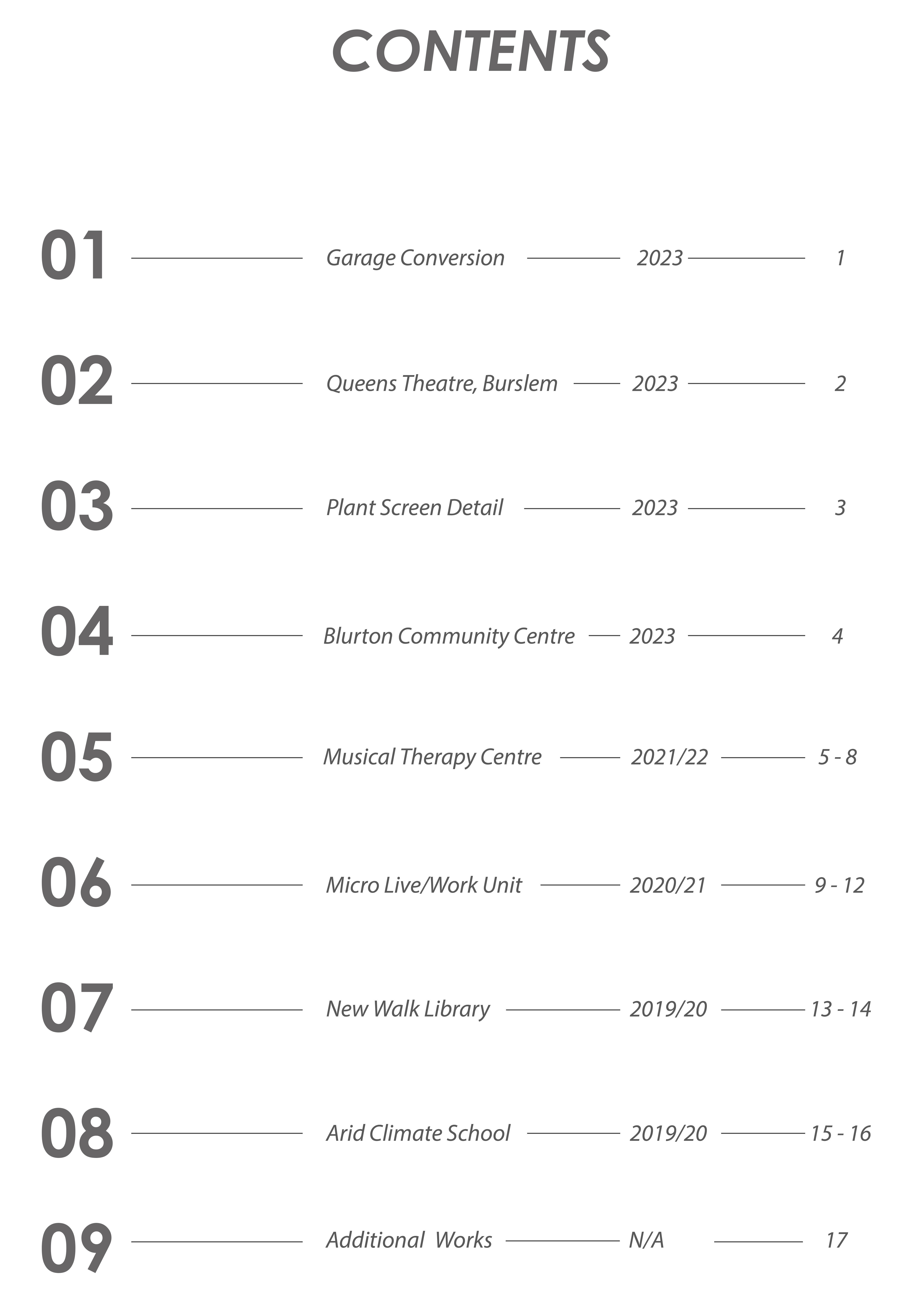

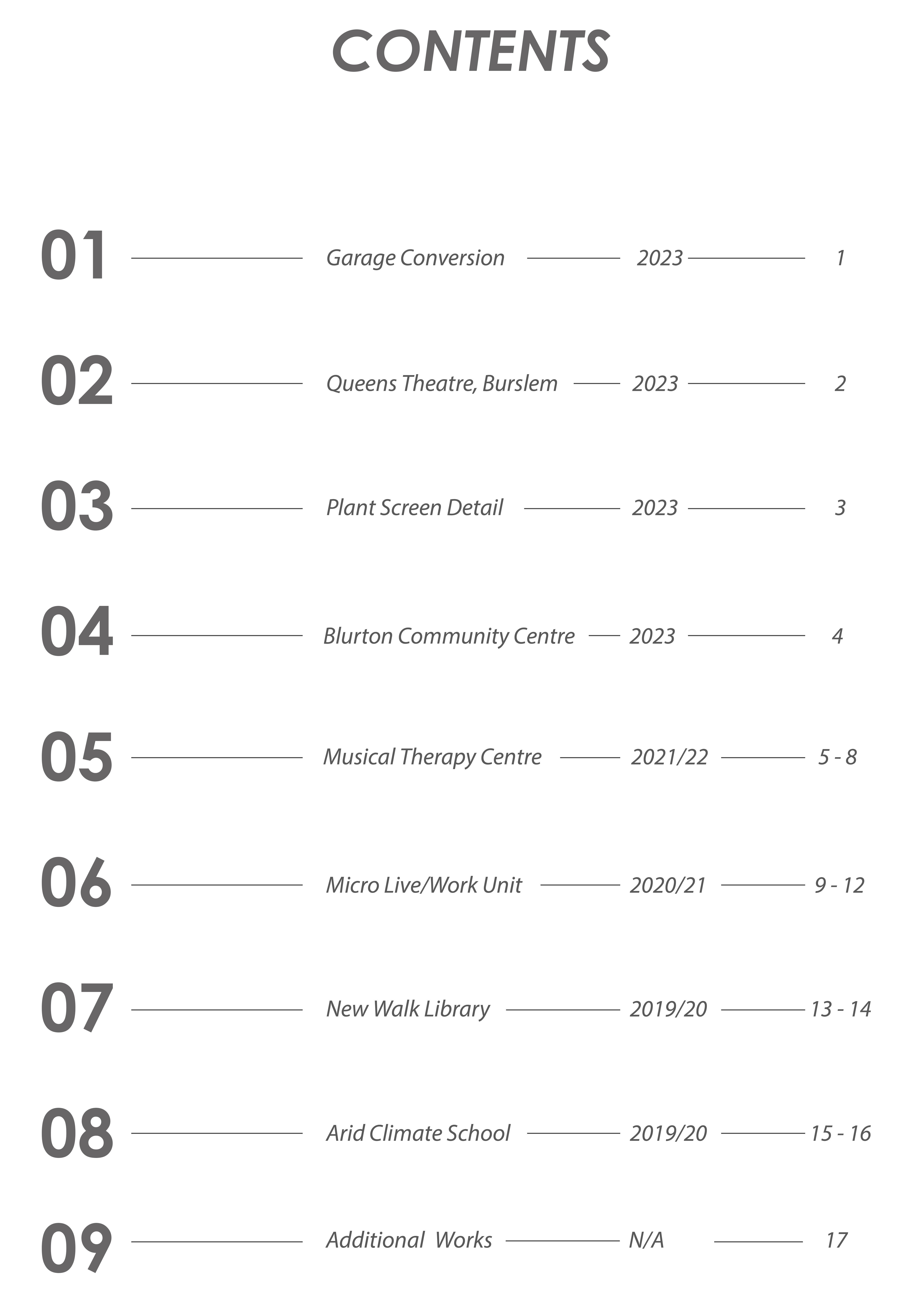

KITCHEN LIVING VERANDA BEDROOM BEDROOM BATHROOM GARDEN ROOM STORE GREEN HOUSE GARAGE 50 sqm EXISTING MATERIALS KEY: 3. EXISTING BRICKWORK 4. EXISTING WHITE UPVC WINDOWS 1. PLAIN CONCRETE TILES TO MATCH EXISTING 2. WHITE UPVC FACIA BOARDS AND SOFFITS 3. BRICKWORK TO MATCH EXISTING 4 4 3 2 1761 Adjacent Ground Level 98.851 Datum Pavement Level 101.761 Adjacent Ground Level 98.851 Garage Roof Ridge PROPOSED LOWER GROUND FLOOR PLAN 1:100 @ A1 Project Title NOTES: 2. All dimensions, levels, sewer inverts to be checked on site by contractor before works commence. 3. All work to comply with the current Building Regulations latest British Standard code of practice. 01782 319956 Revisions Date 24/07/23 Ref A Note Ground levels updated 1:100 @ A1 FEBRUARY 2023 22043 22043-PL-004 PLANNING SUBMISSION MR R GRIME NEW GARAGE AND ROOM CONVERSION TO 116 ASHBANK ROAD, STOKE ON TRENT, ST2 9DU PROPOSED PLANS & ELEVATIONS PROPOSED GROUND FLOOR PLAN 1:100 @ A1 PROPOSED FIRST FLOOR PLAN 1:100 @ A1 PROPOSED NORTH ELEVATION 1:100 @ A1 PROPOSED WEST ELEVATION 1:100 @ A1 PROPOSED SOUTH ELEVATION 1:100 @ A1 PROPOSED EAST ELEVATION 1:100 @ A1 BEDROOM STORE A EXISTING WALL TO BE TREATED UP TO 1200MM ABOVE PROPSED FFL USING PERMASEAL TANKING SLURRY APPLICATION STRICTLY IN ACCORDANCE WITH MANUFACTURERS DETAILS. SITE CHECK EXTERNAL GROUND LEVEL PRIOR TO APPLICATION USE SW TIMBER BATTENS ABOVE STEP IN WALL (SITE CHECK)TO ENSURE WALL IS LEVEL AND THEN APPLY KOOLTHERM K118 42.5MM INSULATED PLASTEBOARD, SKIM & PAINT UPVC WINDOW, COLOUR TO MATCH EXISTING. PROVIDE CATNIC ABOVE REMOVE EXISTING GARAGE ROLLER SHUTTER AND BLOCK UP PART OF OPENING RETAIN EXISTING LINTEL USE 102.5MM BRICKWORK TOOTHED INTO EXISTING ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50mm KOOLTHERM K108 INSULATION 100MM MEDIUM DENSITY CONCRETE BLOCKS KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT ALL TO ACHIEVE MIN. U-VALUE OF 0.18W/m2K B B 150mm WELL CONSOLIDATED LAYERS OF SULPHATE FREE HARDCORE 50mm SAND BLINDING, 1200g DPM LINKED TO DPC CHASED INTO EXISTING WALL 150mm C30P CONCRETE SLAB WITH A252 MESH 100mm CELOTEX GA4000 INSULATION 500g PVC PROTECTION LAYER, 65mm SCREED, FLOOR FINISH TO MATCH EXISTING FFL MIN. U-VALUE OF 0.18W/m2K DPC MIN 150MM ABOVE GROUND LEVEL REMOVE EXISTING GARAGE ROLLER SHUTTER AND BLOCK UP PART OF OPENING RETAIN EXISTING LINTEL USE 102.5MM BRICKWORK TOOTHED INTO EXISTING ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50mm KOOLTHERM K108 INSULATION 100MM MEDIUM DENSITY CONCRETE BLOCKS KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT ALL TO ACHIEVE MIN. U-VALUE OF 0.18W/m2K UPVC WINDOW, COLOUR TO MATCH EXISTING. PROVIDE CATNIC ABOVE NEW WINDOWS TO HAVE MIN. U-VALUE OF 1.6W/M²K OR WER BAND C CEILING OVERBOARDED WITH 9MM PLASTERBOARD ON DABS, SKIM & PAINT EXISTING SECTION A-A 1:25 @ A1 NOTES: 2. All dimensions, levels, sewer inverts to be checked on site by contractor before works commence. 3. All work to comply with the current Building Regulations & latest British Standard code of practice. 5. This drawing may not be copied without prior permission --/--/-Revisions -Date Ref Note SECTION 1:25 DRAFT PROPOSED LOWER GROUND FLOOR PLAN 1:25 @ A1 Ceiling overboarded with 9mm plasterboard on dabs, skim & paint Remove existing garage roller shutter and block up part of opening Retain existing lintel Use 102.5mm brickwork toothed into existing Assumed 75mm cavity partially filled with 50mm Kooltherm K108 insulation 100mm Medium density concrete blocks Kooltherm K118 42.5mm insulated plasterboard on dabs Skim & paint, colour TBC by client All to achieve minimum U-value of 0.18W/m2K UPVC window, colour to match existing, provide catnic above New windows to have minimum U-value of 1.6W/m2K or WER band C 150mm Well consolidated layers of Sulphate free hardcore 50mm Sand blinding 1200g DPM linked to DPC chased into existing wall 150mm C30P concrete slab with A252 mesh 100mm Celotex GA4000 insulation 500g PVC protection layer 65mm Screed Floor finish to match exiting FFL Minimum U-value of 0.18W/m2K DPC minimum 150mm above ground level BEDROOM GARDEN

KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT 50MM X 50MM SW TIMBER BATTENS KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD FIXED TO BATTENS SKIM & PAINT, COLOUR TBC BY CLIENT EXISTING WALL TO BE TREATED UP TO 1200MM ABOVE PROPSED FFL AND BELOW FLOOR SLAB USING PERMASEAL TANKING SLURRY APPLICATION STRICTLY IN ACCORDANCE WITH MANUFACTURERS DETAILS. 1200mm SECTION B-B 1:25 @ A1 BEDROOM GARDEN ROOM STORE A A EXISTING WALL TO BE TREATED UP TO 1200MM ABOVE PROPSED FFL USING PERMASEAL TANKING SLURRY APPLICATION STRICTLY IN ACCORDANCE WITH SITE CHECK EXTERNAL GROUND LEVEL PRIOR TO APPLICATION TIMBER BATTENS ABOVE STEP IN WALL (SITE CHECK)TO ENSURE WALL IS LEVEL AND THEN APPLY KOOLTHERM K118 42.5MM INSULATED PLASTEBOARD, SKIM & PAINT ACTUAL RADIATOR POSITION TO BE AGREED ON SITE WITH CLIENT UPVC WINDOW, COLOUR TO MATCH EXISTING. PROVIDE CATNIC ABOVE REMOVE EXISTING GARAGE ROLLER SHUTTER AND BLOCK UP PART OF OPENING RETAIN EXISTING LINTEL ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50mm KOOLTHERM K108 INSULATION KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT BLOCK UP EXISTING DOOR USING; ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50mm KOOLTHERM K108 INSULATION KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT ALL TO ACHIEVE MIN. U-VALUE OF 0.18W/m2K B B RETAIN EXISTING LINTEL USE 102.5MM BRICKWORK TOOTHED INTO EXISTING CEILING OVERBOARDED WITH 9MM PLASTERBOARD ON DABS, SKIM & PAINT MATERIALS SITE PREPARATION OF VOIDS TO BE CARRIED OUT USING WELL COMPACTED CONSOLIDATED LAYERS OF HARDCORE. ANY LIVE SERVICES TO BE RE-ROUTED DIVERTED A NECESSARY. THE CONTRACTOR SHALL NOTIFY ANY PUBLIC BODY UTILITY TO ALLOW THEM TO ENTER THE SITE AND CARRY OUT ALL NECESSARY WORKS. THE CONTRACTOR SHALL PROVIDE ALL MATERIALS ARE TO BE USED AND INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTIONS AND RECOMM- ENDATIONS. THE QUALITY OF ANY MATERIAL NOTE: IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO ENSURE THAT ALL THEIR WORK IS IN COMPLIANCE WITH THE APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING REGULATIONS,OTHER ALLIED LEGISLATION, NHBC GUIDELINES AND LATEST BRITISH STANDARDS. INTERNAL WALLS EXISTING INTERNAL WALL TO RECEIVE PERMASEAL TANKING SLURRY, TAKEN UP TO 1200MM ABOVE PROPOSED FFL AND BELOW FLOOR SLAB. TO BE A GROUND FLOOR CONSTRUCTION CAREFULLY BREAK OUT AND REMOVE EXISTING CONCRETE FLOOR TO REVEAL REDUCED CONSTRUCTION LEVELS. CLEAN NATURAL STONE SULPHATE FREE HARDCORE LAID COMPACTED 150MM WELL CONSOLIDATED LAYERS. UPPER SURFACE BLINDED WITH 50MM SAND AND 1200GDPM LAID WITH FOLDED AND TAPED SEAMS, UPSTANDS TAKEN UP AND OVER DPC LINKED TO CA WALLS TO PROVIDE CONTINUOUS PROTECTION. 50MM COVER AT BOTTOM. PVC PROTECTING LAYER ABOVE. 65MM STANDARD FIBRE REINFORCED SCREED 4:1 SHARP SAND TO OPC, SEMI-DRY BISCUIT MIX LAID OVER INSULATION. SCREED TO BE LAYED/COMPACTED WITH STEEL AND BROUGHT TO A CLOSE GRAINED SURFACE FINISH TO RECIEVE FLOOR FINISH. STEEL TROWEL FINISH TO BE APPLIED AS CONCRETE SETS TO LEAVE SMOOTH FINISH. SCREED ACHIEVE OVERALL U VALUE OF 0.18W/M2/K. FFL TO MATCH EXISTING FFL EXACTLY. 102.5MM BRICKWORK TOOTHED INTO EXISTING, FACINGS IN STRETCHER BOND, TYPICAL MORTAR MIX 1:4 CEMENT:SAND. WITH BUCKET HANDLE JOIN RENDERED. ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50MM KOOLTHERM K108 INSULATION LIGHTWEIGHT LOAD BEARING MEDIUM DENSITY 3.6N 100MM BLOCKWORK TO INNER LEAF. FACING IN STRETCHER BOND, STAINLESS STEEL WALL TIES TO BE PROVIDED AT 450MM PAINTED TO CLIENTS SPECIFICATION AND IN ACCORDANCE WITH MANUFACTURERS RECOMMENDATIONS. CLOSE CAVITIES AROUND OPENINGS WITH MANTHORPE WCMULTICOR150 CAVITY CLOSERS. CAVITY TRAYS WITH PREFORMED STOP ENDS ARE TO BE PROVIDED ABOVE INTERNAL WALLS CONT. USE 50MM X 50MM SW TIMBER BATTENS TO BUILD OUT WALL FLUSH WITH BOTTOM OF WALL, THEN FIX KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD TO BATTENS WITH AT LOWER PART OF WALL TO ENSURE WALL IS FLUSH CEILING CEILING OVERBOARDED WITH 9MM PLASTERBOARD ON DABS, SKIM & PAINT OPENINGS BS EN 845-2:2013 SPECIFICATION FOR ANCILLARY COMPONENTS FOR MASONRY. LINTELS. MAX SPAN 3600MM CATNIC TS150/100 THERMALLY BROKEN CAVITY WALL LINTEL ALL LINTELS TO BE FIXED IN STRICT ACCORDANCE WITH MANUFACTURERS INSTRUCTIONS INCLUDING PROVISION OF MIN. 150MM AND BEARING. OPENINGS TO BE FULLY PROTECTED WITH ALL NECESSARY DPC'S, INCLUDING THE FOLLOWING PROVISIONS:PROTECTED WITH A DPC EXTENDING 150MM EACH SIDE OF THE OPENING. INCLUDE FOR WEEPHOLES TO CAVITY TRAYS EVERY FOURTH PERPEND. WINDOWS/DOORS PROVIDE BEAMS PRE-INSULATED STEEL LINTELS ABOVE DOORS / WINDOWS ENSURING CAVITIES AT DOOR REVEALS ARE CLOSED USING PATENT PRE-FORMED CLOSURES, INSULATED AND DAMP PROOFED. NEW FRAMES SOLIDLY SCREW FIXED TO ADJACENT FACING OUTERLEAF AND MASTIC POINTED. GLAZING IN CRITICAL AREAS AND WITHIN 800mm OF FFL TO BE TOUGHNED SAFETY GLASS TO BS6206 PT1. FULL DRAUGHT PROOFING / SEALS TO BE PROVIDED TO ALL UNITS. MANUFACTURER TO TAKE DIMENSIONS FROM SITE OF ALL APERTURES PRIOR TO ORDERING/MANUFACTURING DOORS & WINDOWS. ALL HABITABLE ROOMS OF THE EXTENSION TO HAVE A BACKGROUND VENTILATION EQUIVALENT TO 8000MM2. ALL NEW WINDOWS / DOORS TO HAVE RICKLE VENTS. NEW WINDOWS TO HAVE MIN. U-VALUE OF 1.4W/M²K OR WER BAND B, NEW DOORS TO HAVE MIN. U-VALUE OF 1.4W/M²K OR WER BAND C HEATING BE HEATED USING RADIATORS. ALL NEW RADIATORS ARE TO HAVE THERMOSTATIC RADIATOR VALVES APART FROM THE RADIATOR CLOSEST TO THE THERMOSTAT. ALL WORK BE CERTIFIED BY A COMPETANT AND SUITABLY QUALIFIED HEATING ENGINEER ON COMPLETION OF WORKS. NEW RADIATOR POSITIONS TO BE AGREED WITH CLIENT BEFORE ELECTRICAL WORK INSTALLATION TO BE DESIGNED. INSTALLED. INSPECTED AND TESTED ON COMPLETION BY AN APPROVED QUALIFIED ELECTRICIAN TO THE REQUIREMENTS OF BS:7671:2000. CERTIFICATE TO BE PROVIDED UPON COMPLETION. SCHEDULE OF FITTINGS AND POSITIONS INC. INTERNAL AND EXTERNAL LIGHTING, POWER POINTS TO BE AGREED BETWEEN CLIENT AND ELECTRICIAN AS WORKS PROCEED PROPOSED LOWER GROUND FLOOR PLAN A1 1 PROPERTY OF AFFINITY DESIGN AND MANAGEMENT LTD GARAGE CONVERSION Block up existing door using; 102.5mm Brickwork toothed into existing Assumed 75mm cavity partially filled with 50mm Kooltherm K108 100mm Medium density concrete blocks Kooltherm K118 42.5mm insulated plasterboard on dabs Skim & paint, colour TBC by client All to achieve minimum U-value of 0.18W/m2K] Heating engineer to provide radiator output requirements Actual radiator position to be agreed on site with client Remove existing garage roller shutter and block up part of opening Retain existing lintel Use 102.5mm Brickwork toothed into existing