Cleanroom Conceptual Design Paradigm:

Presented by: Matt Dean

September 26, 2024

AES Clean Technology

Advancing Scientific Innovations

About Us

We go where you go

Philadelphia Headquarters

-Engineering

-Project Management

Irvine Office

-Project Management

-Project Development

Atlanta Manufacturing

Manheim Warehouse

-Phased Shipping

-Future Manufacturing

Meet the Presenter...

Matt Dean RA, NCARB, LEED GA

Director of Process Architecture

Process Technology Team Leader

15 years Biopharma/Life Science industry

Specialized in Biopharma/Life Science design

BS. of Architecture, M. Architecture

Registered Architect, NCARB certified, LEED certified

Today’s Agenda

Philosophical Differences

Operations & Level of Compliance

Procedural controls

Commercial vs Industrial Facilities

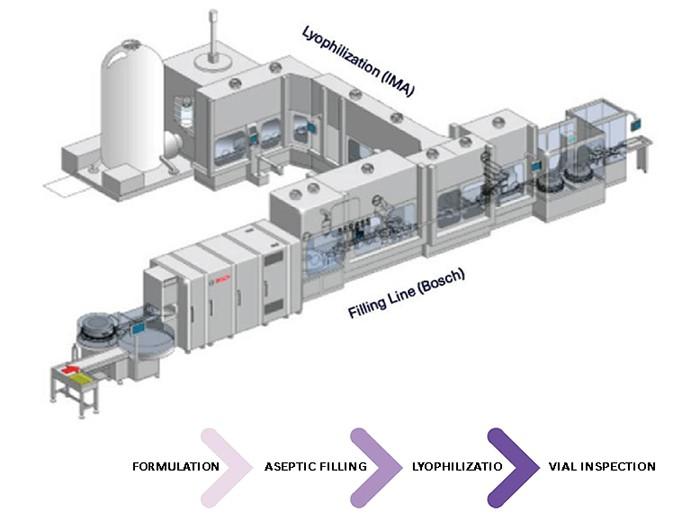

Production Regimen & Process Platforms

GMP Flows & Access Controls

Utilities Infrastructure & Construction Challenges

Systems & Logistics

Questions?

Cleanroom Infrastructure Considerations

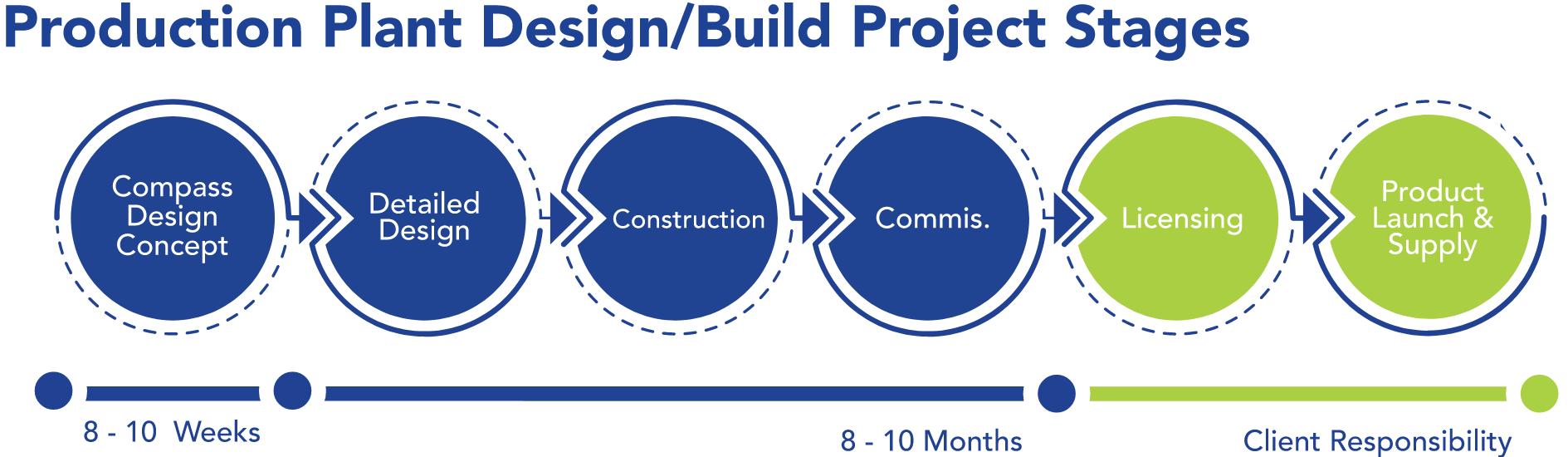

Compass Project Roadmap™

• Warehouse/Logistics

Centers may not exist or be limited or remote

• Site access availability

• Project area access for operations (multi-level configuration?)

