ONE FLIGHT AND YOU’LL SEE WHAT 1000 HOURS PROVED.

SAFETY: LESSONS LEARNED FROM HOP-A-JET CRASH

LEGACY TAILS: THE GROUNDBREAKING CITATION 500

TRAINING: LAPD MAKES TRAINING REAL WITH VR SIM

Roundtable: Tackling the Supply Chain

The Return of the Pre-buy

Love ’em or hate ’em, pre-buy inspections are an essential step in the purchase process

LONDON TO NEW YORK NONSTOP.

Scan the QR code to see the mission

22 Legacy Tails: Cessna’s revolutionary Citation jet

40 LAPD deploys VR simulator for training

49 Gulfstream boosts customer support

4 Gulfstream G800 wins FAA and EASA certification

6 Textron Aviation 1Q jet deliveries dip, t-props surge

8 Bombardier eyes uncrewed future for EcoJet technologies

10 Safety, workforce headline topics at NBAA mx conference

12 FAA’s Rocheleau: Navigating in a time of crisis and transformation

14 Special Report: Back on the plate, pre-buys still face post-Covid challenges

20 Ambassador Program helping Corporate Angel Network spread its wings 26 Roundtable: Managing the supply chain through turbulence 34 Safety: ACSF symposium challenges all to dig deeper on safety

Gulfstream G800 wins FAA and EASA certification

BY HANNEKE WEITERING

Gulfstream Aerospace’s G800 long-range business jet is now certified in the U.S. and Europe. The Savannah, Georgia-based manufacturer announced in mid-April that it had secured type certificates from the FAA and EASA for the new aircraft, the longest-range business jet in its fleet, after exceeding expectations during performance testing.

G800 certification tests demonstrated a range of 8,200 nm (15,186 kilometers) at the long-range cruise speed of Mach 0.85, which is 200 nm farther than the company had originally projected. Its maximum operating speed also increased to Mach 0.935 from Mach 0.925. At the Mach 0.90 high-speed cruise, the jet can travel 7,000 nm. At Mach 0.87, the range is 8,000 nm.

The G800’s balanced field length takeoff distance of 5,812 feet (1,771 meters) and a landing distance of 3,105 feet are also shorter than Gulfstream’s projection. This will give its customers access to more airports, the company said.

“With the certification of the G800, Gulfstream has again exceeded expectations, thanks to the expertise and rigor of our flight test, certification, and manufacturing teams,” said Gulfstream president Mark Burns. “The G800 marks the latest evolution of business aviation as we continue to build the next-generation fleet and bring industry-leading performance and efficiency to the market. With the capability enhancements we have achieved, Gulfstream customers will greatly benefit from the increased flexibility and range the G800 offers.”

During the company’s first-quarter earnings release, Phebe Novakovic, chairman and CEO of Gulfstream parent General Dynamics, said the last G650s will be delivered by July, with the newly certified G800 succeeding the older model. However, Novakovic did not disclose when the first G800 would be handed over to its customer.

Certification followed a year after the company received U.S. FAA approval for the G800’s longer sibling, the G700. z

News Briefs

BOMBARDIER SEES REVENUE RISE AS UNCERTAINTY WANES

Bombardier revenues in the first quarter rose 19% year over year, to $1.5 billion, with a three-aircraft increase in deliveries and continued gains in the services side. The company released its full-year guidance— postponed from earlier this year given uncertainties surrounding tari s—forecasting that it would deliver 150 aircraft and bring in $9.25 billion in revenues in 2025. In the quarter, Bombardier delivered 23 aircraft, including 12 Challengers and 11 Globals.

EMBRAER EXECUTIVE JETS NOTCHES BACKLOG RECORD

Embraer Executive Jets hit a new high water mark for backlog, which rose to $7.6 billion in the first quarter, 3% higher than its previous record established in the fourth quarter. It delivered 23 business jets in the first quarter—14 Phenom light jets (two Phenom 100EXs and 12 Phenom 300s) and nine midsize Praetors (three Praetor 500s and six Praetor 600s). “Our productionleveling initiative, bolstered by the expansion of our industrial capacity, aligns well with Embraer Executive Jets’ market guidance for this year, and we’re very excited to see this increase of 28% in the first quarter customer deliveries,” said company president and CEO Michael Amalfitano.

HEICO BUY OF ROSEN IS COMPANY ’ S 4TH THIS YEAR

Heico subsidiary Mid Continent Controls has purchased “all the ownership interests” of business aviation in-flight entertainment products manufacturer Rosen Aviation. Eugene, Oregon-based Rosen Aviation makes in-cabin displays and control panels, including digital windows and skylights for VVIP jets for aftermarket and OEM customers. Heico bought three other companies in the past six months, including Mid Continent Controls, Capewell Aerial Systems, and Millennium International.

The G800 has a range of 8,200 nm at Mach 0.85, exceeding expectations by 200 nm.

Textron Aviation jet deliveries dip as turboprops surge 50%

BY JESSICA REED

Textron Aviation delivered 31 jets in the first quarter, down from 36 in the same period last year, as the manufacturer continues to recover from production disruptions caused by a labor strike in late 2024. Meanwhile, civil turboprop deliveries increased to 30 from 20 year over year.

The Textron division posted revenues of $1.2 billion, up $24 million from the first quarter of 2024, “largely reflecting higher aftermarket revenue of $27 million,” Textron Inc. CFO David Rosenberg said in an April 24 earnings call. However, segment profit declined to $127 million, down $16 million from the prior year, “primarily reflecting the mix of aircraft sold, partially offset by higher aftermarket volume.”

Textron Inc. CEO Scott Donnelly noted, “Aviation operations continue to improve as the factory progresses toward pre-strike performance levels while ramping production. Textron Aviation’s fleet utilization remains strong in the quarter, contributing to aftermarket revenue growth of 6% as compared to last year’s first quarter.”

The company’s first-quarter jet deliveries included five M2 Gen2s, five Citation CJ3+s, five CJ4 Gen2s, two XLS+

Gen2s, 11 Latitudes, and three Longitudes.

Civil turboprop deliveries showed significant improvement, with 23 Caravans delivered in the first quarter versus 12 in the same period last year. The company also handed over one SkyCourier and six King Airs, including four King Air 260s and two King Air 360s, down from seven King Airs in the same period last year. Textron Aviation’s backlog remains at $7.9 billion

“As we leave the quarter, the metrics that our teams track around productivity and attrition and earned hours and all those sorts of metrics [...], we’re getting back to where we were pre-strike,” Donnelly said.

Supply-chain improvements are contributing to the recovery, he added. “Parts are there, so the flow is much cleaner; that clearly helps to drive the productivity side.”

A significant milestone for Textron Aviation’s Beechcraft Denali program came in February with the FAA certification of the GE Aerospace Catalyst turboprop engine.

The aircraft’s performance in flight testing has been “very good,” Donnelly noted, adding that the program has accumulated “more than 2,700 flight hours across 1,000 flights with three test articles.” z

News Briefs

GULFSTREAM DELIVERIES, REVENUES, EARNINGS SOAR

First-quarter revenues at General Dynamics’ aerospace unit (Gulfstream Aerospace and Jet Aviation) climbed 45.2% year over year, to $3.026 billion, and earnings rocketed 69.4%, to $432 million. Aircraft deliveries at Gulfstream surged 50%, to 36 aircraft—30 large-cabin jets, including 13 G700s, and six super-midsize G280s in the quarter. According to General Dynamics chairman and CEO Phebe Novakovic, Gulfstream is projected to deliver 150 aircraft this year.

SIGNATURE SMOOTHS INT’L ARRIVALS AT TETERBORO

Signature Aviation has streamlined the arrivals and customs clearance process for internationally arriving customers at Teterboro Airport (KTEB). Its northwest facility on the field—Hangar 12, acquired last year from Meridian—has been designated as the company’s international arrivals venue. Signature will provide start-to-finish assistance on the airport’s customs ramp adjacent to the facility. Arriving aircraft will be marshalled onto the ramp by a Signature team member, who will o er baggage assistance following clearance.

