Custom built for Agtegra farmers.

TM

TM

Custom-built planters for Agtegra farmers.

Every ARx Planter™ is unique to each farmer and their operation.

Starting with the bare planter bar, Agtegra Innovation Center specialists work with you to custom design and build your planter.

Every component decision is yours to make!

We partner with brands like Harvest International™, Precision Planting® and Yetter® and even manufacture components in house.

Planters are then assembled right here in Agtegra territory at your local Innovation Center.

All registered trademarks are property of their respective owners.

We trial and select the bestperforming base components to give your planter a strong start.

STANDARD FEATURES

After years of maintaining, upgrading and fixing our farmers’ planters and researching and trialing products, we’ve assembled the best parts on the market to give each ARx Planter™ a strong base to integrate and add components to. Standard features include:

• Harvest International™ UltraPlant™ Series Bar

• Precision Planting® Gen3 20|20® Monitor

• Precision Planting® vDrive® drive system

• Precision Planting® vSet® seed meter system

• Precision Planting® DeltaForce® automated downforce control

Choose the row unit, seed delivery system and closing system that best works for your operation from our list of recommended suppliers and parts.

We build ARx Planters to be color blind to the tractor that runs them.

ADD-ONS

Each farming operation has different challenges and needs. You can choose to add features to your ARx Planter, such as:

• Seed delivery sensors and monitors

• Depth control

• Seed firmers

• Row cleaners

• Fertilizer application systems

• Fertilizer rate control and monitor systems

Many of these add-on features are highly recommended to add to your planter. Your Agtegra Innovation Center specialist will assist you as you make individual component decisions.

You choose which add-ons best fit your operation.

All registered trademarks are property of their respective owners.

PLANTER BAR

We start with a planter bar and build from there! We recommend starting with a Harvest International™ UltraPlant™ bar, which is built for high-speed planting and designed for integration with Precision Planting® technology. Harvest International bars are engineered for versatility, strength and precision and are available in 20’ - 66’ models and many row spacing configurations.

Features:

• Highly customizable row spacing: 15”, 20”, 22”, 30”, twin row, etc.

• Internal vacuum port significantly minimizes external hoses & tubes.

• External steel hydraulic tubes are easier to service & increase oil cooling.

• 10’8” - 13’8” narrow front-fold frame transport.

• Front running or rear running tire configurations.

• Series 2 models feature innovative CommandLift™ independent control hydraulic system.

Main Options:

• Central Seed Delivery w/ 55+bu per bin

• Row Markers

• Many onboard storage capabilities for liquid fertilizer application

• 16.5”-25” tracks available for PB40’ & PB60’ Series models

• 450/55R22.5 & 620/40R22.5 Center Tire upgrade for PB40’ & PB60’ Series models

• Hydraulic wing weight transfer system for Series 2 models only

Start with a strong base for your planter and choose a bar that is engineered for versatility, strength and precision.

All registered trademarks are property of their respective owners.

DISPLAY MONITOR

We recommend using a Precision Planting® Gen3 20|20® Monitor, which maps fields in highdefinition, diagnoses equipment and gives you control over your most challenging applications.

The 20|20 monitor can also monitor and control air seeders and drills, sprayers, combines and liquid or dry fertilizer applicators.

Gen3 20|20® Monitor

The 20|20 monitor provides the most advanced agronomic mapping you’ve ever seen. Optimize planting decisions with a smart, intuitive interface that visualizes performance and field conditions in real-time, seed by seed. The 20|20 can be utilized as a monitor to simply set the planter, but it also powers the most agronomically advanced systems on the market.

Customize display configurations, add sensors, and discover things about your field you may have never known.

Choose a monitor that leads you to better decisions as it monitors, controls, and diagnoses your field conditions and equipment performance in real-time.

All registered trademarks are property of their respective owners.

