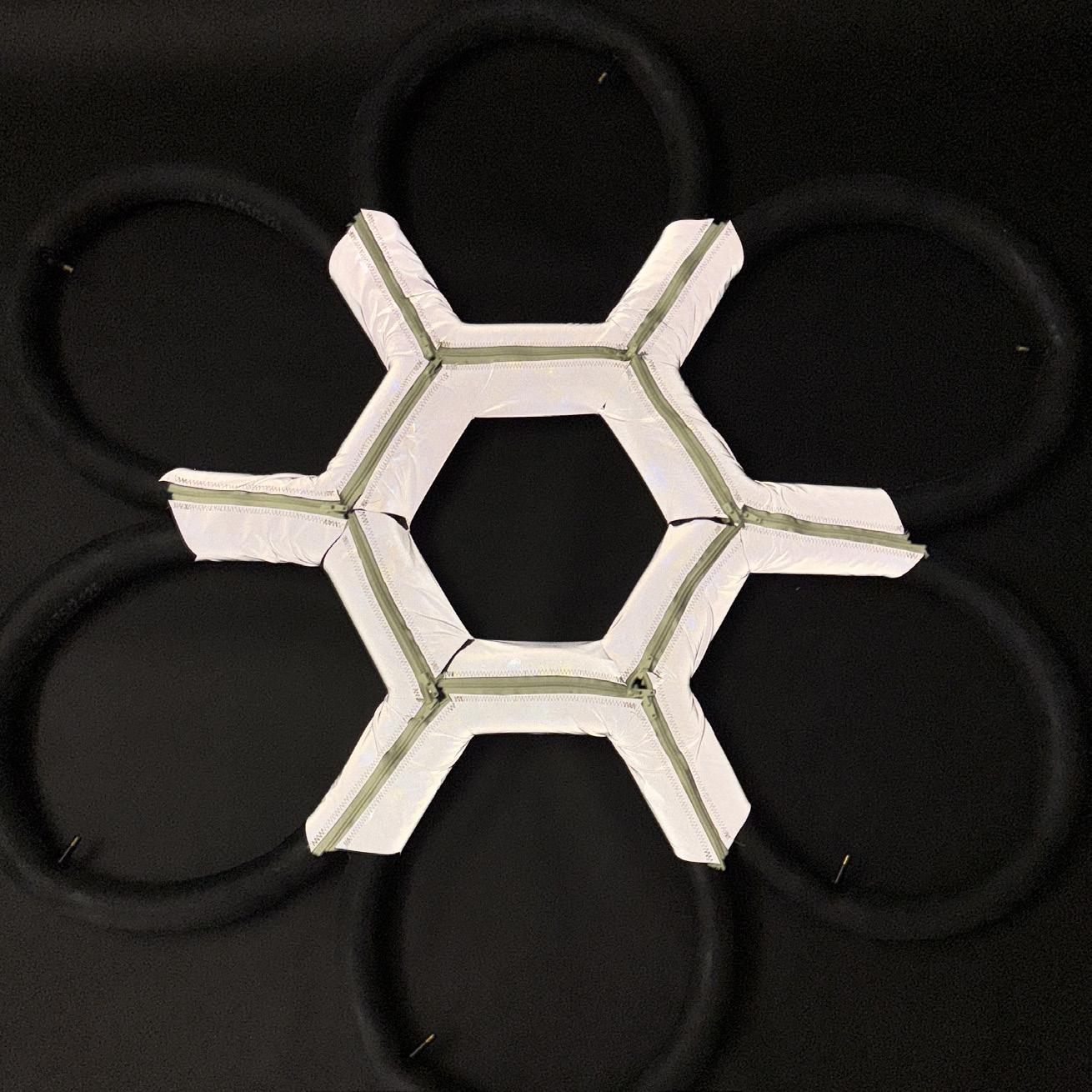

natural geometry as form finding logic

these include circles, hexagons, triangles, spirals, and fractals, all of which demonstrate structural efficiency and spatial logic

how nature defines form

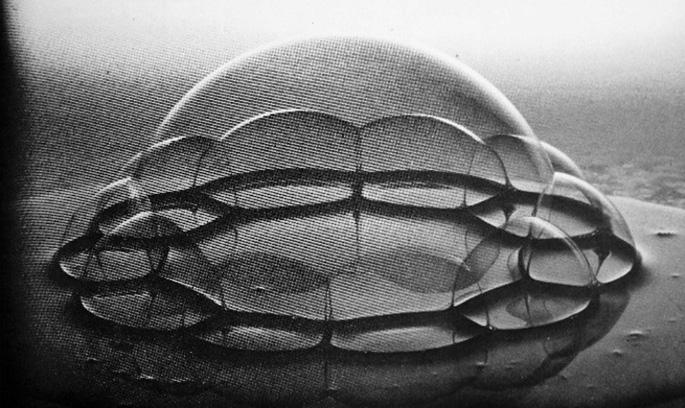

The Institute for Lightweight Structures (IL) Univeristy of Stuttgart

Director: Frei Otto

When two or three bubbles adhere to each other they form an even wall between themselves.

The outer membranes result in a 120° angle. In the case of a grouping of four they develop an angle of 109°.

The is the basis of all foam and these naturally occuring forms have a minimal surface area in relation to their volume.

