Capabilities Deck

OVERVIEW

is a custom packaging solutions provider supporting the world's leading brands.

• Domestic and international solutions

• Global network of manufacturing facilities

• Comprehensive in-house creative teams

• National warehousing and logistics program

• Demand planning & Forecasting

• Patented child-resistant (CR) products

Leading design and manufacturing designs from initial concept to supply chain management and last-mile delivery.

AE Global’s Innovation Lab designs, develops, and prototypes the next generation of packaging solutions leveraging the latest equipment, technical CAD and visualization software to deliver market-leading packaging.

DESIGN

• Research & development

• 2D and 3D sketching / CAD

• Digital product renderings

HI-FIDELITY 3D PRINTING

• Product engineering

• High-resolution 3D printing

• “Looks / Works-like” models

• White & printed mockups

• Paperboard & corrugated

• Plastic & resin-based material

GRAPHIC DESIGN

• Packaging design & development

• Prepress art

• Graphic renderings

• Digital & physical proofs

• Quick-turn proofing & prepress – as short as 1-hour turn time

• Hybrid CloudFlow, a custom-built portal for artwork submission, storage management, proof review & approval

• OpenColor and ICScolor software color-accurate digital, physical, & remote proofing

AE Global’s logistics team delivers seamless supply chain management including demand planning, forecasting, and warehousing services.

DEMAND PLANNING PROGRAM FORECASTING MANAGEMENT & PLANNING INCLUDED IN BOTH:

Forecasting helps to estimate cost and revenue, predict short-term and longterm performance, reduce cost on unutilized material, and accurately ordering the necessary stock to fulfill customers’ orders.

• MTO (Made to order), MTS (Made to stock), ATO (Assembly to order)

• Product classification

• Finished goods inventory management

• Master scheduling

• Budget planning

• Inventory replenishment: (Current inventory / WIP / Recommended replenishment)

• JIT service

• Weekly check-ins & Q.B.R.

The North Carolina facility has the widest range of machinery and capabilities in the United States, allowing AE Global to control the entire manufacturing process.

OWNED ASSETS

AUTOMATIC RIGID & FOLDING BOX LINES

• 17 Automatic Rigid Box Lines

• 2 Semi-Automatic Box Lines

• 4 Moll Automatic Folding & Gluing Lines

• 1 Automatic Windowing Machine

CASE MAKING/LABELING LINES

• 4 Automatic Case Making Lines

• 2 Automatic Labeling Lines

• 2 Semi-Automatic Case Making Lines

DIE CUTTERS

• 2 Automatic 28” x 40” Sheetfed Die Cutters with Auto Stripping

• 2 Automatic Die Cutters 29” x 41” with Auto Blanking

• 4 Platen Handfed Die Cutters up to 38” x 54”

• 1 Automatic Sheetfed Cylinder Die Cutter

KNIFE AND CONVERTING EQUIPMENT

• 4 Computer Programmed Guillotine Cutters up to 54”

• 1 60” Automatic Sheeter Shrink Wrapping Equipment

• 3 Automatic Shrink Wrap Lines

• 1 Semi-Automatic Shrink Wrap Line

DIGITAL PRINT AND FINISHING EQUIPMENT

• 1 UV Digital Printer 4’ x 8’

• 1 UV 23"x29” Digital Press up to 3,000 sheets per hour – Duplexing 1,500 per hour

• 1 Automatic 3D Varnish/Digital Foil 29” x 47”

• 2 Automatic Cutting Tables 66” x 125”

• 1 Automatic Coater for Spot and Flood varnish up to 23”x32” sheet size

MISCELLANEOUS EQUIPMENT

• 4 Foil Stamping Machines

• 1 Automatic Double Head Riveters

• 6 Semi-automatic Double Head Riveters

• 8 Eyeletting / Grommeting Machines

• 6 Hot Melt Pattern Gluing Lines

• 4 Cold Glue Pattern Gluing Lines

• 4 Film Lamination Lines

The Illinois plant provides printing, slitting, lamination, and converting capabilities for flexible packaging.

The New Albany, Indiana facility provides pressure sensitive labels. State of the art Nilpeter FA 17” 9 station press along with digital printing capabilities.