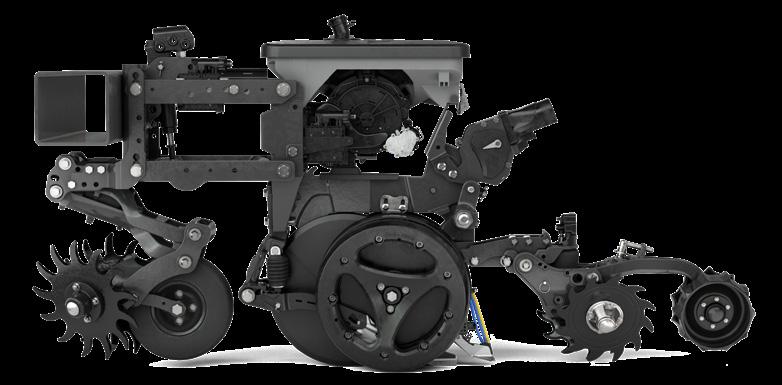

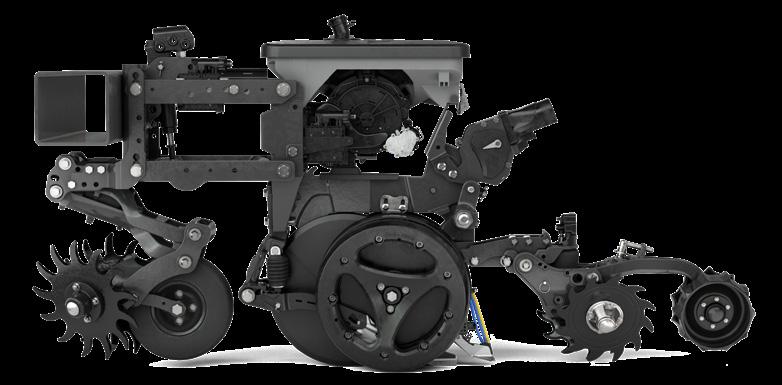

YOU CHOOSE: ROW UNIT

There are plenty of original equipment manufacturer (OEM) row units available on the market, or we recommend a Precision Planting® unit or Harvest International™ LaserPro 1® unit.

Ready Row Unit

The Ready Row Unit is a solution that allows you to keep your existing planter frame, but upgrade to new row units and technology, for a fraction of the cost of a new planter.

LaserPro 1®

• Laser-cut, high tensile steel construction

• QuickRelease™ closing wheel mount

• Hydraulic Down Force-Ready X-Plate

• Parallel link arms w/ tapered, highstrength polymer bushings

• Lateral closing wheel adjustment

• Built-in camber adjustment to easily adjust gauge wheel angle to stay true against disc openers

• Greaseless lateral adjust on gauge wheel arm

• Keeton Seed Firmer™ bracket factory installed

• Designed for use with Precision Planting and Ag Leader® products

Select a row unit that is compatible with the add-on features you want to install on your ARx Planter™.

All registered trademarks are property of their respective owners.

SEED METER & DRIVE SYSTEM

We recommend Precision Planting® vDrive® drive system and vSet® seed meters for the best seed control without maintenance headaches. A vDrive motor is mounted to each vSet meter, controlling each row individually with an electric drive system. vDrive allows for variable rate seeding, individual swath control and steady plant populations on curves.

Maximize genetics and efficiency by pairing multi-hybrid planting with high-speed planting when you combine vDrive® with mSet® to plant multiple hybrids with one vSet® meter.

Control your vDrive with the 20|20® monitor to see high-definition, real-time mapping, visualize seeding data, change the population on the go, manually or automatically control swath and see individual row diagnostics.

vDrive®

Mechanical drive systems require costly and timeconsuming maintenance. vDrive is a maintenance-free electric drive system that lets you breeze through planting without the headaches of a mechanical drive system.

vSet®

Traditional seed meters need continual adjustment to plant accurately which leads to skips, doubles, and ultimately, lost yield. vSet seed meters singulate seeds accurately without any adjustments, resulting in perfect seed placement throughout your field.

mSet®

Typical planters only allow you to plant one seed hybrid at a time, which doesn’t allow you to match hybrid to the field environment. mSet is a multi-hybrid planting system that allows you to plant two hybrids using a divided hopper with one vSet meter.

Seed sizes vary. Select a drive system that provides accurate planting populations.

All registered trademarks are property of their respective owners.

YOU CHOOSE: SEED DELIVERY

Most planting seasons have weather challenges that make it difficult to plant all your fields in ideal conditions. We recommend Precision Planting® SpeedTube® seed delivery system that allows you to plant at high speeds without compromising seeding accuracy.