Assumed 75mm cavity partially filled with 50mm Kooltherm K108 100mm Medium density concrete blocks Kooltherm K118 42.5mm insulated plasterboard on dabs Skim & paint, colour TBC by client All to achieve minimum U-value of 0.18W/m2K UPBVC window, colour to match existing, provide catnic above Existing wall to be treated up to 1200mm above proposed FFL using Permaseal tanking slurry application strictly in accordance with manufacturers details. Site check external ground level prior to application Use SW timber battens above step in wall (site check) to ensure wall is level. Apply Kooltherm K118 42.5mm insulated plasterboard, skim & paint. BEDROOM GARDEN ROOM STORE A A EXISTING WALL TO BE TREATED UP TO 1200MM ABOVE PROPSED FFL USING PERMASEAL TANKING SLURRY APPLICATION STRICTLY IN ACCORDANCE WITH SITE CHECK EXTERNAL GROUND LEVEL PRIOR TO APPLICATION USE SW TIMBER BATTENS ABOVE STEP IN WALL (SITE CHECK)TO ENSURE WALL IS LEVEL AND THEN APPLY KOOLTHERM K118 42.5MM INSULATED PLASTEBOARD, SKIM & PAINT ACTUAL RADIATOR POSITION TO BE AGREED ON SITE WITH CLIENT UPVC WINDOW, COLOUR TO MATCH EXISTING. PROVIDE CATNIC ABOVE REMOVE EXISTING GARAGE ROLLER SHUTTER AND BLOCK UP PART OF OPENING RETAIN EXISTING LINTEL ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50mm KOOLTHERM K108 INSULATION KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT BLOCK UP EXISTING DOOR USING; ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50mm KOOLTHERM K108 INSULATION KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD ON DABS SKIM & PAINT, COLOUR TBC BY CLIENT ALL TO ACHIEVE MIN. U-VALUE OF 0.18W/m2K B B RETAIN EXISTING LINTEL USE 102.5MM BRICKWORK TOOTHED INTO EXISTING CEILING OVERBOARDED WITH 9MM PLASTERBOARD ON DABS, SKIM & PAINT MATERIALS SITE PREPARATION OF VOIDS TO BE CARRIED OUT USING WELL COMPACTED CONSOLIDATED LAYERS OF HARDCORE. ANY LIVE SERVICES TO BE RE-ROUTED / DIVERTED AS CONTRACTOR SHALL NOTIFY ANY PUBLIC BODY / UTILITY TO ALLOW THEM TO ENTER THE SITE AND CARRY OUT ALL NECESSARY WORKS. THE CONTRACTOR ALL MATERIALS ARE TO BE USED AND INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTIONS AND RECOMM- ENDATIONS. THE NOTE: IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO ENSURE THAT ALL THEIR WORK IS IN COMPLIANCE WITH THE APPROPRIATE REQUIREMENTS OF THE RELEVANT REGULATIONS,OTHER ALLIED LEGISLATION, NHBC GUIDELINES AND LATEST BRITISH STANDARDS. INTERNAL WALLS EXISTING INTERNAL WALL TO RECEIVE PERMASEAL TANKING SLURRY, TAKEN UP TO 1200MM ABOVE PROPOSED FFL AND BELOW FLOOR SLAB. TO BE A GROUND FLOOR CONSTRUCTION CAREFULLY BREAK OUT AND REMOVE EXISTING CONCRETE FLOOR TO REVEAL REDUCED CONSTRUCTION LEVELS. CLEAN NATURAL STONE SULPHATE COMPACTED 150MM WELL CONSOLIDATED LAYERS. UPPER SURFACE BLINDED WITH 50MM SAND AND 1200GDPM LAID WITH FOLDED AND TAPED SEAMS, UPSTANDS TAKEN UP AND OVER DPC LINKED TO CA WALLS TO PROVIDE CONTINUOUS PROTECTION. 50MM COVER AT BOTTOM. PVC PROTECTING LAYER ABOVE. 65MM STANDARD FIBRE REINFORCED SCREED 4:1 SHARP SAND TO OPC, SEMI-DRY BISCUIT MIX LAID OVER INSULATION. SCREED TO BE LAYED/COMPACTED AND BROUGHT TO A CLOSE GRAINED SURFACE FINISH TO RECIEVE FLOOR FINISH. STEEL TROWEL FINISH TO BE APPLIED AS CONCRETE SETS TO LEAVE SMOOTH ACHIEVE OVERALL U VALUE OF 0.18W/M2/K. FFL TO MATCH EXISTING FFL EXACTLY. 102.5MM BRICKWORK TOOTHED INTO EXISTING, FACINGS IN STRETCHER BOND, TYPICAL MORTAR MIX 1:4 CEMENT:SAND. WITH BUCKET HANDLE JOINT RENDERED. ASSUMED 75MM CAVITY PARTIALLY FILLED WITH 50MM KOOLTHERM K108 INSULATION LIGHTWEIGHT LOAD BEARING MEDIUM DENSITY 3.6N 100MM BLOCKWORK TO INNER LEAF. FACING IN STRETCHER BOND, STAINLESS STEEL WALL TIES PAINTED TO CLIENTS SPECIFICATION AND IN ACCORDANCE WITH MANUFACTURERS RECOMMENDATIONS. CLOSE CAVITIES AROUND OPENINGS WITH MANTHORPE WCMULTICOR150 CAVITY CLOSERS. CAVITY TRAYS WITH PREFORMED STOP ENDS ARE TO BE PROVIDED INTERNAL WALLS CONT. USE 50MM X 50MM SW TIMBER BATTENS TO BUILD WALL FLUSH WITH BOTTOM OF WALL, THEN FIX KOOLTHERM K118 42.5MM INSULATED PLASTERBOARD AT LOWER PART OF TO ENSURE WALL IS FLUSH CEILING CEILING OVERBOARDED WITH 9MM PLASTERBOARD ON DABS, SKIM & PAINT OPENINGS BS EN 845-2:2013 SPECIFICATION FOR ANCILLARY COMPONENTS FOR MASONRY. LINTELS. MAX SPAN 3600MM CATNIC TS150/100 THERMALLY BROKEN CAVITY WALL LINTEL ALL LINTELS TO BE FIXED IN STRICT ACCORDANCE WITH MANUFACTURERS INSTRUCTIONS INCLUDING PROVISION OF MIN. 150MM AND BEARING. OPENINGS TO BE FULLY PROTECTED WITH ALL NECESSARY DPC'S, INCLUDING THE FOLLOWING PROVISIONS:PROTECTED WITH A DPC EXTENDING 150MM EACH SIDE OF THE OPENING. INCLUDE FOR WEEPHOLES TO CAVITY TRAYS EVERY FOURTH PERPEND. WINDOWS/DOORS PROVIDE BEAMS / PRE-INSULATED STEEL LINTELS ABOVE DOORS WINDOWS ENSURING CAVITIES AT DOOR REVEALS ARE CLOSED USING PATENT PRE-FORMED INSULATED AND DAMP PROOFED. NEW FRAMES SOLIDLY SCREW FIXED TO ADJACENT FACING OUTERLEAF AND MASTIC POINTED. GLAZING IN CRITICAL AREAS AND WITHIN 800mm OF FFL TO BE TOUGHNED SAFETY GLASS TO BS6206 PT1. FULL DRAUGHT PROOFING SEALS BE PROVIDED MANUFACTURER TO TAKE DIMENSIONS FROM SITE OF ALL APERTURES PRIOR TO ORDERING/MANUFACTURING DOORS & WINDOWS. ALL HABITABLE ROOMS OF THE EXTENSION TO HAVE A BACKGROUND VENTILATION EQUIVALENT TO 8000MM2. ALL NEW WINDOWS / DOORS TO HAVE NEW WINDOWS TO HAVE MIN. U-VALUE OF 1.4W/M²K OR WER BAND B, NEW DOORS TO HAVE MIN. U-VALUE OF 1.4W/M²K OR WER BAND C HEATING BE HEATED USING RADIATORS. ALL NEW RADIATORS ARE TO HAVE THERMOSTATIC RADIATOR VALVES APART FROM THE RADIATOR CLOSEST TO THE THERMOSTAT. BE CERTIFIED BY A COMPETANT AND SUITABLY QUALIFIED HEATING ENGINEER ON COMPLETION OF WORKS. NEW RADIATOR POSITIONS TO BE AGREED ELECTRICAL WORK INSTALLATION TO BE DESIGNED. INSTALLED. INSPECTED AND TESTED ON COMPLETION BY AN APPROVED QUALIFIED ELECTRICIAN TO THE REQUIREMENTS CERTIFICATE TO BE PROVIDED UPON COMPLETION. SCHEDULE OF FITTINGS AND POSITIONS INC. INTERNAL AND EXTERNAL LIGHTING, POWER POINTS TO BE AGREED BETWEEN CLIENT AND ELECTRICIAN AS PROPOSED LOWER GROUND FLOOR PLAN 1:25 @ A1 50mm x 50mm SW timber battens Kooltherm K118 42.5mm insulated plasterboard fixed to battens Skim & paint, colour TBC by client Existing wall to be treated up to 1200mm above proposed FFL and below Floor slab using Permaseal tanking slurry application strictly in accordance with manufacturers details Kooltherm K118 42.5mm insulated plasterboard on dabs Skim & paint, colour TBC by client Proposed Lower Ground Floor Plans Proposed Ground Floor Plan Proposed First Floor Plan Section A-A Section B-B Exisiting workshop to be converted into bedroom and insulated to building regulation standards.