• Mechanical systems suitability and availability

• Existing corridor system constraints

• Warehouse/Logistics

Centers upgrading for project suitability

• Site access reconfigurations

• Project area accessible

• Mechanical systems upgrades

• Potential mechanical platforms

• Manual process operations

• Small scale processes

• Limited process automation

• Production regimen higher criticality

• Potentially separate upstream and downstream suites operations

• Process utilities required vs existing

• Process utility local cylinders

• Manual or automated process operations

• Small or large scale processes

• Process automation may be implemented

• Ballrooms for upstream & downstream operations

• Central process utility generation potential

• Opportunities constrained by space or access to project area

• Fit-for-purpose consideration

• GMP operational impacts

• Mechanical system location may be remote

• Impacts of multiple tenants in single facility

• Investigate “bolt on” concepts for expansion

• Opportunities vetted with facility & operations impacts

• Fit-for-purpose vs futureproof

• GMP operational impacts

• Mechanical system location may be remote or on platform

• Minimized interstitial space

• Walkable ceiling access could be compromised

• Mechanical maintenance remote

• Increased interstitial space

• Walkable ceiling access possible

• Mechanical maintenance provided above ceiling

Cleanroom Design Attribute Trends

1 2

Flexibility

Cleanrooms accommodating to operational changes under similar process platforms.

Adaptability

Cleanrooms accommodating to similar process unit operations with minimized shutdown periods utilizing equipment changeover.

3 4 5

Segregation (Room vs Equipment)

Implementing segregation in multiproduct operations via control at highrisk zones in the same room or designing independent suites.

Phased

Implementation

Opportunities to tailor cleanroom design and installation into phases for strategic build-out.

Future Growth

Responsive to business drivers and process development plans.

Cleanroom Design Practices

Efficient Material & Personnel Flows

Room Design Supports Secondary Process Containment

Optimized Process Equipment Adjacencies Mechanical Design Coordinated with Process Design

Plan for the Future

Deciding Operational and Compliance Alignment

cGMP & Compliance Keys: Multi-Product Operations

ATMP Manufacturing, US-FDA Compliance

Independent Suites, Closed Process

ATMP Manufacturing, EU Compliance

Ballroom with Physical Work Zones, Open Process

cGMP & Compliance Keys: Process Design & Scale

Manual Operations

Open Processing Manual Filling

cGMP & Compliance Keys: Process Design & Scale

Automated & Closed

cGMP & Compliance Keys: Room Containment

PROCESS ROOM

PAL MIST

Compliance Guidance Highlights

COMPLIANCE CATEGORY DESIGN COMPLIANCE TOPICS HIGHLIGHTS

Eudrolex Vol 4 Annex 1

Eudrolex Part IV (ATMPs)