OWNED ASSETS

• SQF edition 8.1 Certified

• G7 Certified Master Printer

• Support 5S Manufacturing Practices

• Member, Paperboard Packaging Council

• ISO 9001:2015

• BRC Global Standard AA+

• GMP – Good Manufacturing Practices

• GFSI – Global Food Safety Initiative

Whether it’s a box, pouch, tube, jar, or another form factor, AE Global’s packaging engineers ensure each package creates a lasting first impression.

Materials:

• SUS (Solid Unbleached Sulfate) or CUK (Coated Solid Unbleached Kraft)

• SBS (Solid Bleached Sulfate)

• CRB (Coated Recycled Board)

• MPET (Metalized – PET) – typically mounted to SBS

• WCCN (White Clay Coated News) or CCNB (Clay Coated Newsback)

• CNK (Coated Natural Kraft), Thickness – 10pt up to 28pt

Colors/Coatings/Special Finishes:

• Spot Gloss & Raised UV

• Soft Touch

• Matte & Dull

• Reticulate

• Pearlescent

• Aqueous coatings

• Up to 8C & Double Coaters

• Cold & Hot Foil

• Embossing

Materials:

• Single Face

• Single Wall

• Double Wall

• Triple Wall

Applications:

• E-comm

• Displays

• Shipping Flutes:

• A / B / C / E / F

• Micro & Specialty

Capabilities:

• Digital or Flexo printing / Up to 8-color printing

• Hot & cold foil stamping

• Emboss, Deboss, sculpting

• Rolls, sheeted, fan-folded

• Pressure sensitive

• Thermal transfer & direct thermal

• Peel & seal

• Water-based & UV inks

• Specialty adhesives

• Gloss & matte laminations

• Paper, poly, florescent, & foil options

• Variable data printing

Capabilities

• De-metallization

• Compostable options

• Spot matte varnish

• Resealable zippers

• Hang holes

• Degassing valves

• Pour spouts

• Die-cut handles

• Custom shapes

• Windows

• Child-resistant

Primary Packaging Solutions:

• Jars & bottles

• Caps of varying finish & style

• Triggers sprayers & pumps

• Rigid & flexible tubes

Materials:

• PET & RPET

• PP

• LDPE & HDPE

• Polycarbonate

• High-performance plastics

• Recyclable & biodegradable materials

Capabilities:

• Child-resistant options

• Packaging options for: glass bottles, plastic bottles, & aluminum cans & bottles

• Single & multi-pack options

• Fully-enclosed or open & windowed

• Automated & hand-pack solutions

• Master cases & trays

• Specialty & multi-piece

Materials:

• CRB (Coated Recycled Board)

• CNK (Coated Natural Kraft)

• Thickness – 10pt up to 28pt

Capabilities:

• Temporary, semi-permanent & permanent solutions

• Corrugate, paperboard, poly, metal, & mixed-material

• Floor, shelf, counter, & partial/full-store experiences

• Retail signage (print, LED, neon)