ROOM STORE A B B

Proposed Plans

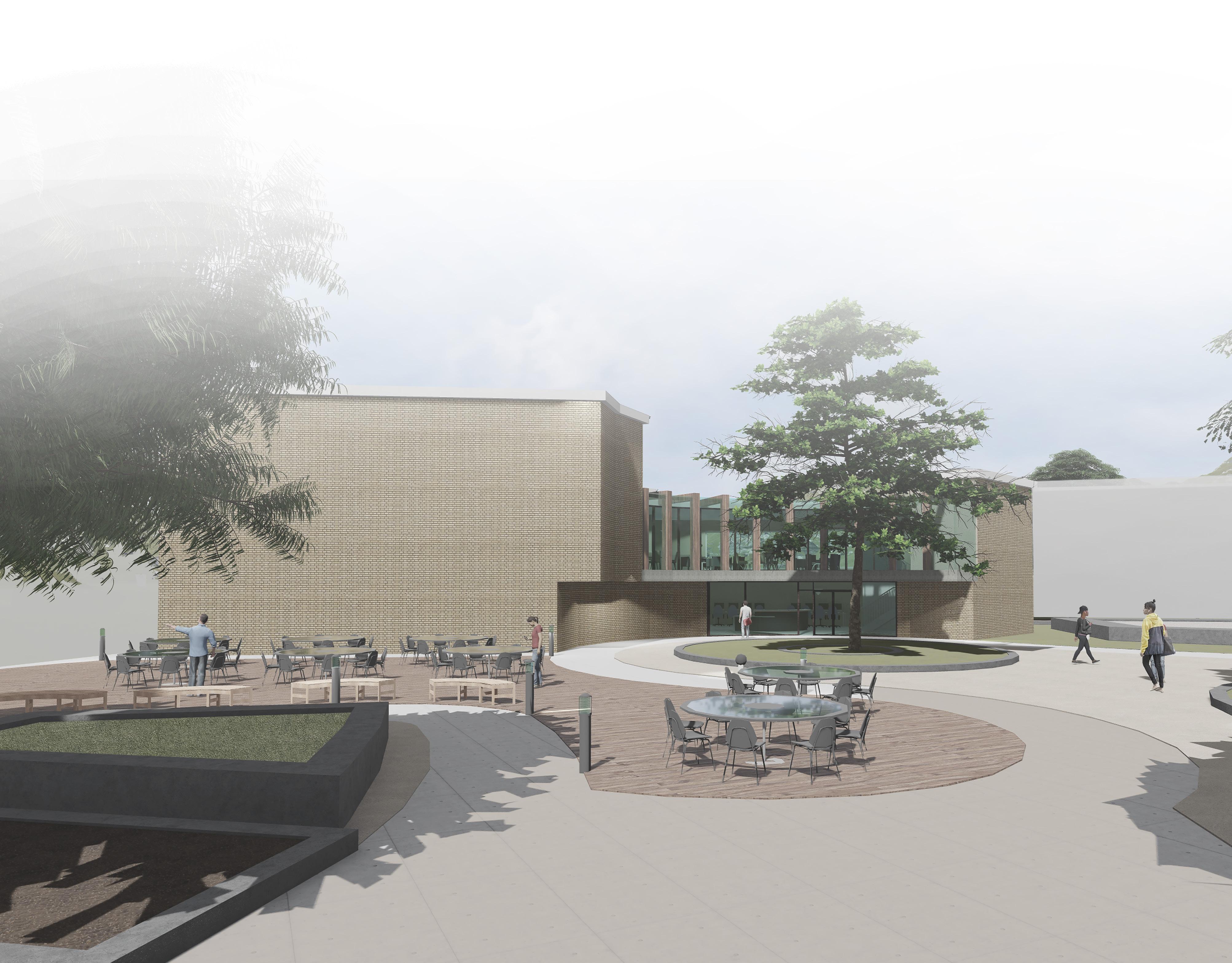

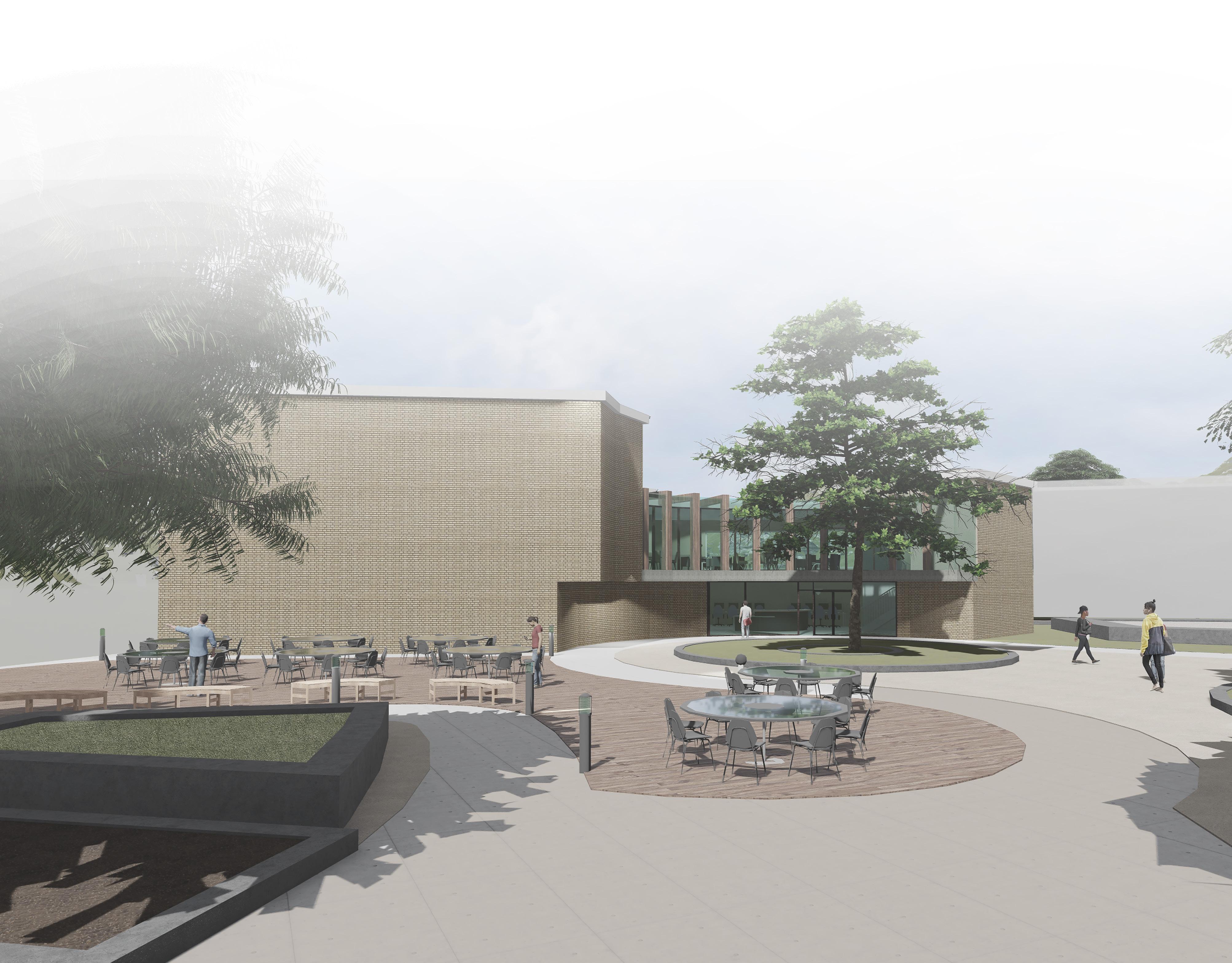

QUEENS THEATRE, BURSLEM

2 PROPERTY OF AFFINITY DESIGN AND MANAGEMENT LTD

Part of a feasibility report to explore options for the existing heritage site in Stoke-on-Trent, Queens Theatre and Princes Hall. The first of these options was a multifunctional hall for events such as weddings, conferences and parties in the Queens Theatre, and residential apartments in the Princes Hall.

