Safari Family Dental

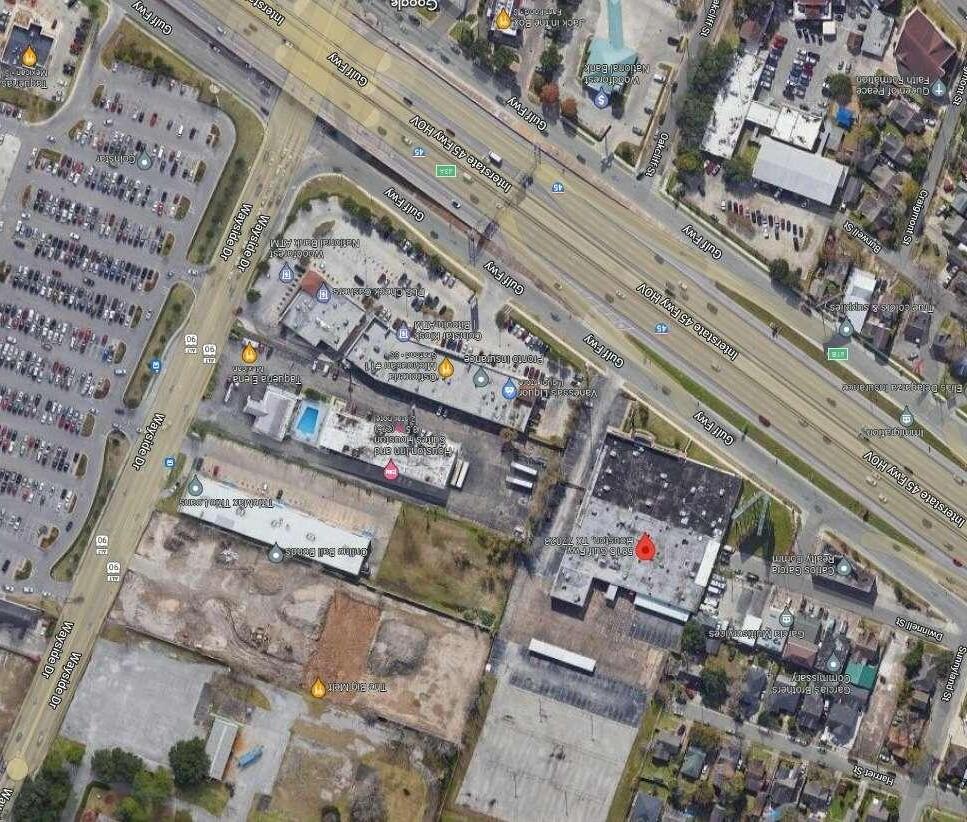

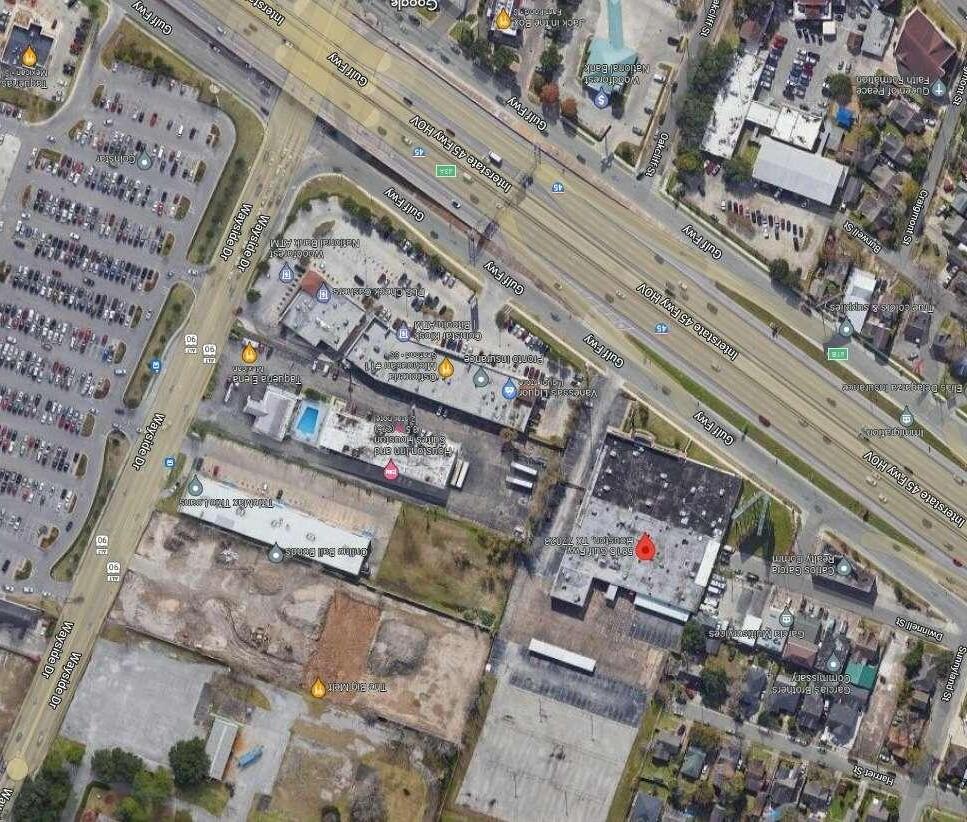

5815 Gulf Fwy Houston, TX 77023

DESIGNER twenty20studio, LLC contact: Ramon Gisbert 1407 Hawthorne Street Houston, TX 77006 t: 346.388.3820

GENERAL CONTRACTOR Custom Practices contact: Trevor Fawcett 1407 Hawthorne Street Houston, TX 77006 t: 713.836.2811

MEP ENGINEER Solutions Engineering contact: Duwan Cotton, PE 6101 Long Drive Houston, TX 77087 t: 713.376.9801

TAS / TDLR Otten Consulting Group contact: Kathy Rodriguez 2825 Wilcrest Dr #608 Houston, TX 77042 t: 713.975.1029

Rosenberg Richmond Greatwood Pleak Beasley Kendleton Orchard Simonton st. Bernard Wallis Fulshear Sugar Land Mission Bend Cinco Ranch Katy Brookshire Pattison Meadows Place Missouri City Fresno Sienna Plantation Manvel Pearland Friendswood League City Webster Seabrook Kemah La Porte Deer Park Pasadena Bellaire Channelview Baytown Beach City Mont Belvieu Cove Old River-Winfree Crosby Highlands Sheldon Stilson Dayton Kenefick Eastgate Huffman Atascocita Humble Porter New Caney Woodbranch Spring The Woodlands Hufsmith Pinehurst Tomball Cypress Jersey Village Aldine Hockley Waller Prairie View Pine Island Monaville Field Stone Houston 5815 Gulf Fwy Houston, TX 77023 P1.0SEWER & WATER PLAN P1.1AIR & VAC PLAN P1.2N2O PLAN P1.3PLUMBING DETAILS P1.4PLUMBING DETAILS P1.5PLUMBING DETAILS M1.0MECHANICAL PLAN M1.1ROOF PLAN M1.2MECHANICAL DETAILS E1.0POWER PLAN E1.1LIGHTING PLAN E1.2ONE-LINE & PANEL SCHEDULE A0COVER PAGE A0.0LIFE SAFETY PLAN A1.0DEMO PLAN A1.1OVERALL FLOOR PLAN A1.2EQUIPMENT PLAN A1.3DIMENSION

A1.4REFLECTED

SCHEDULEELEVATIONS

A6.2FINISH

ARCHITECTURE MECHANICAL ELECTRICAL PLUMBING

PLAN

CEILING PLAN A2.0INTERIOR ELEVATIONS A2.1INTERIOR ELEVATIONS A2.2INTERIOR ELEVATIONS A2.3INTERIOR ELEVATIONS A2.5CASEWORK TYPES/ DETAILS A4.0ENLARGED PLAN A6.0OPENING

A6.1FINISH WALL PLAN

SCHEDULE

Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT 9/22/2022 NTS 14/11/2022 4:10:00 pm COVER PAGE A0

NTS 2 Vicinity Map

3.

classified companies.

Screws - Type S self-tapping screws, 1-1/4 or 2 in. long, (1 Hr) and 2-1/2 in. long (2 Hr). 4. Building Units* - For 1 Hr Rating - Nom 5/8 or 3/4 in. thick, 4 ft wide, faced gypsum wallboard panels with the faced side on the interior wall 5. cavity. Panels attached to studs and floor and ceiling runners with screws spaced 8 in. OC along the edges of the panel and 12 in. OC in the ield

REF. A A A. Life Safety Floor Plan Occupancy Group IIB Business Maximum exit travel distance = 80' feet B. Travel distance C. 2 total fire extinguisher locations, w/ a maximum o 150' between locations (occupants may be no more than 75' distance from an extinguisher). XX' F.E. BUILDING CODE SUMMARY APPLICABLE CODES CONSTRUCTION TYPE IIB TENANT FINISH AREA sq. ft. BUILDING HEIGHT 1 STORY OCCUPANT LOAD FACTOR 1 OCCUPANT/ 100 sq.ft. OCCUPANT LOAD 31 EXIT REQUIRED 2 EXITS REQUIRED 2 EXITS PROVIDED SPRINKLER FIRE ALARM 2012 IBC with City of Houston Amendments 2012 UMC - Uniform Mechanical Code 2012 UPC - Uniform Plumbing Code 2020 NEC - National Electrical Code 2012 IFC - International Fire Code 2015 IECC or ASHRAE 90.1 – 2013 NO NO 3119 DRYWALL METAL STUD PARTITION 1-HR PARTITION WHERE NOTED AS UL465 Long leg runner, 3" deep. Secure to deck @ 24" O.C. Underside of structural deck Scheduled ceiling TYPE "A" HEAD PLAN BASE Mtl. studs @ 16" O.C. See chart for size 5/8" Gyp. board each side Hold gyp. board above floor min. 1/8", max 3/8" Mtl. stud runner anchored to floor @ 24" O.C. Verify Scheduled Ceiling Height Varies Scheduled base Sound batts 1 Hour Tenant separation wall/1 Hour fire rated wal with insulation 6" Stud. To deck UL 263 A1 3 5/8" 4 7/8" 40 49 A2 6" 7 1/4" --/ -PARTITION TYPE STUD SIZE PART THICKNESS STC HORIZONTAL SECTION Floor and ceiling Runners - (Not Shown) - Channel-shaped runners, 3-5/8 in. wide (min), 1-1/4 in. Legs, formed from No. 25 MSG (min) galv teel, attached to floor and ceiling with fasteners spaced 24 in. OC, max. 1. Steel Studs - Channel - shaped 3-5/8 in. wide (min), 1-1/4 in. Legs, 3/8 in. folded back returns, formed from No. 25 MSG (min) galv steel, spaced 24 in. OC max. 2. Batts and Blankets*- (Optional, not shown) - Mineral wool or glass fiber batts partially or completely filling stud cavity. See batts and blankets (BZJZ) category for names of

