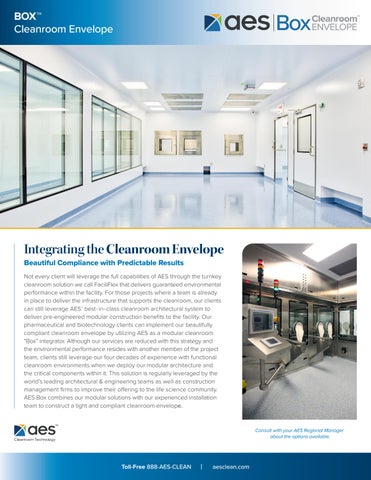

Integrating the Cleanroom Envelope

Beautiful Compliance with Predictable Results

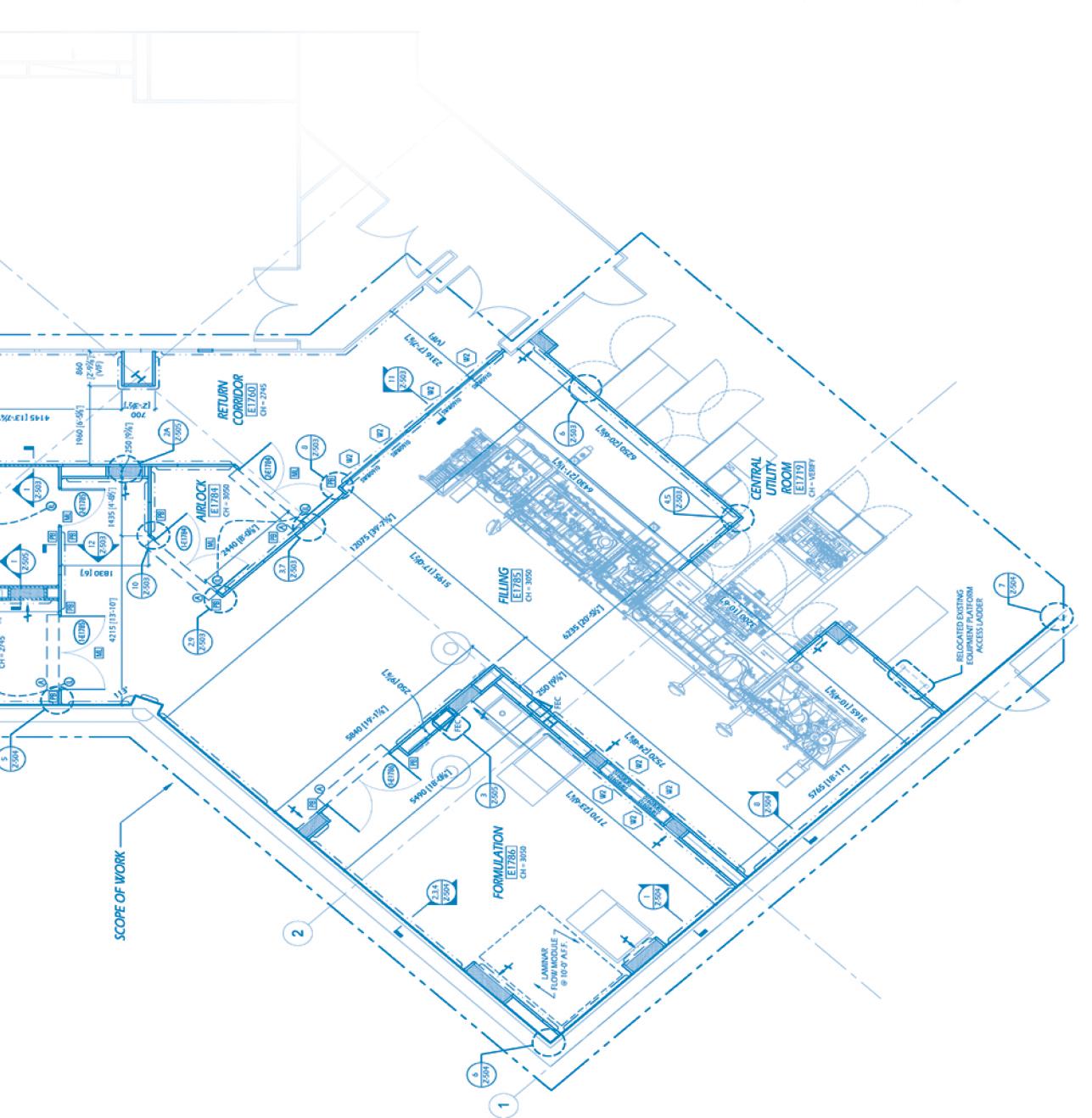

Not every client will leverage the full capabilities of AES through the turnkey cleanroom solution we call FaciliFlex that delivers guaranteed environmental performance within the facility. For those projects where a team is already in place to deliver the infrastructure that supports the cleanroom, our clients can still leverage AES’ best - in - class cleanroom architectural system to deliver pre-engineered modular construction benefits to the facility. Our pharmaceutical and biotechnology clients can implement our beautifully compliant cleanroom envelope by utilizing AES as a modular cleanroom “Box” integrator. Although our services are reduced with this strategy and the environmental performance resides with another member of the project team, clients still leverage our four decades of experience with functional cleanroom environments when we deploy our modular architecture and the critical components within it. This solution is regularly leveraged by the world’s leading architectural & engineering teams as well as construction management firms to improve their offering to the life science community. AES Box combines our modular solutions with our experienced installation team to construct a tight and compliant cleanroom envelope.

