Quality Products for Metallographic

Sample Preparation & Analysis

Product Catalog

Quality Products for Metallographic

Sample Preparation & Analysis

to the Allied High Tech Products catalog and to a world of technology, equipment and consumables for metallographic sample preparation and analysis.

For over 41 years, Allied has been meeting the needs of companies in the materials science, materials manufacturing, aerospace, military, microelectronics, photonics, fiber optics, research & development and many other industries. We aggressively pursue the advancement of preparation procedures related to each of these industries, and therefore promote close working relationships with hundreds of the world’s leading research universities, laboratories and institutions.

The Allied commitment is simple and complete: We provide our customers the finest and most advanced equipment and consumables for metallographic sample preparation, expert technical assistance and unequalled service, before and after purchase.

Every day. Worldwide.

Our measure of success has always been, and always will be, your complete satisfaction with Allied’s products and services. As you browse our catalog, I invite you to see for yourself the variety of ways Allied can support your pursuit of success. We look forward to helping you get there.

Thank you for choosing Allied.

Sincerely,

Clay Smith Chief Executive Officer

Situated in prime locations in California and Oklahoma, each facility represents a unique facet of our expanding vision.

Edmond: Our new research and manufacturing facility was purchased and remodeled from the ground up in 2022. Initially focusing on software creation, circuit board production and other electrical assemblies, we’ve recently duplicated almost all of the functions of our California facilities, with a focus on equipment research and development.

Spanning 11,000 ft2, this dynamic space promotes collaboration, creativity and community.

And with the ability to more than triple facility space, coupled with Oklahoma's motto “Labor Omnia Vincit,” meaning “work conquers all things,” Edmond will absolutely play a bigger future role in the Allied story!

Cerritos: Our new headquarters was purchased and remodeled from the ground up in 2023, and marks a significant milestone in Allied’s history.

Covering 24,000 ft2, this state-of-theart facility reflects our commitment to quality, innovation, growth and excellence. It has been customized to improve operational efficiencies and streamline our capabilities to meet the growing needs of our customers.

Norwalk: This 4,000 ft2 logistics center is used to receive, process, store and ship various raw materials, equipment parts and bulk consumables to support operations worldwide.

At Allied, we know that successful outcomes depend on integrated, well-conceived solutions. That’s why our focus is on the research, design, manufacture, distribution, service and support of high-quality equipment and consumables for metallographic sample preparation and analysis to support a wide variety of industries.

Our products are utilized in laboratories and production environments where quality assurance, reliability and failure analysis are used as measures for worldwide compliance and safety. Because we believe the ability of our customers to effectively use our products is just as important as the effectiveness of the products themselves, we offer comprehensive personalized training and expert technical assistance. Allied products are backed by a complete satisfaction guarantee.

With our headquarters located in Cerritos, California, a research/manufacturing facility in Edmond, Oklahoma, an extensive domestic sales force and a network of international distributors, Allied’s equipment, consumables and technical expertise are utilized and supported worldwide.

We invite you to investigate the world of Allied High Tech Products, Inc.

Allied is committed to “the ultimate service experience,” starting with our friendly and helpful customer service personnel. Our goal is your complete satisfaction!

Using the latest 3D CAD design software, a team of dedicated mechanical, electrical and design engineers assures that Allied’s equipment is designed and built for maximum performance and durability.

If you are not completely satisfied with any Allied product, simply return it within 30 days, and we’ll either replace it or refund your money. Allied equipment carries a full 2-year warranty.

We're Not Satisfied Until You Are!

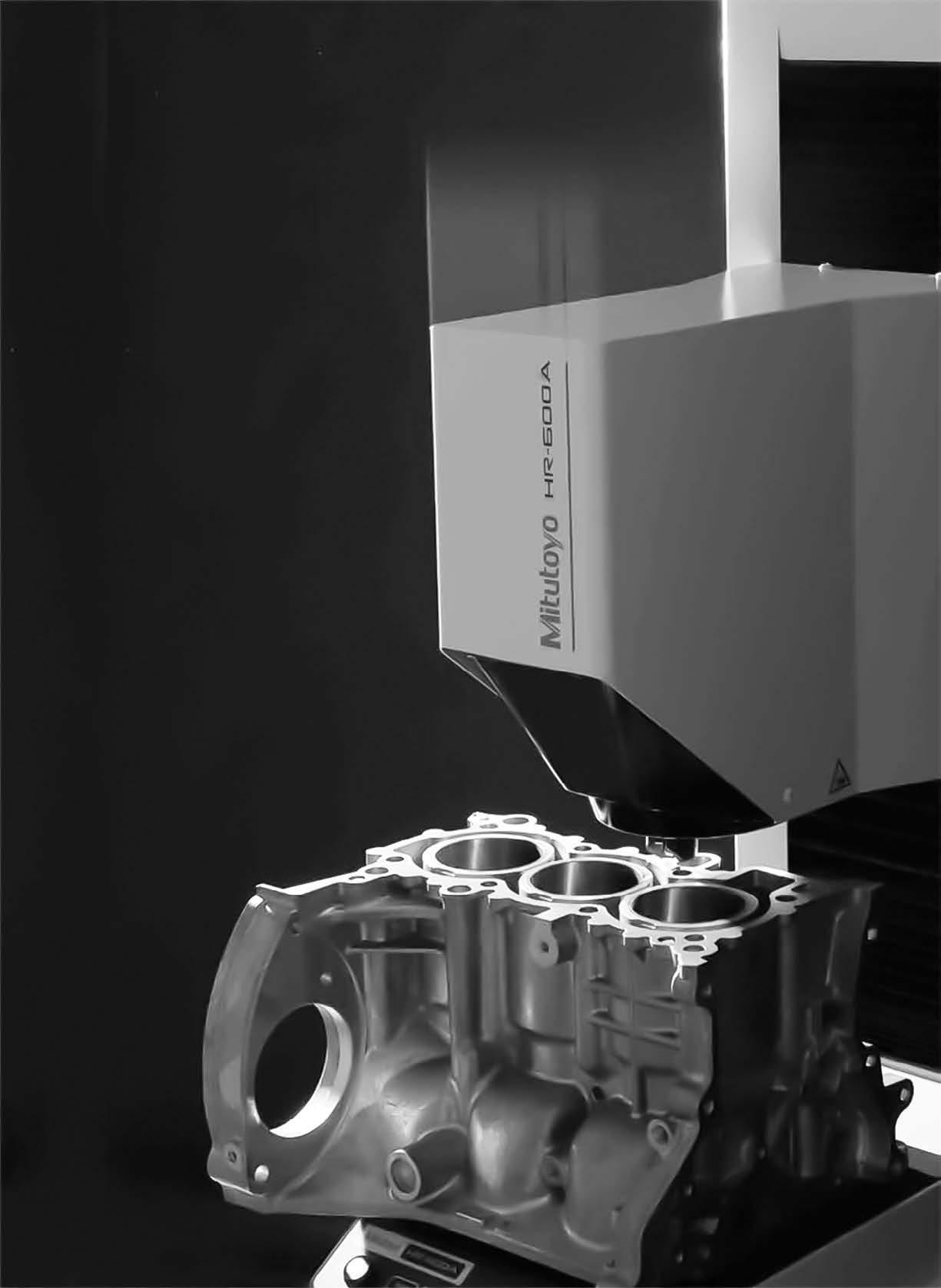

In-house precision machining capability allows critical parts processing, rapid prototypes and custom manufacturing.

Allied designs and manufactures a complete range of state-ofthe-art equipment at its 24,000 ft2 California headquarters and at its 11,000 ft2 Oklahoma facility.

Allied materials engineers and lab technicians provide product demonstrations and training, develop specialized sample preparation procedures for customers worldwide and evaluate new products prior to introduction. "Our lab's for you!"

In scheduled programs, Allied offers technical expertise and training on the latest processes, equipment and consumables.

Allied’s warehouse team receives, inspects and repackages products daily, ensuring that consistent, high quality standards are met. With the largest inventory of its kind, Allied’s next-day order processing supports the immediate needs of customers worldwide.

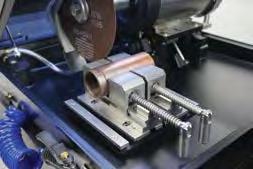

Robust manual and semiautomatic cutting machines for various applications, from bulk to precision sectioning.

Excellence in Sectioning

PowerCut 10x™

Cut-Off Saw

Features

Manually operated saw for a wide variety of materials

10" (254 mm) diameter blade capacity

Cutting capacity: up to 3.75" (95 mm) bar stock

Powerful 3.5 HP (2600 W) stainless steel waterproof motor

5" (127 mm) distance between blade and motor, allowing longer/larger parts to be sectioned

Side port for cutting long samples

Optional blade position laser indicator and electro-mechanical safety lock

5-4200 Item Description 230 V 50/60 Hz 3 Phase

5-4200-415 415 V 50 Hz 3 Phase

5-4200-480 480 V 50/60 Hz 3 Phase

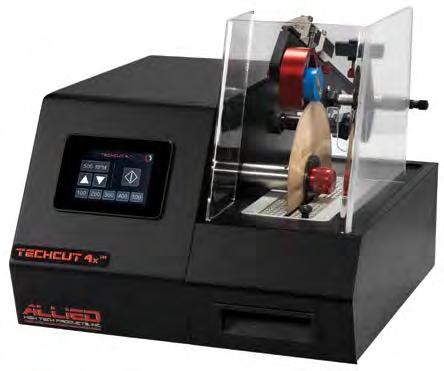

TechCut 5x™

Semiautomatic High Speed Saw

Features

Versatile, programmable saw for a wide variety of materials

Accepts 3−8" (76−203 mm) diameter blades

Cutting capacity: up to 2.5" (63 mm) bar stock

Color LCD touchscreen to control all functions

Programmable RPM, force, cut depth and feed rate

Y-axis operation: motorized (joystick) or manual (handwheel)

Closed loop load monitoring to reduce blade binding/breakage

Allows either indexing or T-slot tables with a variety of fixtures

Variable speed: 500−5,000 RPM 100−240 V 50/60 Hz 1 Phase

5-5750-IR

Precision Low Speed Saw

Features

Gravity-fed saw for smaller, delicate samples

Accepts 3−6" (76−150 mm) diameter blades

Cutting capacity: 2" (51 mm) thickness

Color LCD touchscreen to control all functions

Variable speed: 10−500 RPM, with 5 adjustable presets

Micrometer sample indexing with 2 μm resolution

Spring-retractable dressing stick attachment

Optical shut-off sensor with adjustable stop

Manual Table Saw

Features

Reliable saw for rapid sectioning of nonmetals

6" (152 mm) blade diameter capacity

Color LCD touchscreen to control all functions

Variable speed: 500−3,000 RPM, with 4 adjustable presets

Adjustable table rip fence for guided sectioning

Slotted table to accept fixtures for linear cutting

Large cutting platform: 6.75" W x 12.5" D (171 x 318 mm)

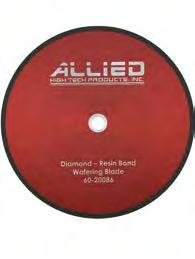

High Concentration (HC)

Recommended for general laboratory sectioning, excluding ferrous alloys. Most commonly used at higher (>1,000 RPM) speeds.

Low Concentration (LC)

Recommended for sectioning very hard or brittle materials such as ceramics, silicon, glass and refractories where chipping and pullout need to be minimized. Most commonly used at lower (<1,000 RPM) speeds.