of the panel. Joints oriented vertically and staggered on opposite sides of the assembly. General Electric Company - Type CoreGuard. National Gypsum Co., Charlotte, NC - Type Gold Bond Fire-Shield Type X Hi-Impact Wallboard or Gold Bond Fire-Shield Type X Kal-Kore Hi-Impact Plaster Base. Joint Tape and Compound - (not shown) - Vinyl, dry or premixed joint compound, applied in two coats to joints and screw heads; paper tape 2 n. wide, embedded in first layer of compound over all joints. 6. Wallboard, Gypsum* - For 2 Hr Rating any Classified 5/8 in. thick (minimum), 4 ft wide, wall board applied over exterior face of building Unit Item 5). Wallboard to be applied vertically with joints staggered 24 in. from Building Unit (Item 5) and attached to studs and floor and ceiling runners with screws spaced 8 in. OC. 7. See Wallboard, Gypsum (CKNX) Category for names of manufacturers *Bearing the UL Classification Marking 1-HOUR TENANT SEPARATION WALL Design No. U495 Nonbearing Wall Rating -1 or 2 HR. (See Items 5 and 7) 2 4 5 7 DRYWALL METAL STUD PARTITION TYPE "B" 3 1/2" Stud. With insulation (Not to deck) Sound attenuation batts Stagger any boxes or fixtures in the wall HEAD PLAN BASE Continous sound seal tape Sealant, continous Continous sound batts over partition Schedule ceiling Underside of structural deck PARTITION TYPESTUD SIZEPART THICKNESS B1 3 5/8" 4 7/8" STC 40 49 B26" 7 1/4" --/ -Sound batts TYPE "C" BASE Existing exterior wall HEAD PLAN Schedule ceiling Acoustical sealant @ all base joints 7/8" Furring hat channel Tenant side 1 1/2" Channel stud. Againts CMU or Concrete C1 1 1/2"2 1/8" --/ -C2 3 5/8"4 1/4" --/ -PARTITION TYPESTUD SIZEPART THICKNESS STC TYPE "D" Half Wall Stagger any boxes or fixtures in the wall PLAN BASE PARTITION TYPESTUD SIZEPART THICKNESS D13 5/8" 4 7/8" STC 40 49 Dry wall top HEAD Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Waiting Reception Hallway 01 PAN CEPHTreat 04Treat 05 Hallway 02 Hallway 02 Hallway 02 Staff N2O IT MECH R. R. 2 Storage Steril LAB Office Marketing Billing Billing B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1 TOTAL D I STANCE = 130 FT 3 I N F E F.E B1 B1 B1 B1 B1 B1 B1 B1 B1 Partition Type B B NTS Partition Type C C NTS Partition Type D D NTS Partition Type A A NTS NOT AN AMBULATORY CARE FACILITY ALL INDIVIDUALS AND PATIENTS ARE CAPABLE OF SELF-PRESERVATION AND CAN RESPOND AS AN INDIVIDUAL TO AN EMERGENCY SITUATION. N 1/4" = 1'-0"1 Life Safety Plan Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:02 pm LIFE SAFETY PLAN A0.0

REF. A A 10'0" 11' 6" 11' 6" 6'0" 68 110 110 110 " 110 Exam 01 Exam 02 Treat 01 Treat 02 Treat 03 Staff MECH IT N2O Treat 04 Treat 05 3' 9 1/2" 4'6" 3' 11 3/4" C D Waiting PAN CEPH Hallway 02 R. R. 1 Hallway 01 Billing 5' 0" 6' 4 3/4" 5' 0" 12' 10 3/4" 2' 0" 5 - 10 R. R. 2 4'4" 7'2" LAB Office 5 - 0 Reception 4' 0" 3'0" 1 - 6" Storage 6' - 8" 40 110 10 - 0" 6' 5 1/2" 21' 2 1/2" 5'0" 1 2 10 10 10 Steril 12 15 15 15 15 8 15 10 10 10 10 10 1 2 Marketing Hallway 02 Hallway 02 10 10 15 15 10 3 10 10 11 10 10 1/4" = 1'-0"1 Overall 1st Floor Plan N Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 1/4" = 1'-0" 14/11/2022 4:10:04 pm

FLOOR PLAN A1.1

ValueKey note Text Keynotes 2 3 Overall Plan 1 Blocking for wall hung sink Provide (2) 2 x 12 blocking for Pan/ Ceph

Remote Exposure 6 Shut-off for Air & Vac

Surface mounted electrical panels

Angle stop

washout Note: add

on

&

to be weather

jambs

Blocking for grab bars

Feature wall

Blocking for TV

for sign

Blocking for IT equipment

Blocking for barndoor track

existing door new location 15Blocking for dental light

OVERALL

Key

5

7

8

w/

sound board

walls, ceiling

door

stripped @ head

4

9

10

11Blocking

12

13

14Salvaged

REF. A A OP-1 Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 Waiting Marketing Billing Reception Billing Hallway 01 PAN CEPH Treat 04 Treat 05 Hallway 02 Hallway 02 Hallway 02 Steril StorageLAB Office MECH IT N2O Staff EQ-1 EQ-1 EQ-1 EQ-1 EQ-1 GC-14 OP-6 GC-12 GC-11 IT-2 IT-2 IT-2 IT-2 IT-2 IT-2 IT-2 IT-2 EQ-7 EQ-1 EQ-10 EQ-1 EQ-10 IT-2 IT-2 IT-2 EQ-5 GC-9 EQ-11 GC-14 OP-6 GC-12 GC-11 EQ-2 EQ-10 EQ-10 EQ-10 EQ-10 EQ-10 OP-3 GC-9 GC-1 GC-15 GC-15 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 IT-1 EQ-9 EQ-9 EQEQ-9 EQ-3 EQ-4 EQ-9 EQ-9 EQ-9 OP-8 OP-8 S-1 1/4" = 1'-0"2 Equipment Plan N Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 1/4" = 1'-0" 14/11/2022 4:10:06 pm

A1.2 Key ValueKey note Text Keynotes GC -1 OP -1 OP -2 OP -3 Owner provided Under Cab Ref. Microwave Refrigerator EQ -1 EQ -2 EQ -3 EQ -4 EQ -5 EQ -6 EQ -7 Equipment specialist provided Dental Chair Autoclave Air Compressor Vacuum Pump Model Trimmer Plaster Trap Pan/Ceph General contractor provided Reception cabinet IT-1 IT-2 T.V. IT specialist provided Computers GC -2 Coffee/Tech bar GC -3 Digital cabinet GC -4 R.R. cabinet GC -5 Lab. cabinet GC -7 Steril. cabinet OP -4 Desk GC -8 Sink GC -9 Lavatory GC -10 Toilet tissue dispenser Toilet GC -11 Staff cabinet GC -12 Sign contractor S-1Sign Storage shelves GC -13 IT-3 Tiny computer IT-4IT equipment OP -5 Mobile cart EQ -8Shelf A/V EQ -9Dental Light Grab bars GC -14 OP -6 Toilet Paper OP -7 Mobile cart Paper Towel OP -8 12 o' clock unit EQ -10 Sterilization Sink EQ -11 Mirrors GC -15

EQUIPMENT PLAN

REF. A A Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Waiting Reception Hallway 01 Treat 04 PAN CEPH Treat 05 Billing Hallway 02 Storage LAB Office Staff R. R. 2 MECH IT N2O 37' 7 1/2" 3' 9 1/2" 7' 8" 11' 6 1/2" 7' 8" 6' 11 1/4" 3'11 3/4" 4'2 1/4" 4'11" 6'5" 6'9 1/2" 5'5" 10'5" 26'7 1/2" 68'8 3/4" 70'1 3/4" 9' 6" 10' 1 1/4" 10' - 3 1/2" 10'9 1/4" 40 - 0" 2'4 3/4" 29' - 10 3/4" 9' 1 1/4" 813 3/4 " 2310 1/2 60 37 1/2 50 37 411 38 50 1/2 69 1/2 5 '2 1/2 33 1/2 51 1/4 34 3/4 410 211 3/4 " 71 177 1/4 115 110 10705 28 1/4 26 15 1/4 7 15 1/4 6 3/4 1 - 6" 4 10 - 0 11 - 0" 6 3/4 " 15 1/2 " 15 1/2 6 1/2 3 - 11/4 31/2" 7 - 11" 7' 2 1/2" 3' 0" 5 - 0" 5'0" 1'6" 1'0" 1'8" 3' - 2 1/2" 4' 0" 20' 2 1/2" 11' - 6" 11' 11" 4' 9 3/4" 9' 6" 2' - 11 3/4" 1' 6" 8'0" 8'4" 31 2 - 5" 60 1/2 " 5'0" 1' 3" 9' - 0" 3' 2" 9' 0" 7' 11 1/4" 5' 9 1/4" 9' - 1 1/2" 7' 6" 4' 0" 8' - 6 3/4" 2' 0" 1' 0" 9' 9 1/2" 2'6" 6' 5 1/2" 4' 6 1/2" 13' 4 1/2" 2' 5" 7' 1" 2'0" 4'4" 2' 9" 25 3/4 40 64 3/4 2'0" 63' 4 3/4" 7' 2 1/2" A2.0 1 A2 0 2 A2.0 3 A2.0 4 A2.0 5 A2.0 6 A2 0 7 A2.3 9 A2 1 5 A2 2 5 - A22 4A2.1 3 A2.1 2 A2.2 10 A2.2 11 A2.2 12 A2.2 1 A2.2 8 A2.1 7 A2.1 8 9" 6'8" 115 115 " A4.0 1 A4.0 2 A2 3 2 A23 3 A2 3 4 A23 1 A2.3 7 A2.3 6 A2.3 5 A2.3 8 A2 2 3 A2 1 9 A2.1 10 3' 0" Steril 1 - 4" 36 4' - 10 1/4" 1' 10 1/4" 4' - 7 1/4" 3 - 51/4 12'0" 9'0" 2' 0" Marketing A2.3 12 A2 2 3 A2 2 3 A2 2 3 A2 2 3A2.2 3 A2.2 3 A2 2 5 A2 2 5 A2 2 5 A2 2 5 A2.2 5 A2.2 5 A22 4 A22 4 A22 4 A22 4 A2.2 4 A2.2 4 Hallway 02 Hallway 02 Hallway 02 Hallway 01 Waiting Hallway 01 Billing 5'1 1/4" 1/4" = 1'-0"1 Dimension Plan N Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 1/4" = 1'-0" 14/11/2022 4:10:08 pm DIMENSION PLAN A1.3