THOMA BRAVO BUYING BOEING DIGITAL AVIATION SOLUTIONS

Investment firm Thoma Bravo is acquiring Boeing’s Digital Aviation Solutions business in an all-cash transaction valued at $10.55 billion. Expected to close by year-end, the deal includes Boeing’s Jeppesen, ForeFlight, AerData, and OzRunways assets. According to Boeing, it will retain digital capabilities for the provision of predictive and diagnostic maintenance insights for commercial and defense customers that use its fleet maintenance services. Boeing Digital Aviation Solutions employs about 3,900 people, including those who will remain with Boeing and those who are part of the assets being sold.

Aftermarket growth bolstered revenues during Textron Aviation’s post-strike recovery.

AHEAD OF THE CURVE

A proven predictive analytics system that forecasts the service you need—before you need it.

Bombardier eyes uncrewed future for EcoJet tech

BY KERRY LYNCH

Bombardier is eyeing uncrewed possibilities, potentially in the military market, as it explores technologies it could derive from its EcoJet blended-wing project, according to company president and CEO Éric Martel. In the shorter term, the Montrealbased company remains on track for entry into service of the Global 8000 this year as it nears completion of the first production model, Martel told analysts and reporters as the company released its firstquarter results.

In the works for nearly 17 years, Bombardier’s EcoJet sustainability and technology research initiative in 2022 entered its second development phase with flight-testing of an 18-foot-wide, blended-wing prototype. Martel noted that “strategic discussions are happening at Bombardier and still continue” on the future of the program and its technologies. Given Bombardier’s vertical integration of its defense business, “the discussion of [an] unmanned airplane is on the table,” he added.

Bombardier is weighing the appetite of different governments for such a product. “But clearly, there are quite a few possibilities. The EcoJet will be quite a capable product, so this is definitely one thing we’re looking into.”

With the way the world is evolving, there are numerous reasons why the concept of uncrewed operations is becoming popular, he explained, pointing to a shortage of pilots and a desire to reduce the risk to people’s lives on the battlefield.

“That’s why we foresee that there could be interest in the technology. So, maybe the first application could be in the defense world as there’s less restriction in terms of certifying versus commercial.”

He noted that the program is one of continuous improvement, and Bombardier is maturing the technology on the demonstrator. “There are things we will be able to put on our actual products or potential future products we will be developing.”

He did not have a timeline yet on when some of this may be in the market.

As for the Global 8000, Martel said the Mach 0.94, 8,000-nm successor to the Mach 0.925, 7,700-nm Global 7500 remains on track for delivery in the fourth quarter, pending required approvals.

Assembly of the first production Global 8000 began in October and is nearing completion, he said. Having “basically completed flying,” the company is finalizing the documentation stage to ensure it is in line with certification requirements. z

News Briefs

SAUDI ARABIA LIFTS FOREIGN CHARTER RESTRICTIONS

Cabotage restrictions for air charter operations in Saudi Arabia were eliminated under General Authority of Civil Aviation (GACA) rules that took e ect May 1. This opens Saudi Arabia’s domestic private aviation market to international on-demand operators that apply for permission from GACA and follow specific requirements set by the agency. Opening of the domestic market comes as part of GACA’s General Aviation Roadmap, which aims to transform the sector into a $2 billion industry by 2030.

GULFSTREAM COMPLETES EXPANSION AT ST. LOUIS MRO

Gulfstream Aerospace completed a $30 million expansion of the aircraft completions operations at its St. Louis Downtown Airport (KCPS) service center. Announced in 2023, the facility enlargement provides the resources for full aircraft interior outfitting activities at the location. The project brings Gulfstream’s St. Louis MRO facility to a total footprint of 645,013 sq ft. It also builds on an expansion finished at the location in 2017 that provided dedicated hangar space and service to support the entire Gulfstream fleet. The company also added 200 new jobs in St. Louis.

INDIA BIZAV SEEKS TAX, REGULATORY REFORM

Increased demand for private aviation in India’s burgeoning economy has made the case for reforming the sector’s regulatory structure even more urgent, according to industry leaders who recently gathered for the annual conference of the country’s Business Aviation Operators Association (BAOA) in Delhi. Speakers highlighted key challenges including unhelpful tax rules that impede progress, a lack of regulation for services such as fractional ownership, and inadequate provisions for training, pilot recruitment, and maintenance.

Bombardier’s EcoJet research program aims to reduce business jet emissions by 50%.

Spotlight on safety, workforce at NBAA Mx Conference

BY CURT EPSTEIN

With the recent spate of fatal accidents and a looming mechanic shortage, NBAA’s Maintenance Conference brought a more urgent focus on safety and workforce this year.

Kicking off the four-day event held in April in Columbus, Ohio, NBAA president and CEO Ed Bolen addressed the recent highprofile accidents and its impact on public perception. “They are asking me and everyone in aviation, ‘Is it safe to fly?’” he told the audience. “Now the empirical data suggests yes; the emotional data, maybe not as much.”

As a result, the entire aviation community has come together to back a proposed $12.5 billion allocation to the FAA included in the budget reconciliation bill to cover controller hiring and upgrade air traffic control facilities and equipment, Bolen said.

“We’re no longer going to have people asking if it’s safe to fly because they will know we have enough well-trained people using the best equipment and keeping the United States what it’s always been: the largest, safest, the most efficient, and the most diverse mix of aircraft anywhere in the world,” he said.

Gregory Feith, a former senior accident investigator with the NTSB, addressed the role that maintenance has to play in his keynote address.

“We don’t want those accidents and the people that are involved in those accidents and incidents to have either perished or at least sustained any kind of injury in vain,” said Feith, who spearheaded numerous high-profile accident investigations during his more than two decades with the agency. “We have to take those lessons, we have to bring them back into aviation.”

Now a consultant, media commentator, and a host of the Flight Safety Detectives podcast, Feith cited a quote by Wilbur Wright: “Carelessness and overconfidence are usually more dangerous than deliberately accepted risk.” Indeed, it was his brother, Orville Wright, who was involved in the first fatal aircraft accident in September 1908, where the passenger was killed.

“We do what we need to do to mitigate that risk to as close to zero,” he said, explaining that it can never be eliminated entirely. “As long as you have interaction between humans and machines, there is always going to be that possibility of failure in some way, shape, or form.”

One of the key accident factors Feith examined during his tenure with the NTSB was the organizational safety culture of aircraft operators. He acknowledged that

on page 45

News Briefs

NEWARK ATC FAILURES PROMPT CONTROLLER TRAUMA LEAVE

Multiple air tra c controllers were placed on trauma leave following a system outage on April 28 that left them unable to see or communicate with aircraft arriving into Newark Liberty International Airport (KEWR) for 90 seconds, contributing to widespread delays, sta ng gaps, and a reduced flight schedule. The lapse in radar and radio contact occurred at the Philadelphia Tracon facility, which manages arrivals and departures at Newark. The FAA issued a statement attributing the disruption to “antiquated” telecommunications infrastructure.

NETJETS, FLIGHTSAFETY REVENUE

GROWS 10.4% IN 1Q

First-quarter revenues at NetJets and FlightSafety International climbed by 10.4% thanks to growth in NetJets’ shared ownership programs, increased flight hours, and higher average flight-hour rates, parent company Berkshire Hathaway reported early last month. Pre-tax earnings for Berkshire’s broader services group rose 9.6% to $648 million, with aviation services among the primary contributors. “The earnings increase from aviation services was primarily attributable to increased revenues, partially o set by higher flight crew, maintenance, fuel costs, and depreciation expense,” the company said.

STANDARDAERO TAKES 1,500TH

HTF7000 FOR HEAVY MX

Erika Armstrong, Suresh Narayanan, David Sturdy, and Chris Poliak held a panel on mechanic retention and leadership challenges.

StandardAero recently hit a milestone in its engine services, receiving the 1,500th Honeywell HTF7000-series engine for major maintenance at its Augusta, Georgia service center. With the event, StandardAero said it now has performed more major HTF7000 workscope events than any other company. StandardAero is also expanding its MRO capacity at Augusta Regional Airport to keep up with increasing demand for HTF7000 engine support facility.

FAA’s Rocheleau: Navigating through a time of crisis and transformation

BY KERRY LYNCH

Chris Rocheleau was named deputy administrator of the FAA in January but also took on the role of acting administrator with the departure of FAA Administrator Michael Whitaker. A U.S. Air Force veteran, Rocheleau most recently had served as COO at NBAA. The move to the FAA marked a return to the agency where he had previously held numerous senior leadership roles for more than 20 years. Rocheleau spoke with AIN about his decision to rejoin the FAA, the immediate crises he faced with the agency, his long-term vision, and what was at the time the pending confirmation of Republic Airways CEO Bryan Bedford as permanent administrator.