Recommended for cutting hard, brittle or delicate materials including ceramics, carbides, composites and exotic metals where low heat generation or improved surface finishes are desired. Most commonly used at higher (>1,000 RPM) speeds.

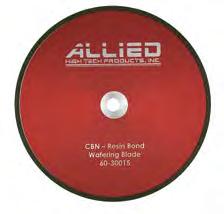

CBN, Cubic Boron Nitride

Metal Bond

Recommended for low speed (<1,000 RPM) sectioning of ferrous metal alloys including steels, iron, cobalt, nickel and lead-based alloys.

Resin Bond

Recommended for higher speed (>1,000 RPM) sectioning of ferrous metal alloys

>50HRC/750 HV.

Bonded blades are composed of an inner metal core and an outer rim. The rim consists of either metal or resin mixed with abrasive, cured under high temperature and pressure to bond the matrix together. Metal bonding offers long life and durability, while resin bonding creates less heat and provides better surface finish.

60-20065 3" x .006" (76 x .15 mm)

60-20070 4" x .012" (102 x .31 mm)

60-20075 5" x .015" (127 x .38 mm)

60-20080 6" x .020" (152 x .51 mm)

60-20081 7" x .025" (178 x .64 mm) 60-20084 8" x .030" (203 x .76 mm)

60-20069 4" x .020" (102 x .51 mm)

60-20074 5" x .020" (127 x .51 mm)

60-20079 6" x .020" (152 x .51 mm)

(152 x .51 mm)

6" x .020" (152 x .51 mm)

60-20083 7" x .025" (178 x .64 mm) 60-20087 8" x .030" (203 x .76 mm)

These blades are recommended for coarse sectioning of materials such as polymer resins, PCBs, fiber composites and plastics.

Plated Segmented Rim, .5" (12.7 mm)

65-10010 4" x .020" (102 x .51 mm)

65-10025 6" x .020" (152 x .51 mm)

65-10030 6" x .040" (152 x 1 mm)

Bonded Continuous Rim, .5" (12.7 mm) Arbor Hole

75-20010 4" x .024" (102 x .61 mm)

75-20020 5" x .024" (127 x .61 mm)

75-20030 6" x .024" (152 x .61 mm)

Segmented Rim

Recommended for sectioning resin or plastic

These sticks are used to remove accumulated material from plated and metal bonded blades.

60-20105 6" x .5" x .5" (152 x 12.7 x 12.7 mm)

These blades consist of abrasive mineral mixed with resin to form a continuous matrix through the entire blade. Aluminum oxide is recommended for cutting ferrous metals and super alloys, while silicon carbide is best used for cutting non-ferrous metals and alloys. They produce minimal odor, cut cool and are suited for higher speed sectioning on non-gravity-fed saws. Two arbor sizes are offered.

Resin

.5" (12.7 mm) Arbor Hole

<HV 450 HV 450–800

- Aluminum Oxide

80-11505 7" x .030" (175 x .76 mm)

80-11510 8" x .035" (200 x .8 mm)

These resin bond blades provide hardness specific options

80-11705

80-11710

<HV 450 HV 450–800

- Silicon Carbide

80-11605 7" x .030" (175 x .76 mm)

80-11610 8" x .035" (200 x .8 mm)

80-11805

80-11810

80-11300 6" x .024" (150 x .61 mm)

80-11305

80-11310

x .030" (175 x .76 mm)

x .030" (200 x .76 mm)

80-11400

80-11405

80-11410

1.25" (32 mm) Arbor Hole

These resin bond blades are for general purpose use.

These blades are specially engineered for laboratory sectioning. Aluminum oxide (Al2O3), silicon carbide (SiC), diamond and cubic boron nitride (CBN) abrasives are offered in various bond types for sectioning a wide variety of materials. Choosing the right blade for the right material is crucial in reducing thermal and structural deformation.

Protective metal arbor inserts are molded into resin bonded blades. Blade arbor holes fit both 32 mm and 1.25" spindle arbors. All blades are precision ground to slightly less than the stated diameter to universally fit all makes and models of cutting machines. Blotters are supplied to shield vibration from the metal flanges and help protect the blade from breaking during use.

Resin Bond blades cut cooler with less friction and minimal odor. Rubber Bond blades come thinner and are ideal for environments where durability is desired, although they emit a burned rubber odor. Metal Bond blades provide longer life and durability than resin bond, but result in a coarser surface finish. Blades designated with the letter "P" feature a special textured pattern and those with a letter "R" are fiber reinforced. See page 14 for more information.

(250

(300

80-50024

80-50025 80-50030

80-50035

80-40021

80-40024

80-40024P

80-40025

80-40030

80-40035

80-30024

80-30025

80-30030 80-10024

9" (235 mm)

9" (235 mm)

9" (235 mm)

9" (235 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

12" (300 mm)

12" (300 mm)

12" (300 mm)

14" (350 mm)

.060" (1.5 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.032" (0.8 mm)

.040" (1.0 mm)

.060" (1.5 mm)

.065" (1.6 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.032" (0.8 mm)

.080" (2.0 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.100" (2.5 mm)

Recommended for softer materials such as annealed, ferrous metal alloys.

Aluminum

Oxide

Recommended for materials such as medium carbon steel, case-hardened/ nitrided and carburized steels, cast-iron and similar ferrous metal alloys.

80-50007

80-50010

80-50015

80-40007

80-40010

80-40015

80-30007

80-30010

80-30015

80-10007

80-10007P

80-10007R

80-10010

Pk/10 Pk/10 Pk/10 Pk/10

Pk/10 Pk/10 Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

9" (235 mm)

9" (235 mm)

9" (235 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

12" (300 mm)

12" (300 mm)

12" (300 mm)

14" (350 mm)

14" (350 mm)

14" (350 mm)

14" (350 mm)

.060" (1.5 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.060" (1.5 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.080" (2.0 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.100" (2.5 mm)

.105" (2.6 mm)

.118" (3.0 mm)

.062" (1.6 mm)

9" (235 mm)

10" (250 mm) 10" (250 mm)

12" (300 mm)

12" (300 mm)

14" (350 mm)

14" (350 mm)

.062" (1.6 mm)

.060" (1.5 mm)

.065" (1.6 mm)

.080" (2.0 mm)

.085" (2.1 mm)

.100" (2.5 mm)

.105" (2.6 mm)

Aluminum Oxide

Recommended for materials such as nickel-based alloys and heattreated ferrous metal alloys.

Aluminum Oxide

Recommended for materials such as tool & die steels and other very hard/tough ferrous metal alloys.

Abrasive Item Unit

80-50047

80-40047

80-30047

80-10047

9" (235 mm)

10" (250 mm) 12" (300 mm) 14" (350 mm)

.060" (1.5 mm)

.060" (1.5 mm)

.080" (2.0 mm)

.100" (2.5 mm)

80-50046

80-50055

80-50060

80-40046

80-40054

80-40055

80-40060

80-30046

80-30050

80-30052

80-30055

80-10030

80-10046

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

Pk/10

9" (235 mm)

9" (235 mm)

9" (235 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

10" (250 mm)

12" (300 mm)

12" (300 mm)

12" (300 mm)

12" (300 mm)

14" (350 mm)

14" (350 mm)

.060" (1.5 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.060" (1.5 mm)

.040" (1.0 mm)

.062" (1.6 mm)

.040" (1.0 mm)

.080" (2.0 mm)

.062" (1.6 mm)

.060" (1.5 mm)

.040" (1.0 mm)

.062" (1.6 mm)

.100" (2.5 mm)

Blades designated with a P feature a special side pattern that helps draw coolant into the kerf/blade path for improved cutting efficiency on highly ductile metal alloys.

Blades designated with an R feature a fiberglass reinforcement that adds rigidity to help keep the blade on path when cutting through thicker samples.

Silicon Carbide

Recommended for materials such as aluminum, copper, brass and bronze.

Silicon Carbide

Recommended for materials such as titanium and refractory alloys.

Abrasive Diameter Unit

Recommended for materials such as tool & die steels and other very hard/tough ferrous metal alloys.

Diamond Metal Bond is a more durable, though coarser option compared to resin bond, recommended for materials such as ceramics, resin impregnated composites and nonmetal refractory materials.

10" (250 mm) 12" (300 mm) 14" (350 mm)

(1.3 mm)

Diamond

Resin bond provides superior heat dissipation and a finer finish with less chipping compared to metal bond, recommended for materials such as carbide and nitride ceramics, glass and quartz.

Cutting fluid enhances blade performance, extends blade life, and minimizes material deformation by reducing heat during cutting. In addition to their cooling and lubricating functions, these fluids also offer rust inhibition properties that help protect the equipment from corrosion. Use Deli-Cut low speed cutting fluid for gravity-fed saws at full strength. Use Maxi-Cut or LubriCut diluted 2-5% with water for speeds above 1,000 RPM Lubri-Cut has a low oil content and is easier to clean.

The 7-gallon (26.5 L) recirculating coolant system is constructed of corrosion-resistant materials for maximum durability. The reservoir fits conveniently in the available cabinet, or can be placed near the machine in existing lab furniture. A removable catch screen enables quick cleaning of larger particles, and baffles inside the reservoir trap particulates. An optional roller cart (included with Cabinet/ Stand) allows easy transfer for cleaning.

Item

5-4211

5-4211-415

5-4211-480

Description

for 230 V PowerCut 10x™ saw for 415 V PowerCut 10x™ saw

for 480 V PowerCut 10x™ saw

The cabinet/stand is designed to provide a solid platform to support the PowerCut 10x™ or TechCut 5x™. Made of cross-braced aluminum for vibration control, strength and stability, it is configured for proper routing of electrical cords, drain hose and coolant supply tubing. It features a large, deep drawer for storing fixtures, tools and blades, and a hinged door to house the recirculating coolant system. Roller Cart is included.

Item

5-4230

for PowerCut 10x™ or TechCut 5x™

Superior quality hot and cold mounting systems for every application.

Robust Mounting Solutions

Duplexing Spacer Provided With Each Mold Assembly Allows Two Mounts Per Cycle

Intuitive, Icon-Based Interface

TechPress 3x™

Automatic Mounting Press

Features

For hot compression mounting powders

Preparation of up to 2 mounts in less than 8 minutes

Interchangeable duplexing molds from 25 mm to 2" diameter

Dual modes: “input” or “programs” with 80 editable routines

Color LCD touchscreen to control all functions

Bayonet cap with safety sensor and heat-resistant handles

Heating power: 1500 W

Compact, narrow footprint

10 selectable languages

TechPress 3x™ Accessory

Features

Environmentally friendly for stand-alone or “green” operation

Saves water (~12 gallons per cycle)

Eliminates clogging associated with hard water deposits

Allows stand-alone press operation without water source

Seamless integration and automatic activation with the TechPress 3x™

Pressure Chamber

Features

For bubble-free cold mounting

Quiet, pump-free operation

Accommodates a variety of mount shapes and sizes

Convenient stacking tray that allows for easy loading

Large 8.5" diameter x 7.5" deep (216 x 191 mm) chamber

Regulated, nominal operating pressure: 29 psi (2 bar)

Epoxy Impregnation System

Features

For epoxy impregnation of porous samples

Quiet, pump-free operation

Clear lid to allow sample viewing during process

Through-port for epoxy fill under vacuum

Turntable model available for multiple mount fills under vacuum

Pulls up to 28 inHg vacuum

Large 10" diameter x 4.5" deep (254 x 114 mm) chamber

Holds up to thirty (30) 1.25" (32 mm) cups

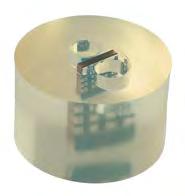

Hot/Compression mounting is an economical method of encapsulating samples that can withstand the pressure and heat of the mounting process. A variety of mounting powders are available and include a measuring scoop.

