captivate

Turning prospects into long-term clients.

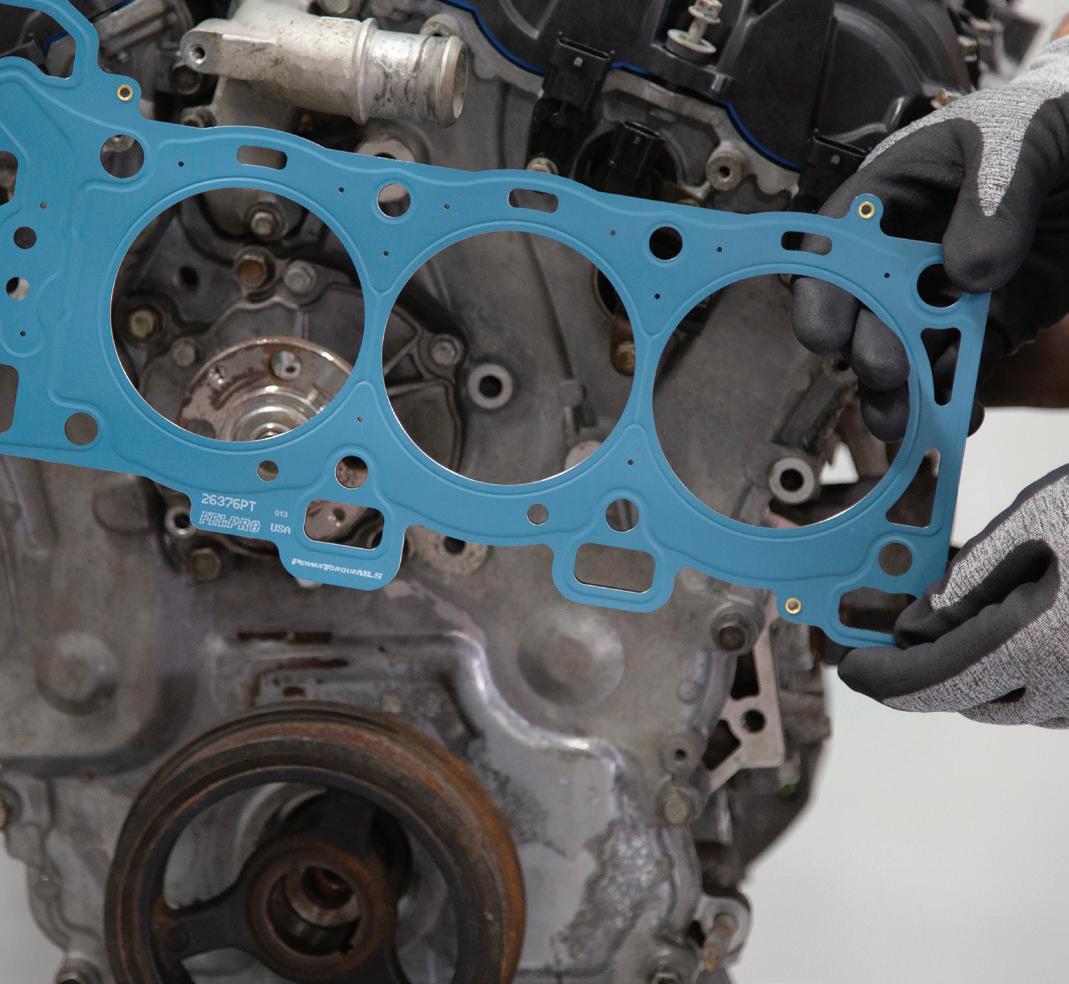

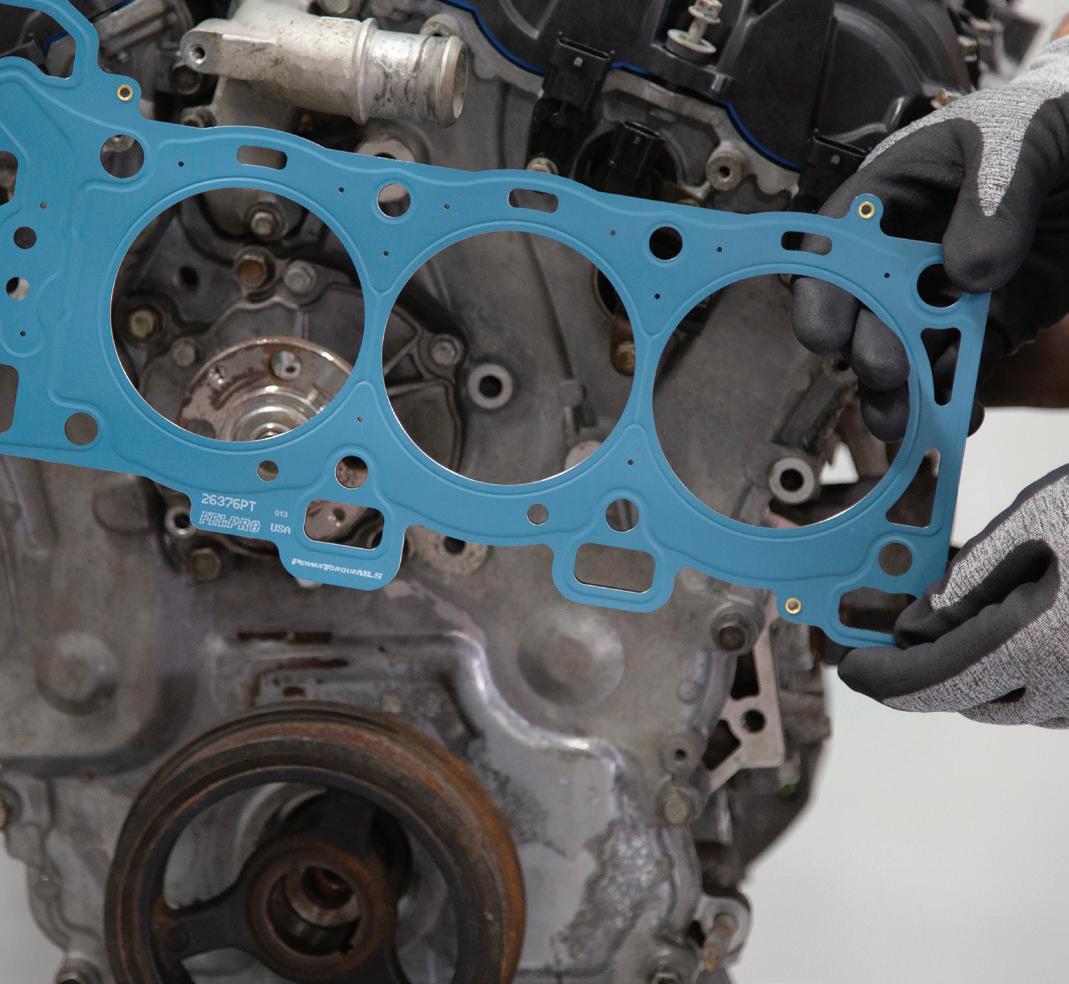

DESIGNED FOR THE REAL WORLD. Fel-Pro sets the standard for sealing solutions with gaskets designed specifically for the repair environment to help seal imperfect surfaces. Whether you need a sealing solution for your everyday vehicle, performance or classic vehicle, you can install Fel-Pro with confidence. Visit FelPro.com 2023 DRiV Automotive Inc. one its affiliates in one or more countries repairForover100years,Fel-Prohasbeenengineeringandmanufacturingsealingsolutionsdesignedforthe environment.Weknowavehiclewillneverbeasperfectasitiswhenitrollsoutofthefactory. Withtherightmaterialsandtechnologies,Fel-Procanhelpyouseallessthanperfectsurfaces. VisitInstallFel-Pro—TheGasketsProfessionalsTrust™ FelPro.com THECHANGE,THINGSTHEMORE NEEDMOREYOU FEL-PRO. 2022DRiVAutomotiveInc.orone affiliatesinone morecountries.Printed U.S.A.FP181418 FM-18287Fel-ProBrochure_102522.indd 12 10/25/22 4:12PM NOT ALL GASKETS ARE CREATED EQUAL. For more than 100 years, we’ve been doing things differently because we design and manufacture Fel-Pro gaskets specifically for the repair environment. Professional technicians know worn and imperfect sealing surfaces call for different materials and technologies, that are application-specific, to create reliable seal. So, rest assured, even though things change, Fel-Pro can help you seal less than perfect surfaces. Put simply: we design for the repair environment. Whether you need a sealing solution for Engine Repair, Leak Repair, or System-Specific Repair, we have you covered. PROPRIETARY TECHNOLOGIES REAL-WORLD TESTING DESIGNED FOR THE REPAIR ENVIRONMENT In the real-world nothing is perfect—including gasket sealing surfaces. Heat, torque and the stress of internal combustion make perfect sealing surfaces not so perfect. That’s why you should install Fel-Pro, the gaskets designed specifically for the repair environment. vehicle will never be the same once it rolls out of the factory. That’s why we test and validate our products under real-world conditions, collect the data and evaluate the results to ensure they’ll perform on the road. New sealing technologies require new approaches. Our engineering and product development teams have created portfolio of exclusive sealing innovations—including proprietary materials and unique design features—which set the standard for sealing technology that you can count on. Since 1918, our goal has been the same—manufacturing high-quality gaskets that install easily and provide lasting leak-free seal. As the industry leader, we respond to each new challenge with innovative