FABRICATION FOCUS

Explore how Betaweld SL-Series can elevate your welding game with premium consumables designed for reliability and precision.

What is Flux Cored Seamless Technology?

Seamless cored wires are among the latest in welding wire technology, resulting in multiple advantages to both the operator and end user. As illustrated in the diagram below, the metal strip is first folded to a round tube, joined by high frequency welding process, then drawn down to the filling diameter. The tube is then filled with agglomerated flux by a vibration system, ensuring consistency of the flux throughout the welding wire. After this process is complete, the wire is then annealed, drawn down to final diameter and put through a copper shealth coating process. The end result is a completely sealed flux cored wire, with extreme resistance to moisture absorption, both when in storage and also when in use.

1. Strip material

2. Manufacturing tube from solid strip using HF welding

3. Recrystalisation annealing and calibration to filling diameter

4. Manufacturing agglomerated flux and filling of the tube by vibration

5. Pre-drawing and annealing of tube

6. Drawing to final dimension and copper coating

7. Spooling of wire

Features and Benefits of Seamless Cored Wired

• Very low content of diffusible hydrogen

• AWS H4/EN ISO HS Classifications

• No moisture absorption during handling and storage

• Reduced tendency to hydrogen induced weld cracking

• Excellent wire feeding even at high speeds

• Does not require knurled rollers

• Copper coated to optimise conductivity

• Excellent operator appeal featuring single parameter all positional capabilities

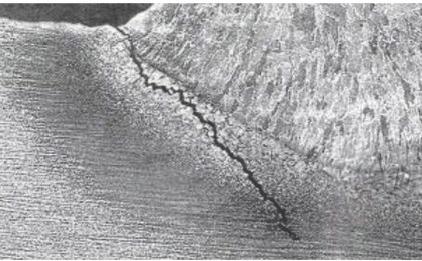

What is Hydrogen Induced Cracking (HIC)?

Hydrogen Induced Cracking (HIC) is a common type of weld failure, caused by the introduction of hydrogen or moisture into the weld material. The transfer of the hydrogen is normally through the flux component of the welding wire or welding electrode. HIC does not always occur immediately after the weld process is complete, often it will occur once the weld has returned to ambient temperature. The effect of HIC is normally a costly rework procedure. This will consist of either grinding back or gouging out the faulty weld, then re-doing the welding process.

SEAMLESS TECHNOLOGY

Seamless Flux Cored Wire

Seamed Flux Cored Wire

THE BETAWELD SL SERIES RANGE

•

•

•

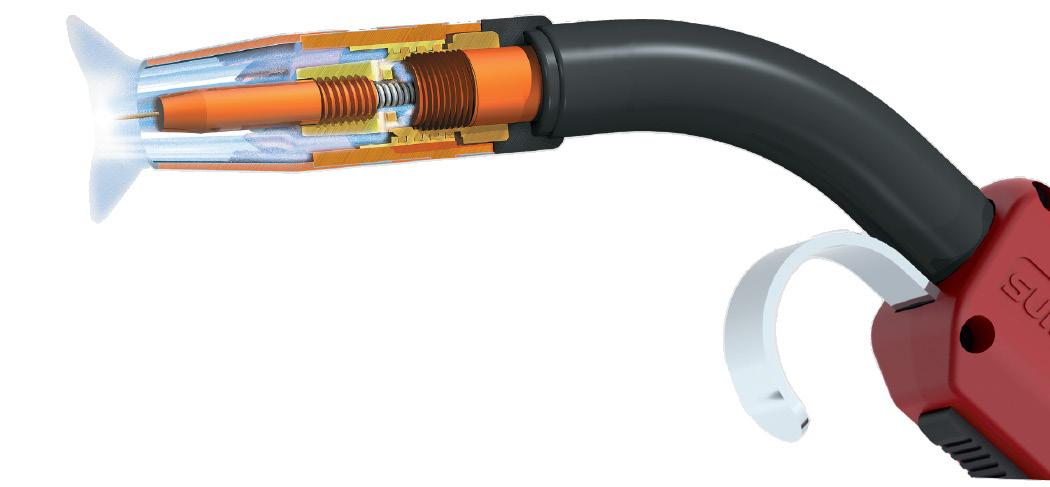

WELDING TORCHES

WORLD’S STRONGEST WELDING GUNS

SUMIG Welding Torches are renowned as the “world’s strongest welding guns,” expertly crafted to cater to the demands of welding professionals across a variety of industries.