Black, green and red phenolic powders are used for routine applications, when color coding for material identification, or as backfill for more expensive powders.

ItemDescription

135-10005

135-10007

135-10005-B

135-10010

135-10012

135-10010-B

135-10015

135-10017

135-10015-B

Black Powder, 5 lb. (2.3 kg)

Black Powder, 25 lb. (11.5 kg)

Black Powder, 250 lb. (113 kg)

Green Powder, 5 lb. (2.3 kg)

Green Powder, 25 lb. (11.5 kg)

Green Powder, 250 lb. (113 kg)

Red Powder, 5 lb. (2.3 kg)

Red Powder, 25 lb. (11.5 kg)

Red Powder, 250 lb. (113 kg)

This powder provides excellent adhesion, chemical resistance and edge retention. It also offers very good flow characteristics for mounting samples with complex shape/geometry. The glass filler increases its hardness, and is recommended for mounting medium-hard to hard materials. A mold release product is required. (See page 24.)

ItemDescription

150-10105

150-10110

Black Glass-Filled Powder, 5 lb. (2.3 kg)

Black Glass-Filled Powder, 25 lb. (11.5 kg)

This powder provides high hardness, excellent edge retention and chemical resistance for mounting extremely hard materials.

ItemDescription

160-10005

160-10006

This acrylic powder cures transparent, making it suitable for site-specific sample preparation when there is a need to see the approaching target.

165-10005

165-10025

ItemDescription Transparent Powder, 5 lb. (2.3 kg) Transparent Powder, 25 lb. (11.5 kg)

These powders are used to make conductive samples for scanning electron microscopy and electrolytic polishing. The copper-based powder should be used when analyzing samples where copper is not a primary constituent. The graphite-based powder is recommended for specimens without carbon as a component.

Cold mounting is recommended when encapsulating samples that cannot withstand the heat and pressure of compression mounting, when better flow and penetration of the mounting resin is needed, or when a large quantity of samples must be encapsulated at once.

Acrylics: Typically used for their rapid cure times, or when large volume sample throughput is needed.

When cured under pressure (>20 psi), it produces a clear, bubblefree mount. The longer cure time (15–20 min.) allows improved flow and penetration.

ItemDescription

170-10000

170-10020

170-10005

170-10035

170-10025

170-10026

QuickCure Kit Includes: 5 lb. powder, two 32 oz. liquid, 50 mixing cups, 50 stir sticks and measuring scoop

2 lb. Powder (0.9 kg)

5 lb. Powder (2.3 kg)

25 lb. Powder (11.5 kg)

32 oz. Liquid (950 mL)

2.5 gal. Liquid (9.5 L, in (10) 32 oz. containers)

Used to encapsulate a wide variety of specimens, especially PCB coupons and other electronic components. Its rapid, 6–8 minute cure time is ideal for high-volume applications. Pressurization can help to minimize bubbles for improved clarity.

ItemDescription

QuickSet Kit Includes: 5 lb. powder, 64 oz. liquid, 50 mixing cups, 50 stir sticks and measuring scoop

185-10020

185-10005

185-10030

185-10040

185-10010

185-10025

185-10035

185-10036

2 lb. Powder (0.9 kg)

5 lb. Powder (2.3 kg)

25 lb. Powder (11.5 kg)

100 lb. Powder (45 kg)

64 oz. Liquid (1.9 L)

32 oz. Liquid (950 mL)

2.5 gal. Liquid (9.5 L, in (5) 64 oz. containers)

5 gal. Liquid (19 L, in (10) 64 oz. containers)

With very low viscosity, EpoxySet offers excellent flow and penetration. It is extremely hard, crystal clear and exhibits firm adhesion with virtually no shrinkage. Its low curing temperature is ideal for heat sensitive samples.

ItemDescription

145-20000

145-20005

145-20015

145-20010

145-20020

EpoxySet Kit Includes: 128 oz. resin, 16 oz. hardener, 50 mixing cups, 50 stir sticks and dispensing pump

128 oz. Resin (3.6 kg) 63.5 oz. Resin (1.8 kg) 16 oz. Hardener (450 g) 7 oz. Hardener (200 g)

*Regulated- incurs additional charges for air shipments

This fast-curing epoxy hardens in 2 hours at room temperature while still maintaining quality characteristics such as good adhesion, hardness and minimal shrinkage.

ItemDescription

145-10005

145-10010

145-10025

145-10015

EpoxyMount Kit Includes: 120 oz. resin, 40 oz. hardener, 50 mixing cups, 50 stir sticks and dispensing pump

120 oz. Resin (3.4 kg)

48 oz. Resin (1.4 kg) 40 oz. Hardener (1.1 kg)

* 145-10030 16 oz. Hardener (450 g)

Regulated- incurs additional charges for air shipments

Epoxies: Typically used for excellent flow and penetration, or when better adhesion, chemical resistance, less shrinkage and clarity are required.

Indexing pins are used to align through-holes when encapsulating multiple printed circuit board coupons in one mount.

132-10000

Item 1" Length x .094" Diameter

132-10005

132-10030

132-10040

132-10045

41 mm Length x 2 mm Diameter

43 mm Length x 2 mm Diameter

50 mm Length x 2 mm Diameter

50 mm Length x .094" Diameter

Adhere cover slips to delicate or small samples to support and protect the surface when preparing unencapsulated cross-sections. Use slides for preparing petrographic thin sections or when using vacuum fixtures.

72-20000

72-PS2746

Cover Slips, 18 mm Square Glass Slides, 27 x 46 mm

These cups and sticks are for mixing epoxies or acrylics. The chemical-resistant plastic cups are graduated for volumetric measurement.

This dissolver is a blend of solvents that removes cured epoxy from a specimen when heated.

145-50210 ItemDescription Epoxy Dissolver, 16 oz. (480 mL) Pk/160 Pk/144 Pk/100 Pk/1,000

Release sprays, powder and liquid prevent hot or cold mounting materials from adhering to the mold/cup.

200-10004

200-10006

200-10011

oz. (397 g) Spray (Hot)

oz. (340 g) PTFE Spray (Hot or Cold) 12 oz. (340 g) Spray (Cold)

oz. (240 mL) PTFE Liquid (Hot or Cold)

oz. (57 g) Powder (Hot)

*Regulated- incurs additional charges for air shipments

A variety of clips hold thin samples on edge for encapsulation. Use metal for compression mounting and plastic for cold mounting. Clips with stand-offs isolate the sample, eliminating gaps or air bubbles at the clip/sample interface.

205-10000

205-10005

205-10050

205-10200

205-10205

Steel Coil

Coil

Coil Clear with Stand-Offs Multicolor with Stand-Offs

These stands hold thin samples on edge for encapsulation.

Item Description

205-10300

205-10305

205-10310

Four (4) 1 mm wide positions

Four (4) 2 mm wide positions

Three (3) 3 mm wide positions

These cups are reusable and have a separate bottom allowing easy mount removal after curing.

197-10000

197-10005

197-10010

197-10025

197-10030

197-10040

197-10050

30 mm Diameter x 25 mm Deep

40 mm Diameter x 25 mm Deep

50 mm Diameter x 25 mm Deep

197-15005 1" Diameter x 1" Deep 1.25" Diameter x 1" Deep 1.5" Diameter x 1" Deep 25 mm Diameter x 25 mm Deep

Mount Extraction Press for 2-Part Mold Cups

Reusable, 1" deep silicone mold cups for use with epoxy or acrylic mounting resins. They are designed with thick walls for maximum durability, shape retention and heat dissipation.

197-20005

197-20011

Item Size 2" (51 mm) Diameter, Round 1" x 2" (25 x 50 mm), Rectangle

197-20025

197-20030

197-20050

1.95" x 1.95" (49 x 49 mm), Square 2" x 3.6" (50 x 91 mm), Rectangle Item Description

1.3" x 2.6" (33 x 66 mm), Rectangle

Kits include mixing cups and assorted alligator clips.

These 2-part, low viscosity epoxy resins are engineered for specialized bonding applications, featuring excellent adhesion, chemical resistance and thermal/electrical resistance.

EpoxyBond 110™ is rapid curing and heat-activated, ideal in applications where a thin bond line is desired. It has a high transition temperature and extraordinary resistance to post cure, high heat exposure.

EpoxyBond 14™ is clear, colorless and cures very hard either at 65° C in 1 hour or in 24 hours at room temperature. It is ideal for filling small cavities (pocket, underfill) and for glass slide bonding.

M-Bond 610 is excellent for adhering multiple samples for TEM dimpling and bonding of post-polished samples to grids for TEM and FIB observation. It is chemically resistant and provides a very thin glue line that ion mills evenly.

71-10000

71-10005

71-10025

71-20000 Item

EpoxyBond 110™, 0.5 oz. (15 mL) Kit

EpoxyBond 110™, 4 oz. (120 mL) Kit

EpoxyBond 14™, 140 g Kit

M-Bond 610, 25 g System (Pk/4)

These high purity adhesives cure rapidly without heat. LOCTITE® 460™ is a low-viscosity liquid and LOCTITE® 454™ is a gel for more controlled application.

Item Description

71-40045G

71-40045

LOCTITE® 454™ Gel, 3 g Tube

LOCTITE® 460™ Liquid, 20 g Bottle

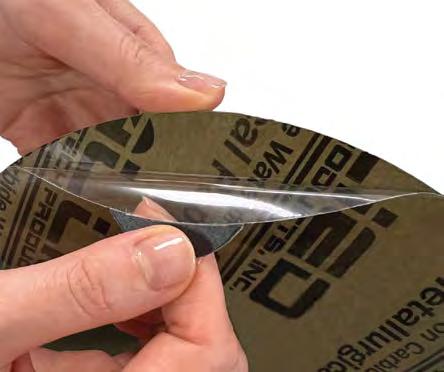

Clear wax provides a quick and strong bond between samples and fixtures for cutting and/or polishing. It melts at 49° C (120° F) and is soluble in acetone.

Sheet wax provides uniform distribution of wax to improve registration accuracy of the sample to the fixture (i.e., dicing applications). It flows at 100° C (212° F) and is soluble in sheet wax dissolver.

Item Description

71-10040

71-10400

*

71-10210

Mounting Wax, Clear, 50 g Stick

Sheet Wax, 4" Diameter Disc (Pk/50)

Sheet Wax Dissolver, 8 oz. (240 mL) Bottle

*Regulated- incurs additional charges for air shipments

Powerful systems for manual and semiautomatic operation, ideal for low to high volume and precision sample preparation requirements.