WaveVision®

Traditional seed sensors count dust and seed, giving you inaccurate population counts. WaveVision is a seed sensor that counts only seeds and not dust, giving you confidence that the population you see on your monitor is the population that you’re planting.

SpeedTube®

SpeedTube is a seed delivery system that allows you to double your planting speed without sacrificing performance. Use with mSet® for high-speed multi-hybrid planting.

Delivering seed to the furrow accurately and efficiently is vital to achieving yield goals.

All registered trademarks are property of their respective owners.

DOWNFORCE CONTROL

While there are other downforce control systems to choose from, we recommend Precision Planting® DeltaForce® to automate the optimal downforce on your row units.

The 20|20® monitor provides downforce metrics by row inside your cab so you can quickly ensure all rows have enough downforce to maintain 100% ground contact. You can see exactly how much margin each row is carrying or how often that row is losing contact with the ground on the downforce details page. You can also view side-by-side maps to see which rows are working harder to achieve consistent downforce.

DeltaForce®

Running a single downforce setting across an entire field causes yield loss because the setting is rarely correct. DeltaForce is an automated row by row downforce control system that measures and adjusts downforce every time there is variability in your field, so your crops will thrive for optimal yields.

Consistent downforce on a row unit is important for uniform seed placement and emergence.

All registered trademarks are property of their respective owners.

YOU CHOOSE: DEPTH CONTROL

The same depth setting doesn’t mean consistent depth. With a depth control system, you’ll be able to make precise depth changes from the cab, enabling you to respond to changes in conditions immediately and effortlessly.

In the image, all planting depths have adequate moisture. However, when planting into adequate moisture, a shallower setting emerges better.

If planted too shallow, seeds potentially are not in moisture and will not germinate consistently. As seen in the plants to the left, planting deeper than necessary will cost you emergence speed and consistency due to less heat being available at the deeper depths.

SmartDepth®

Adjusting depth on your planter is timeconsuming. SmartDepth allows you to quickly and easily make depth adjustments, from inside the cab, as conditions change. This saves you time and gives you the confidence that each row is set right where you need it to be.

While getting seeds into moisture is important, there are tradeoffs to planting too deep or too shallow.

All registered trademarks are property of their respective owners.

YOU CHOOSE: SEED FIRMER

While there are many seed firmers to choose from, we recommend Precision Planting® SmartFirmer® or Keeton® firmers to make sure your seed makes it to the bottom of the furrow.

You can also select to use a FurrowJet® Compatible SmartFirmer that is designed to sit in front of FurrowJet on the same row unit. FurrowJet firms the seed in the trench and places bands of fertilizer on and near the seed.

Pair your SmartFirmer with a 20|20® monitor to get real-time feedback on every inch of the furrow,

including organic matter, seed-available moisture, clean furrow, live CEC data and temperature.

SmartFirmer®

Digging a few seeds per field doesn’t give you a complete picture of whether your depth setting is correct. SmartFirmer is a seed firmer-sensor that measures the amount of moisture available to the seed, organic matter, and temperature, so you can adjust your depth correctly and know you will have a consistent crop stand.

Keeton®

When seeds don’t make it to the bottom of the furrow, there is an air gap that causes a delay in emergence. Seed firmers press each seed to the bottom of the furrow to improve seed-to-soil contact and give you a crop stand you can be proud of.

A consistent environment is essential for uniform seed germination and plant growth.

All registered trademarks are property of their respective owners.

YOU CHOOSE: CLOSING SYSTEM

While there are many closing systems to choose from, we recommend Precision Planting® FurrowForce® or Copperhead Ag® Furrow Cruiser® systems for the best seed to soil contact.

Customize your closing system with wheels that match your soil conditions. You can also choose to add load sensors and control modules to automate and maintain your desired pressure.

We also partner with Yetter®, Martin-Till®, Pro-Stitch and many more closing system manufacturers.

FurrowForce®

Setting your closing system correctly is tough.

FurrowForce is a two-stage closing system that adapts to your planting conditions to remove air pockets and firm soil to keep moisture, giving you confidence that your crops will germinate the best that they can.

