This book is dedicated to the pilots that are my partners in the endeavour. They volunteer their time, their wisdom and their equipment to help me find and photograph these industrial scars. My ideas must often initially appear as being completely insane, but they join with enthusiasm and good humour. I am humbly grateful, and cannot express my gratitude deeply enough. – J Henry Fair

First published in Great Britain in 2016 by Papadakis Publisher. This edition 2019.

An imprint of Academy Editions Limited

Kimber Studio, Winterbourne, Berkshire, RG20 8AN, UK info@papadakis.net | www.papadakis.net

@papadakisbooks PapadakisPublisher

Publishing Director: Alexandra Papadakis

Design Director: Aldo Sampieri

Editor: Alexandra Papadakis

Production: Megan Prudden

Publishing Assistant: Helen Naish

ISBN 978 1 906506 70 4

Copyright ©2016, 2019 J Henry Fair and Papadakis Publisher.

All photographs ©2016 J Henry Fair, unless otherwise stated below.

Foreword ©2016 Bill McKibben

Chapter texts © Lewis Smith

Introduction, Behind the Scenes and all captions © J Henry Fair

All rights reserved.

J Henry Fair hereby asserts his moral right to be identified as author of this work.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any other information storage and retrieval system, without prior permission in writing from the Publisher.

A CIP catalogue record of this book is available from the British Library.

Printed and bound in China.

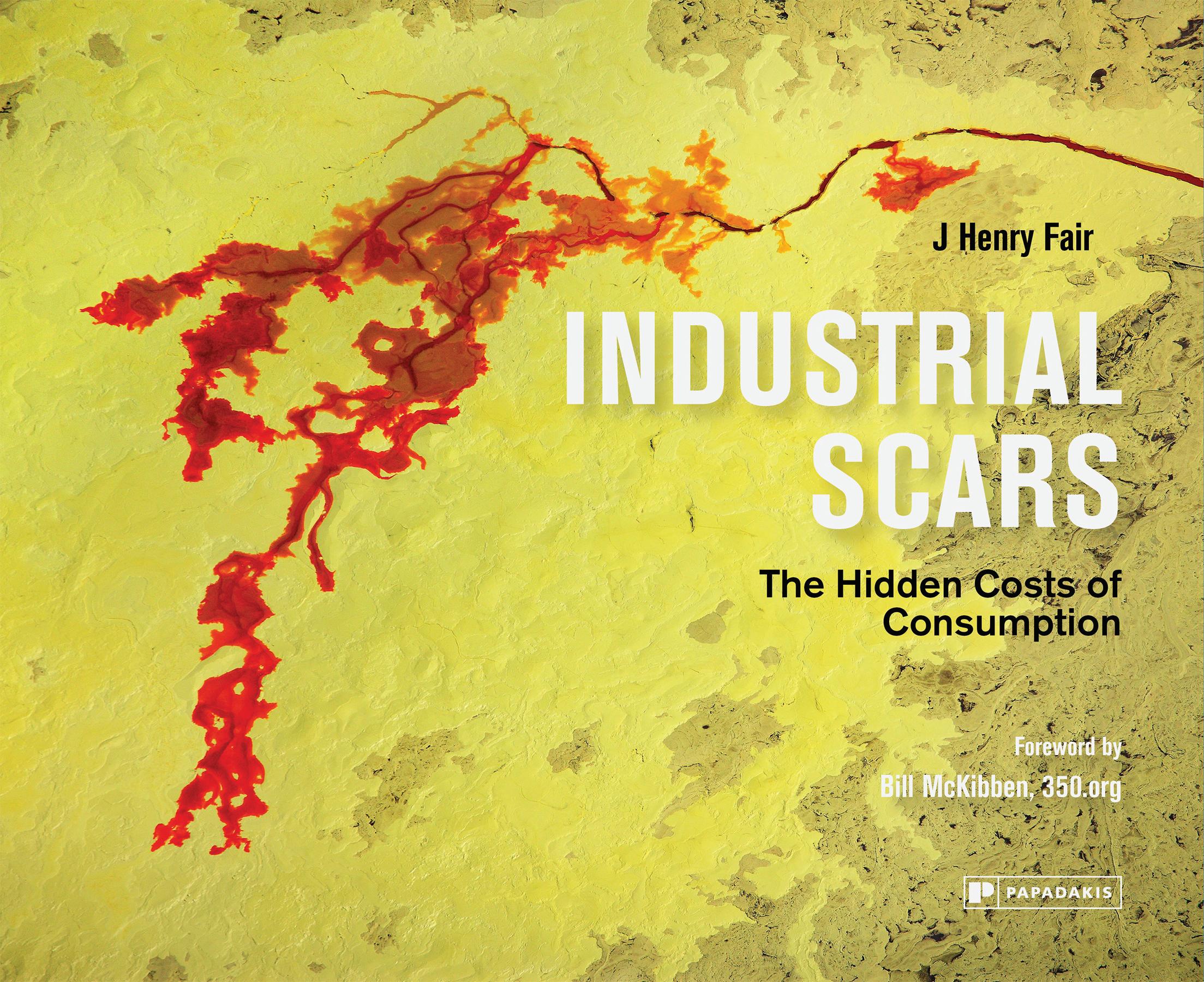

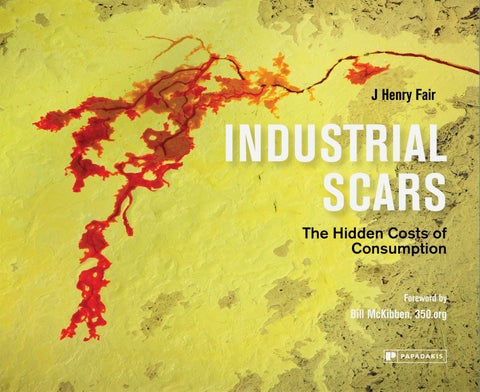

Page 1: NEW YORK HARBOR, NEW YORK, USA. A motorboat runs through a ‘red tide’ algal bloom. Algal blooms are indicative of an overload of nutrients (principally human waste and fertilizer runoff) into an estuarine system. These phytoplankton are toxic both to aquatic and human life, contaminate bivalve populations, and deplete the water of oxygen, thus killing any other aquatic species. The warming trend in water bodies is a contributing factor toward algal blooms.

Pages 2–3: COAL – NEW ROADS, LOUISIANA, USA. This coal ash power plant is the 27th worst carbon emitter of USA power plants, one of the 50 worst mercury polluters, and is known to be contaminating the groundwater around it with selenium which is leaching from its ash waste ponds. Coal ash is known to contain a variety of toxins including lead, mercury, arsenic, cadmium, boron, selenium.

Pages 4–5: FRACKING – WILLISTON, NORTH DAKOTA, USA. Drill rig for hydro-fracking oil from the Bakken shale formation stands in a field of rapeseed.

Pages 6–7: OIL – GULF OF MEXICO, USA. Oil floating on the Gulf of Mexico from BP Deepwater Horizon spill at the Macondo well.

Pages 8–9: ALUMINIUM – GRAMERCY, LOUISIANA, USA. Overview of aluminum refinery where raw bauxite ore is processed to produce alumina, an aluminum oxide compound from which pure metal is smelted. This view shows the primary components of the Bayer Process, including ore storage and milling at upper left, feed slurry production at top center, tall cylindrical digestors at center right, low round settling tanks beyond at center left, and tubular rotary calcining kilns at lower left.

Pages 10–11: COPPER – RIO TINTO, SPAIN. Waste at copper mine. Rio Tinto, literally ‘red river’, is one of the oldest and most productive mines in the world. It has produced a wealth of different metals over centuries, and is the home of the international mining company bearing the same name. It is rumored to have been King Solomon’s mine, and the reason the Moors invaded Spain.

Pages 12–13: STEEL – KIRUNA, SWEDEN. So much subterranean earth has been excavated at this Arctic iron mine that the ground is collapsing, forcing the relocation of the adjacent town.