2250 2250 2712 2712 2712 9013 10113 343 701 300 UC1 152x152x30 UC1 152x152x30 UB152x152x23 UC1 152x152x30 UB152x152x23 UC1 152x152x30 UB152x152x23 UC1 152x152x30 UB152x152x23 UB152x152x23 UB152x152x23 UB152x152x23 UC1 152x152x30 UC1 152x152x30 UB152x152x23 UB152x152x23 Position of ventilation duct BASL300 BY BESPOKE ACOUSTIC SOLUTIONS See section A Fixed to structural frame in accordance with structural engineer's details. AP50 + BASL100 BY BESPOKE ACOUSTIC SOLUTIONS See section B Fixed to structural frame in accordance with structural engineer's details. 557 A A B B 2601 100 152 2913 above FFL Kemperol system applied to face of parapet (NBS- J31) 3mm Powder coated parapet capping (NBS- F30) 12mm Fibre cement construction board (NBS- L10) 146mm SFS framework supporting aquapanel Timber angle fillet (NBS- L10) Timber packer 18mm Marine ply on firrings 50mm Acoustic rockwool 45kg Kemperol system applied to face of parapet (NBS- J31) 1.2mm Galvanised steel 0.7mm Perforated sheet AP50 ACOUSTIC PANEL (NBS- L10) BASL100 DUMMY LOUVRE 2601 100 152 2913 above FFL 3mm Powder coated parapet capping (NBS- F30) Timber angle fillet (NBS- L10) Timber packer 18mm Marine ply on firrings Kemperol system applied to face of parapet (NBS- J31) 75mm Acoustic rockwool 45kg BASL300 ACOUSTIC LOUVRE (NBS- L10) 10mm End plates with 4No M20 Grade 8.8 bolts Ancon balcony thermal break with galvanised finish, reference STS (NBS- G10) Code 4 lead flashing (NBS- L10) Code 4 lead flashing (NBS- L10) Ancon balcony thermal break with galvanised finish, reference STS (NBS- G10) 8mm Rockpanel soffit board See drawing 0618 for Rockpanel soffit detail. (NBS- G10) 10mm End plates with 4No M20 Grade 8.8 bolts Thermabate cavity closer (NBS- F30) Thermabate cavity closer (NBS- F30) NOTE Louvre to be oriented as shown to ensure no view through from ground level. 8mm Rockpanel soffit board See drawing 0618 for Rockpanel soffit detail. (NBS- G10) NOTES: Revisions Drawn by PLANT SCREEN DETAIL PLAN 1:25 @ A1 PLANT SCREEN SECTION B-B 1:10 @ A1 PLANT SCREEN SECTION A-A 1:10 @ A1 PLANT SCREEN DETAIL Plant screen design as part of a larger scientific lab extension. Plant Screen Detail Plan Plant Screen Section A-A Plant Screen Section B-B 3 PROPERTY OF AFFINITY DESIGN AND MANAGEMENT LTD

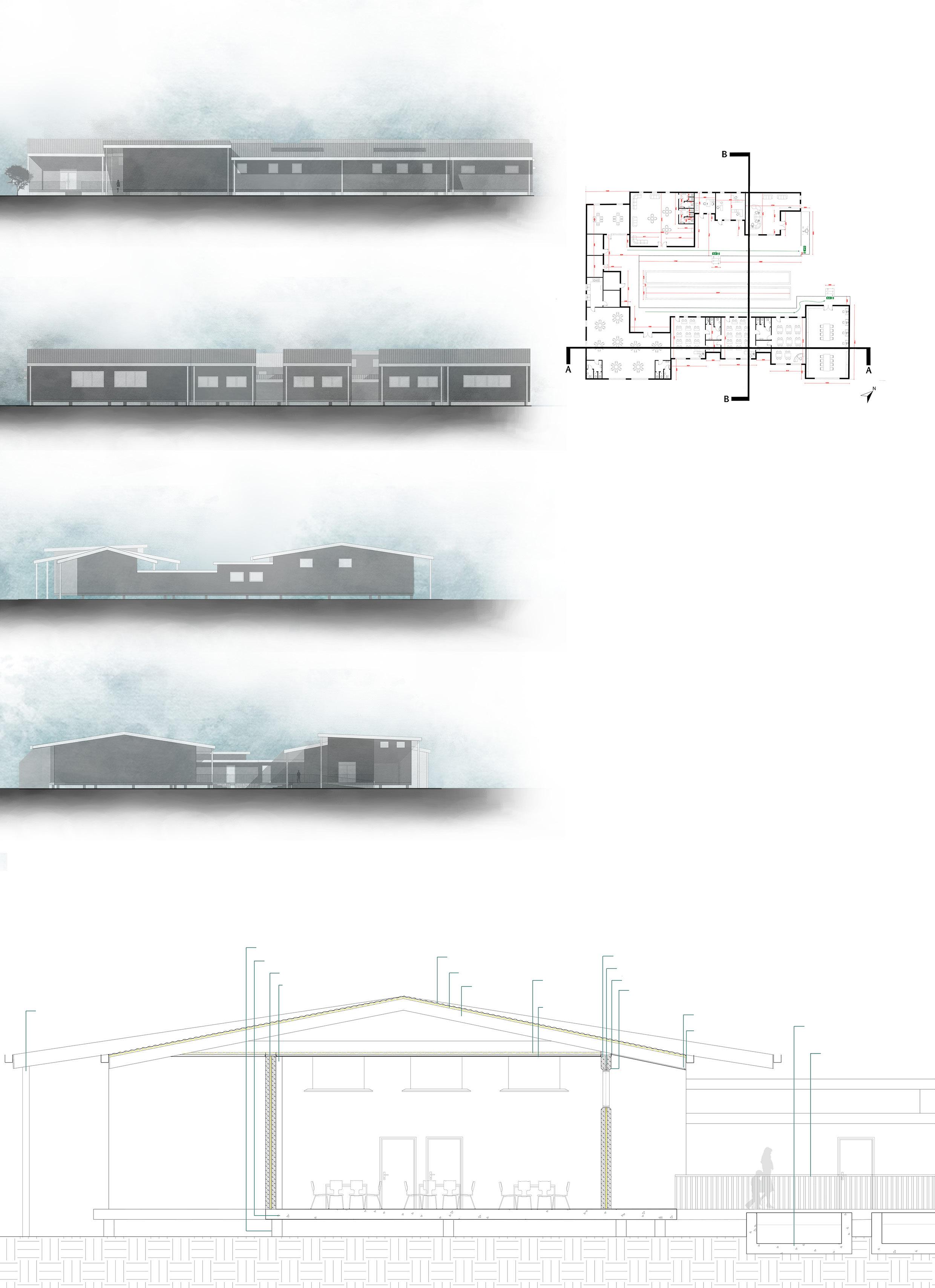

BLURTON COMMUNITY CENTRE Proposal to convert an existing community centre into a 3 bedroom bungalow. South West Elevation North West Elevation North East Elevation South East Elevation South West Elevation North West Elevation North East Elevation South East Elevation Existing Elevations Proposed Elevations Existing Plan Proposed Plan 4 PROPERTY OF AFFINITY DESIGN AND MANAGEMENT LTD

A A B B Floor Plan Render 5

MUSICAL THERAPY CENTRE

This design proposal combats the economic effects inflicted upon the entertainment industry in Leicester, specifically focusing on the music and arts sector; a rehabilitation centre which combats the effects of mental health caused by the Covid-19 pandemic, serving as a form of therapy through its adaptable and incluvise spaces along with its natural surroundings in the Waterside location, a place to allow creativity to flourish and improve ones wellbeing.

Music Room

Theatre/Auditorium Space

Karaoke Bar

Exterior View

Interior Renders

6

Dance Rehearsal Room

Section

A Call-Outs

Concrete

Waterproof membrane

Rigid insulation Sand

Earth

18mm Timber roof cladding

Drain

Ventilation gap/ counter battens

Roof membrane

Mineral wool insulation/ timber joists

Vapour membrane

Three layer cross-laminated timber

Wood finishing

Versalayer

Soundproof membrane

Timber joists with insulation

Concrete

Rigid insulation

Waterproof membrane

Concrete footing

Wood flooring

Timber joists with insulation

Cross laminated timber floor panel

Cross laminated timber

Structural panel

Vapour control layer

Wood fibre insulation

Plasterboard

Oak timber cladding

Steel angle bracket with engineered spiral nails

Polished screed floor Insulation

Sand

Column foundation

Pile foundation Earth

PRODUCED BY AN AUTODESK STUDENT VERSION

0 1 2 3 4 5 10m Originally drawn @ 1:50

Section A

1 2 3 4 5 6 1 3 5 6 4 2 7

Section B 8

9

Handmade Physical Model

MICRO LIVE/WORK UNIT

This was a proposal to address high-risk working conditions faced by the ‘Dark Factory’ workers within Leicester’s textile industry. It involved designing a modular, off-grid cabin featuring both a living and working unit with a maximum 60m2 footprint.