US-FDA: Sterile Drug

Products Produced by Aseptic Processing – cGMP

Cross-Contamination

CCS

Aseptic Filling background environment

Pass-through Chambers

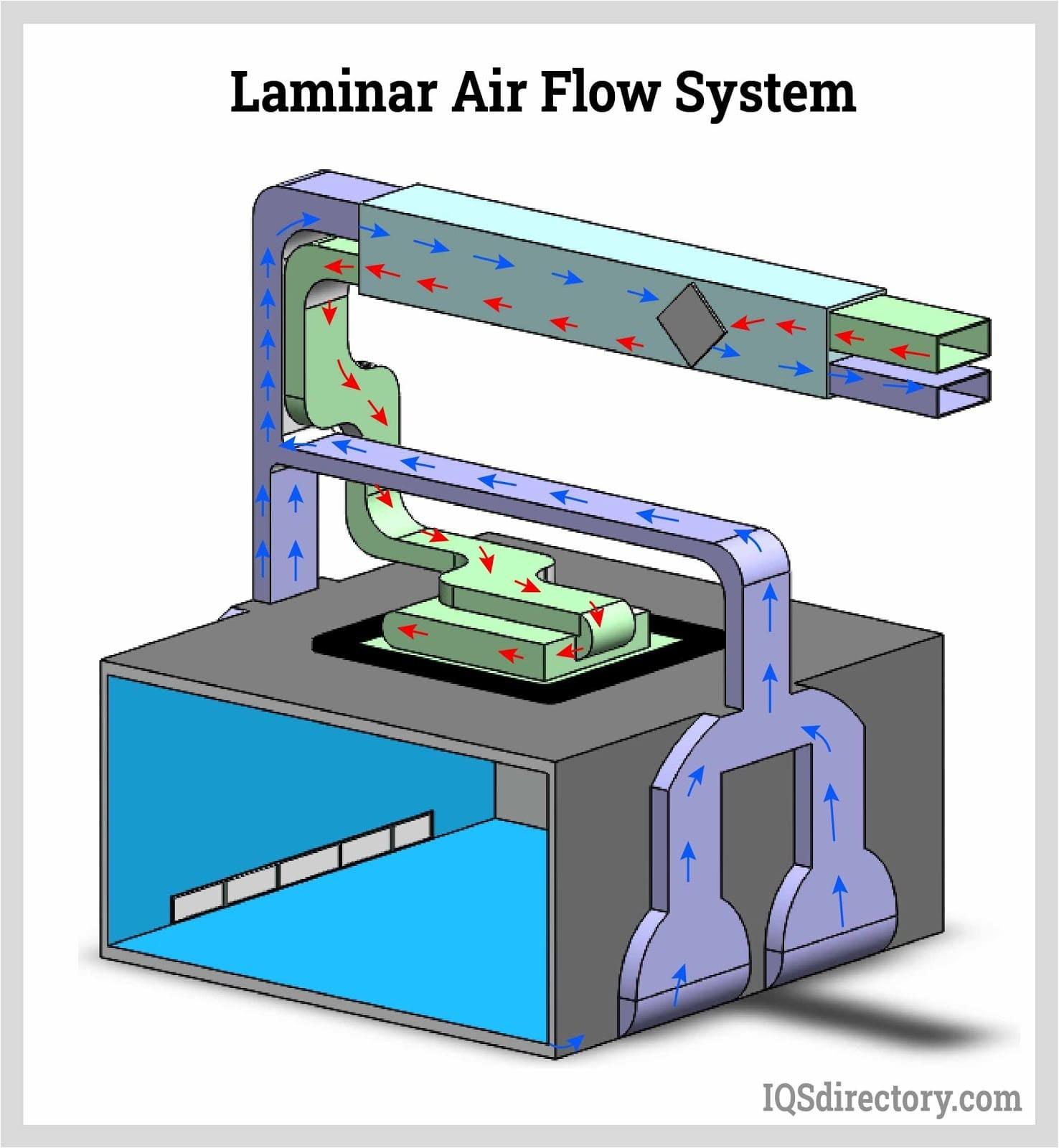

Unidirectional flow

Airflow Visualization Studies

Containment

CCS

Multi-product facility

Concurrent production

Closed systems

Containment

Multi-product operations

Drains

Closed systems

ISPE ATMPs – Autologous Cell Therapy

Containment

CCS

Multi-product operations

Aseptic Processing

EM

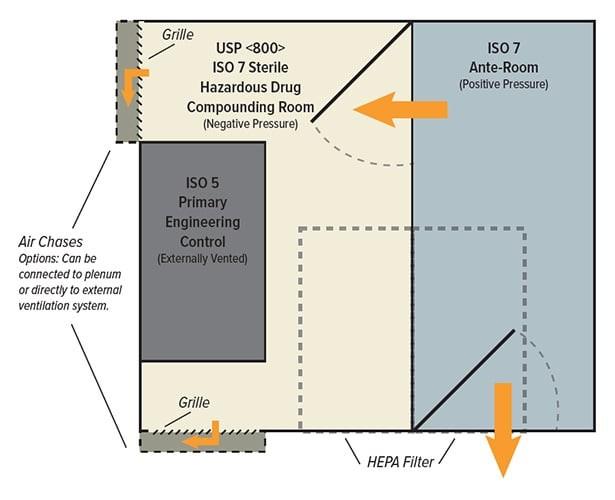

USP <797>, updated 2022

USP <800>, updated 2019

Pressurization scheme + DPs

P-PEC + P-SEC

Revised CSPs

BUDs

Reference to USP <800>

Pressurization scheme + DPs

P-PEC + P-SEC

Containment & Ventilation

Once-through air system (room or containment zone) in high-risk zone, AHUs prevent cross-contamination

