Like most businesses, you want yours to be the best it can be. Whether this is the through the products and services you provide, the prices you offer or the locations in which you are based.

So, why not provide the best experience? You could:

Enhance the environment, set the tone, boost the mood and create a more upbeat atmosphere

Boost customer engagement by using music to create an entertaining environment

Stand out from your competitors

06 07 08

Foster customer loyalty and retention through improving their shopping experience

Attract new customers

Boost employee engagement, collaboration and motivation

Set the spending mood by creating an upbeat and positive atmosphere

Create a feel-good factor through the use of music

Support the future of music

Define and reinforce your brand

Business Development Director James Scrivens james@abbeypublishing.co.uk

Production Sarah Daviner sarah@abbeypublishing.co.uk

Accounts Manager Katie Brehm accounts@abbeypublishing.co.uk

BFM is published digitally 10 times a year by Abbey Publishing Ltd. To receive a copy free of charge, contact our offices.

Tel: 01933 316931

Email: bfm@abbeypublishing.co.uk www.bfmmagazine.co.uk www.abbeypublishing.co.uk

www.twitter.com/ BFM_Magazine

Subscriptions are available via www.bfmmagazine.co.uk/subscribe

Janitza is pleased to announce that its CPD presentation “Maximise Uptime by Transparency: All-In-One Metering Solutions for All Industries” has secured official accreditation by the Chartered Institution of Building Services Engineers (CIBSE), with participating engineers therefore receiving CPD certification points required for initial and subsequent certification.

Commenting for Janitza, UK Country Manager Tim Andrews says: “This recognition demonstrates Janitza’s commitment to delivering highquality, industry-relevant training that supports the ongoing professional development of engineers, consultants, and

technical specialists across the UK and beyond.”

The accredited CPD session delivers comprehensive insights and empowers understanding of the latest all-in-one metering solutions, focusing on transparency, energy management, predictive maintenance, and the integration of power quality and residual current monitoring technologies.

Attendees will learn how these solutions can maximise uptime, reduce costs, and ensure compliance with regulatory standards, making them essential for missioncritical environments such as data centres, hospitals, and industrial facilities. In addition, Janitza’s speakers will provide

practical insights and expert recommendations based on more than 60 years of experience in energy measurement technology and power quality monitoring.

The training course will be available from December 2025 onwards. Those interested can secure their attendance via the CIBSE portal at https://bit. ly/janitza_cpd or by emailing Tim Andrews at tim.andrews@ janitza.com or William Lloyd at william.lloyd@janitza.com.

Janitza UK Limited

Janitza delivers smart measurement solutions for transparent energy – for greater efficiency and longterm sustainability.

Janitza offers energy measurement technology that helps customers to increase energy efficiency and monitor power supply reliability. The company, headquartered in Germany, provides a portfolio of versatile measuring devices and the matching GridVis® Power Grid Monitoring software – complemented by highquality system components.

Customers around the world benefit from Janitza solutions in the fields of energy data management, power quality monitoring, load management, and residual current monitoring – all within a single system environment. Made in Germany. https://www.janitza.com

OUTCO is one of the UK’s trusted partners for grounds maintenance, along with winter gritting and reactive works. We deliver dependable grounds care that supports day-to-day operations, backed by teams who understand the practical needs of your sites. Our solutions are tailored to the specific requirements of each location, ensuring a smooth, efficient and hassle-free experience for every client.

0800 0432 911 enquiries@outco.co.uk

Kidde Safety Europe has introduced a new Fire and CO Alarm Control Switch that enables remote testing and silencing of interconnected Kidde FIREX hardwired alarms, providing a practical solution for properties where alarms are installed in locations that are difficult to access or require regular inspection.

The Fire and CO Alarm Control Switch makes the process easy with a convenient Test/Hush button that eliminates the need for physical access to the alarms. This is particularly valuable for elderly or disabled individuals and in properties with high ceilings. It also enhances safety and compliance where alarms are installed in nonoccupied areas, such as lofts with photovoltaic (solar) equipment. The solution aligns with BS 5839-6:2019, the British Standard for domestic fire detection systems, which highlights the importance of providing remote testing capability for alarms installed in inaccessible locations.

will sound. In the event of an activation, pressing the Test/ Hush button will silence all alarms in the system except the initiating device – this allows for easy and convenient alarm source indication.

The new control unit features separate visual indicators for fire and carbon monoxide detection to provide a quick and clear identification of the hazard. For simplicity, it also has a single multifunction button. To test the system, users simply press the button, and all the alarms

The Fire and CO Alarm Control Switch can be connected into any part of a new or existing Kidde FIREX hardwired alarm installation and can support up to 24 interconnected devices. The switch, which fits into a standard wall back box or standard surface mounted electrical box, should be mounted to a wall in an easily accessible, central location such as a hallway or landing space. It is supplied with a 10-year warranty for long-term reliability.

“The safety of residents depends on fire and carbon monoxide alarms being in full working order, and it is imperative that they are tested regularly,” said Brad Taylor, General Manager at Kidde and a 20-year veteran firefighter. “Landlords have a duty to ensure their properties remain compliant, and our new alarm control switch simplifies this process across all Kidde FIREX hardwired alarms, supporting more effective management of life safety devices.”

For more information about the RTHL Fire and CO Alarm Control Switch and Kidde’s full range of fire safety solutions, visit: www. kidde.com/fire-safety/en/uk/.

The Cleaning & Hygiene Suppliers Association (CHSA) has published a fact sheet designed to help its members make informed, evidence-based decisions on sustainable products, packaging and operations.

