What is a heat exchanger in HVAC?

Surging industrial growth led to a huge demand for industrial equipment like heat exchangers for industrial applications – from power generation to chemical processing. Heat exchanger maker are constructing and developing many different types of heat exchangersovertheyear.Heatexchangersareconstructedwiththermallyconductedtubes orplates,usedtotransferheatfromonemediumtoanother.

Put simply, heat exchangers are corrosion-resistant equipment that is employed in industriestotransferheatfromonemediumtoanother.

Heatistransferredandexchangedbetweentwoseparatemediumsthrough

conduction

What are Heat exchangers?

Asthenameimplies,heatexchangerdevicesruntwodifferentfluidsatdifferenttemperaturesand exchangeenergyintheform of heat.It doesn’tneed anysourceofmechanical orelectricalenergy fromtheoutside.

Heat exchangers are usually dependent on power, recycle heat, and prevent processes from overheatingthroughtheenergytransferprocess.Industriesthatuseheatexchangersarebasedon the thermodynamics principle, inwhich heat transfer is managed through heat exchangers during the processes and equipment including automotive, electronic, chemical, petrochemical, semiconductor,marine,andaerospace.

For waste heat recovery, heat exchangers are majorly used. In this process, excess heat is transferredfromoneparttotheotherprocessthatrequiresheat.Thisprocesshasbeenadaptedso farforairconditionersandrefrigeration.

How is heat exchanged?

Thermal energy is transferred via three methods.

For HVAC purposes, heat exchangers mostly used the process of convection and conduction both. Radiationheattransfercontributesonlyasmallpercentage.

Let’s take a look that what types of heat exchangers are available in the market, according to their applications:

Types of heat exchangers in HVAC

A heat exchanger allows the heat to pass from one state to the other state (liquid or gas) without coming in direct contact with each other. Different kind of heat exchangers has different applications,dependingontherequirementofyourbusiness.

1. Double Tube Heat Exchangers:

Doubletubeheatexchangersasthenamesuggestsarestructuresinwhichoneisbuiltoutsidethe othertubetofacilitatefluidflowsthroughtheinnerpipetotheouterpipe.

Basicandaffordable

Suitablefortightplaces allowingforsomeextraflexibility

2. Shell and Tube Heat Exchangers:

Out of all the types of heat exchangers, shell and tube heat exchangers are the most versatile, as there are few tubs placed inside a cylindrical shell allowing for a wide range of pressures and temperatures.Alsocanbeeasilybrokendownforcleaningandmakerepairseasy.

3. Tube Bundles Heat Exchangers:

Similar to the other heat exchangers, there are two tubes placed inside one tube, for each fluid. However,thetubesarecoiledtogether,somakingitacompactkindofdesign.

Canwithstandhightemperatureandhighpressure

Greaterefficiency.

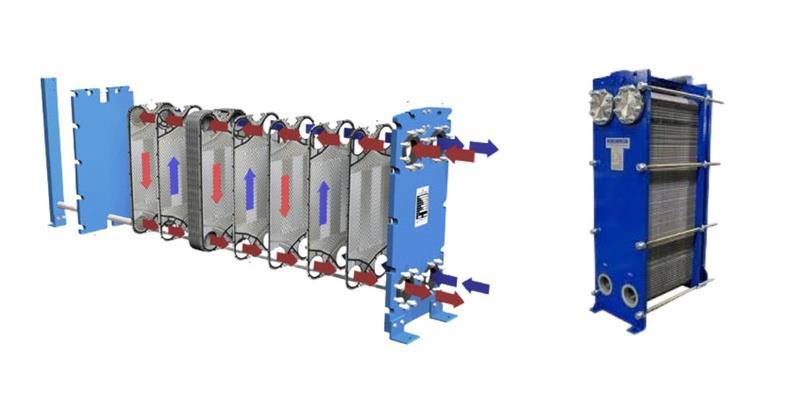

4. Plate Heat Exchangers:

Plateheatexchangerdesignisanexceptionasmetalplatesareusedtotransferheatbetweentwo fluids instead of coils. These plate heat exchanger offers a greater surface area to come in contact withthefluids,soitexhibitsbetterheattransferascomparedtoallothertypes.

Moreexpensive

Designisaplus

Moredurabilityandlowrepairrates.

Read More:- What is a heat exchanger in HVAC?