Grade B for manual filling, Grade C or D when closed isolator is used

Pass-through chambers with active filtered air supply flush. interlocked

Recommended physically segregated personnel and material flows (temporal acceptable) and unidirectional

personnel flow (Grade B specifically or result of CCS)

Final stage AL to be same classification as process room into which it leads

Sink and Bubble pressurizations for BSL2 aerosolization, AHUs designed to prevent cross-contamination

Once-through air system (room or containment zone) in high-risk zone

AHUs designed to prevent cross-contamination

Segregated sterile and non-sterile flows

Recommend unidirectional flows

ISO 7 background adjacent to aseptic processing, ISO 5 equipment environment

Segregated personnel entry & exit flows, AHUs designed to prevent cross-contamination

Inappropriate in aseptic processing areas other than ISO 8 with rare exceptions

LPZ for stopper vials prior to capping

Protocols at critical aseptic areas

Open processing conducted in BSC with ISO 5 environment in ISO 7 background

Physical segregations, temporal requirements

Sink and Bubble pressurizations for BSL2 aerosolization, AHUs designed to prevent cross-contamination

Electronic barcoding

Segregated personnel entry & exit flows

Positive pressure for sterile compounding (non-HD), 30ACH, 0.01-0.03wc

Non-sterile compounding

CSP 1,2,3 - CSP 1 only may be in C-PEC in C-SCA in unclassified area

BSCs, RABS (CACI or CAI), LAFW

PPE and protocols

Negative pressure for sterile compounding (HD), 30ACH, 0.01-0.03wc

C-PEC & C-SEC externally ventilated, BSCs Class II A2, B1 or B2 or CACI for sterile HDs

Antineoplastic compounding and storage segregation

Designing for SOPs & Controls in Cleanrooms

Architectural control systems are intended to:

• Control access to critical areas

• Accommodate frequent cleaning & equipment

• Segregate personnel from processing exposure

SOPs are intended to:

• Prevent cross-contamination

• Align production schedule with operations

• Enable cleanroom operator occupancy

• Segregate flows where required

• Protect operators

Architecture Controls:

• Personnel, materials, waste

• Classified area access

• secure IP, critical materials & product

Environmental Controls:

• Temperature

• Humidity

• Pressurization

• Cleanliness (particle removal)