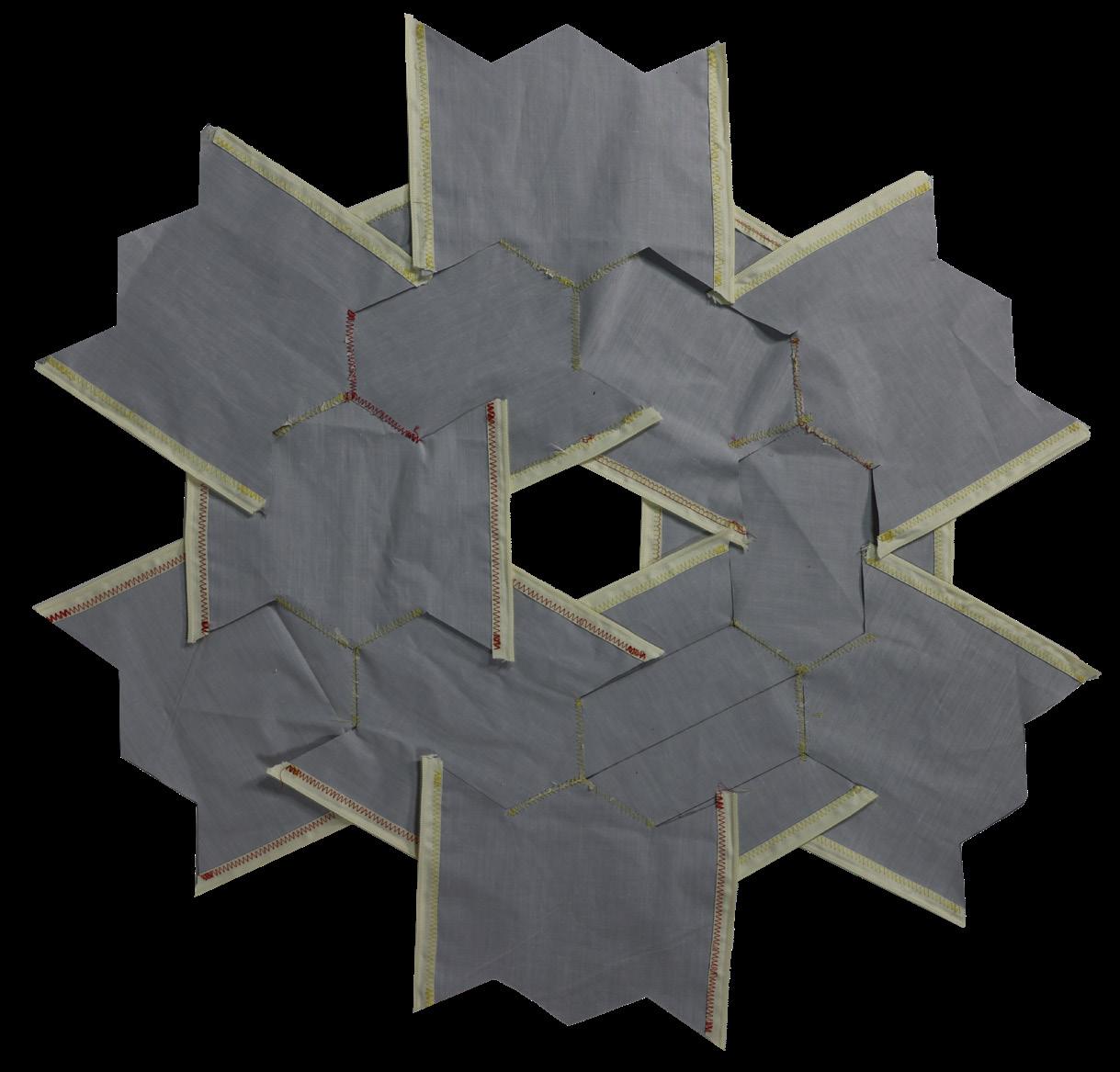

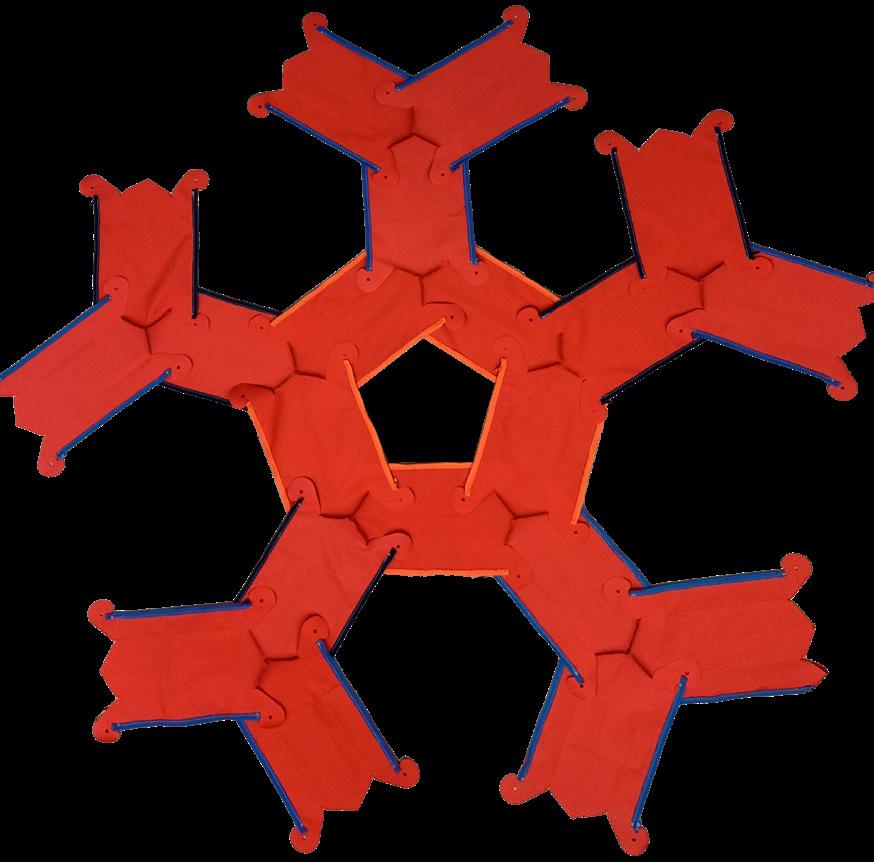

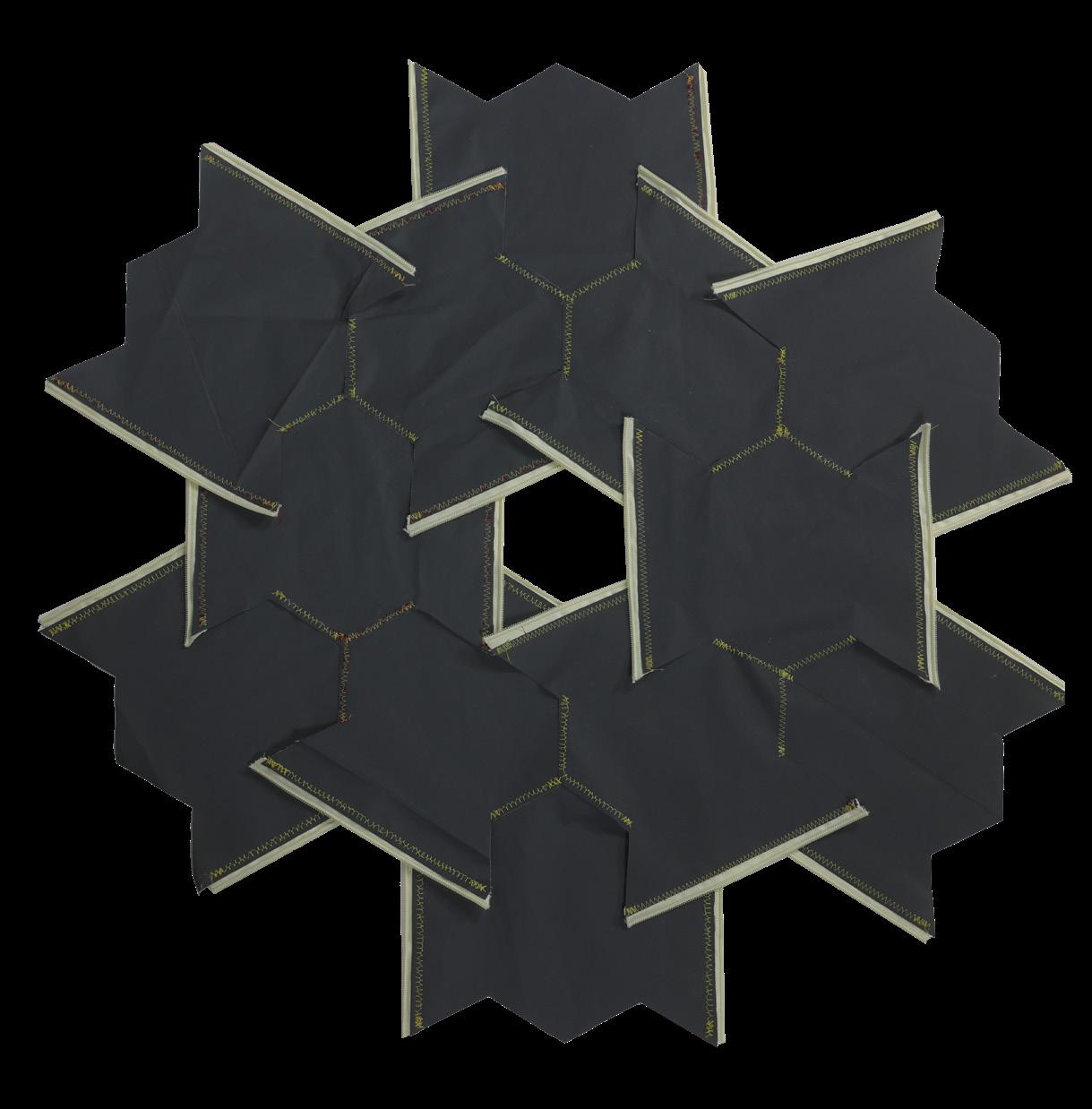

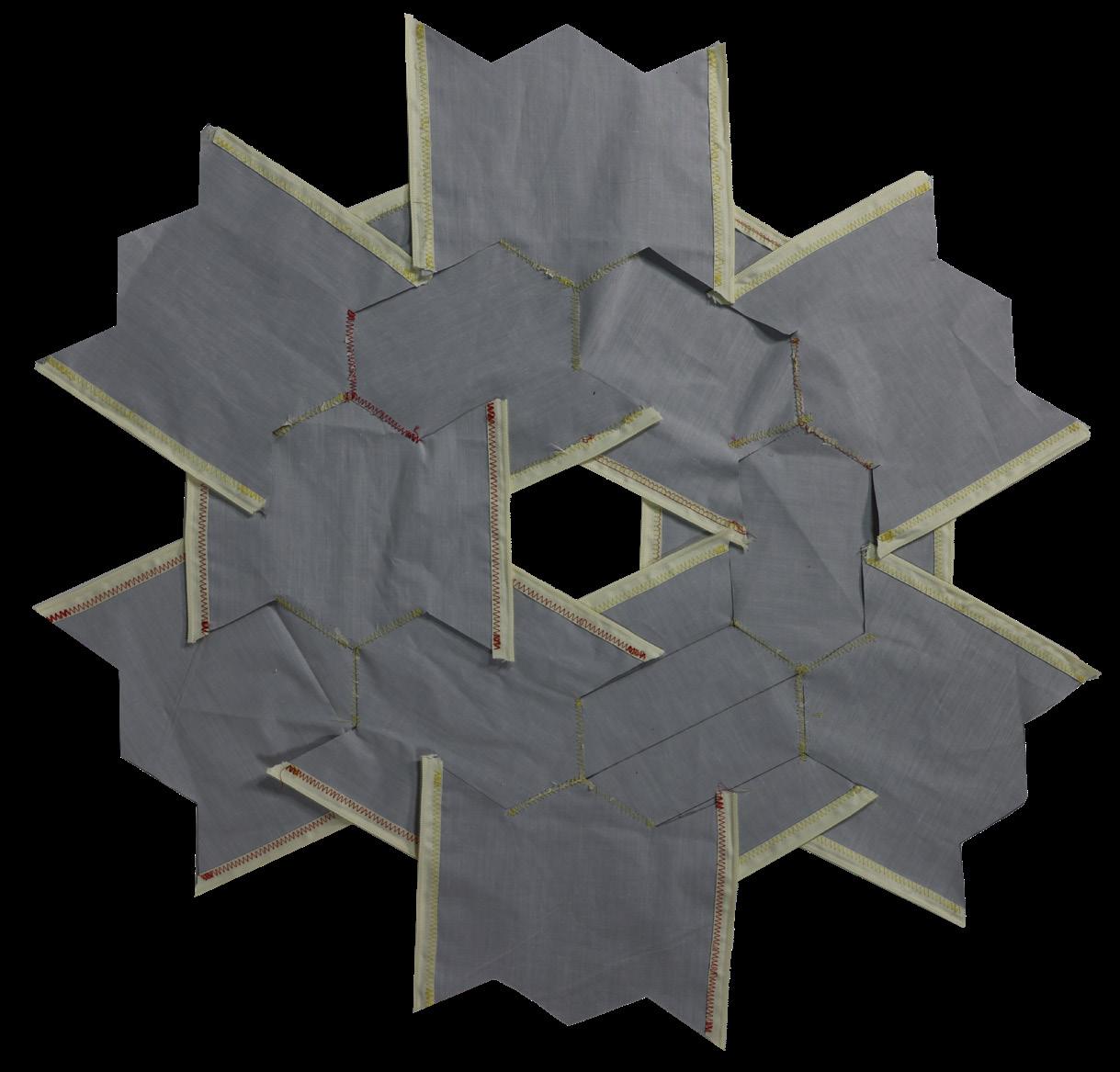

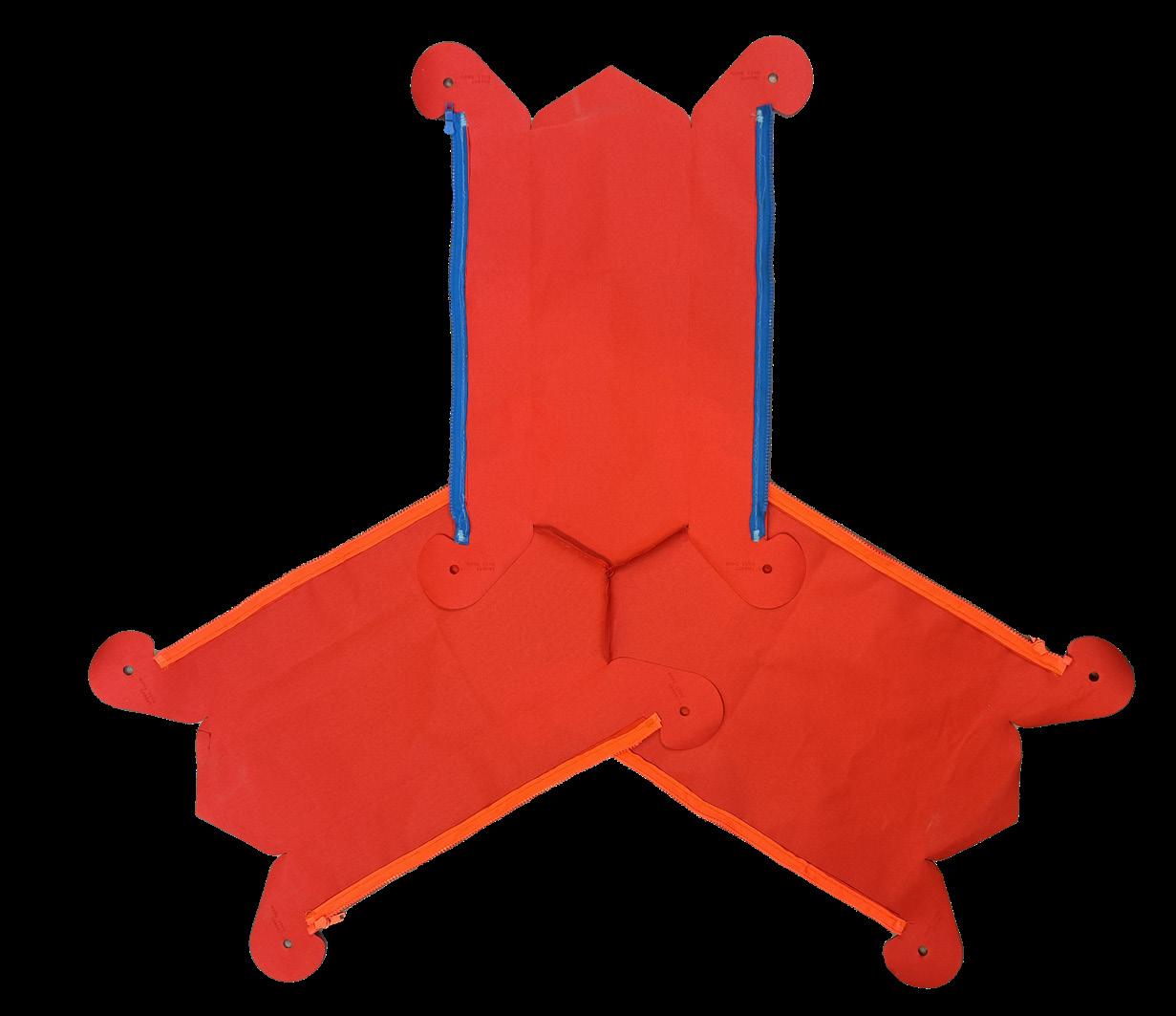

Starting from a single cluster of units, each module connects edge-to-edge, allowing the system to grow outward organically.