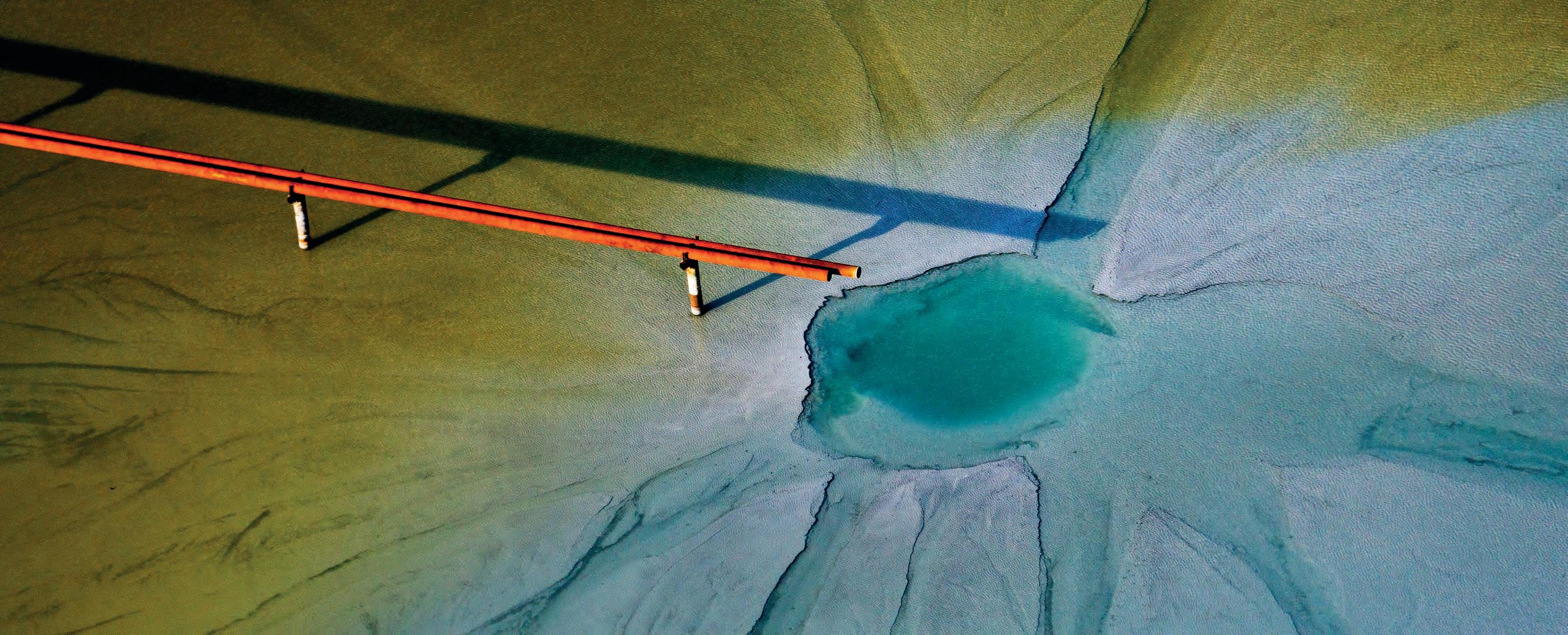

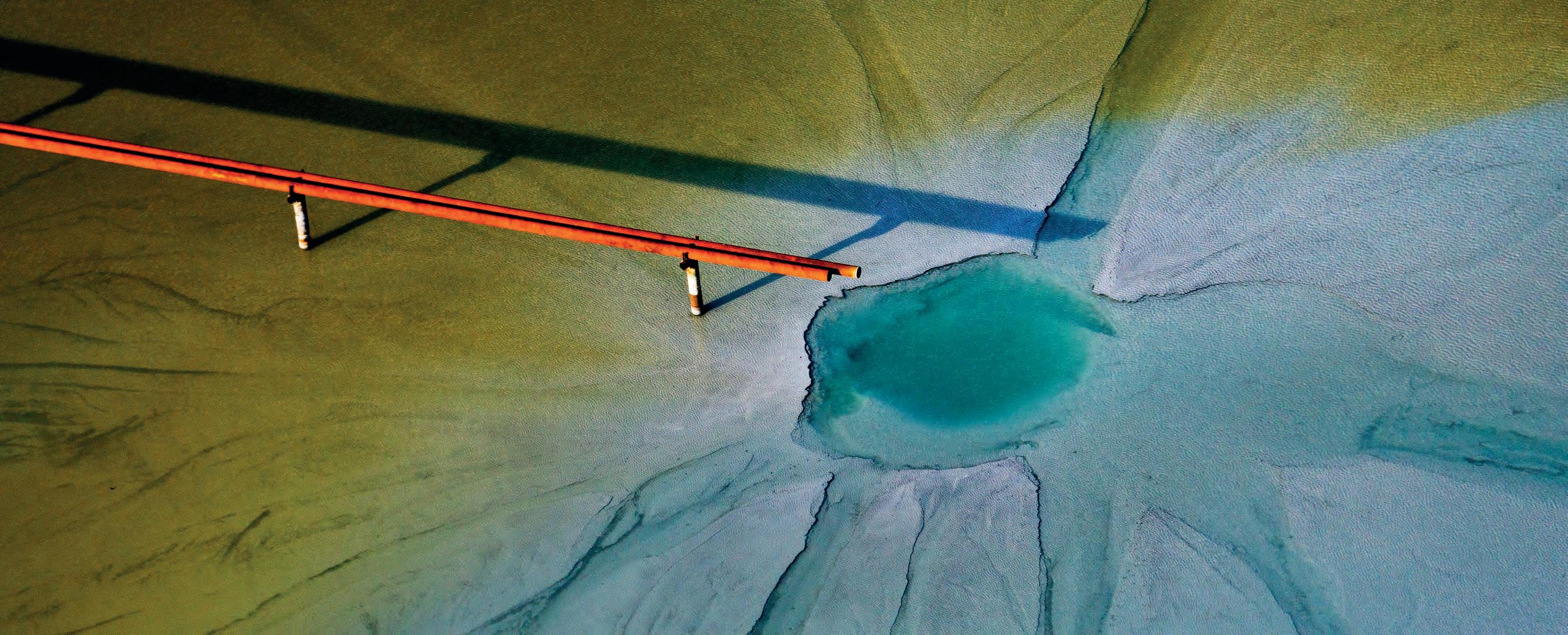

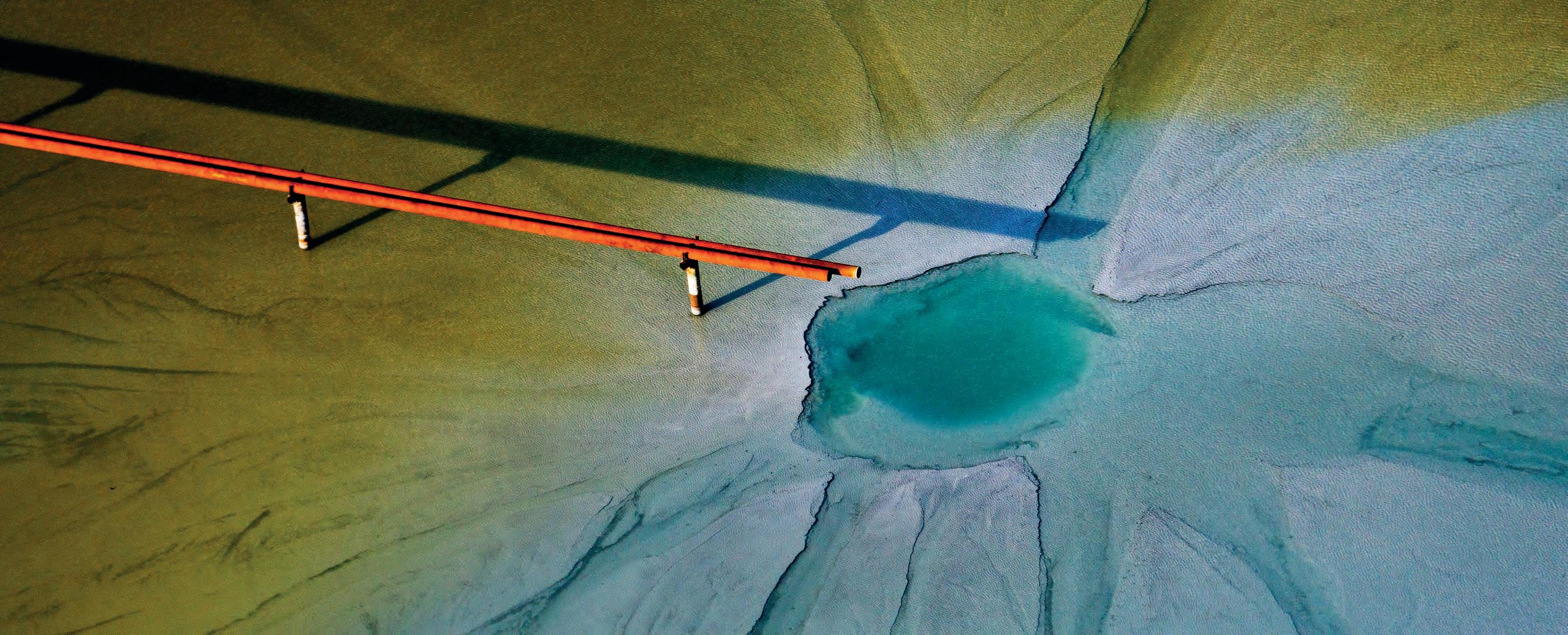

Pages 14–15: FOOD – BARTOW, FLORIDA, USA. Fertilizer waste impoundment. This fertilizer plant disposes of 81,600 kilograms of lead and 1,000 kilograms of mercury within its on-site impoundments annually. The local high school is one mile from the factory building and 1,000 feet (300 metres) from some of the waste impoundments.

Page 16: KAYFORD MOUNTAIN, WEST VIRGINIA, US. Mountaintop removal mining operations work around the clock at amazing speed; this lonely stand of trees disappeared in barely a day. The small bulldozer on the upper level pushes loose material down to the loader, which scoops it up into the next earth mover in line, which will in turn dump it into a nearby ‘valley fill’, burying the stream there.

19 20 FOREWORD Bill McKibben, 350.org 24 INDUSTRIAL SCARS J Henry Fair ENERGY 28 COAL 62 FRACKING 78 OIL RAW MATERIALS 112 ALUMINIUM 132 COPPER 152 STEEL FARMING 172 FOOD BEHIND THE SCENES 196 THE PILOTS 198 ABOUT THE CONTRIBUTORS 200 ABOUT THE AUTHOR 202 ACKNOWLEDGMENTS CONTENTS

CCOAL

oal wreaks havoc on the environment at every stage of the production process, from the moment it is mined until long after it is burned, with its legacy of air- and waterborne toxins, greenhouse gases, blasted, blighted, barren landscapes, mounds and pools of poisonous wastes, and death. Every year, according to the World Health Organization, one million people die early because of airborne coal pollution. Also every year, across the globe, thousands of miners lose their lives in the attempt to wrest “the dirtiest of all fossil fuels” from the Earth’s crust. Worldwide, we face a clean-up operation of daunting magnitude.

