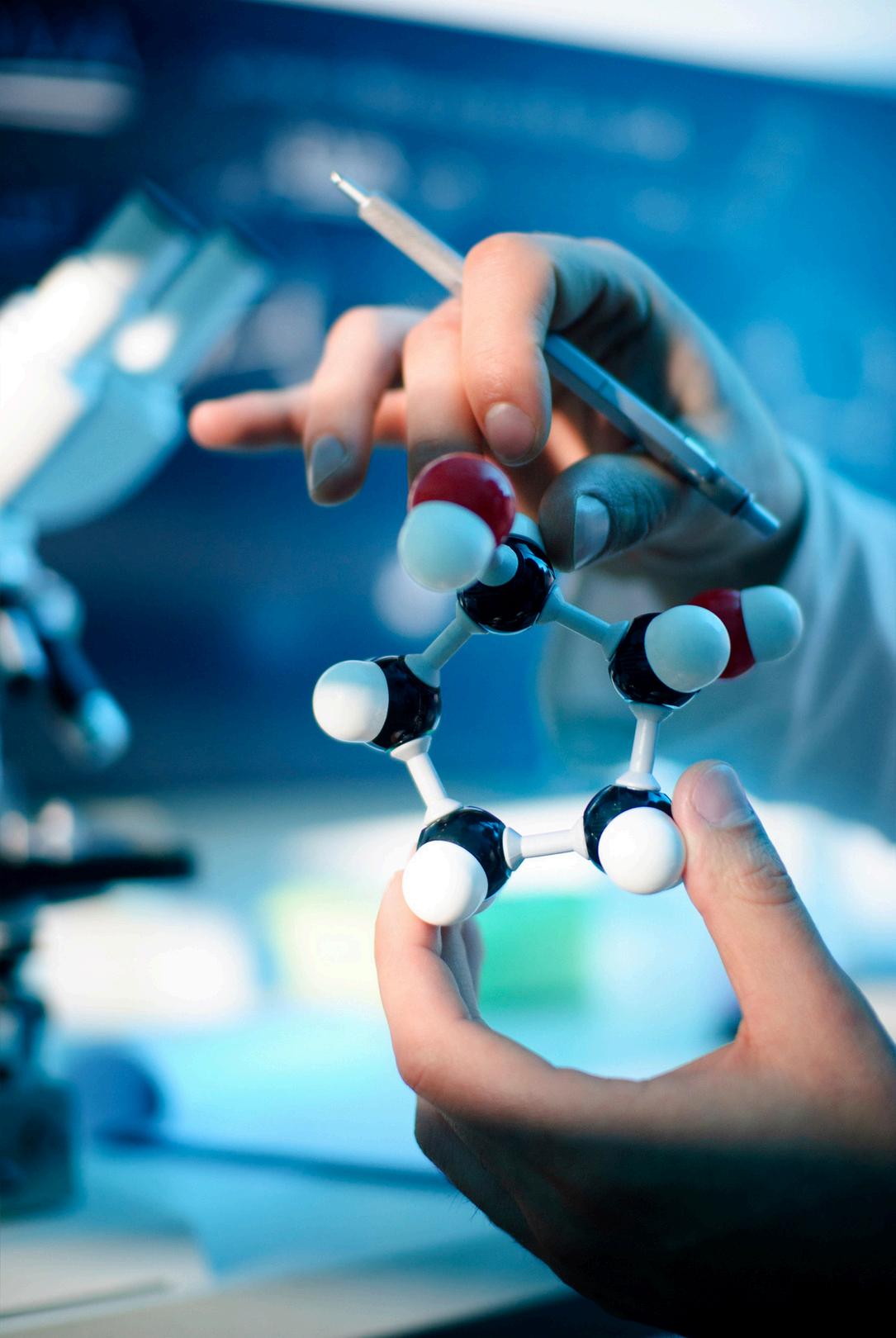

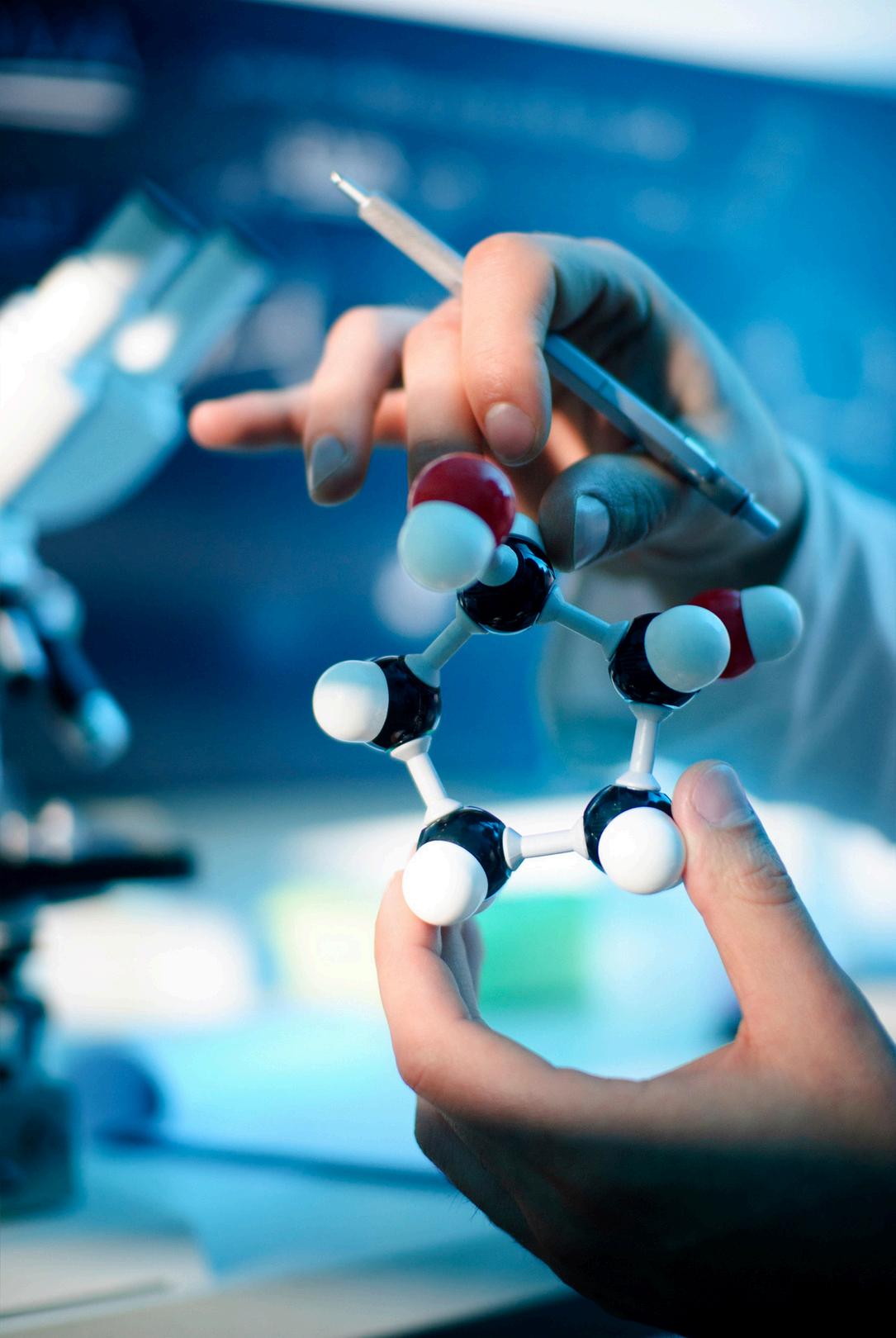

Polyurethane amine catalysts serve as critical reaction accelerators in polyurethane production, precisely balancing polymerization and gas formation during foam manufacturing. Their ability to optimize production efficiency while enhancing foam quality makes them indispensable in modern manufacturing processes. Recent advancements have focused on developing lowemission variants to comply with tightening environmental regulations worldwide.

Market expansion is further supported by technological advancements in catalyst formulations, particularly in developing low-emission and high-performance variants. For instance, in Q3 2023, BASF launched a new generation of amine catalysts with reduced VOC emissions for compliant foam production. USD 1.45 BILLION USD 2.18 BILLION 5.8%

BY TYPE

Reactive Amine

Catalysts Non-Reactive Amine

Catalysts Hybrid Catalysts

BY APPLICATION

Foam

Adhesives & Sealants

Coatings

Elastomers

The global polyurethane amine catalyst ma robust growth driven by increasing demand foams across multiple industries. Polyureth heavily on amine catalysts for production, a use in construction, automotive, furniture, applications. The construction sector alone of polyurethane foam consumption, with ri development in emerging economies creati These catalysts play a critical role in optimiz and production efficiency, making them ind manufacturers seeking to meet growing ma maintaining product quality standards.

The growing focus on sustainable materials is creating significant opportunities for bio-based polyurethane systems and their associated catalysts. Manufacturers are developing amine catalysts specifically designed for use with bio-polyols and other renewable raw materials. These specialized catalysts must address the unique reactivity profiles of bio-based feedstocks while maintaining performance standards. With the bio-polyurethane market expected to grow at an accelerated pace, catalyst producers investing in this niche stand to gain first-mover advantages in an increasingly sustainability-conscious marketplace.