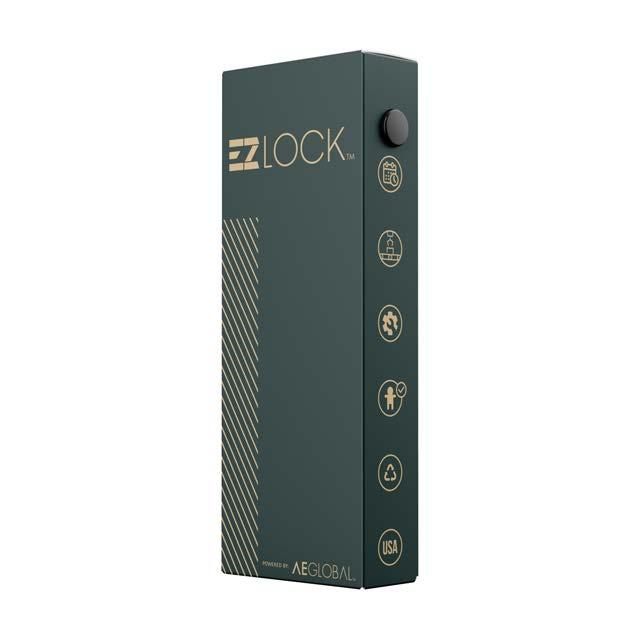

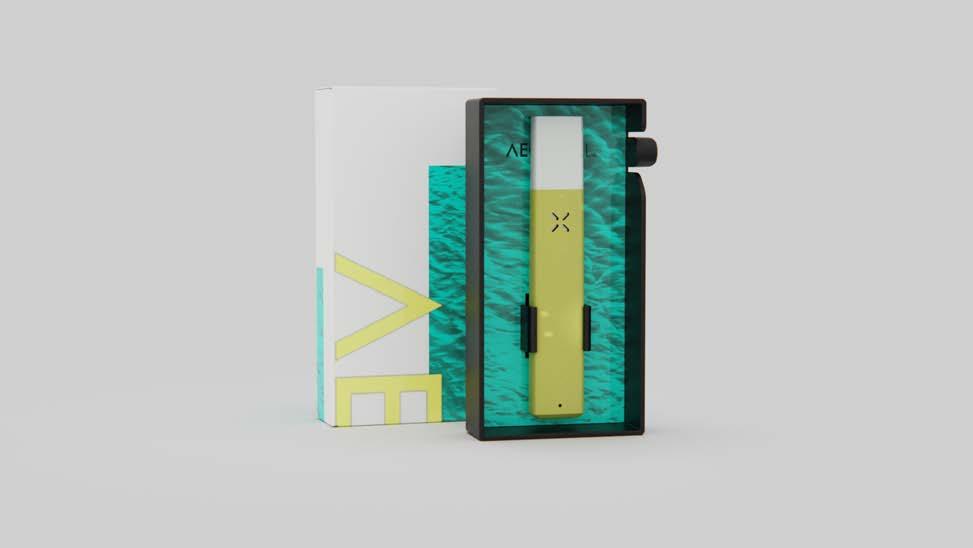

• Streamlined fulfillment & reduced labor costs with shorter pack-out time

• Reduced lead time through domestic manufacturing

• Integrated CR button for efficient use of space

• Plastic components made from recycled post-industrial & ocean-bound plastics Vape cartridges, batteries, & pre-rolls

We have carefully-designed these custom solutions with the end-user in

• Available in 30ml, 60ml or 100ml sizes

• Transparent CR cap with engraved dosing marks

• Inner leak-proof cap

• Precision tip

• Flexible body

• Available in a variety of special finishes & coatings

• Single-hole for CR button keeps user experience efficient & friendly

• Options of 10%-100% post-consumer recycled & biodegradable material, stackable base

• Core can be customized to fit variety of hardware and pre-rolls

• Available in 80mm or 116mm sizes

• Tube cap can be customized with your logo

• Offered plain or can be labeled in a variety of styles & material

• Custom colors available for certain MOQ’s

• Tamper-evident, CR, & customizable beverage solution for 202 Ball can lids

• Removing the Can Topper is an intuitive two-step process

• Space for branded label

• Molded teeth are designed to securely nest in stacked formats

• Recyclable

Ez-Lock

ORG CR Tray With AVD/ Syringe Molded Clip. Paperboard Sleeve and Insert Card

Custom Printed Autobottom Folding Carton With Paperboard Insert for Carts

CR Pop Tubes With Pre-Applied Label

Custom Printed CR Paper Tub Custom Boma Vape Gussetted & GussetLess CR Pouches

Ez-Lock ORG CR Tray With 510/Custom

Clip Paperboard Sleeve & Insert Card

Direct Printed CR Jar With Custom-Colored

Cap Custom-Printed French Tuck Folding

Carton Fin & Lap Seal Printed Sachet

White Bopp Label Applied to 60ml CR

Tincture Custom Printed Reverse Tuck Folding Carton

In the Present, For the Future.

Ocean Recovery Group (ORG) is working to solve the planet’s ocean-bound plastic crisis in the Western Hemisphere.

AE Global launched the Ocean Recovery Group (ORG) in the Dominican Republic, which collects, cleans, and recycles ocean-bound plastics that can then be used to create everyday packaging products.