What brought you back to the FAA?

I had served for 22 years in the agency in a variety of roles and was very fortunate to have the opportunities over time to progress within the agency. Whether it was in the chief of staff role or international affairs, [I was able to] understand the corporate nature and the importance of all the different pieces of the agency working together to accomplish the goals, whether for the FAA, the wider industry, or the Department o f Transportation.

I felt I’d accomplished something in my career, and when the opportunity was given to kind of retire and move on to NBAA, I jumped on it. The COO role at NBAA was enlightening and invigorating. Then the opportunity came to help with the presidential transition. Someone said, “You’ve been through two transitions, both from Obama to Trump and then Trump to Biden. How would you like to help in this next transition?”

Talk a little about the transition.

I thought I’d be able to help because transitions are bumpy. Admittedly, this one is equal to or, even in some ways, greater than bumpy. But what is exciting about it is that the FAA does crisis management well because we have a very resilient workforce. I felt that if I could get in there and tap into that, I’ll have done my part.

A week after my arrival and on [Transportation Secretary Sean Duffy’s] first day, we had the tragic crash at DCA [Ronald Reagan Washington National Airport]. That’s where I think my training was able to help the secretary manage this crisis and help the team get their arms around what we needed to do immediately, like restricting the airspace around DCA, working with the stakeholders, working with the NTSB, and of course working with our controllers. There was a lot of news around what happened in the tragedy, but there was also a real workforce there that needed to make sure someone was paying attention to them and they had the support they needed. To me, that was the big piece of this—to help manage through that transition, but also the subsequent crises when we got here.

Coming in as deputy, with knowledge you’d likely become acting, what was your vision and has it changed now?

I certainly didn’t expect this to be my beginning, with the series of crises, also including the Bering Air accident in Alaska and the [Learjet medevac] tragedy in Philadelphia. But I did come in knowing this agency and what helps it drive. It was coming in saying safety is our priority. At a recent town hall, I said, “With all the other noise out there—and there’s a lot out there—focus on the job. Come to work,

look out for each other, and focus on the safety job that we do every day.” Someone quoted me as saying, “We deliver safety to the American people every day,” and I was really proud of getting that in. To me, it came down to safety first.

And then we have to modernize this agency, whether it’s on medical certification work, our air traffic processing, or our notam system, which was another big one. A major focus right up front was to let people know that for the next three, four, or five years, certainly for this administration, we will focus on modernizing the FAA.

The other piece, and this was a passion of mine, was bringing new innovative technologies into the airspace. I was very involved at the beginning with the Virginia Tech experiment on drone integration. That’s expanded appreciably since I left. I wanted to get back in and help with safe drone integration and safe advanced air mobility. Those are two major technologies [that] I think are going to transform not just the U.S. airspace system but the world.

The final piece, which you’ve heard plenty about because the secretary was all in, was the controller hiring and making sure that we preserve safety positions as we seek to reshape the agency as we become more efficient. There’s been a lot of talk about DOGE and chopping and getting rid of people. But perhaps because of what happened at the beginning of the

Actual photo of client expressing concern about recent aircraft transaction

When you reflect on the best decisions you’ve made, hiring Mesinger Jet Sales will surely be one of them.

Our clients enjoy the confdence that comes from having the most experienced team of aviation asset advisors in their corner.

Our reputation for integrity and professionalism go before us into every transaction.

Dedicated to giving you the peace of mind to focus on what matters most

aircraft acquisitions brokerage services

Mesinger Jet Sales clients enjoy signifcant advantages when selling their aircraft.

Our deep knowledge of the evolving market and our negotiating expertise give you a competitive edge when selling your aircraft. Our research is the most thorough in the industry, so you can know you are benefting from expert analysis available nowhere else.

Serious aircraft buyers and their representatives check our listings frst when seeking an aircraft. They trust that our specifcations are accurate, our knowledge of the aircraft is unsurpassed, and our relationships with the sellers we represent are strong and committed. Among the many advantages our clients enjoy are:

• Maximum selling price and minimum days on market based on accurate market data, proven pricing formulas, vast industry networks, and innovative marketing

• Surprise-free sales process, inspections, and closings that save our clients money and time based on our expert technical oversight and experience

• 100% transparency in all aspects of the transaction, with regular reporting and consistent communication

We anticipate potential issues and address them promptly. We know how to keep a transaction on track, making ourselves available 24/7 to all parties until the sale is closed. We never represent multiple directly competitive aircraft at the same time, so you will have our undivided attention in pursuit of a successful sale.

Purchasing the right aircraft at the right price is a specialized science requiring decades of experience.

We invest unsurpassed resources in time and talent to bring about the successful purchase of a new or pre-owned aircraft on your behalf. We never take on directly competitive acquisition projects at the same time, so you know that we are 100% focused on your best interests.

Our acquisition solutions are built on the experience of hundreds of successful acquisitions in all market environments. Our acquisition solutions start with thorough mission profle analysis and are founded on the best market intelligence.

Sellers and their representatives call us frst when an aircraft is ready to come to market. They know that we represent our acquisition clients on an exclusive basis, that we are knowledgeable about the market and the aircraft, and that we conduct only ethically based transactions. This frst-mover advantage gives you more and better choices of aircraft to consider.

Our technical oversight and deep understanding of aircraft and markets means that we set accurate expectations and avoid costly surprises, resulting in a successful, regret-free purchase.

An aircraft purchase is far too important to entrust to anyone but the best professional representation. With Mesinger Jet Sales as your dedicated partner, you can know that we will be with you every step of the way and long after the acquisition.

tranquility in the midst of complexity

An aircraft transaction is a complex interaction of myriad details amidst ever-evolving market dynamics.

That’s why you need a partner alongside you whose expertise, integrity, and commitment will make the purchase or sale of your aircraft a supremely tranquil experience.

Call us today to explore your opportunities.

year, what happened here with the tragedies, the secretary from day one has been in to preserve any of our safety capabilities, air traffic controllers, safety inspectors, and certification engineers. We have not stopped hiring those, and we have just pressed on with all of that.

Since the high-profile accidents, you’ve had to testify before Congress. Do you feel like you’ve had a different mandate because of this?

That hearing [before the Senate Commerce Committee in March] was my first ever. I’ve done a lot of prep for different administrators over my time. I never sat in the chair, and so that was pretty significant for me. But I felt confident in all the preparation and knowing the agency and being able to answer some of the tough questions, whether it was on Elon Musk or do we have enough people while we’re terminating folks or people are retiring.

I also understood the need to respond to Congress. Yes, there are a lot of demands on this agency, and for a good reason, right? We’re responsible for making sure the skies are safe every day.

We’re responding intentionally; responses involving the NTSB investigation are a perfect example. There’s a lot of information that people think they know initially, and it’s a challenge. An important thing to remember is that we need to use discipline when we’re coming to a conclusion, that we just don’t have all the facts. So, I think that the FAA has been very good about being deliberative and being careful about how we respond until all the facts are in.

Yet it didn’t hold us back from stopping mixed traffic at DCA or starting our reevaluation of what we call hotspots, or areas where we had mixed traffic or high reports of losses of separation.

Can you talk about these studies, including on hot spots?

When we did our initial scrub of where we were seeing potential losses of separation,

TCAS [traffic collision avoidance system] alerts, and those kinds of things, we identified Las Vegas early on because of the nature of the mixed traffic with commercial airlines and air tours.

We identified that there were numbers there that we needed to pay attention to and similarities as they related to the horizontal and vertical separation requirements. We had our team look very carefully at the airspace makeup, as well as what controllers were telling helicopters and airplanes, as it related to traffic advisories. That was a really big thing.

In the past weeks, we’ve been working with the controllers and the air tour community there to make sure that they work through the airspace. Just over the past few weeks of that work, we’ve seen a roughly 30% reduction in the alerts that we were getting.

Another location that we’ve looked at is in the LA basin area with Van Nuys and Burbank airports. We’ve got two airports that are fairly close that see private jets that move very quickly, and we’ve got Cessna 172s. And that’s a dense airspace we’re looking into as well. Anything we see that we don’t like, we take action on immediately.