materials, new technologies and a relentless focus on designing sealing solutions for the real-world conditions technicians face in the repair environment. With more than 100 years of expertise, we’ve earned our reputation as The Gaskets Professionals Trust™. MORE THAN JUST A GASKET FOR OVER 100 YEARS. FM-18287 Fel-Pro Brochure_102522.indd 2-3 10/25/22 4:12 PM DESIGNED FOR THE REPAIR ENVIRONMENT A SEAL FOR AN IMPERFECT WORLD. FM-18287 Fel-Pro Brochure_102522.indd 10/25/22 4:12 PM

QUALITY COMPONENTS Strut rods engineered to bend up to 15mm with no fractures or cracking helping to vehiclemaintain control. BUILT TO LAST bearingPTFE-coated protects the rod by reducing damage to the seal, while the chrome piston rod durabilityprovides and long service life. MADE TO LAST Meets or exceeds OE structural quality standards & durability requirements. CONTROL AND DURABILITY PTFE-banded piston consistentprovides betweensealing piston and pressure tube for better control and durability. REDUCED VIBRATIONNOISE, AND HARSHNESS Vehicle-speci c technology delivers improved control and isolates impact-related noise, vibration and harshness under most driving conditions. PRECISELY APPLICATION-SPECIFICCALIBRATED, COIL SPRINGS Meets or exceeds original equipment standards for spring performance. Made from high-quality SAE, US-grade steel. Up to 2x stronger than some competitors. HELPS CARRY THE LOAD Variable rate coil spring maintains ride height for hard-working vehicles operating under various load conditions. CONSISTENT PERFORMANCE Full displaced valving, tuned specifically to each vehicle, adjusts to road extremes while the larger bore provides more ef cient damping control for a consistent ride. MAINTAINS VEHICLE CONTROL Premium, vehicle specific technology automatically adjusts to absorb road impacts, helping to reduce vehicle roll and dive during weight transfer for improved stability. RESTORES OE Ride Height 100% FIT-CHECKED and Ride Tested LIKE-NEW Control & Handling HAULING Half-Ton Trucks PLOWING Half-Ton Trucks DELIVERYon Fleet Vehicles Monroe® Quick-Strut assemblies are fit-checked, ride-tested, and engineered to strict performance and durability standards. Monroe Quick-Strut® assemblies are proudly assembled in Paragould, AR in U.S.A. of U.S. and imported components. NOW WITH EXCLUSIVE GTL OIL BLEND Delivers performance improving benefits already experienced by technicians using engine oil formulations with similar gas-to-liquid technology. Features innovative GTL oil blend, validated to OE requirements and protects internal components against wear. Available in Monroe shocks, struts and assemblies sourced from Paragould, AR, manufacturing facility. Designed