In addition to ORG, AE Global has partnered with rePurpose Global to offer companies a platform that finances the recovery of verified nature-bound plastic waste in areas with minimal waste management infrastructure. Together we can set an example for other businesses and drive positive change in the packaging industry.

Big change can come in small packages.

Visit ecopackage.org to learn more.

The Dominican Republic's location, lack of recycling infrastructure, and inefficient waste management systems have made it a significant contributor to ocean pollution.

• Government lacking tools to manage landfills from an environmental point of view1

• Waste separation is practically nonexistent and nearly all the country’s trash ends up in one of about 350 landfills.2

• Our goal is to build a best practice in the Dominican Republic that can be the model for other Caribbean countries.

Source:

1.Dominican Today, Landfills, serious environmental problem in Dominican Republic

2.International Climate Initiative, Dominican Republic: The battle against trash

Fund the collection of nature-bound plastic by participating in the Plastic Waste Removal Credit program.

1

Identify the product(s) that will have their weight in plastic removed from impact areas.

2

The cost of the plastic waste removal credit is determined by the weight of the package.

3

The cost to recover one kilogram of nature-bound plastic is $0.55. The cost for brands per unit, pending package weight, is $.005 - $.015.

4

Waste removal credits will fund the collection of nature-bound plastic.

5

Provide product sales forecast to AE Global to calculate projected collection impact over time.

6

With AE Global's Marketing Tool Kit, empower your customers to share their plastic collection impact.

5 g/unit

CALCULATE PACKAGING WEIGHT

25k units

MULTIPLY BY NUMBER OF UNITS SOLD

125 kg RECOVER WEIGHT IN PLASTIC FOR EVERY PACKAGE

6,945 Plastic Bottles

CREATE IMPACT TODAY USING TOOLKIT EXAMPLE

We have one of the widest ranges of machinery and capabilities among packaging manufacturing companies in the United States. This allows us to deliver product faster, control quality better and offer the best pricing to our customers.

• Strengthen the Sustainability Story for Your Brand

• No Additional Work

• Immediate Impact Story

• Competitive Differentiation

• Contributing to Corporate Social Responsibility

It’s like throwing potential earnings into the trash. Whether you’re an emphatic believer or indiferent agnostic it doesn’t matter. What does matter is that 50% of your customer base is 100% invested in supporting businesses that support sustainability.

Not saying this is you, and not saying it’s not…but for brands looking to gain a competitive edge in the marketplace, having an emotional or ideological reason for consumers to be loyal to your brand is huge. Even if going green is not your thing, making green most definitely is your thing. Tug on those sustainability heart strings.

The

short version is that it sucks.

The good news is that it can be solved now, in our time.

Ocean bound plastics are discarded materials within 50 kilometers of our seas, streams, rivers, and lakes that are likely to enter the ocean. OBP is a critical element in the fight against the plastic pollution crisis. About 80% of the oceans’ plastic contamination is from land, so capturing OBP before it becomes ocean plastic is one of the most impactful solutions to this global crisis.

It has a devastating impact on the environment and the local communities. If not cleaned up it will eventually make its way into our oceans, causing calamity for the open blue ecosystems.

Yes, we just gave you the plastic horror story, but the truth is that plastic has been given a bad rep. It needs a new publicist for sure. While we may not be able to change its public image right away, we can take its trashy notoriety and put it to good use.

AE Global found that the core issue behind the plastic problem is a lack of infrastructure, including limited trash pickups, inadequate waste processing, and low recycling priority in areas with socioeconomic challenges. This leads to plastic trash becoming pollution and OBP.

AE Global provides waste management infrastructure, with the community as the workforce. We pay fair wages for collecting OBP, stimulating the economy, raising living standards, and empowering communities to restore their environment.

New product line launch, kicked off November 2020 in the middle of the COVID pandemic; executed through Chinese New Year for a March 2021 launch.

Curaleaf, a leader in the Cannabis space, needed an exact dosage package solution for their new product, a THC infused beverage enhancer “Select Squeeze.” Curaleaf needed an “all in one solution” – including proprietary packaging & label development, manufacturing, and full project management & distribution. The desire was to launch the new product in 14 states simultaneously, with the industry constraint of specific labeling and distribution requirements for each state.

