Ali Huda PORTFOLIO

Welcome to my portfolio! My name is Ali Huda, and I am a fourthyear Architectural Studies major at Northeastern University. I’m a Muslim-American, born and raised in Boston, MA. Initially interested in mechanical engineering and design, architecture perfectly blends my interests in art and science. One of the fundamental things you should know about me is that I love to learn. I take advantage of every opportunity to do so. Surrounding myself in new learning environments has been a big part of my education. Understanding from people with different experiences and perspectives is so important to me. We grow from each other. Architecture is a field where you can always keep evolving. There is so much I still want to explore, to find my place in this exciting field. Thanks for reading this bio. I hope you learned a little bit about me!

Chess

3D Studio

Pavilion Case Study

DECEMBER 2024

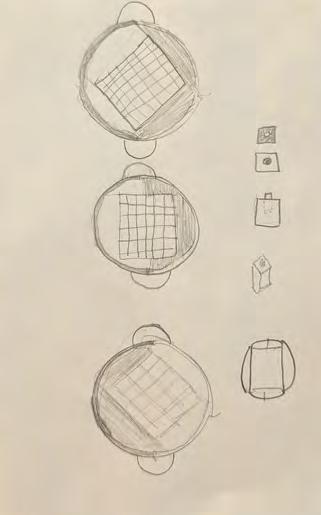

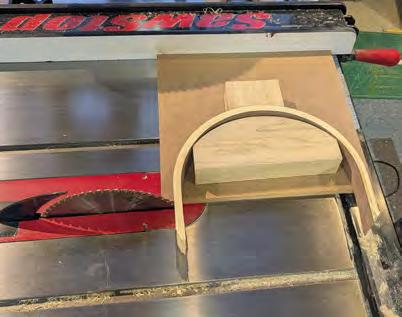

This project explores the process of wood fabrication through the creation of a chessboard.

This project showcases the intersection of design and craftsmanship, where the goal was to explore the creative process of designing and building a playful, interactive object. The process involved careful consideration of material selection, joinery techniques, and finishing details to achieve a durable and delightful final product.

The design of this chessboard captures the essence of the battle that unfolds as the game begins. The interplay of walnut and maple veneers brings this battle to life, with the dark and light woods mirroring the opposing forces, a theme echoed in the chess pieces themselves. The circular form elegantly contains the game within its boundaries, bringing this design together.