The fact sheet forms part of the CHSA’s Roadmap to Sustainability. This is the Association’s longterm initiative designed to provide members and the wider industry with practical guidance on sustainability.

Environmental claims, used to differentiate one product or service from another, are common and often based on ill-informed assumptions or misconceptions. The Fact Sheet

highlights key points when assessing such sustainability claims. They include the importance of evidence, that there are no universal ‘good’ or ‘bad’ materials, many green claims are legally or technically meaningless and considering the full life-cycle is essential.

Lorcan Mekitarian, Chair of the CHSA, explained: “People generally want to opt for the sustainable solution. The challenge is when decisions are based on assumptions. These include products made from recycled materials are always more sustainable than those made from virgin materials, that buying locally always has a lower carbon footprint. They may assume a product certified as ‘eco-friendly’ is

sustainable in all aspects.

“The fact sheet encourages buyers and end-users to challenge their assumptions. By doing so they will be able to consider the full lifecycle impacts of products and services and consider multiple environmental indicators. Ultimately it means prioritising genuine environmentally sustainable solutions over headlinedriven marketing claims.”

All CHSA members have signed the Association’s Code of Practice, which includes the Competition and Markets Authority’s Green Claims Code.

The myth-busting Fact Sheet is available on the CHSA’s website: www.chsa.co.uk.

Building & Facilities Management magazine covers all of the major FM areas of interest within the workplace and the built environment.

To subscribe to BFM magazine, please visit www.bfmmagazine.co.uk

Energy

Contact us for a FREE site survey or online demo to learn more about our industry leading environmental monitoring solutions and how they can help to reduce your energy costs. Scalable, with Ethernet and WiFi connectivity, over 20 sensor options for temperature, humidity, water leakage, airflow, AC and DC

and

Fusion21 has announced the renewal of its national Grounds Maintenance Framework, worth up to £85 million over four years, and is now inviting bids from interested suppliers providing regional or national coverage.

The national procurement specialist is seeking competent firms operating in the public sector, including SMEs, to support its members in delivering grounds maintenance services across outdoor spaces of any scale, from green spaces and communal areas to external sports surfaces and play areas.

Offered as a single lot and now in its fourth iteration, the framework is suitable for all Fusion21 members, including housing providers, local authorities, education, blue light and the NHS.

From routine upkeep to seasonal tasks, it covers hard and soft landscaping services, such as arboricultural work, hedges and shrubs, cleaning and waste management.

Peter Francis, Group Executive Director (Operations) at Fusion21, said: “Set to launch in June 2026, our renewed Grounds Maintenance Framework makes it easier for members to maintain and improve outdoor spaces while delivering social value you can see.

“The framework is fully compliant with the Procurement Act 2023, and members accessing this offer will benefit from value for money and a fast route to market with flexible

call-off options – including the ability to direct award.”

Tender applications are welcome from suppliers that meet the criteria set out in the tender documentation. To find out more and apply, visit http:// fusion21.co.uk/tenders and click on ‘Current opportunities’.

The submission deadline is Wednesday 4 March 2026 at 12 noon.

Steve Juson, Managing Director,

It was back in 2012 in its Living Planet Report when the World Wildlife Fund asserted that, if the Western developed nations continued with their pattern of consumption, we would need three planet’s worth of resources by 2050. During the years since then, consumerism and population have expanded across regions like Africa and parts of Asia, with supposedly sustainable activities such as sourcing the minerals required for electrical vehicles steadily scarring once pristine landscapes.

Meanwhile, the extra 1.1 billion people added to the population over that time not only have to be fed but also accommodated which means the need to access sufficient environmentally-friendly, and ideally carbon negative, building materials has become just as important a goal as maximising the cultivation of drought resistant plants. Undoubtedly, the UK is by no means the only country where housebuilding is failing to keep up with the crisis in demand.

MMC solutions require material advancements

The past quarter century has seen significant increases in the use of Offsite technology or Modern Methods of Construction (MMC), with engineered timber being the most popular primary material across the sector in most of Europe; with producers of

competing materials also embracing sustainability goals. Carbon negative materials are defined as those which sequester more carbon than they emit during their life cycle with other examples including hempcrete and recycled steel, aluminium or concrete. All of them, though particularly the trio of metals, constitute a precarious balance involving embodied energy, the depletion of natural resources and the time required for their replacement. Significantly, however, the formation of ores and other mineral deposits are defined by geological epochs rather decades.

As an increasingly important and costly factor, the amount of energy which goes into producing common building materials is well understood, with recycled steel requiring 74% less energy for its

manufacture than the virgin product, a figure which rises to 95% for recycled aluminium which is popular for secondary structural elements like curtain walling. Recycled steel is also now being utilised for a minor proportion of the rebar required to take the tensile forces within reinforced concrete, while recycled aggregates and waste products, like pulverised fuel ash and ground granulated blast furnace slag, are routinely specified to offset the use of energy intense cement. Ironically though, the supply of PFA and GGBS is rapidly reducing as coalfired power plants and steel foundries are razed to the ground in the fight to counter Climate Change, making the construction industry’s quest for “ConcreteZero” ever more difficult.

The harsh reality, then, is that the heavyside construction methodologies which shaped so much of the infrastructure which surrounds us is desperately scrabbling to reach the level of sustainability which for timber can quite literally come naturally. This fact does not, of course, mean that timber-based building systems are automatically virtuous, and due diligence has to be employed to ensure that their specification will be good for the planet.

As the recent COP 30 in Brazil reminded us, forests are the lungs of the Earth, a resource we squander at our peril which is why chain of custody and whole life strategies for the use of wood are crucial. Indeed, the need for constant vigilance was highlighted last year by the

organisation Earthsight when it produced the video entitled “Blood stained Birch” which exposed how since the start of the war in Ukraine, more than €1 billion of Russian plywood has been wrongly given FSC- accreditation by China and sold into Europe.