At the same time, we’re going to look through how the airspace is redesigned and how we might want to change that to make it clearer for helicopters, training aircraft, private jets, and any others going in and out of those airports.

After the Bering Air crash, I was able to go to Alaska and meet with both the investigators as well as [those involved with] the Don Young Aviation Alaska Safety Initiative to talk about the airspace around Anchorage. You’ve got high-performance F-35s flying around. You’ve got float planes. You’ve got a real mix of traffic in the airport area. That’s another area, as they’re doing an airspace redesign, that we’re going to take the lessons we’ve learned from DCA and now in Las Vegas, and apply them there.

There is a lot of discussion about modernizing technology. What can people expect?

It’s clear that for years, the FAA has worked through this thing they called NextGen. Some of the technologies and capabilities have been delivered, but not in a timely manner, and not to fully realize the benefits of those technologies.

Partly because of the outages—think about it, we had not just the crashes, but we had two notam outages since the secretary arrived—we’ve been fortunate to have the secretary lean in with us, not just tell us what to do or stand in the way.

We have outages throughout the system on a regular basis. It’s because we’ve had technologies that have been in place from the 60s, 70s, and 80s. We’ve heard plenty about floppy disks, paper strips, and vacuum tubes.

There are a series of things that we use every day in the air traffic system that are functional, that are safe. We moved over a billion people safely last year. When you look at the trend lines, even though we’ve had this very unfortunate period with loss of life, the system is incredibly safe. But it is showing signs of decay. It is time that we call people’s attention to this problem. The agency has talked about funding instability before, but now we feel it, and so the secretary has made this a priority to build the infrastructure again.

Where are your priorities on AAM and drone technology?

On the AAM and drone deliveries, a lot is going on there. I’m going to Dallas to experience firsthand the UTM, the UAS traffic management systems being used in the area. To me, those are game changers when we think about the beyond visual line of sight [BVLOS] rule and enabling drone deliveries.

On advanced air mobility, the agency has been working on that for some time. I understood on my return that there’s been continues on page 56

Back on the plate, pre-buys still face post-Covid challenges

BY KERRY LYNCH AND MATT THURBER

The days of the pandemic business jet buying frenzy are over, and so too, for the most part, are decisions to skip pre-buy inspections in desperation to secure an aircraft. However, lingering issues such as supply chain and MRO capacity, along with new concerns such as tariff-related market uncertainties, are still proving challenging for the pre-buy inspection process and, as a result, threaten to complicate certain aircraft deals.

Jay Mesinger, who is CEO and president of an aircraft brokerage that has been in business for more than 40 years, Mesinger Jet Sales, has an adage about pre-buys: “Can’t live with them and should never live without them.”

However, years of practice surrounding pre-buys were upended during the pandemic. When the pandemic began, Mesinger explained, the industry was facing a standstill. “Customers didn’t want you to come visit, so corporations pretty much stopped flying,” he said.

JAY MESINGER PRESIDENT AND CEO, MESINGER JET SALES

That changed the number of aircraft bought and sold. “We looked at the market and thought it’s going to go down between 5% and 20%.” Mesinger feared that older aircraft values would plummet even further, reminiscent of the late 2000s, when values dropped between 50% and 70% overnight.

But the market took an unexpected turn. “We were completely wrong,” he conceded. Flying returned, and values went up as much as by 40% over a year’s time during the pandemic.

“There was so much wealth created during the pandemic in all sectors of the economy, and also there was so much fear

created during the pandemic about public travel. People didn’t want to go to airports,” Mesinger explained. “First-time buyers came into our industry like never before.”

As a result, the entire sector saw a bump. “During that time, sellers got greedy. It became a seller’s market, and buyers were paying whatever they had to get an airplane regardless of common sense, good value, statistics, and demographics,” Mesinger said.

The supply of available airplanes went from a balanced market of 7% to 10% of the fleet to almost zero. “An airplane would come on the market in the morning, and by lunchtime, there’d be 10 fullprice offers.”

WANTING THE LEAST

Sellers would start bidding wars, not just over price, but “who is going to want the least. Wanting the least was the pre-buy,” he added. “Sellers said you’re not going to get a pre-buy. You pay me the most, you come into my hangar, you look at the records, you take it around the patch, and you buy it or not, period.”

As a result, Mesinger maintained, “Huge numbers of people began to forgo the prebuy for the opportunity to just buy. Terrible idea.”

In fact, things became so bad on that front, Mesinger “pretty much stopped” on the acquisition side of the business for a short time. “We wouldn’t suggest that anybody buy an airplane without a pre-buy, and sellers weren’t allowing it,” Mesinger said. “The lack of pre-buy or due diligence was a critical factor in our industry.”

Particularly with older aircraft, people have found corrosion in areas that are typical and could have been caught through a full pre-buy, Mesinger said.

If significant findings such as corrosion slip through, they erode the airplane’s value. “Had you been allowed to do the pre-buy at the time of purchase, you would have had a contractual ability to reject the airplane. You paid the highest dollar for the airplane during the pandemic, and you

THE PERFECT PLACE FOR BUSINESS AIRCRAFT

paid it without the knowledge of what the mechanical integrity of the airplane was.”

David Mayer, a member of the Global Aviation Group at Shackelford, McKinley, & Norton, agreed that during the pandemic, “The buyers wanted lift, and they knew that there’d be other buyers in the wings. They sometimes skipped all diligence other than a books and records review and confirming airworthiness. It was a different time when waiving inspections seemed imperative to anxious buyers. I said then, and I still would say, that that’s not a good idea to waive or bypass a thorough inspection unless you have a big wallet and don’t mind seeing your airplane sit like an expensive paperweight pending or during repairs.”

Mayer underscored the importance of a full pre-buy inspection. “Most buyers today remain objective and arrange appropriate pre-buy inspections based on expert advice on the scope and objectives of an inspection. However, I’ve seen other buyers fail to do an adequate pre-buy inspection, which leads to finding squawks and other aircraft-related issues post-closing, like corrosion, broken systems, or damage. The finding may not affect airworthiness, but they have reduced the aircraft’s value, availability, or utility,” Mayer said. “Buyers can find out quickly that omitting or limiting an appropriate inspection is a bad idea.”

He pointed to other important areas of the due diligence process. During the prebuy process, as a key element of a broader inspection, a facility should examine the paperwork, looking for compliance with the manufacturer’s recommended maintenance and inspection schedules. The delivery condition in the aircraft purchase agreement should specify standards for passing an inspection.

“Non-standard items are essentially red flags that people need to investigate, repair, and price into the transaction,” he said. “Quality inspection facilities will alert a buyer to any of these items. The parties

Special Report

need to discuss whether there will be a deal if the seller cannot or will not satisfy a delivery condition. If this happens, some buyers may seek an accommodation of price, share repair costs, or walk away from the purchase, depending on the problems found.”

However, problems can arise if the buyer really wants a particular airplane and gets emotionally attached, Mayer said. “They accept the airplane despite its known or unknown flaws and don’t look forward to selling the airplane to prospective buyers in the future.” Later on, someone else may pass on the purchase, require extensive repairs, or insist on a price reduction of that airplane, he said.

‘SLAMMED’

Now, the business aircraft market is better balanced, Mesinger said. “There’s more inventory for sale. They have an opportunity to negotiate for price and make smart, intelligent decision-making with respect to evaluation—and they have a chance to do the thorough due diligence and do a pre-buy.”

While the market has right-sized, not all the Covid challenges have eased. “Our maintenance facilities were slammed during the pandemic, not doing pre-buys necessarily, but because there was so much flying again,” Mesinger said. “Shops were just as full and busy as they could ever be.”

For sellers, space availability can be daunting. Sellers typically were asked to

stop using their airplane between the time of the contract and inspection. That was common and was not considered a big ask. But today, it could take a month or two to get it into an available slot in a shop.

“It’s impossible to say to a seller, ‘Hey, you got this airplane you’re paying for these two months, and you can’t touch it,’” Mesinger said. “A seller can get very nervous about not being able to start the process of selling their plane after a contract for two or three months because the market could shift.” A buyer could walk away from a deal or demand different terms. “That time creates all kinds of headaches in a transaction.”