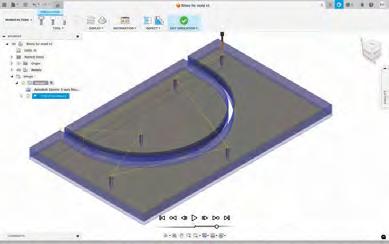

CONCEPT RENDERS

ALHAIDARI/HUDA

KANA ARCH 3450

PROJECT 3: FABRICATION MOLDING AND LAMINATION PROCESSES

ALHAIDARI/HUDA

MOLDING AND LAMINATION PROCESSES

KANA ARCH 3450

PROJECT 3: FABRICATION

MOLDING AND LAMINATION PROCESSES

ALHAIDARI/HUDA

KANA

ARCH 3450 PROJECT 3: FABRICATION

JANUARY - AUGUST 2024

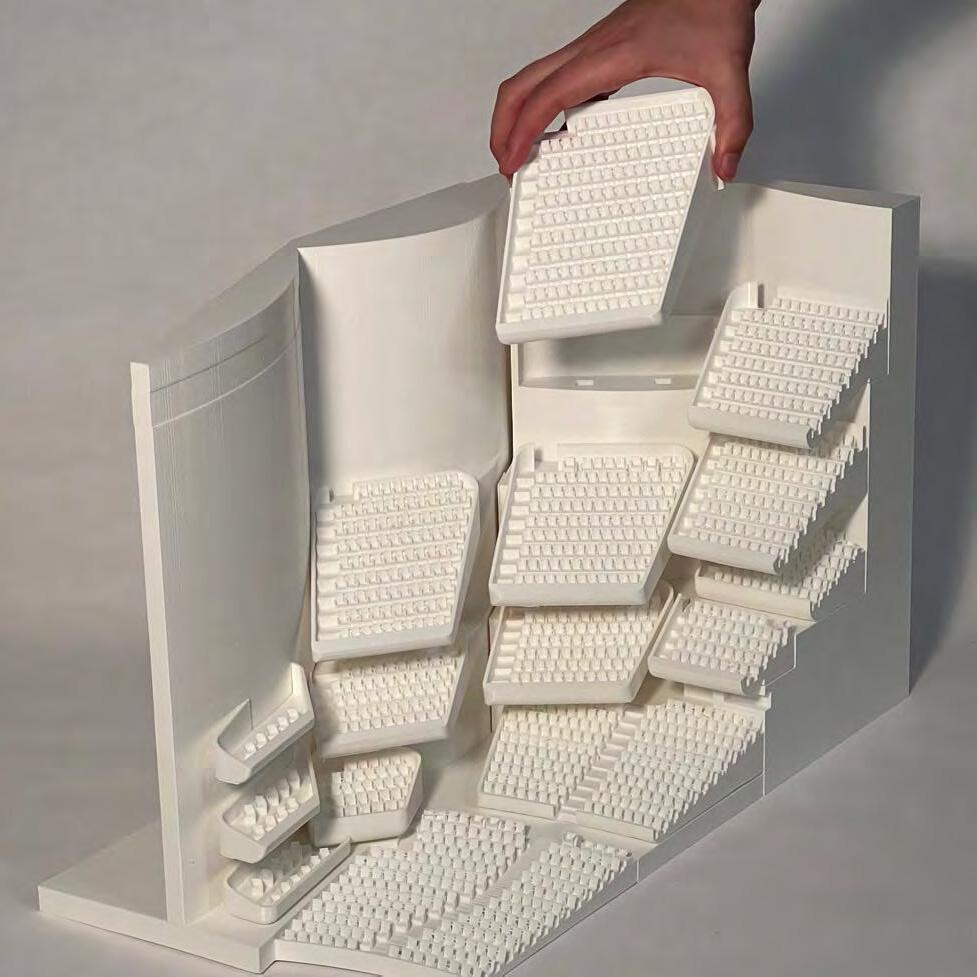

The following projects demonstrate a wide variety skills across all design stages.

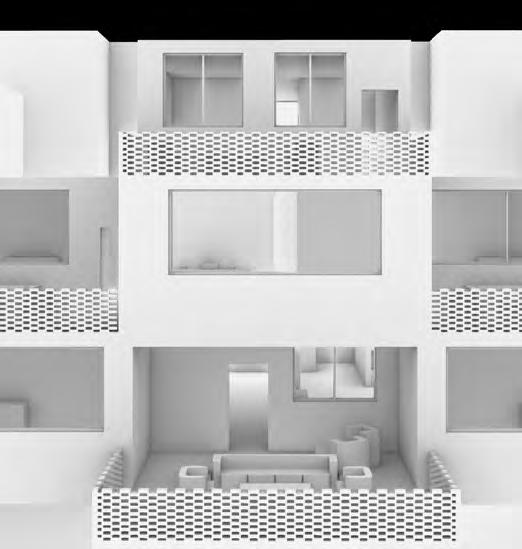

As part of the 3D Studio, I produced models that played a vital role in client presentations, ensuring clear communication and constructive desgin discussions. The range of models presented here reflects a versatility in skills and techniques, adapted to the specific needs of each design phase. Working alongside two Northeastern Co-op’s led to great collaboration and communication amoung projects.

Models were created from wood, 3D prints, cork, paint, and museum board. These materials were used with one another to produce models that could serve specific functions. Often models were adaptable. They could be taken apart or modified which was especially helpful during client meetings, to showcase different design concepts.