The solution provider would need to be able to ramp up quickly, understand the challenges of the cannabis industry, and meet full-service capabilities from design to implementation.

Curaleaf turned to AE Global to develop a solution which could be implemented quickly and be highly scalable.

With extensive design capabilities including rapid prototyping, AE Global’s team developed a consumer-friendly CR squeeze bottle, capable of dispensing a precise dosage of product every time. AE Global also managed the entire third-party testing and certification process.

Launching four flavors simultaneously in 14 states, AE Global’s team operated as a control tower managing everything from managing design to production of the bottles, 56 different label and 56 different folding carton SKU’s. At any given time, AE Global was traffic manager to 175 different shipments of components to 14 different markets (with the added challenge of COVID impacts.)

AE Global delivered a robust suite of solutions to Curaleaf, enabling them to achieve the largest ever simultaneous launch in the cannabis industry in the US.

Lion Order, a cannabis and CBD lifestyle brand led by Rohan Marley, had a six-month deadline to develop packaging for their new brand. Lion Order encompassed a variety of SKUs and products, each with distinct needs.

As the brand's initial launch, they aimed to make a lasting impression in a competitive market. Their goal was to create packaging that captured consumer interest to grow sales, while also addressing sustainability goals.

AE Global designed the packaging dielines and artwork, and managed prototyping and print setup. Intricate embossed patterns, foil elements, and curated color choices created a high-end, regal look. To achieve their sustainability goals, Lion Order offset the plastic in their pouches via AE Global's Ocean Recovery Group program in partnership with rePurpose Global. In addition, all paperboard packaging used FSC-certified and recyclable materials.

Lion Order's 4/20 launch was a success, garnering widespread media attention from Forbes, The New York Times, Herb, and more. Lion Order became one of 305 Farms best performing brands and continues expanding into new markets.

AE Global partnered with Lion Order to create distinct, sustainable packaging under a tight deadline. Their innovative design solutions resulted in a successful launch and solidified Lion Order as a leading cannabis brand.

TYSON 2.0 is a premier cannabis company featuring legendary boxer, entrepreneur, and icon, Mike Tyson. They came to AE Global to help them design, manufacture, and launch the brand’s hero product – Mike Bites. Having reintroduced the brand (2.0) recently, they required a packaging solution that would help them stand out in the celebrity-endorsed sector of the cannabis industry.

With a tight deadline of 3 months, we worked closely with Tyson 2.0’s team to create this iconic product.

Starting with a product name and a company logo, AE Global’s Innovation Lab developed the brand and packaging that would become Tyson 2.0. AE Global quickly provided initial concepts, renderings and mockups including folding cartons, pouches, and custom containers. With Tyson's collaboration, AE Global produced the final brand concept and packaging.

The result was a product that received attention from major news outlets, TV features and interviews, went viral on social media, and garnered global recognition - creating one of the cannabis industry’s most iconic products. Originally only for sale in California, Mike Bites expanded into 24 states, Europe and Asia. The brand has expanded its portfolio to multiple flavors along with an expanding hemp line totaling 20+ skus.

AE Global and Tyson 2.0 continued to develop the brand’s look including logo refinement, brand development, strategic planning, personality delineation, color palette development, custom graphics and illustrations, typography guidelines, retail merchandising, social content and asset guides. With the success of Mike Bites, Tyson 2.0 selected AE Global to develop their subsidiary brands: Toad, Ric Flair Drip, EVOL by Future, and Hulk Hogan.

Healthy snack brand Magic Dates' sales and popularity were growing quickly, amplified further by a successful appearance on Shark Tank. As a new brand, their product was available online and at select retailers in packs of eight to nine snacks.

Magic Dates received a phone call on a Wednesday that American Airlines was interested in carrying their products for their in-air snack portfolio. American Airlines requested 25 sample pouches in a different format than currently in market for a meeting on Monday.

Magic Dates Founder, Diana Gerard, was referred to AE Global. AE Global's rapid design and prototyping capabilities were a great fit for meeting the tight deadline.