Performance in Grinding & Polishing

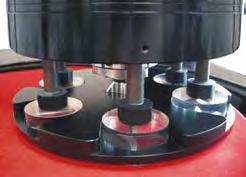

PH-3TM Central Force

Unique Tilt-Up Feature for Easy Access to Sample Holder and Platen

Grinder/Polisher with Power Head

Features

Low to high volume sample preparation

Utilizes either 8" or 10" (203 or 254 mm) platens

Semiautomatic preparation of 1–9 samples

Color LCD touchscreen to control all functions

Store and recall user-programmable sequences

Accommodates up to 2" (51 mm) mount diameter

Central and individual force capability

Seamless integration of optional ID-5x™ Fluid Dispenser for automatic operation

Optional protective shield available for added safety

100–240 V 50/60 Hz 1 Phase

Grinder/Polisher with Power Head

Features

High volume/large surface area sample preparation

Utilizes either 10" or 12" (254 or 305 mm) platens

Semiautomatic preparation of 1–12 samples

Color LCD touchscreen to control all functions

Store and recall user-programmable sequences

Accommodates large and odd-shaped samples

Central and individual force capability

Seamless integration of optional ID-5x™ Fluid Dispenser for automatic operation

Optional protective shield available for added safety

V 50/60 Hz 1 Phase

Grinding & Polishing

Grinder/Polisher with Power Head

Features

Economical low to medium volume sample preparation

Utilizes either 8" or 10" (203 or 254 mm) platens

Individual force sample preparation of 1–4 samples

Accommodates up to 2" (51 mm) mount diameter

Color LCD touchscreen to display all parameters

Powerful, quiet 0.6 HP (440 W) brushless DC motor

Unique power head tilt-up feature for easy access

Compatible with optional AD-5™ Fluid Dispenser

Integrated Fluid Dispenser

Features

Quantitative dispensing for consistent, repeatable results

Five (5) dispensing positions, 16 oz. (500 mL) glass beakers

Pre-dosing function to “charge” the cloth at cycle start

Magnetic stirring for use with non-suspended abrasive solutions

In-cycle priming; allows operator intervention during use

Pump reverse after cycle to prevent dripping/ contamination

Two (2) high volume positions with rinse/flush function

Retractable Coolant Nozzle Allows Quick and Easy Sample and Bowl Cleaning

Grinder/Polisher

Features

Ideal for general preparation requirements

Utilizes either 8" or 10" (203 or 254 mm) platens

Color LCD touchscreen to control all functions

Two speed range options: 10–500 RPM or 20–1,000 RPM with five (5) adjustable presets

Clockwise/counterclockwise platen rotation

Powerful, quiet 0.6 HP (440 W) brushless DC motor

Low profile, tabletop design

Intuitive Controls and User Friendly Functions

Grinder/Polisher

Features

Recommended for larger samples

Utilizes either 10" or 12" (254 or 305 mm) platens

Color LCD touchscreen to control all functions

Two speed range options: 10–500 RPM or 20–1,000 RPM

Clockwise/counterclockwise platen rotation

Powerful, quiet 0.6 HP (440 W) brushless DC motor

Grinder/Polisher

Features

For multiuser or segregated preparation

Utilizes either 8" or 10" (203 or 254 mm) platens

Color LCD touchscreen to control all functions

Two speed range options: 10–500 RPM or 20–1,000

RPM with five (5) adjustable presets

Clockwise/counterclockwise platen rotation

Powerful, quiet 0.6 HP (440 W) brushless DC motor that drives both platens simultaneously

Low profile, tabletop design

5-7650

Grinding & Polishing

5-7650-M 100–240 V 50/60 Hz 1 Phase, 10–500 RPM 100–240 V 50/60 Hz 1 Phase, 20–1,000 RPM

Easy-to-Use, User-Friendly Controls

Grinder/Polisher

Features

Ideal for unencapsulated preparation using hand tools/fixtures

Utilizes either 8" or 10" (203 or 254 mm) platens

Color LCD touchscreen to control all functions

Variable platen speed: 5–350 RPM (5 RPM increments) with five (5) adjustable presets

Clockwise or counterclockwise platen rotation

Timer for count up or count down operation

Powerful, quiet 0.7 HP (535 W) brushless DC motor

Low profile, tabletop design

Item

5-2350 100–240 V 50/60 Hz 1 Phase

Dual Manual Sample Preparation

Manual Unencapsulated Preparation Using Hand Tools

Digital Indicators Enable Quantifiable Material Removal

Easy-to-Read Micrometer Heads Provide 0.02° Angle Adjustment for Sample Alignment/Correction

Site-Specific Grinder/Polisher

Features

Ideal for precise, quantitative semiautomatic preparation

Utilizes either 8" or 10" (203 or 254 mm) platens

Color LCD touchscreen to control all functions

Digital indicator; displays real-time material removal, 1 µm

Dual axis adjustable micrometer positioning, 0.02° angle resolution

Maintains geometric position of sample relative to abrasive plane

Seamless integration with optional AD-5™ Fluid Dispenser

V 50/60 Hz 1 Phase, Gear-Drive

V 50/60 Hz 1 Phase, O-Ring Drive

Site-Specific Grinder/Polisher

Features

Ideal for larger scale, precise quantitative semiautomatic preparation

Utilizes 12" (305 mm) platens

Color LCD touchscreen to control all functions

Digital indicator: displays real-time material removal, 1 µm

Dual axis adjustable micrometer positioning, 0.02° angle resolution

Maintains geometric position of sample relative to abrasive plane

Seamless integration with optional AD-5™ Fluid Dispenser

Site-Specific Grinder/Polisher

Features

Designed for optoelectronic device and optical component polishing

Utilizes either 8" or 10" (203 or 254 mm) platens

Color LCD touchscreen to control all functions

Digital indicator; displays real-time material removal,1 µm

Maintains fixed angle control relative to abrasive plane

Seamless integration with optional AD-5™ Fluid Dispenser

Grinder/Polisher Accessory

Features

Allows stand-alone grinder/polisher operation without water source

Environmentally friendly; saves up to 0.5 gallon (1.9 L) of water per minute

Roll out reservoir with 7-gallon (26.5 L) capacity

Configurable with up to 3 in-line filtration stages down to 2 microns

Cabinet mounted filtration system with quick-change filters

Accepts reusable stainless steel or disposable polymer filters

Cabinet/Stand that supports all Allied grinding & polishing machines

Pull-out storage drawer

Wired for 115 or 230 VAC, 50/60 Hz 1 Phase

Adjustable Range of Motion To Accommodate All Fixtures

Central Force Sample Holder Loading/Unloading System

Features

Reduces initial planarization time and consumable usage

Ergonomic, efficient loading/unloading of samples

Compatible with all central force sample holders

Pneumatic loading; ensures mount/sample planarity

Rotating base; supports rapid loading and unloading

Graduation scale for quick, repeatable loading

Uniform mount protrusion to 3 mm

Designed for either right or left hand use

High-Volume PCB Coupon Preparation

Features

For precise preparation of up to fifty-four (54) multilayer coupons

Preparation of through-holes as small as 3 mils (0.003")

Pin insertion press that allows rapid gang-mounting of coupons

Six (6) position mount holder with wear-resistant adjustable stops

Magnetic mount retention; allows in-process removal, inspection and replacement

Durable, reusable two-part mold cups

Grinding & Polishing

Manual Mechanical Preparation

Features

For preparing wedge shaped samples for TEM

Lightweight anodized aluminum body for corrosion resistance

Low profile micrometer option for lighter tool weight

Nonrotating micrometer option for improved angle control

Ambidextrous cam-lock lever position according to operator’s preference

Low profile, removable fixtures that fit under upright microscope objectives

Replaceable Delrin® wear pads; easily glides on abrasive films

69-42000 69-42005

Item Description Kit with Low Profile Micrometer Heads Kit with Nonrotating Micrometer Heads

Manual Mechanical Preparation

Features

For preparing small-scale unencapsulated samples

Lightweight anodized aluminum body for corrosion resistance

Ambidextrous cam-lock lever position according to operator’s preference

Low profile, removable fixtures that fit under upright microscope objectives

SEM compatible cross-sectioning paddle

Replaceable Teflon™ wear pads; easily glides on abrasive films

Item Description

69-50000 Cross-Sectioning Tool Kit

Standard platens are recommended for manual and semiautomatic grinding/polishing machines. Precision platens are lapped parallel to within +/- 2 microns with a smooth surface necessary for precision polishing applications on the MultiPrep™ and OptiPrep™ systems. Both type platens are made of aluminum with a hard anodized surface for maximum durability.

(203 mm)

(254 mm)

(305 mm)

Double sided adhesive discs are adhered to a standard platen and used to secure non-adhesive back silicon carbide discs. Each provides 25–75 disc pulls, depending on grit size, cycle time and force.

52-10005-H

(203 mm)

(254 mm)

(305 mm)

These bands feature a protrusion around the top that allows nonadhesive back discs of variable size (± 3 mm) to be secured to a standard platen.

Adhesive back magnetic bases adhere to standard platens, allowing magnetic system cloths/abrasive discs or ferromagnetic discs to be utilized. 90-208300

Magnetic platens combine a standard aluminum platen with a cross-hatched magnetic surface for maximum flatness and grip. Only one platen is needed throughout the grinding and polishing process, allowing all magnetic system cloths/abrasive discs or ferromagnetic discs to be utilized.

5-2005M

5-6010M

5-6005M

(203 mm)

(254 mm)

(305 mm)

Ferromagnetic adhesive discs combine a rigid stainless steel disc with an adhesive surface that allows non-adhesive back silicon carbide discs to be secured to magnetic platens. The nonslip backing keeps the disc in place even for coarse grinding. Each provides 25–75 disc pulls, depending on grit size, cycle time and force.

52-20008

52-20010

52-20012

(203 mm)

(254 mm)

(305 mm)

These reusable ferromagnetic stainless steel discs feature a nonslip backing and allow adhesive back cloths/abrasive discs to be changed quickly and easily when using magnetic platens.

55-51000

55-51002

55-51005

8" (203 mm) 10" (254 mm) 12" (305 mm)

These durable ferromagnetic support discs combine a PTFE surface with a rigid stainless steel disc. This allows adhesive back abrasive discs/polishing cloths to be easily removed after use without any adhesive transfer. The nonslip backing keeps the disc in place even for coarse grinding.

55-52000

Designed for metallographic applications to coarse and fine grind a wide variety of materials, these discs feature superior mineral grading, a unique resin system and a latex additive in the paper. This combination resists water penetration, creating a durable, long-lasting disc with uniform cutting characteristics that minimizes sample deformation. They are made with high quality thick C-weight backing and are recommended for general laboratory requirements.

50-1000050-1100050-10145 60 (P60)50-1004550-1104550-10215

50-1000150-1100350-10146 80 (P80)50-1004650-1104750-10217

50-1000550-1100550-10150120 (P120)50-1005050-1105050-10220

50-1001050-1101050-10155180 (P180)50-1005550-1105550-10225

50-1001550-1101550-10160240 (P280)50-1006050-1106050-10230

50-1002050-1102050-10165320 (P400)50-1006550-1106550-10235

50-1002550-1102550-10170400 (P800)50-1007050-1107050-10240 50-1002850-1102850-10173500

Premium resin bonding system that retains abrasive for sustained material removal and long life

Premium thick C-weight base with high latex content for superior waterproofing

Special low-tack adhesive for easy removal from the platen without adhesive transfer

Tab for easy liner removal prior to use (120–1200 grit)

Tab for easy disc removal from platen after use

CAMI Grit

Grading

• 1200 fine grit is electrostatically coated where the SiC particles stand on end, providing more of a cutting action for continued material removal. It is recommended for softer materials that smear, step grinding for failure analysis, and serial sectioning.

• 1200 (P4000) grit is sputter coated, which randomizes the orientation of the SiC particles, providing more of a polishing action and does not remove as much material as 1200 fine grit. It can be used for a wide variety of applications.