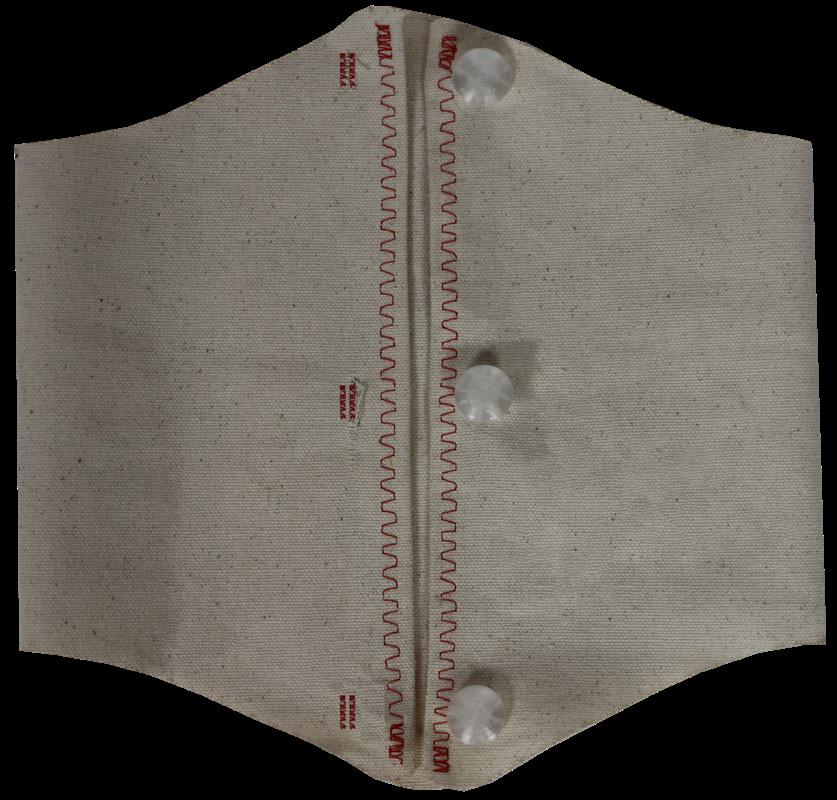

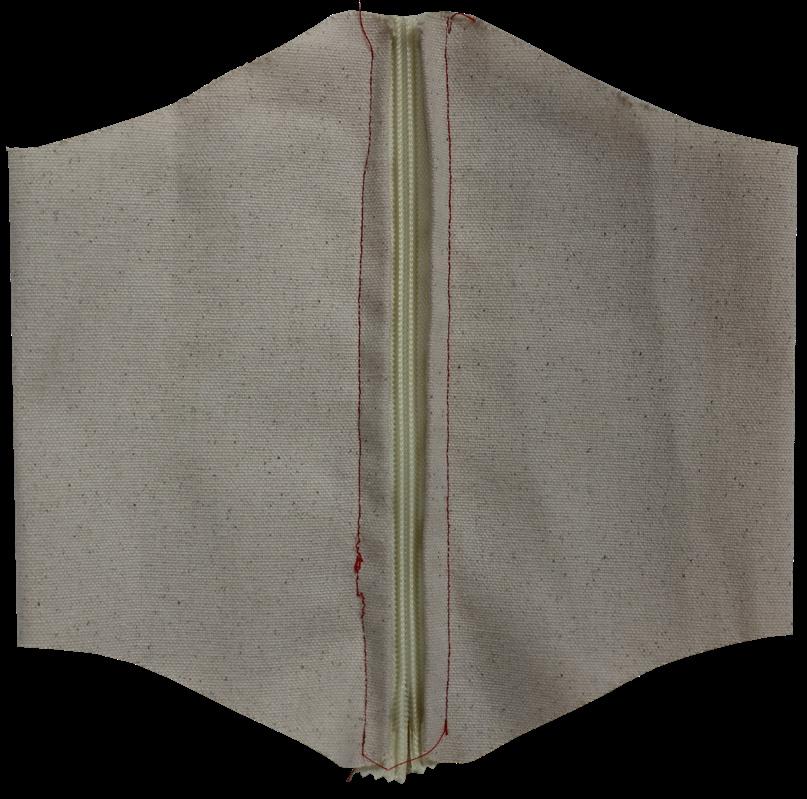

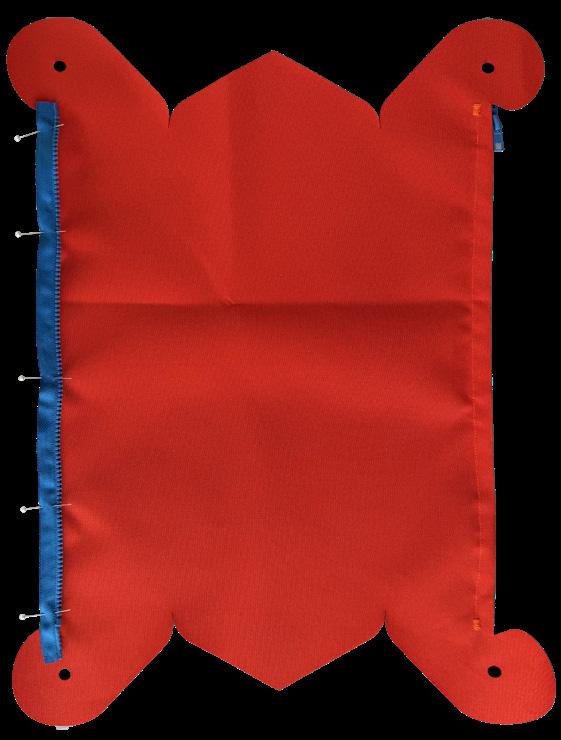

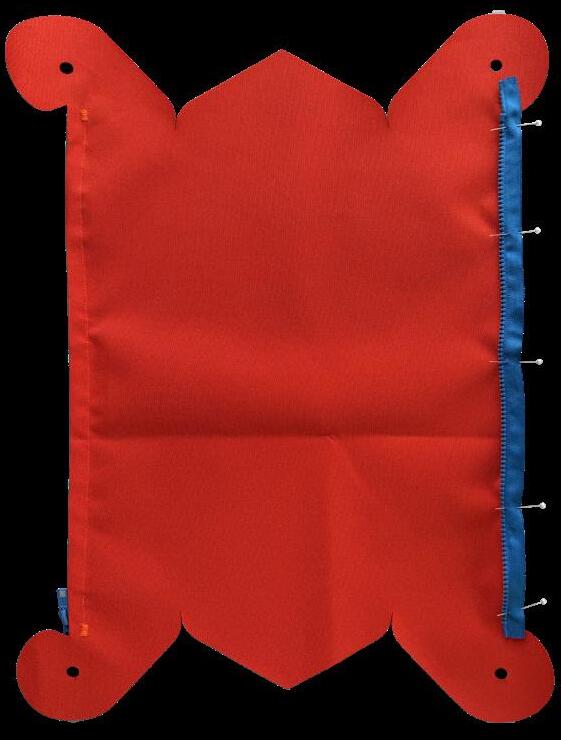

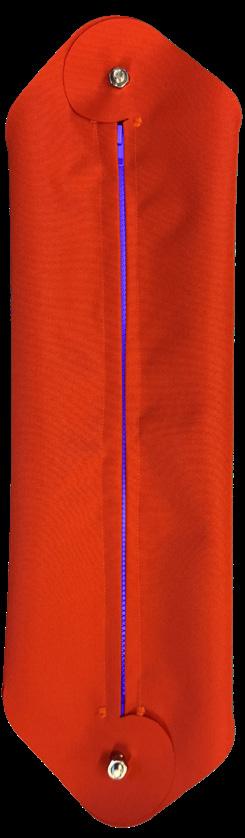

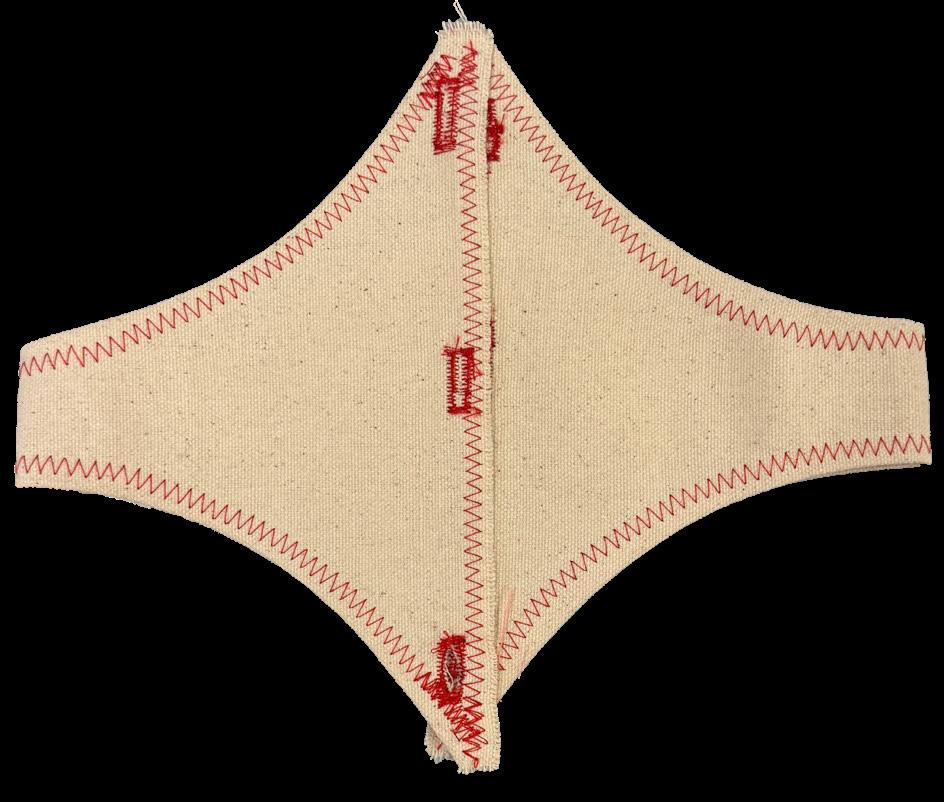

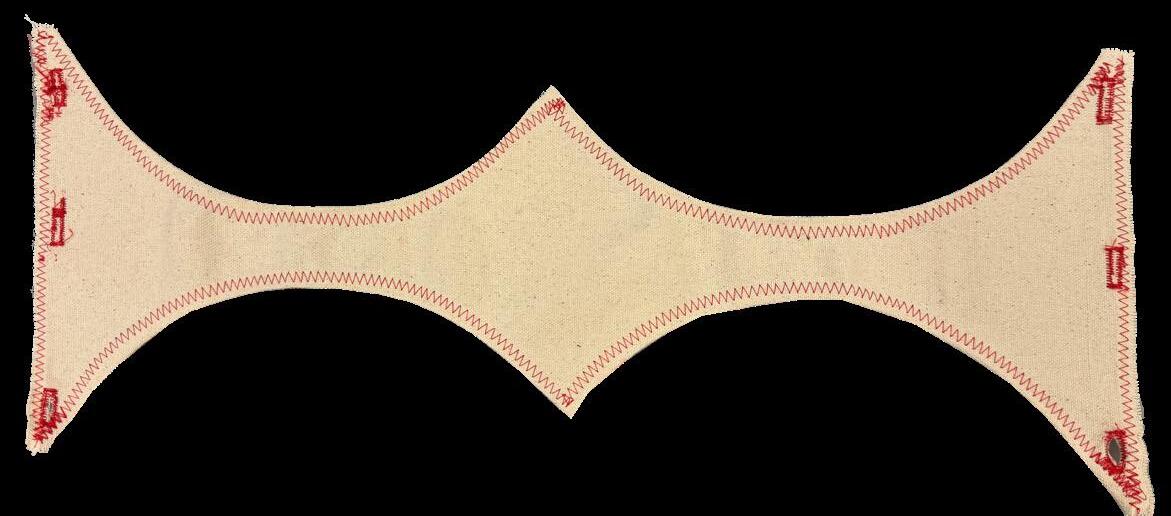

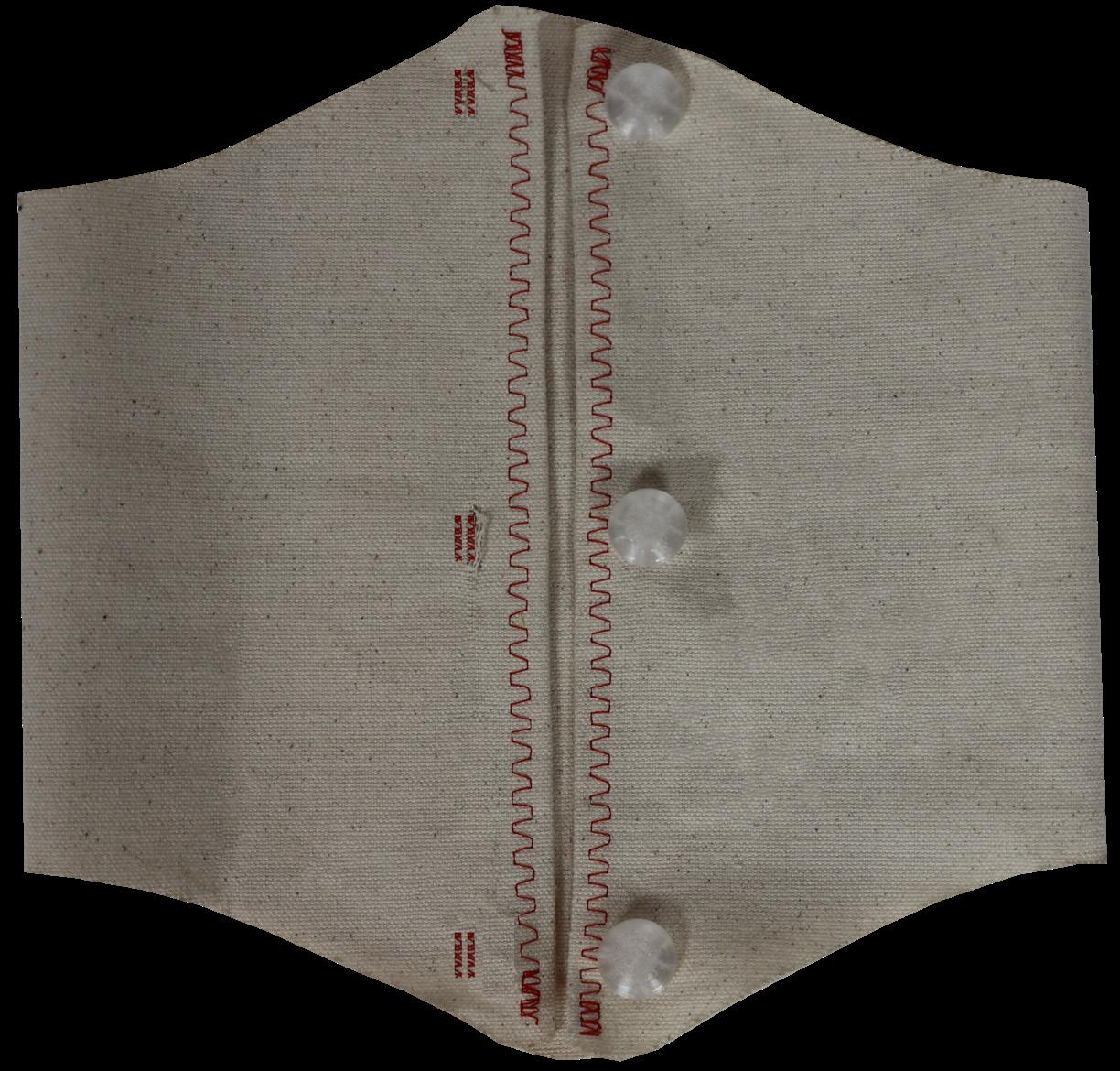

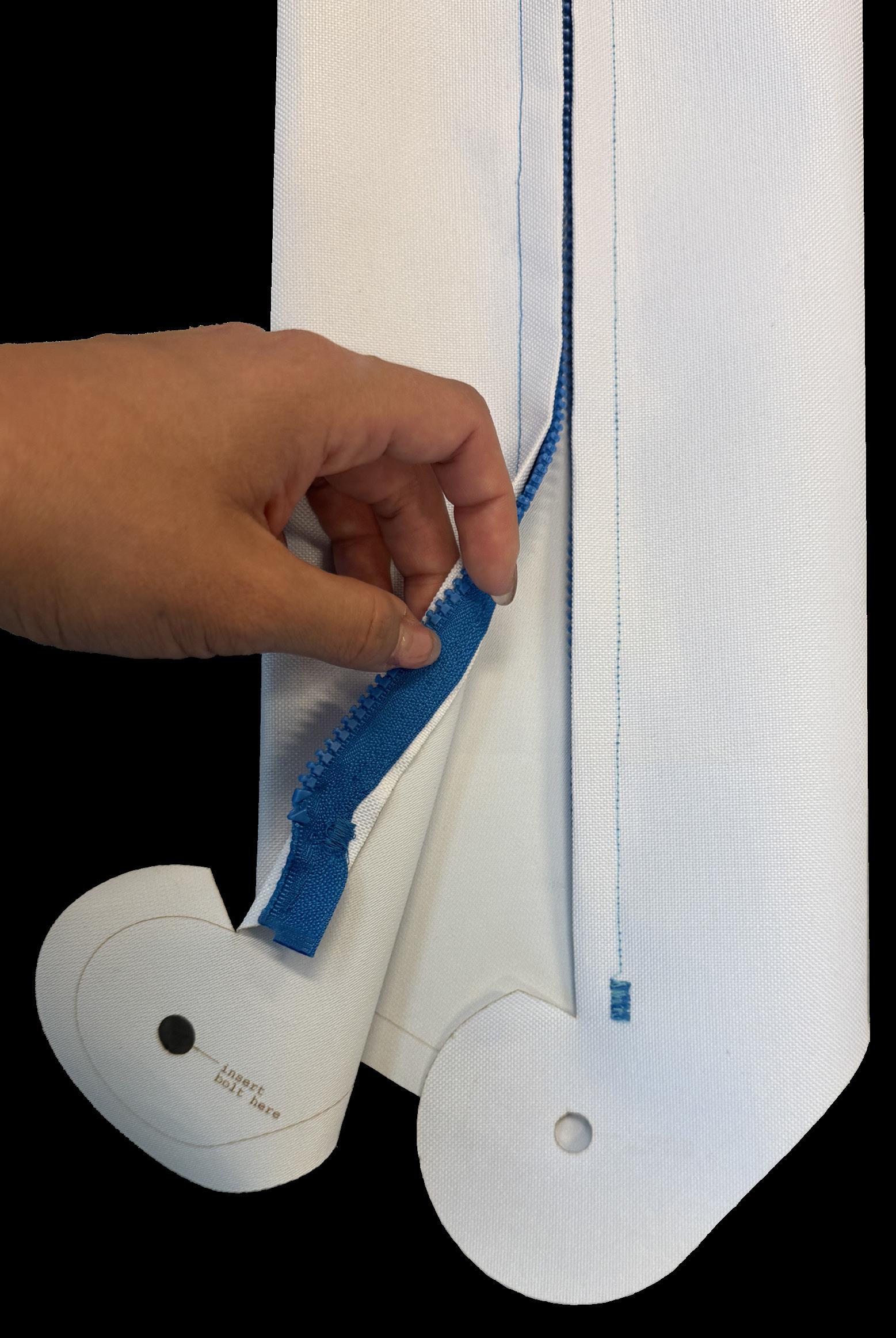

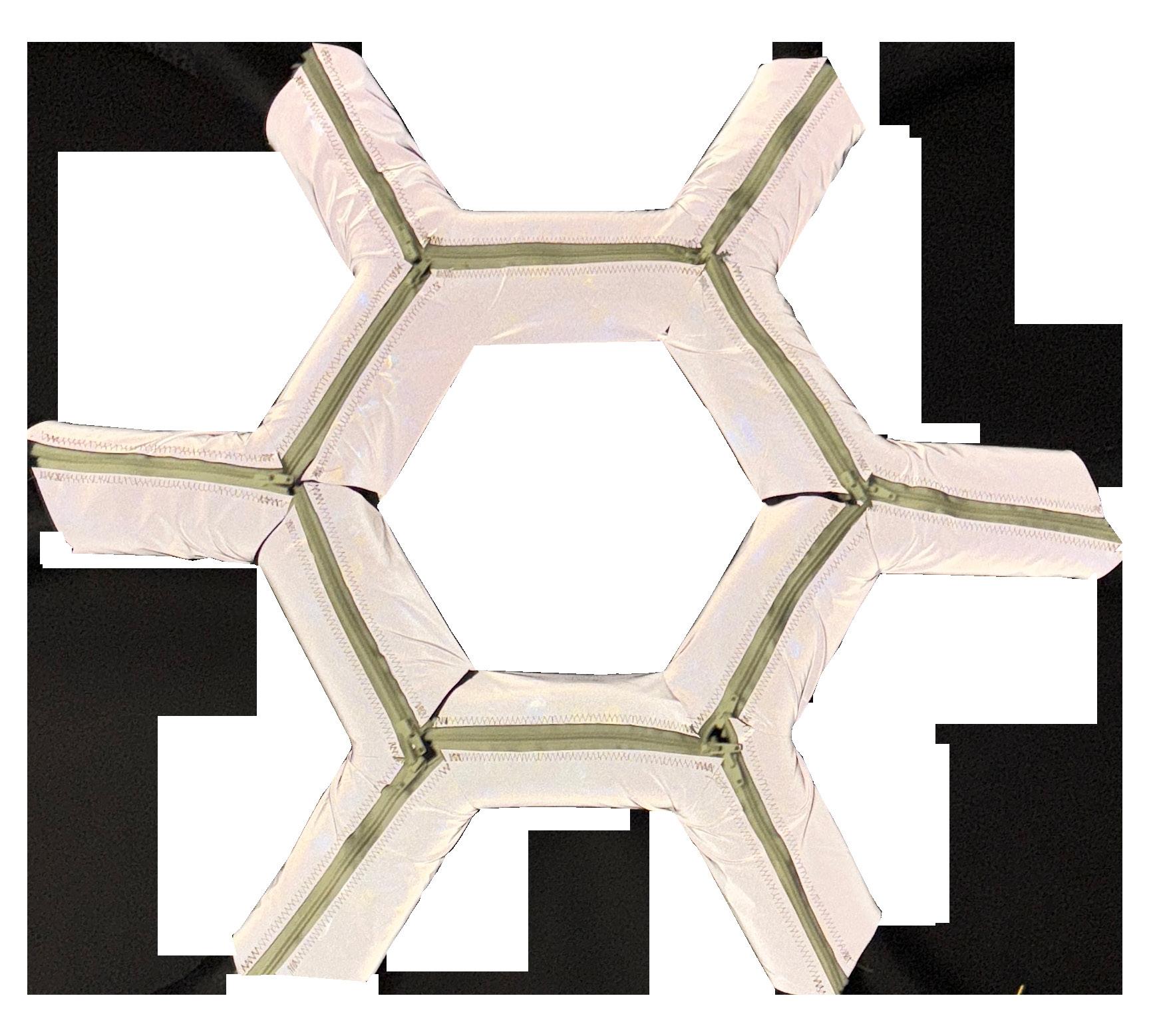

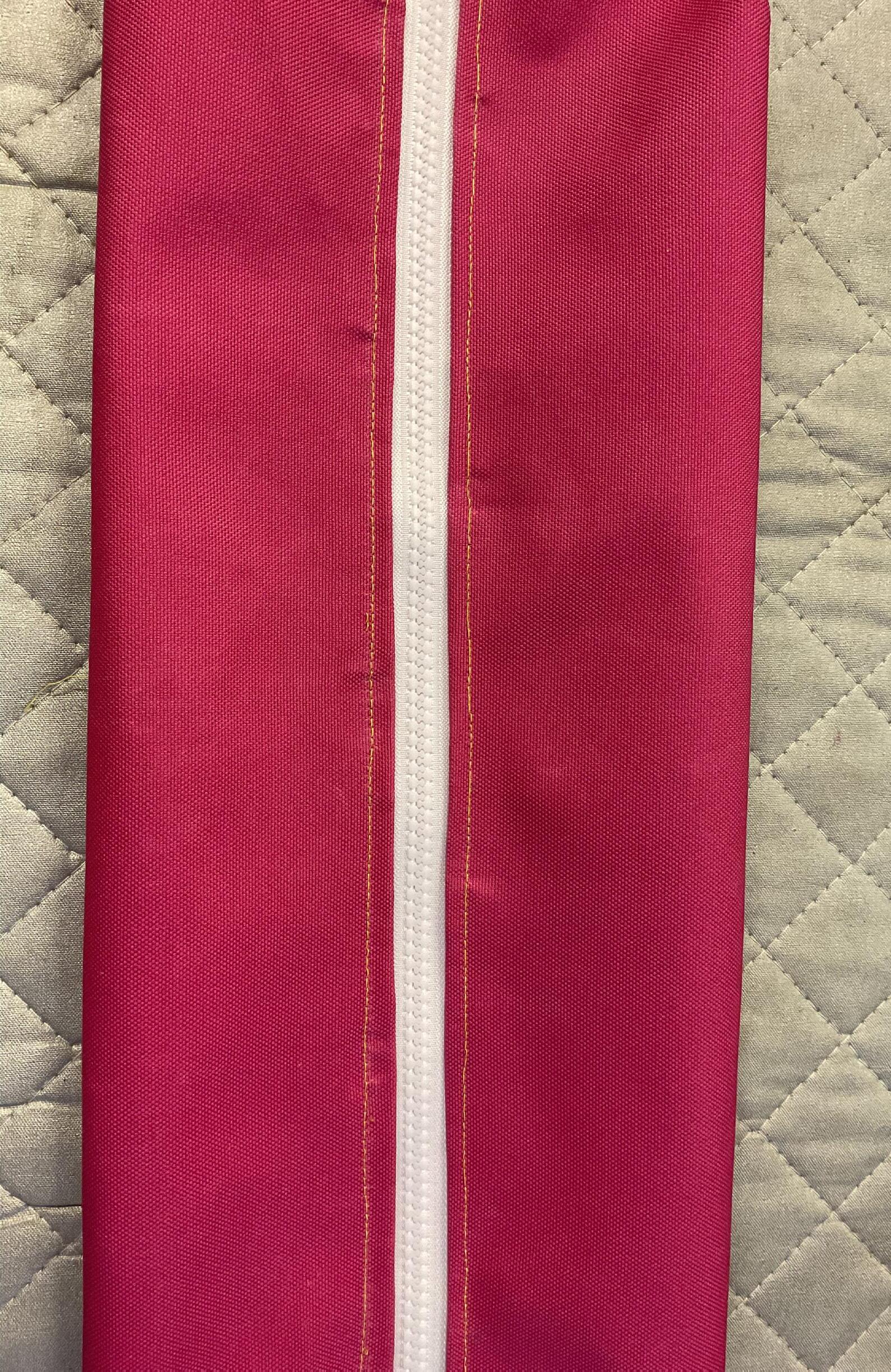

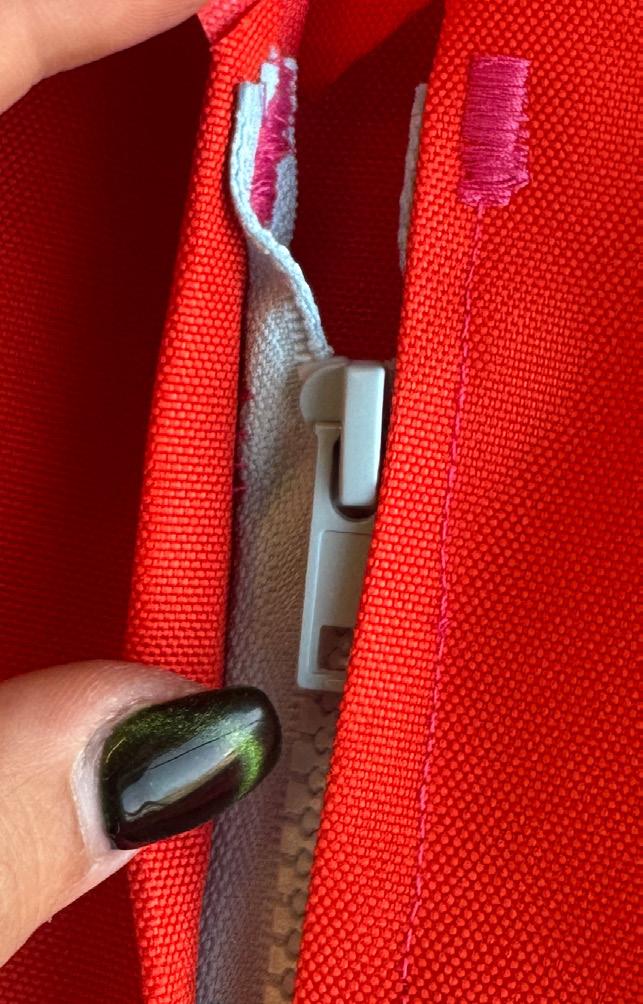