From light work in automotive garages and repair shops, to heavy-duty work performed in shipyards, rail, and automotive industries, among many others.

Alphaweld Supply Group is proud to be the exclusive distributor of SUMIG torches here in Australia, and is always ready to offer you expert advice when it comes to choosing a welding torch.

THE SUMIG DIFFERENCE

WELDING TORCHES

Recommended Amperage Range

150A - 260A

Duty Cycle

260@60% (CO2) / 225A@60% (Argon mixed)

Wire Capacity

0.6mm to 1.0mm Air Cooled

Recommended Amperage Range 200A-300A

Duty Cycle

260@60% (CO2) / 225A@60% (Argon mixed)

Wire Capacity 0.8mm to 1.2mm

Recommended Amperage Range

250A - 400A

Duty Cycle

400@60% (CO2) / 355A@60% (Argon mixed)

Wire Capacity 0.9mm to 1.6mm

400@60% (CO2) / 330A@60% (Argon mixed)

Wire Capacity 0.8mm to 1.6mm

WELDING SAFETY

ESSENTIAL SAFETY FOR EVERY WELDING ENVIRONMENT

Betaweld Welding Screen & Frame Kits are designed to provide a high level of protection against welder’s flash and hazardous ultraviolet rays, ensuring a safer environment for those in the vicinity. Its transparent yet effective shielding reduces glare for the welder while maintaining visibility and adaptability in both indoor and outdoor settings.

Crafted from premium fire-resistant material, Betaweld welding screens are built for longevity - they won’t crack, harden or degrade over time, even under demanding conditions. Their reinforced eyelets allow for secure and hassle-free mounting, making it an essential safety solution for any welding environment.

FEATURES & BENEFITS

Protects against welder’s flash and ultraviolet rays

UV stabilised and fire-retardant welding screen featuring premium stitched edging

Transparent for increased safety

Durable galvanised steel construction frame with heavy-duty castors

Sturdy RHS steel bolt-together system with welded corners

Each castor has an in-built brake for secure positioning

Reinforced eyelets for secure mounting

Suitable for internal or external use

Complies with AS3978

WELDING SAFETY

3m Length x 1.2m Width x 2m Height

Engineered for the toughest environments, the Betaweld Mine Spec Welding Curtain & Frame Kit is purpose-built to meet the demanding safety standards of Australian mine sites. This heavy-duty welding curtain kit provides essential protection against welding hazards, ensuring a safer and more controlled work area. Ideal for mining, heavy industry and fabrication workshops.

Unlock Exclusive Benefits - Join Over 2,000+ Satisfied Online Customers!

✔ Shop Anytime, Anywhere: 24/7 access to over 5,000+ premium welding products online

✔ Exclusive Online Pricing: Special online-only prices tailored for trade customers

✔ Flexible Payment Options: Pay by PO (purchase order), credit card, bank transfer, PayPal or ZIP

✔ Flexible Payment Terms: Convenient 30-day payment options on approved trade accounts

✔ Streamlined Reordering: Customisable reorder templates, perfect for your monthly reordering

✔ Effortless Account Management:

• View and download all account invoices

• View and manage online quote requests

• Track your ordering history with ease

✔ VIP Perks: Stay ahead with Alphaweld’s exclusive updates and unbeatable deals!

✔ Easy Application Process: Applying takes just minutes and can be easily completed online