10

South Elevation

A) PV cell

B) Solar water heater

C) Skylight

D) Upper deck

E) Working unit

F) Batteries

G) Water tanks

H) Steel adjustable legs

I) Larch cladding

J) Timber sheeting

K) Counter battens

L) Insulation

M) Cross laminated timber

N) Insulation

O) Service cavity

P) Plasterboard

A B C D E F G H I J K L M N O P 11

1) Solar water heater

2) Roof: - Timber cladding - 42mm Ventilation gap/ counter battens

- Roof membrane - 175mm Mineral wool Insulation/175mm timber joists

- Vapour membrane

- 104mm Three layer crosslaminated timber

3) Drainage system

4) External wall:

- 18mm Larch cladding - 21mm Timber sheeting

- 60mm Ventilation gap/ counter battens

- Wind seal

- 140mm mineral wool insulation

- 100mm Three layer crosslaminated timber

- Vapour retarder

- 45mm Studs and service cavity (with insulation) - 13mm Plasterboard

5) Floor: - 14mm Wood flooring

- 5mm Polyester fibre mat

- 25mm Gypsum fibreboard - 95mm Insulation and 70mm joists - 25mm Sylodyn - 220mm Five layer crosslaminated timber

6) 200mm Steel beam

7) R20 adjustable steel post base

8) PVC cell

9) Timber frame triple thermal glazing with krypton gas filing

10) Triple glazing in wood frame

11) Sliding door

12) Joint glue

13) Self tapping screw (Konstrux St countersunk head) and metal plate

14) Inverter

15) Batteries

16) Hydraulic pump

17) Grey water tank

18) Water tank

Section AA Scale 1:20 @ A2 Section BB Scale 1:20 @ A2 FRONT ELEVATION SCALE 1:50 LEFT ELEVATION SCALE 1:50 BACK ELEVATION SCALE 1:50 RIGHT ELEVATION SCALE 1:50 ROOF PLAN SCALE 1:50 UPPER DECK PLAN SCALE 1:50 GROUND FLOOR PLAN SCALE 1:50 ALIYAH HUSSAIN P2508342 ARCH3054 STORYBOARD FRONT ELEVATION SCALE 1:50 LEFT ELEVATION SCALE 1:50 BACK ELEVATION SCALE 1:50 RIGHT ELEVATION SCALE 1:50 ROOF PLAN SCALE 1:50 UPPER DECK PLAN SCALE 1:50 GROUND FLOOR PLAN SCALE 1:50 ALIYAH HUSSAIN P2508342 ARCH3054 STORYBOARD Upper deck plan Ground floor plan 12

UP A204 2 A204 1 A204 3 A204 4 By Room Name Legend ADMINISTRATION OFFICE CIRCULATION COMPUTER CLUSTER LOWER FLOOR TOILETS READING HALL SPECIALISED ROOM STAIRS TECHNICIAL SUPPORT ROOM 25346 12651 North 1 A205 DN A204 2 A204 1 A204 3 A204 4 By Room Name Legend CAFE CINEMA GAMES ROOM KITCHEN STORAGE UPPER FLOOR TOILETS North 1 A205 14535 8163 4330 11156 3393 2660 2703 10174 32783 DN A204 2 A204 1 A204 3 A204 4 By Room Name Legend CAFE CINEMA GAMES ROOM KITCHEN STORAGE UPPER FLOOR TOILETS North 1 A205 14535 8163 4330 11156 3393 2660 2703 10174 32783 DN A204 2 A204 1 A204 3 A204 4 By Room Name Legend CAFE CINEMA GAMES ROOM KITCHEN STORAGE UPPER FLOOR TOILETS North 1 A205 14535 8163 4330 11156 3393 2660 2703 10174 32783 Room Schedule 2 Area Level Name 105 m² Level 0 READING HALL 98 m² Level 1 CINEMA 23 m² Level 0 ADMINISTRATION OFFICE 101 m² Level 0 CIRCULATION 111 m² Level 1 CAFE 13 m² Level 1 KITCHEN 23 m² Level 1 UPPER FLOOR TOILETS 50 m² Level 1 GAMES ROOM 30 m² Level 0 COMPUTER CLUSTER 26 m² Level 0 TECHNICIAL SUPPORT ROOM 18 m² Level 0 SPECIALISED ROOM 6 m² Level 1 STORAGE 12 m² Level 0 STAIRS 23 m² Level 0 LOWER FLOOR TOILETS 13

