Everything You Should Know About Concrete Batching Plants

If you’ve ever wondered how those smooth highways, strong bridges, and solid foundations are made to last for years, well, it all starts with concrete And behind every successful concrete mix is a reliable concrete batching plant. Let me take you through the basics, benefits, types, process, and what really makes a great batching plant worth the investment

So, What Is a Concrete Batching Plant?

In simple words, a concrete batching plant is where all the magic happens before concrete reaches a construction site. It’s a setup where ingredients like cement, sand, aggregates, water, and additives are carefully measured and mixed together to form concrete

Think of it like baking a cake You need the right ingredients in the right amounts You can’t just throw everything in and hope it turns out fine. That’s exactly why batching plants are essential they ensure consistency, quality, and accuracy in every batch

Why Is It So Important in Road Construction?

Now, imagine constructing a long highway under the blazing sun If the concrete mix isn’t just right, you’re looking at cracks, potholes, and a lot of maintenance headaches. A well-designed batching plant ensures uniformity and strength in the concrete, making it perfect for road construction and other infrastructure projects. Most road construction equipment manufacturers in India understand how vital this step is. After all, roads are the backbone of connectivity, and you don’t want weak links in that system

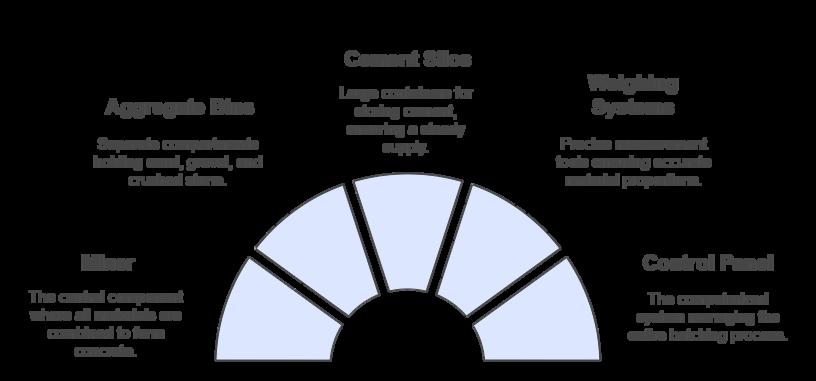

Key Components of a Batching Plant

If you’ve never seen one up close, you might be surprised at how technical and structured the whole setup is. Here are the essential parts:

Every component works in sync to produce a concrete mix that’s strong, reliable, and perfectly blended

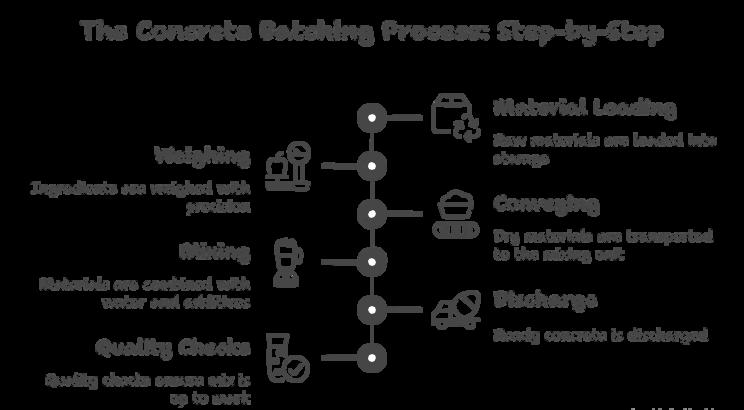

The Concrete Batching Process (Step-by-Step)

Let’s walk through what actually happens in a batching plant step by step:

1 Material Loading

The first step involves loading raw materials into storage compartments Aggregates (sand and gravel) are placed in bins, while cement is stored in a silo. Water and additives are kept in separate tanks.