Staff N2O IT MECH LAB Storage R. R. 2 Hallway 02 Treat 04 Treat 05 Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Reception Waiting Billing PAN CEPH Office 10' 0" 10' - 0" 10' 0" 10' 0" 10' 0" 10' 0" 10' 0" 10' 0" 10' 0" 10' 0" 10' 0" 9' 0" 9' - 0" 9' 0" 10' - 0" 10' 0" 10' 0" 9' 0" Hallway 01 1 1 1 1 1 1 1 9' 0" 10' 0" 2' - 6" 3' 0" 1'0" R1 -6 R2 -6 9' - 0" 10' - 0" 10' 0" 3 2 2 4 3 5 11/4" 11/4" 20 20 " 1 - 11/4" 20 1 - 11/4" 20 1'0" 5 - 0" 5 - 10" 5' 0" 1' 7 1/4" 9 1/2" 10' 0" 1'1" 2' 0" 1' 6 1/2" 1'2 1/2" 1' 1 1/2" 1'6" 1'6" R16 R1 ' -0 1 - 6" 4 4 4 4 4 4 4 34 " 34 38 30 36 3 - 9 2'3" 2'3" 3' 2 1/2" 1' 0" 3' 2" 1' 6" 3' 4" 3'7" 3'0" 3'0" 2'0" 1' 0" 4' 0" 1' - 0" 5 1/2" 2' 2 3/4" 8' 0" 10' 0" 5 5 5 5 6' 0" 6' 0" 5' - 0 1/2" 4'9 1/4" 4'5 1/2" 4'9 1/4" 6'7 3/4" 5 - 0 5 - 0 1 - 11/4 4 - 0 5' 6" 4'9 1/4" 5 9" 2' 0" 5 1/2" 1' - 6" 10 10 " 1 - 103/4 9 1/2" 4 3/4" 5 5 - 0" 4 - 0 66 3 / 4 1 - 6" 1/4" = 1'-0"1 RCP Key ValueKey note Text Keynotes 1Blocking for TV VTW Open Ceiling Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 1/4" = 1'-0" 14/11/2022 4:10:09 pm REFLECTED CEILING PLAN A1.4 Blocking for Dental Light Flushed in ceiling 6.5" speaker 2 3 4 5

A. Field verify all dimensions and conditions.

B. Provide matching filler pieces scribed to abutting surfaces where cabinet is indicate to be abutting adjacent surfaces or dissimilar materials or construction

C. Close all perimeter joints between cabinets, countertops, splashes, sinks, trim, dissimilar materials and finishes with sealant.

D. Finish all visible surfaces of cabinets, countertops, knee spaces, end panels, etc.

E. Scheduled room base finish to be applied continuously around all assembly items including knee spaces, cabinets, and panels, toe-boards, etc.

F. It is the design intent that all door and drawer faces be flush with the face of filler panels and scribes. Provided filler panels, wall scribes, finished fur downs, and all other components flush with the faces of doors and drawers.

G. Provide grommets, 1 ¾ diameter, unless otherwise noted in all plastic laminate countertops with knee spaces, at 30 o.c., to be field located.

H. Dimensions indicated are nominal industry standards for manufactured wood or plastic laminate cabinets. Manufactured steel cabinets are similar.

I. Provide a 2 valance when a task light is indicated U.N.O.

J. All cabinets are to be [plywood/mdf] with [plastic laminate] U.N.O.

K. Refer to Finish Schedule for cabinet and countertop finish materials.

PL1 PL1 PL1 PL1A SS SS PL1A PL1 PL1 SS PL1A Q1 SS PL1A PL1 PL1A OPEN Q1 Q1 PL1 PL1A PL1A SS PL1 PL1A PL1A SS PL1 SS SS PL1

1'0" 4'6" 2'6" 1'6" 2' 7 1/4" 2' 7 1/2" 2' - 7 1/2" 2' 7 1/2" 3' 6" 4'6" 1' 0" 4'6" 8' 0" 1' 6" 1'0" 2'6" 2'6" 2' 9" 2' 9" 2' 9" 2' - 9" 2'6" 2'6" 3'6" 2' 0" 11' 2 3/4" 2' 1" 4'6" 1'0" 2'6" LVT Note: GC to provide cabinet shop drawings for owner approval Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:12 pm INTERIOR ELEVATIONS A2.0 3/8" = 1'-0"1 Reception 1 -1 3/8" = 1'-0"2 Reception 1 -2 3/8" = 1'-0"3 Reception 1 -3 3/8" = 1'-0"4 Reception 1 -4 3/8" = 1'-0"5 Reception 1 -5 3/8" = 1'-0"6 Reception 1 -6 3/8" = 1'-0"7 Reception 1 -7 8 Reception Perspective View 1

A. Field verify all dimensions and conditions.

B. Provide matching filler pieces scribed to abutting surfaces where cabinet is indicate to be abutting adjacent surfaces or dissimilar materials or construction

C. Close all perimeter joints between cabinets, countertops, splashes, sinks, trim, dissimilar materials and finishes with sealant.

D. Finish all visible surfaces of cabinets, countertops, knee spaces, end panels, etc.

E. Scheduled room base finish to be applied continuously around all assembly items including knee spaces, cabinets, and panels, toe-boards, etc.

F. It is the design intent that all door and drawer faces be flush with the face of filler panels and scribes. Provided filler panels, wall scribes, finished fur downs, and all other components flush with the faces of doors and drawers.

G. Provide grommets, 1 ¾ diameter, unless otherwise noted in all plastic laminate countertops with knee spaces, at 30 o.c., to be field located.

H. Dimensions indicated are nominal industry standards for manufactured wood or plastic laminate cabinets. Manufactured steel cabinets are similar.

I. Provide a 2 valance when a task light is indicated U.N.O.

J. All cabinets are to be [plywood/mdf] with [plastic laminate]

PL1 OPEN PL1 OPEN PL1 PL1A PL1A PL1 PL1A PL1A PL1 PL1 PL1 PL1A PL1A PL1A PL1A PL1A PL1 PL1A PL1A

U.N.O. K. Refer to Finish Schedule for cabinet and countertop finish materials. LVT 2'6" 1' 6" 7' 7 1/2" 1' 6" 4' 10 3/4" 2'6" LVT 2'10" 3' 0" 5' 5 1/4" LVT 2' 7 1/2" 1' 10 1/2" 2'10" 2'6" 2'2" 2'6" 2'2" 2'10" 2' 8 1/2" 3' 10 1/4" 1' 6" 2'10" 3' 0" 1' 6" 2'10" LVT LVT Note: GC to provide cabinet shop drawings for owner approval Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:13 pm INTERIOR ELEVATIONS A2.1 1 Reception Perspective View 2 3/8" = 1'-0"2 Office 1 -1 3/8" = 1'-0"3 Office 1 -2 4 Office Perspective View 3/8" = 1'-0"5 Pan 1 -1 6 Pan Perspective View 3/8" = 1'-0"7 Steril 1 -1 3/8" = 1'-0"8 Steril 1 -2 3/8" = 1'-0"9 Steril 1 -3 3/8" = 1'-0"10 Steril 1 -4 11 Steril Perspective View 1 12 Steril Perspective View 2

A. Field verify all dimensions and conditions.

B. Provide matching filler pieces scribed to abutting surfaces where cabinet is indicate to be abutting adjacent surfaces or dissimilar materials or construction

C. Close all perimeter joints between cabinets, countertops, splashes, sinks, trim, dissimilar materials and finishes with sealant.

D. Finish all visible surfaces of cabinets, countertops, knee spaces, end panels, etc.

E. Scheduled room base finish to be applied continuously around all assembly items including knee spaces, cabinets, and panels, toe-boards, etc.

F. It is the design intent that all door and drawer faces be flush with the face of filler panels and scribes. Provided filler panels, wall scribes, finished fur downs, and all other components flush with the faces of doors and drawers.

G. Provide grommets, 1 ¾ diameter, unless otherwise noted in all plastic laminate countertops with knee spaces, at 30 o.c., to be field located.

H. Dimensions indicated are nominal industry standards for manufactured wood or plastic laminate cabinets. Manufactured steel cabinets are similar.

I. Provide a 2 valance when a task light is indicated U.N.O.

J. All cabinets are to be [plywood/mdf] with [plastic laminate] U.N.O.

PL1A PL1 PL1 PL1A PL1 PL1A PL1 PL1A OPEN PL1A PL1A PL1A PL1A PL1A PL1A PL1A PL1A

K. Refer to Finish Schedule for cabinet and countertop finish materials. 2'10" LVT 2'6" 2' 0" 5' - 0" 1' 6" 2' - 0" 1' 6" 2' 0" 2'6" LVT LVT 1' 3" 3' 0" 2' 0" 2'10" 2'2" 2'6" LVT 2'0" 1' 0" 1' - 0" 6' 9 1/2" 1' 6" 1' - 6" 3' 9 1/2" 1' 0" 1' 0" 1' 0" 2' 11" 7'0" 2'0" 2' 0" 2' - 0" 4' 9 1/2" 9' 9 1/2" 3' 0" 7'0" Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:15 pm INTERIOR ELEVATIONS A2.2 Note: GC to provide cabinet shop drawings for owner approval 3/8" = 1'-0"1 Lab 1 -1 2 Lab Perspective View 3/8" = 1'-0"3 12 o'clock Unit 1 -1 3/8" = 1'-0"4 12 o'clock Unit 1 -2 3/8" = 1'-0"5 12 o'clock Unit 1 -3 6 12 o'clock unit Perspective View 1 7 12 o'clock unit Perspective View 2 3/8" = 1'-0"8 Staff 1 -1 9 Staff Perspective View 3/8" = 1'-0"10 Storage 1 -1 3/8" = 1'-0"11 Storage 1 -2 3/8" = 1'-0"12 Storage 1 -3

A. Field verify all dimensions and conditions.

B. Provide matching filler pieces scribed to abutting surfaces where cabinet is indicate to be abutting adjacent surfaces or dissimilar materials or construction

C. Close all perimeter joints between cabinets, countertops, splashes, sinks, trim, dissimilar materials and finishes with sealant.

D. Finish all visible surfaces of cabinets, countertops, knee spaces, end panels, etc.

E. Scheduled room base finish to be applied continuously around all assembly items including knee spaces, cabinets, and panels, toe-boards, etc.

F. It is the design intent that all door and drawer faces be flush with the face of filler panels and scribes. Provided filler panels, wall scribes, finished fur downs, and all other components flush with the faces of doors and drawers.

G. Provide grommets, 1 ¾ diameter, unless otherwise noted in all plastic laminate countertops with knee spaces, at 30 o.c., to be field located.

H. Dimensions indicated are nominal industry standards for manufactured wood or plastic laminate cabinets. Manufactured steel cabinets are similar.