Grinding & Polishing

Providing rapid material removal and excellent wear resistance without generating excessive heat, these discs are recommended when grinding hard, ferrous metals and alloys on automatic or high speed manual grinding machines. All discs are adhesive backed.

These durable cloth-backed abrasive belts support various grinding requirements. Use silicon carbide for general laboratory applications, aluminum oxide for ferrous metals and zirconia alumina for heavy stock removal.

These SiC strips and rolls are used for metallographic applications to coarse and fine grind a wide variety of materials.

Use Al2O3 for grinding ferrous metals and alloys, and SiC for nonferrous metals such as titanium and aluminum or when mixing non-ferrous and ferrous metals.

Recommended for hard-to-grind materials, these discs feature diamond particles either nickel plated or resin bonded in raised patterns that provide increased cutting rates, enhanced cooling and efficient removal of debris. They are extremely durable and provide excellent edge retention and sample flatness. Wide, low-profile tabs allow easy removal after use. Each disc features a rigid ferromagnetic stainless steel backing with nonslip coating for magnetic platens.

Recommended for materials including ceramics, carbides and metal matrix composites. Adhesive back discs are also available. To order, remove 'M' from the item number.

260

125

70

30

15

9

6

50-50005M50-50105M50-51005M

50-50010M50-50110M50-51010M

50-50015M50-50115M50-51015M

50-50025M50-50125M50-51025M

50-50035M50-50135M50-51035M

50-50040M50-50140M50-51040M

Use resin bonded discs for a wide variety of materials including hard metals and nonmetal coatings. Adhesive back discs are also available. To order, remove 'M' from the item number.

50-80800M50-81000M50-81200M

50-80805M50-81005M50-81205M

50-80810M50-81010M50-81210M

50-80820M50-81020M50-81220M

50-80825M50-81025M50-81225M

50-80830M50-81030M50-81230M

Designed for aggressive removal of materials such as sintered materials, ceramic, hard metals and optical glass, these discs offer 0.5 mm-tall abrasive segments to provide excellent flatness and durability.

(P1200)

50-70805M50-71005M50-71205M

50-70810M50-71010M50-71210M

50-70820M50-71020M50-71220M

Used to remove accumulated material from the diamond segments to restore grinding performance.

60-20108 4" x 1" x 0.5" (102 x 25 x 12.7 mm)

Color Coded for Ease of Identification

Standard diamond discs consist of precision graded diamond particles resin bonded to a uniform film. They provide excellent edge retention and maintain coplanarity regardless of varying materials or hardness within the sample. These discs are typically used for unencapsulated cross-sectioning, TEM wedge/plan-view polishing, backside polishing and FIB sample thinning. *Assortment includes one (1) of each grade except 45 μm & 60 μm.

50-30030

50-30035

50-30038

50-30040

50-30045

50-30050

50-30055

50-30060

50-30065

50-30070

50-30073

50-30075

50-30076

50-31238

50-31240

50-31245

50-31250

50-31255

50-31260

50-31265

50-31270

50-31275

50-30135

50-30140

50-30145 50-30150

Typically used for encapsulated samples, Type B discs have diamond particles contained in ceramic beads that are resin bonded to a uniform film. As the beads wear away, new diamond particles are exposed to allow continuous, aggressive material removal. These discs provide a coarser finish grade-for-grade compared with standard diamond films.

50-30050B

50-30055B

50-30060B

50-30065B

50-30140B

50-30145B

50-30070B 50-30130B 50-30135B

Grinding & Polishing

These discs consist of a mylar film coated with resin containing either aluminum oxide, silicon carbide or silicon dioxide abrasive. They are recommended for applications where edge retention is important with either encapsulated or unencapsulated samples. Not recommended for power head applications. *Assortment includes ten (10) of each grade.

Micron (µm) Plain Back, 8" (203 mm)

50-20040

Designed to store, dry and protect films in between use, the book has lint-free, moisture-absorbing paper separating each blotter.

Item Description Storage Book for 8" (203 mm) Discs

50-30000

50-30012Storage Book for 10" (254 mm) and 12" (305 mm) Discs

Squeegees are used to eliminate air pockets when applying lapping films to a platen.

Item Description Squeegee, Rubber, 2" x 3" (Pk/10)

50-05518

50-05520Squeegee with Handle, Rubber, 4"

Diamond is preferred for most polishing applications because of its superior removal rate and resulting surface finish, while producing fewer artifacts (smearing, scratches, etc.). All products are precision graded by Swiss micronizing standards for high performance.

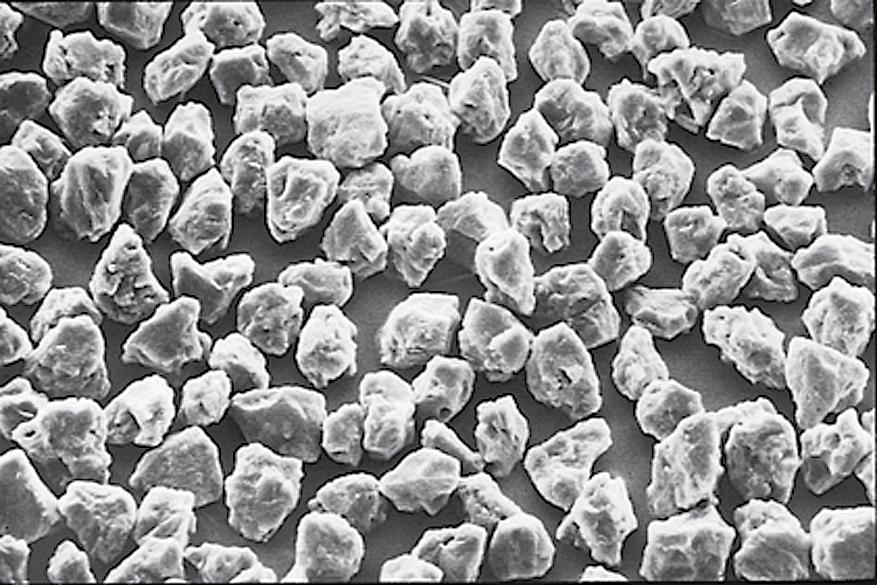

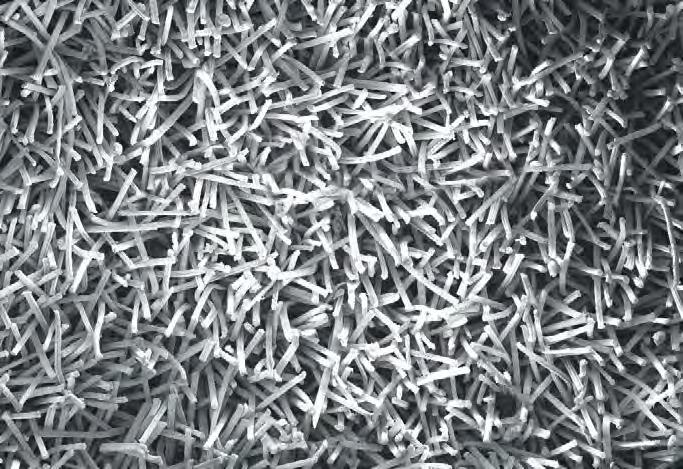

Polycrystalline which provides higher removal rates than monocrystalline abrasive. As it cuts, it breaks down in its original shape, allowing for finer finishes in less time. Because polycrystalline has no cleavage planes, it cannot splinter like monocrystalline diamond. It causes less subsurface deformation and is excellent when polishing samples composed of different materials or hardness.

Monocrystalline cutting edges. It is a lower cost option for less critical applications where polycrystalline’s superior removal rate and finish features are not required.

DiaLube is a water soluble blend of polycrystalline diamond suspension and propylene glycol based lubricant. It is excellent for quick application of both abrasive and lubricant without the need for precise dripping ratios.

90-3DL1S-G

90-3DL1H-G

Alcohol based slurry is recommended for water-sensitive materials such as zinc, magnesium and steel with nonmetallic inclusions. For use with alcohol based lubricants only. This formula is recommended for manual application or automatic “spray/drip” dispensing systems, where lubricant is also applied.

Water Based

Water soluble and environmentally friendly, this 99% water based formula is recommended for manual application or automatic “spray/ drip” dispensing systems, where lubricant is also applied.

90-31995-G

90-32000-G

90-32005-G

90-32010-G

90-32015-G

90-32020-G

90-32025-G 90-32030-G

90-32035-G

90-32040-G

Water soluble and environmentally friendly, this diamond suspension has a glycol base for improved cooling and is ideal for manual application or automatic “drip” dispensing systems, where lubricant is also applied.

Polycrystalline

90-29995-G

90-30000-G

90-30005-G

90-30010-G

90-30015-G

90-30020-G

90-30025-G

90-30030-G

Specifically formulated for metallographic sample preparation, these compounds offer a higher concentration of diamond compared to suspensions. Water soluble and compatible with all lubricants, they are typically used as a stand-alone product or to charge polishing cloths before applying diamond suspension.

90-20995-S

90-21000-S

90-21005-S

90-21010-S

90-21015-S

90-21020-S

90-21025-S

90-21030-S

90-21035-S

90-21040-S

Grinding & Polishing

Used for final polishing, these colloidal silica solutions are mixtures of abrasive particles dispersed throughout a chemically aggressive liquid carrier. This combination provides a chemical-mechanical polishing action, resulting in deformation-free surfaces. The modified pH of these products can provide delineation of grain boundaries and other microstructural features on some materials.

These suspensions feature a pH of 9.8 and produce an excellent surface finish on a variety of materials, especially non-ferrous metals, ICs and other electronic components. The 0.02 µm formula produces ultra fine surface finishes for demanding SEM/TEM analysis.

An excellent final polishing suspension for most materials, this unique formula features a pH of 10 and rinses easily from samples and equipment, even after it dries. It is slow drying, making it an ideal choice for prolonged polishing requirements such as those for EBSD. The pH may be modified with chemical solutions to improve microstructural contrast.

This unique 8.5 pH mixture combines colloidal silica and alumina. The addition of gamma alumina allows improved mechanical polishing. It is used to final polish both ferrous and non-ferrous metals, metal matrix composites and various nonmetallic materials.

Made with 99.9% pure white aluminum oxide, de-agglomerated suspensions are premixed formulas that provide a cleaner alternative to powder. The medium viscosity can be lowered by adding filtered water.

Stabilized in an acidic (~4 pH) solution, this product is ideal for final polishing of ferrous metals and ceramics, providing microscopic contrast. The non-clogging formula flows easily through fluid dispensing systems, and it can be diluted with filtered water up to 3:1.

FinalPrep is a de-agglomerated, polycrystalline alumina solution excellent for final polishing applications on nearly any material. With a pH of 9 to 9.5, the basic chemical element enhances microstructural features. It works exceptionally well for polishing PCBs and soft, ductile or precious metals, such as gold (Au), silver (Ag), platinum (Pt) and solder alloys.

0.0590-18772590-18774090-187775

This unique water-based polycrystalline alumina solution has a pH ranging between 9 and 10.5 that is excellent for polishing optical materials such as fused glass, BK-7, borofloat, fiber optics, quartz, sapphire and ceramics.

These alumina powders are made to the tightest quality specifications and are used for final polishing a variety of materials. Accurately controlled purity levels and particle size distribution ensure optimum polishing results. Alpha alumina removes material faster, while gamma alumina is better for final polishing. Mix with filtered water to produce a liquid slurry.

De-Agglomerated

De-agglomerated alumina powder is specially treated to reduce the number of agglomerates (groups of particles in each grade of manufactured alumina), providing fast, uniform surface finishes.