2. Weighing

Precision is everything Each ingredient is weighed according to the required concrete mix design This step ensures that the proportions are accurate because even a small deviation can a�ect the quality

3. Conveying

Once measured, the dry materials are transported usually by conveyor belts or skip hoists into the mixing unit Cement flows through a screw conveyor, while aggregates and sand are lifted together

4 Mixing

Now comes the core part The materials enter the mixer, where they are combined with water and additives. Depending on the type of plant, the mixing can be done in a pan mixer, twin-shaft mixer, or drum mixer

The mixing time is typically 30 to 90 seconds It might sound short, but with the right mixer, that’s more than enough to produce a uniform and high-quality batch.

5 Discharge

Once the concrete is ready, it’s discharged into a transit mixer or directly into a concrete pump for immediate use. Some plants even o�er automatic discharge options to speed up the cycle.

6. Quality Checks

Before the concrete leaves the plant, a few quality checks are often done. Slump tests, temperature checks, and strength samples help ensure that the mix is up to the mark

And that’s it the whole process usually takes just a few minutes, but each step plays a critical role in ensuring durability and consistency

Types of Concrete Batching Plants

Not all batching plants are the same Depending on the requirement, scale, and location, di�erent types are used Here are the most common ones:

1. Stationary Batching Plant

These are set up at one location and used for large projects like dams, bridges, or highways. They’re built for high capacity and long-term use

2 Mobile Batching Plant

As the name suggests, these can be easily moved from one site to another. Perfect for temporary projects or when construction is spread over a large area.

3 Compact Batching Plant

Ideal for small sites or urban settings where space is limited Despite the compact size, they o�er good output and quality.

Each type has its own advantages, and the choice really depends on what kind of project you’re taking on

Choosing the Right Concrete Batching Plant Manufacturer

Now here’s the tricky part finding the right manufacturer There are plenty of options out there, but what sets a good one apart is the combination of experience, technology, after-sales support, and the

ability to customize based on your needs.

One name that’s been steadily gaining trust in the industry is Alfa Omega India. Known for manufacturing reliable and high-performance road construction equipment, the company o�ers batching plants that are not only e�cient but also easy to operate and maintain. They’ve been catering to both domestic and international markets with an emphasis on quality and service

What customers really appreciate is their attention to detail Whether it’s customizing the plant layout or o�ering tech support post-installation, they’ve got it covered.

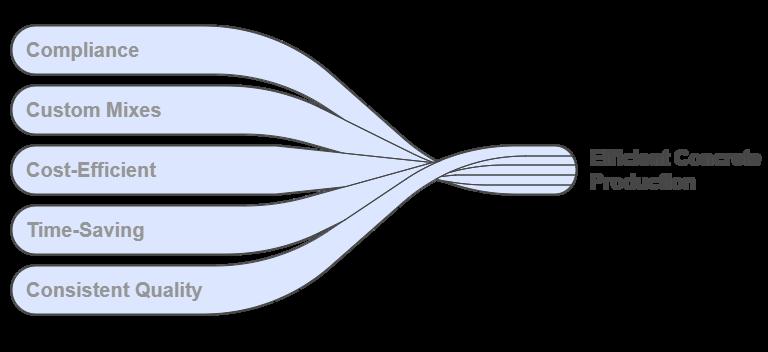

Advantages of Using a Batching Plant

Let’s break down why using a batching plant makes a big di�erence:

In short, it’s a win-win for both the contractor and the client.

Trends in the Industry

The construction world is moving fast, and so is the technology behind batching plants Today, many setups come with advanced automation, IoT integration, and real-time monitoring systems These features help detect issues early, reduce downtime, and improve productivity.

Sustainability is another big focus. New-age batching plants are being designed to minimize dust emissions, recycle water, and optimize power usage all important steps toward greener construction

Final Thoughts

When you look around and see towering buildings, flyovers, and neatly paved roads, just remember that they all began at a humble batching plant. It’s the starting point of quality construction.

If you’re planning a project and want something dependable, choosing the right equipment and the right manufacturer can make all the di�erence. Companies like Alfa Omega India are helping shape the

future of infrastructure with technology-driven solutions and a customer-first approach.

Concrete might set in minutes, but the right foundation lasts a lifetime.