Looking closer at the connection, I designed different fabric sleeves to wrap tightly around the tires, compressing them together.

This creates strong joints and turns the curved forms into flat, wall-like surfaces.

Buttons

A 3 different tire sizes

Duck Canvas was the best result

Interior corner connection needed

chapter six-

LOGIC

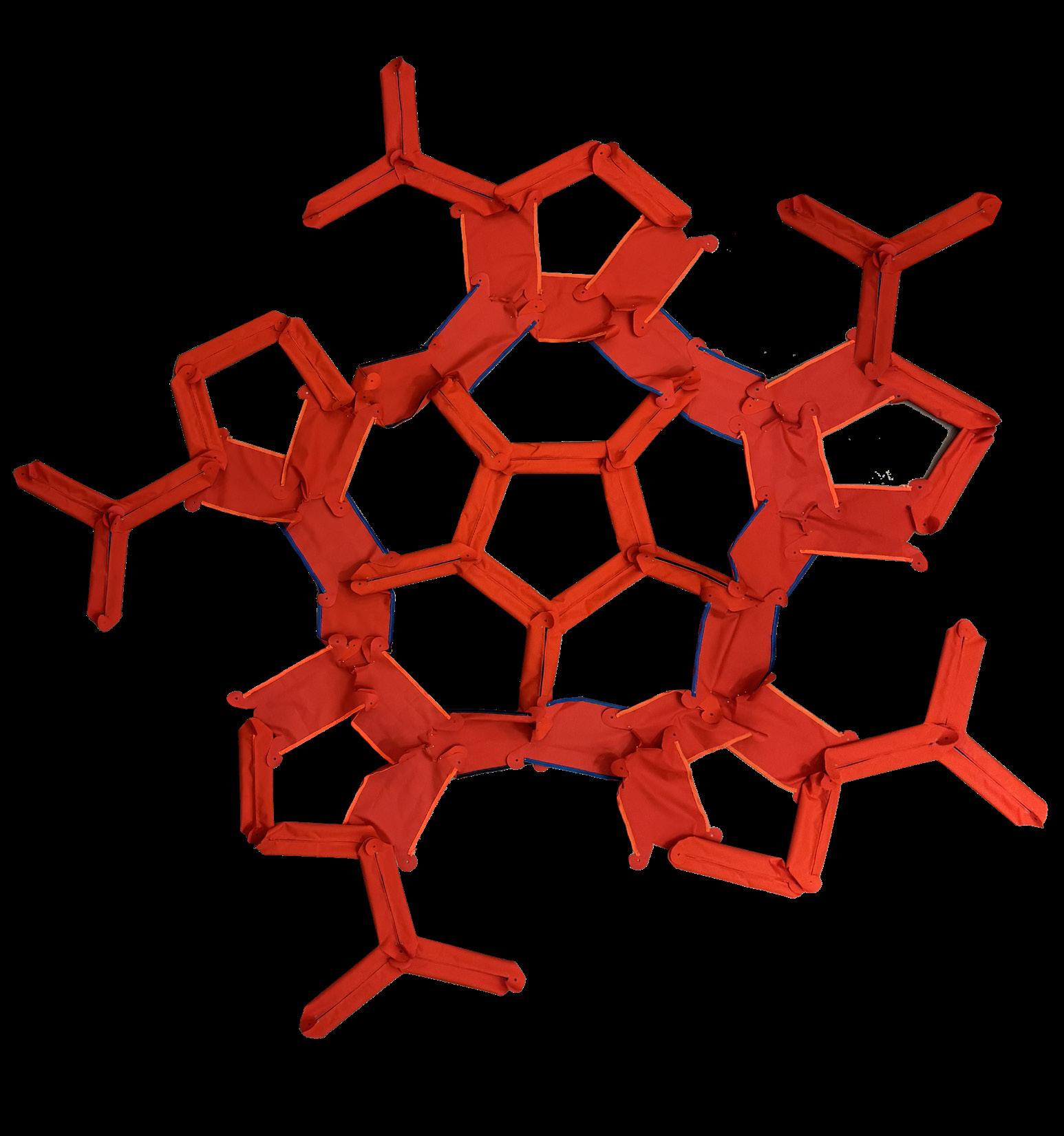

In geometry, the truncated icosahedron is a polyhedron that can be constructed by truncating