SEPTEMBER 2023

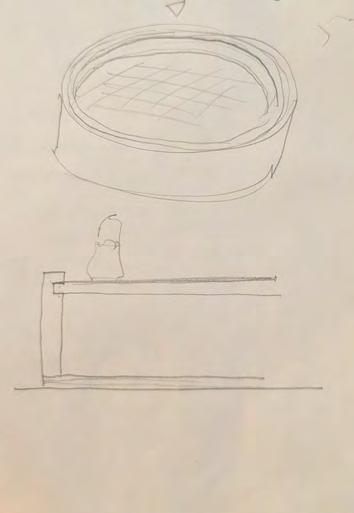

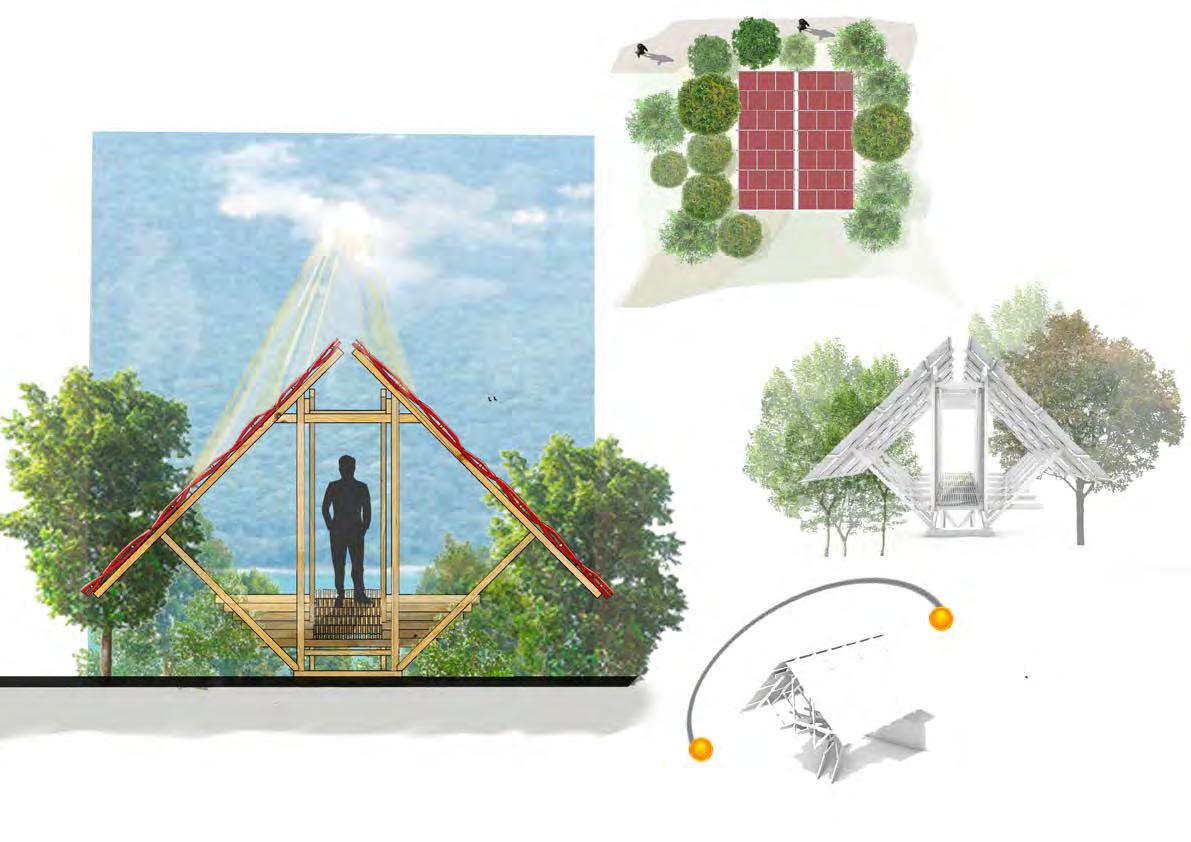

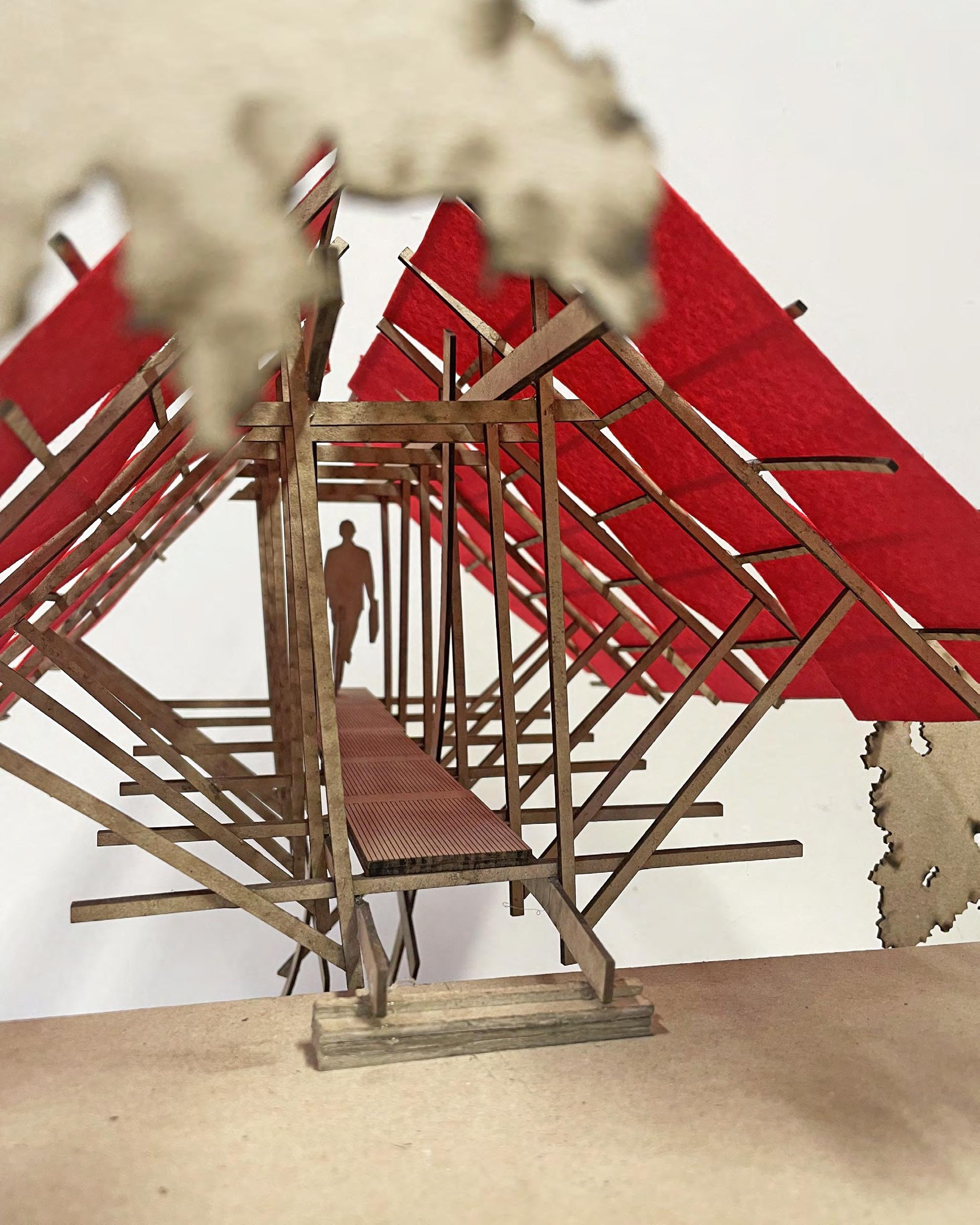

This project explores the logic between design, material, and technique through a case study model.