I. Provide a 2 valance when a task light is indicated U.N.O.

J. All cabinets are to be [plywood/mdf] with [plastic

Tile backer board,PTD Tile backer board,PTD Tile backer board,PTD Tile backer board,PTD Tile backer board,PTD Tile backer board,PTD Tile

board,PTD PL1A PL1 OPEN OPEN PL1 PL1A

backer

laminate] U.N.O. K. Refer to Finish Schedule for cabinet and countertop finish materials. 5'0" 2'10" 6 5 1 3 7 2 4 5'0" 2 3 7 4 5'0" 5'0" 2'10" 6 5 1 2'10" 6 5 3 1 2 4 5'0" 5'0" 3 7 2 3 4 5'0" 5'0" 2'10" 6 1 5 4 2'6" 1' 6" LVT FT FT LVT Note: GC to provide cabinet shop drawings for owner approval Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:17 pm INTERIOR ELEVATIONS A2.3 3/8" = 1'-0"1 R. R. 01-1 3/8" = 1'-0"2 R. R. 01-2 3/8" = 1'-0"3 R. R. 01-3 3/8" = 1'-0"4 R. R. 01-4 3/8" = 1'-0"5 R. R. 02-1 3/8" = 1'-0"6 R. R. 02-2 3/8" = 1'-0"7 R. R. 02-3 3/8" = 1'-0"8 R. R. 02-4 3/8" = 1'-0"9 Billing 1 -1 10 Marketing Perspective View 13 R. R. 1 Perspective View 14 R. R. 2 Perspective View 11 Billing Perspective View 3/8" = 1'-0"12 Marketing 1 -1 Key ValueKey note Text Keynotes 1 2 3 Lavatory Toilet Grab bar Paper Towel Mirror Vanity sconce selected by owner Toilet Papers 5 6 7 4

A. Field verify all dimensions and conditions.

B. Provide matching filler pieces scribed to abutting surfaces where cabinet is indicate to be abutting adjacent surfaces or dissimilar materials or construction

C. Close all perimeter joints between cabinets, countertops, splashes, sinks, trim, dissimilar materials and finishes with sealant.

D. Finish all visible surfaces of cabinets, countertops, knee spaces, end panels, etc.

E. Scheduled room base finish to be applied continuously around all assembly items including knee spaces, cabinets, and panels, toe-boards, etc.

F. It is the design intent that all door and drawer faces be flush with the face of filler panels and scribes. Provided filler panels, wall scribes, finished fur downs, and all other components flush with the faces of doors and drawers.

G. Provide grommets, 1 ¾ diameter, unless otherwise noted in all plastic laminate countertops with knee spaces, at 30 o.c., to be field located.

H. Dimensions indicated are nominal industry standards for manufactured wood or plastic laminate cabinets. Manufactured steel cabinets are similar.

I. Provide a 2 valance when a task light is indicated U.N.O.

J. All cabinets are to be [plywood/mdf] with [plastic laminate] U.N.O.

K. Refer to Finish Schedule for cabinet and countertop finish materials.

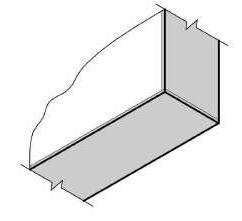

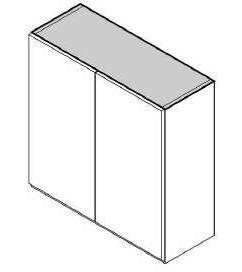

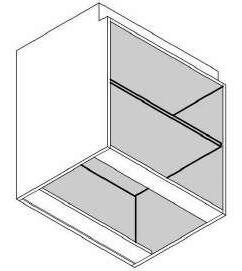

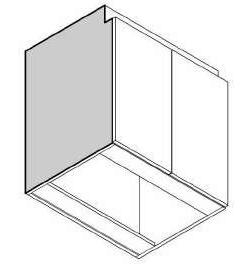

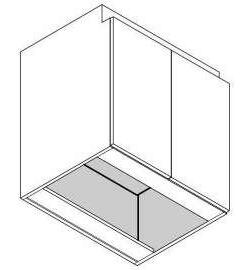

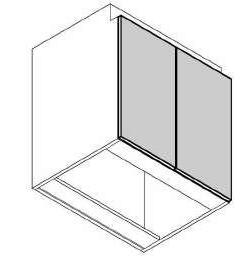

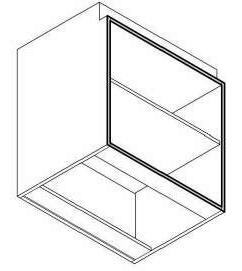

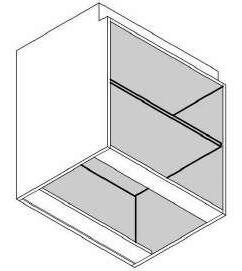

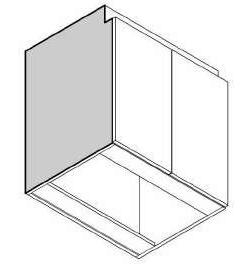

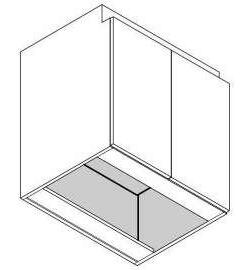

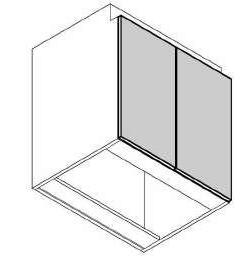

Base cabinet Double door w/ 2 drawers Adjustable shelf RE: Elev. 4" 2'10" 4" E Upper cabinet Single door 2'6" 4' 8 1/2" AFF RE: Elev. B Base cabinet Single door w/ drawer Blind corner Adjustable shelf Upper cabinet Double door @ sink 1'2" 6'0 1/2" AFF RE: Elev. Base cabinet Single door w/ drawer Adjustable shelf RE: Elev. 4" 2'10" 4" A A1 RE: Elev. RE: Elev. Solid surfacing countertop and splash 4" 2'10" 4" Upper cabinet Double door 2'6" 4' 8 1/2" AFF RE: Elev. F F1 Adjustable shelf Adjustable shelf Solid surfacing countertop and splash Solid surfacing countertop and splash Accessible sink cabinet RE: Elev. 2'1" 4" D 1' 8" min. 8" min. 1' 7" Solid surfacing countertop and splash 2'10" 2 '3" min Base cabinet Double door Adjustable shelf RE: Elev. 4" Sched. Height 4" B2 Solid surfacing countertop and splash Base cabinet Single door 4" 2'10" 4" B4 Adjustable shelf Solid surfacing countertop and splash RE: Elev. C 1' 8" 6" Drawer 4" 2'4 1/2" C1 1' 8" Drawer 4" 2' 8 1/2" Base cabinet Double door w/ 2 drawers Adjustable shelf RE: Elev. 4" 2'10" 4" B1 Solid surfacing countertop and splash Base cabinet Single door w/ 1 drawers Adjustable shelf RE: Elev. 4" 2'10" 4" B3 Solid surfacing countertop and splash EQ EQ EQ EQ 9" 9"

CABINET FACE CABINET FACE SURFACES ARE COVERED WITH VERTICAL GRADE HIGH-PRESSURE LAMINATE. COLOR TO MATCH FINISHED EXTERIOR CLOSED INTERIOR ALL INTERIOR SURFACES ARE MELAMINE (EXCEPT FOR DOORS). DOORS WILL HAVE CABINET LINER. UNLESS OTHERWISE SPECIFIED. OPEN INTERIOR EXPOSED INTERIOR SURFACES ARE COVERED WITH VERTICAL GRADE HIGH-PRESSURE LAMINATE COLOR TO MATCH FINISHED EXTERIOR. EXPOSED ENDS EXPOSED END SURFACES ARE COVERED WITH VERTICAL GRADE HIGH-PRESSURE LAMINATE. COLOR TO MATCH CABINET EXTERIOR. WALL BOTTOMS EXPOSED WALL BOTTOM SURFACES ARE COVERED WITH VERTICAL GRADE HIGH-PRESSURE LAMINATE. COLOR TO MATCH CABINET EXTERIOR. CABINET EDGING EXPOSED CABINET EDGES WILL HAVE 1mm PVC (NOMINAL). COLOR WILL MATCH CABINET EXTERIOR. DOOR DRAWER EDGING DOOR DRAWER EDGES WILL HAVE 1mm PVC (NOMINAL). COLOR WILL MATCH CABINET EXTERIOR. ADJUSTABLE SHELF EDGING CABINET INTERIOR SHELVES TO HAVE 1mm PVC FRONT EDGE. COLOR TO MATCH CABINET INTERIOR COLOR. CABINET SURFACES CABINET CORE MATERIAL CABINET BODY CORE CABINET BODY CORE MATERIAL IS 3/4" PARTICLE BOARD CABINET FACE CORE CABINET FACE CORE MATERIAL IS 3/4" PARTICLE BOARD DRAWER BOX 3/4" MELAMINE DRAWER SIDES & 1/4" BOTTOM FULLY CAPTURED. NTS Casework Legend Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:18 pm CASEWORK TYPES/ DETAILS A2.5

2" 50mm 3-1/8" 80mm -1/4" 55mm -5/8" 65mm 3-1/8" 80mm 2-1/4" 55mm 1-1/2" 38mm 3-1/4" 85mm Dia. -1/8" 80mm 5/16" 8mm Snap Flange Cover 42" 1065mm 4" 100mm 50" 1270mm 45-7/8" 1165mm 57-7/8" 1470mm Edge of Flange to Wall Edge of Flange to Wall 1 1/2" (38mm) Diameter Stainless Steel Grab Bars with Snap FLange B-6806 Safety Warning: Grab bars are no stronger than the anchors and walls to which they are attached and, therefore, must be firmly secured in order to support the loads for which they are intended. To avoid potential injury, the building owner or maintenance personnel should remove the grab bar from service if the grab bar is not adequately secured to wall or there is any observed damage to the welds. Note: Grab Bars shall resist a 250 LB Load in Any Point and direction. TWO-WALL TOILET COMPARTMENT BAR 42 x 54 B-6897 A2 3 2 A23 3 A2 3 4 A23 1 5'-0" Turning Radius 7 - 6 Min cearence 5 - 0 ADA Min c learence 50" ADA 68 1 2 7 5 3 4 34 3/4 30 4 A2.3 7 A2.3 6 A2.3 5 A2.3 8 5'-0" Turning Radius Min. clearence 5' - 0" ADA 6' 8" Min. clearence 5'0" ADA 7'2" 3 7 2 1 5 4 4'2 3/4" 3'0" 4" Grab Bar Mounting Kits Product ID WINGITS-MAW35 MOUNTING KITS - REFINED ENGINEERED SAFETY MASTER Anchor WingIts - World's Strongest FastenerTM - WingiIts are rated up to 300 lbs. (depending on application) and will neverLoosen, Millions of Installaions and No Issues. WingIts utilizes a # 8 stainless steel crew, which is ideal for installing Bath Accessories, Window Dressings and Shelving, Typical installations include Bath Accessories, Window Dressings,Mail Boxes, Hose Reels, Heavy Drapery Rods, Shelving, Cabinets, Pedestal Sinks, Dispensers, Coa Hooks, Railings, and for most Wall Mount Accesories with a base over 1 in, made in USA. Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:18 pm ENLARGED PLAN A4.0 3/8" = 1'-0"1 Enlarged R.R. 1 3/8" = 1'-0"2 Enlarged R.R. 2 Key ValueKey note Text Keynotes 1 2 3 Lavatory Toilet Grab bar 4Paper Towel 5Mirror 6Vanity sconce selected by owner 7Toilet Papers/Tissue Papers

Schedule

17Hallway 02R. R. 23'0"8'0"0'1 3/4"ALRe:Finishing Schedule

18StaffHallway 023'0"7'0"0'2"FRe:Finishing Schedule

19MECHStaff3'0"7'0"0'1 3/4"NoneRe:Finishing Schedule

20ITStaff3'0"7'0"0'1 3/4"NoneRe:Finishing Schedule

21N2OStaff3'0"7'0"0'2"FRe:Finishing Schedule

Note:

A readily visible durable sign is posted on the egress side on or adjacent to the main entry door stating: THIS DOOR TO REMAIN UNLOCKED WHEN BUILDING IS OCCUPIED. The sign shall be in letters 1 inch (2 mm) high on a contrasting background.