Standard

1 Standard alumina powder is recommended where the benefits of de-agglomerated powders are not required.

Dispensing non-suspended slurries and solutions is challenging because when they sit, the solids separate from the liquid, creating a non-uniform mixture.

The ID-5x™ Fluid Dispenser (page 29) features two (2)high speed pumps, both with magnetic stirring functions, that uniformly mix the solid/liquid to ensure consistency.

Note: When mixing powder with distilled water or a lubricant, use a ratio based on the desired viscosity.

Lubricants are used to enhance the polishing performance of diamond suspensions, compounds and films. They reduce friction and increase the life of polishing cloths. All 16 oz. and 32 oz. bottles include a trigger sprayer and flip-top for dispensing, and can be applied manually or used with automatic dispensers. Gallons include a pre-labeled 16 oz. empty bottle for dispensing convenience.

A water-free, high viscosity glycol-based lubricant, RedLube is typically used for metallographic preparation of softer and/or ductile materials.

90-207010

Unit 16 oz. (480 mL)

90-207005 32 oz. (950 mL)

90-207000 128 oz. (3.8 L)

90-206995 5 gal. (19 L, in five 128 oz. containers)

*Regulated- incurs additional charges for air shipments

A medium viscosity glycol/water-based lubricant, GreenLube is used for general metallographic preparation.

90-209010

Unit 16 oz. (480 mL)

90-209005 32 oz. (950 mL)

90-209000 128 oz. (3.8 L)

90-208995 5 gal. (19 L, in five 128 oz. containers)

A low viscosity, water-free, ethyl alcohol-based lubricant, PurpleLube is formulated to minimize alcohol scent. It is excellent for increased stock removal, for water-sensitive materials or for use with alcohol-based diamond slurries.

90-205010

16 oz. (480 mL)

90-205005 32 oz. (950 mL)

90-205000 128 oz. (3.8 L)

90-204995 5 gal. (19 L, in five 128 oz. containers)

incurs additional charges for air shipments

A wide range of polishing cloths is offered for fine grinding or for coarse, intermediate and final polishing of all materials. Adhesive back cloths attach to standard platens, while flexible or rigid discs with ferromagnetic backing secure to magnetic platens.

Each cloth is secured to an individual, dedicated platen or support disc using its adhesive backing. Removal and reapplication is discouraged because of reduced adhesion. Adhesive backed polishing cloths are the most economical choice.

These cloths feature a flexible ferromagnetic backing that adheres to magnetic platens. Multiple discs can be used with one magnetized platen, reducing the number of platens needed for each procedure, machine or lab.

Each cloth features a rigid ferromagnetic backing that adheres to magnetic platens. Multiple discs can be used with one magnetized platen, reducing the number of platens needed for each procedure, machine or lab. The backing offers corrosion resistance, high stiffness and a rounded, burr-free edge for safer handling. Rigid discs are also well suited for applications that utilize alcohol-based slurries and lubricants, where prolonged polishing times are needed.

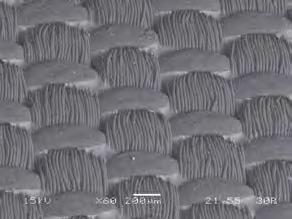

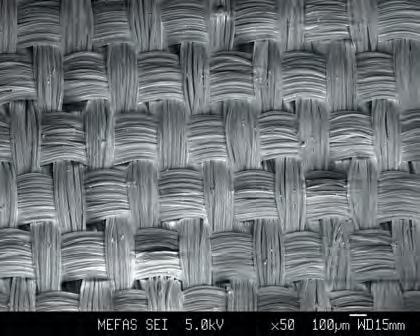

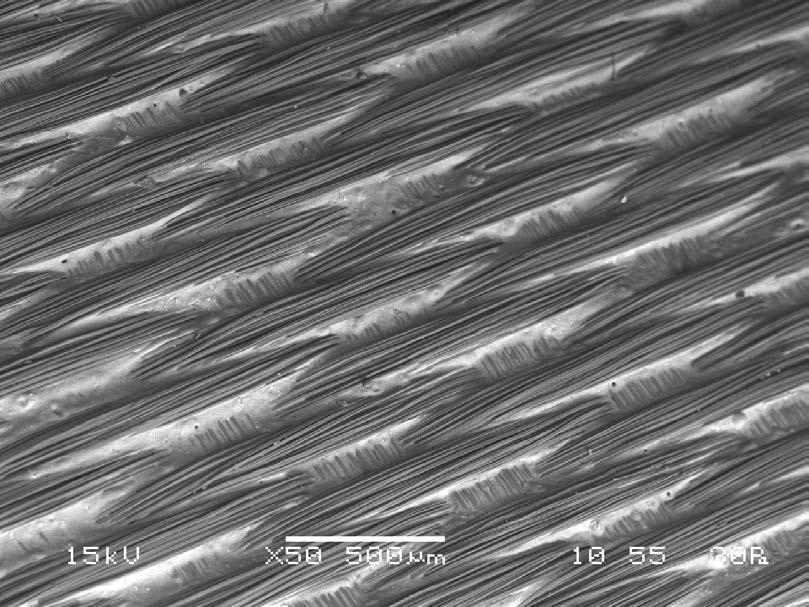

These cloths feature a cross-weave pattern, where abrasive particles embed and provide efficient material removal. They feature low compression, applying effective pressure to the loose abrasive particles for maximum material removal and flatness. This pattern is ideal for fine grinding, or coarse and intermediate polishing, and is more aggressive than nonwoven cloths.

Very hard, resin coated, durable, coarse-woven polyester for use with diamond (30–6 µm). Produces high material removal rate and excellent flatness for fine grinding, or coarse and intermediate polishing on a variety of materials.

Very hard, resin coated, dense-woven polyester for use with diamond (15–3 µm). Maintains superior edge retention and flatness and provides aggressive material removal for coarse to intermediate polishing of metals, ceramics and refractory materials. Not recommended for cold mounted materials.

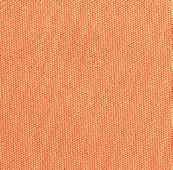

Dense, uniquely woven nylon, extremely durable for use with diamond (15–3 µm). Produces excellent flatness and provides a very high material removal rate on a wide variety of materials. Exceptional for intermediate polishing. Gold Label

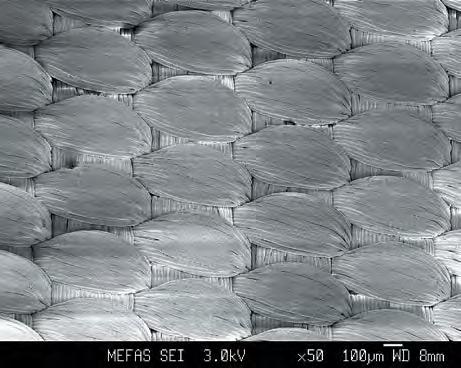

Woven wool with a medium nap and low resilience for use with diamond (6–0.25 µm), colloidal suspensions or alumina. Provides very good edge retention and surface finish on a wide variety of materials including metals and polymers.

TECH-Cloth

Dense, woven, synthetic silk for use with diamond (9–1 µm). Produces very good edge retention and provides excellent finish and flatness. Especially good for coatings and samples composed of materials with varying hardness.

Rigid

Very dense, woven, low-nap silk for use with diamond (6–0.25 µm). Provides excellent flatness and edge retention prior to final polishing on a wide variety of materials. Ideal for eliminating pullout in the final polishing steps.

90-150-500

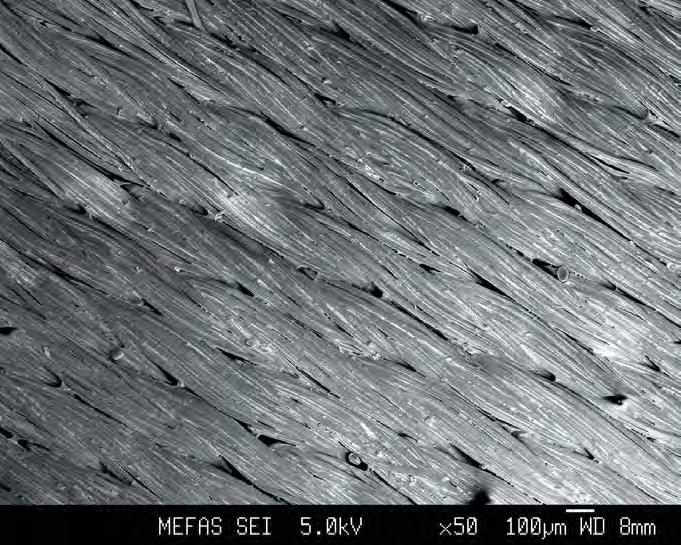

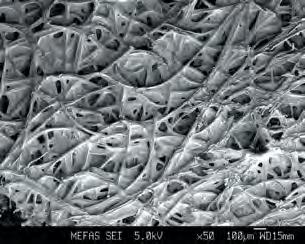

Non-woven cloths feature low compression, with surfaces that tend to be softer than woven cloths. A non-woven cloth can have fibers interlaced throughout the surface, but the pattern is random rather than a cross-weave. Non-woven cloths are less aggressive, so they are better suited for intermediate and final polishing steps.

Kempad 8" (200 mm) 10" (250 mm)

Non-woven, very low-nap textile for use with diamond (9–1 µm). Provides good removal and flatness on a wide variety of materials.

Adhesive

BackingQty 10 5

90-150-005

90-150-015

90-500-005

Pan-B

90-500-015

90-150-020

90-500-020

Flexible MAG 12" (300 mm)

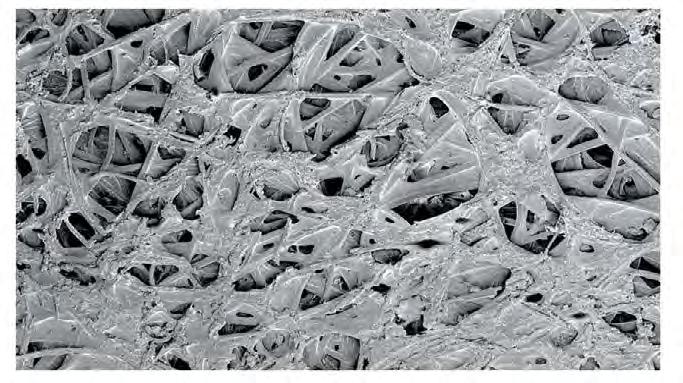

Dense, non-woven, planarized textile for use with diamond (6–0.25 µm). Provides good removal rates and edge retention on a wide variety of materials.

Adhesive

BackingQty 10 5

85-150-100

85-500-100

85-150-105 85-500-105

85-150-110

85-500-110

Flexible MAG 12" (300 mm)

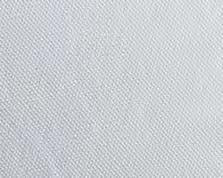

These cloths are engineered specifically for final polishing applications using alkaline, acidic or oxide polishing solutions.