Through recreating the Pavilion for a Patagonian Shadow, both in documentation and a 1:3 scale model, our team gained invaluable insight into the project. This hands-on experience illuminated the intricate relationship between design intent and the final built form.

Process photos of constructing the 1:3 model are presented, replicating the same sequence used to build the pavilion. Through large-scale recreation, students could incorporate the same techniques used in the project. An additional smaller study model displays the surrounding site. Research on the surrounding area and the architect’s intentions helped form a complete understanding of this pavilion and its design objectives.

protecting from di erent weathconditions instead it is used to provide to serve as signpost to direct towards the landscape and the lake

analyzed that the roof is angled attract the viewer and to be able from far in contrast to the surroundgreenery.

Ali Huda

Patagonian Shadow Pavilion DRAA, 2023

More trees exist at the begenning of the path causing more shade on that part of the pavilion where the user experience the rst step into the pavilion. y the end of the path more light starts appearing. The two faces of the pavilion face east and west, meaning the sun comes out and goes down towards two opened sides of the pavilion, which allows more light to get through it.

The pavilion lies humbly within the tree line while allowing its red roof to stand out from its surroundings. The roof plan shows the symmetry of this project. The exploded axon shows the structure as very complex, but there are many organized components to this construction.

DECEMBER 2023

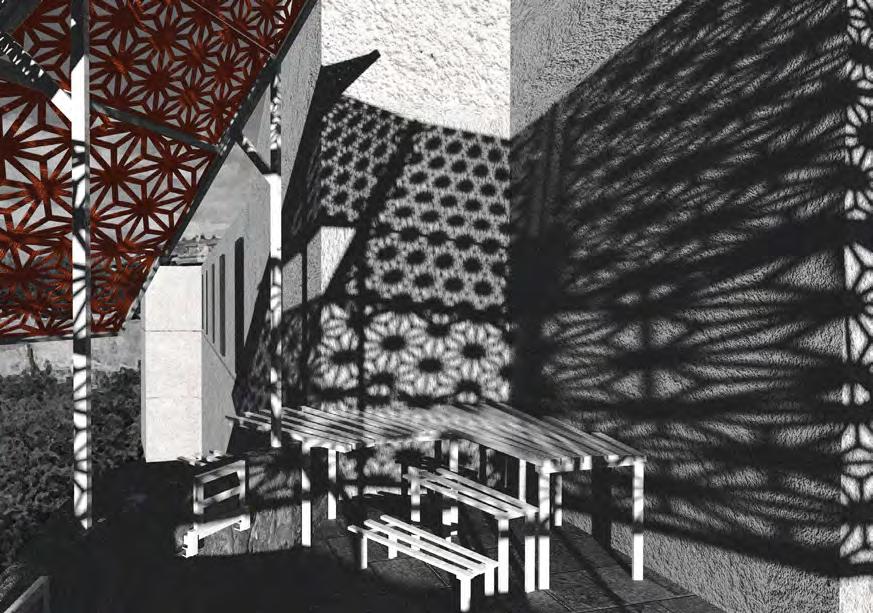

Kinetic Shadows uses the materials and concepts understood in the Pavilion case study, to create a new structure within the context of Segovia.

While the Pavilion case study was a static strucutre, this pavilion shows the beauty of kinetic shadows. The materials from the case study are repurposed to create this pavilion. The staircase leads to an outlook overlooking Segovia’s landscape and Alcazar. The structure works as one to create an interactive pavilion. As visitors walk up the stairs, panels above move with them. As they sit down, panels open letting a breeze in. Sgraffito is introduced reminiscing the architecture of Segovia. The pavilion changes a lookout point into an interactive experience. It reflects the culture of Segovia and developes the concepts of the case study.

-string: 0.1

-I put sgraffito as 0.1 as well

-everything else, 0.25 - 0.5

This diagram explains how the kinetic systems work. The idea is that as a visitor puts their weight on the stair, the panel lifts up. A 1:3 scale model was made to test this hypothesis. As shown in the illustrations below, it worked!