Once fully implemented, the European Union’s Deforestation Regulation (EUDR) will offer a substantial bulwark against illegal and unsustainable cropping of timber, but responsible manufacturers have already made significant strides to ensure their own operations are as well managed and transparent as possible.

With a high proportion of the company’s supplies of raw materials coming from properly-managed forests

within the British Isles, and huge investment having been made in areas like production, transport and cutting waste, coupled with the use of biomass for the drying processes and a policy of only buying power from guaranteed renewable sources, the entire product range of West Fraser in the UK has now achieved Carbon Negative status. This ensures its own customer network can be assured that the panel products they are using to produce structural insulated panels (SIPs) and other offsite systems like floor cassettes, as well as for sheathing, decking and other applications, all fully meet the spirit as well as the regulations which will expand the use of carbon negative building materials.

www.westfraser.com

Winvic Construction Ltd, a leading main contractor that specialises in the design and delivery of private and public sector construction and civil engineering projects, has announced its expansion into the Data Centre market.

Building on 25 years of proven delivery, Winvic will now deliver purpose-built, resilient, and scalable data centre solutions to meet growing market demand, reinforcing its commitment to innovation, operational excellence and supporting the digital economy.

Data Centres is Winvic’s fourth core sector, sitting alongside Industrial & Logistics, Multi-room, and Civils & Infrastructure.

As a Tier 1 partner of the UK’s most complex industrial and infrastructure developments, Winvic has built an enviable record of disciplined delivery and the highest standards

of quality. Its move into the Data Centre market is part of its ongoing growth and diversification, bringing its core values and expertise to a rapidly expanding market.

Danny Cross, DirectorHead of Data Centre Delivery at Winvic, said: “Over the last eighteen months we have focused on developing our supply chain, upskilling our teams and recruiting new expertise. Working alongside specialist MEP partners, we’re combining civil engineering scale and management with technical precision to deliver data centres designed for uptime, resilience, and scalability.

“This marks a significant milestone in Winvic’s evolution as we expand into one of the fastest-growing construction sectors whilst maintaining our commitment to quality,

collaboration, and excellence.”

Danny Nelson, Managing Director of Industrial, Logistics and Data Centres at Winvic, said: “Our entry into the Data Centre market is a natural evolution of our capabilities as these developments share similar attributes to buildings we’ve been specialising in for over 25 years. Our proven delivery of large-scale and complex industrial and logistics projects, rigorous safety and quality standards through our ‘Doing It Right’ culture, and a collaborative approach gives us a strong advantage. “

Building & Facilities Management editorial content covers all the major FM areas of interest within the workplace and the built environment.

This includes industry developments, company news, case studies and application stories, product news as well as articles from leading authorities within the marketplace.

To find out more information about BFM Magazine or to subscribe, please visit www.bfmmagazine.co.uk