with the right technology for each application, OESpectrum shocks restore a vehicle’s factory drivability and performance, with an enhanced level of handling precision and control. Designed to help get the job done, Magnum strut assemblies meet the performance and durability demands of high-mileage, heavy load and frequent stop start, hard-working vehicles. QUICK-STRUT® ASSEMBLIES OESPECTRUM® SHOCKS MAGNUM® STRUT ASSEMBLIES FOR ADDITIONAL SUPPORT Contact the Gurus On Call staffed by ASE-Certified Master Technicians 800-325-8886 M-F, 8:30 a.m. - 5:30 p.m. Eastern Access invaluable warranty, cataloging and diagnostic information at our website: MONROE.COM FOLLOW US © 2023 DRiV Automotive Inc. or one of its affiliates in one or more countries. Printed in U.S.A. MON231107 WHEN IT COMES TO PERFORMANCE OF SHOCKS & STRUTS, IT’S NOT JUST ABOUT COMFORT, IT’S ABOUT SAFETY. Choose Monroe® products built for strength and durability and designed to simplify the installation process to help reduce comebacks. BUILT FOR EASY INSTALLATION, THE FIRST TIME BUILT FOR DURABILITY TO REDUCE COMEBACKS BUILT TO SUPPORT YOUR BUSINESS • Vehicle fit-checked to ensure OE-style fit and mounting locations for bolt-on installation • Easily accessible step-by-step instruction guides, how-to videos and installation tips to complete installation right, the first time Inspection guides, business support tools and exclusive access to Garage Gurus® training program • Coverage for over 148+ million domestic and 120+ million import vehicles in the U.S. and Canada • Products backed by Limited Lifetime Warranty and Feel the Difference™ Guarantee • Visit Monroe.com for details • Engineered in Monroe, MI and manufactured at Monroe’s Paragould, AR facility* 67,000+ hours invested annually into research and development • Bi-frequency and fatigue tested for durability Environmental chamber climate-tested ensuring consistent performance in wide range of temperatures Tested in anechoic chamber to meet OE noise standards Exclusive cyclical salt spray corrosion tested • Built with 600 quality checks and inspection points (for a standard shock at Monroe’s Paragould, AR manufacturing facility) *Monroe operates manufacturing facilities in the U.S. and around the world. See product packaging for the country of origin. At our primary North American aftermarket plant in Paragould, AR we manufacture and assemble Monroe products from U.S. and imported components. FULL APPLICATION-ENGINEERED PRODUCT PORTFOLIO BACKED BY OE EXPERTISE AND INNOVATIVE TECHNOLOGIES TRUSTED BY OE MANUFACTURERS TO MAXIMIZE VEHICLE PERFORMANCE HIGH UTILIZATION FLEET RESTORING YOUR RIDE EXTENDING THE RIDE CARRYING THE LOAD THE LONG HAUL