Cleanroom Envelope

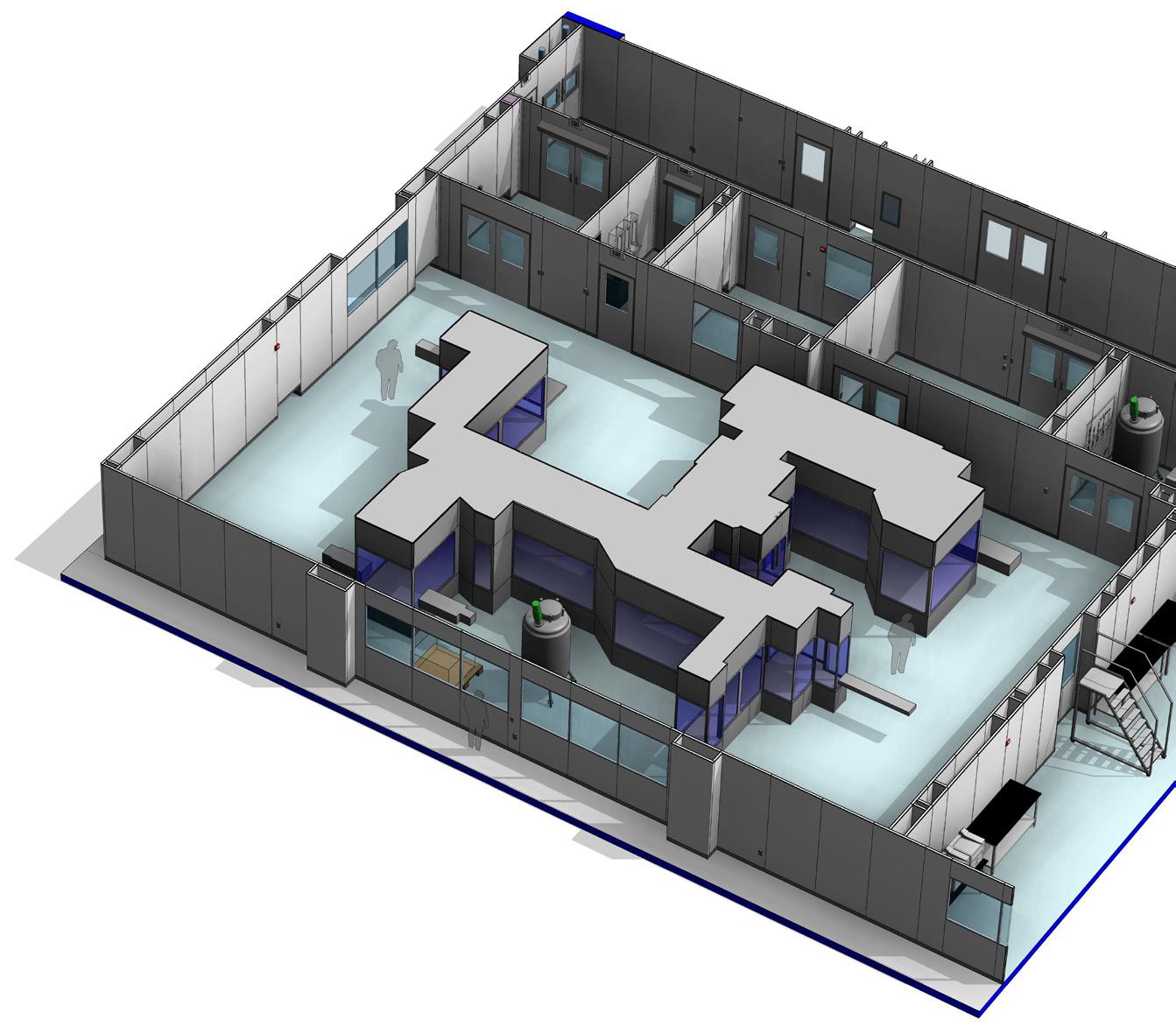

Key Features:

Monolithic PVC surface finishes to withstand harshest environments

PVC corner coving details to promote contamination control and support cleaning regimen

Flush door and window details eliminate opportunities for microbial growth

Walkable cleanroom ceilings create interstitial maintenance access

Flooring details provide ledge-free wall to floor integration

Integral door automation and interlocking controls manage people and material flows

HEPA filter supply and airwall return details manage proper airflows

Specialty cleanroom components seamlessly incorporate into the architectural envelope

“Modular cleanroom construction helped move the project forward with speed and significantly reduced waste and construction materials. The modular approach also helped increase flexibility, allowing us the ability to move large pieces of equipment in and out of rooms and even modify the manufacturing facility layout itself. This enables our company to grow and expand capabilities as the needs of our business evolves.

- Satisfied AES Box Client