all of the regular icosahedron’s vertices. Intuitively, it may be regarded as footballs (or soccer balls) that are typically patterned with white hexagons and black pentagons

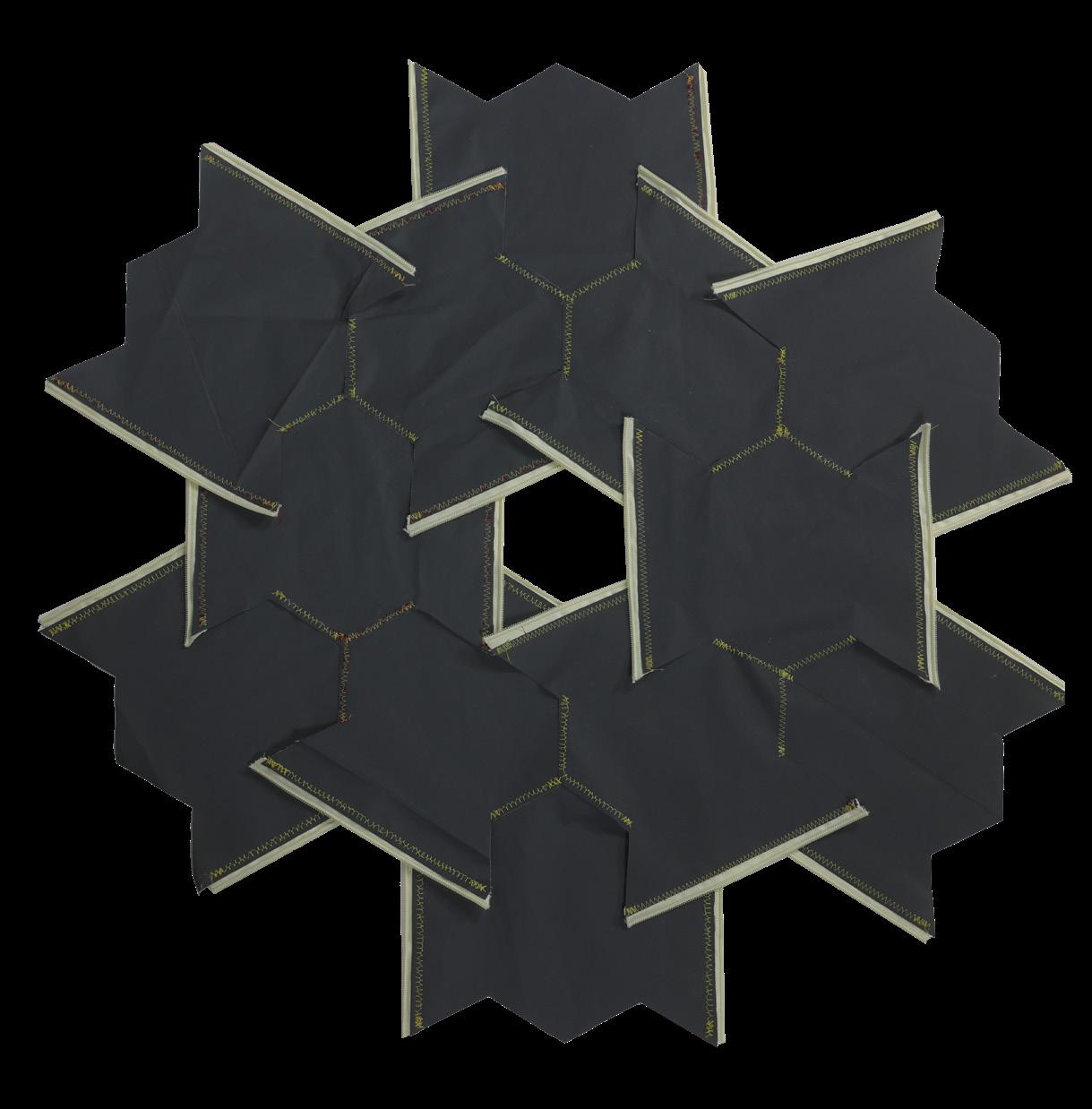

Inspired by Goldberg polyhedra, this thesis taps into a logic of geometric subdivision—where each reused pneumatic module mirrors the scalable, adaptive nature of geodesic constructions, enabling structures that can grow, shift, and reconfigure without fixed boundaries.