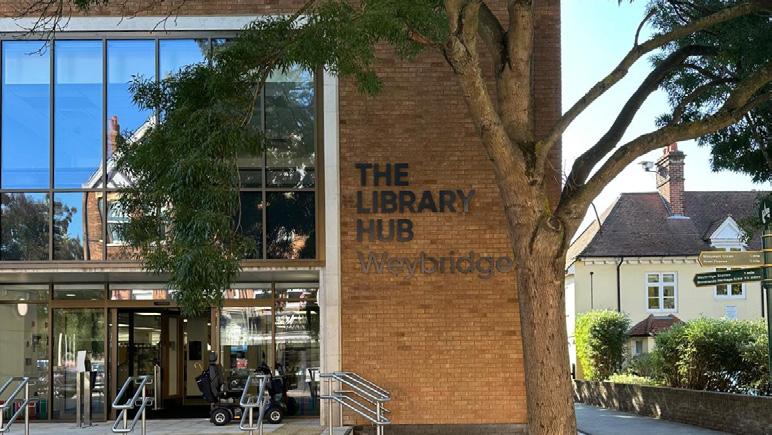

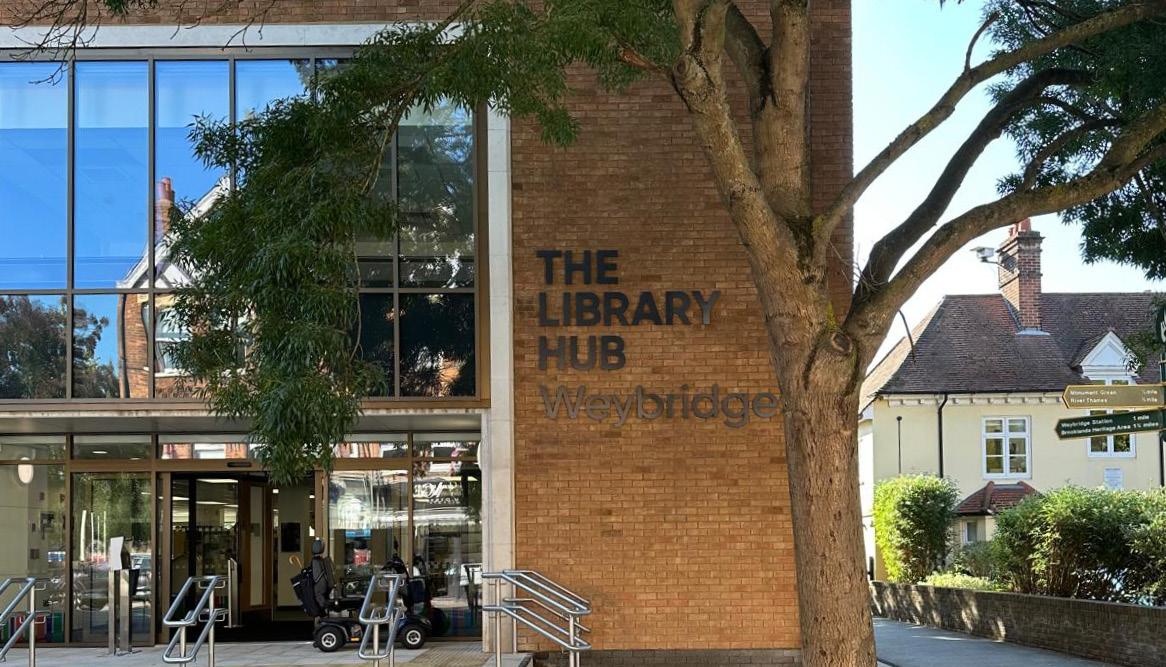

A new multi-million pound community hub has opened to the public in Weybridge delivering a modern library and flexible civic space.

Designed to support community services, youth provision, commercial activity and broadcasting, the scheme was delivered by Pick Everard for Surrey County Council in collaboration with AtkinsRéalis and main contractor Neilcott.

The project involved a comprehensive external refurbishment of the existing Weybridge Library site in Church Street, alongside a full internal refit to accommodate a wide range of partners and the needs of residents of all ages and backgrounds. The building will enable them to come together through activities and services to tackle isolation and strengthen community resilience.

Pick Everard provided principal design, architecture, interior design and landscape architecture services, acting as lead designer through RIBA Stages 1–3 under the Surrey Framework and as technical advisor for RIBA Stages 4-6.

Aligned with the Department for Culture, Media and Sport standards, the hub includes an activity space with bookable multi-use spaces and meeting rooms, a business hub offering co-working facilities for Surrey County Council, a base for regional broadcaster Brooklands Radio and a designated area on the first floor for Elmbridge Borough Council Community Services provision.

Deputy Leader of Surrey County Council and Cabinet Member for Customer and Communities, Denise TurnerStewart, said: “Our community

hubs are the very ethos of what Surrey County Council are investing in, to deliver in the heart of our communities, working together with external partners and residents, to provide places that bring our services, support and social events and activities all under one roof for our residents to

access and enjoy. Our modern, sustainable, accessible and multi-purpose Library Hubs are about building stronger communities together, providing a legacy for future service and support provision within our local areas. We are proud to have been able to deliver another Library Hub, this time

in the heart of Weybridge.”

Architecturally, the scheme enhances the Church Street elevation with fully glazed ground and first floors, clearly signalling the main entrance, library and business hub while improving visibility and engagement with the public realm. A deep-set entrance, formal stepped access and an integrated ramp improve accessibility, reinforcing a strong sense of arrival within a sensitive conservation area setting adjacent to listed buildings, including St James’ Parish Church.

Sustainability was a key driver throughout the design process, with the project targeting high energy efficiency and carbon reduction in line with LETI guidance. Measures include the installation of solar photovoltaic panels, the removal of gas boilers and their replacement with variable refrigerant volume systems and highefficiency air handling units.

Sainaja Feroz, Associate of Architecture at Pick Everard, said: “Flexibility and accessibility were central to the design of the Weybridge community hub, particularly given its location within a conservation area and alongside listed buildings with protected views. The result is a highly adaptable, inclusive facility that supports Surrey County Council’s long-term vision for community-focused spaces while responding sensitively to its historic context.”

Surrey County Council’s 2030 vision and asset management strategy, which aims to enhance local assets, expand access to public services and create welcoming community spaces that meet evolving needs, including safe spaces and facilities capable of supporting 24/7 operational requirements.

The project forms part of

To find out more about Pick Everard and its services, please visit: https://www. pickeverard.co.uk/

Leading hygiene services provider phs Group has launched the UK’s first 100% recycled washroom essentials collection.

The ReVive range, is the UK’s first and only up to100% recycled washroom range and includes paper towel dispensers, soap dispensers, air fresheners, sanitary disposal units, nappy disposal units, and hand dryers.

The ReVive family of sustainable washroom products has been designed by phs Group’s in-house development team following direct feedback from customers for support to reach their sustainability targets. Forty-six per cent of UK businesses have implemented sustainability reporting, with a further 43% clamouring to hit sustainability targets. [1]Each product has been designed to help businesses dramatically reduce their carbon footprint while still providing a premium user experience.

Made from recycled ABS plastic, ReVive products release four times less CO2 emissions than non-recycled products. All products in the ReVive range are also recyclable at the end of their useful life contributing to phs’ circular economy strategy.

All waste collected from these units will also be converted into renewable energy via phs Group’s LifeCycle Strategy, continuing the circular economy, and further allowing businesses to contribute positively to a more sustainable future.

The products’ design mirrors its recycling credentials, with a speckled finish indicating there are recycled materials included in every piece in the collection.

Amanda Haywood, head of product development at phs Group said: “Every product

in the ReVive range wears its sustainability with pride. The speckled, premium finish isn’t a design choice, it’s proof recycled materials are built into our products.

“For facility managers, that proof is powerful. ReVive helps organisations cut carbon but also visibly showcase their green credentials to teams and customers. With our ReVive Range, sustainability looks different, because it is different. We have gone further than any other hygiene supplier with our sustainable and recyclable products – and the proof is in the product.”

The phs ReVive range includes:

100% recycled Sanitary Bins

create a fresh and welcoming atmosphere in any environment. The Air-Freshener is available in a choice of seven vegan and vegetarian-friendly fragrances. phs is the leading hygiene services providers in the UK, Ireland and Spain with 120,000 customers over 300,000 locations.