29

76

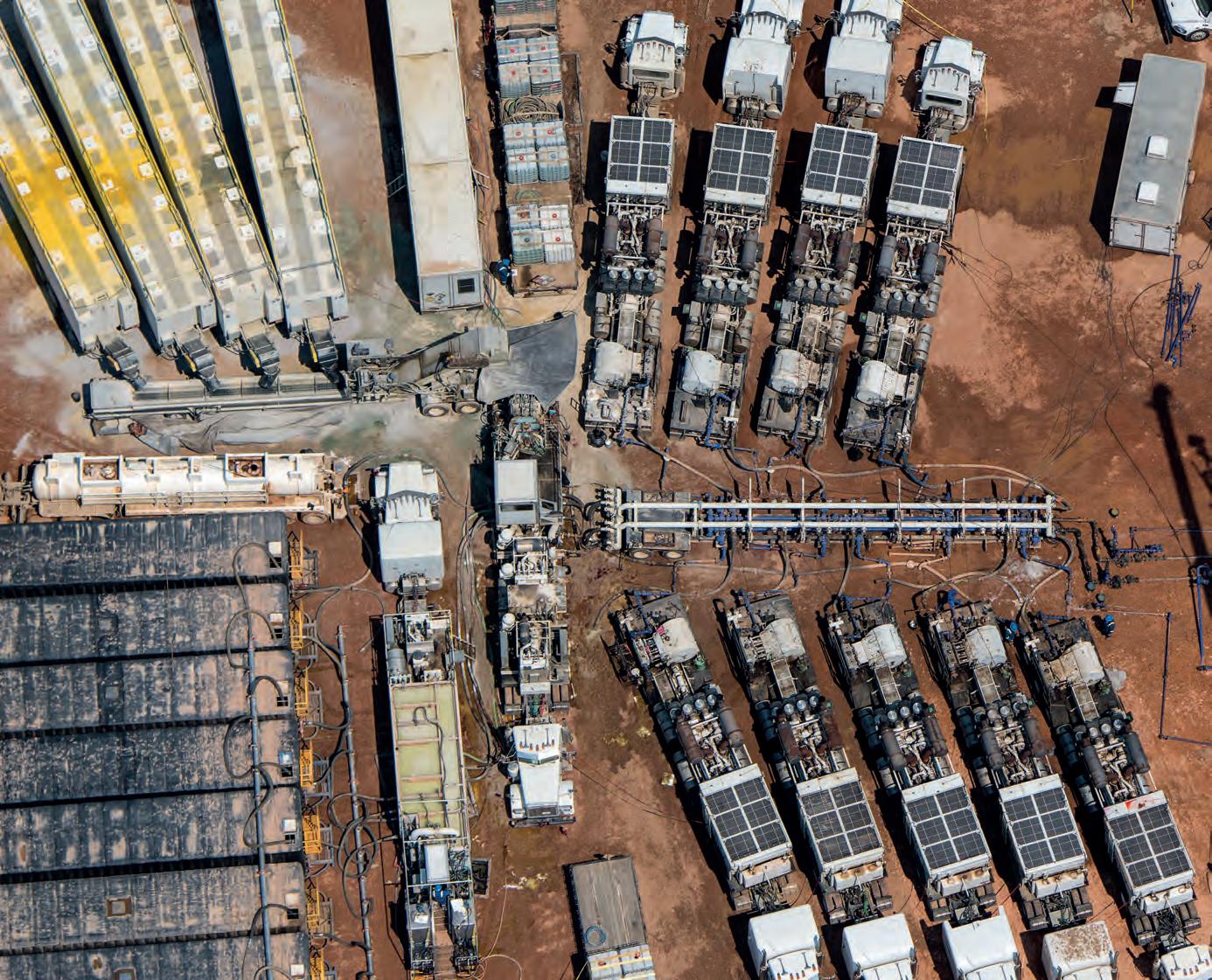

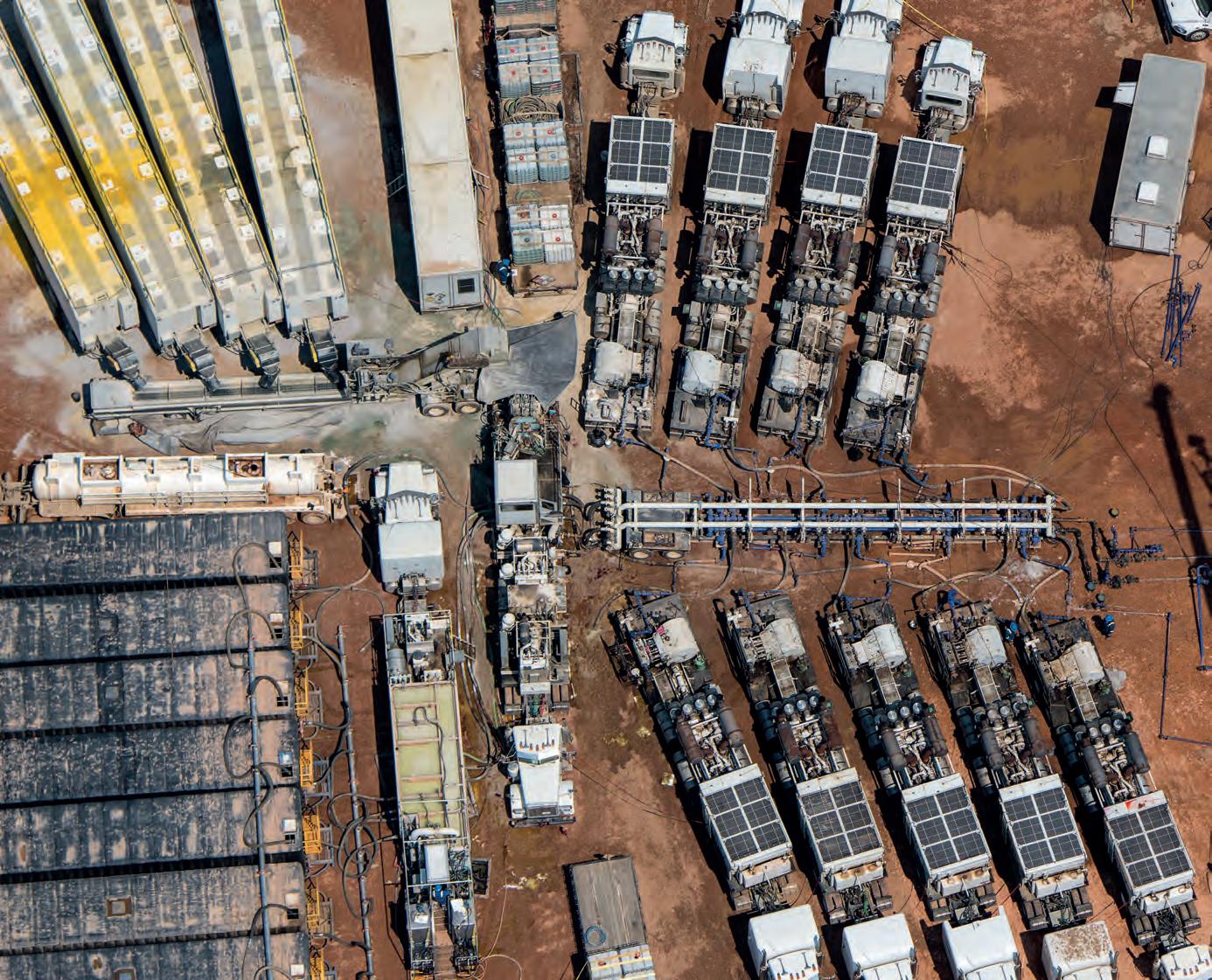

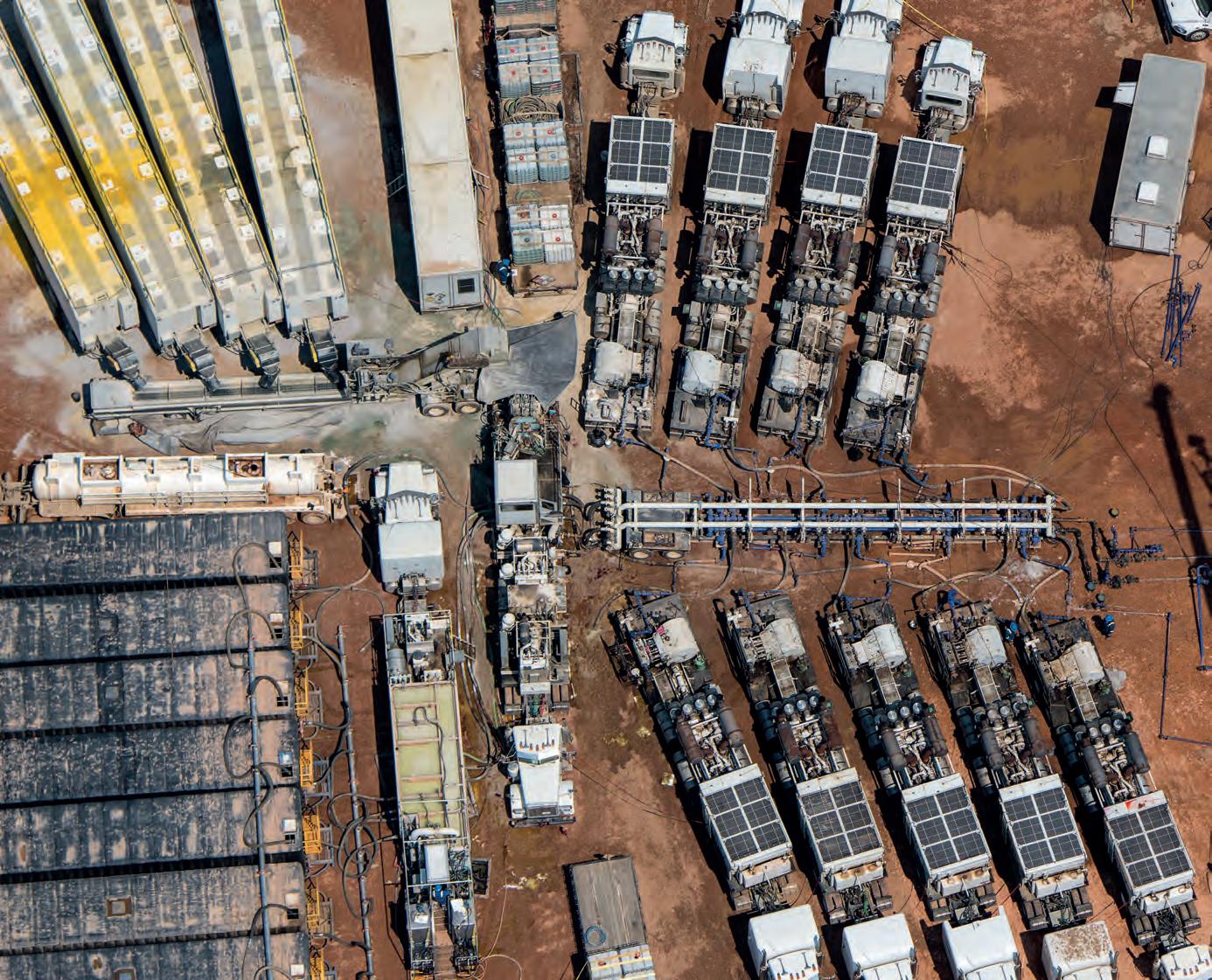

Above: LACEYVILLE, PENNSYLVANIA, USA. After drilling is complete, the second stage of hydrofracking involves arraying multiple high-pressure compressors around the well head and pressurising the drill holes with millions of gallons of water and toxic chemicals to fracture the shale layer far below the ground in order to release the natural gas trapped there.

Opposite: WILLISTON, NORTH DAKOTA, USA. Hydro-fracking compressor trucks and trailers of fracking fluids arrayed around well head at Bakken shale oil well. Here they are fracturing the shale layer for oil instead of natural gas.

existed in the Pliocene era, over 2.5 million years ago, when the sea level was at least 50 feet (15 metres) higher than it is now. In such a world, the ice sheets will have melted, temperatures across the globe would be intolerable, coastal cities would be drowned and up to 50 per cent of the planet’s species would be driven to extinction.

