Design-Build Approach to Project Execution

Cleanroom Design

Modular Cleanrooms, Designed for Compliance

Our in-house cleanroom design team includes architectural, mechanical, and electrical disciplines. AES designs cleanrooms for superior performance, cleanliness, and compliance. Highly motivated and results-oriented, the AES Design Team works with you and your project execution strategy to deliver a high-quality facility focused on performance.

Design Assist

Attention to detail

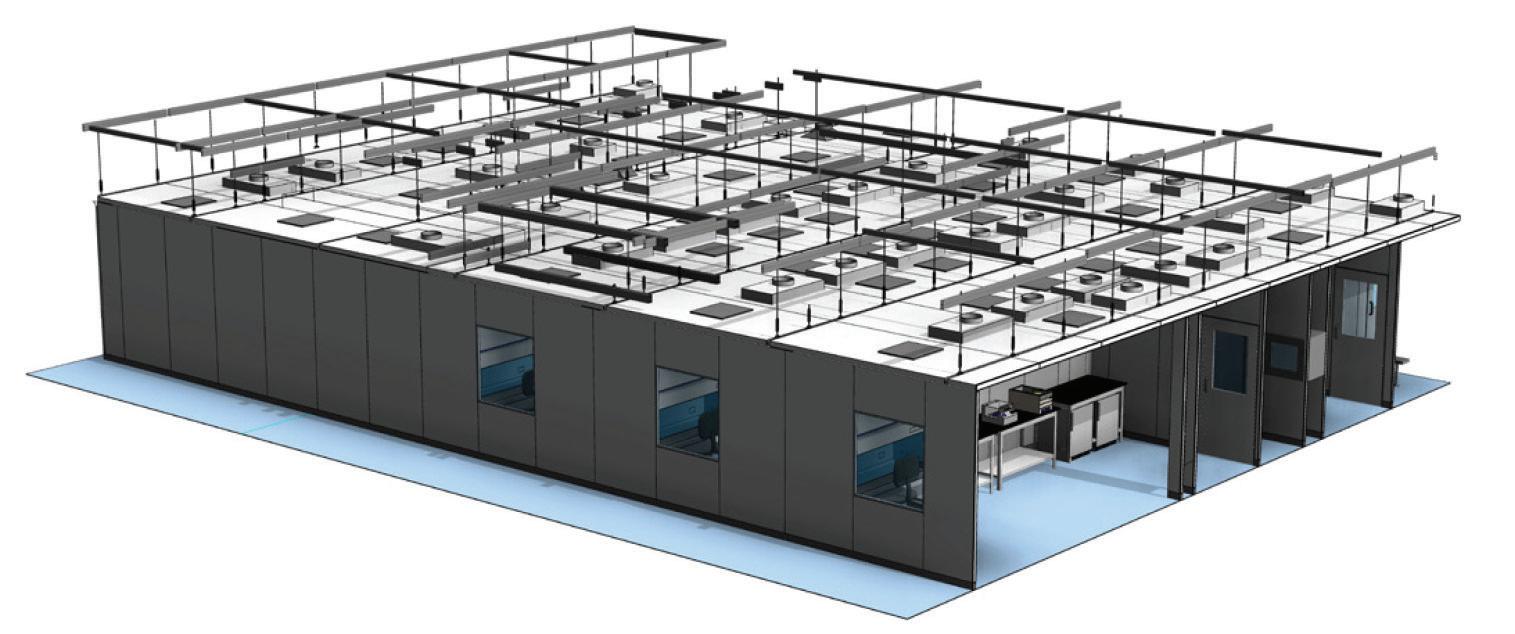

Your next cleanroom is more akin to a piece of equipment than a room. Operational efficiencies, compliant flow of materials and personnel, and lifecycle considerations should dictate the selection of your cleanroom partner AES designers have been engineering functional cleanroom facilities for over three decades, guaranteeing the performance of each and every facility. Our in-house designers work as a team with our cleanroom construction personnel to engineer a cost-effective project while maximizing performance, value, and constructability. The greatest value is realized when AES is integrated into the design team at the start of the project. Early project integration with our experts helps the infrastructure team decide what support and cleanroom solutions the clean space requires. Early participation by AES saves design costs, expedites schedule, and eliminates a duplication of services.

