AgriScope

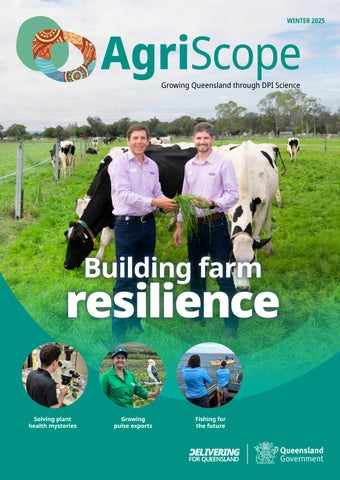

Paul Roderick.

The Roderick family has been farming at Tredegar Park at Harrisville in Southeast Queensland for over 150 years. It’s a legacy that 5th generation farmer Paul Roderick wants to continue.

“I’ve got two boys who might want to farm one day,” Paul said. “So being able to continue to do that in the future is one of the things that drives me.”

Droughts, floods, feed shortages, market fluctuations – the Rodericks have experienced it all and they know just how important it is to protect their dairy business.

“Our biggest challenge that we face here on farm is the weather. When it’s dry, feed costs more because it’s harder

Paul Roderick and DPI extension officer

Roslyn D’Addona on the Rodericks’ Harrisville dairy farm, Tredegar Park.

Behind every glass of milk, prime cut of beef and bale of cotton lies a primary producer and their farm. But even the most skilled businesses need a little extra support.

Our extension officers are giving producers the tools they need to build strong and sustainable businesses as part of the Farm Business Resilience Program, a collaboration with the Australian Government’s Future Drought Fund.

From enhancing the strategic management skills of grain producers to helping livestock producers beef up their environmental resilience and addressing the unique challenges faced by dairy farmers, we’re actively supporting farmers to plan for and navigate risk.

Since 2022 we’ve worked with industry partners to support more than 2,150 producers to holistically assess their farm’s performance, and over 1,400 producers have successfully developed or updated their farm business resilience plans.

Want to get involved? Read more about the Farm Business Resilience Program.

to get. So every bit that we can grow and store on farm is one less thing to worry about.”

The Farm Business Resilience Program, through developing a resilience plan and framework, has provided the Rodericks with a far more effective way to do business and manage risk.

“We already had an idea of where the business was going and what some of our priorities were, but what the resilience framework really highlighted was the cost of production around feed and our limitations with irrigation.”

An effective irrigation solution was particularly needed on a 40-hectare block adjoining the Rodericks’ original family farm. Purchased in 2000 to grow forage crops for conserved fodder, this block was serviced by a single hard hose travelling irrigator.

Our DPI dairy extension team provided technical advice on the expected boost in forage production and energy efficiency gains a new centre pivot could deliver. They projected a new pivot irrigator would provide an extra 50 days of stored feed annually for the Rodericks’ 400-cow milking herd.

They also assisted with the Rodericks’ successful application for a drought preparedness grant, which covered 25% of the new pivot’s cost.

“The new pivot system has allowed us to broaden our horizons in what and how much we grow. We’re now growing twice as much feed.

“It really sets us up for the future. We can have a reserve of feed and put away extra silage for the dry times. It’s one less piece of the puzzle we’ve got to worry about.”

They might be small, but flies and other insects play a big role helping us deliver cutting-edge research and innovation to safeguard Queensland’s agriculture industries.

Maintaining insect colonies – from fruit flies to common house flies – allows us to study their life cycles and genetics, the diseases they spread, their resistance to insecticides, and the effectiveness and safety of new control methods.

Our sheep blowfly colonies are crucial in the fight against flystrike, allowing us to test new chemical and natural solutions that could offer prolonged protection for sheep. A new project led by Dr Mona Moradi in collaboration with Australian Wool Innovation is exploring the potential of nanotechnology to deliver eco-friendly biopesticides made from Australian tea tree oil.

“Producers are facing the challenge of sheep blowfly resistance to current chemical treatments, but there are a number of other reasons – like consumer preferences – to move towards safer, more environmentally friendly alternatives with fewer residues,” Mona said.

“We’re hoping to overcome the limitations of current delivery methods by developing a nano-formulation that enables tea tree oil to provide extended, low residue and safe protection against sheep blowfly.”

Flies are also playing a central role in the market access research undertaken as part of the Fresh and Secure Trade Alliance (FASTA) - a national initiative with Hort Innovation and numerous research partners.

“Fruit fly is arguably the single biggest pest threat to Australian horticultural exports,” senior entomologist Brendan Missenden explains.

“We maintain fruit fly colonies in Cairns and Brisbane, housing between 200,000 and 300,000 insects at each location.

“Established from local pest populations, our fruit fly colonies are reared under ideal lab conditions, allowing for rigorous, controlled experiments.”

Postharvest research involves infesting fruit and testing the efficacy of heat, cold, fumigation and other disinfestation treatments against all life stages for multiple species of fruit fly.