Over the next few decades we can expect to see semi-permanent drought coupled with occasional severe floods in some regions, more heat waves like the one which killed thousands of people across Europe in 2003, and more forest fires – like the one which temporarily curtailed oil production at Alberta’s tar sands.

Our long love affair with oil has lasted over a century. It has indeed become an addiction and one that we would find very hard to break. But it may well be that we cannot afford not to.

Previous spread (page 87): BARATARIA BAY, LOUISIANA, USA. Oil from BP Deepwater spill in the Gulf of Mexico sweeps through an inlet into Barataria bay, a tremendous breeding ground for many bird and fish species, especially brown pelicans, populations of which have recently rebounded from the threat of DDT.

Left: GULF OF MEXICO, USA. The wake from a ship moving through oil on the Gulf of Mexico from the BP Deepwater Horizon accident.

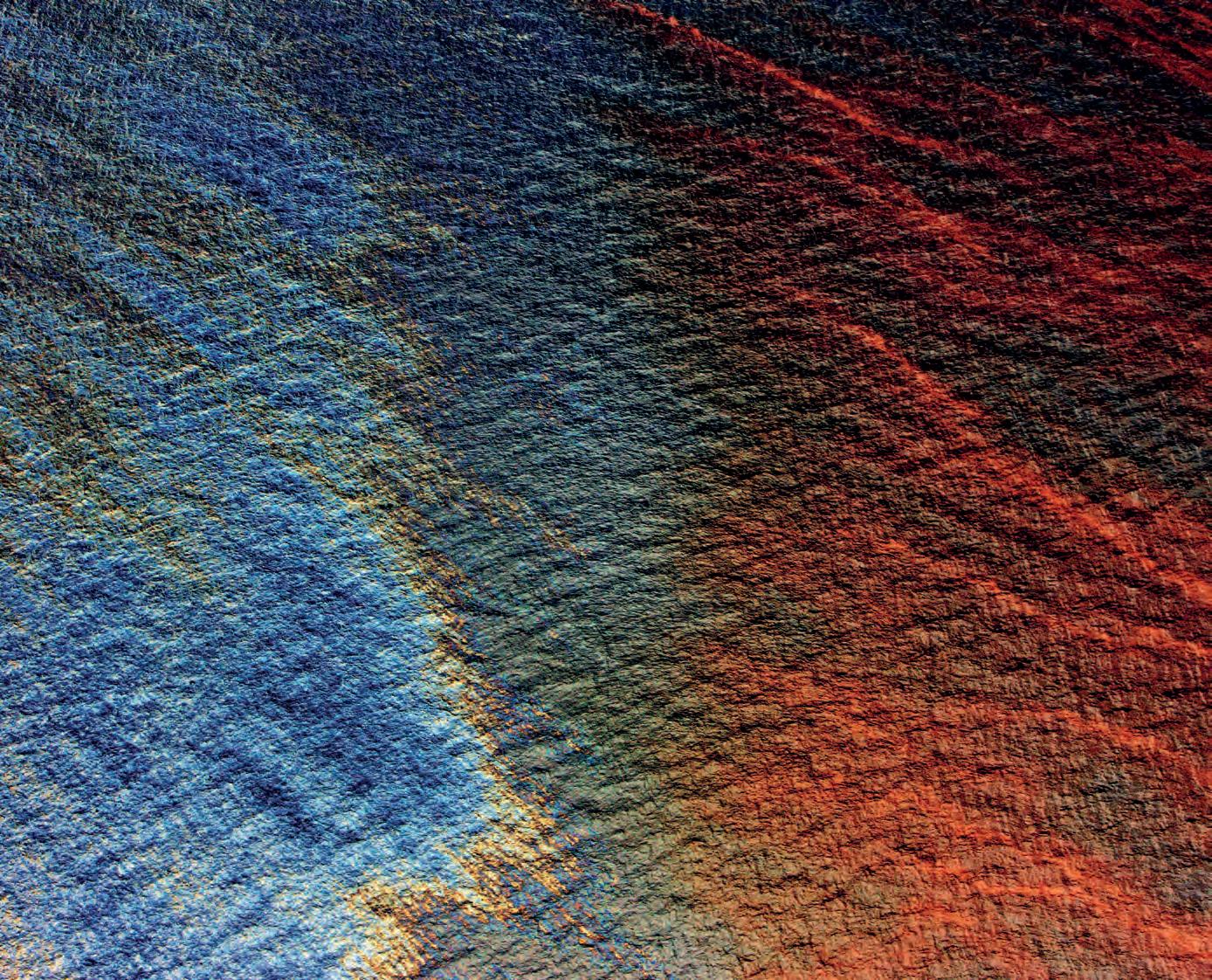

Opposite: GULF OF MEXICO, USA. Oil of different weights from BP Gulf Macondo well blowout floating on the Gulf of Mexico.

88

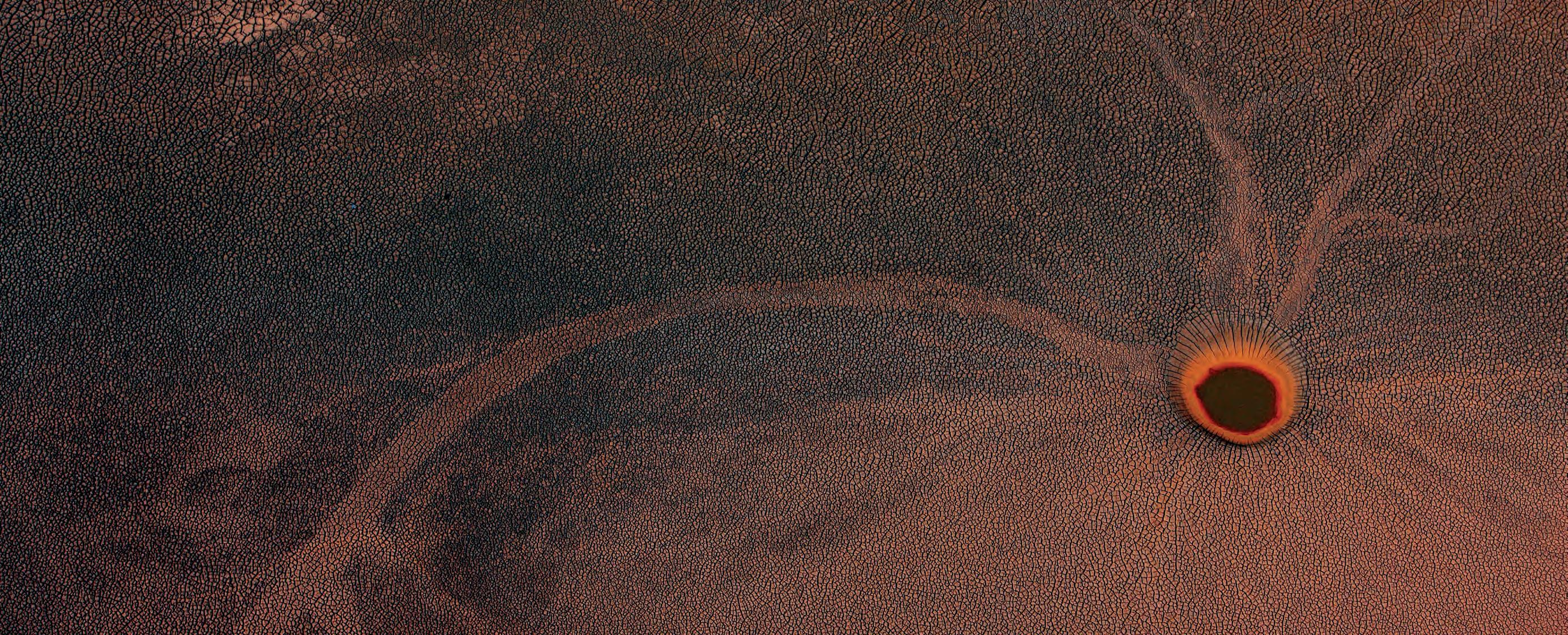

Opposite: GULF OF MEXICO. Over the course of the Deepwater Horizon spill, an estimated 1.84 million gallons (6.97 million litres) of the dispersant Corexit were sprayed on the surface of the Gulf of Mexico, or injected at the well head. Dispersants break up the oil into tiny drops, making them disappear from view, but actually increase the toxicity significantly, and the bio-availability, meaning the spread of the toxics through the ecosystem.

