An area developed and patented with the help of engineers in acoustic & mechanic fields from the famous French University of Technology of Compiegne (UTC). The steel range was built to answer your most demanding needs while promoting togetherness.

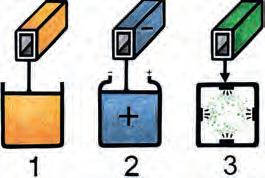

Unique on the market, this process is well used in the automobile industry (galvanization, cataphoresis & thermo-lacquering). It has allowed us to double the duration of our guarantees on dip-galvanized parts

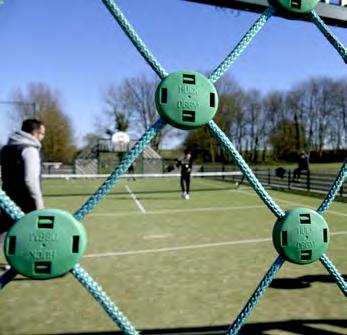

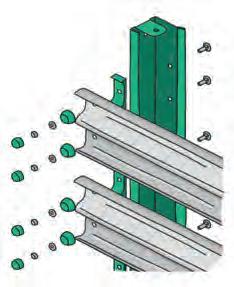

FixNET fittings

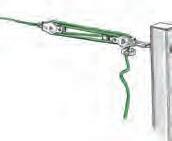

Fixnet Patented System The goal net is held in place by a round stainless steel bar, which increases the lifetime of the nets thanks to less friction. REMOVAL of WELDED SEAMS

Because welded seams rust first and vibrations from the repeated shock of balls can cause them to collapse, we decided to remove them.

The stainless steel screws and bolts are completely hidden by the anti vandalism protection. SHOCK ABSORBERS for each piece

To limit the spread of sound waves, each component is cushioned by shock absorbers.

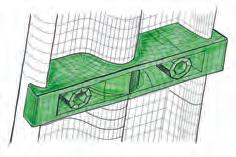

Because our aim is to create a meeting place which can be used all year round, all our pitches are equipped with an anodized aluminum handrail with a lifetime anti-corrosion guarantee.