APRIL 2023

design. The apartments imitating that

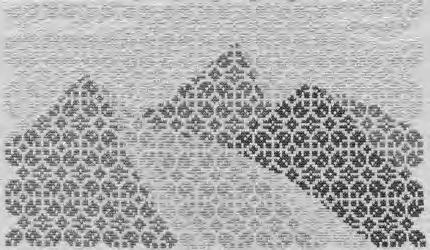

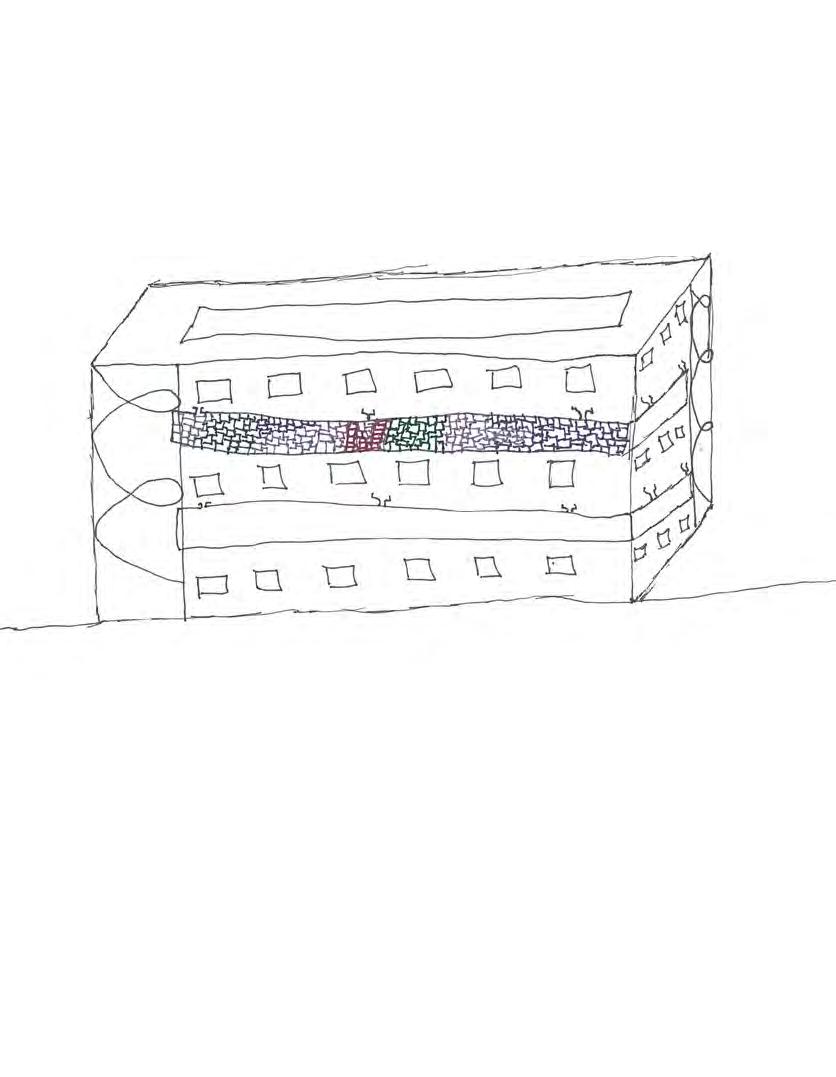

This project takes inspiration from Tatreez, a traditional Palestinian embroidery, that led to a concept of woven architecture.

Tatreez is intricate in design, starting with small patterns that make up an artistic whole. The patterns originate from the heritage of Palestinian communities and are incorporated in different ways into this project. This Tatreez inspiration continues throughout the site, from the form of the apartments to the pedestrian street design.

Woven architecture:

This concept was formed by attempting to bridge embroidery and architecture. Woven architecture creates strong bonds within its modules that create a bigger picture. The apartments are arranged in relation to one another to fit together. This strong interconnected form is fundamental to weaving. A more personal space is developed by pushing the building to the outskirts of the site, creating a connected inner courtyard. Using a brick material, the apartment buildings can give a similar texture to embroidery. The apartments aim to create a community within their space while imitating that experience in its exterior form.

FOURTH FLOOR PLAN 1/16” = 1’-0”

THIRD FLOOR PLAN 1/16” = 1’-0”

An outside perspective of apartment 1 is shown above, with the shared space in front of it. To the left is a perspective showing the pedestrian road with apartments on either side.

SECOND FLOOR PLAN 1/16” = 1’-0”

This diagram illustrates how the modules of Apartment 1 were transformed to create Apartment 2. The structure changed from a singleloaded corridor to a point-load building. Stairs were implemented by combining modules and adapting them to these new conditions, as represented above.

This site analysis diagram represents the Northeastern campus. All of the shaded structures denote buildings with Northeastern’s white brick material. The project’s apartment buildings incorporate the same material to integrate them with the rest of the campus.

This circulation diagram portrays the movement of the residents when entering and exiting the building. Apartment 1 has two main stairways connected to the amenity spaces and four inner stairways off the single-sided corridor.

This ground plan of the apartments shows their relationship with Jarvis Street. The street was re-imagined as a pedestrian road wide enough for emergency vehicles. The brickwork takes inspiration from traditional tetreez designs, connecting back to the project’s original concept.

This section perspective illustrates different components of the buildings. It also shows how the two buildings speak to each other—facing one another with a common ground in between.