100

Above: GULF OF MEXICO, USA. The drill rig Development Driller 3 (DD3) drills one of the two relief wells on site at BP Macondo well. The other vessel is probably delivering supplies. Built in Singapore in 2009, the DD3 is 255 × 257 × 121 feet deep (77.7 × 78.3 × 36.8 metres deep), with the drilling derrick 200 feet (61 metres) tall, and draws 67 feet (20.4 metres) of water during operations. She can accommodate 200 people, can drill down to 37,500 feet (11,430 metres), and holds 21,000 barrels of ‘muds’ the toxic, heavy-metal-laden lubricants used in the drilling process.

107

Opposite: GULF OF MEXICO, USA BP Deepwater Horizon spill site with West Sirius drill rig in the foreground and flares of captured gas burning on the Discoverer Enterprise and Q4000 rig. Some of the other ships remotely operate submersible robots working on the well a mile below; others are delivering supplies. The rigs Development Driller One and Two were drilling the relief wells. The West Sirius came and went to the spill site several times with no explanation as to its function.

Above: GULF OF MEXICO. Drill rig Q4000 with flare burning gasses captured from the leaking Macondo Well. This is the utility rig that did the heavy lifting, lowering the big equipment down to the ocean floor in attempts to cap the free-flowing well.

144

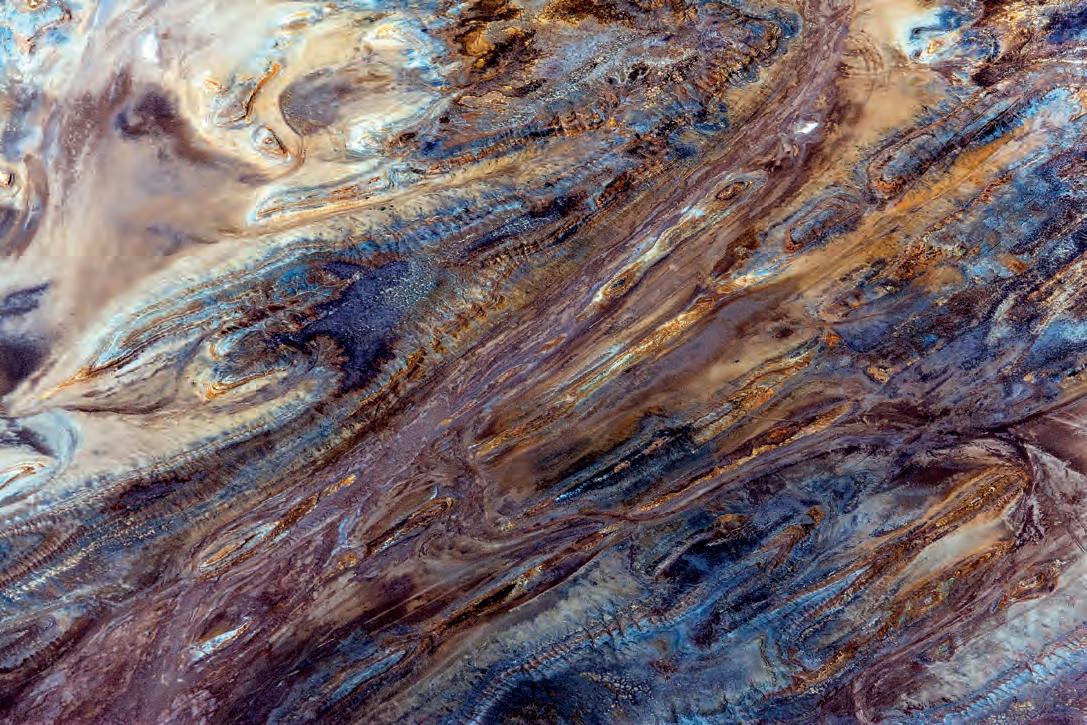

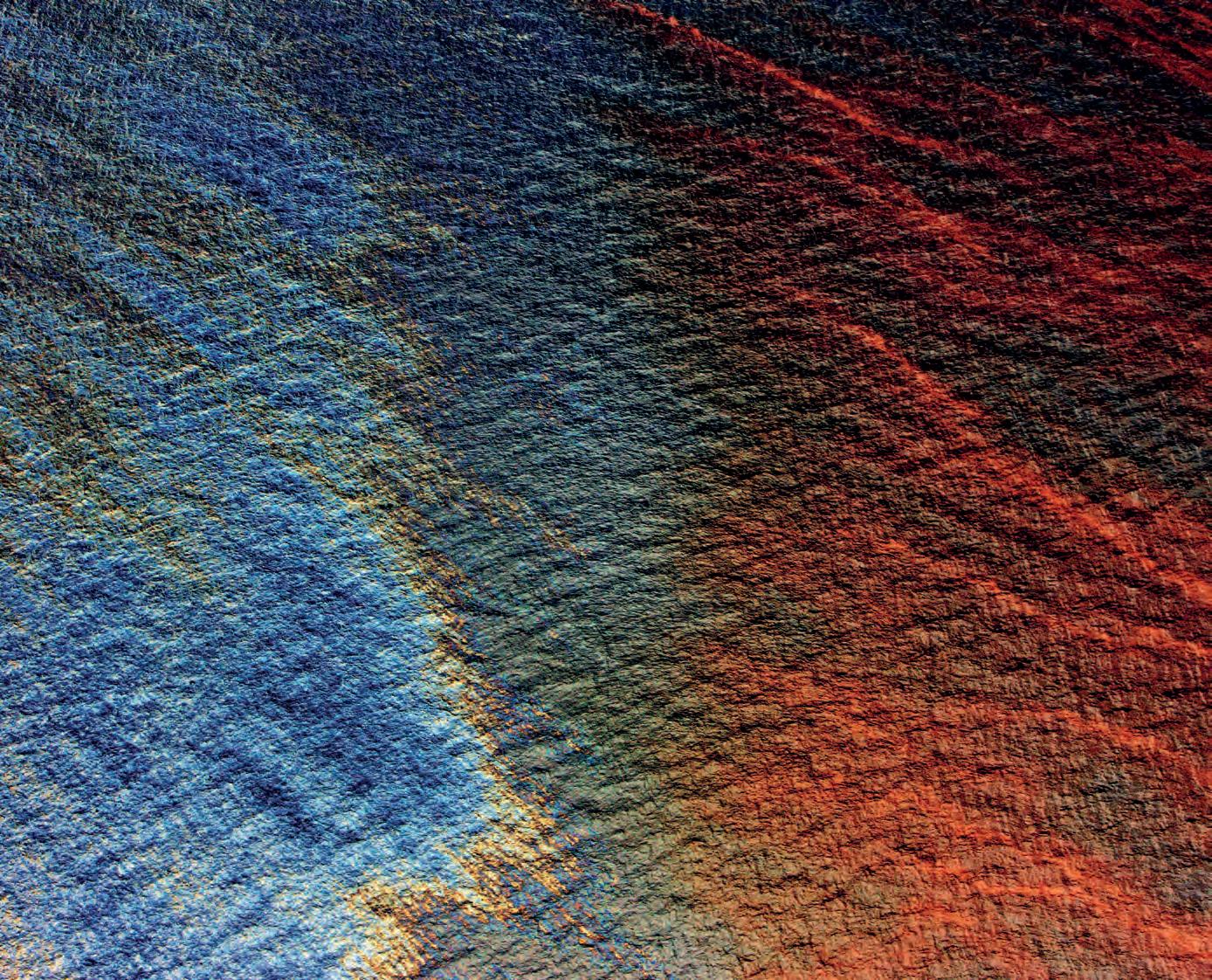

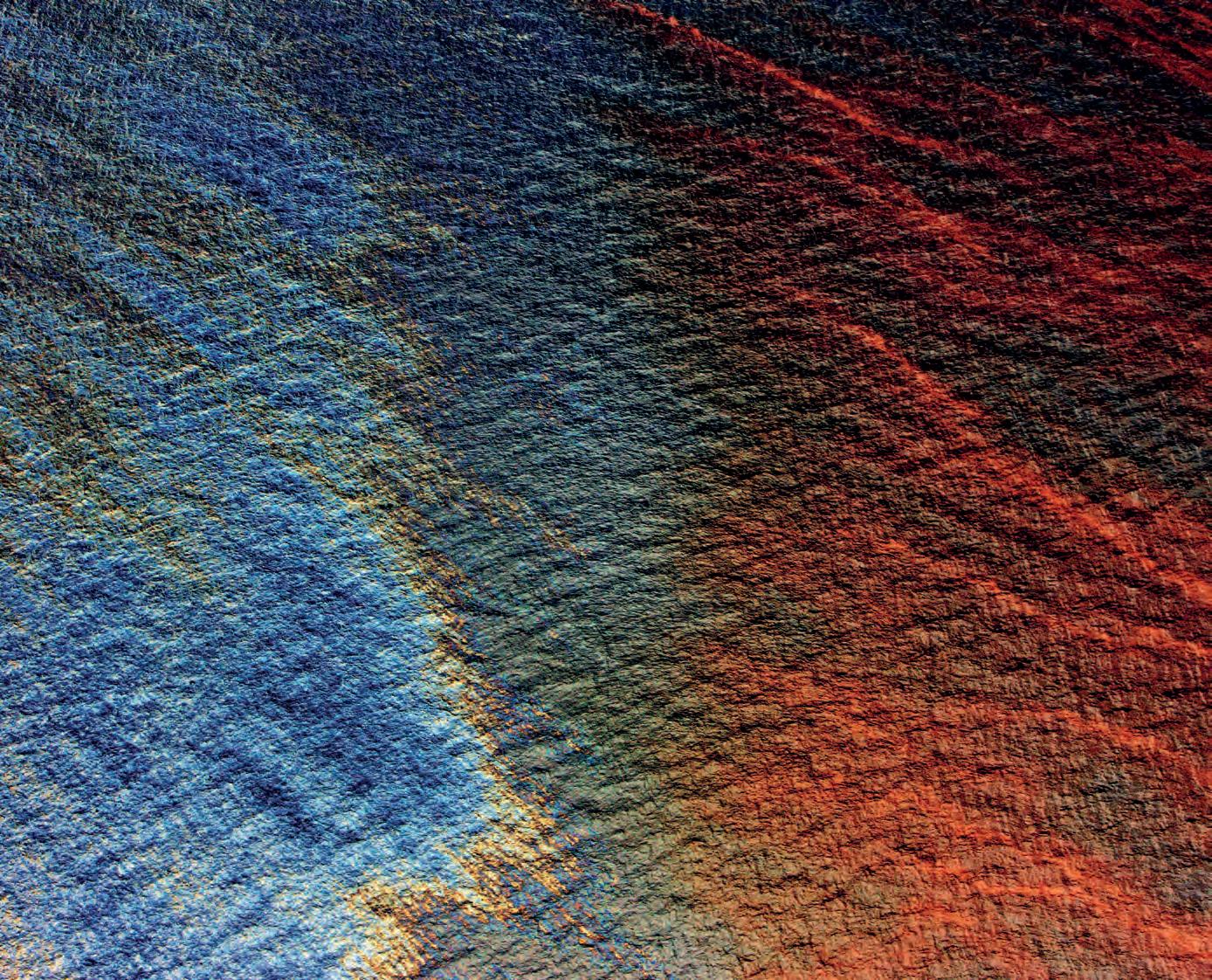

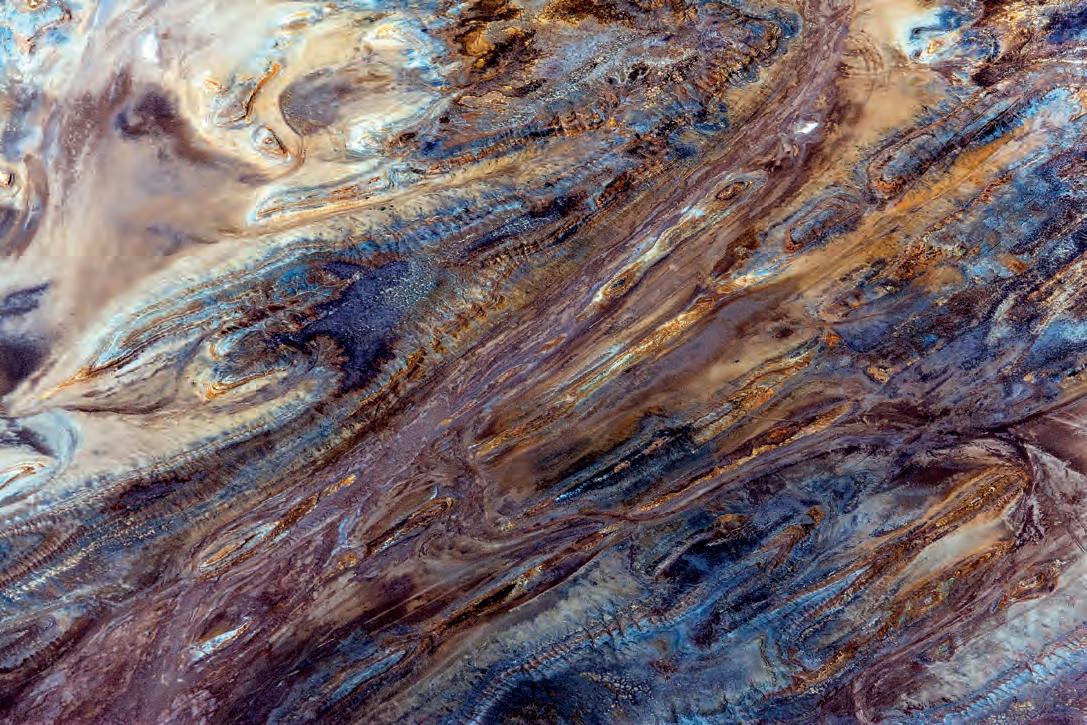

Above: HURLEY, NEW MEXICO, USA. Copper ore mill tailings impoundment at copper smelter. Colourful metallic compounds are formed by water and air interacting with trace amounts of metals left behind in the tailings by the flotation milling process

Opposite: HURLEY, NEW MEXICO, USA. Graded copper ore mill tailings and mine haul truck, copper smelter reclamation site. Copper ore mill and smelter site cleanup efforts include stabilising, grading and capping the flotation mill tailings and diverting water away to prevent discharge to the surrounding environment.