Alan Monk, manager of airframe service sales for Duncan Aviation’s Battle Creek, Michigan facility, noted that demand for pre-buys is cyclic and typically depends on the economy. “It seems to be strong right now,” he noted. “We do our absolute best to take every single one that we can.”

He said the capacity issue is likely the same at most MROs. “Coming out of the pandemic, backlog has just been way out beyond what we normally have seen for years and years. We’re talking people wanting to book 12 months out for small annual type inspections and 18 months to 24 months for anything significant,” Monk said. “That really makes us stretch and try to find solutions for pre-buys, which typically have nowhere near that kind of lead time.”

By the time a shop gets the call for one, typically, there is a letter of authorization signed, and the parties may be close to a purchase agreement. “They’re going to want to move the airplane late that week or early the next week, and sometimes, MROs can’t respond that quickly,” he said. “We try our best. We have some overflow capacity and hangars, and we can usually put together enough labor, but it’s a challenge.”

While the lead time for them varies, Duncan advises brokers: “Regardless of what you hear as far as our backlog, [reach out] and we will put our best foot forward.”

DAVID MAYER

ATTORNEY, SHACKELFORD, MCKINLEY, & NORTON

Duncan typically will assemble a team with expertise in the make and model of the aircraft incoming for a pre-buy inspection. “When a pre-buy comes in, we can adjust teams and work schedules a little bit,” he explained.

As far as the inspection itself, Duncan will accept specific lists that meet certain parameters. But the MRO has its own pre-buy check list that includes routine inspection items, functional checks, and visual checks that vary per airframe model. “We also have optional items that can go a little deeper if the buyer wishes.” The scope of the pre-buy is laid out in advance of the work, Monk noted, so buyers and sellers are aware of what it entails.

“The biggest thing is establishing what the pre-purchase inspection requirement is up front with the parties involved,” said Suresh Narayanan, founder and CEO of Jets MRO. “It’s not an official inspection.” Jets MRO will offer its own pre-purchase checklist, but he added, “We need something to sign off on or else it could turn into an unmanaged process. That’s what we want to avoid. The biggest thing is working with the parties to establish what is the requirement.”

Duncan will typically have its “squawk list” or discrepancy list ready after about 10 to 14 days, Monk estimated. “From there, there’s usually some negotiating between the representatives on both sides, and then if there are any discrepancies found, somebody will approve the work.”

Once completed, the aircraft is ready to return to service. However, he noted:

“From the time we are done [with the inspection] until we can return the airplane to service, that gap can be days, weeks, sometimes months, depending on the communication style between the buyer and the seller, how willing they are to work with one another, how quickly whoever is going to pay for the discrepancies approves us to work them.” And it varies by airplane, he added.

“If a problem is found, it can be weeks or even months to resolve it,” Mesinger agreed. This is particularly true if the problem is fairly extensive or complicated and if the necessary parts can’t be readily obtained. Then it could become an issue of how the costs of the work are passed along. That could become a negotiation between the parties.

Generally, the seller does the repairs within the scope. But if the work increases the cost significantly, the seller may hesitate to solely foot the bill. That may open the door to a negotiation, possibly a change in purchase price.

As far as primary problem spots, corrosion is a common theme across all models, Monk said. Some aircraft will have more than others. Fuel contamination, depending on where in the world the airplane’s been, is another major issue that comes up. Most of the rest of the issues tend to be less impactful, he said.

“We’ve seen the output of a bad prepurchase inspection,” said Jets MRO’s Narayanan. While doing a simple repair on a Cessna Citation, mechanics found severe corrosion from a lavatory that had been

leaking for two years. “I poked my finger through the belly of the aircraft,” he said, “it was so bad.”

The Citation had just emerged from a Phase 5 inspection and then the prepurchase inspection, neither of which caught the corrosion. “They had a bunch of issues that 100% should have been caught during the pre-purchase inspection,” he said. “We had to do this big repair to save it from scrap and basically redo the entire inspection that they already paid for.” The new owner, who thought he got a great deal on the Citation, had to wait another six months to get back in the air.

SUPPLY CHAIN WOES

A lot of the timing of the repair process also comes back to the supply chain. “We didn’t really have supply chain issues prepandemic. Then all of a sudden, we had supply chain issues on toilet paper and paper towels and engine parts and all kinds of things,” Mesinger said.

While it’s better, issues persist. Shops still can’t get some parts, and an aircraft could sit for a few months awaiting them. Mesinger cited as examples auxiliary power units (APUs) and landing gear. “If an APU comes out of an airplane and has to go into a shop, it’s not unlikely it will get stuck in the shop for two or three months because of a part,” he said. As for landing gear, he said, this “is the worst to find.”

“When you have an airplane sitting in a shop and the landing gear has been pulled out from underneath it and it’s on jacks, that’s wasted space for the shop because they can’t move the airplane,” he noted.

Another big issue involves engines, Mesinger added. “There are very few loaners. Engines come out and have to go off-wing and ship out to get work done, and they can’t get parts, and they can’t get a loaner. The airplane is sitting in a shop somewhere without an engine and can’t be flown. So, supply chain is still a real issue right now.”

“There is a lot unknown in the inspection and repair scenarios,” Mayer said. While

ALAN MONK

DUNCAN KBTL MANAGER AIRFRAME SERVICE SALES

SURESH NARAYANAN FOUNDER AND CEO JETS MRO

most inspections and repairs last a few weeks or months, he did say he has seen customized repairs that extended more than a year.

He also has heard stories where a windshield couldn’t be found anywhere in the world for a preowned airplane. “It takes months to find one or get one that you do find.”

Monk agreed “the lead time on some of those can be significant.” Duncan will try repair options for windshields rather than replacement, when possible. Ultimately, he has found, “the supply chain is better, but it still isn’t where it was pre-pandemic, and I don’t know when it’ll ever be.”

Throwing another wrinkle into this are tariffs, or the uncertainty of them. “We’re creating another complexity in our supply chain issue and cost issue,” Mesinger said. “It’s also the parts, it’s not just the whole airplane, that could be impacted by the tariff.”

Mayer further expressed concern that the potential U.S. and reciprocal tariffs may exacerbate the unavailability and costs of parts, components, and services. “The unpredictability of tariffs makes the risk calculation so difficult that some sellers have already pulled back from selling their aircraft or even consider defaulting on a signed sale transaction,” he said.

SHORTENING THE PRE-BUY

Another concern for Mesinger is the temptation to shorten the pre-buy. “To this day, there are dealers that are instructing buyers that an airplane just went through a big inspection six months ago or a year ago, and there’s no need to do a full pre-buy. ‘Let’s just take it around the patch, do a foreign object damage inspection of the engines, and look at the records.’”

Some buyers go along with that, he said. “That’s not a way we’d sell an airplane. I don’t care what was recently done to it.”

Jets MRO CEO Narayanan agreed. “We’ve had people ask us, ‘Can you do a general visual inspection and just sign it off ?’ We stay away from those. We focus on if we do our job, we should earn another customer. We get a lot of folks asking us for what we’ll call obscure pre- purchase inspections, and we say no to those, because I think it’s a recipe for disaster.

...the supply chain is better, but it still isn’t where it was pre-pandemic, and I don’t know when it’ll ever be.

— Alan Monk Duncan KBTL manager airframe service sales

“I’ve seen the output of non-defined pre-purchase inspections, and every MRO is different. They’re not all professionally standardized. We seek to be very professional in how we standardize it to avoid an issue like that. We have folks ask us, ‘Can you be cheaper or faster?’ We stay away from those discussions because we know what the output is, and it could be subpar maintenance or things signed off that weren’t properly looked at. We want to avoid that world completely and maintain a high level of reputation professionalism.”

Mesinger noted that if a seller is trying to dissuade duplication of work, it raises the question of whether there is something they don’t want found. “A different set of eyes [and] a six-month period between the event [may uncover issues]. Corrosion moves fast. That’s the kind of thing that you typically would have missed, corrosion.”

However, Mesinger does try to honor “nearby” inspections if done by a known

facility, and said there may be some carveout of some inspections.

Mayer is also seeing some opt out of a robust inspection, even though they should be the norm. “There’s a propensity to accept airplanes having a minimum inspection. That means a purchase from an inadequately informed position,” he said. “That can turn out to be an avoidable mistake. Maybe you do a boroscope, and you assume that’s good enough. That’s probably not good enough. It’s incomplete because an inspection facility can do a better review of the internal workings of all of the equipment, right down to coffee makers.”