Engineering / Pre-Construction Phase:

AES becomes an extension of your team, serving to integrate the cleanroom facility into the host building context. The goal of this phase is to integrate the AES cleanroom solutions – engineering, construction, and commissioning of the critical cleanroom facility – without duplicating efforts among members of the project team.

Identification of potential gaps or overlaps in responsibility are addressed early in the pre-construction phase to eliminate the risk that can develop during construction.

AES helps the project team to maximize the aseptic details of modular cleanroom construction.

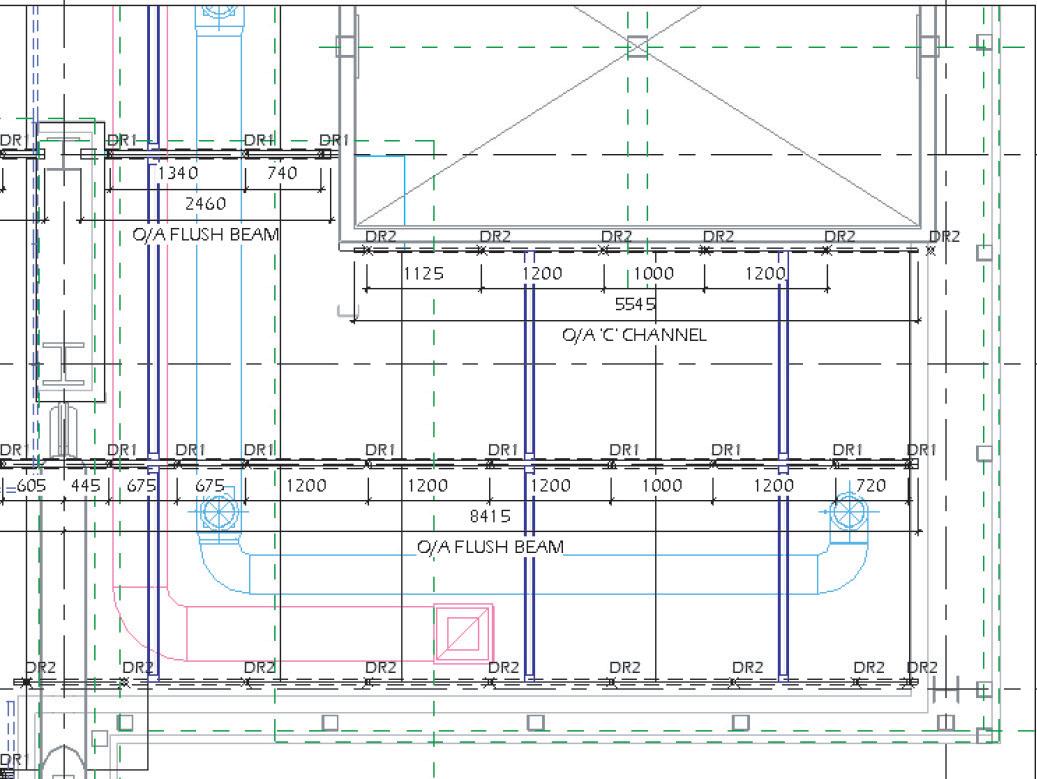

AES focuses the team on the integration between the cleanroom facility and the host building infrastructure. 3-D modeling is utilized for coordination of all disciplines including structural tie-in details, HVAC systems, electrical services, process equipment interfaces, and process utility distribution within the cleanroom facility. These 3-D design tools then transition to the construction phase through BIM coordination with all of the trades that will bring the facility to life.

AES’ focus during the engineering phase is ultimately on the construction strategy so that we can ensure that the facility will be built in a cost-effective, high quality, rapid, and safe manner.

The AES Construction Quality Plan (CQP) is then used to commission the cleanroom facility to ensure that it meets all of the performance objectives that are required for compliance. This CQP becomes the tool for transitioning the facility into validation and ultimately toward launch of our clients’ products to the marketplace.

For more information on AES Clean Technology, please visit us on the web at aesclean.com or email us and we will put you in touch with one of our Regional Sales Managers: sales@aesclean.com