In a span of 24 hours, AE Global adjusted the art to a sampler size, printed the required film and converted 25 pouches in time for UPS shipment to overnight the samples to Southern California. There, Diana filled and sealed the pouches and got them out the same day to arrive at American Airlines' office on Monday morning.

New rebranding, packaging, and product line launch, kicked off in the summer of 2021.

Twice's mission is to evolve oral care into a more elevated experience every single day. Daily routines becoming moments of pleasure with a purpose, must be reflected within the brand refresh and packaging project. The branding had to create a statement, while the packaging needed to deliver a refined, luxury product through the unboxing experience.

The solution provider would need to meet an aggressive sixmonth timeline to support in-store delivery dates for mass retail chains; from concept through mass production.

Twice chose AE Global as packaging partner, honing-in on product packaging for the company's various SKUs, including dental floss, toothpaste, toothbrush, mouthwash, and whitening pen.

Creating a balanced and memorable experience required meticulous attention from each package's components. Design iterations saw AE Global experimenting with various design finishes and processes to achieve the final look and feel of the packaging components. In-house mock-ups and concept samples were utilized to maintain control of quality and lead-times.

Meeting the six-month project, from concept through production, was no simple task. It took the cooperation of many teams, spanning two countries, various regions, and continuous communication and planning to ensure everything from concept samples to production print color matching was completed accurately, efficiently, and on schedule.

AE Global completed the rebranding project, delivering the full suite of rebranded product SKUs on time to meet the strict timelines set by Target corporate. Twice products are featured in Target and CVS stores across the country, and prominently across social media and online ads.

AE Global worked with NuHerbs on rebranding, packaging, and product line launches for NuTraditions, which kicked off in the summer of 2021.

When it was time to expand the line and roll it out at Expo West, AE Global helped expand the branding across five new items. In their initial production runs, NuHerbs needed to balance the expense and risk of manufacturing packaging and products, while having the right amounts of the products that the retailers are going to order.

AE Global worked with NuHerbs to produce small quantities of commercial quality packaging for each SKU to be used at Expo West in their booth, highlighted in the new products category and limited amounts to share with target retailers.

NuHerbs landed product placements with Sprouts, Grove, Fresh Market and Whole Foods.

The strategy was a great way to win new business without making a large investment.

Following their complete brand transformation and expansion, Rebel turned their focus on giving their food and products inside the store a corresponding look and feel.

Rebel was looking for a partner to help them achieve their vision in creating an engaging and positive food service experience for their customers. To accomplish this, Rebel needed a partner they could trust with their new identity to create products that they felt were commensurable to the rest of the in-store experience.

AE Global worked within the parameters of these newly developed brand guidelines to completely reimagine the food and beverage experience. We worked with key stakeholders to design and develop cups, food containers and delivery boxes, bags, security tape, and more and added a custom ‘Rebel’ touch to every product.

Each product was developed with purpose and presentation in mind. The food containers fit the specified amount of food in way that was easy to fill, carry, and provided a visual cue of ‘fullness’ that is ever-present in food service. The cups provided a Rebel-forward appeal while delivering a premium experience for the customer. The delivery products provided a billboard marketing experience without sacrificing the quality.

The five months of work culminated in a family of twenty products across multiple packaging formats from concept call to last mile delivery. More than 500 Rebel stores across the country are using these products to amplify their in-store experience.

Sandland Sleep needed help developing a comprehensive D2C program for a premium nutraceutical product mix. They wanted an elevated unboxing experience for first time subscribers and a streamlined subscription reorders solution. Challenges included a complex SKU offering regarding products and packaging needs, sustainability directives, cost efficiency, and the need for a onesize-fits-all solution.

AE Global was able to design a sustainable program meeting these challenges:

• One size fits all solution, custom ecommerce shipper which is able to accommodate multiple SKU variations with branded inserts

• Elevated reusable/refillable branded jars with color coded caps (keeps SKUs simple to manage with one jar SKU)

• Streamlined shipping solution for refills/reorders utilizing flexible packaging and shipping solutions

• Identified need and solution for fast, short-run packaging for wholesale selling efforts and subsequent full retail solutions