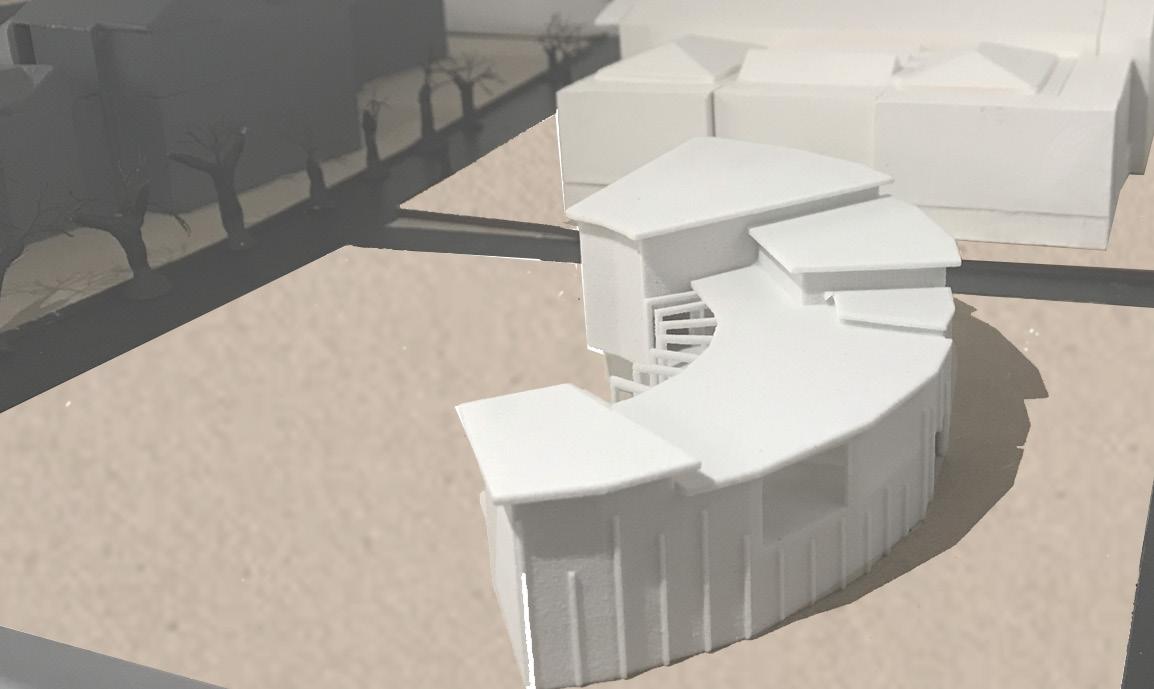

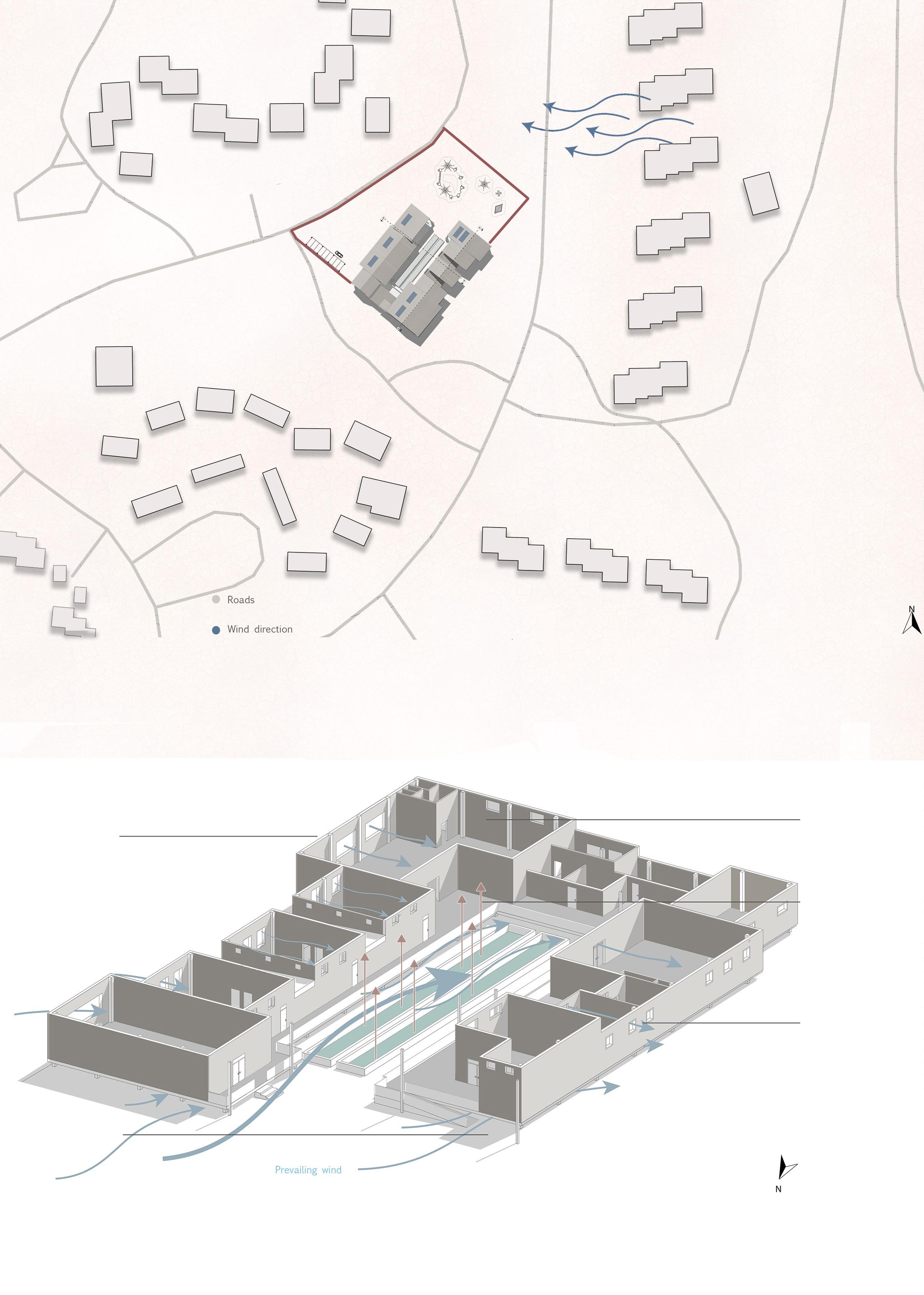

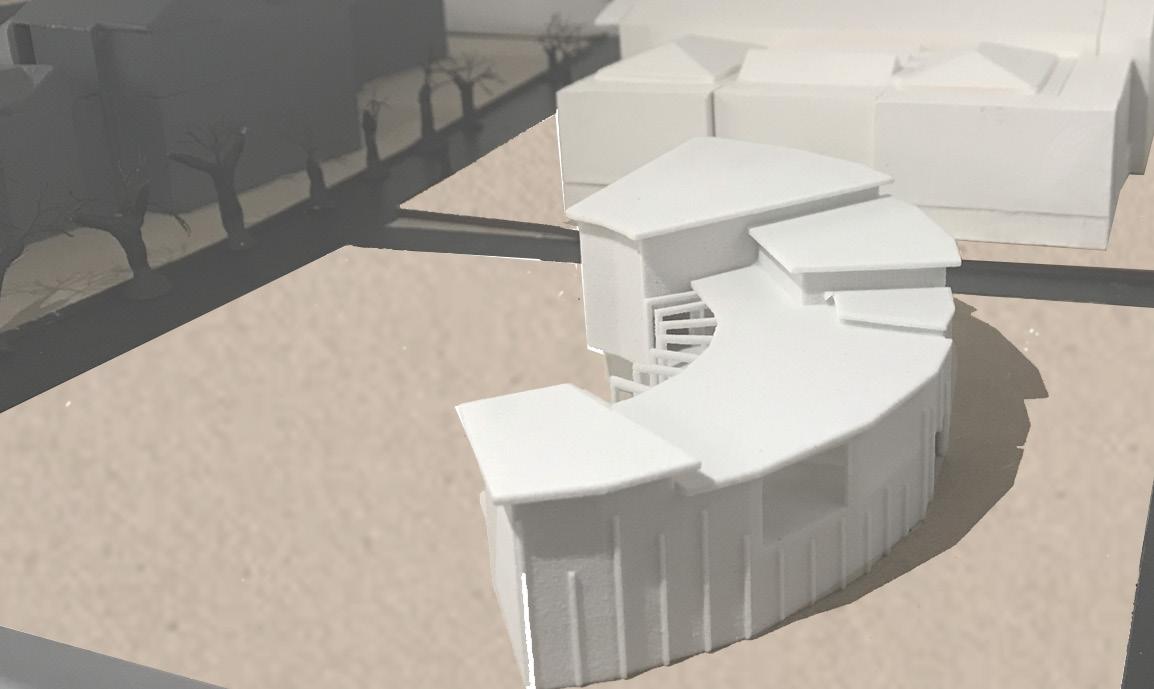

NEW WALK LIBRARY

The concept of this New Walk Library derived from themes associated with the New Walk Museum which the proposed project sits adjacent to. The museum featured themes of art, history and science, thus the scheme was inspired by ammonite fossils along with the bone structure of dinosaurs, hence the curved form of the building. Site traditions (such as materials) are followed within the project, therefore flowing as though it is a part of the site itself, but also acts as a successful extension of it.

The concept of this New Walk Library derived from themes associated with the New Walk Museum which the proposed project sits adjacent to. The museum featured themes of art, history and science, thus the scheme was inspired by ammonite fossils along with the bone structure of dinosaurs, hence the curved form of the building. Site traditions (such as materials) are followed within the project, therefore flowing as though it is a part of the site itself, but also acts as a successful extension of it.

14

Physical 3D Printed Model

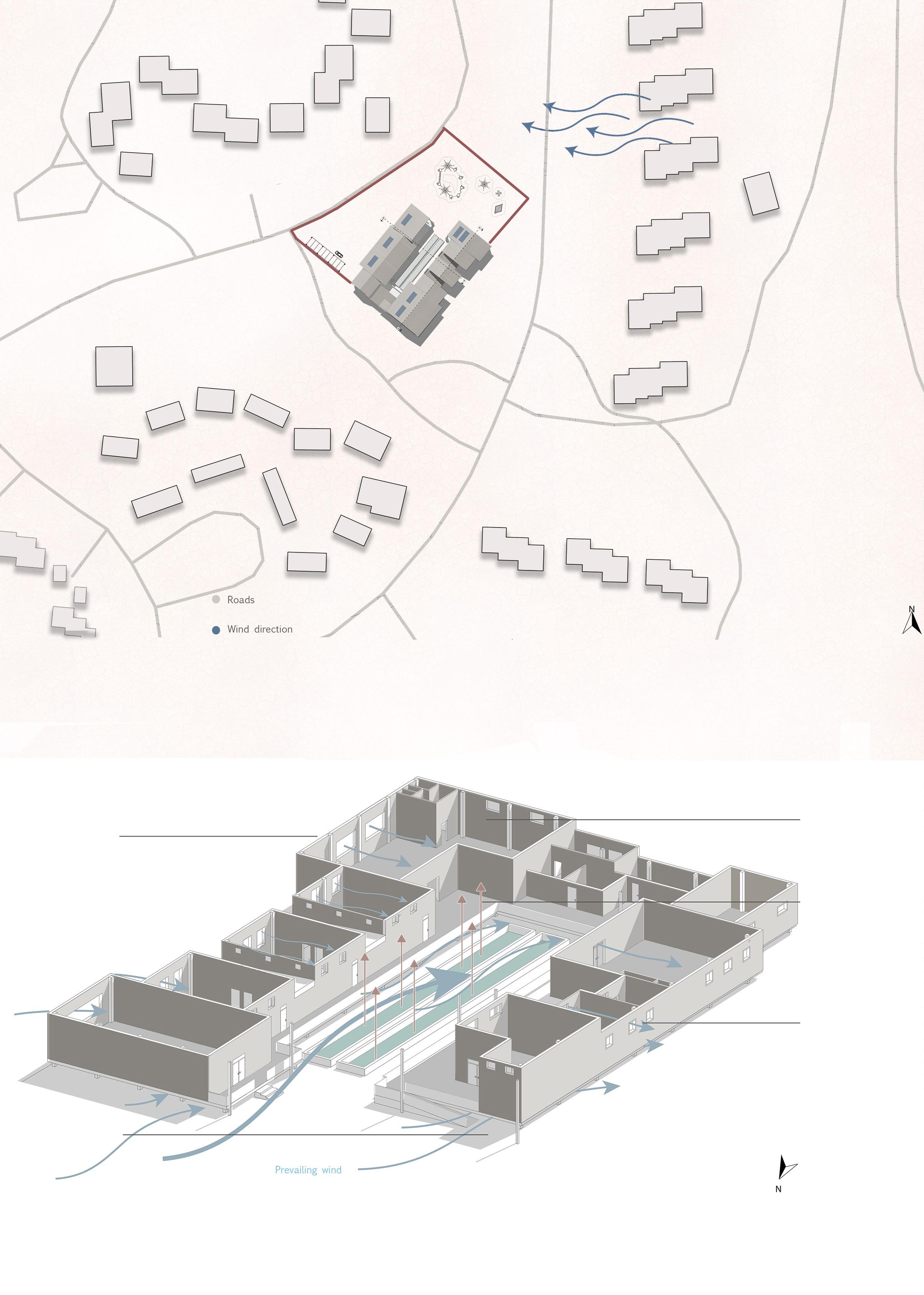

The building is oriented to face north which is where the sun travels along and hits during the peak times of the day. This allows full sun penetration in the winter and the roof overhang allows it to be shaded during the summer and therefore the longest facades face north and south.

The south facade is the longest to ensure maximum views since most of the windows are situated here. The east side is left fairly open to allow wind (as this is the most prevalent direction wind flow occurs throughout the year) to pass through into the courtyard to ensure cooling.

Site Plan

Environmental Strategy Diagram

Large widows facing south to ensure maximum views, shaded by the roof overhang, as they do not face the sunlight directly and will therefore not lead to overheating and glare

The wall heights are large in all the common areas in order to allow space for heat to escape upwards towards the windows for thermal comfort.

Evaporation from the pool creates a passive cooling system, reducing the overall temperature. Low number of clerestory windows on the north, east and west facades in order to minimise heat gain, therefore they are positioned higher up to allow for effective ventilation due to heat rising.

