Nickel Alloy Fittings: Enduring Performance Under Extreme Conditions

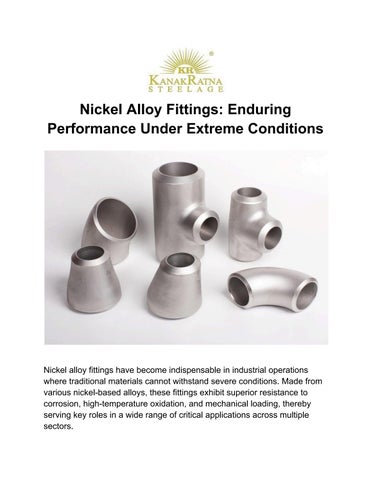

Nickel alloy fittings have become indispensable in industrial operations where traditional materials cannot withstand severe conditions. Made from various nickel-based alloys, these fittings exhibit superior resistance to corrosion, high-temperature oxidation, and mechanical loading, thereby serving key roles in a wide range of critical applications across multiple sectors.

Composition and Alloy Families

Nickel alloy fittings represent a large class of materials in which nickel is the principal element, complemented by chromium, molybdenum, iron, copper, and trace additions tailored to specific environments. Alloy families are structured according to these constituents and the service climates they are engineered to withstand.

Nickel-copper alloys, typified by Monel 400, contain 63 to 70 percent nickel and 28 to 34 percent copper, providing exceptional immunity to seawater, reducing media, and a spectrum of acids.

Nickel-chromium alloys, including Inconel 600 and 625, contain 60 to 76 percent nickel and 15 to 23 percent chromium, resulting in remarkable resistance to oxidation and high-temperature corrosive attack.

Nickel-chromium-molybdenum grades, such as Hastelloy C-276, combine nickel, chromium, and elevated molybdenum levels to withstand aggressive oxidizing and reducing environments, especially in elevated-temperature acidic solutions.

The individual alloy composition infuses fittings with distinct characteristics that dictate their best field of use. By judiciously selecting and balancing alloying components, metallurgists can engineer the microstructure and mechanical behaviour of the material for requirements ranging from subzero cryogenic applications to sustained exposure above 2000°F (1093°C).

Nickel alloy fittings possess several performance attributes that set them apart from conventional metals Their superior resistance to corrosion in hostile media is linked to the formation of a durable and self-repairing passive oxide layer that staves off further attack.

This behaviour allows the fittings to endure media that contain chlorides, concentrated acids, caustics, and organic solvents conditions that would rapidly deplete standard materials.

At the opposite end of the temperature spectrum, the fittings sustain mechanical properties and dimensional stability in high-temperature environments where conventional alloys lose tensile strength and ductility.

The oil and gas sector specifies them for sour gas compression, sour well completions, and subsea pipelines, where hydrogen sulfide and carbon dioxide impose a uniquely corrosive exposure.

Refineries depend on the fittings within high-temperature catalytic reactors, fluid catalytic cracking circuits, and transfer lines that handle heated acids.

In the pharmaceutical sector, they are specified for high-purity formulation trains, where even trace contamination by metallic ions must be avoided and other alloy alternatives are disqualified on resistance grounds.

Power generation installations employ nickel alloy fittings in supercritical steam boilers, nuclear steam generators, and in flue gas desulfurization circuits. Marine settings call for them in seawater-cooled circuits, reverse osmosis plants, and offshore platform systems subjected to continuous chloride exposure.

The aerospace and defense sectors depend on these components in gas turbine engines, afterburner ducts, and in assemblies facing extreme thermal and mechanical loads.

Selection Criteria and Engineering Considerations

The choice of nickel alloy for any particular fitting application demands a methodical analysis of a suite of parameters. The precise chemical makeup and concentration of process media, the expected thermal and pressure envelope, and the likelihood of erosion or imposed mechanical loads must all be quantified

The engineer must determine if the degradation risk stems primarily from oxidizing acids, reducing atmospheres, chloride-mediated stress corrosion, or high-temperature oxidation to pinpoint the most suitable alloy group.

Manufacturing variables exert a decisive influence on the in-service behaviour of fittings. Rigorous heat treatment, comprising solution annealing followed by controlled cooling, is critical to securing the desired microstructural features and corrosion resistance.

Tight quality assurance protocols, spanning alloy composition analysis and non-destructive evaluation, are imperative, owing to the critical nature and elevated costs associated with these components.

Welding and joining of nickel alloys must be approached with thorough engineering discipline, as the development of specific precipitation phases can compromise joint durability.

Detailed welding protocols, selection of appropriate filler metals, and tailored post-weld heat treatment schemes are essential to preserve both corrosion resistance and the mechanical properties required in service.

Additionally, any mixed-metal assembly must be assessed for galvanic compatibility, since less noble components can suffer accelerated corrosion when electrically coupled to nickel alloys. Careful design of electrical, material, and environmental interfaces is, therefore, an obligatory step in the material selection process

Economic Considerations and Lifecycle Analysis

The initial cost of nickel alloy fittings is considerably higher than that of carbon and standard stainless steels, typically ranging from four to ten times the price of the equivalent austenitic option, depending on the specific alloy and commodity indices.

Lifecycle cost evaluation, nevertheless, frequently reveals a net economic benefit in their intended applications. The alloy’s resistance to pitting, crevice corrosion, and stress corrosion cracking translates into longer service intervals, minimizing both direct material replacement costs and the indirect costs linked to unplanned downtime and lost production

Furthermore, the ability of nickel alloys to sustain higher design pressures and temperatures may allow for the design of smaller, lighter assemblies that use less energy and raw material during fabrication.

The savings in heat and power that typically accompany more efficient process regimes can, therefore, amortize the greater up-front expense. In high-consequence applications, such as pressure vessels in the oil and gas, aerospace, and nuclear sectors, the avoidance of catastrophic failure incidents introduces an economic value that is difficult to quantify yet undeniably significant

By deliberate material selection, rigorous specification, and judicious integration, nickel alloy pipe fittings achieve outstanding durability within the harshest process environments.

Their outstanding blend of resistance to localized corrosion, retention of strength at elevated temperatures, and high-yield strength establishes a performance envelope that standard steels and non-ferrous alternatives cannot match

In critical systems where both system integrity and personnel safety are prioritized, the elevated initial cost is in fact a judicious trade-off against the lower risk of catastrophic failure and unplanned downtime.