20182023

ALSHEHRI

ROBOTIC FABRICATION ARCHITECT

PROFILE

A multidisciplinary designer and architect who integrates advanced technologies such as robotics, automation, and computation within the creative realm. She holds a master’s degree in design in robotics and autonomous systems from the University of Pennsylvania, making her the first Saudi to enroll in this MSD-RAS program and a bachelor’s degree from Effat University’s College of Architecture and Design. Her focus on design and research centers around the celebration of cultural practices with technology and innovation.

WORK EXPERINCE

Art Resident at Misk art Institute, Riyadh, Saudi Arabia

September 2023 - December 2023

-Worked on a research, and experimentation around a theme on the future of traditions.

Robotic Lab Operator at University of Pennsylvania, Philadelphia, United State

October 2022 - September 2023

-Assisted in the development of the laboratory and fabrication process using robotic hot wire cutting, foam graving, and pen drawing.

Teaching Assistant at University of Pennsylvania, Philadelphia, United State

July 2023 - August 2023

-Assisted Professor Alicia Nahmad in teaching master’s students in Advanced Architecture program in the robotic fabrication process and grasshopper script.

Contractor at Beit Alsharbatly Historical Building, Jeddah, Saudi Arabia

Februray 2022 - April 2022

-Led the design and layout of exhibitions and museum space and supervised the maintenance and restoration of the building.

Architect at Elkhereiji Commerce & Contracting Company, Jeddah Saudi Arabia

October 2019 - June 2022

-Coordinated the design team and reviewed drafts and BIM models for governmental projects, and developed architectural plans of highrise buildings.