• Surface cleaning

cGMPs for Access Controls

cGMP for Airlock Scheme

Pressure Bubble Pressure Sink Pressure Cascade

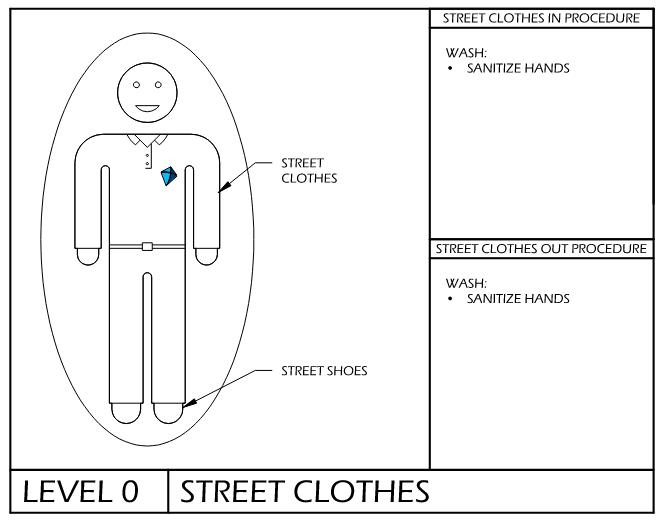

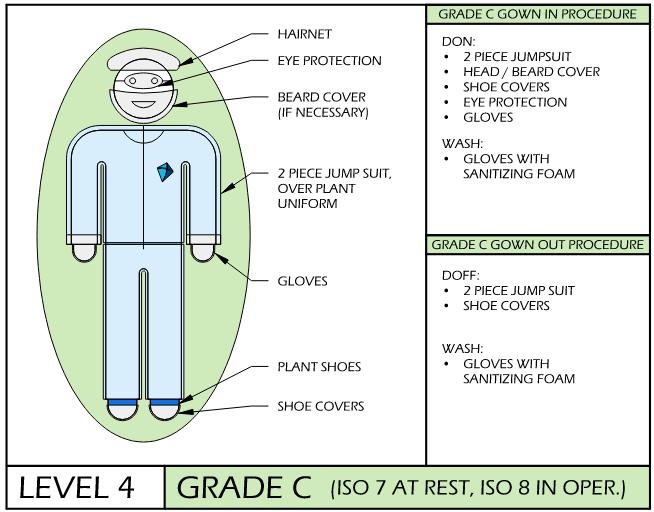

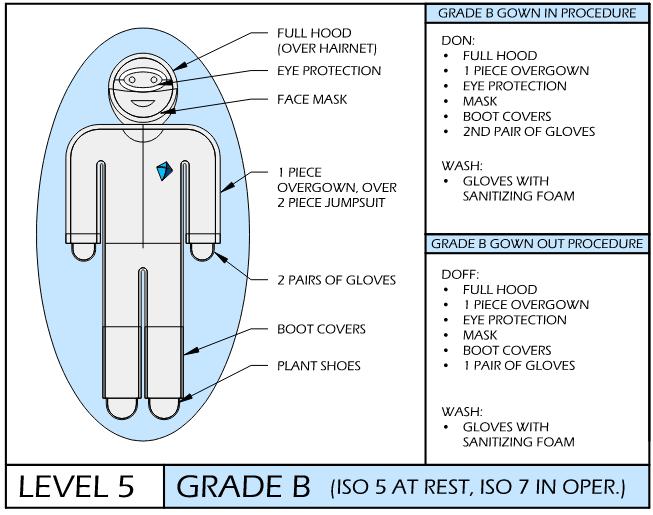

cGMP & Compliance Keys: Gowning SOPs

Temporal Procedures

cGMP & Compliance Keys: Process Design

PEOPLE PRODUCT

Cleanroom HVAC Design Practices

AHU Zoning

• 1 AHU per FlexSuite

• Cell & Gene Therapy

• BSL-2 or lower

• Recirculation (10-30%OA)

• Optional once thru (100%OA)

Environment al

• 66°F Grade B

• 68°F Grade C

• 70°F Grade D/CNC

• Temp +/- 4°F

• Summer Humidity max 60%

• Winter

Humidity min 30%

Classificatio n

• Grade B –60ACH

• Grade C –45ACH

• Grade D –25ACH

• CNC –15ACH

Containment Strategy

• Supply / Return Corridors

• ++Bubble MAL/ PAL in

• + Processing room

• - Sink MAL/PAL out

Cleanroom HVAC Design Schematic

Cleanroom HVAC Design Practices

Critical Zone Airflow Design Example

Cleanroom Mechanical Design Considerations

Cleanroom AHU Cooling & Heating Source

Cleanroom AHU

Cooling / Heating Options

• Chilled Water + Heating Hot Water AHUs

• Central Chiller / Boiler

• Hydronic piping

• Precise temperature control

• Best heating/cooling performance for large loads

• Lowest energy costs

• Direct Expansion + Elec Re-Heat / Heat Pump

• Packaged units mounted outside or Split System

• Refrigerant piping for split systems

• Less precise temperature control

• Higher energy costs

Total Cost of Ownership

HVAC Equipment location options

C• Mezzanine Supported

• Structural additions

• Space under Mezz. can be utilized

• Risk of leaks from Chilled/Heating water

• AHUs protected from elements, easier maintenance

• Roof Supported

• Structural reinforcement/additions

• Consumes no interior space

• Risk of leaks from Chilled/Heating water

• Packaged DX RTU’s are cost effective

• RTU’s exposed to elements

• Floor Supported

• No structural additions / seismic

• Consumes floor space

• Lower risk of leaks from Chilled/Heating water

• AHUs protected from elements

•Hung in Interstitial space

•Requires structural additions

•Uses no space at perimeter

•Shorter duct runs

•Higher risk of leaks from Chilled/Heating water

•Can be difficult to install/maintain (requires access)

•AHUs protected from elements

Construction Challenges in GMP Space Conversion

Access

• Location for construction material entry relative to project area

• Corridor system

• Project area above grade can affect constructability

• Proximity to project area impacts efficiency

• Exterior points of entry

• Shared corridors/access points with other facility tenants

Rigging

• Rigging equipment impacted by project area location (central or exterior access)