Also, some buyers assume a newer model must not have issues. “Not so; there is an opportunity to miss a warranty repair or to cause a seller to repair items that are outside of warranty, even on newer airplanes,” Mayer said.

There may be issues that are unique to specific models, he noted. Quality brokers will know about them and should advise buyers so they are aware of them. “Making assumptions about a condition of an airplane that is well taken care of, even by a big company, is not a good idea because sometimes the owners just don’t find things,” he said.

Those types of pre-buy inspections, “a walk around plus review of books and records, are not uncommon still,” Mayer said. This pushes the risk of bigger problems onto the buyer. If they are emotionally attached to a certain airplane, “they’ll go ahead and buy it and take the risk.”

Despite the obstacles of the pre-buy, the preowned market has remained stable after the pandemic, with more inventory encouraging more sales. And the pre-buy is remaining a central part of that transaction.

“I think they’re vital,” Mesinger said. “They cause consternation, they cause headaches, they cause a lot of stress, but they’re absolutely critical when you’re purchasing a piece of equipment that’s this expensive and this complex.” z

Ambassador Program helping Corporate Angel Network spread its wings

BY AMY WILDER

When retired industry executive Bob Blouin received a call from Corporate Angel Network (CAN) president and CEO Robert “Bob” Stangarone asking if he’d be interested in serving in the new Ambassador Program for CAN, Blouin didn’t hesitate. The invitation was a chance to give back to an industry that had defined his life.

“Our paths had crossed many times over the years,” said Blouin, whose decades-long career has spanned senior roles at companies and organizations including NBAA, Bombardier/ Shorts, Hawker Beechcraft, Imperial Airlines, and Island Airlines, along with other organizations.

He and Stangarone had known each other since the 1980s, when the latter worked for Fairchild Dornier. Both had also worked in Wichita for a time—Stangarone at Cessna Aircraft, while Blouin was at the helm of the Hawker Beechcraft flight department. When Stangarone reached out about the new Ambassador Program last year, it felt like a natural progression.

The CAN Ambassador Program is a grassroots effort to expand the organization’s reach. Ambassadors are seasoned aviation professionals who leverage their extensive networks and industry knowledge to raise awareness about CAN’s mission of arranging flights aboard available seats on business jets for cancer patients to access care.

For Blouin, the decision was deeply personal and serendipitous. He and his wife Kathleen—also a former NBAA official— had spent years volunteering with Angel Flight, flying patients to hospitals like Children’s Hospital Philadelphia and Johns Hopkins. When they sold their Bonanza, they thought their days of service in medical transport were over. Then came Stangarone’s call.

“One door closes, and another door opens,” said Blouin. “It was like a month after we sold the airplane that Bob called and asked if we’d like to be Corporate Angel Network ambassadors.”

CAN’s new Ambassador Program is crucial in connecting more corporate

CAN provides cancer patients with free corporate jet travel to treatment centers as often as needed.

flight departments with patients who require transportation. Ambassadors like the Blouins visit flight departments, FBOs, and industry events to spread the word. And the work isn’t limited to formal interactions. The ambassador’s role is multifaceted. They’re part networkers, part storytellers, and part aviation evangelists. Blouin’s approach is hands-on and personal.

“We keep a packet of brochures and giveaways in our car,” Blouin says. “When we stop at a flight department or FBO, we always have something to leave behind.”

These personal connections help demystify the program and encourage participation. And that stems from the organization’s origins. Founded by Leonard Greene in the early 1980s, following his wife’s cancer diagnosis, and initially supported by cancer survivors like pilot Priscilla “Pat” Blum, who flew the organization’s first mission, CAN has always been about personal connection and compassion.

The program is deliberately flexible. Ambassadors might attend regional aviation events or spread the word through their networks. For Blouin, this means sharing CAN’s story at his monthly aviation lunch club, which includes retired pilots from various backgrounds.

One such conversation led directly to a potential patient. A fellow pilot mentioned a neighbor with metastatic breast cancer who needed transportation from Delaware to MD Anderson Cancer Center in Houston—precisely the type of mission CAN supports.

The ambassadors are still defining their role. Their first official meeting was a Zoom call, during which Stangarone and his staff provided guidance and answered questions for the scattered ambassadors. It’s a new program, less than a year old, but is already gaining momentum. More than a dozen industry executives, both retired and active, have signed up as ambassadors.

Social media plays a crucial role. Ambassadors are encouraged to share stories,

BOB BLOUIN RETIRED INDUSTRY EXECUTIVE

post about CAN, and use their networks to spread awareness.

“In this day and age of networking,” Blouin said, “the more we get the word out through social media, the better.” It’s about creating a ripple effect of awareness and support.

The Ambassador Program reflects a broader trend in aviation—using industry expertise for social good. For corporate flight departments, participation

offers more than just a charitable opportunity. It’s an opportunity to demonstrate corporate social responsibility and use aircraft more efficiently. “The majority of corporations use these airplanes as tools,” Blouin explained. “How can we use those tools to do something meaningful?”

For the Blouins, it’s more than a volunteer role. It’s a continuation of a lifetime spent in aviation, a way to give back to a broader community and an industry that has been their home for decades. “To give back through aviation,” he said, “is a wonderful thing to do when you’ve spent your whole career flying.”

As CAN’s Ambassador Program continues to grow, it represents an intersection of professional expertise, personal dedication, and compassionate service, proving that in aviation, there’s always room to lift others higher. z

LOOKING FOR AIRCRAFT FOR SALE?

SEARCH BY AIRCRAFT CATEGORY FROM TURBO PROPS TO LARGE JETS, BY MANUFACTURERS OR POPULAR MODELS.

Legacy Tails

Citation: Cessna’s revolutionary jet

BY DAVID DONALD

Looking like a production aircraft, the second Citation displays the modifications applied during prototype flight trials. The aircraft is now on display at the Kansas Aviation Museum in Wichita.

Cessna’s Model 500 Citation was a groundbreaker in several senses. It was the first successful entry-level business jet and the first to provide for single-pilot operations. It also brought Cessna—the world’s leading airplane maker in terms of production numbers—into the world of civilian jet aircraft, and the name “Citation” would become synonymous with the company’s top-line offerings through to today’s Ascend, Latitude, and Longitude.

Cessna cut its teeth on jet-powered aircraft in the early 1950s. The company’s Model 318 was one of eight projects bid for a U.S. Air Force competition for a basic jet trainer. Powered by a pair of ContinentalTeledyne J69 engines—a license-built version of the French Turbomeca Marboré turbojet that powered the MS.760 Paris light private jet/trainer—the Model 318 was successful and became the T-37 Tweet, of which more than 1,200 had been built by the time production ended in 1975. It also

spawned a light attack version, the A-37 Dragonfly, which accounted for another 577 airframes.

In the mid-1950s, Beechcraft—Cessna’s great rival and today’s stablemate within Textron Aviation—had secured a deal with Morane-Saulnier to market the four-place Paris as the first business jet in North America. In response, Cessna schemed a civilian light jet variant of the T-37, which was known internally as the Model 407. It had a fuselage stretched by two feet to accommodate four seats in a pressurized cabin.

Customer interest was poor, and only a wooden mock-up of the Model 407 was completed before the project was terminated. The private/business aviation market was not ready for the concept of a light business jet, and to validate Cessna’s decision, Beechcraft only sold two of the Paris jet and ceased marketing the type in 1961.

For much of the 1960s, the business jet market was dominated by larger aircraft such

as the Lockheed JetStar and North American Sabreliner, which were joined by the Dassault Falcon 20 and Grumman Gulfstream II. These high-end products lay outside the traditional markets of either Beechcraft or Cessna, which were both masters of cheaper, smaller aircraft that were aimed more at the general aviation market rather than the very rich, governments, and large corporations.

In 1964, the private/small company marketplace was revolutionized by the arrival of the remarkable Lear Jet 23, and to a lesser extent the Jet Commander 1121. They were far more affordable to acquire and operate than larger jets and appealed directly to a wide range of customers.