THE PILLARS

Misk Art Institute

Sculpture Installation 2023

THE ONE PERSON DINNER

Misk Art Institute

Video Installation 2023

University of Pennsylvania

Robotic Clay 3D Printing 2023

HOT WIRE CUTTING ROBOTIC FABRICATION

University of Pennsylvania

Robotic Fabrication 2022

ULTRA HIGH PREFORMANCE CONCRETE PRODUCTION

University of Pennsylvania

Precast Concrete 2022

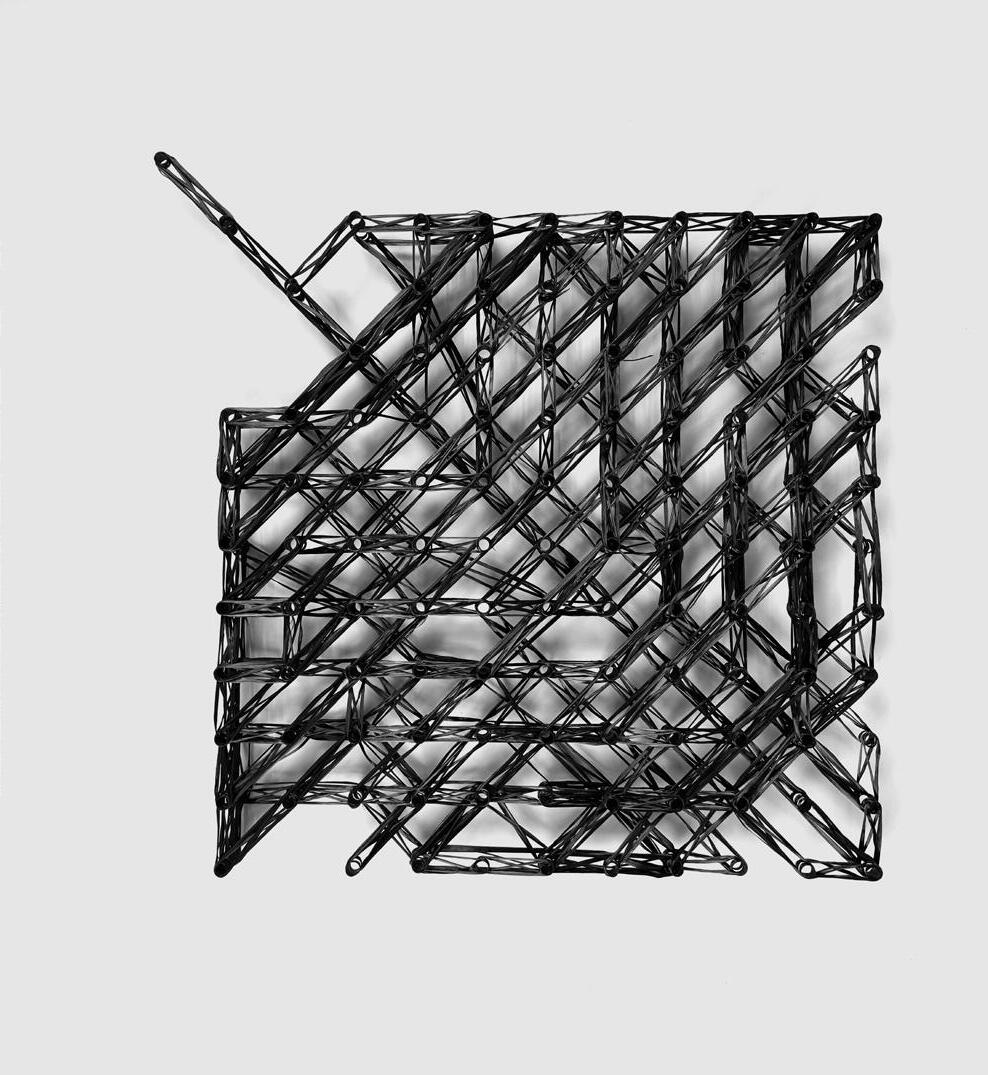

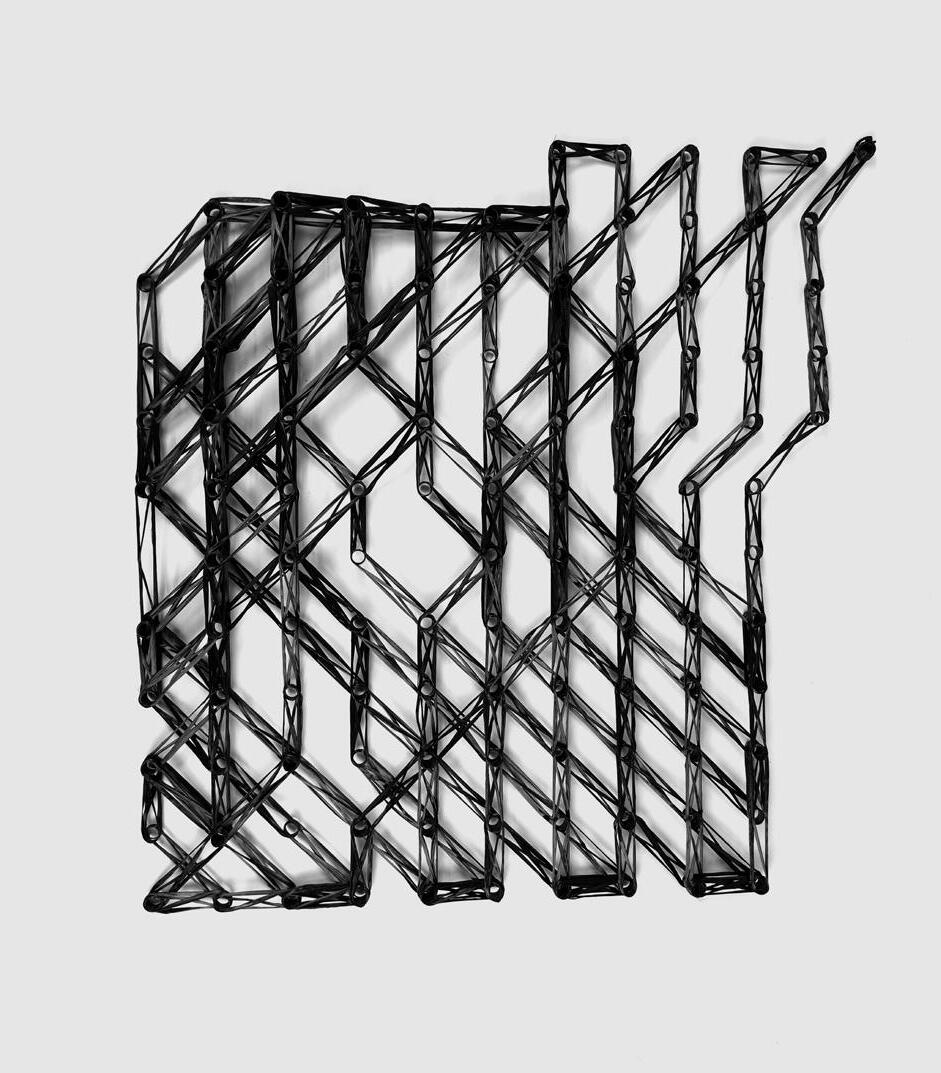

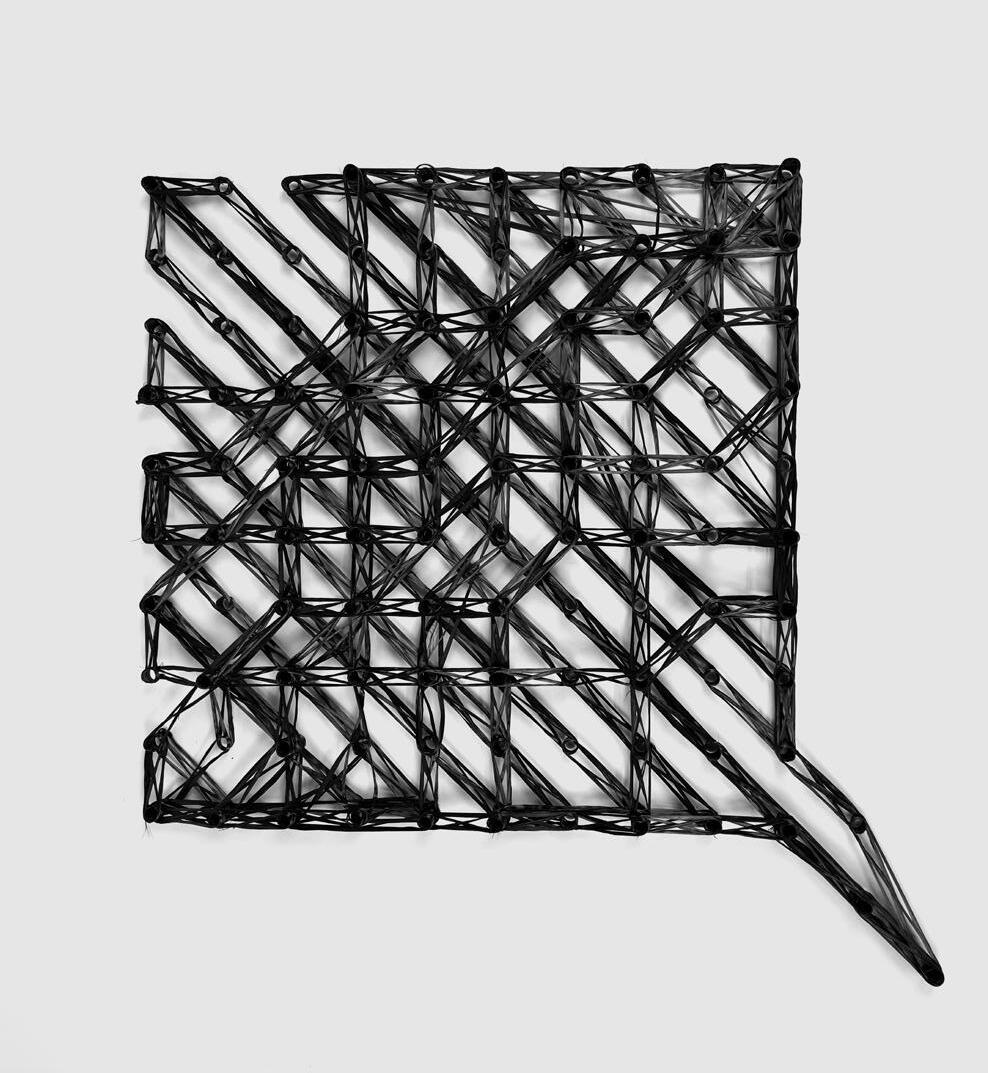

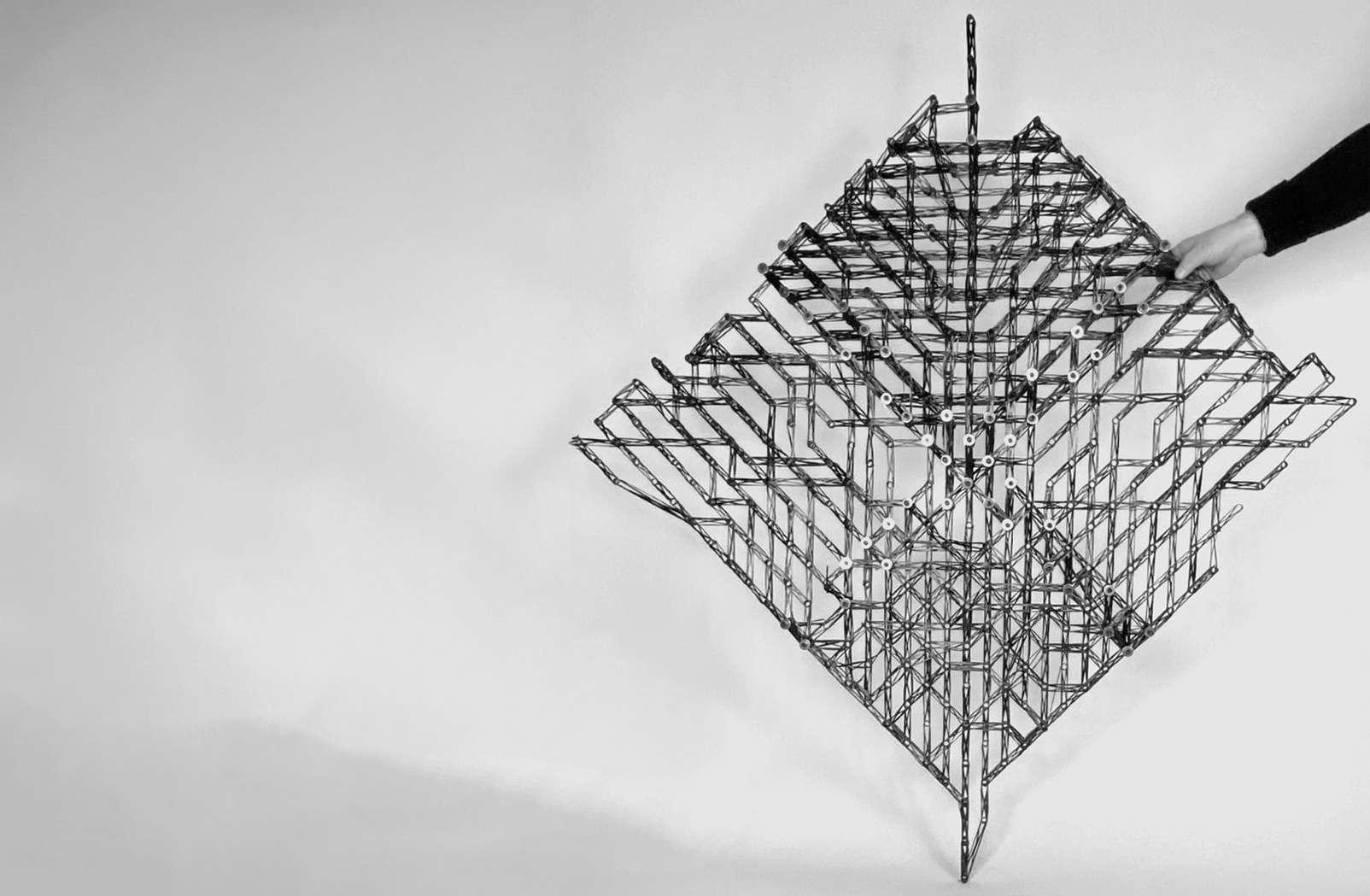

LACHESIS

University of pennsylvania

Robotic Carbon Fiber Filament Fabrication 2022

STEREOTOMIC ÆQUILIBRIUM

DRONE PORTS

AA visiting School Dubai 5.0

Additive Manufacture 2019

AL-ULA INTERACTIVE HOUSE FOR ARTS AND CRAFTS

Effat University

Architecture Design 2018

AL-ULA INTERACTIVE HOUSE

ADAPTIVE MODULAR UNIT

Effat University

Product Design 2018

THE PILLARS

Misk residency project, part one: The research focuses on exploring the relationship between social practices within Saudi houses, taking into account the evolving economic and resource factors. It aims to question the concept of hospitality