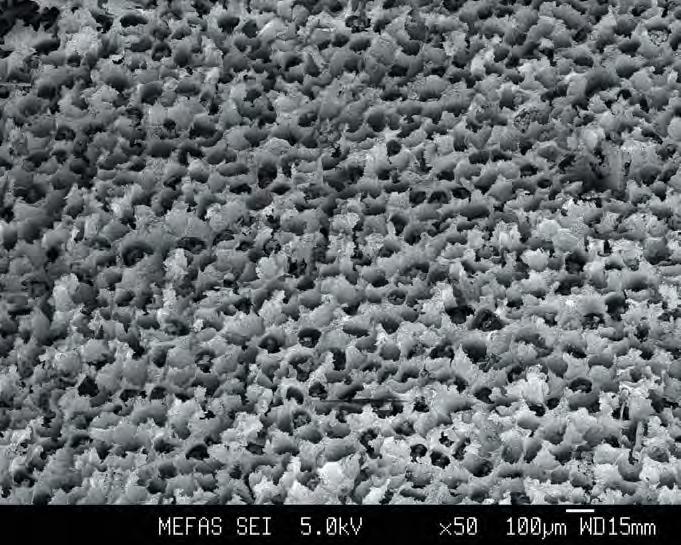

Dense, low-nap, porous polyurethane for chemical/mechanical polishing using colloidal suspensions or alumina (1–0.02 µm). Long-lasting cloth provides an excellent final polish for a wide variety of materials.

Highly dense, low-nap, porous polyurethane pad for use with colloidal suspensions or alumina (1–0.02 µm). This durable cloth is excellent for final polishing a wide variety of materials. Especially effective in eliminating smearing and pullout when preparing soft metals such as copper and aluminum, porous structures/materials or materials for SEM or TEM evaluation.

These cloths, also known as “napped,” have various length fibers and fabric stiffness. They are mostly used for final polishing, as the fibers remove intermediate scratches. Firm fibers are commonly used for soft materials, while soft fibers are useful for hard materials.

Firm, medium-nap, synthetic rayon flock for use with diamond (1–0.25 µm) or alumina. For general polishing of a wide range of materials.

Soft, medium-/low-nap synthetic flock for use with diamond (1–0.25 µm) or alumina. Provides very good flatness on a wide variety of materials.

Soft, dense, medium-nap, synthetic silk flock for use with diamond (3–0.25 µm), colloidal suspensions or alumina to provide an excellent final polish on a wide variety of materials. Especially effective when preparing electronic materials for SEM or TEM evaluation.

Final P

Dense, low-nap, firm, synthetic flock for use with diamond (3–0.25 µm), colloidal suspensions or alumina. Ideal for final polishing soft metals such as copper, aluminum and solder.

Very durable, soft, low-nap, synthetic flock for use with diamond (3–0.25 µm), colloidal suspensions or alumina. Excellent for final polishing ferrous metals and composites.

Soft, low-nap, rayon flock for use with diamond (3–0.25 µm), colloidal suspensions or alumina. Provides excellent finish and flatness, especially with hard materials, ferrous metals and glass.

The most advanced, intuitive, automated milling machine in the world.

5-axis, specialized mechanical milling instrument for lab use

Large color LCD touchscreen graphic user interface

Easy-to-use, wizard-based workflow

Closed-loop Z-axis force and position control

Live HD video navigation to set X/Y milling/grinding/polishing region Automatic 3-point sample leveling

With X-Correct™

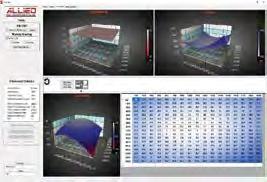

Features

3D software module for the X-Prep®

For contoured device deprocessing (convex/concave)

Visualization, RST correction of milling contour/maps

Physical profile mapping

Support of package level failure analysis, laser photon EFA tools, high-throughput FIB processing and nano/e-probing

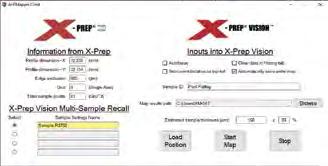

X-Prep® Vision™

Metrology Instrument for Measuring Semitransparent Materials

Features

Visible and IR (1310 nm) spectrometers for measuring from 20 nm to 1 mm

Motorized, automatic X/Y/Z positioning for multipoint measurements

Includes a material library with over 130 materials (i.e., GaAs, InGaAs, SiC, SiGe, etc.) for film stack measurements

Stage adapter for X-Prep® fixtures that ensures accurate registration between systems

Custom software to manage the mapping data of up to four (4)samples

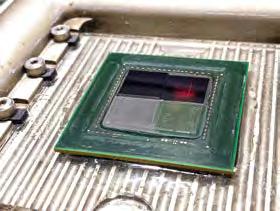

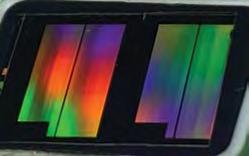

Well established in the semiconductor industry, the X-Prep® is a specialized tool that can expand the sample preparation capabilities to many other applications.

Utilizing conventional sample preparation techniques and methodologies with a different approach, it adds/brings the power of a CNC machine to the lab looking for solutions to unique, challenging applications.

Unlike a CNC, which requires special knowledge of G-code programming, the X-Prep® features a user-friendly operator interface with a workflow function that logically guides the operator through a sequence of setup screens to execution of the process step.

X-Prep®-prepared samples pictured below are examples of localized/partial area deprocessing that preserves the larger piece's complex geometry, and radius machining that addresses linear sectioning limitations.

Available in a variety of solid carbide end mills with specialized coatings for material-specific applications. They offer extreme heat resistance, durability and high stiffness for superior performance.

When choosing between 2-flute and 4-flute, consider the material being milled, tool feed rate and desired surface finish. For milling low glass content (<50%) PCB/FR4 substrates, PCB end mills feature a durable coating that is optimized to maximize tool life.

Two-flute end mills are recommended for milling non-ferrous alloys and softer materials. They feature greater spacing between cutting points allowing better chip removal, and are available in smaller diameters than 4-flute end mills.

15-922FS0.05

15-922FS0.10

15-922FS0.15

15-922FP0.2

15-922FP0.25

15-922FP0.5

15-922FP0.7

15-922FP1.0

15-922FP1.5

15-922FP2.0

15-922FP3.0

15-922FS0.20

15-922FS0.25

15-922FS0.5

15-922FS0.7

15-922FS1.0

15-922FS1.5

15-922FS2.0

15-922FS3.0

mm

mm

mm

mm

mm

mm

mm

mm

Four-flute end mills are recommended for faster bulk milling and for harder materials. They feature more cutting surfaces, better rigidity and stability during milling, and provide a better surface finish when run at slower feed rates.

15-924FP0.7

15-924FP1.0

15-924FP1.5

15-924FP2.0

15-924FP3.0

15-924FS0.7

15-924FS1.0

15-924FS1.5

15-924FS2.0 15-924FS3.0

Long-reach end mills feature cutting flutes that extend up from the tip, approximately 3 times its diameter, to allow cutting into deeper cavities.

15-924FP0.7-3

15-924FP1.0-3

15-924FS0.7-3

15-924FS1.0-3

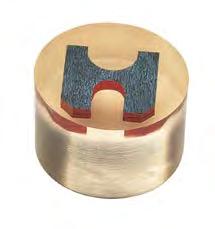

These tools are for grinding non-metal alloys such as silicon, silicon carbide and mineral-/silica-filled resins in molded electronic devices.

When compared with plated tools, bonded tools produce a finer surface finish and allow grinding closer to end point targets with significantly less damage.

Bonded tools retain their shape and last longer than plated tools, because as the bond and diamond section wear, new diamond is exposed.

15-92VFMB0.2

15-92VFMB0.4

15-92VFMB0.5

15-92VFMB0.70

15-92VFMB1.0

15-92VFMB1.5

15-92VFMB2.0

15-92VFMB3.0

15-92VFMB5.0

15-92FMB0.55

15-92FMB0.70

15-92FMB1.0

15-92FMB1.5

15-92FMB2.0

15-92FMB3.0

15-92MMB1.0

15-92MMB1.5

15-92MMB3.0

15-92CMB3.0

Resin bond is recommended for grinding hard, brittle materials that have a higher chance of cracking.

15-92MRB1.5

15-92MRB3.0

These grinding tools provide aggressive material removal and a rougher finish compared to similarly graded bonded tools.

A silicon carbide dressing stick can be used to remove embedded material and extend tool life.

15-92FP0.7

15-92FP1.0

15-92FP1.5

15-92FP2.0

15-92FP3.0

15-92CP1.0

15-92CP1.5

15-92CP2.0

15-92CP3.0

These durable, film-backed abrasive discs are used as an alternative to bonded diamond tools for high material removal rates.

Discs are secured to mounts using a high performance adhesive such as LOCTITE® 460™ or 454™, and peel off easily when worn.

15-92VFGD3

15-92VFGD5

15-92VFGD9

15-92VFGD12

15-92FGD3

15-92FGD5

15-92FGD9

15-92FGD12

15-92MCGD5

15-92MCGD9

15-92CGD3

15-92CGD5

15-92CGD9

15-92CGD12

These plain back pads/cloths are secured to mounts using a high performance adhesive such as LOCTITE® 460™ or 454™, and peel off easily when worn.

180-10083

180-10084

180-10085

180-10023

180-10024

180-10025

90-150-733

90-150-734

90-150-735

90-150-543

90-150-544

90-150-545

180-10951

180-10952

180-10953

180-10960

180-10105

180-10930

180-10950

180-10940

180-10910

Chem-Pol

Chem-Pol

Chem-Pol

Final A

Final A

Final A

Final-POL

Final-POL

Final-POL

DiaMat

DiaMat

DiaMat

Planar Pad

Planar Pad

Planar Pad

Chem-Pol

Final A

Final-POL

Planar Pad Red Final C X-Pad II

Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50 Pk/50

Punches feature a durable, razor sharp, stainless steel tip used to extract polishing discs.

Item

15-92P0.5-D

15-92P1-D

15-92P1.5-D

15-92P2-D

15-92P3-D 70875A41

Punch with Ejector, 0.5 mm

Punch with Ejector, 1 mm

Punch with Ejector, 1.5 mm

Punch with Ejector, 2 mm

Punch with Ejector, 3 mm

Cloth & Grinding Disc Punch Mat, 9" x 12"

Mounts are used in conjunction with grinding discs or polishing pads/discs that are secured using high performance, instant adhesives.

15-92PM0.5

15-92PM1.5 15-92PM2

15-92PM3

15-92PS5

15-92PS9

15-92PS12

This is used to align the center axis of both the mount and punch to accurately adhere the polishing disc.

Polishing Tool Disc Applicator

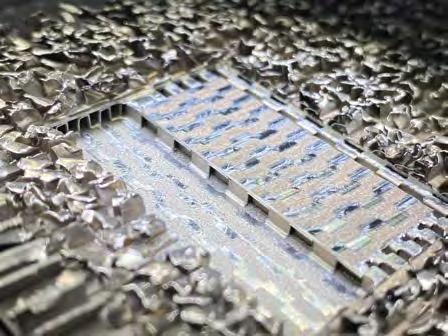

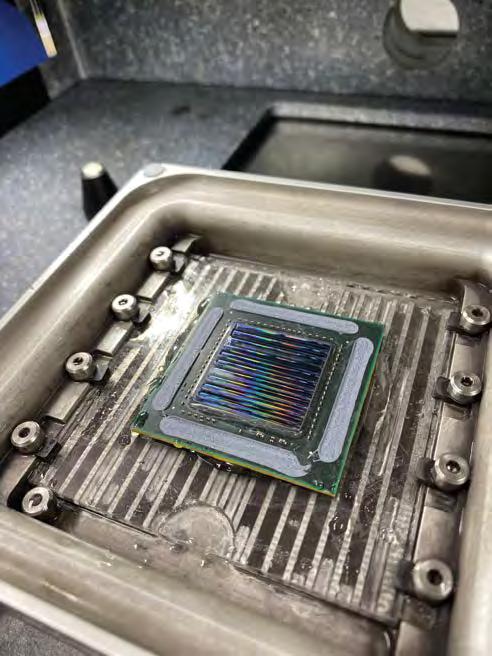

X-Lube™ is a solvent-free lubricant that helps maintain a cooler cutting temperature, traps cutting debris and reduces tool wear. It is also used with diamond compound for polishing operations.