170

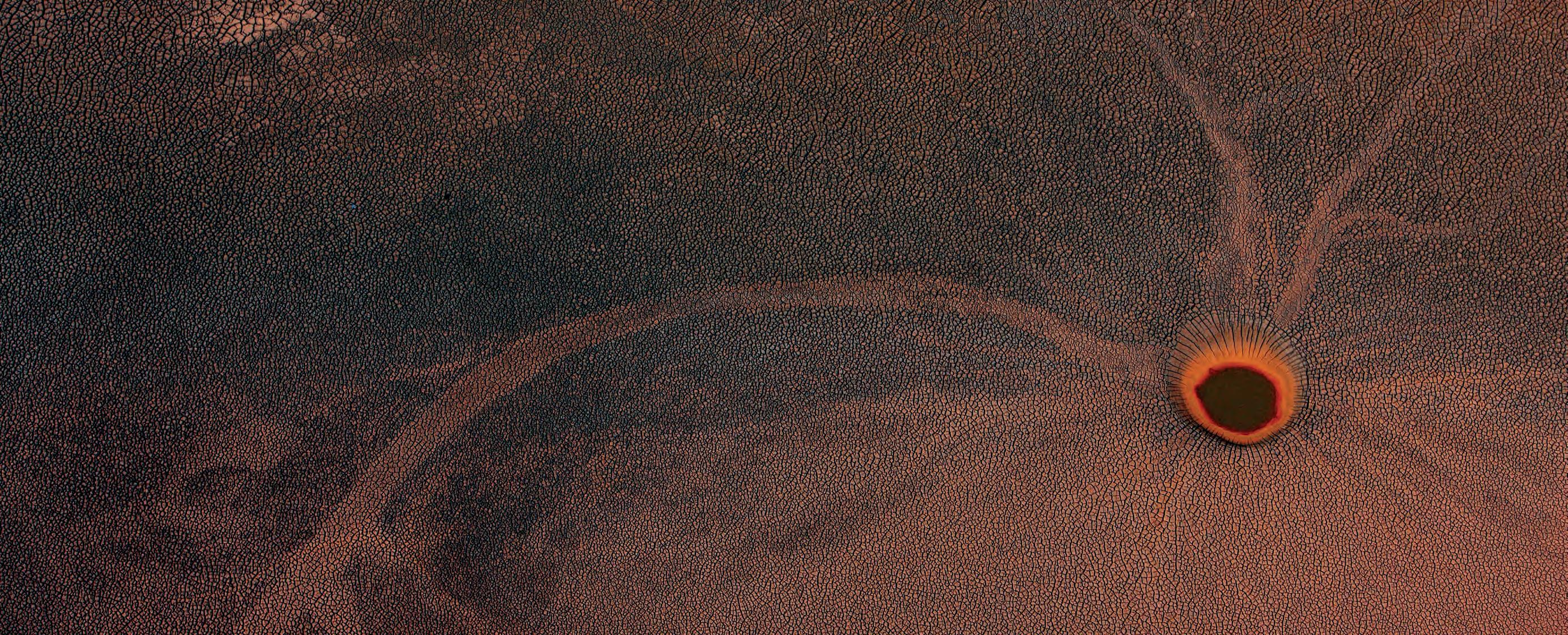

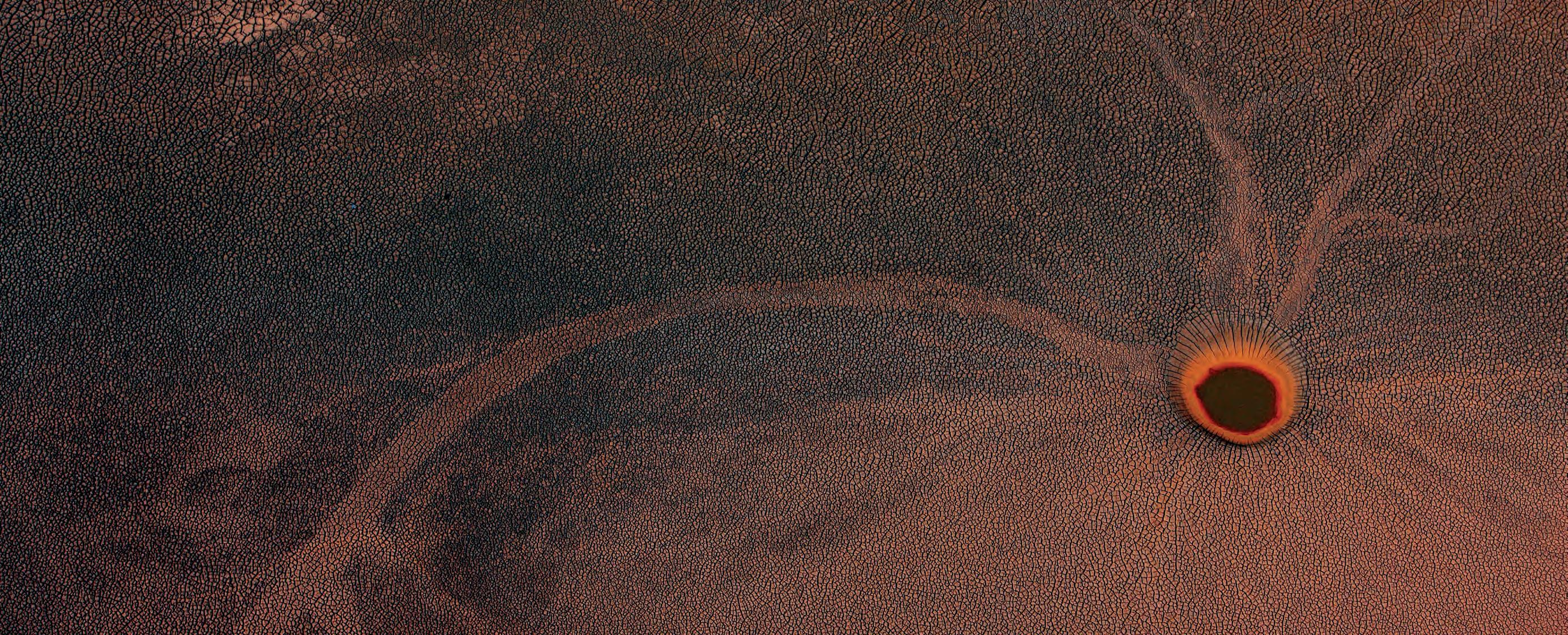

KIRUNA, SWEDEN. Waste impoundment at Kiruna Iron Mine. The Kiruna Mine draws on the world’s largest underground deposit of magnetite, a rich ore containing 60 per cent iron as well as unwanted rock that is separated and disposed of in large waste impoundments.

ACKNOWLEDGMENTS

My humble gratitude to my very good friend Dirk Vandenberk for his unwavering good advice, technical support, and emergency management.

Special thanks to Matt Kierstead for providing invaluable technical information on mining, metallurgy and mineral processing.

I would like to express my grateful thanks to Bill McKibben for taking the time from his vital work to write the foreword. He is one of the great thinkers and actors on climate change. With his organization 350.org, he has collaborated with scientists to disseminate knowledge and recommend sensible action.

Notable people include: Lisa Evans, one of the world’s great experts on coal ash; Willie Fontenot, for his extensive knowledge of industry and environmental issues on the Mississippi River Corridor; Larry Gibson, posthumous, one of the great fighters on Mountaintop removal mining (MTR), and a personal inspiration; James Hansen, the NASA scientist who risked his career to speak up about climate change and calculated the atmospheric ‘safety line’ of 350 ppm of CO2 (a figure we have long passed); David Hawkins, one of the world’s experts on coal and its dangers; Allen Hershkowitz, a great innovator in environmental efforts, and an authority on waste streams; Maria Gunnoe, a tireless warrior on MTR who led me to some great sites; Jack Hitt, for providing a wealth of ideas on many topics; Karsten Smid, who knows all there is to know about coal in Germany; Burney Terry, who knows about numerous industrial processes; Tensie Whelan, an environmental entrepreneur and global thinker with a grasp of the big picture. My apologies to anyone else who I have forgotten to mention.

The organizations SouthWings and LightHawk are heroic ‘wings for the environment’. Their network of volunteer pilots convey journalists, activists, and politicians over ravaged areas so that they can see for themselves the impact that is being created and influence positive change. Their generous support of this project is humbly appreciated.

I support environmental groups that work to keep our world clean and safe for our children. Several of my favorites are: 350.org • EarthJustice • NRDC • Waterkeeper

At Papadakis, I would like to thank Aldo Sampieri for his gorgeous design, and dedication throughout the entire production process. It was he who introduced me to my publisher Alexandra Papadakis some years ago and suggested that we would make a great partnership for a book, and it has been a joy to finally realise that dream. Finally, I would like to thank Alexandra for her vision of the book and continued support, and for finding hidden gems in the series that I had overlooked.

204