Beechcraft responded by securing a deal to market the HS.125 and also launched the turboprop-powered King Air. Cessna had no immediate answer to the King Air, and it was not until the mid-1970s that it adopted turboprop propulsion with the Model 441. Instead, it identified a clear gap in the

market between the King Air and the Lear Jet, a gap that could be filled by a jet that was faster than the turboprop aircraft, yet cheaper to buy and operate, more versatile, and easier to fly than Lear’s “rocket ship.”

FANJET 500

In October 1968, Cessna launched its new program, then known as the Fanjet 500. The financial gamble was considerable: various estimates put the cost of the project at between 35% and 50% of Cessna’s net worth. However, with production of piston-engine aircraft drastically dwindling in the early 1970s, the decision to proceed could be said to have kept the company afloat.

It was an eight-seat aircraft with a cabin and two-place cockpit mounted ahead of the main spar, although it was usually operated with five seats in the cabin. The fuselage design with a flattened oval nose section drew on that of Cessna’s large twin-piston aircraft. A straight wing was adopted to provide ease of flying and to keep approach speeds low, albeit at the penalty of a modest cruise speed of 411 mph compared to the Lear Jet’s 518 mph, a fact that drew sneering comments and derogatory nicknames from its competitors.

With high speed not the principal design driver, Cessna could reduce cost and complexity through features such as leaving the mainwheel doors uncovered after retraction. Moreover, the low approach speed and frugal runway requirements permitted the Model 500 to use many more airfields than its rivals, and it could also operate from semi-prepared strips.

As its name suggested, the most innovative of the Fanjet 500’s new features was its fuel-efficient turbofan powerplant, which was considerably more efficient than the thirsty turbojets of the Lear Jet. The aircraft was the first application for the Pratt & Whitney Canada JT15D, which went on to power several aircraft types, including the Mitsubishi Diamond/Beechjet and Aérospatiale Corvette business jets.

Having first flown in a pod carried by an Avro Canada CF-100 fighter, the JT15D-1 for the Fanjet 500 had a bypass ratio of 3.3 and developed 2,200 pounds of thrust at maximum takeoff power. It had a centrifugal compressor. The initial version employed an outsize fan from the JT9D engine, but later versions such as the JT15D-4 for the Cessna 550 Citation II had a smaller fan and an axial booster component, with a corresponding reduction in bypass ratio to 2.6.

As development continued, the Fanjet 500 received the new name of Citation, after the Triple Crown-winning champion racehorse. The name has stuck throughout the development of Cessna’s jet aircraft family, along with the associated horseshoe logo.

Milt Sills and J.L. LeSueur took the prototype Citation 500—appropriately registered N500CC—aloft for its first flight in Wichita, Kansas, on Sept. 15, 1969. Flight trials uncovered several issues, and development was relatively protracted. Changes made to the design included a lengthening of the forward fuselage and relocation of the engine nacelles. The tailfin was enlarged and more dihedral was added to the tailplanes. Certification was finally granted after two years of flight tests on Sept. 9, 1971.

CITATION INTO SERVICE

With a unit cost of just $695,000, the Citation 500 was an attractive proposition for many customers with limited budgets. Sales

were brisk and included high-profile buyers such as golfer Jack Nicklaus, who replaced his JetStar with a Citation in 1976. Initial operators found the Citation not only cheap to operate but pleasant to fly with no surprises. Cessna’s original intentions to make the type no more challenging to handle than its Model 421 piston-twin were achieved.

While Citation sales flooded in, Cessna continued to develop the type. In 1972, a bleed air system to deice the windshield replaced the original electrical system. The first major development was the addition of thrust-reversers as an option in 1974. That year, a new pressurization controller was introduced that permitted operations at up to FL410 instead of the previous authorized limit of FL350. From late 1975, Collins Pro Line avionics replaced the original RCA system, and in the following year, gross weight was increased by 1,000 pounds to 10,850. At around the same time, longer-span wings were introduced.

These new features were incorporated into the first new variant, the Cessna 500 Citation I, which was introduced in late 1976. It also had improved JT15D-1A engines, offering better performance, while cabin pressure at altitude was increased for greater cabin comfort. A sizeable number of original Citations were re-engined with the JT15D-1A.

Another important development became available in early 1977 in the form of the

Wearing “Fanjet 500” titles, the mock-up is displayed next to the Model 500’s fuel-e cient JT15D-1 turbofan engine.

Legacy Tails

Model 501 Citation 1/SP, which was certified for single-pilot operation. This further cemented the Citation’s position as the entry-level jet of choice and became particularly popular amongst the growing community of owner-operators.

Cessna had always envisioned the Citation as a single-pilot aircraft, and had designed the original cockpit with most of the system switches on the left-hand side. With an mtow of 11,850 pounds, it was under the 12,500-pound limit for Normal category certification. However, the desire to provide Cat II approach capability with only one flight director/ autopilot was deemed by the FAA to impose too great a workload on a single pilot, and the Model 500 was certified in the transport category. Substituting the original Bendix FGS-70 with a Sperry SPZ500 flight guidance system satisfied the FAA that the Citation could be certified in the Normal category for single-pilot Cat II operations, and with this system, the Model 501 was born.

Production of the 500 and 501 models came to an end in 1985, with 689 built, and by that time Cessna was committed to follow-on models. The most important of these was the Model 550/551 Citation II, a stretched eight/10-place variant with JT15D-4 engines.

This first flew in January 1977, and by the time production ended in 2006, more than 1,000 had been built, including the Citation S/II and Citation Bravo models. Both of these had supercritical airfoil wings, while the Bravo introduced PW530A engines. Further development resulted in the Model 560 Citation V/Ultra/Encore family, stretched from the Citation II.

Another Citation I-derived family emerged in the mid-1970s in the form of the Citation III. This was originally a long-range development with three JT15D-1 engines but emerged as the Model 650—a larger, T-tailed, swept-wing aircraft powered by a pair of Honeywell TFE731 engines and with a standing- room cabin. Its Citation VII development became

Cessna’s flagship business jet before it was usurped by the larger Citation X and subsequent Citation-branded models.

Despite carrying the same name, such aircraft can fly much faster, reach a lot farther, and carry far more than the original Citations. Today’s true inheritors of the pioneer’s entry-level DNA are the variants of the six- to 10-seat Model 525 CitationJet family. This was based on the forward fuselage of the Citation II, with straight wings, Williams FJ44 engines, and a T-tail. More than 2,000 have been delivered since the type’s first flight in 1991. The basic Model 525 also provided the basis for a tandem two-seat military jet trainer—the Model 526 CitationJet—which was unsuccessfully bid to replace the long-serving Cessna T-37.

LONG-LIVED CITATION

Despite the arrival of newer models, the original Citation continues to be an operational success and a regular sight around the world. Sierra Industries developed a Longwing modification package for early Citations that became popular. It added wingtip extensions that had beneficial effects on range, climb rate, cruise altitude, landing speed, and fuel economy, and added new deicing boots. More than 120 aircraft received the upgrade. Sierra later introduced the Stallion and Eagle II upgrades, which replaced the JT15D engines with better-performing and more efficient Williams FJ44s.

In recent years, the Model 500/501 has remained a popular aircraft, thanks to its ease and cost of operation and its low purchase price. It still plays its part in the used aircraft market, particularly the modernized aircraft.

In 2015, a Textron Aviation technical report noted that fleet size numbered 586 aircraft and that they had logged more than five million flight hours. The fleet leader at the time had amassed 25,547 hours: the Model 500/501 has no specified airframe life limitations. z

Although the first Model 500s required two pilots, especially during Cat II approaches, the cockpit was designed from the outset with single-pilot operation in mind.

INTRODUCING CALS EUROPE

SEPTEMBER

15 - 17, 2025

| BASEL, SWITZERLAND

“The AIN CALS event has been a refreshing experience for leaders within the corporate aviation community and the vendors that support their businesses. 100% engagement for 2.5 days. Truly a working event that leaves us all a bit tired but very enthused!”

–

2024

CALS FLIGHT DEPARTMENT ATTENDEE

“The AIN CALS event provides excellent opportunities for high level interaction between vendors and clients. The one-on-one time and small group sessions are very valuable settings.”