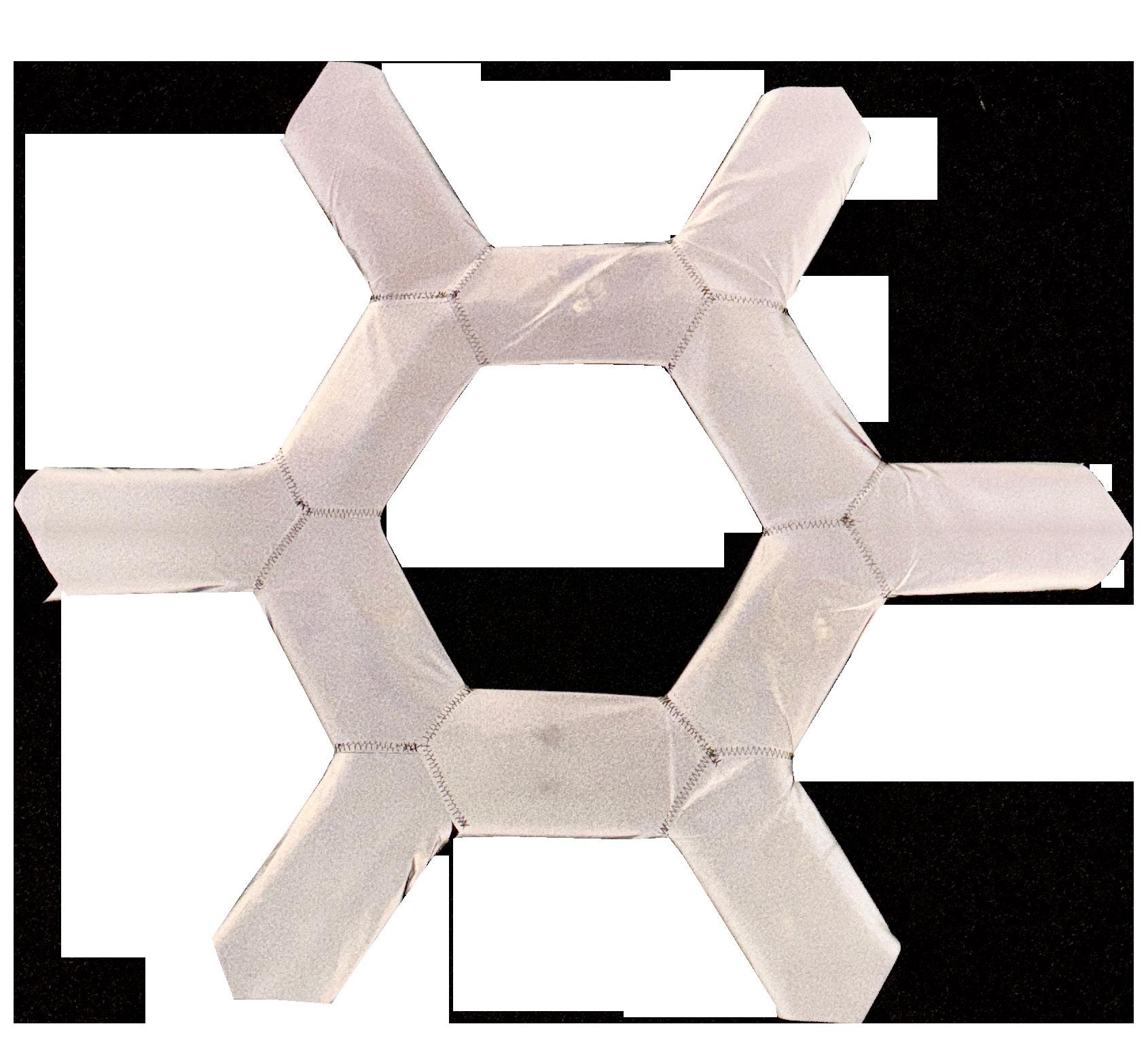

A Full hexagon enclosure

Reflective utility material 16in tires

chapter seven-

1:1 TYPEPROTO-

6.5 FT

The simplicity of the module enables complexity through repetition: curved becomes linear, linear becomes spatial.

chapter eight-

HOW TO AIR

Component Assembly

Quantity A

5 C sleeves

11 A sleeves

15 B sleeves

sleeves

Attach 5 B sleeves to A 5A

Attach 5 A sleeves to their corresponding B sleeves

5B

Attach 5 B sleeves to their corresponding A sleeves

5B

Attach 5 B sleeves to their corresponding A sleeves

Attach 5 A sleeves to their corresponding B sleeves 5C

Attach 5 C sleeves to their corresponding A sleeves

Final unrolled geometry

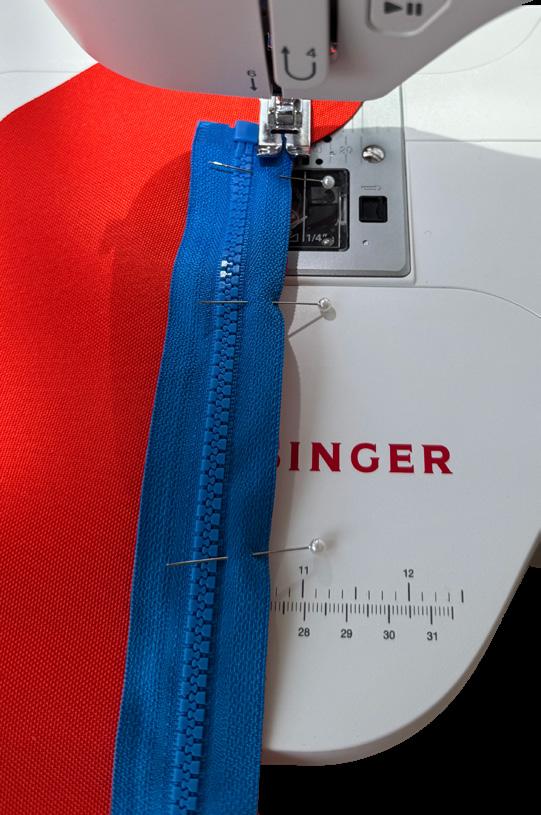

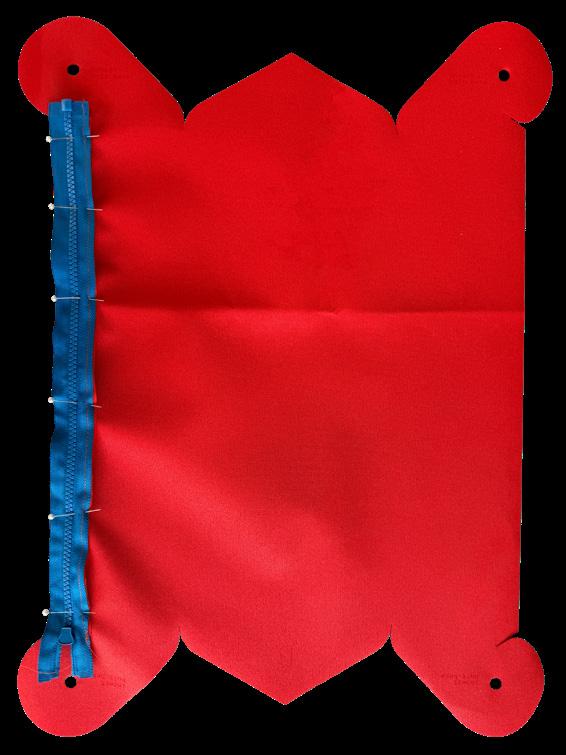

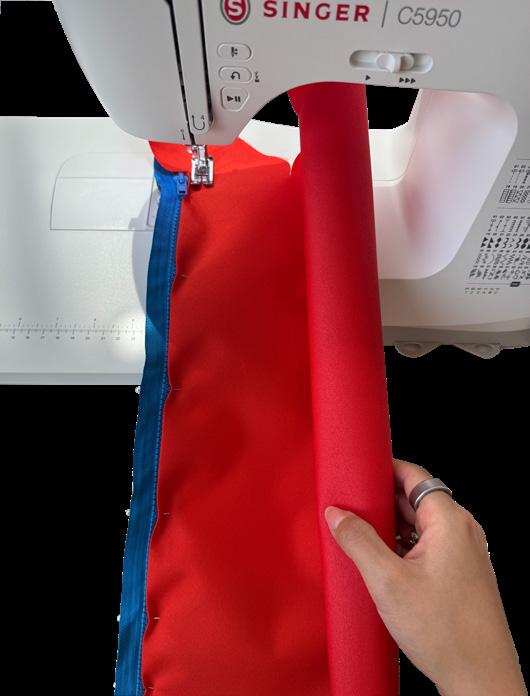

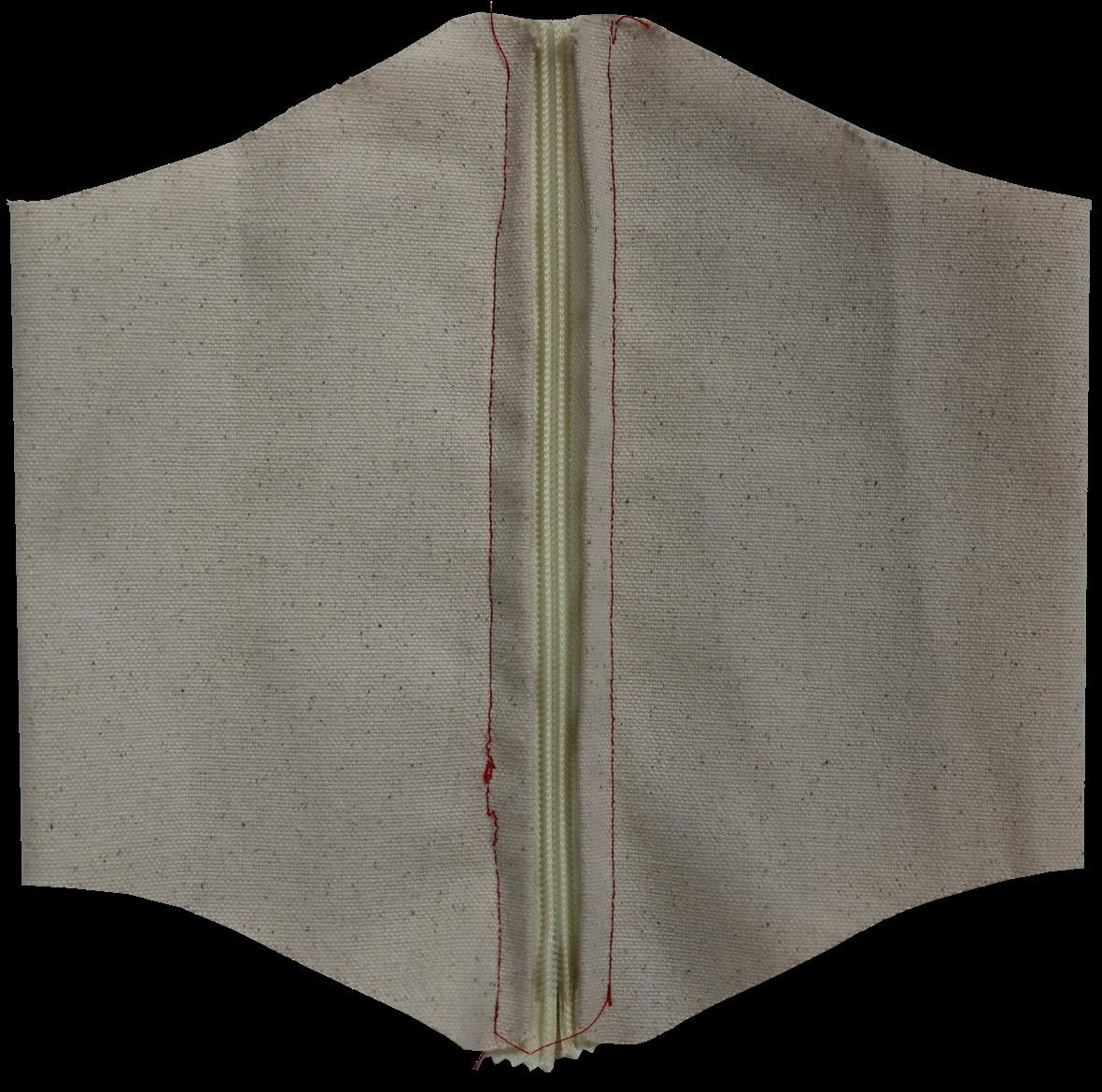

To bring air into form, the system needs a skin. The “outfit sleeves” acts as the architectural joint— negotiating between softness and structure, pressure and flexibility.

Pin the back of the zipper to the front side of the fabric

Start at the bottom of the zipper and work your way up

Rest the sewing foot up against the zipper for guidance when straight stitching all the way down

Flip onto other side

Lift and fold over scored dashed line

Flip the piece on its front and place the sewing foot against the zipper

Start and end with the cross stitch and have a straight stitch going in the middle

First zipper done!