derived from natural elements and the Saudi way of life, with a specific emphasis on creating a social interaction space known as the “majlis.” Additionally, the research examines the challenges that hospitality may encounter in the future, considering lifestyle changes and available resources. In contemplating the future of rooted cultural traditions like hospitality, we ponder the materials that will shape this surreal space.

The installation represents a timeline that showcases the evolution of building materials in relation to associated Saudi traditional practices. It begins with clay as a representation of the past and culminates with aluminum to symbolize the future of Saudi houses. Along this timeline, various techniques, such as concrete and clay 3D printing, highlight existing building technologies. In addition to capturing futuristic worlds using AI imagery.

THE ONE PERSON DINNER

Misk residency project, part two: The tradition of gathering and sharing a meal holds profound significance in Saudi society, but there are broader aspects to consider beyond simply food and socializing. The noise created by materialism and individualism seems to influence our collective understanding of future behaviors.

This film-making project intends to tell a story that delves into a surreal reality, highlighting the essence of one of Saudi Arabia’s cultural practices centered around dinner: the presence of food and people. It raises questions about whether the food will remain as enjoyable as ever.

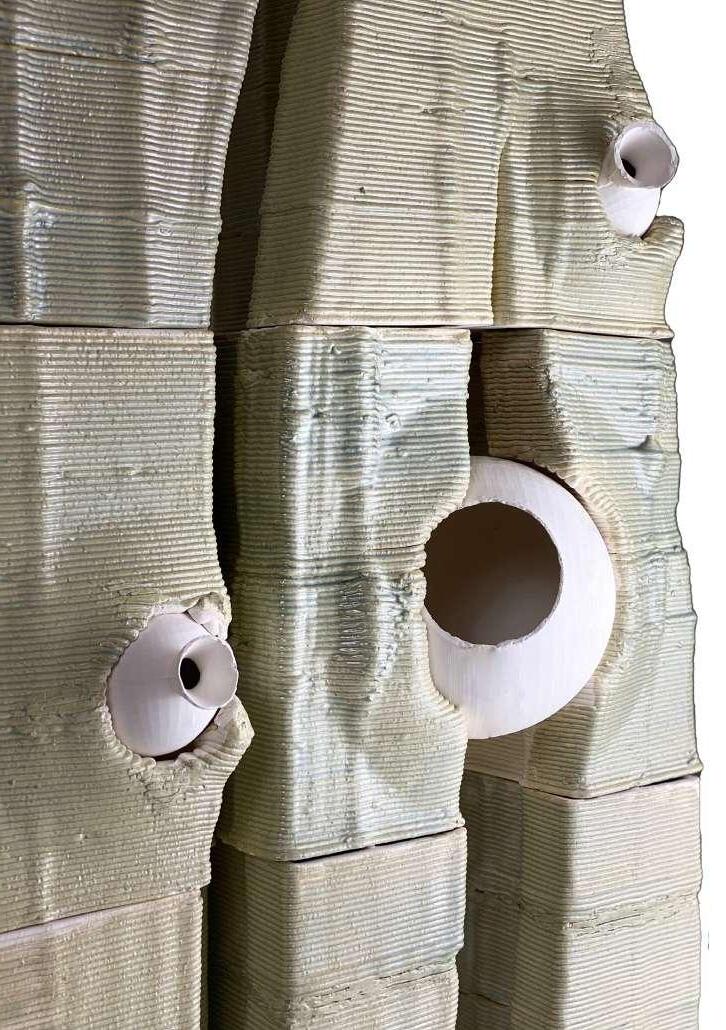

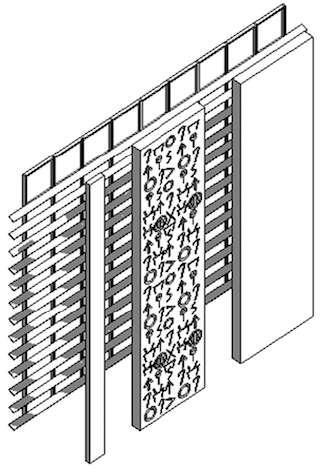

VITA WALL

This project aims to conduct research on mono-material use in architectural ceramics by embedding slip-cast geometries in robotically additively deposited clay to create nesting architectural prototypes. This research draws upon prior studies on porosity, robotic additive manufacturing (RAM), and multi-material embedment.

The value is to increase the configurability of the clay with rotatable geometries. Multiple physical and computational experiments are conducted to explore the combination of two manufacturing processes (slip casting and clay additive manufacturing) and address the complications of ceramic-to-ceramic joints using customized hardware and software tooling.