DECEMBER 2O23

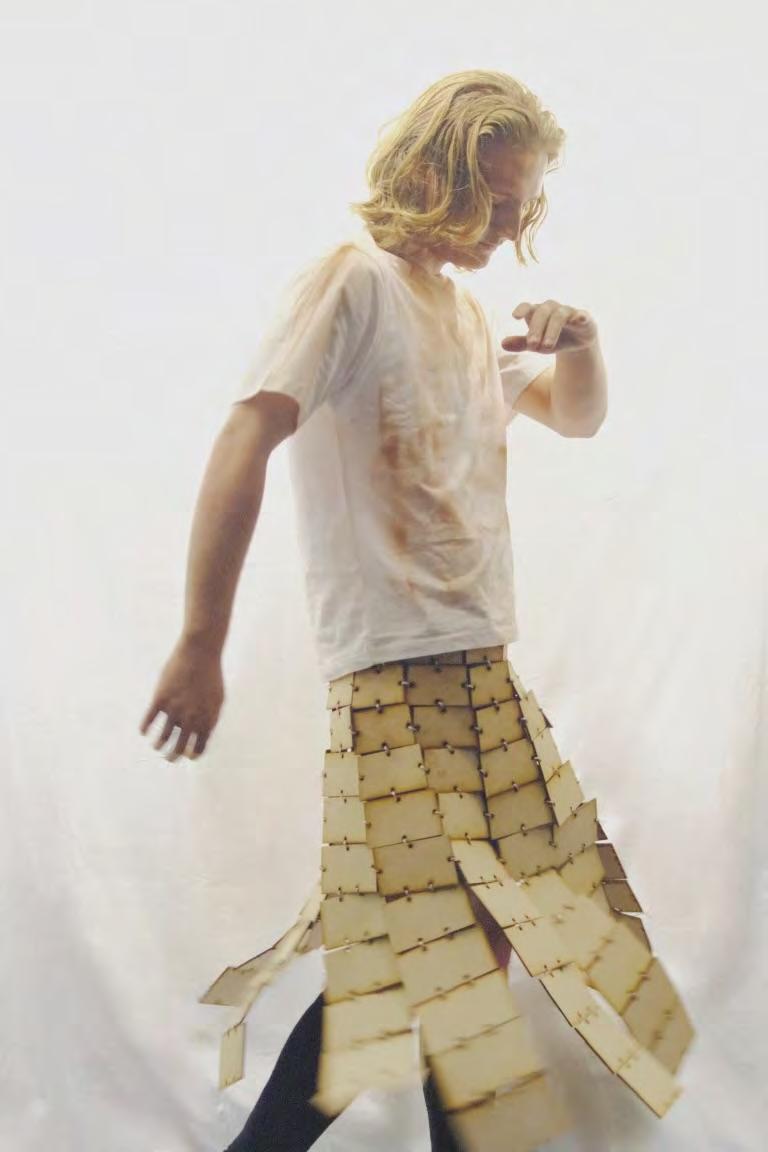

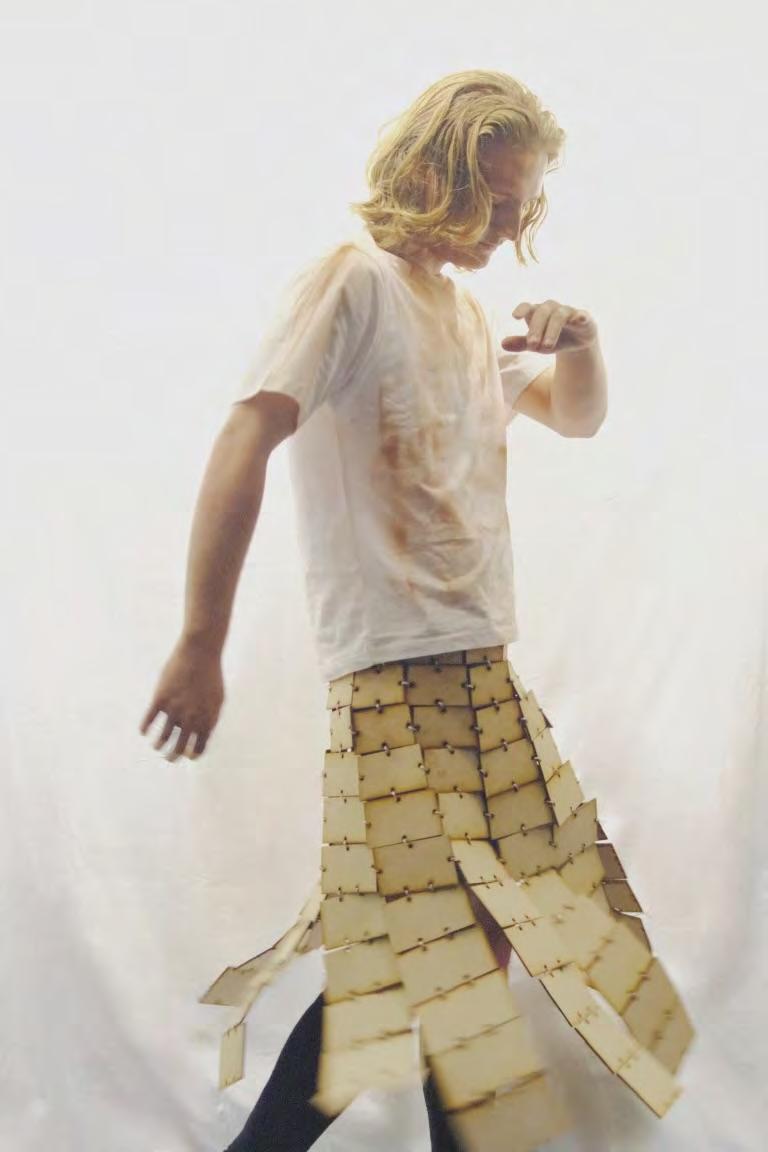

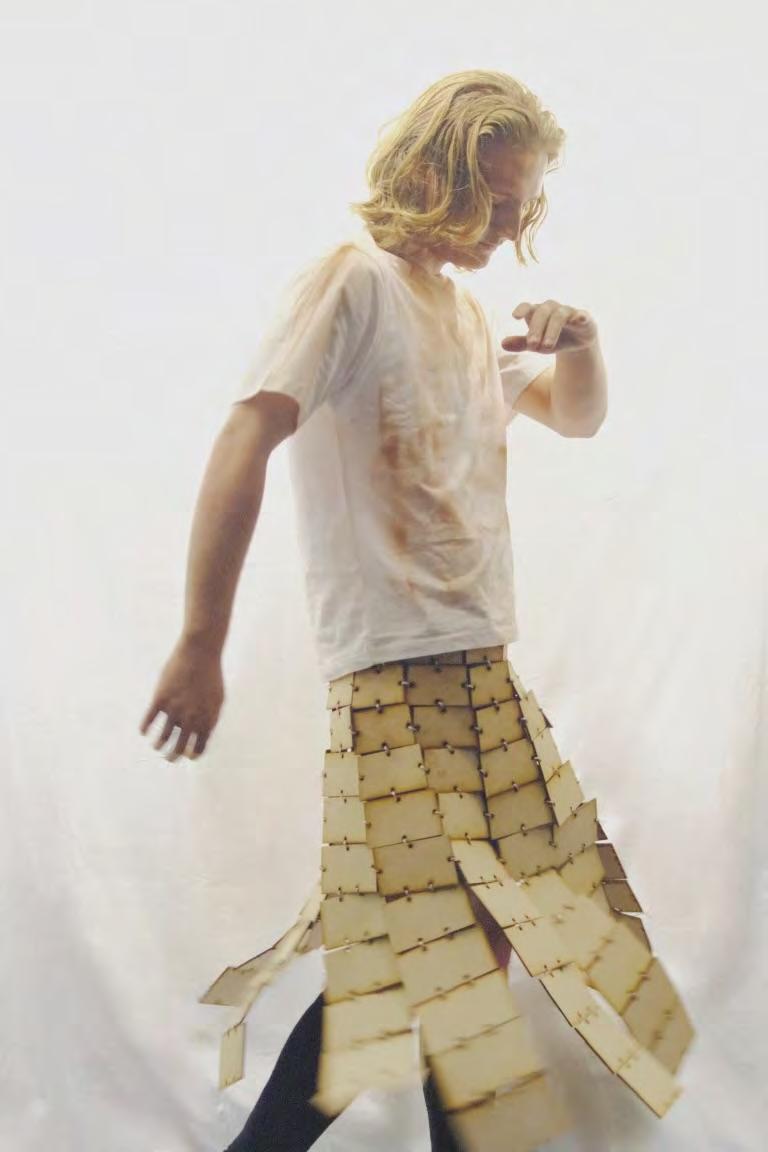

This project is a combination of a kinetic sculpture and wearable art.