Fold and transfer the alternate zipper over to the other side

Repeat step 2

Repeat steps 3-5

Repeat step 6

Second zipper done!

chapter nine-

PUMP UP THE JAM

(PUMP IT UP)

Panel of Critics

AAP Critics

Guest Critics Advisors

chapter ten-

AIRCHIVE

This change ensures that the force is distributed across the stronger axis of the fabric, reducing stress on the seam

magnets and snap buttons to snap on enclosure

Polypropylene Blend

Content:

71.4% Polypropylene (Filament)

28.6% Polyester (Filament)

A Material doesn’t fray when cut

Cube taking form

Corner connection needed B C

Reflective Utility Material

A Day and night quality difference

need for corner detail connection

credits-

Unless otherwise noted, all photos, diagrams, and drawings by the author.

pg 13

On Space Time Foam, installation view at HangarBicocca, Milan, 2012.

Photograph by Camilo Brau and Alessandro Coco.

© Studio Tomás Saraceno. Courtesy of Trendlan

pg 14

Yellow Heart, 1968.

Design by Haus-Rucker-Co.

Image courtesy of Architectuul.

pg 15

Architecture on Stage: Graham Stevens Image courtesy of World-Architects.

pg 17

The Hindenburg disaster, May 6, 1937. Photograph by Sam Shere.

© Associated Press.

pg 19

An aerial view of the tire graveyard, which threatens the environment and human health due to the dangerous components and durability of the material, located 160 kilometers away from the capital Kuwait City in al Salmi area, Kuwait, in August 2021.

Photograph by Anadolu Agency / Getty Images

© BuzzFeed News.

pg 20

Cushicle and Suitaloon conceptual design, 1960s.

Design by Michael Webb (Archigram). Image courtesy of Archigram Archive

pg 22

The Threefold Nature of Man, chart by Clarence Larkin.

Image courtesy of Blue Letter Bible.

pg 24

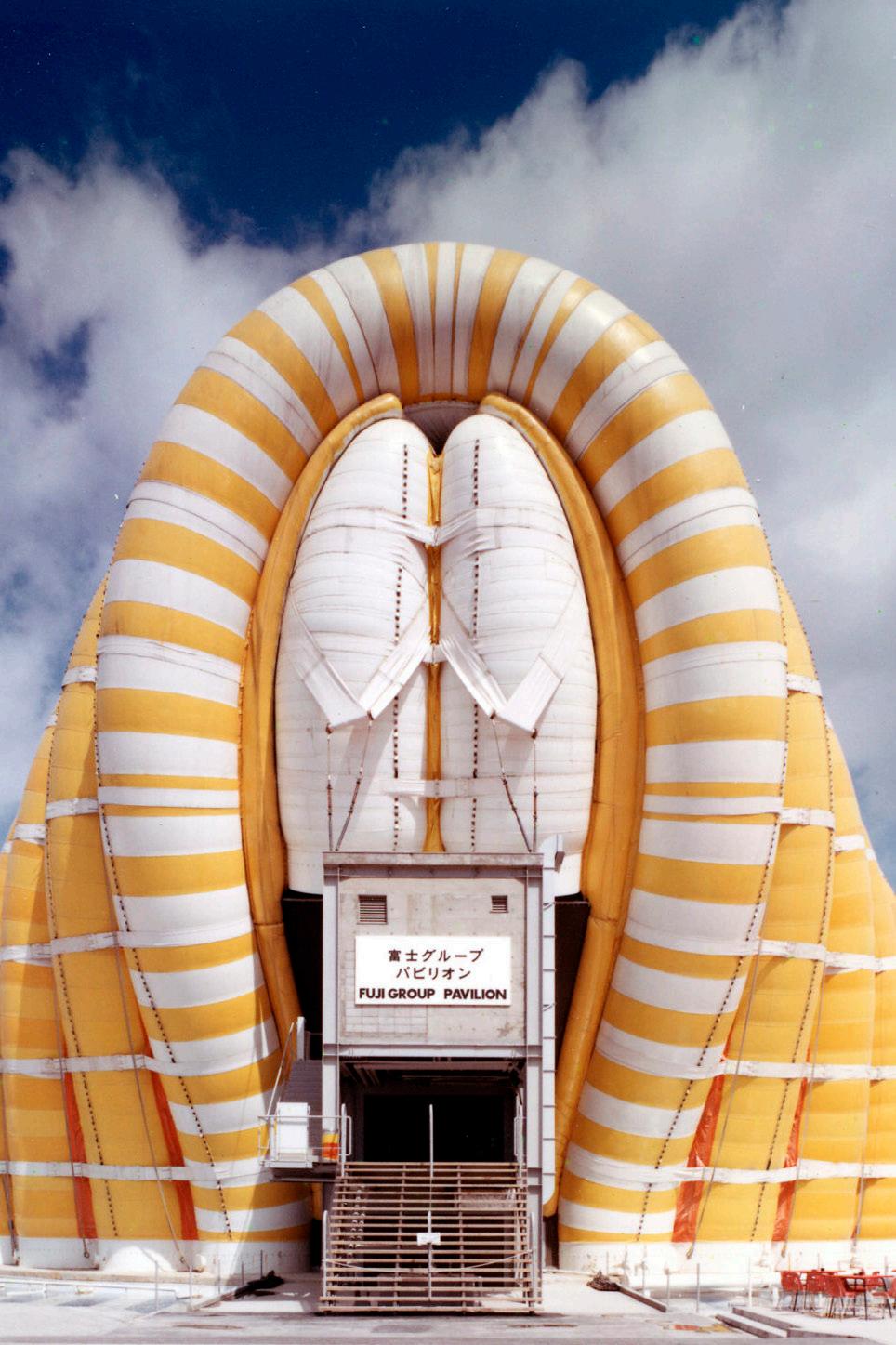

Fuji Group Pavilion, Expo ‘70, Osaka, 1970.

Design by Yutaka Murata and Kawaguchi & Engineers.

Image courtesy of Kawa Structural Design.

pg 26

International Terminal at Waterloo Station, London, 1993.

Design by Nicholas Grimshaw.

Photograph by Jo Reid & John Peck. Image courtesy of The Guardian.

pg 35

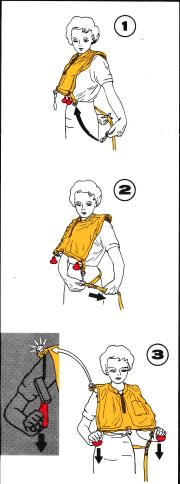

Airline Safety Card Collection. Image courtesy of the World Airline Historical Society.

pg 36

10-Person Liferaft ZMEC TO PA Xtrem.

Image courtesy of De Wolf Maritime Safety.

pg 38

Low-Pressure Rapid Response Inflatable Shelter. Image courtesy of i2k Defense.

pg 41

100-Ton Inflatable Lifting Cushions.

Image courtesy of Buitink Technology.

pg 42-43

Screenshots from Giant 3ft Balloon Pop (in Slow Motion)

Video by Slow Mo Lab.

YouTube, uploaded Mar 7, 2015

pg 45

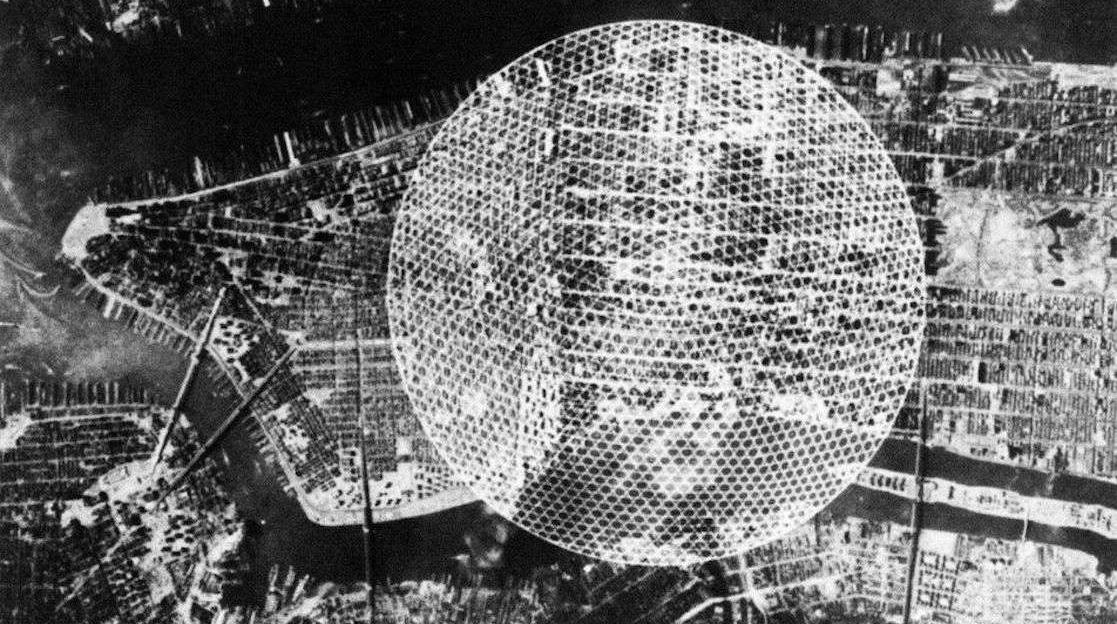

Dome Over Manhattan, conceptual rendering, 1960s.

Image by Buckminster Fuller Institute.

Reproduced via The New York Times, November 2016.

pg 47

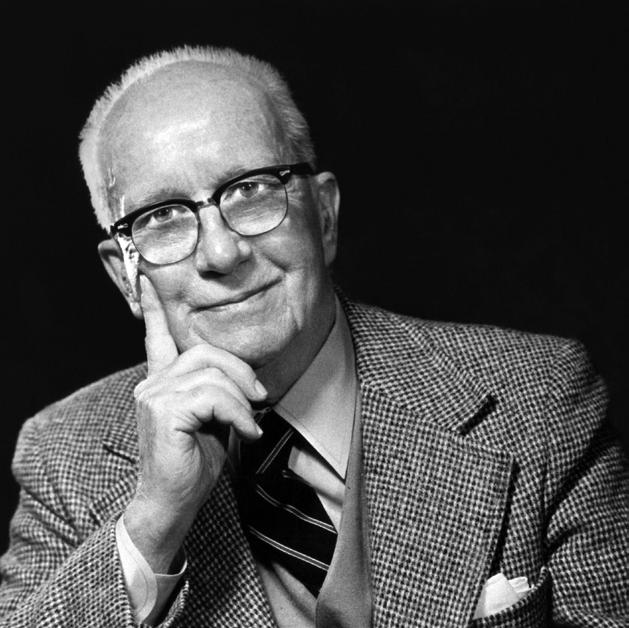

Buckminster Fuller in front of a geodesic dome, date unknown.

Photograph by Bettmann Archive. Courtesy of Fine Art America.

pg 48

Crane lifting steel beams at a construction site (AIgenerated).