Furrow Cruisers use a wide wheel combined with a spike to crumble sidewall compaction and firm the soil around the seed on both sides of the seed trench, leading to the best seed depth and most even seed emergence possible.

Closing systems provide consistent seedto-soil contact, a necessity for uniform emergence.

All registered trademarks are property of their respective owners.

Furrow Cruiser®

YOU CHOOSE: ROW CLEANER

While there are many row cleaner options to choose from, we recommend using Innovation Center® Residue Commander or Precision Planting® Reveal™ for the best emergence outcome.

We also partner with Yetter®, Martin-Till® and many more row cleaner manufacturers.

Residue Commander

Air cylinders can crack and leak over time, and air lines are often destroyed by stalk residue. Residue Commander hydraulically controls your trash whippers from the cab.

Reveal™

Row unit-mounted row cleaners hurt row unit ride and affect down force requirements. Reveal is frame-mounted, removing its impact on the row unit. With its own internal gauge wheel, Reveal precisely controls the depth of the cleaning tines to create a consistently clean and ideal seeding environment for even emergence to occur.

Keeping residue out of the seed trench is imperative to get consistent germination and emergence.

All registered trademarks are property of their respective owners.

YOU CHOOSE: FERTILIZER APPLICATION

There are several fertilizer application systems on the market that can be added to your planter.

Select a system that places fertilizer where you want it (reference the photo and legend below).

Fertilizer placement location:

• Conceal® (pictured)

• Bandit™

• Totally Tubular

• Keeton® Seed Firmer

• Wave™

• V-shots

• L&D

• FurrowJet® (pictured)

Conceal®

Banded nitrogen placement

FurrowJet®

In-furrow starter fertilizer placement

Keeton® Seed Firmer

Seed firmer that also acts as a liquid application tool

BANDIT ™

Banded nitrogen placement

Creates a wave of moist soil that rolls over the seed WAVE ™

Fertilizer Tubes

In-furrow starter fertilizer or banded nitrogen placement

V-shots

In-furrow starter fertilizer placement

L&D Ag Starter Kits & Placement Tubes

Complete starter fertilizer kits and placement tubes

Applying a starter fertilizer at planting time improves earlyseason uptake, nutrient use efficiency, and crop growth under cool and moist soil conditions.

All registered trademarks are property of their respective owners.

YOU CHOOSE: FERTILIZER RATE CONTROL & MONITOR

While there are several fertilizer rate controllers and monitors on the market, we’ve narrowed our preferred list of products based on our research and past customer experiences.

vApplyHD®

A single device that uses a pump control module and control modules on the toolbar that control flow, measure flow and swath.

FlowSense™

FlowSense allows you to measure the rate of fertilizer you are applying on each row of your planter or sidedress bar, to make you aware of any row-to-row variability that is occurring so that you can be confident in your application rate.

Rate Control Module

User-friendly universal controller for hundreds of applications.

JD Rate Controller

Controls liquid or dry products simultaneously.

OnSite FMS

Accurate real-time flow rates using individual flow meters to digitally monitor the amount of liquid being applied to each row.

Wilger Visual Ball Flow Indicator

Simple gauge that allows you to visually monitor proper flow rate of your liquid fertilizer and herbicide applications.

Control your application from the cab with a monitoring system that integrates with your ARx Planter™.

All registered trademarks are property of their respective owners.

32491

INNOVATION CENTER LOCATIONS Agtegra Innovation Centers are conveniently located throughout Northeast SD.

133rd Street Aberdeen, SD 57401

725-1890 BATH INNOVATION CENTER

4th Street NW Huron, SD 57350

846-1212 HURON INNOVATION CENTER

39278

(605)

800

(605)

US Hwy 12

SD 57428

846-1047 BOWDLE INNOVATION CENTER

Bowdle,

(605)

Don’t farm close to an Innovation Center? We deliver and service on-site. 94 Eldridge Jamestown Bath Fargo Bowdle Huron Steele Legend:

Bath, SD (605) 725-1890 Huron, SD (605) 846-1212 Bowdle, SD (605) 846-1047 www.agtegra.com ©2024 Agtegra Cooperative.