Professor: Robert Stuart-Smith - rssmith@design.upenn.edu - Group Members: Aisha Alshehri, Adhityan Anbumozhi,Cem Akgun, and mahsa masalegoo

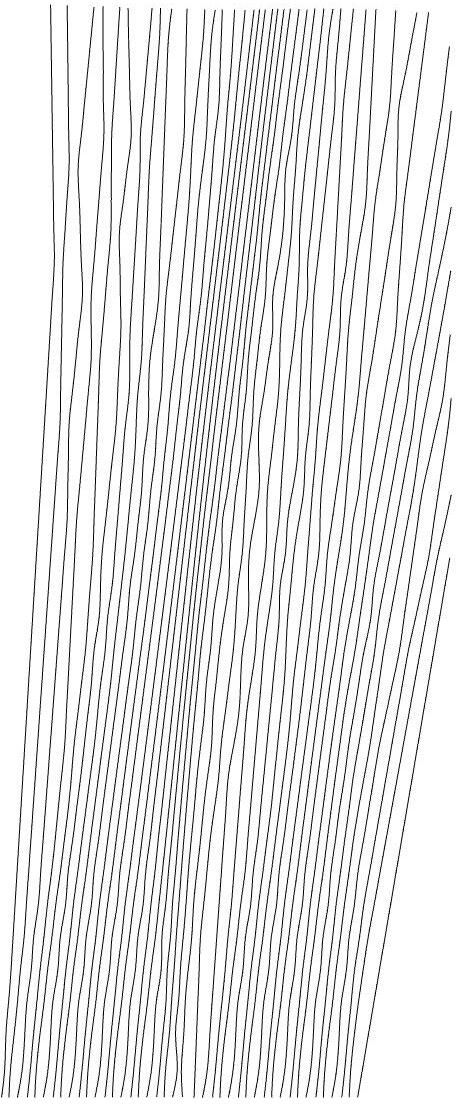

Facade Generation: using the multi-agent design logic

Building Full Facade Proposal

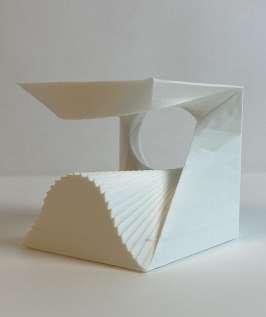

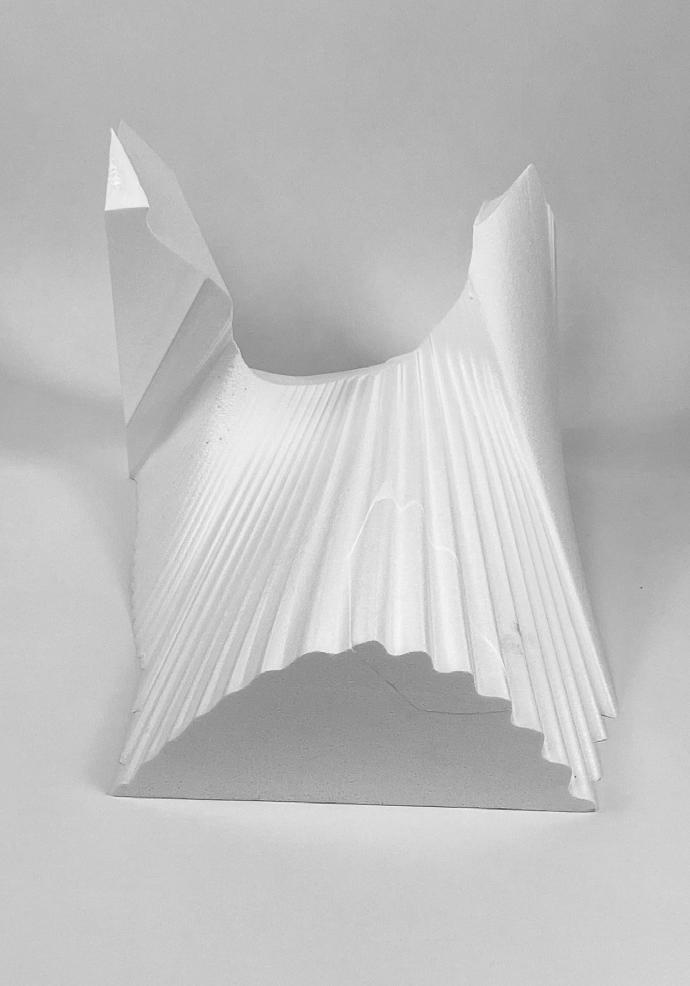

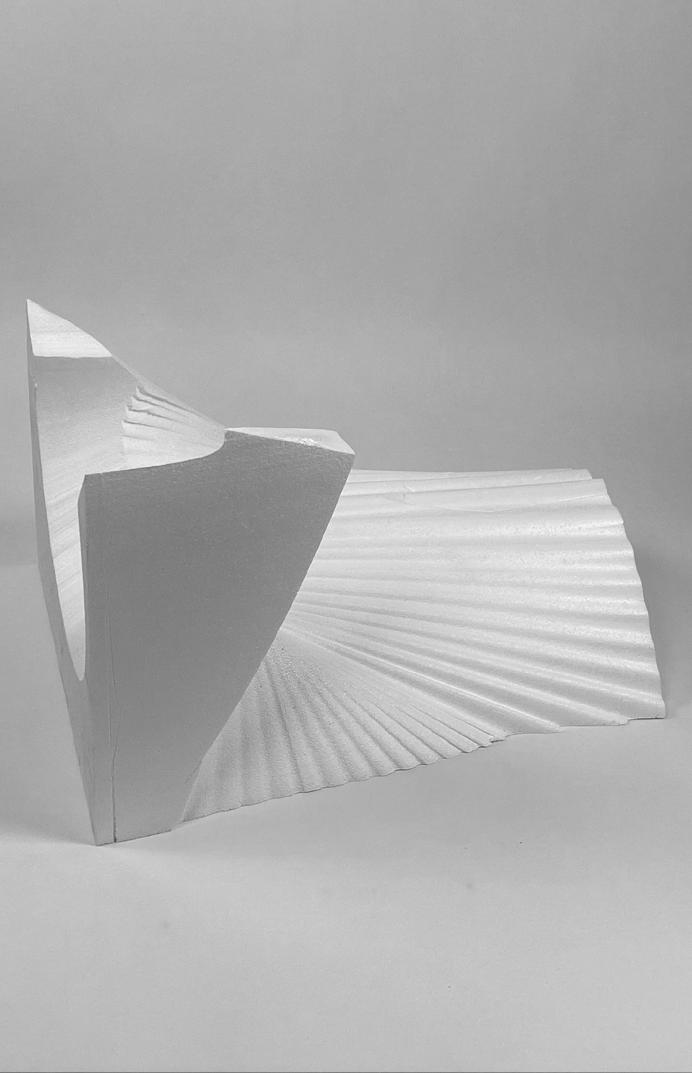

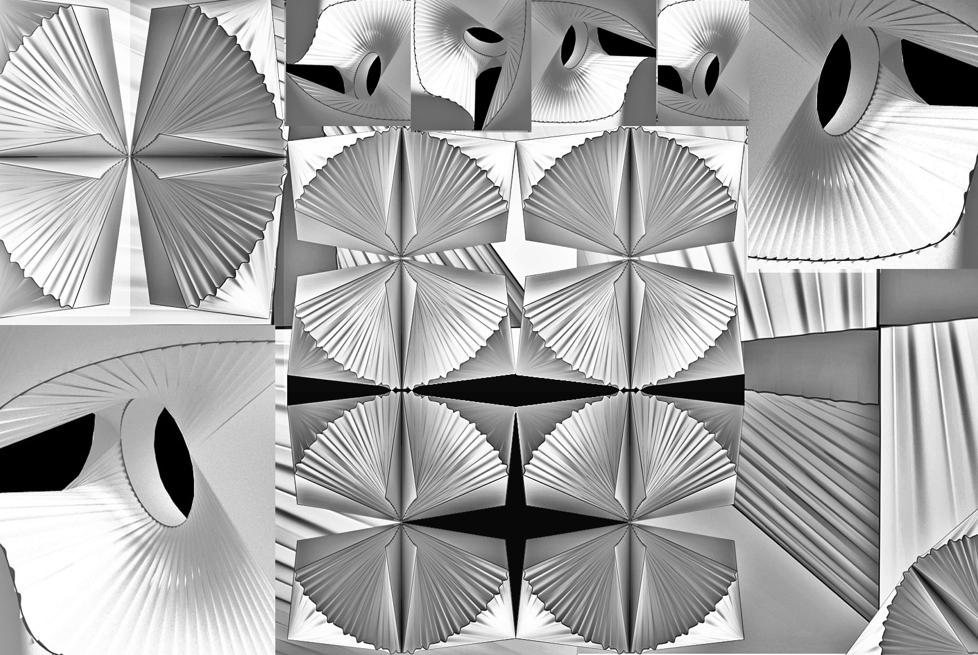

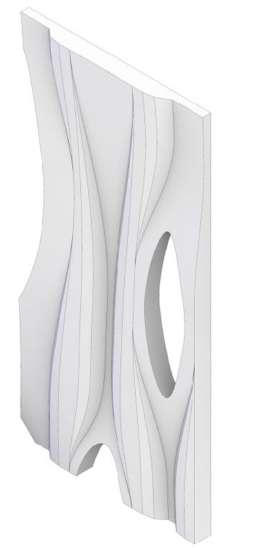

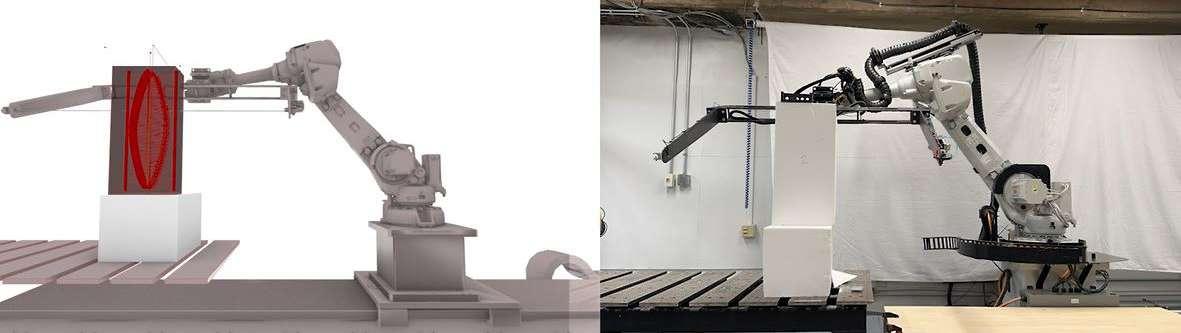

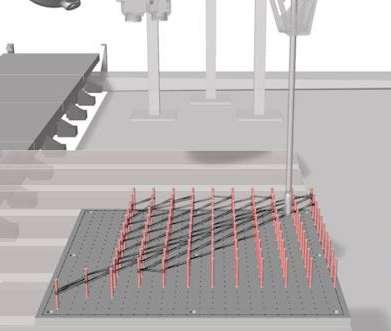

HOT WIRE CUTTING ROBOTIC

FABRICATION

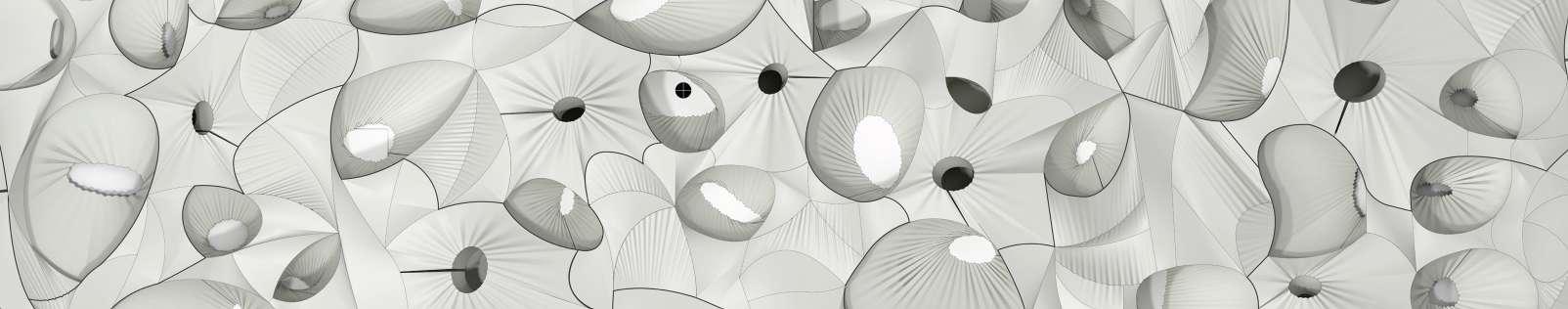

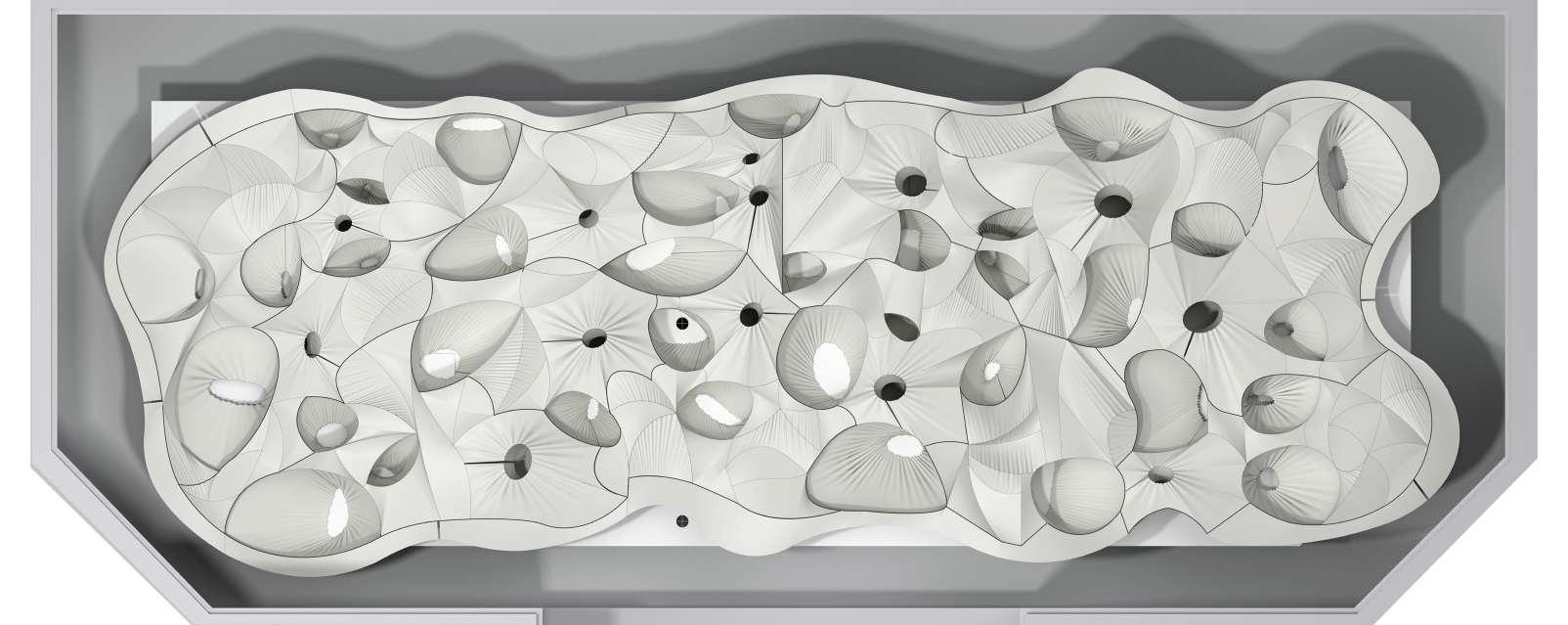

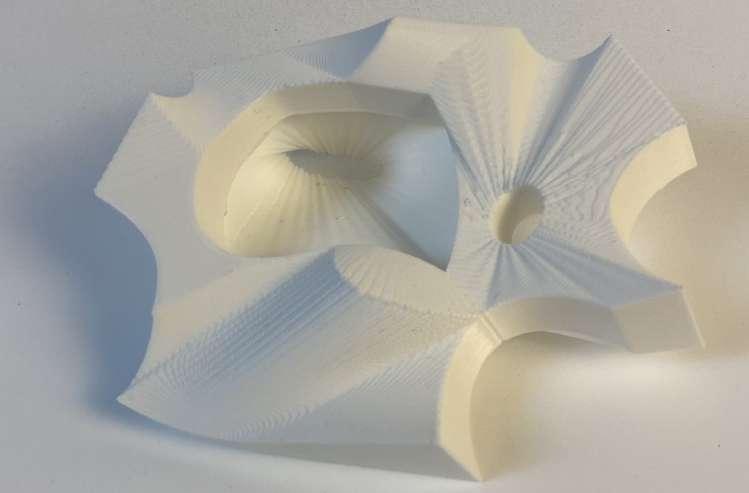

The goal of the project was to propose an immersive ceiling installation designed in collaboration with AI and meticulously fabricated with a state-of-the-art robotic hot-wire cutter.

The design concept was inspired by re-imagining Antoine Pevsner›s «Le Lis Noir» and collaging its renderings, which acted as the style transfer image run through a convolutional neural network (CNN), with a microscopic image of bone used as the CNN input. The CNN output served as the basis for the ceiling design. The interpretation depicted a flowing foreground with soft, curvilinear tooling that was interrupted by a background of deep eddies with sharp tooling.

In the prototype, an interactive lighting design was also imagined for the model, which was connected to a motion sensor coded by Arduino.

Professor: Andrew Saunders - asaun@upenn.edu - Group Members: Aisha Alshehri, Adam Blood, Matt Ward, and Hrishi Rajasekar

Original Sculpture Complete prototype 3D printed prototype

surfaces model Process to cut prototype Foam prototype

Final result of the hanging ceiling prototype

ULTRA HIGH PERFORMANCE CONCRETE

PRODUCTION

The project involved creating a precast mock-up at Northeast Precast Company in collaboration with Ultra High Performance Concrete. Because of the strength of UHPC, we were able to experiment with thin panel designs that could be poured without rebar.

Formwork drawings, including the layout for metalsheet cuts, were sent to Northeast Precast, where the formwork was created and built. The foam inserts used to form the voids in the panel were cut with a six-axis industrial IRB 4600 robotic arm. After we finished caulking and preparing the formwork, the final panel was cast.

Professor: RichardGarber - garberr@upenn.edu - Group Members: Aisha Alshehri, Cem Akgun, Joanne Zhao, and Shunta Moriuchi