DESIGNED WITH THE RIGHT TECHNOLOGY

CONTROL AND DURABILITY

PTFE-banded piston provides consistent sealing between piston and pressure tube for better control and durability

REDUCED NOISE VIBRATION AND HARSHNESS

Vehicle-specific technology delivers improved control and isolates impact-related noise, vibration and harshness under most driving conditions

NEW!

PROPRIETARY GTL OIL BLEND

Reduces friction against internal components helping to protect against wear

FOR ADDITIONAL SUPPORT Contact the Gurus On Call staffed by ASE-Certified Master Technicians 800-325-8886 M-F, 8:30 a.m. 5:30 p.m. Eastern Access invaluable warranty, cataloging and diagnostic information at our website: MONROE.COM FOLLOW US © 2022 DRiV Automotive Inc. or one of its affiliates in one or more countries. Printed in U.S.A. MON221141 SELF-LUBRICATING SEAL Retains gas and reduces excessive friction against the piston, helping reduce premature wear NEW! PROPRIETARY GTL OIL BLEND Reduces friction against internal components helping to protect against wear PTFE-BANDED PISTON Provides consistent sealing between piston and pressure tube for better control and increased durability FULL DISPLACED VALVING Specifically tuned to each vehicle and adjusts to road extremes for improved handling NITROGEN GAS CHARGE Maintains tire-to-road contact for improved ride performance and handling by reducing aeration and shock fade LARGER BORE Provide more efficient damping control for consistently smooth ride ASD Technology delivers greater control and handling while improving ride comfort. Twin Technology Active Control System delivers exceptional control under most driving conditions while isolating noise, vibration, and harshness. Monotube Technology maintains vehicle control over bumps, dips and potholes for vehicles originally equipped with monotube shocks. PREMIUM TECHNOLOGY Based on application for improved vehicle handling and control while reducing noise, vibration and harshness 22-FMM-178 OESpectrum Sell Sheet_102622B.indd 2 2/22/23 9:00 AM

each application, OESpectrum® shocks restore a vehicle’s factory drivability and performance, with an enhanced level of handling precision and control. Available for over 212 million import and domestic vehicles in North America.