HARDWARE

1. All doors shall have lever handle 36" A.F.F., butt hinges, no closures, and passage set. restrooms shall have button type lock with key on outside. front entry doors are existing.

2. Hardware based on schlage 'A' series.

NOTUSED NOTUSED NOTUSED

REF. A A Schd. Height Schd. Width F Full Flush Schd. Height Schd. Width P Pocket Door Schd. Height Schd. Width M Metal Door BP Bypass Glass Door Schd. Width G Glass Half Lite 8" 6" 6" L Door w/ Louver Schd. Height Schd. Width 2" Cut for ventilation Schd. Width FG Full Glass 8" 6" 6" Schd. Height 1'1" 8" 1' 4" 8" 6" 8" Schd. Width Schd. Height Schd. Height Narrow Lite, 8" N8 Schd. Width Schd. Height EQ EQ 2" 2" HM Hollow Metal AL Aluminum 1 1/2" 1 1/2" Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Waiting Reception Hallway 01 Hallway 01 Billing Billing Marketing Treat 05 Treat 04 PAN / CEPH Hallway 02 Hallway 02 Hallway 02 Hallway 02 Steril StorageLAB Office MECH IT N2O Staff R. R. 2 01 02 04 05 08 03 09 06 07 10 11 12 13 14 15 16 17 18 19 20 21 JUPITER 3-3/8" 11/16" 21/2" 4-1/2" Mark Width Height Frame Finish Frame type W1 Window Schedule 13' -7 3/4" 4'-0"ALMatch Door Frame Glass: 1/4" Tempered clear (See documents for placement) 1/4" = 1'-0" Door Types 1/4" = 1'-0" Frame Types Door Schedule Mark From Room: Name To Room: NameWidthHeightThickness Door Type Fire Rating Frame Type Frame Finish Door FinishHardware Schedule HW Set 01Waiting3'6 25/32" 7'11"0'1 3/4"NoneStorefront1,11 02Waiting2'10"7'11"0'1 3/4"NoneRe:Finishing Schedule 03Marketing3'0 13/32" 7'11"0'1 3/4"FGNoneRe:Finishing Schedule 04WaitingR. R. 13'0"8'0"0'1 3/4"ALRe:Finishing Schedule 05Hallway 01Waiting3'0"8'0"0'1 3/4"NoneRe:Finishing Schedule 06Exam 01Hallway 013'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing Schedule 07Exam 02Hallway 013'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing Schedule 08Hallway 01Billing3'0"7'0"0'2"FRe:Finishing Schedule 09Hallway 02Hallway 013'0"7'0"0'2"FRe:Finishing Schedule 10Treat 01Hallway 023'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing Schedule 11Hallway 02Treat 043'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing Schedule 12Hallway 02Treat 053'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing Schedule 13Hallway 02Office3'0"7'0"0'2"FRe:Finishing Schedule 14Treat 02Hallway 023'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing Schedule 15StorageLAB3'0"7'0"0'2"FRe:Finishing Schedule 16Treat 03Hallway 023'0"8'0"0'1 3/4"BPNoneStorefrontRe:Finishing

1/4" = 1'-0"1 Door Plan

1. DEADBOLT W/LOCK INDICATOR 2. LOCK 3. PASSAGE 4. PRIVACY LOCK 5. CLOSER 6. ALUM. RIM PANIC DEVICE 7. PEEP HOLE 8. DOOR SWEEP 9. WEATHER STRIPPING 10. STORAGE LOCK 11. CROSS BAR PANIC BAR EXIT DEVICE

Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:27 pm OPENING SCHEDULE / ELEVATIONS A6.0

Practices

Trevor Fawcett t: 713.836.2811

Engineering Contact: Duwan Cotton, PE t: 713.376.9801

TDLR Otten Consulting Group

Kathy Rodriguez t: 713.975.1029

REF. A A Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Waiting Marketing Billing Hallway 01 Reception Treat 05 Treat 04 PAN CEPH Steril Storage Office LAB MECH IT N2O Staff R. R. 2 Hallway 02 1/4" = 1'-0"1 Paint Wall Plan Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston,

77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS

Solution

Safari Family Dental PERMIT9/22/2022 1/4" = 1'-0" 14/11/2022 4:10:28 pm

WALL PLAN A6.1 FINISH SCHEDULE GENERAL FINISH SELECTIONS: Class-A Finishes, Typical WALL FINISH: Wall shall be painted with two coats of latex Sherwin Williams. Install water resistant gyp board on all wet walls. Level 4 finish with smooth roll -on texture PAINT: MFR.: STYLE: FIELD COLOR FC $8.50 PSF INSTALLED ALLOWANCE WALL TILE WT WALL FEATURE MFR.: STYLE: 1x1 CLEAR SEALED YELLOW PINE WS WT2 MFR.: FLOOR AND DECOR STYLE: 100112689 FESTIVAL BRIGHT WHITE ICE CERAMIC WALL TILE COLOR: WHITE WT1 MFR.: FLOOR AND DECOR STYLE: 100837033 COLOR: BLUE MFR.: STYLE: COLOR: NAVY BLUE AC1 MFR.: STYLE: SMALL DUMBO WALLPAPER BY CHRIS BENZ COLOR: NAVY WP1

TX

Contact:

Custom

Contact:

FINISH

2x2 Ceiling Tile: Certainteed BET-154 24x24x5/8 Reveal Beveled Baroque Grid: 15/16"

REF. A A PL2 PL2 PL1 PL1 PL1 PL1 PL1 PL1 PL1 PL1 Q1 PL2 PL1 PL2 Q1 PL1 PL1 PL1 PL1 PL1 PL1 PL1 LVT FT PL1 Q1 PL2 FT LVT LVT LVT LVT LVT LVT LVT LVT FT LVT LVT LVT LVT LVT LVT LVT Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Waiting Reception Marketing Billing Billing Hallway 01 Treat 04Treat 05 PAN CEPH Hallway 02 Hallway 02 Hallway 02 Hallway 02 Hallway 02 Steril Office LAB Storage Staff MECH IT N2O R. R. 2 LVT 1/4" = 1'-0"1 Finish Floor Plan Floor Material Legend1/4" = 1'-0"3

SCHEDULE GENERAL FINISH SELECTIONS: Class-A Finishes, Typical DOORS: WILSONART HARDWARE MFR.: SCHLAGE OR EQUAL COLOR: DOOR FRAMES MFR.: RACO COLOR: FLOORING: MFR.: STYLE: LOC.: LVT WALL BASE: MFR.: STYLE: CEILING/SOFFIT: A. Hallway:

24x24x5/8

B. Rooms:

C.

CABINETS: MFR.: COLOR: STYLE: FACE OF RECEPTION DESK ST MFR.: STYLE: TRANSACTION TOP Q1 MFR.: STYLE: WRITING SURFACE PL1 MFR.: STYLE: UPPER & LOWER CABINETS: PL1A TILE: MFR.: STYLE: SIZE: GROUT: PATIENT RESTROOM FLOORING FT PL1A MFR.: STYLE: COUNTER-TOP PL2 MFR.: STYLE: LOC.: SS MFR.: STYLE: LOC.: PL2A STYLE: MELAMINE WHITE PANEL PL3 Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 1/4" = 1'-0" 14/11/2022 4:10:33 pm FINISH SCHEDULE A6.2

FINISH

2x2 Ceiling Tile: Certainteed BET-154

Reveal Beveled Baroque Grid: 15/16"

Restrooms, Mechanical rooms, and furr downs: Sheetrock ceiling painted

LEGEND:

TRANSFORMER DETAIL ABOVE CEILING

REF. A A Sign 1 B-1 F 2 B-21 44" 44" 44" C F 2 B-25 65" 44"44" C 72" F 2 B-27 65" 44"44" C 72" F 2 B-29 65" 44"44" C 72" F 2 65" 44" 44" C 72" B-11 F 2 65" 44" 44" C 72" B-13 3 6 A-40,42 3 4 For WH B-32,34 A-28,30,32 For RTU #1 A-34,36,38 For RTU #2 B-47 B-45 72" 36" 65" B-36,38 220 B-40,42 220 5 5 44" 65" 44" 44" B-31 36" 36" 36" 36" 44" 44" 44" Staff StorageLAB MECH N2O IT Hallway 02 Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 Treat 05 Treat 04 Hallway 01 PAN CEPH Reception Waiting Billing R. R. 1 R. R. 2 Office Hallway 02 B-35 B-37 110 110 36" 36" 72" F 2 B-23 44" 44" 44" C 72" 84" B-17 B-19 110 220 B-15 B-5 36" 36" 36" 36" 36" 36" 36" 36" 36" 60" 36" 36" 36" 36" 36" 36" B-3 B-7 B-9 B-39 B-49 B-33 B-41 B-43 S S S S S S Steril 36"

CEILING OUTLET DUPLEX RECEPTACLE DEDICATED OUTLET; 110 V DATA JACK DOUBLE DUPLEX RECEPTACLE GROUND FAULT CURRENT INTERRUPTER RECEPTACLE (GFCI) Transf. ELEVATION PLAN Spring vibration isolators sized for weight of transformer Hang from top chord of joist at panel point ½" ⌀ Threaded rod (4 Req'd) 1 ½" Unistrut channel frame Bolt Transformer to be base channel (Typ. 4 places) Platform sized for individual transformer

1/4" = 1'-0" 1 Power Plan 2" CHASE UNDER FLOOR BETWEEN CHAIR, J-BOX AND REAR CABINET, TYP. GC TO PROVIDE COVER BOX FOR EQUIPMENT WIRES (TYP.) KEY NOTE 1 2 3 4 KEYNOTE TEXT SIGN POWER: DEDICATED 20 AMP, 120 VOLT CIRCUIT WITH A TIMER. ELECTRICAL SUB-CONTRACTOR TO RUN BRANCH CIRCUIT AND JUNCTION BOX TO THE BACK WALL OF THE SIGN. SEMI-RECESSED ELEC. PANEL PROVIDE BUCKBOOSTER FOR DENTAL EQUIPMENT 5 WATER HEATER LOCATED IN CEILING TRANSFORMER IN CEILING 6 Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT 9/22/2022 As indicated 14/11/2022 4:10:34 pm POWER PLAN E1.0

LIGHTING FIXTURE SCHEDULE

TBD by Owner O1 TBD by Owner 120V TBD by Owner Surface TBD by Owner TBD by Owner TBD by Owner O2 120VCeiling TBD by Owner TBD by Owner TBD by Owner TBD by Owner OFCI OFCI TYPE MANUFACTURER & MODEL INPUT VOLTAGE LUMENS MOUNTING LEGEND SIZE TRIM COLOR TEMP NOTES