Both the grey and premium sleek black onyx sanitary disposal units are made from 100% recycled plastic and the recycled plastic used in our ReVive bin range uses 50% less carbon in its manufacturing process than virgin plastic.

The only recycled Hand Dryer

The range also features the world’s only recycled hand dryer with fire-retardant and antimicrobial accreditations, allowing businesses to combine safety with sustainability.

Eco-Friendly Air Fresheners and hand soap dispenser

Made from recycled materials the certified 100% carbon neutral and fully recyclable air fresheners and soap dispensers offer an eco-friendly way to

Matthew Brabin, CEO at phs Group said: “phs is a business that can have a genuine positive impact on our customers’ carbon footprint. We are dedicated to achieving Net-Zero emissions by 2040, and our own efforts to achieve this can directly positively benefit all the organisations we work with too.

“The ReVive range is further evidence of our commitment which complements several sustainable initiatives at the business including our service fleet of Euro VI-compliant vehicles, electric vans, and e-Cargo bikes as well as our renewable energy from waste LifeCycle scheme.

“Each ReVive product proudly displays our recycled logo, making it easy to show customers and employees that organisations care about the environment, just like we do.”

Leading office refurbishment specialist, OP, has completed the transformation of a 1970s office building into Techspace’s newest flexible workspace at 9-13 St. Andrew Street, London.

The 16-week project has converted 16,800 sq ft of previously vacant office space into a contemporary flexible workspace environment, accommodating 274 workstations across the basement, ground floor and office floors 1 to 6.

The design approach centred on implementing Techspace’s ‘Distinctly Techspace’ design language whilst celebrating the building’s original features, including warm terracotta ceiling tiles and structural elements exposed throughout the workspace.

A key design intervention involved reconfiguring the ground floor layout through the strategic removal of an oversized entrance staircase.

This created space for a centrally positioned café bar with feature mesh screen backdrop, forming the social heart of the building and encouraging interaction between members.

The workspace includes a suite of five meeting rooms in the basement serving the entire building, complemented by additional meeting spaces distributed across floors and a large boardroom behind the ground floor café. Phone booths are positioned adjacent to member offices, whilst breakout areas feature mixed seating with integrated power throughout.

The project demonstrates OP’s commitment to sustainable design through extensive reuse of existing materials. All glazing was retained and repurposed, and ground floor pillars were stripped back to expose their original character.

Alannah Laud, designer at OP, said: “Our vision was to

create an authentic Techspace environment that would bring their “Distinctly Techspace” design principles to life in this unique building. By carefully stripping back to reveal the building’s character, we’ve created a flexible space that feels both contemporary and rooted in place.”

Paul Sandilands, Property Director of Techspace said “We’re delighted with how OP has transformed this challenging building into a space that truly feels like Techspace. They worked collaboratively with our team throughout, adapting the design during construction to meet incoming tenant requirements.”

The project was delivered whilst accommodating incoming tenants, with layouts adapted during construction to provide flexible workspace configurations across the building.

Analogue telephone lines have copper conductors. These are being updated with fibre connections to provide broadband connections to commercial and domestic users.

BT Openreach has an objective for all buildings to be on fibre connections by the end of 2025 when support of existing analogue lines will be no more! This has been further exstended to 2027 depending on your area and service provider.

Many lift alarm systems use analogue telephone lines and need a dial tone and dual-tone multi frequency (DTMF) signalling to work.

Your lift alarm communication systems will need to work over fibre connections. However, fibre cannot carry a voltage and routers so you will also need a backup power supply to maintain the lift alarm in the case of power failure. See BS EN 81-28:2022

Telephone lines are the responsibility of the building owner. Who need to be prepared.

1. Talk to your communication provider to understand the changes to your line and when it will happen.

2. Check with your lift maintenance company for advice on equipment that can be fitted. Check you are complying with BS EN 81-28:2022

1. Test the emergency call system: Check test calls use the same method as the actual lift alarm calls.

2. Battery Back-up: - Make sure both the autodialler and GSM gateway have a monitored backup.

Or you may simply contact our friendly team Who have the correct solution for you. Supplied Installed and Tested.

B&K Hybrid Solutions (BKHS) have played a pivotal role in the delivery of a new Design, Technology & Engineering (DTE) building at Stowe School - an inspiring and sustainable educational facility located within the historic, Grade I-listed grounds of Stowe House in Buckingham. Designed to support advanced robotics, manufacturing, and engineering education, the £5.9 million project is redefining how a building itself can actively support curriculum delivery.

On behalf of Beard Construction, BKHS were selected to deliver an innovative timber solution, combining 108.237m³ of glulam beams, 2,042m² of Cross Laminated Timber (CLT) panels, and 46

tonnes of ground-floor steel grillage. The expert project team included architects Design Engine, structural engineers Buro Happold, specialist timber engineers Engenuiti, and CLT manufacturer Stora Enso. The collaborative result is a visually expressive, low-carbon, twostorey facility that functions not only as a high-quality learning space but also as a living laboratory; with visual elements allowing students to explore and engage with the building’s engineering principles first-hand.

Aligning with Stowe’s vision to become a leader in STEM education, the DTE building celebrates construction transparency. Exposed CLT and glulam structural elements

are left purposefully exposed and visible throughout, with mechanical and electrical systems (including ductwork, pipework and cabling) colourcoded and surface-mounted, enabling students to observe and explore the inner workings of the building. The highly aesthetic quality of visual-grade timber, afforded by precision manufacturing, has been embraced as part of a broader biophilic approach that elevates both the learning environment and student wellbeing. The exposed elements left no margin for error, meaning that detailing, fabrication, installation sequencing and coordination had to be rigorously aligned and precisely executed.