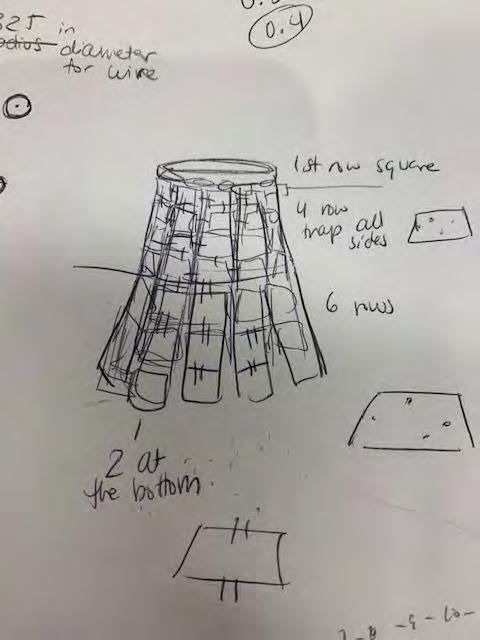

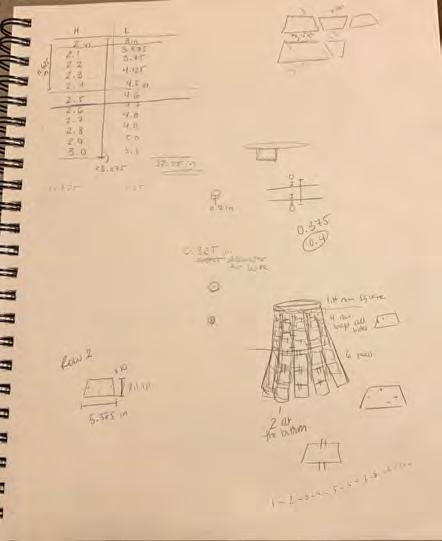

the skirt (fitted to me), how big we wanted each of each row. We decided to connect the first 5 rows the sides, and then let the remaining pieces flow freely fabric.