Image © Adobe Stock.

pg 49

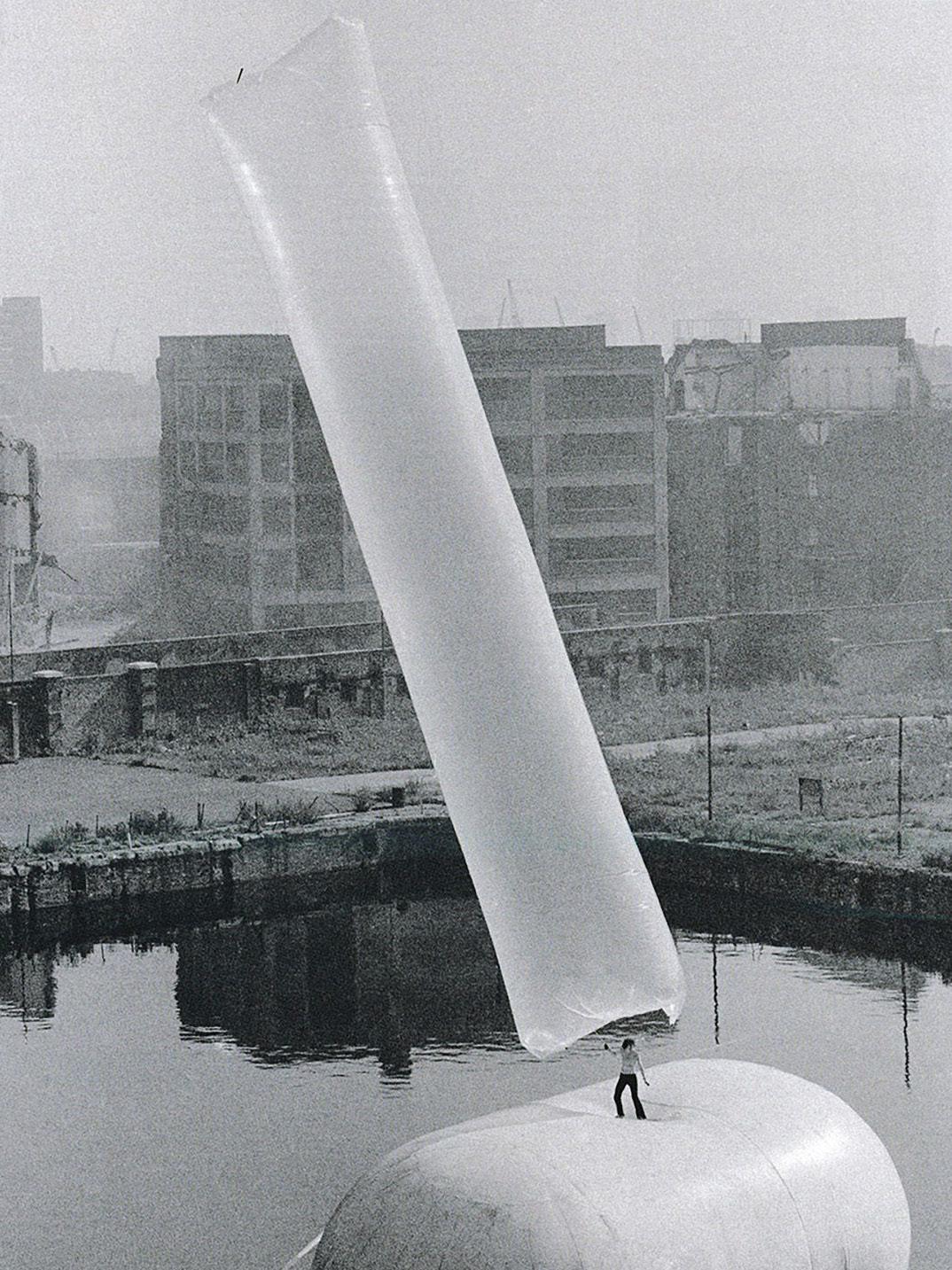

Graham Stevens, Atmosfield, St. Katharine Dock, London, 1968.

© ADAGP, Paris, 2021.

pg 56

Changing a flat tire.

Photograph by Sergiy Zavgorodny.

© Getty Images.

pg 76,78-81,83

“Visions of Utopia” exhibition, Milstein Dome, Ithaca, NY, 2024.

Inflatable Bubble by Amanda Choi, Jack Mieszkalski, and Raihaan Bose

Photographs by Anson Wigner. Courtesy of the artists and the photographer.

pg 102

PAO WIN 13x5.00-6 Inner Tube Replacement. Product image from Amazon.com.

© PAO WIN, via Amazon.

pg 102

CalPalmy 20” x 2.125” Bike Inner Tube with Schrader Valve. Product image from Amazon.com.

© CalPalmy, via Amazon.

pg 110-111

Geometry and symmetry in nature and architecture, based on studies by Berlage and Frei Otto.

From The Fuller’s Heritage: Organic Models and Artificial Microcosm in 20th Century Domes. Available on ResearchGate.

pg 112

Frei Otto bubble form studies

Figure from Frei Otto: Light Structures Inspired by Nature, in Architecture Inspired by Nature, edited by M.R. Cervera Sardá et al.

© Springer Nature Switzerland AG, 2023.

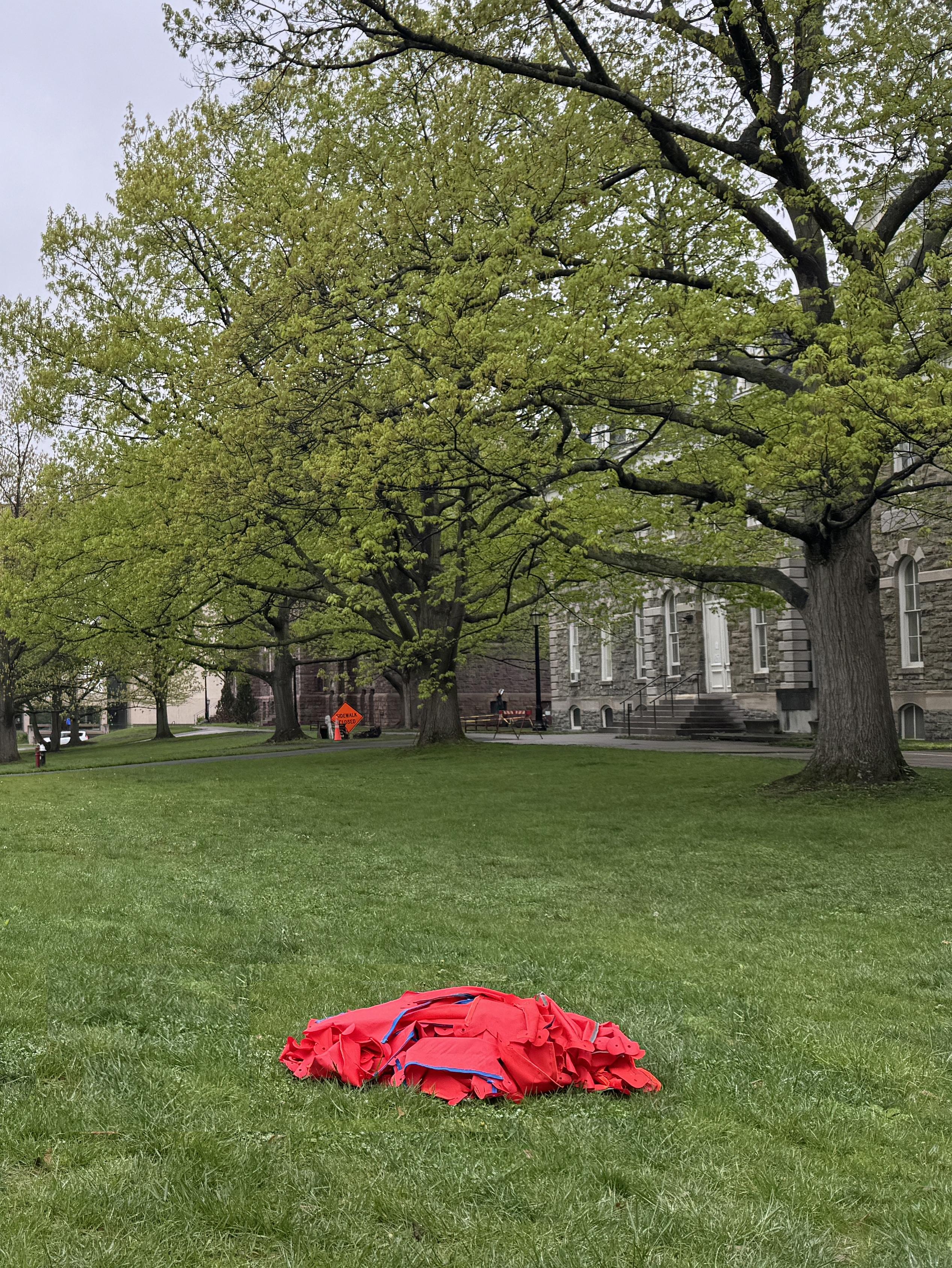

pg 186-187, 270-271

Final Review inflatable dome on the Arts Quad, Cornell University, 2025.

Photographs by Anson Wigner. Courtesy of the photographer.

pg 188-189

Final Review inflatable dome on the Arts Quad, Cornell University, 2025.

Photographs by Manu Nores. Courtesy of the photographer.

pg 196-199

Drone view of the inflatable dome on the Arts Quad, Cornell University, 2025.

Photographs by HP Park. Courtesy of the photographer.

pg 266-269

Assembly of dome on the Arts Quad, Cornell University, 2025.

Photographs by Anson Wigner. Courtesy of the photographer.

bibliography-

Andrić, Davor. “Contemporary Pneumatic Structures in Architecture: Critical Review and Analysis.” Prostor: Scholarly Journal of Architecture and Urban Planning 28, no. 1(59) (2020): 142–153. https://doi.org/10.31522/p.28.1(59).9.

Bieber, Susanneh. “Atmospheric Pressures: Victor Lundy’s AEC Pavilion and the Sociopolitical Climates of Inflatable Architecture.” Journal of Architectural Education 73, no. 1 (2019): 32–45. https://doi.org/10.1080/10464883.2019. 1688219.

Chi, Jung Yun, and Ruy Marcelo de Oliveira Pauletti. “Design and Analysis of Pneumatic Structures.” Paper presented at the IASS-SLTE 2008: International Symposium on Lightweight Structures in Civil Engineering and Architecture, Universidad Central de Venezuela, Caracas, 2008. https://www.researchgate.net/publication/326673085.

Craven, Wesley Frank, and James Lea Cate, eds. The Army Air Forces in World War II. Vol. 1, Plans and Early Operations, January 1939 to August 1942. Chicago: University of Chicago Press, 1948. Reprint, Washington, D.C.: Office of Air Force History, 1983. https://www.afhso.af.mil/Portals/86/documents/Operations/Volume1.pdf.

Dent, Roger Nicholas. Principles of Pneumatic Architecture. London: Architectural Press, 1971.

Eryılmaz, Emine Burcu. Architecture as a Discursive Discipline: Inflatable Spaces of Radical Avant-Gardes. Master’s thesis, Middle East Technical University, 2019. https://www.researchgate.net/publication/354162371.

Francis, Sharon. Bubbletecture: Inflatable Architecture and Design. New York: Van Nostrand Reinhold, 1973.

Herzog, Thomas. Pneumatic Structures: A Handbook of Inflatable Architecture. Contributions by Gernot Minke and Hans Eggers. London: Thames and Hudson, 1976.

Hebel, Dirk E., Marta H. Wisniewska, and Felix Heisel. “Constructing Waste: Investigating an Alternative Resource for Future Cities.” Building from Waste, November 2015. https://www.researchgate.net/publication/295912128.

Ishii, Kazuo, ed. Membrane Designs and Structures in the World. Tokyo: Shinkenchiku-Sha, 2001.

Krauel, Jacobo. Inflatable Art, Architecture & Design. Edited by Naomi Ferguson. Introduction by Imma Muñinos and Jacobo Krauel. Barcelona: Links International, 2006.

McQuaid, Matilda, and Phil Patton. The Inflatable Moment: Pneumatics and Protest in ’68. New York: Princeton Architectural Press, 1998.

Meissner, Irene, and Eberhard Möller. Frei Otto: Forschen, Bauen, Inspirieren = A Life of Research, Construction and Inspiration. Berlin: Jovis Verlag, 2005.

Migayrou, Frédéric, and Valentina Moimas, eds. Aerodream: Architecture, Art, Design et Structures Gonflables. Paris: Éditions du Centre Pompidou, 2021.

Pauletti, Ruy Marcelo de Oliveira. “Some Issues on the Design and Analysis of Pneumatic Structures.” International Journal of Structural Engineering 1, nos. 3–4 (2010): 217–240. https://doi.org/10.1504/IJSTRUCTE.2010.033480.

Rudolph, Rebecca. NOMADIC:PNEUMATIC – Buildings that Moves: An Atlas of Nomadic Devices as a New Cultural Institution to Mobilize Culture. Master’s thesis, Umeå School of Architecture, Umeå University, 2021. https:// digitalcommons.unl.edu/cgi/viewcontent.cgi?article=1003&context=jccemafac.

Thangavelu, Madhu, and Claire Stevlingson. “HALIE – Hybrid Approach to Lunar Inflatables and Erectables (HALIE) for Initial Operational Capability.” Paper presented at the AIAA ASCEND 2023 Conference, December 2023. https://www. researchgate.net/publication/376682032.

Topham, Sean. Blowup: Inflatable Art, Architecture, and Design. Munich: Prestel, 2002.