Lee Roberts, Pre-

Construction Director at BKHS, said: “We are delighted to have delivered Stowe School’s new DTE building in collaboration with our project partners. Every detail, from structural timber connections to sequencing logistics, was carefully considered to meet the highest environmental and aesthetic aspirations for the client. BKHS and Beard Construction worked closely to minimise disruption for staff and students and align with school term times. All components were delivered to site via dedicated routes to help protect sensitive infrastructure within the grounds while streamlining the overall construction phase.”

Precision was critical to the project’s success. For the timber elements, a frozen IFC model ensured that all service penetrations were pre-cut to millimetre tolerances in the factory, improving installation accuracy while reducing material waste. Each element was coordinated for sequential delivery and erected quickly via designated access routes.

Environmental performance was a guiding principle throughout the design stages, and the building was conceived with its entire lifecycle in mind. At RIBA Stage 2, Buro Happold assessed four structural options and identified that an all-timber solution would reduce embodied carbon by approximately 75% compared to a concrete-based frame. In total, the 476m3 of PEFC-certified timber delivered for the project ultimately sequestered 360 tonnes of CO₂e, and through sustainable harvesting and responsible management of European forests, the timber will have been replaced by new growth in just 1 minute and 44 seconds. The structural timber elements are also fully demountable, supported by helical steel screw piles and dry screed systems, which allow the building to be dismantled at end of life or reconfigured as the school’s

educational needs evolve.

Alex Brock, Pre-Construction Manager at BKHS, said: “Timber is increasingly shaping the future of educational environments, not just for its sustainable credentials, but for the way it actively enhances the learning experience. At Stowe School’s new DTE building, the exposed glulam and CLT structure doesn’t just support the building, it supports the curriculum, turning the space itself into an interactive educational tool. This kind of transparent construction invites curiosity, encourages engagement with engineering principles, and fosters wellbeing through natural materials. It’s a compelling example of how timber can deliver high-performance, low-carbon solutions that educate and inspire.”

As a flagship facility for the school, the DTE building has already received enthusiastic feedback from staff and students alike. Martin Quinn, Head of Design & Technology at Stowe School, said: “The new DTE building has transformed the way our students learn. The workshops are brighter, more vibrant, and provide an inspiring space where students can create and showcase their work. With this facility, Stowe is now firmly positioned as the ‘go-to’ destination for future engineers,

designers, and architects.”

Stowe School’s new DTE building sets a precedent for low-carbon, educational architecture - where timber technology, offsite manufacture and circular economy principles have combined to shape not only the building’s design, but its function as an evolving educational tool.

As timber continues to redefine how educational spaces are conceived and constructed, B&K Hybrid Solutions stand at the forefront of this movement. Their expertise in timber and hybrid solutions, precision offsite manufacture, and seamless project coordination has not only delivered an architecturally striking and environmentally responsible building, but one that reinvents how students learn and interact with their surroundings.

The DTE building at Stowe School exemplifies BKHS’ commitment to pushing the boundaries of low-carbon design, showcasing how timber construction can support a school’s vision, curriculum, and sustainability goals, while setting a new benchmark for what educational buildings can achieve.

To learn more about B&K Hybrid Solutions, visit: www. bkhybridsolutions.co.uk

NHS patients in east Somerset and west Dorset are set to benefit from faster diagnoses and improved healthcare access with the opening of the cutting-edge Yeovil Diagnostic Centre.

Developed by Prime plc in partnership with Somerset NHS Foundation Trust, this state-ofthe-art facility will offer a onestop shop for diagnostic tests and outpatient appointments, enabling the Trust to deliver on its diagnostic strategy and reducing waiting times.

The achievement was marked at a celebratory event attended by Prime and the Trust along with funder M&G, contractor Darwin Group, employers agent Ridge and radiology and

endoscopy service providers

InHealth, recognising the collaboration and dedication that made the project a success.

Located adjacent to Yeovil District Hospital, the new threestorey, 2,687m² centre will provide over 70,000 diagnostic tests and outpatient appointments annually. Open seven days a week, the centre will offer a comprehensive range of diagnostic services, including MRI, CT, ultrasound and X-ray, as well as outpatient services such as consultations, treatment facilities, ECHO and ECG,

endoscopy and adult and paediatric audiology testing. By enabling patients to receive diagnostic tests outside of a busy hospital environment, the centre will free up capacity for those requiring more complex care.

A key feature of the scheme is its focus on sustainability, meticulously designed to achieve net zero embodied carbon. The building achieved BREEAM Excellent certification, placing it among the top 10% of newbuild non-domestic buildings in the UK for environmental performance. Prime achieved significant Biodiversity Net Gain on site that far exceeds Local Authority requirements, by reaching nearly 300%.

Additional sustainability measures include a sitewide sustainable urban drainage system incorporating attenuation tanks, a rain garden and bio-retention planters. The centre also features a roof-mounted solar PV array providing 45 kilowatts of peak power output and an allelectric mechanical services strategy, including air-source heat pumps and heat recovery ventilation in non-clinical areas. The project utilised Modern Methods of Construction (MMC), ensuring an efficient construction timeline.

Radiology and endoscopy services will be provided by InHealth, the UK’s largest specialist provider of diagnostic and healthcare solutions, while the Trust will deliver all other diagnostic and outpatient consultation, treatment and testing services.

Phil Holland, Chief Investment Officer at Prime, said: “Prime has been proud to work in partnership with Yeovil District Hospital since 2014 and more recently with Somerset NHS Foundation Trust.