for

22-FMM-178 OESpectrum Sell Sheet_102622B.indd 2/22/23 9:00 AM

LEADER IN PREMIUMINNOVATIVE, PROVEN FULL LINE AFTERMARKET BRAKING

PREFERRED AND TRUSTED BRAND

AMONG N.A. TECHS

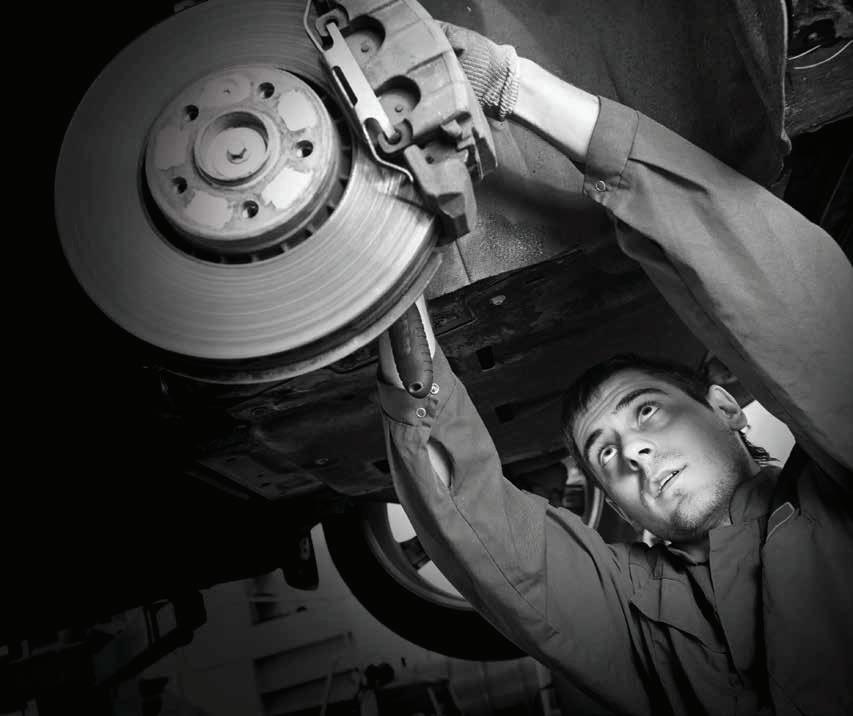

Founded in 1891, Wagner® has been an innovator in braking technologies for passenger cars, trucks, SUVs,

medium-duty and commercial applications. Wagner sets industry standards with leading engineering expertise

and a commitment to ensuring that our parts deliver superior braking performance. With comprehensive

coverage, Wagner offers the right brake parts for every brake repair.