• Mechanical equipment highest impact

• Site or facility restrictions on equipment used

Material Staging

• Interior or Exterior location

• Protection of materials is important

• Constraints on material movement through occupied spaces

• Proximity to project area impacts efficiency

Building Volume

• Potentially limited interstitial space above cleanroom

• Height to structure above impacts sequencing and modular system design

Sequencing

• Installation starting point (build-out concept)

• Interface with other trades

• Work schedule with other trades

• Safety & Logistics in work area

• Intent to avoid disruption of current ongoing operations

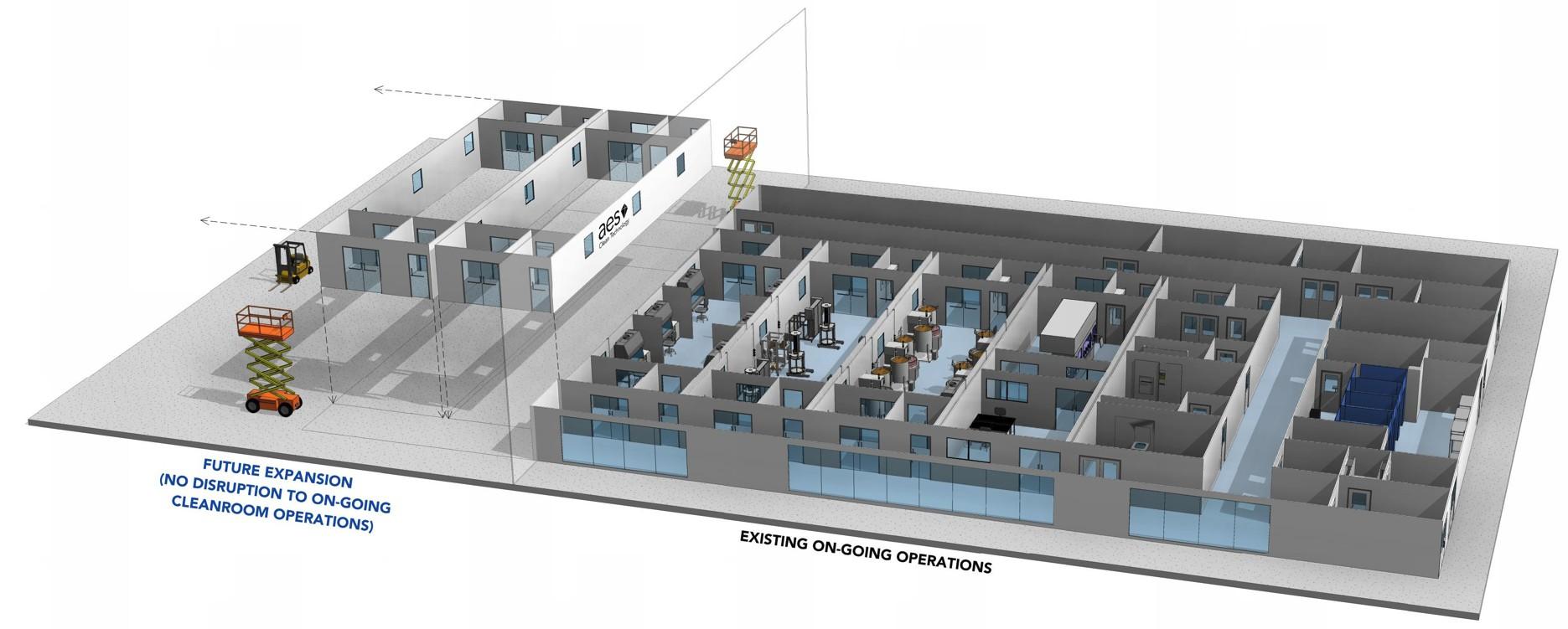

Future Phasing

• Phased expansion internal or external

• Intent to avoid disruption of current ongoing operations

• Consider “bolton” concept

Construction Phasing Strategies in Spatial Conversions

Roadmap to Project Success

CONSTRAINT IDENTIFICATION REGULATORY & cGMP ALIGNMENT

PROCESS

ARCHITECTURE & MECHANICAL ENGINEERING

PHASED IMPLEMENTATIO N STRATEGIES

Capital Projects Start with Conceptual Design

Prepare for strategic review with scope, schedule, and cost schematic design data