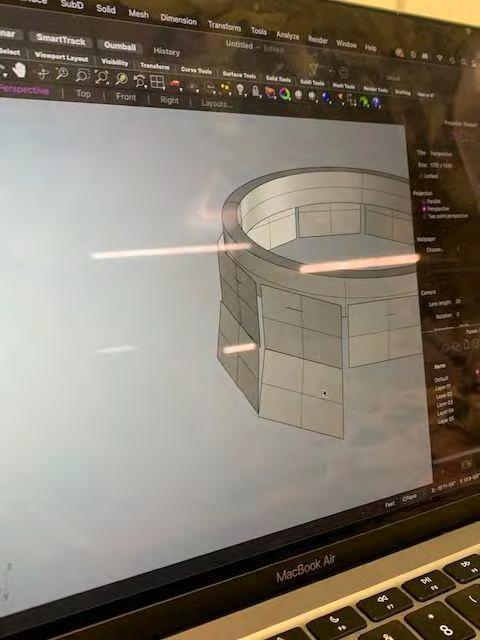

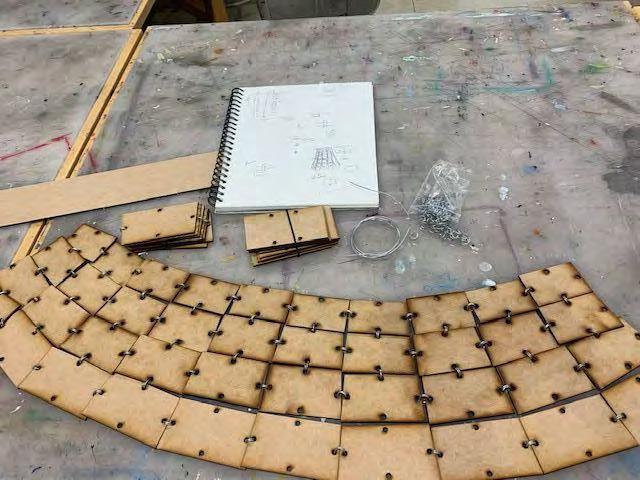

The wooden skirt results from every step of the design process: From brainstorming, to sketches, physical and computer models, and working through the construction process. The various obstacles and failures within this project led to a more complete outcome.

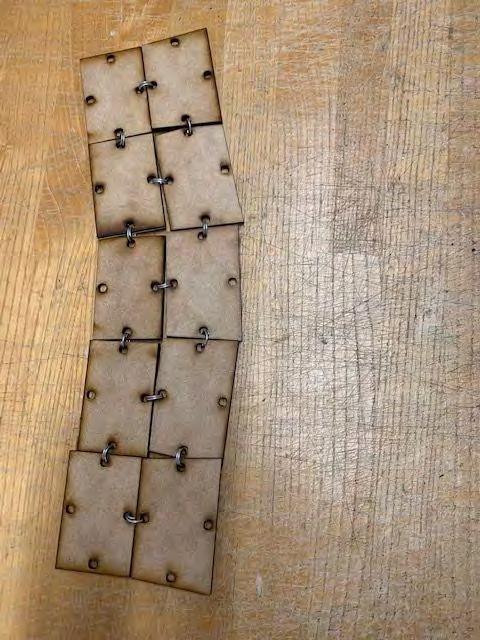

Once we had all the measurements and the correct wire rings, it was just a matter of putting it all together. However, we ran into issues with the amount of holes we had to cut and had to redo multiple rows. We have an additional row that is connected at the sides than we had originally planned, however, it works better that way and flows much more like a cloth skirt. We left a gap in the first three rows so I can get it on and off, but other than that, it’s all filled in.

My partner and I decided to expand this project. We created a bigger team of peers, including a photographer, model, and creative director, to create a photo shoot highlighting the wooden skirt.

We started by measuring piece to be, and the increasing (changed to 6 rows later in columns in order to

by measuring the proportions of the skirt (fitted to me), how big we wanted each and the increasing increments of each row. We decided to connect the first 5 rows 6 rows later in the project) at the sides, and then order to make it move like a fabric.

and the correct wire rings, it was just a matter of putting it all with the amount of holes we had to cut and had to redo row that is connected at the sides than we had originally way and flows much more like a cloth skirt. We left a gap and off

The issue with our first test strip was that the holes in the woo ere both too small. We had to connect two wire circles to attach two wood pieces that caused them to flip around. So we laser cut new wood with larger holes, and made circles with the wire, overlapping like a keychain ring for eas

The issue with our first test strip was that the holes in the wood pieces and the wire connections were both too small. We had to connect two wire circles to attach two wood pieces together, but that caused them to flip around. So we laser cut new wood with larger holes, and made bigger circles with the wire, overlapping like a keychain ring for ease of assembly.

holes in the wood pieces and the wire connections

Once we had all the measurements and the correct wire rings, it was just a matter of putting it

The finished product!! I’m really happy with how it turned out; it has the motion we wanted and makes a great sound. Below are some behind the scenes photos of a collaborative photoshoot we did to add to our portfolios, which we should have the results of on Friday for our presentation. I’ve been having a lot of fun, and it was so exciting to work with such creative eople outside of class.

We started by measuring the proportions of the skirt (fitted to me), how big we wanted each