Wall Sconce Pendant C1 Halo LT560WH12950 H550ICAT 120V1170 Recessed 5" 5000K Recessed Can Light E1 Sure-Lites APX7R 120/277V---Ceiling Surface W-11-5/8" H -7-3/16" D -1-5/8" ----120/277V Ceiling Surface Emergency Battery Pack Option 90 Minutes; Green Letters Sure-Lites APEL White E2 ----120/277V Ceiling Surface Sure-Lites SEL25 White E3 Exit light Emergency light indoor Emergency light outdoor W-9" H -4-11/16" D -1-15/16" W-7-7/8" H -7-15/16" D -2-3/16" T1 Metalux 24CGT4550C 120/277V4432 Lay-in 2'x4' 5000K Direct Indirect 2'x4' Troffer Leviton Decora Rocker Slide; ODS10-TDW Standard White-------------------- Switch S1 Metalux SLSTP LENSED LED 120/277V2571 Surface 48" White4000K Strip Light Emergency Battery Pack Option 90 Minutes; Green Letters Emergency Battery Pack Option 90 Minutes; Green Letters T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1 T1T1 See note #12 See note #12 See note #12 See note #12 See note #12 See note #12 C1 EF-1 EF-2 EF-3 EF-4 O2 O2 O2 O2 O2O2O2O2 O1 O1 C1 C1 B-16 A-1 B-2 B-4 S1 A-29 B-6 B-8 A-5 A-7 A-9 A-11 A-13 A-17 A-15 A-31 A-3 A-23 B-20 Staff MECH IT N2O Hallway 02 R. R. 2 Treat 03 Treat 02 Treat 01 Exam 02 Exam 01 R. R. 1 Waiting Reception Hallway 01 Billing Treat 05 Treat 04 PAN / CEPH Storage Office LAB A-19 B-22 A-21 A-23 A-27 A-25 B-18 B-14 T1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 O2O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 B-10 B-12 Hallway 02 Hallway 02Hallway 02 Steril 1/4" = 1'-0"1 Lighting Plan Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:36 pm LIGHTING PLAN E1.1

ONE-LINE RISER DIAGRAM

NOTES:

CONTRACTOR TO FIELD VERIFY ALL EXISTING CONDITIONS AND NOTIFY ARCHITECT IMMEDIATELY IF ANY DISCREPANCIES OR HIDDEN CONDITIONS OR CITY/STATE CODE COMPLIANCE CONFLICTS OCCUR. FAILURE TO NOTIFY ARCHITECT WILL RESULT IN CONTRACTOR TAKING FULL FISCAL RESPONSIBILITY FOR ANY AND ALL COSTS WHICH ARE INCURRED. THE CONTRACTOR IS RESPONSIBLE FOR THE ENTIRE INSTALLATION WHICH SHALL BE PERFORMED IN STRICT ACCORDANCE WITH ALL NATIONAL, STATE AND LOCAL CODES. THIS MAY INCLUDE ADDITIONAL ITEMS NOT INCLUDED IN THIS PLAN.

CONTRACTOR IS TO VERIFY ALL EXISTING MECHANICAL SYSTEMS.

CONTRACTOR IS TO MODIFY EXISTING MECHANICAL SYSTEMS AS REQUIRED BY CONSTRUCTION. CONTRACTOR IS TO PROVIDE NEW MECHANICAL SYSTEM EQUIPMENT AND DIFFUSERS AS REQUIRED BY NEW CONSTRUCTION.

ELECTRICAL GENERAL NOTES

SITE OF THE PROPOSED WORK AND SHALL BE FULLY INFORMED REGARDING THE FACILITIES. NO ADDITIONAL COMPENSATIONS WILL BE ALLOWED FOR WORK OR MATERIAL OMITTED FROM BIDDER'S CONTRACT PROPOSAL DUE TO HIS FAILURE TO INFORM HIMSELF BY SUCH INVESTIGATION.

10. PROVIDE TEMPORARY SERVICE AS REQUIRED FOR CONSTRUCTION AND REMOVE SUCH TEMPORARY SERVICE WHEN WORK IS COMPLETED

11. GC TO MAKE ALL ARRANGEMENTS WITH LOCAL POWER COMPANY AND DO ALL WORK NECESSARY TO PROVIDE PERMANENT SERVICE TO THE BUILDING.

12. ALL FUSES SHALL BE BUSSMAN "CURRENT LIMIT" TYPE FOR MINIMUM FAULT CURRENT LET THRU UNLESS 0/W INDICATED

13. CONDUIT RUN IN BLDG. SHALL BE CONCEALED IN WALL OR ABOVE CEILING SHALL BE E.M.T. (USE GALVANIZED WHERE EXPOSED). UNDERGROUND FEEDERS RUN UNDER SLAB OR GRADE (AT PROPER DEEP) CAN BE SCH 40 PVC WITH GROUND WIRE SIZED IN ACCORDANCE WITH NATIONAL ELECTRICAL CODE.

14. ALL UNDERGROUND ELECTRICAL WIRING CONDUITS TO BE INSTALLED AT LEAST 30" BELOW FINISHED GRADE IN ANY TRAFFIC AREAS.

15. ALL WIRE SHALL BE COPPER USING TYPE THHN OR THWN MINIMUM #12 UNLESS OTHERWISE INDICATED ON THE PLANS. ALUMINUM AND ALUMINUM ALLOY CONDUCTORS ARE NOT ACCEPTABLE.

16. COORDINATE LOCATION OF TELEPHONE W/ GENERAL CONTRACTOR OR OWNER. PROVIDE 3/4" CONDUIT SIZE WITH PULL STRING AS NEEDED FOR PHONE WIRING.

17. ALL SWITCHES @48" AFF & ALL RECEPTACLES @17 1/2 " AFF UNLESS OTHERWISE INDICATED.

18. PROVIDE SPECIFIED LIGHT FIXTURE WITH FINAL LOCATION WITH ARCHITECT OR OWNER.

19.COORDINATE ALL ELECTRICAL WORK WITH OTHER TRADES TO AVOID ANY CONFLICTS.

20. VERIFY ALL DIMENSIONS AND CONDITIONS AT JOB SITE AND FROM ARCHITECTURAL PLANS

21. CONTRACTORS SHALL COORDINATE WITH THE ARCHITECT AND STRUCTURAL ENGINEER PRIOR TO THE PLACEMENT OF ELECTRICAL EQUIPMENT ON THE BUILDING.

22. BEFORE ANY ELECTRICAL INSTALLATION, ELECTRICAL CONTRACTOR SHALL VERIFY NAME PLATE OF EQUIPMENTS AND PAY ATTENTION TO LATEST DEVICES ELECTRICAL SPECIFICATION OF RATE AMPS VOLTS, PHASE, WIRE SIZE CIRCUIT PROTECTION AS WELL AS THE LOCATION AND MOUNTING DETAIL PER VENDOR'S SPECIFICATION DRAWING. NOTIFY THE ARCHITECT ANY CHANGE FROM DESIGN DRAWING.

23. COORDINATE LOCAL POWER COMPANY FOR EXACT LOCATION OF ELECTRICAL SERVICE. ELECTRICAL CONTRACTOR SHOULD CHECK AND BALANCE AMPS PHASE CONDUCTOR ALL PANELS AND SERVICE.

24. ALL ELECTRODES SPECIFIED IN SECTIONS NEC 250.52(A)1,3-6 THAT ARE PRESENT AT EACH BUILDING OR STRUCTURE SERVED SHALL BE BONDED TOGETHER TO FORM THE GROUNDED ELECTRODE SYSTEM. WHERE NONE OF THESE ELECTRODES ARE PRESENT, ONE OR MORE OF THE ELECTRODES SPECIFIED IN NEC 250.52(A)4-6 SHALL BE INSTALLED AND USED.

25. RECEPTACLES IN PATIENT CARE AREAS: IN AREA USED FOR PATIENT CARE, THE GROUNDING TERMINALS OF ALL RECEPTACLES AND ALL NON-CURRENT CARRYING CONDUCTIVE SURFACES OPERATING AT OVER 100 VOLTS SHALL BE GROUNDED BY AN INSULATED COPPER CONDUCTOR. RE: PATIENT CARE AREA ARTICLE 517.13 (A) & (B) N.E.C. AND DEFINITION OF HEALTH CARE ARTICLE 517.13 N.E.C.

26. GROUND-FAULT, CIRCUIT-INTERRUPTOR PROTECTION ALL 125 VOLT, SINGLE-PHASE, 15 OR 20 AMPERE RECEPTACLES INSTALLED IN THE LOCATIONS SPECIFIED IN (1) THROUGH (5) BELOW SHALL HAVE GROUND-FAULT, CIRCUIT-INTERRUPTER PROTECTION FOR PERSONNEL: (1) BATHROOMS (2) KITCHENS (3) ROOFTOPS (4) OUTDOORS (5) SINKS, WHERE INSTALLED WITHIN SIX FEET OF THE OUTSIDE EDGE OF THE SINK (ARTICLE 210.8(B), 2011 N.E.C.)

PRIOR TO TAPPING INTO MAIN ELECTRICAL GUTTER,

1. ALL WORK SHALL COMPLY WITH THE LATEST EDITION OF NATIONAL ELECTRICAL CODE, BUILDING CODE, ALL APPLICABLE STATE AND LOCAL ORDINANCES 2. ELECTRICAL CONTRACTOR SHALL COORDINATE ALL UTILITY REQUIREMENTS WITH ELECTRICAL PROVIDER. MAKE ARRANGEMENTS AND PAY ALL FEES REQUIRED FOR CONNECTION OF ELECTRICAL UTILITY. 3. OBTAIN ALL PERMITS REQUIRE TO DO THIS WORK AND PAY ANY FEES REQUIRED FOR ASSOCIATED WORK. CONTRACTOR AND SUB-CONTRACTOR SHALL PAY FOR ALL PERMITS AND ASSOCIATED WORK. CONTRACTOR AND SUB-CONTRACTOR SHALL PAY FOR ALL PERMITS AND CHARGES REQUIRED AND COMPLY WITH ALL GOVERNING CODES AND ORDINANCES 4. ALL WORK SHALL BE GUARANTEED FOR PERIOD OF ONE YEAR FROM TIME OF OWNER ACCEPTANCE WORK OR EQUIPMENT FOUND TO BE SUB-STANDARD OR FAULTY SHALL BE CORRECTED DURING THIS PERIOD AT NO COST TO OWNER, LAMPS ARE EXCLUDED. 5. ALL WORK SHOULD BE GROUNDED TO COMPLY WITHOUT EXCEPTION WITH ALL PROVISION OF ARTICLE 250 NEC OF LATEST EDITION OF THE NATIONAL ELECTRICAL CODE. 6.ALL WORK SHALL BE PERFORMED AS PER N.E.C. REQUIREMENTS 7. THE ELECTRICAL CONTRACTOR SHALL PROVIDE ALL MATERIALS, MACHINERY, LABOR, EQUIPMENT AND OTHER CRITERIA ESSENTIAL FOR A COMPLETE AND OPERATIONAL INSTALLATION OF THE ELECTRICAL WORK IMPLEMENTED ON THE PLANS. 8.ALL EQUIPMENT AND MATERIALS BROUGHT TO THE SITE ARE THE PROPERTY OF THE CONTRACTOR UNTIL THE OWNER HAS OFFICIALLY ACCEPTED THE FINAL INSTALLATION. 9. EACH BIDDER SHALL VISIT THE

GC TO CONFIRM LOCATION OF TAP WITH GC TO PAINT ALL CONDUIT AND ELECTRICAL BOXES TO MATCH REAR WALL LANDLORD TO PROVIDE COLOR. 27. 28. NOTE: ALL 15 AND 20 AMPERES, 125-VOLT AND 250 VOLT NON-LOCKING TYPE RECEPTACLES IN THE AREAS SPECIFIED IN 406.12(1) THROUGH (7) SHALL BE LISTED TAMPER-RESISTANT RECEPTACLES 29. SCALE: N.T.S.