ROTORS

All Wagner brake pads feature zero-copper friction formulations

PREMIUM BRAKING PERFORMANCE. For Passenger Car, Pickups, SUVs and CUVs IMPROVED STOPPING POWER CREATES TURBULENT AIRFLOW PATENTED, CUSTOMIZED SHAPE AND SLOT DESIGN CREATES TURBULENT AIRFLOW ROTOR WEAR REDUCES DES GN REDUCES DUSTING RESTORING LIKE-NEW BRAKING PERFORMANCE. Hardware included on specific applications. ENGINEERED FOR THE EXTREME AND FLEETS. ENGINEERED TO PERFORM UP TO 1000° Hardware included on specific applications. Carbon-based metallic formulations engineered for extreme brake system temperatures Friction-to-backing plate attachment optimized by application for exceptional strength and long life OE style shims, slots & chamfers. Hardware kits included key applications. Results based on independent and internal testing comparing Wagner OE to competitors’ brake pads and other Wagner offerings ** Patented design based on gross vehicle weight Results based on internal testing comparing Wagner OE to other Wagner offerings. Hardware included. Product configuration varies by application. PREMIUM WAGNER® ROTORS REDUCES NOISE-CAUSING VIBRATION APPLICATION-SPECIFIC CHAMFERS, SHIMS AND SLOTS EVEN FRICTION PERFORMANCE THROUGHOUT THE LIFE OF THE PAD GRADUAL POST-CURED PROCESS PREMIUM STAINLESS STEEL HARDWARE FOR SELECT APPLICATIONS PREMIUM PERFORMANCE PROPER BALANCE precision-cut finish of the outer diameter of the rotor limits vibration for improving stability and control UNIQUE VANE DESIGN (application specific) Provides greater cooling capabilities for more effective stopping power Helps control noise, vibration and harshness (NVH), resulting in smoother braking PREMIUM PROTECTION E-SHIELD® COATING Protective coating applied non-braking surfaces help resist corrosion EASY INSTALLATION TURNED/SMOOTH SURFACE FINISH Requires less pad break-in time and aids in proper bedding VAPOR CORROSION INHIBITOR (VCI) BAG Eliminates the need for an oil coating which reduces prep time Wagner premium brake rotors are engineered with technology focused on providing maximum performance, corrosion resistance and ease of installation. LEARN MORE AT WAGNERBRAKE.COM RESISTS CORROSION Exclusive combination of superior galvanized steel plates with mechanical retention for corrosion resistance and longer service life ENGINEERING FOR EXTREME HEAT Our high-strength friction materials are optimized for extreme heat and are designed to perform at temperatures up to 1000°F QUIET OPERATION Multi-layer shim and advanced formulation combine to reduce vibration and ensure consistently quiet braking HARDWARE INCLUDED Premium stainless-steel hardware included for all applications LASER ETCHING FOR EASY PART NUMBER REFERENCE WAGNER SD®

most advanced, reliable brake pads possible. 218

IN-HOUSE ENGINEERING EXPERTISE

END-TO-END INNOVATION

36

Our technical development centers are home to our best-in-class, in-house engineering team that designs, validates and supports Wagner brake products. From experimenting with new friction formulations to developing new designs, we’re constantly tweaking and testing toward the industry’s next break- through in performance.

At Wagner, we develop proprietary friction formulations and patented design technology and we never stop looking for ways to improve the performance of our products. That focus has led to a stream of brake innovations such as the first integrally- molded insulator (IMI) design and now, our patented, customized shape and slot designs on Wagner OEX

TESTED AT EVERY TURN Wagner engineers perform 1000s of hours of testing each year both on- and off-vehicle to optimize each design, eliminate noise, extend pad life, simulate conditions and validate real-world performance. Additionally, we perform a rigorous engineering process to ensure form, fit and function.

100+ YEAR OLD BRAND *According to 2020 IMR Survey Results. © 2023 DRiV Automotive Inc. or one of its affiliates in one or more countries. WB231067

PATENTS S UED PE DNG

From design and development to extensive testing and validation, we go further to ensure we deliver the PATENTS

WE PUT EVERYTHING INTO THEM SO YOU CAN GET THE MOST OUT OF THEM

Wagner brake pads are specifically designed for different vehicle types, ages, driving habits and conditions.

Designed for high-strength durability and extreme heat management, these rotors provide ideal braking power for municipal vehicles driven in demanding conditions. PROPER BALANCE Precision-machined rotor braking surfaces limits vibration for improving stability and control and less pad PREMIUM PERFORMANCE Unique vane design dissipates heat and provides effective braking power, while controlling noise, vibration and harshness for smoother braking EXTREME DURABILITY Superior high-carbon, lightly alloyed metallurgy ensures high strength, excellent durability and effective heat management high temperatures CORROSION RESISTANCE Protective E-Shield coating applied non-braking surfaces to inhibit corrosion EASY INSTALLATION Packaged Vapor Corrosion Inhibitor bag, eliminating the need for an oil coating, which reduces prep time LONGER CAN LAST

DESIGNED FOR EVERY BRAKING NEED

Foreign Nameplate Specialists

nameplate OE specifications for form, fit and function. How do we know? Because our product specialists work with a network of global sourcing partners so you can install the If it has to be an OE match for your foreign nameplate vehicle, Check with Beck. BeckArnley.com Braking | Engine: Electrical Engine: Mechanical | Fluids | Steering/Suspension/Driveline Fo eign Nameplate Specialists CHECK WITH Need Premium Foreign Nameplate Braking Parts? BeckArnley.com Braking Engine: Electrical Engine: Mechanical | Fluids Steering/Suspension/Driveline Need Premium Foreign Nameplate Parts? CHECK WITH BECK Anyone can sell you replacement parts. But Beck/Arnley parts meet foreign nameplate OE specifications for form, fit and function. Our product specialists work with network of global sourcing partners so you can install the right part with confidence. With 24,000 parts that cover 80 makes and nearly 1,800 models — if it has to be a match for your foreign nameplate vehicle, Check with Beck.