Export growth relies on our ability to ensure fresh produce arrives in market free of the pests of concern to our trading partners.

“Our trials often require demonstrating complete mortality in over 120,000 individual fruit flies to meet international standards for market access,” Brendan said.

We’re exploring innovative ways to keep Queensland’s seafood industry thriving while reducing impacts on threatened, endangered and protected marine species.

Our Fish-LIGHT (Low-Impact Gear and Harvest Technologies) program is taking a deep dive into smarter, more sustainable alternatives to gillnets so consumers can continue to enjoy fresh local seafood from our fisheries.

We’re trialling fishing methods from around the world that selectively target the species you love – like barramundi and whiting – while minimising unintended impacts on other marine life. We’re also developing and refining our own gears, putting them through rigorous real-world trials.

“It’s about finding that sweet spot,” Dr Sam Williams explains.

“We want to protect the livelihoods of our hardworking fishers, meet the demands of consumers and safeguard our fisheries for generations to come. It’s a balancing act, but one we’re tackling head-on.”

Our researchers are testing and tweaking low-impact gears to ensure they are not only environmentally sound but also practical and economically viable for fishers.

“We’re not working in isolation – the knowledge and experience of our commercial fishers are invaluable,” Sam said.

“Their input is shaping the development and refinement of these technologies, ensuring they are fit for purpose and can be seamlessly integrated into their operations.”

Rynn’s Seafoods – a Bowen-based family-owned fishing business encompassing seafood processing, wholesale and a fish and chip shop – is taking part in the trials.

Owner and operator Travis Rynn is passionate about finding a solution that safeguards the future of the fishing industry for future generations.

“We have to think about our employees and our consumers – we want to make sure the industry survives and that our community can still enjoy fresh-caught local seafood at affordable prices,” he said.

“At the end of the day, we need to find fishing apparatuses that can commercially and viably harvest seafood for the consumer. As a fisher and business owner I want to be part of finding that solution and securing our future.”

Fish-LIGHT is co-funded by the Queensland Government and Fisheries Research and Development Corporation.

Dr Temitope Jekayinoluwa (GRDC), Agri-Science Queensland executive director Wayne Hall (DPI), Rebecca Raymond (GRDC) and Merrill Ryan (DPI) inspecting a trial

Queensland’s pulse industry is spreading its wings thanks to the launch of 2 high-performing mungbean varieties – Brolga and Kookaburra.

With high yields, superior grain quality and greater resistance to diseases such as halo blight, tan spot and powdery mildew, these varieties position Queensland’s $113 million export industry for growth.

“Mungbeans are a major pulse crop for Queensland, and the launch of these new varieties is a huge step forward for productivity and grower profitability,” DPI principal scientist Dr Merrill Ryan said.

“With planting seed expected to be available this year, these varieties will immediately benefit growers, processors and exporters—helping meet the national target of 100,000 tonnes and maintain Queensland’s position as the world’s top supplier of quality mungbeans.”

The new varieties were developed through the $8.3 million National Mungbean Improvement Program—a partnership between the DPI and the Grains Research and Development Corporation.

Our Pigeonpea Initiative is also breaking new ground in a bid to provide Queensland growers with more resilient summer legume cropping options and help them thrive in a competitive global market.

In partnership with our international partners and industry, we’re testing diverse genetics and the crop’s viability in lower rainfall zones of southern and central Queensland, where mungbeans and soybeans often struggle.

We recently completed 2 years of trials with new pigeonpea genetics and will commercialise the best of these in the coming year. Our research on managing pest and disease – particularly Helicoverpa, which is expected to be the main pest problem in pigeonpea – continues.

We’re driving long-term growth in Australia’s pulse industry by diversifying crop choices and opening new international markets – particularly in India. This supports the Queensland Government’s 25-year blueprint, which aims to boost primary production to $30 billion by 2030.

Australian Mungbean Association president James Hunt.

Collaboration is at the heart of Queensland’s mungbean success story. Our partnership with the Australian Mungbean Association (AMA) ensures our research delivers real-world results for growers and global markets.

“As our commercial partner, the AMA is helping deliver new, high-performing mungbean varieties that meet both grower needs and market expectations,” DPI principal scientist Dr Merrill Ryan said.

“Their involvement ensures our scientific breakthroughs are backed by industry intelligence—from seed multiplication to export readiness.

“Our ongoing work with AMA helps us stay connected to the entire supply chain – linking science with seed producers, processors and exporters to make sure our varieties deliver value from paddock to plate.

“By working together, we’re building a more competitive and sustainable pulse industry for Queensland.”

AMA president James Hunt says the partnership continues to deliver real impact where it matters most.

“The recently launched Kookaburra and Brolga mungbean varieties are the result of years of focused collaboration,” he said.

“They’re not only meeting the demands of international buyers but also providing growers with the resilience and returns they need to remain competitive.