“The facility is a testament to the collaborative work between Prime, the Trust, InHealth, Darwin, M&G and all the organisations who contributed to its design, development and construction.

“The completion of the Yeovil Diagnostic Centre reinforces Prime’s commitment to delivering innovative,

high-quality healthcare infrastructure that meets the evolving needs of patients and healthcare providers and aligns with national strategy.”

Mr Jonathan Ockrim, a consultant colorectal surgeon and Somerset Foundation Trust’s clinical lead for the Yeovil Diagnostic Centre, said: “The opening of our new diagnostic centre today is fantastic news for people in Yeovil, North Dorset and the surrounding area.

“This is the latest in a series of major healthcare developments underway at Yeovil Hospital and in the community, and it’s excellent news to see such continued investment in our local services.

“The development of the new centre is very much in line with the government’s aim of expanding diagnostic services, which are separate from the acute hospital.

“The modern, state-of-theart centre will further enhance patient experience, and will help reduce waiting times for a range of core services, ultimately meaning a much improved service for our patients.”

Nick Dawe, Managing Director at Darwin Group said “Reducing waiting times and

improving access to timely diagnostics is one of the most pressing challenges facing the NHS. The Yeovil Diagnostic Centre demonstrates what can be achieved when partners come together with a shared focus on patient outcomes.

“By delivering this facility using modern methods of construction, we’ve helped create much-needed diagnostic capacity that will keep services moving, support clinicians, and enable more patients to receive the care they need sooner.”

Geoff Searle, InHealth’s Chief Executive, said: “We’re proud to have worked in partnership with Somerset NHS Foundation Trust to provide key clinical services to the local population through this new centre.

“Across our nationwide network of CDCs, we’ve seen the real difference and positive impact that centres like these can bring for patients, focussed on improving health outcomes, so it’s fantastic to be doing that here in Yeovil. There has been a huge amount of hard work and dedication from all the teams involved to get us to this point, so a huge thank you to everyone involved and who worked tirelessly to ensure that this centre became a reality.”

People arrive at A&E and have a long wait to be seen or admitted. Ambulances cannot ‘decant’ their patients and so have to remain on site, supporting the person in the vehicle. Delays in handing over patients to A&Es have the added impact of ambulance crews losing hundreds of thousands of hours per month, potential harm to patients due to long waits for ambulances and the poor experience of people remaining in ambulances as they wait to be admitted.

Delayed admission to wards from A&E

Within 12 hours, emergency department patients should be seen, triaged and moved to a ward or discharged. There are safety reasons why that is the case but there are also reputational and financial reasons – the ‘optics’ of people waiting in ambulances or on corridors are not good and Trusts are fined if they breach this timeframe too.

Trusts have seen people waiting in ambulances for 12 hours and for up to 48 hours before they are discharged from emergency departments. That means they are exceeding, by more than double, the targets they are set.

Delayed discharges from hospital

This is where people are medically fit to discharge – it is estimated around 1 in 7 patients are medically fit to go home – but there’s nowhere for them to go as no ‘package of care’ is in place. In the old days they’d be called ‘bed blockers’. Some Trusts might usually expect to have between 150200 people every day ready to be discharged but who can’t,

for various reasons. This year, it’s exponentially worse, with that number rising to closer to 300 each day. This results in packed wards and blockages throughout the system.

So, what can be done? - Practical and quickly deployed solutions

There are practical solutions which can be quickly and effectively deployed by Trusts looking to add capacity at various points of the emergency care patient pathway.

Ambulance handover and discharge lounges

Using a modular or mobile ward as an A&E ambulance handover facility can help Trusts add ‘capacity at the door’.

People arriving via ambulance, and who were suitable for the facility, would come onto the mobile or modular ward and decisions be made there about diagnosis and decision to admit. This means people are in a warm, safe, clinical space while this happens, close to emergency help if it is needed and it also means an ambulance is deployed back onto the road as quickly as possible to help others. Evidence suggests mortality is affected by where/how a person is supported in the first eight hours. This solution can help provide a warm and comfortable place for people to wait for a bed if need be.

It’s a solution which has already been deployed successfully. Peterborough City Hospital worked with

Vanguard Healthcare Solutions to install a mobile ward in its ambulance arrival bay as an A&E ambulance handover facility. Operational 24-hoursa-day and staffed by the Trust with paramedics and emergency department staff, up to eight patients arriving by ambulance could be admitted onto the ward for initial assessment and monitoring.

The project was planned and mobile ward delivered within weeks and commissioned to be fully operational within just a few days. It supported more than 15,000 patients while it was in place, increased capacity in the emergency department at Peterborough City Hospital and, at busy times, reduced the need for patients to remain being treated in ambulances while they waited to be seen in the emergency department. This allowed ambulances and their crews to be available to respond to calls more quickly.

Using a modular or mobile ward as an A&E ambulance handover facility can help Trusts add ‘capacity at the door’ and mobile and modular capacity solutions could also be used in other areas of the patient pathway as

ambulance handover delays are only one area where pressure can build. Delays can also occur when a patient is ready to be discharged.

That issue was also addressed using a Vanguard solution through the creation of a discharge lounge at Peterborough City Hospital. The lounge, built using two mobile wards, accommodated patients medically fit and ready to leave hospital.

This facility was larger than the hospital’s existing discharge lounge and was a comfortable area including both trolley and seating space for patients waiting to go home, freeing up beds for the hospital’s sickest patients and helping it manage the demand on services across the Trust.

A discharge lounge, housed in a modular Vanguard-built facility at Kettering General Hospital, has also been successfully deployed.