N 3R M N 3R PNL "A" PNL "B" 3#4 1#8G 1 1/4"C #4G 45 KVA 3PH TRANSF. 480 -208/120 V 4# 1/0,1#6 GND, 2"C 200A 3P METER DISCONNECT SWITCH 4# 1/0 1#6G. 2"C' 200A. 3P SERVICE DISCONNECT SWITCH FUSED WITH 150A CL FUSES: LTC=15,000A EXIST. TAP BOX FAULT CURRENT: 42872A.SYM 3 -SETS OF 4 -300 KCML EXISTING 800A WIREWAY 277/480V. 3Ø TO EXIST XFMR BANK SERVICE GND 1 -#2/0 AWG 5/8" ROD TO BUILDING STEEL LOAD ANALYSIS________________________ LOAD DESCRIPTION OCCUPANCY CLINIC 1. LIGHTING: 3.6 KVA X 125% 2. RECEPTACLES: 98 X 180 VA 3. SIGN: 1.2 X 125% 4. EQUIPMENT: 5. HVAC (ELECT. HEAT) SUBTOTAL + 25% OF LARGEST MOTOR TOTAL 71.4 KVA @ 480V. 3Ø SERVICE: 4# 1/0, 1#6G AMPACITY SF @ 2VA/SF = 3.6 KVA Connected WTG LOAD = 2.7 KVA 3119 LOAD IN KVA = 13.8 = 16.5 = 1.5 = 14.5 = 60 = 104.3 = 4.5 = 114.5 = 137.6 AMPS = 150.0 AMPS TOTAL: 91.1 KVA @ 480V. 3Ø= 110 AMPS TOTALS: C"* WIRE* PANEL: A LOAD DESCRIPTION VOLTAGE: KVABKR.CKT 1 NEMA 1NEMA 3R CKTBKR.KVA REMARKS: LOAD DESCRIPTION WIRE* C"* All branch circuits are #12, 1 #12G; 3/4"C (U.O.N) MAIN: LUGS: 277/480 200 AMPS SUB-FEEDFEED-THRU 3Ø 4W MLO MCB SURFACE FLUSH AIC:22,000 PANEL: B LIGHTING -RECEPTION 20/1 3 20/1 5 20/1 7 20/1 9 20/1 11 20/1 13 20/1 15 20/1 17 20/1 19 20/1 21 20/1 23 25 20/1 27 20/1 29 20/1 31 .2 .2 .2 .2 .2 .2 .2 .2 .2 .2 .2 .2 .2 .2 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 45 KVA 45 70 3 TRANSFORMER RTU -2 18 30 3 #10 RTU -1 18 30 3 #10 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 20/1 1.5 C"* WIRE* LOAD DESCRIPTION VOLTAGE: KVABKR.CKT 1 NEMA 1NEMA 3R CKTBKR.KVA REMARKS: LOAD DESCRIPTION WIRE* C"* MAIN: LUGS: 120/208 150 AMPS SUB-FEEDFEED-THRU 3Ø 4W MLO MCB SURFACEFLUSH AIC:22,000 20/1 3 20/1 5 20/1 7 20/1 9 20/1 11 20/1 13 20/1 15 20/1 17 20/1 19 20/1 21 20/1 23 20/1 25 20/1 27 20/1 29 20/1 31 20/1 33 20/1 35 20/1 37 20/1 39 20/1 41 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 #12 20/1 20/1 20/1 20/1 1.5 RECEPT. -SIGN 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 #10 30 2 4.5WTR HTR #10 20 2 3.6 VAC #10 20 2 3.6 AIR 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 #12 #12 #12 #12 TOTAL: 32.3 KVA@208V. 3Ø = 90AMPS All branch circuits are #12, #12G; 3/4"C (U.O.N) TOTALS: #12 20/1 43 1.5 44 20/1 .2#12 20/1 .2#12 20/1 .2#12 33 35 37 39 41 43 20/1 .2#12 RECEPT. -WAITING RECEPT. -RECEPTION RECEPT. -RECEPTION RECEPT. -BILLING RECEPT. -TREAT 05 RECEPT. -TREAT 04 RECEPT. -PAN/CEPH RECEPT. -PAN/CEPH RECEPT. -PAN/CEPH RECEPT. -EXAM 01 RECEPT. -EXAM 02 RECEPT. -TREAT 01 RECEPT. -TREAT 02 RECEPT. -TREAT 03 RECEPT. -OFFICE RECEPT. -STERIL RECEPT. -STERIL RECEPT. -STERIL RECEPT. -STAFF RECEPT. -STAFF RECEPT. -STAFF RECEPT. -IT RECEPT. -IT #12 20/1 45 1.5 20/1 47 1.5 RECEPT. -LAB 20/1 49 1.5 #12 EF-1 -R.R.1 EF-2 -R.R.2 EF-3 -MECH EF-4 -EF-4 LIGHTING. R.R.1 LIGHTING. R.R.2 LIGHTING.-WAITING LIGHTING.-RECEPTION LIGHTING.-HALLWAY #12 LIGHTING.-PAN/CEPH 20/1 .2 20/1 .2 20/1 .2 LIGHTING.-HALLWAY #12 #12 LIGHTING -BILLING LIGHTING -EXAM 01 LIGHTING -EXAM 02 LIGHTING -TREAT 01 LIGHTING -TREAT 02 LIGHTING -TREAT 03 LIGHTING -TREAT 04 LIGHTING -TREAT 05 LIGHTING -PAN/CEPH LIGHTING -STERIL LIGHTING -STORAGE LIGHTING -OFFICE LIGHTING -LAB LIGHTING -MECH LIGHTING -STAFF #12 #12 20/1 .2 20/1 .2 #12

LIGHTS AS REQUIRED TO AVOID EXISTING STRUCTURE, MECHANICAL DUCTS, OR CUTTING OF MAIN TEES. VERIFY NEW LOCATIONS WITH TENANT. REPAIR OR REPLACE ALL DAMAGED AND OR MISSING LIGHT FIXTURES, CEILING TILES AND GRID AS REQUIRED. VERIFY EXACT REQUIREMENTS AND PRICE CONSTRUCTION WITH ARCHITECT OR TENANT BEFORE PROCEEDING FURTHER. ALL LIGHTING FIXTURES ARE NEW UNLESS NOTED OTHERWISE. CONTRACTOR IS TO PROVIDE AND INSTALL EXIT SIGNS AS REQUIRED BY IBC CHAPTER 10, SECTION 1011 AND NEW VISIBLE ALARMS (STROBE LIGHTS) AS REQUIRED BY IBC CHAPTER 9, SECTION 907. CONTRACTOR SHALL PROVIDE MINIMUM NUMBER OF CODE REQUIRED LIGHT FIXTURES TO EMERGENCY 24 HOUR NIGHT BATTERY BACKUP. VERIFY LOCATIONS WITH ELECTRICAL INSPECTOR PRIOR TO CEILING INSTALLATION. ALL CEILING TILES AND GRID THROUGHOUT LEASE SPACE PER ARCHITECT SPECIFICATION. CONTRACTOR TO PROVIDE FIREPROOFING OF ALL LIGHT FIXTURES. FIELD VERIFY EXACT REQUIREMENTS WITH PROPERTY MANAGEMENT PRIOR TO START OF CONSTRUCTION. ALL LIGHT FIXTURES MUST HAVE FIREPROOFING.

GENERAL

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. CONNECT ALL EMERGENCY LIGHTS AND EXIT LIGHT UNSWITHED, WIRE LIGHTING FIXTURE IN SUCH MANNER THAT FIXTURE WILL AUTOMATICALLY SWITCH ON UPON DETECTION OF NORMAL POWER FAILURE. 13. GENERAL NOTES: 1) FINAL CONNECTION TO DENTAL CHAIR SHALL BE MADE WITH HOSPITAL GRADE MC CABLE WITH REDUNDANT GROUNDING CONDUCTOR AS PER NEC ARTICLE 517. MCSTAT CABLE FROM AFC OR EQUAL. 2) ELECTRICAL EQUIPMENT SUCH AS PANELBOARD THAT ARE IN OTHER THAN DWELLINGS AND ARE LIKELY TO REQUIRE EXAMINATION, ADJUSTMENT, SERVICING, OR MAINTENANCE WHIL ENERGIZED SHALL BE FIELD OR FACTORY MARKED TO WARN QUALIFIED PERSONS OF POTENTIAL ELECTRIC ARC FLASH HAZARDS. MARKING SHALL MEET NEC 110.21 (B) AND SHALL BE CONSPICUOUSLY LOCATED AND CLEARLY VISIBLE. FAULT CURRENT CACULATION NOTE USING POINT TO POINT METHOD, FAULT CIRCUIT CURRENT CALCULATION IS BASED ON 300KVA, 480V TRANSFORMER AT THE SHELL BUILDING WIREWAY GUTTER, WITH 75 FOOT OF 4 #600KCMIL COPPER CABLE IN METAL RACEWAY. THE CALCULATED FAULT CURRENT IS 10619 AMP L-L AT THE PANEL "A", 7263AMP L-N. THEREFORE NEW PANEL "A" WITH 18KAIC RATING IS ADEQUATE. AVAILABLE

PROVIDE LABELING 2" X 3" IN SIZE IN BLUE LETTERING ON A CONTRASTING BACKGROUND. THIS LABEL SHALL ALSO INCLUDE THE DATE OF THE CALCULATION. Checked By: Drawn By: Sheet Name/Number: Project Team: Issue Revisions: Plot Date: Project Name/Number: SCALE: © Copyright 2021 All information, drawn, written, or implied, appearing in this document constitutes the original and unpublished work of twenty20 Studio, LLC. and may not be duplicated, distributed, or disclose by any means without the prior written consent of twenty20 Studio, LLC. This is an instrument of services and sole property of the author. The use of this document shall be revoked any of the design intent or the construction methods shown herein are not adhered to, or the terms of the contractual agreement for its use violated. Written dimensions on these drawings shall have precedence over scale dimensions. Contractors shall be responsible for al dimensions and conditions on the job. twenty20 Studio, LLC must be notified of any variation from the dimension and conditions shown by these drawings. Contractor: MEP: A B C D E F G 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Designer: twenty20Studio, LLC Contact: Ramon Gisbert t: 346.388.3820 formerly RJG Design Studio, LLC 5815 Gulf Fwy Houston, TX 77023 Sheet Size: 24" x 36" RJG SA. Aftab Ur Rahman 21027 ARCHITECTURE + PLANNING studio TAS TDLR Otten Consulting Group Contact: Kathy Rodriguez t: 713.975.1029 Solution Engineering Contact: Duwan Cotton, PE t: 713.376.9801 Custom Practices Contact: Trevor Fawcett t: 713.836.2811 Safari Family Dental PERMIT9/22/2022 As indicated 14/11/2022 4:10:38 pm ONE-LINE & PANEL SCHEDULE E1.2

CONTRACTOR IS TO PROVIDE TO PROPERTY MANAGEMENT A DIAGRAM OF NEW MECHANICAL SYSTEM CONFIGURATION PRIOR TO CONSTRUCTION. LIGHT LOCATIONS SHOWN ARE FOR DESIGN PURPOSES ONLY. CONTRACTOR SHALL RELOCATE

LIGHTING PLAN

FAULT CURRENT LABELING

(IMC 2015)

DIFFUSERS, GRILLES, AND REGISTERS

QUANTITY

BORDERS TO ACCOMMODATE GYPSUM BOARD CEILING OR T-BAR LAY-IN CEILINGS.