Building raised off the ground to create a cool space underneath to allow air to move through and permeate successfully

15

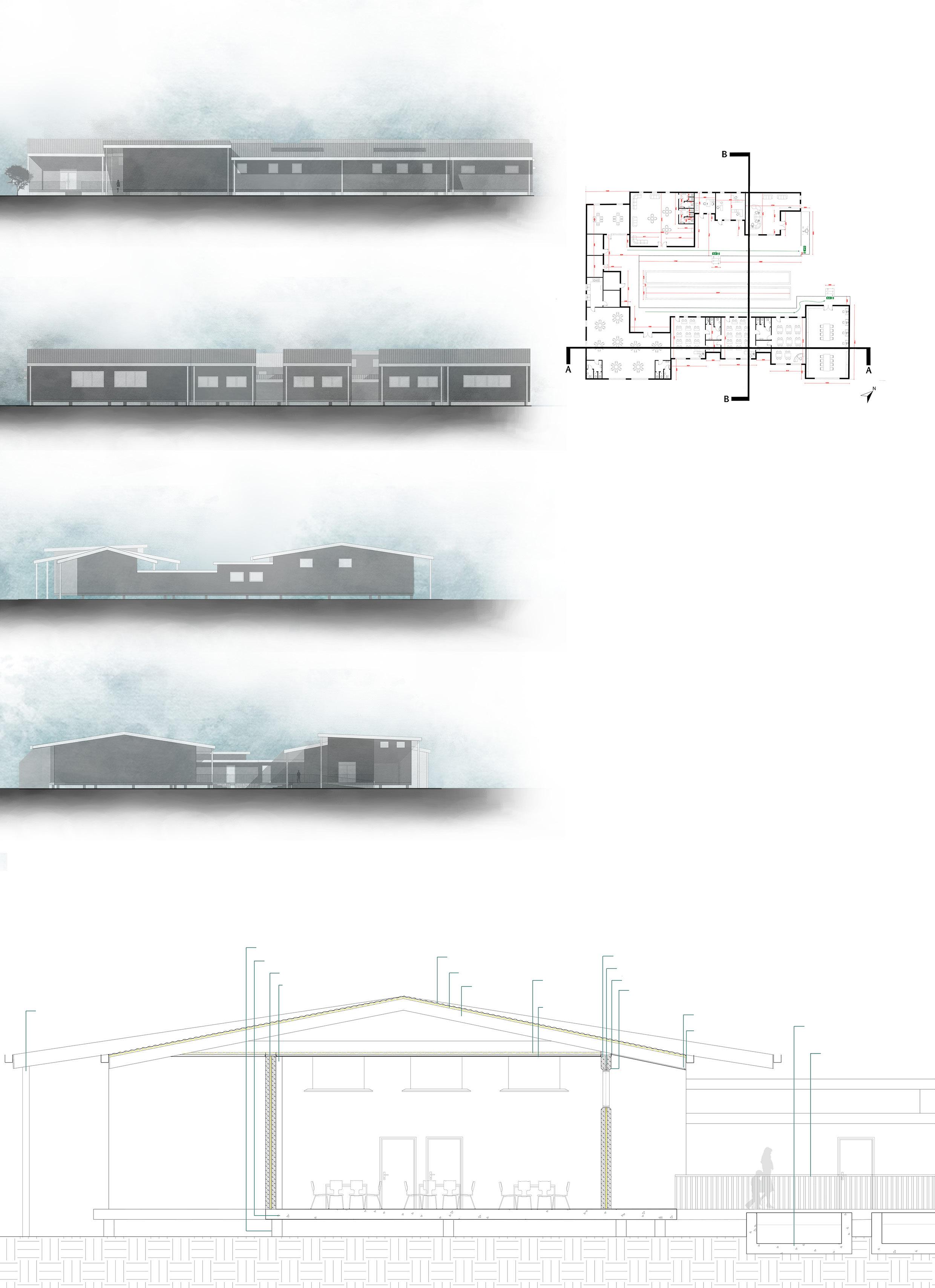

ARID CLIMATE SCHOOL

North Elevation

South Elevation

West Elevation

Floor Plan and Access/Fire Exits

East Elevation

Timber structure column

Steel reinforced concrete stilt

(Pad foundation)

Concrete deck

Top plate

Steel reinforced concrete column

Renewable Technologies

Photovoltaic panels are used to ensure the building remains at a consistent temperature over the wintertime to allow optimal thermal comfort and also offer an energy efficient alternative to power electricity using heat gain from the sun.

Rammed earth walls have high thermal mass to control the temperature inside the school by absorbing sunlight and releasing small amounts of heat into the building.

Roof is coated with corrugated iron which is cost efficient to produce and easy to make, does not require insulation and also reflects heat away. It is sloped to allow rainfall to be removed and the overhang allows shading to protect the windows.

Corrugated metal sheet Insulation

Timber truss

Ceiling insulation

Plasterboard

Insulated rammed earth

Lintel above openings

Trim to eave and wall

50mm Chamfer to rammed earth

wall at window junction

Eaves batten

Fascia and gutter

Concrete water pool for cooling

Timber railing

16

A

primary school situated in Yulara, Australia designed to address cost-effective and sustainable methods of climare control.

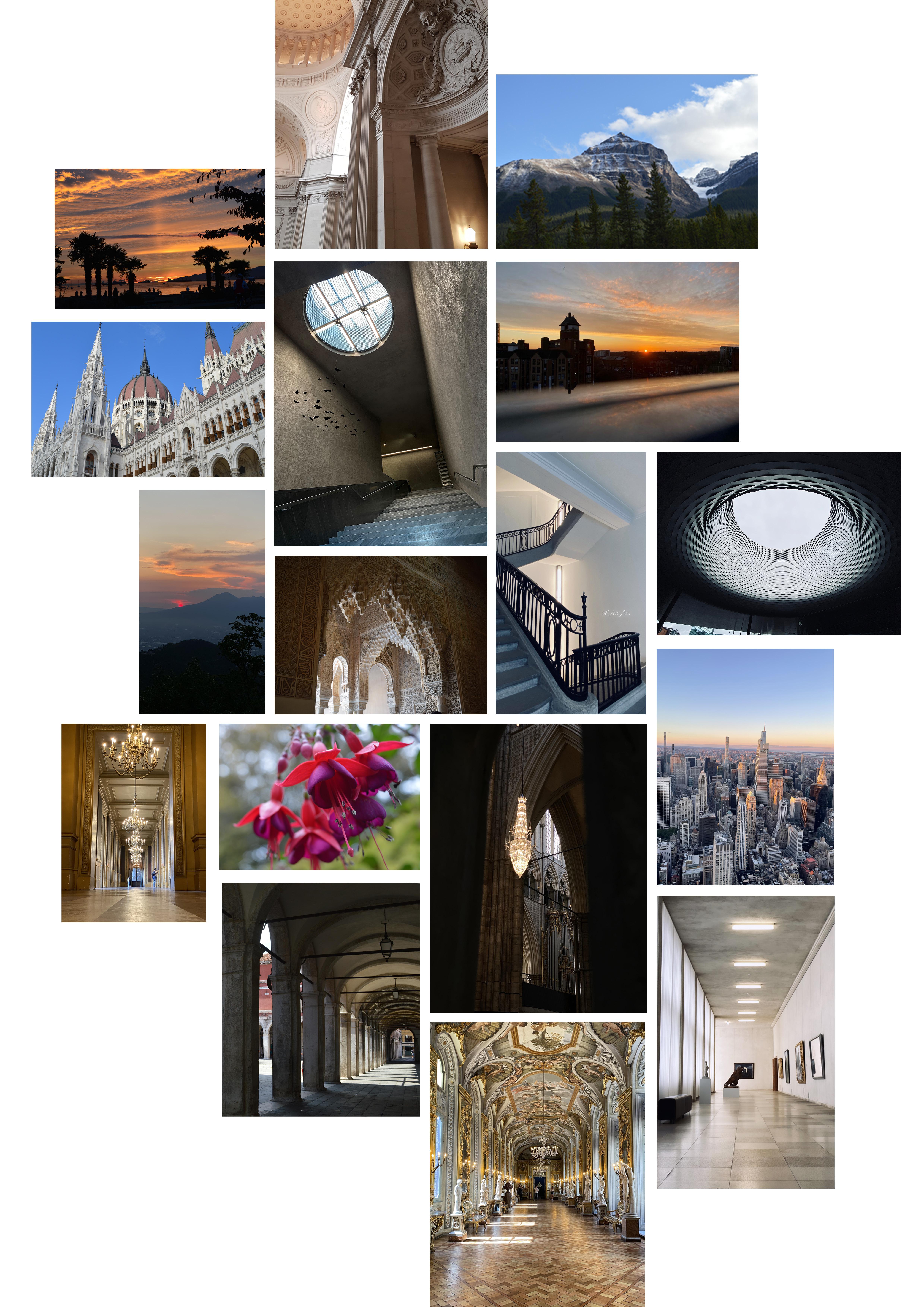

PHOTOGRAPHY COLLECTION 17 Compilation of photographs taken by myself over the years.

The concept of this New Walk Library derived from themes associated with the New Walk Museum which the proposed project sits adjacent to. The museum featured themes of art, history and science, thus the scheme was inspired by ammonite fossils along with the bone structure of dinosaurs, hence the curved form of the building. Site traditions (such as materials) are followed within the project, therefore flowing as though it is a part of the site itself, but also acts as a successful extension of it.

The concept of this New Walk Library derived from themes associated with the New Walk Museum which the proposed project sits adjacent to. The museum featured themes of art, history and science, thus the scheme was inspired by ammonite fossils along with the bone structure of dinosaurs, hence the curved form of the building. Site traditions (such as materials) are followed within the project, therefore flowing as though it is a part of the site itself, but also acts as a successful extension of it.