Assembly steps of formwork

Location of foam inserts - cut by a six axis industrial IRB robotic arm

Post-pour

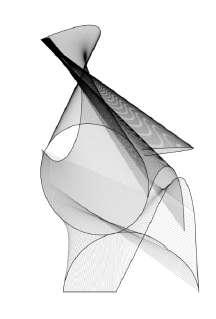

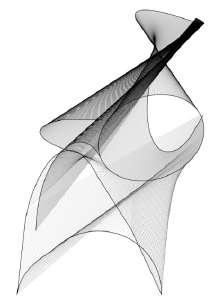

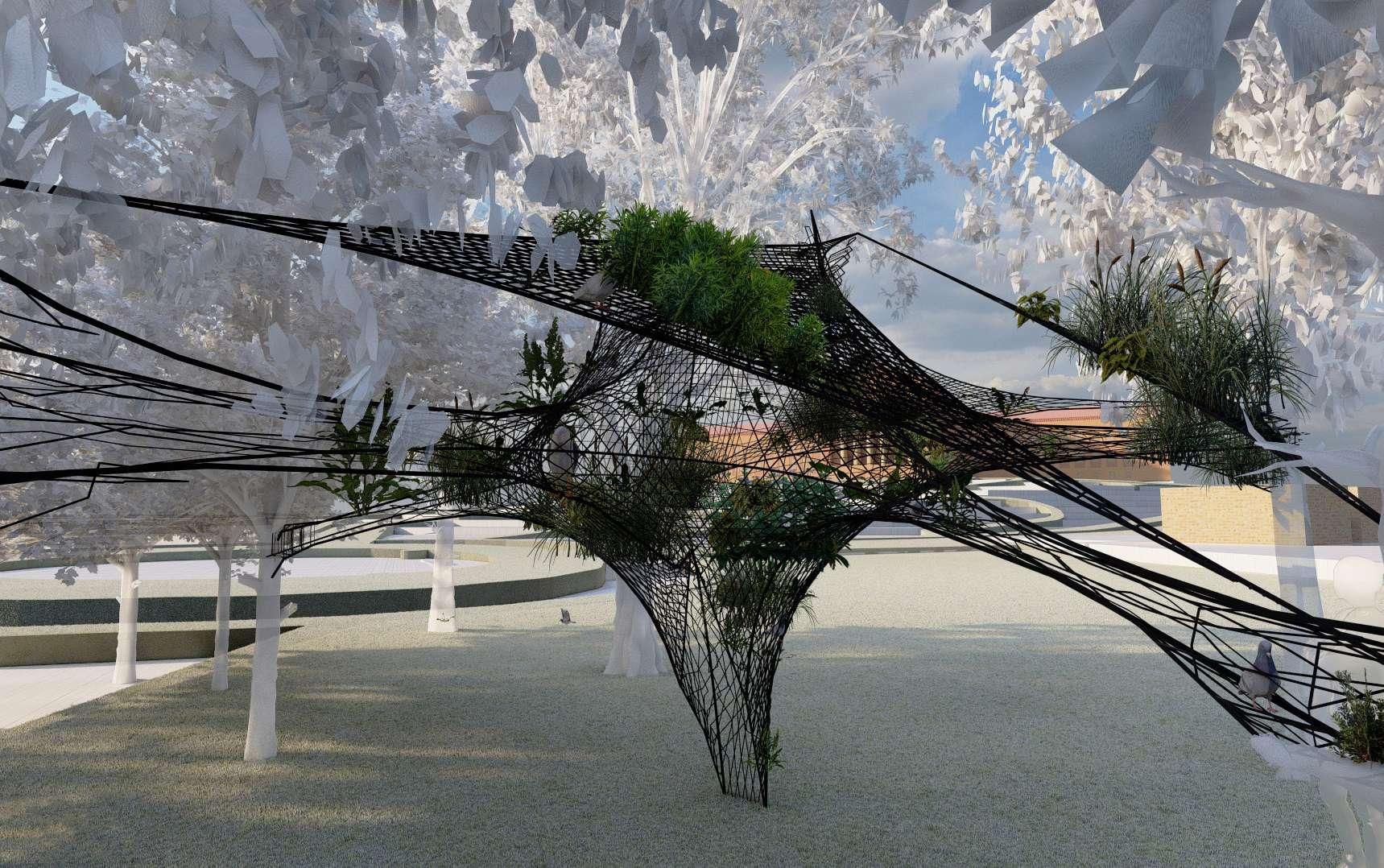

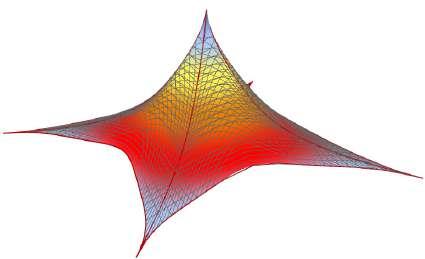

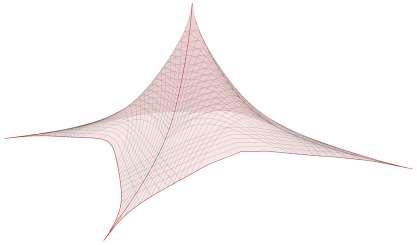

LACHESIS

The project was inspired by a heterotopic intervention in Philadelphia›s Fairmount Park, which was to be created of carbon fiber filament and fabricated robotically and generative algorithmic methods in architectural design.

Given the excellence of carbon fiber in tension versus compression, our team concentrated on developing a tensile structure. Each iteration received an initial structural analysis in order to develop a general understanding of the flow of forces through the structures.

In order to design a weaving pattern from the structural analysis, an algorithmic process was developed to connect anchor points via geodesic lines mapped across the mesh surface of our structure. After the primary geodesic curves were mapped, another algorithm was used to array a series of curves outward from the primary geodesics, reinforcing the flow of forces between the anchors.

Weaving carbon fiber with a 6 axis industrial IRB 4600 robotic arm generated the prototype. To strengthen the fiber, the four quadrants that comprised it were baked in an oven. Bolts were used to connect them in pre-planned locations.

Professor: Ezio Blasetti - ezioblasetti@gmail.com - Group Members: Aisha Alshehri, Adam Blood, Adhityan Anbumozhi, and Cem Akgun