– 2024 CALS SPONSOR

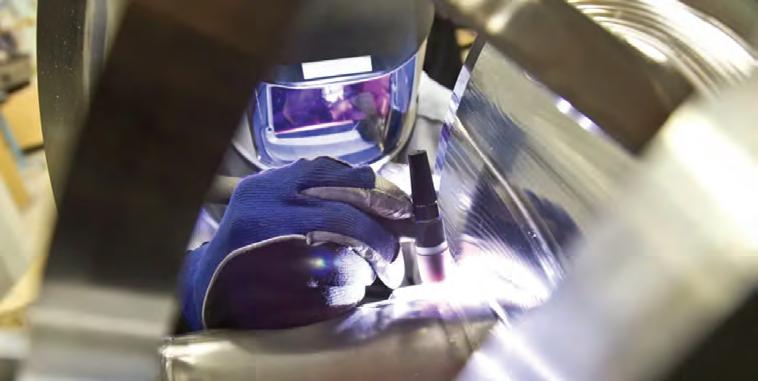

Managing the supply chain through turbulence

BY AIN STAFF

As the market evolved post-Covid, operations came roaring back and, along with it, demand on global aerospace suppliers. Demand alone presented challenges, but other issues have placed pressures on the supply chain, from regional conflicts and workforce shortages to one-off disruptive events such as a factory fire at SPS Technologies in Jenkintown, Pennsylvania. AIN brought together thought leaders in the supply chain and broader market to share insights on how the industry is tackling these challenges. Here are highlights from those discussions. FDH Aero sponsored this roundtable

AIN ROUNDTABLE

IAN WALSH CEO OF FDH AERO

THE PARTICIPANTS :

Walsh joined FDH Aero this year with 35 years of leadership experience, including as chairman of Kaman Aerospace and COO of REV Group, along with senior roles with Textron. With a more than 60-year history, FDH Aero is one of the largest independent aerospace distributors, supplying hardware, electrical, and other products and services across the military and civil aerospace markets with 14 locations globally and 1,500 employees.

ALEX TRAPP SENIOR V - P OF BUSINESS DEVELOPMENT FOR STANDARDAERO

Trapp, who joined StandardAero in 2016 after serving as v-p commercial at Rolls-Royce North America, leads enterprisewide strategy development and activity around new engine platforms, joint ventures, and mergers and acquisitions. StandardAero o ers engine and component services for business aviation, commercial aviation, military, fixed-wing, helicopter, and industrial power customers. The company operates 49 primary facilities worldwide with 7,500 employees.

MIKE STENGEL PARTNER AT AERODYNAMIC ADVISORY

Stengel joined AeroDynamic in 2017 after serving with ICF International’s aerospace practice. At AeroDynamic, he oversees the firm’s aftermarket-related intellectual property and has led or contributed to more than 100 consulting engagements surrounding business strategy, market analysis, and transaction advisory for clients across the aerospace industry. AeroDynamic provides expert aerospace consulting services in areas of strategy, growth, and transaction support for OEMs and aftermarket organizations.

JAMES ALLEN — CHIEF PROCUREMENT OFFICER OF GKN AEROSPACE’S CIVIL BUSINESS

Allen joined GKN Aerospace’s Civil Business in September 2023 with a background in asset management and procurement with companies including Arriva Group, where he served as chief procurement o cer, and Babcock International. GKN Aerospace is a global tier 1 supplier of airframe and engine structures, landing gear, electrical interconnection systems, transparencies, and aftermarket services for commercial and military aircraft.

IAN WALSH

ALEX TRAPP

MIKE STENGEL

JAMES ALLEN

THE DISCUSSION

ON THE STATE OF THE SUPPLY CHAIN AND HOW IT HAS EVOLVED

IAN WALSH It is a very complex, evolving problem. In business, we love stability, but the reality is there’s constant variation. Everybody witnessed Covid as a unique situation that created a very dramatic shift in the availability of materials and parts.

Before Covid, the [OEM] environment was, “Let’s put the thumbs on everybody so we can get costs down.” People were trying desperately to become much more affordable manufacturers, and they found that it actually had the opposite effect. It compromised quality; it compromised a lot of things. Then Covid hit, which created another shift, and that was about availability.

After Covid, the premium now is not around cost. It’s not around availability. It’s actually full circle. It’s around quality. Are you a reliable quality supplier? People will pay a premium for that versus before, when it was a constant battle to find a low-cost solution.

FDH is striving to demonstrate that we are the most reliable, capable, and quality supplier out there.

ALEX TRAPP The supply chain in the aerospace business pre-Covid and postCovid has always been challenging. It’s always one part, one group of parts, one supplier, or one OEM or another that is having a particular challenge, and that varies. We’re pretty used to that, especially in MRO.

Some things have changed since Covid, with the uptick in supply and demand and the geopolitical impacts on the general supply chain. But things have evolved where you look to diversify your supply base and digitize your supply chain. And so, some positive things have accelerated.

MIKE STENGEL I think the most obvious impact that we’re seeing from all these kinks and bottlenecks is that the fleet has

gotten older quickly over the last five to six years. It started with the [Boeing] Max grounding, and then it was accelerated by the downshift in aircraft production and deliveries during Covid. In 2022, the airlines were expecting to get their Maxes and [Airbus] Neos that they deferred back pretty quickly. Then, that didn’t happen. It’s been a slow ramp-up. There have been some other issues, like the Boeing strike. Now that’s behind them.

But we don’t expect aircraft production to get back to pre-Covid levels until about 2028. Meanwhile, air travel demand is back above 2019 levels. So, you have this gap in air travel demand versus supply of aircraft.

We’re not out of the woods yet. There’s still a lot more downside risk that things continue to slip to the right. There are still a lot of kinks in the supply chain. I call it a game of Whac-a-Mole: as soon as one issue is solved, another unexpected issue arises. Like back in February, there was the fire at a key fastener facility in Jenkintown, Pennsylvania. So, it’s going to be a bumpy ride back up for sure.

JAMES ALLEN I think in recent months we are seeing some stabilization. Before Covid, we had growth in volumes of aircraft produced and in defense programs. That ramp-up was incremental. OEMs were at record volumes pre-Covid, went to almost zero [during Covid], and then recovered back at a pace that was multiples faster than they’d ever ramped up in the first instance. The speed of the ramp-up post-Covid put incredible stress on the supply chain.

During Covid, the supply chain had challenges in terms of deferred investment and people leaving the workforce. So, we’ve had a perfect storm in terms of an unprecedented speed of ramp-up with a supply chain that had been weakened by what had happened during Covid.

At GKN Aerospace, that situation is stabilizing now. We expect further increases to come, but it’s slowed certainly from 2024

to 2025, and that allows the supply chain time to stabilize and to recover.

We have particular challenges in specific niches, and that might be of a product type a particular geography, or transportation links. Those aren’t systemic issues, but they’re things we’ll have to manage.

ON MANAGING THROUGH SUPPLY CHAIN UNCERTAINTIES

IAN WALSH Something that we’re looking at, which is not out of the ordinary, is trying to become closer with our suppliers. The other part of it is to get closer to our customers and understand their needs and how predictive they can be in their schedules.

Even though a Boeing or an Airbus or whoever will tell you a schedule, many times those move around. And, certainly in the aftermarket side, it’s very unpredictable. When maintenance needs come up, [some parts can be] hard to source.

The types of parts that we do are small consumable things—hundreds of thousands of different types of parts, and no single bolt or collar is the same. You can’t be everything to everybody. You’ve got to focus on certain families of parts, things that we feel are the right parts in terms of how we like to source and distribute. So, we’re trying to understand the global supply base.

It’s not overly complex. You can’t wait for the phone to ring. You’ve got to be tight with your supply base and your customer base.

JAMES ALLEN We invest a lot of time, resources, people, and technology into how we manage our supply chain. You’ll always have to manage those challenges. Looking forward, I think the production rates will start to increase again in the period to the end of this decade. That will undoubtedly unveil some new challenges that we’ve got to solve to get there.

The fire in Pennsylvania impacted a large part of the supply chain; it was

significant. So, we spent a lot of time understanding what the impact would be and how good the mitigations we had in place were.

Structurally, in our supply chain, we carry an appropriate level of inventory— not necessarily us carrying it, [but] people in the supply chain carrying that on our behalf. That protected us from the immediate impacts of the fire. That gave us the time to solve the problem in terms of understanding the challenges of the availability of specific parts, and if we need to find alternative sources.

We work to have the right amount of stock or inventory at the right level, and whether we hold that or whether it’s held within the supply chain, that provides a degree of buffer effectively against shocks.