“This is testament to what can be achieved through close collaboration between DPI and industry.”

Colleen and Peter McLucas have been running beef cattle on the Atherton Tablelands for almost 20 years.

They know the land, the seasons and their herd better than anyone – but like many of us, they find the topic of carbon accounting a little daunting.

After attending a Department of Primary Industries cattle, carbon and sustainability workshop, the McLucas family took principal extension officer Niilo Gobius up on his offer to help them get a baseline for their operation’s carbon emissions.

“Measuring and reducing carbon emissions will help industry keep access to existing markets, gain access to new markets and maintain its social licence,” Niilo said.

“It also makes good economic sense – producers that turn off their animals quicker have less mortalities and greater reproductive efficiency. They produce more kg of beef per animal unit, reducing their emissions intensity measured as kg CO2 emitted per kg of beef produced.

“A good start for any farmer wanting to develop a carbon baseline is to keep accurate herd and weight gain data.”

It took a while to convert the McLucas family’s cattle records into a format that would fit in the emissions calculator spreadsheet, but Niilo said it would be easier next time.

Handing a profitable and sustainable property to the next generation has always been a priority for the McLucas family.

“The beef industry gets a bad rap, but sustainability is at the heart of everything we do. From my perspective the current method of calculating the baseline of carbon is not practical and it will impose an unnecessary burden on cattle producers,” Colleen said.

“Since we purchased our home property in December 2005, we have used rotational grazing – 3.5 days per paddock with 28 days rest – to support pasture and legume regeneration.

“We manage our stocking rate by kilos – not by the number of cattle – and we do not fertilise our paddocks. The results are clear with regular soil tests confirming drastic improvement in the pasture and legumes over the years. We’ve also installed solar power, which generates more kilowatts than we use.”

Visit the DPI e-hub to read about our Carbon Outreach program or to register for upcoming workshops.

When it comes to plant pests and diseases, our Grow Help team will help you get to the root of the problem

Deep in the basement of Brisbane’s EcoSciences Precinct, a team of detectives is hard at work.

Their mission: to identify pests and diseases affecting plants and provide advice to help growers manage them.

“Our lab is a bit like CSI, without the glamour,” says Andrew Manners, who co-manages Grow Help Australia with Sarah Dodd.

“Each day brings a new mystery to unravel.

“We do a lot of work with the nursery industry – testing plants that are produced for sale to vegetable producers, retail nurseries, landscapers and the forest industry.

“Our main purpose is to identify pests and diseases and provide recommendations for management.

“People that use our service report enhanced outcomes, with less plant losses and lower pesticide use.

“I love hearing a grower say they took our advice on board and reaped positive results. It makes it all worthwhile.”

Grow Help Australia also conducts testing to support market access.

Australian production nursery businesses can access free testing for 6 samples a year and receive a 50% discount on most tests after that.

“We test anywhere from 10 to 100 samples at a time, providing peace of mind and opening the door to international trade opportunities.”

The team works across 2 labs: one for triaging, culturing and detecting fungal pathogens, insect and mite pests; and another for PCR testing and sequencing. They loop in specialist plant bacteriology, virology and nematology teams as required.

We’re on the case!

We conduct tests for:

• production nurseries

• horticultural industries

• cut flower industries

• the forest industry

• council and wildlife parks with evidence of environmental dieback.

The Gatton AgTech Showcase is returning – bigger and better – on 15 and 16 October. Attendees will be treated to demonstrations of global AgTech options including the Ecorobotix ARA Smart Sprayer and a range of protected cropping technologies.

Vegetable growers can talk to manufacturers and explore ways these technologies can help their businesses become more profitable.

Register now

We’ve been working our magic with Queensland mangoes for more than 60 years –and it’s paying off big time, with development of some exciting new varieties!

Landline recently went behind the scenes with our mango breeding team – creators of iconic Australian varieties such as Calypso and R2E2 – and joined one of our taste testing panels.

Watch the story to learn more

ABC Landline recently went behind the scenes with scientist Dr Sam Williams in Innisfail to see how our Fish-LIGHT program is working with industry to develop and trial innovative low-impact fishing gears as sustainable alternatives to gillnets.

Watch the story to learn more

We’ve planted the seed for an even stronger horticulture industry by signing a memorandum of understanding with leading United States-based non-profit organisation F3 Innovate.

This partnership will enable growers and researchers to tap into a global network of AgTech innovators and fast-track access to new technologies.

It will support Queensland’s goal to grow primary production output to $30 billion by 2030 through: AgTech development and adoption; climate-resilient farming systems; access to key F3 Innovate partners; student hosting; and grower exchanges.

AgriScope is brought to you by Agri-Science Queensland, Department of Primary Industries.

QldAgriculture QldAgriculture QldAgriculture

Department of Primary Industries (Queensland)

Subscribe to AgriScope