Used to mount objects with complex geometries or to create temporary lubricant reservoirs for heat sensitive samples, this silicone-based resin is dispensed with a reusable handle through disposable mixing tips. 145-80000 145-80005 145-81005

Dispensing Handle for 2-Part Resin Cartridge

Mixing Tips for 145-81005

TP Green Light Viscosity Resin Kit, including two 50 mL cartridges and 24 mixing tips

Compatible with all X-Prep® fixtures, borosilicate glass offers the most thermally stable (anti-warping) platform, ideal for securing samples with hot mounting wax. Aluminum inserts are easier to mill/machine, ideal when creating alignment pockets that are used to mount samples for improved stability and registration.

Borosilicate Glass Inserts, 2" x 2" x 1/8" Thick

Borosilicate Glass Inserts, 3" x 3" x 1/8" Thick

Borosilicate Glass Inserts, 4" x 4" x 1/8" Thick

Borosilicate Glass Inserts, 4" x 6" x 1/8" Thick

Aluminum Inserts, 2" x 2" x 1/8" Thick

The ruby tipped probe is used for leveling and profiling samples. The probe stylus can be replaced should it become damaged or chipped.

Ruby Tipped Leveling Probe, 1 mm Ø

Ruby Stylus Replacement Tip, 0.5 mm Ø

Ruby Stylus Replacement Tip, 1 mm Ø

Quality cleaning solutions and storage accessories help keep your laboratory clean and organized, supporting safe and consistent results.

Clean and Clutter-Free Laboratories

Ultrasonic cleaners create microscopic bubbles in cleaning solutions that penetrate small crevices and explode upon contact, removing debris that regular washing can leave behind. Cleaning is useful prior to mounting, as it improves adhesion of the mounting material to the sample and prevents particles from contaminating cloths or scratching samples during the polishing process. All units have a stainless steel tank, mechanical timer and cover. Units with digital timers and/or heaters are also available.

CALL FOR CONFIGURATION/QUOTATION

Use applicators for cleaning and applying etchant to samples.

ItemDescription Unit

210-30000Cotton Tipped Applicators, 6" Pk/1,000

GP is a general purpose biodegradable, caustic-free solution that is effective removing light oils and other contaminants from a variety of materials. Mixed with water at 10–12% by volume.

Micro Organic Soap is an alkaline/mildly ionic, powerful solution that is effective at removing micro-contaminants from the surface of electronic components, stainless steel, glass and other non-metal alloys. Mixed with water at 2–5% by volume.

CS10 is an environmentally friendly non-ionic solution with a pH of 7, safe for cleaning aluminum, zinc, electronic components and other highly oxidizing metal alloys. Mixed with water at 1–2% by volume.

ItemDescription

*

95-10230 148-10000 148-10010

GP Cleaning Solution, 32 oz. (950 mL)

Micro Organic Soap, 32 oz. (950 mL)

CS10 Cleaning Solution, 32 oz. (950 mL)

*Regulated- incurs additional charges for air shipments

This dry, nontoxic, nonflammable air spray removes water, dust or other particles from polished samples, optics and laboratory items.

ItemUnit

*

*

200-20000 200-20005

14 oz. (392 g) Can Twelve (12) 14 oz. (392 g) Cans

*Regulated- incurs additional charges for air shipments

This sturdy cabinet provides storage for polished mounts to prevent corrosion and dust contamination. The 10 cloth-lined drawers absorb moisture and hold mount dividers for easy organization. The locking door provides a sealed environment. Rechargeable desiccant canister is included. Dividers are sold separately.

Item Description

30-8000

30-8005

30-8010

30-8015

30-8020 Mount Storage Cabinet

Mount Divider, (144) 1" or 25 mm diameter

Mount Divider, (100) 1.25" or 30 mm diameter

Mount Divider, (61) 1.5" or 40 mm diameter

Mount Divider, (36) 2" or 50 mm diameter

This durable aluminum cabinet accommodates up to 10 aluminum trays/shelves (reversible) for storage of platens, discs or cloths up to 12" (305 mm) diameter. The hinged, clear plastic door with magnetic lock prevents dust contamination. Five (5) trays are included.

Item Description

5-8100Platen Storage Cabinet 5-8105Aluminum Tray/Shelf

Designed to store, dry and protect films in between use, the book has lint-free, moisture-absorbing paper separating each blotter.

Item Description

50-30000

Storage Book for 8" (203 mm) Discs

50-30012Storage Book for 10" (254 mm) and 12" (305 mm) Discs

Youronestopsolution from sample preparation to image analysis.

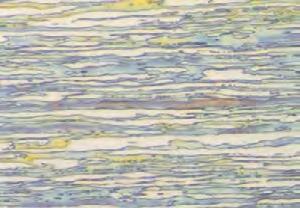

Since 1999, Allied has offered the complete line of materials microscopes from Carl ZEISS, including inverted, upright, stereo and digital/zoom configurations. ZEISS products are world-renowned for their superb optics, precision, quality and versatility.

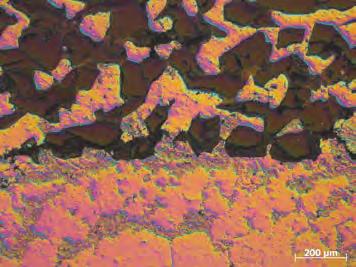

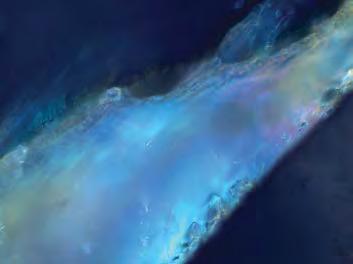

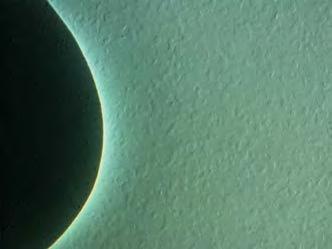

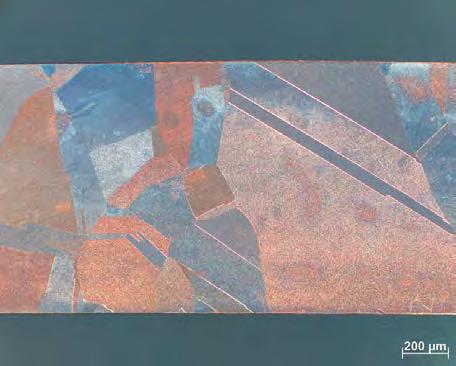

A wide range of components, objectives and contrasting methods (brightfield, advanced darkfield, circular differential interference contrast [C-DIC], polarization, total interference contrast [TIC] and fluorescence) are available to customize the ideal instrument for your particular application.

Increase productivity and efficiency with ZEISS microscopes and imaging options.

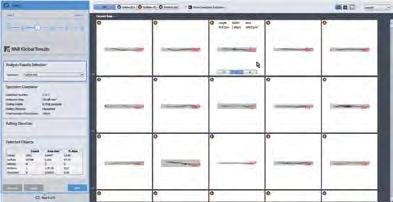

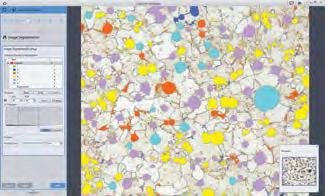

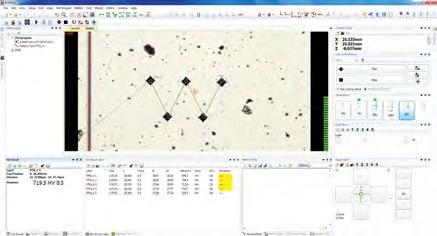

From materials research and development to industrial quality control and assurance, more and more materials laboratories are utilizing the advantages of digital microscopy. A major component is ZEN core, the preferred image analysis software for the microscopist. With its unique modular architecture, it is equally suited for both newcomers and advanced users. It features seamless integration between camera and microscope for all imaging and analysis needs.

• Full integration with ZEISS microscopes

• Customized routine jobs and workflows

• Interactive and automatic control of motorized components

• Panoramic acquisition

• Extended depth of focus (combining images from multiple focal planes)

• Online Measurement (measurement on live images)

• Information transfer of encoded components to the software

• Full camera control

•Exposure

•White balance

• Shading correction

•Image orientation

• Post-processing: contrast, brightness, gamma, colors, smoothing, sharpening, geometric corrections and more

• Optional User Management for multiuser environment

• Report creation and modification of Microsoft Word report templates using ZEN Word add-in

• Support of Windows 10 (64-Bit) operating system

• Motorized Functionality (Auto Focus, Motorized EDF, Automated Tiles Acquisition − only on motorized microscopes)

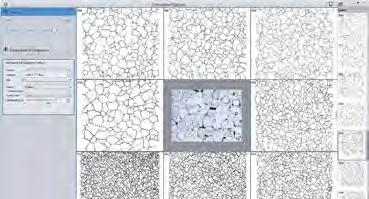

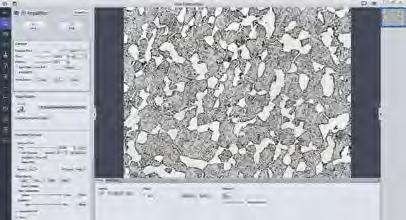

• Materials Analysis (Grain Size, Cast Iron, Multiphase, Comparative Diagrams, Layer Thickness Measurement)

• Non-Metallic Inclusion & Technical Cleanliness Analysis

• Machine Learning Segmentation

• Macro Environment − Python scripting functionality

• Data Storage Server – server-based database

• 2D/3D Image Analysis tools

These cameras offer seamless integration with ZEN core software, providing full control over all camera functions including exposure, white balance, shading correction and image orientation. They range in resolution from 2.8 to 20 megapixels. CALL FOR CONFIGURATION/QUOTATION

• Three measurement methods: Planimetric (automatic reconstruction); Intercept (chord pattern); Comparison (wall charts)

• ASTM E 112-13 Plate I - IV; ASTM E 1382-97; DIN EN ISO 643; GB/T 6394 standards

• Routine sample analysis of particle size, phase content, porosity

• Up to 32 phases: B/W or color

• Percent area, volume fraction and classifications

• Pearlite/ferrite content of steel

• Non-metallic inclusions in steel: oxides, sulfides and nitrides

• ASTM, ISO, JIS, GB/T, EN, SEP and DIN standards

• Evaluation of particulate contamination on prepared specimens

• VDA, ISO, NAS, SAE and VDI standards

• Automatic measurement of coating thickness: raw thickness values, average thickness and statistics

• Single image or batch processing of multiple images

Imaging/Analysis

• Wizard for guided generation of programs

• Image processing, global/local segmentation and thresholds

• Data export into CSV and XML

• Measurement of porosity, particles, impurities and more

• Graphite measurement in cast iron

• DIN EN ISO 945 - 2019 standard

• Shape and size distribution in area percentage (optional: graphite arrangement with wall charts)