EXHAUST FAN SCHEDULE

4"Ø EXHAUST OUTLET, PROVIDE CEILING GRILLE, GRAVITY BACKDRAFT DAMPER AT FAN OUTLET AND ROOF CAP

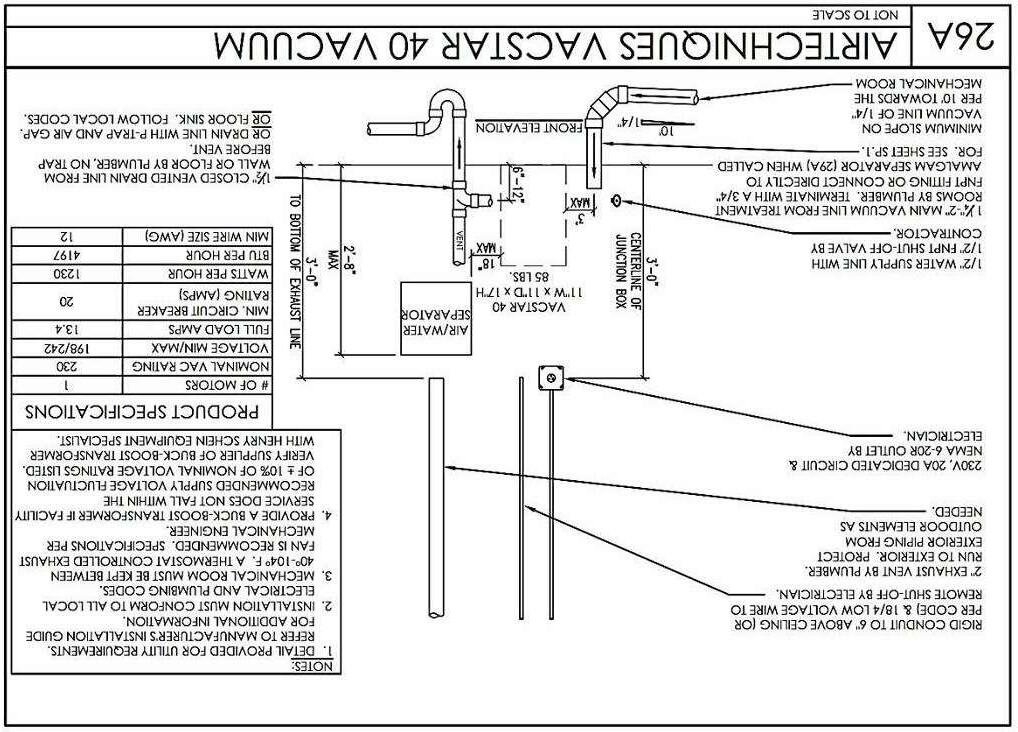

A A RTU #1 RTU #2 Location of RTU to be verified with Landlord. All roof penetrations to be completed by landlord's roofer. Location of RTU to be verified with Landlord. All roof penetrations to be completed by landlord's roofer. 20" x 16" 20" x 16" 20"x 16 16 x 14 20" x 16" 16 x 14 20" x 16" 20 x 16 16" 14" 16"x 14" R/A R/A R/A R/A S2-75 S2-75 8" Ø FLEX S2-150 S1-150 8" Ø FLEX EF-4 EF-3 EF-2 EF-1 T T 1 ½" Ø Fresh air intake through roof sched. 80 PVC 2" Ø Exhaust pipe through roof sched. 80 PVC S1-150 S1-150 S1-150S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S1-150 S2-150 S2-150 S2-150 S2-150 S2-150 S2-150 S2-150 S2-150 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 8" Ø FLEX 6" Ø FLEX 6" Ø FLEX Waiting Exam 01 Exam 02 Treat 01 Treat 02 Treat 03 Staff MECH N2O IT LAB Storage Hallway 02 Treat 05 Treat 04 Hallway 02 Hallway 01 Reception Billing R. R. 1 R. R. 2 S3-200 S3-200 S3-200 S3-200 S3-200 S3-200 S3-200S3-200 16" x 14" 16" x 14" 16" 14" 16" 14" 16" x 14" 16" x 14" MFR. MODEL CFM O.A.CFM TESP (in.w.g.) BHP (AHU 1, 2) COOLING TOTAL COOLING CAPACITY (MBH) SENSIBLE COOLING CAPACITY (MBH) EDB (°F) EWB (°F) LDB (°F) LWB (°F) MIN. ROWS MAX. FPI AMBIENT (°F) COMP. KW HEATING BTUH (KW) HEATING STAGE EAT (°F) LAT (°F) FLA MIN CKT AMPS MAX OCP AMPS V-P-H ELECTRICAL UNIT TO BE FURNISHED WITH FOLLOWING OPTIONS: 1) LOW AMBIENT CONTROL, ANTI-SHORT LOCK OUT TIMER, 20% EFF. FILTER. 2) UNIT TO BE EQUIPPED WITH HAIL GUARD 3) RA+SA SMOKE DETECTOR WITH CO2 SENSOR. 4) FURNISH WITH FACTORY EQUIPPED NON-FUSED DISC. WITH UNPOWERED 120V OUTLET. 5) PROVIDE

FABRICATED

6)

WITH BAROMETRIC

7)HINGED PANEL 8) MOTORIZED O/A DAMPER. 9)SINGLE POINT ELEC. HEAT CONNECTION. 10 BELT DRIVE REMARKS 200 0.85 1.30 460V 3PH 57.5 41.4 78.2 69.7 54.6 53.4 4 15 95.0 4.6 27.3 2 59.6 90.0 42 42 50 2000 BRANCH DUCT SIZE 0-125

FACTORY

ROOF CURB.

PROVIDE ECONOMIZER

RELIEF.

AIR QUANTITY (CFM) DEVICE NECK SIZE ROUND DUCT ALTERNATE RECTANGULAR DUCT 126-250 251-375 376-450 451-600 6"Ø 8"Ø 10"Ø 12"Ø 14"Ø 8X4 10X6 10X8 12X10 16X10 S1-50 TYPE (TYP.) AIR QUANTITY FLEXIBLE CONNECTION (TYP.) VOLUME DAMPER (TYP.) SQUARE CEILING SUPPLY DIFFUSER, STEEL CONSTRUCTION, 3 CONES -ONE PIECE DIE STAMPED, ADJUSTABLE VANES, 24X24 CEILING MODULE, TITUS MODEL TMSA-FR OR EQUAL. R/A PERORATED CEILING DIFFUSER FOR RETURN AIR UL CLASSIFIED FIRE RATED TITUS MODEL PAR-FR ARCHITECT TO SELECT COLOR. COORDINATE CEILING TYPES WITH ARCHITECTURAL PLANS. PROVIDE APPROPRIATE

S2-50AIR

6"Ø 8"Ø 10"Ø 12"Ø 14"Ø

1.

COORDINATE TEMPERATURE SETTING WITH ARCHITECT 2. 3"Ø EXHAUST OUTLET, PROVIDE CEILING GRILLE, GRAVITY BACKDRAFT DAMPER AT FAN OUTLET AND ROOF CAP WHERE NOTED ON PLANS. 3. FAN TO BE CONTROLLED BY WALL MOUNTED SWITCH. TAG CFM RPMSP MOTOR AMPS/VOLT EF-1,2 EF-3,4 1.3 AMPS, 110V -1PH 501750 0.125 FAN TYPEDRIVE TYPEMANUFACTURER NOTES CEILINGDIRECT 2,3 1 1.3 AMPS, 110V -1PH 751750 0.125 CEILINGDIRECT GREENHECK SP-B-50 GREENHECK SP-B-80

S2-50AIR QUANTITY SQUARE CEILING SUPPLY DIFFUSER SLOT DIFFUSER NOTES:

WHERE NOTED ON PLANS. EXHAUST FAN CONTROLLED VIA THERMOSTAT.

HVAC COMPLIANCE REQUIREMENTS: A) HVAC RECORD DRAWINGS OF THE ACTUAL INSTALLATION AND PERFORMANCE DATA FOR EACH EQUIPMENT SHALL BE PROVIDED TO THE OWNER B) HVAC O&M DOCUMENTS FOR ALL MECHANICAL EQUIPMENT AND SYSTEM SHALL BE PROVIDED TO THE OWNER. C) WRITTEN HVAC BALANCING REPORT SHALL PROVIDED TO THE OWNER MECH. SCHEDULE PER 2015 IECC DUCT LOCATIONMIN. R-VALUE IN FURRDOWN4 IN UNCONDITIONED SPACE6 IN ATTIC SPACE8 T-STATPROGRAMABLE REFRIGERANT PIPING 1" INSULATION IN ATTIC SPACE APPLICATION DENTAL NOTE: SET THE MINIMUM O/A AT 200CFM AND MAXIMUM O/A AT CFM BASED ON CO2 LEVEL. RTU MOTORIZED DAMPER SHALL BE MODULATING BETWEEN MIN AND MAX BASED ON C02 LEVEL FROM RTU'S CO2 SENOR. UNIT MOUNTED CO2 SENSOR. AREA (SQ.FT.) DEFAULT OCCUPANT 5 "Az"PER 1000FT^2 TOTAL OCCUPANT "Pz" 18 PEOPLE OUTDOOR AIR RATE "Rp" 5 (CFM/PERSON) AREA OUTDOOR AIR RATE "Ra" 0.06 (CFM/FT^2) OUTSIDE AIR REQUIRED: = (Rp X Pz + Ra X AZ) = (5 X 18 + 0.06 X = CFM OUTSIDE AIR PROVIDED: CFM 2026 212 212 212 2026 OUTDOOR AIR VENTILATION CALCULATION