The global polyurethane amine catalyst market is experiencing significant growth due to technological advancements in polyurethane foam production. Recent innovations in catalyst formulations have enabled manufacturers to achieve better control over reaction kinetics, leading to improved foam quality and processing efficiency. The development of low-emission amine catalysts has been particularly impactful, addressing environmental concerns while maintaining high catalytic activity.

The North American market is characterized by stringent environmental regulations from agencies like the U.S. EPA, which have accelerated the demand for low-emission reactive amine catalysts. The region boasts advanced polyurethane applications in construction, automotive, and furniture industries, driving innovation in catalyst formulations. Major players like Dow Chemical and Huntsman maintain strong R&D investments to develop specialty catalysts for high-performance foam systems.

Europe's market is shaped by REACH regulations and sustainability initiatives that favor eco-friendly catalyst formulations. The region leads in adopting reactive amine catalysts that chemically bond to polyurethane matrices, reducing VOC emissions. Germany and France dominate consumption due to their robust automotive and insulation sectors. BASF and Evonik have introduced several innovative catalysts in recent years, including delayedaction amines for improved processing control.

BASF SE (Germany)

Covestro AG (Germany)

Huntsman Corporation (U.S.)

Evonik Industries AG (Germany)

The Dow Chemical Company (U.S.)

Kao Corporation (Japan)

Momentive Performance Materials (U.S.)

These companies represent some of the major key players driving innovation and growth in the market, contributing significantly to global supply and competitive dynamics.

Founded in 2015, 24chemicalresearch is a trusted name in global chemical industry intelligence. We specialize in delivering high-quality market research reports, empowering over 30+ Fortune 500 clients with data-driven insights for strategic growth. Our team of experienced analysts delivers customized, reliable, and timely research backed by a rigorous methodology. From mining regulatory trends to forecasting market opportunities, our reports help companies navigate industry challenges, stay competitive, and grow confidently.

As a one-stop platform for the chemical sector, we offer:

Deep specialization in chemical market analysis

Customized reports tailored to your needs

A robust portal with free samples, consulting, and competitive insights