AsianandEuropeanNameplates BeckArnley.com Braking | Engine:Electrical | Engine:Mechanical | Fluids | Steering/Suspension/Driveline ProductPrefix 085/089 083 072/073 084 081 ProductPrefix 252 AutoTransmissionFluid&DualClutchFluid 252 252 252 ProductPrefix 201 204 203 FuelDelivery ElectricalFuelPumps 152 ElectronicThrottleBodies 154 FuelInjectionProducts 158/159 Ignition IgnitionCoils 178 IgnitionWireSets 175 GlowPlugs 176 Sensors Cam/CrankSensors 180 Sensors(TPS,MAP,MAF,Knock&Temp.Sensors) 158 VehicleSpeedSensors 090 Engine:Mechanical ProductPrefix 131 143 147 130 EngineComponents EngineMounts 104 ValveCoverAssemblies 036 VariableValveTimingSolenoids 024 AncillaryEngineParts 016 CrankcaseVentValves&PCVValves 045 CanisterPurgeControls 046 Filtration AirandCabinFilters 042 FuelFilters 043 OilFilters/OilFilterHousingCaps 041 TransmissionFilterKits 044 Gaskets ValveCoverGaskets 036 ManifoldGaskets 037 AncillaryGaskets 039 HeadGasketSets 032 Steering,Suspension&Driveline ProductPrefix Steering InnerTieRod/InnerTieRodBootKits 101 OuterTieRods 101 SteeringRackBootKits 103 IdlerArms 101 Suspension ControlArms 102 StabilizerLinks 101 BallJoints 101 Bushings 101 Driveline Hub&RollerBearings&WheelSeals 051/052/053 ClutchHydraulics 072/073 TransmissionMounts 104 CVBootKits 103 DriveshaftCenterSupportAssemblies 101 Fo eignNameplateSpecialist NeedPremiumForeignNameplateParts? BeckArnley.com ©2021DRiVAutomotiveInc.oroneofitsaffiliatesinoneormorecountries.Allothertrademarksshownaretheproperty heirrespectiveowners. BA211119 STEERING & SUSPENSION Beck/Arnley offers a full-line of quality Steering & Suspension parts for foreign nameplate vehicles. TIE RODS AND TIE ROD ASSEMBLIES OE form, fit and function Ball studs are pre-greased and sealed units • Coated or plated for corrosion protection • Quality materials and processes ensure a durable product • Hardware included where applicable • Wrench flats added for easy installation Assemblies include inner and outer tie rod and sleeve for complete repair Tie rod housing materials are heat treated for optimum strength STABILIZER LINKS OE form, fit and function Manufactured from quality materials for durability Hardware included where applicable CONTROL ARMS The control arm is a critical component of the vehicle’s suspension system and helps contribute to the overall ride experience. This includes maintaining proper alignment and reducing noise and vibration. • Control arms with and without ball joints • New hardware and bushings included where applicable • Also encompasses trailing arms – application specific • Preinstalled ball joint (dependent on application) • Steel, iron or aluminum construction ensures durability; material is dependent on OE construction Wide variety of bushings including single bushings, Manufactured from a high grade rubber compound Anyone can sell you replacement parts. But Beck/Arnley Steering & Suspension parts meet foreign nameplate OE specifications for form, fit and function. How do we know? Our product specialists work with a network of global sourcing partners so you can install the right part with confidence. If it has to be an OE match for your foreign nameplate vehicle, Check with Beck. BeckArnley.com Braking Engine: Electrical | Engine: Mechanical Fluids | Steering/Suspension/Driveline Fo eign Nameplate Specialist CHECK WITH BECK Need Premium Foreign Nameplate Steering & Suspension Parts?

PRODUCTOFFERING

11653 Gravois Road Suite 100 St. Louis, MO 63126 www.graphxco.com The Graphics Company