Exploded axon of component

Prototype assembly diagram

Structural analysis - Prototype

Geodesic lines in red - Prototype

Structural analysis - Final proposal

Geodesic lines in red - Final proposal

Simulation and Robotic Fabrication of One Quadrant

Prototype Creation and Assembly for Each Quadrant

Final

Fabricated Prototype

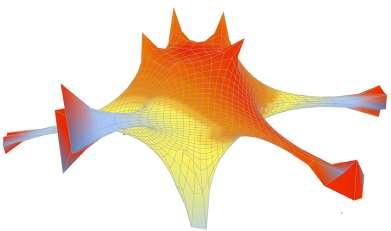

STEREOTOMIC ÆQUILIBRIUM

DRONE PORTS

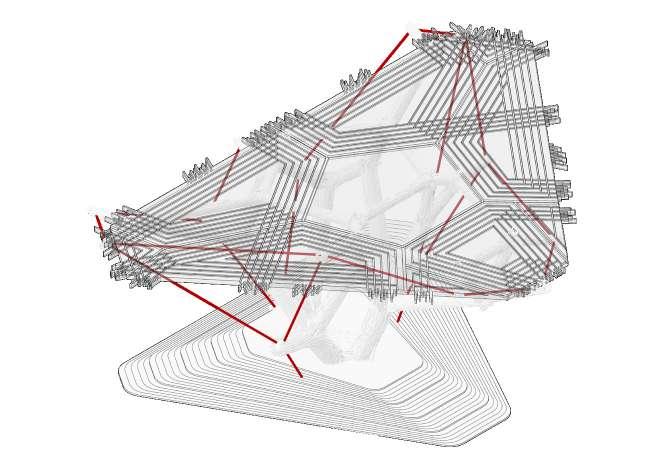

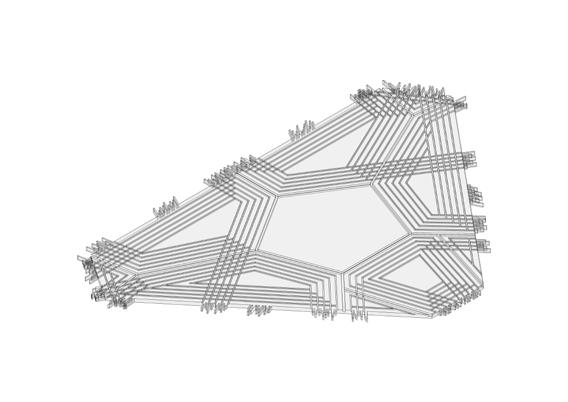

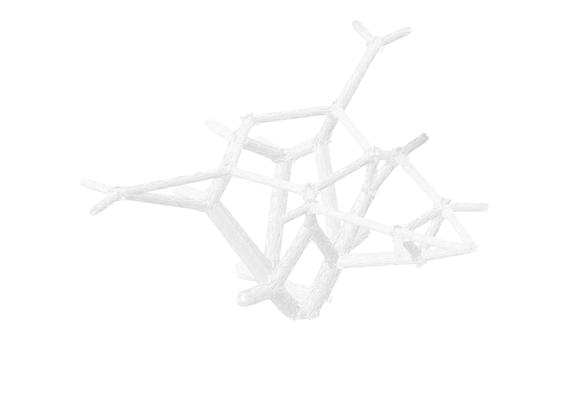

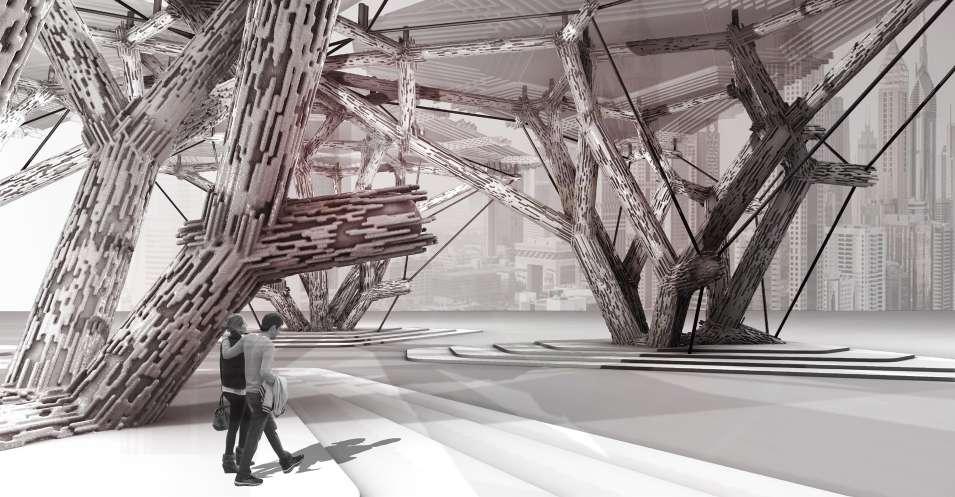

This project interprets the art of stereotomy in a new and radical manner. Stereotomic Æquilibrium uses a funicular design method at the base of historical structures made of heavy elements and extends its potential through computational formfinding. We use generative tools for 3D graphics statics in order to explore a wide range of architectural configurations and deepen into structural expressionism.

Our design arises from manipulating polyhedra, balancing external and internal forces, and creating a reciprocal relationship between forces and form through dualistic diagrams.

This approach supports very diverse explorations, culminating in a final design proposal for a lightweight stereotomic system to be used as an infrastructure for drones. A discrete architectural piece that takes place on the roof-top of high-rise buildings in Dubai, and is assembled from components manufactured additively. This design is made to host drones, provide logistics for aerial transportation, and offer shelter from the sun for people.

Professor: Roberto Naboni - roberto.naboni@gmail.com - Group Work

Detail Diagrams of Structural Elements

A Complete Additive Manufactured Prototype

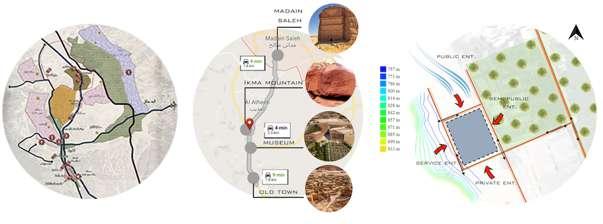

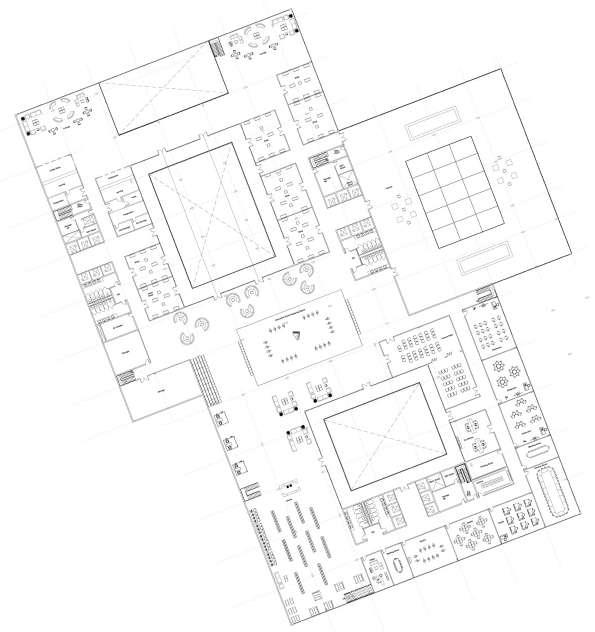

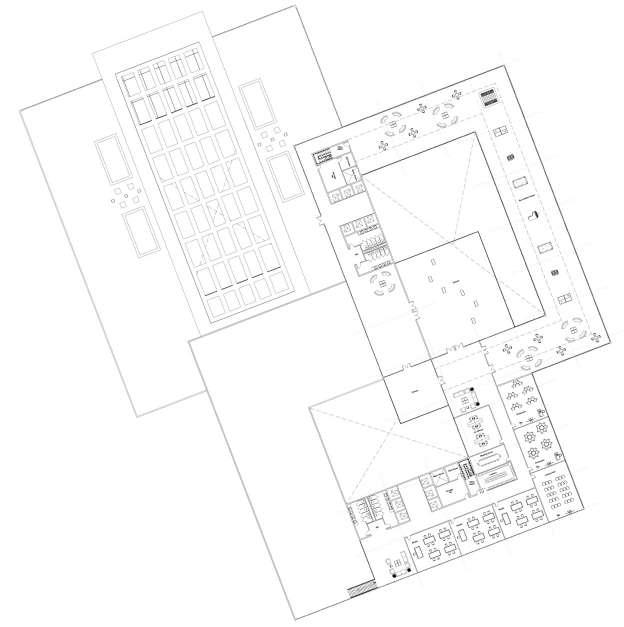

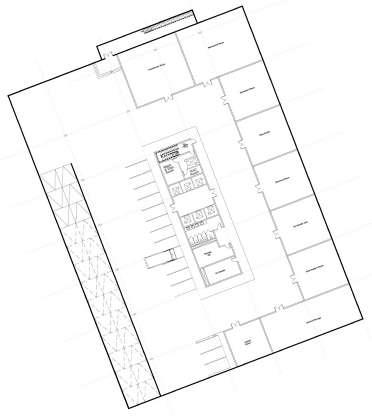

AL-ULA INTERACTIVE HOUSE FOR ARTS AND

CRAFTS

The interconnectedness of the architectural buildings of the old town of Al-Ula in Saudi Arabia reflects the deep connection and attachment between its people. It is the chosen idea to begin the design process of creating the journey that connects artists and craftspeople in acquiring and exchanging experiences in simple forms that represent the simplicity of its people.

Professor: Dr. Kholod Moumani - kmoumani@effatuniversity.edu.sa

L cy: Courtyard Length W cy: Courtyard width H cy: Average height of courtyard

A cy: Area of courtyard SH cy: Shape of courtyard

A wt: Area of Water in courtyard

A sl: Area of Soil in courtyard

Courtyard efficient ratio is: 1.33

Making horizontal louvers in the south to block perpendicular sun radiation will provide shading and reduce energy consumption.

Exterior Night View

ADAPTIVE MODULAR UNIT

An abstraction of the old town of Al-Ula in Saudi Arabia, inspired by its characteristics in the complexity and connectivity of its urban fabric within its simplicity in form.

The modular unit has been designed to be very simple in form yet adaptive and flexible for multiple functions depending on the needs of the user, such as chair, Arabic chair, table, and stand, and it can even be replicated in a certain way to create more functions.

The unit contains four square pieces of wood joined together. It is also easy to assemble, disassemble, and carry.

Professor: Dr. Kholod Moumani - kmoumani@effatuniversity.edu.sa

Detail Diagrams

Unit Prototype