A proactive and planned patient journey

While the A&E ambulance handover addresses one area of issue, bedspace is required all the way along the emergency patient journey, from potentially preventing hospitalisation to post release from acute care. Using modular or mobile solutions is an opportunity to create that added capacity in a planned way, Communitybased admissionprevention facilities

Modular and mobile spaces lend themselves also to helping prevent admission to hospital in the first place. An ICS may consider the benefits of having a place locally (perhaps at a GP or health centre) - an admission avoidance centre - to which people could be taken by ambulance or directed by 111, triaged and treated if need be.

A mobile or modular ward could also offer a solution where people have been assessed as

requiring admission to hospital after their A&E visit but where no beds are immediately available in the hospital. The creation of a ‘bed wait area’ in the grounds of a hospital again ensures people are in a warm and safe clinical space – not a corridor on a trolley – while they wait for a bed.

but for whom there is no bed on a ward immediately available.

We are getting to the stage where tents in car parks are going to be deployed to provide beds and shelter for people who are medically fit for discharge but have no care package in place, so can’t leave hospital. That is clearly not good for people’s health, they are cold and damp environments and predominantly we are talking about elderly people with comorbidities who would be cared for there. A mobile or modular solution to create additional ward space, that can be used while people are waiting for discharge, frees up beds across the pathway from A&E through to general and specialist wards.

Same day emergency care (SDEC) aims to benefit both patients and the healthcare system by reducing waiting times and hospital admissions. SDEC allows specialists to assess, diagnose and treat patients on the same day of arrival who would otherwise have been admitted to hospital. Mobile and modular solutions can be used to create these healthcare spaces.

Creating an Urgent Admission Centre can assist healthcare providers rapidly admit patients who will clearly need to be admitted for treatment and care,

Urgent Care Centres are designed to treat minor injuries and illnesses that require immediate attention but are not life-threatening. These include sprains, broken bones, minor head injuries, minor cuts and burns, ear or throat infections, and urinary tract infections. They are a key method in diverting less urgent cases out of A&E environments, and to create the high-quality clinical spaces required for an UCC, mobile and modular solutions can be rapidly deployed.

Both UACs and UCC’s, using a Vanguard solution, can be built and operational quickly and efficiently.

With a more severe strain of flu circulating this year, and flu admissions surging, A&E diversions escalating, and corridor care remaining an issue, healthcare providers cannot rely on traditional winter planning alone. Mobile and modular solutions offer agile, high-quality clinical spaces that relieve pressure at every stage of the patient journey – from ambulance handover to discharge. Winter pressures are now permanent pressures, and only proactive, flexible capacity planning will protect patients and staff in the years ahead.

By Brendan Aherne, Chief Operating Officer, Outdoor & Estate Services, OUTCO

For decades, outdoor estate management has relied on predictability. Maintenance schedules, asset-life assumptions, planting schemes and budgets were all built on the idea that tomorrow’s weather would look broadly like yesterday’s. But that assumption no longer holds true. Climate data now paints a clear picture: extreme weather is no longer the exception but more the rule. This fundamentally changes how we plan, maintain, and invest in our outdoor spaces. The evidence is stark. The World Meteorological Organization (WMO) and the Copernicus Climate Change Service both confirmed that 2024 was Europe’s warmest

year on record, continuing a run of unprecedented temperatures that has made every year from 2015 to 2024 one of the ten warmest in modern history. ¹ ² Last year, widespread flooding, prolonged heatwaves and major storm events affected almost every part of Europe. According to the 2024 European State of the Climate report, there were “striking east–west contrasts” in temperature and rainfall, with the report warning that Europe is warming faster than any other continent on Earth. ³ Here in the UK, the evidence is just as stark. The Met Office’s State of the UK Climate report confirms that our nation has been warming at roughly a quarter of a degree per decade since the 1980s, while the decade from 2011 to 2020 was around nine per cent wetter than the long-term average from 1961 to 1990.⁴ As

warmer air holds more moisture, it means heavier downpours when rain arrives. Hence, more days of extreme rainfall, more saturated ground conditions and more frequent flooding. At the same time, temperature extremes are increasing at a faster rate than average temperatures, and the intensity of both hot and cold spells is growing. The UK Climate Projections (UKCP18) point to a future defined by warmer wetter winters and hotter, drier summers, punctuated by more frequent and more intense extremes.⁵ Under higheremission scenarios, some parts of the country could see winters several degrees warmer and up to forty per cent wetter than the late-twentieth-century baseline, while summers become significantly hotter and markedly drier.⁶ In other words, the familiar “mild and changeable” British climate has shifted into

something more volatile.

For outdoor estate managers, the implications are obvious. An asset designed or resurfaced today may still be in service in the 2050s or 2060s, when the local climate could look entirely different to the one it was built for. But how do we translate these climate facts into practical action?

At OUTCO, we have already seen extreme weather reshaping maintenance patterns across every sector, from retail parks and logistics hubs to education campuses and transport networks. Winters are bringing prolonged periods of heavy rainfall, often followed by rapid freeze–thaw cycles that cause surface deterioration, joint failure and potholing. Some drainage systems designed for older rainfall intensities are struggling to cope, and clients are seeing increased expense due to reactive callouts

to deal with blocked gullies and flooded access routes.

The traditional “winter service season” is no longer bounded neatly between November and March; storm events can arrive weeks earlier or later, forcing a shift towards flexible, riskbased response planning.

Summer brings a different set of problems. Rising temperatures and prolonged dry spells can stress both hard and soft landscape elements. Asphalt surfaces can soften or deform under sustained heat, while decorative paving joints degrade and open. Planting schemes that once thrived with minimal irrigation are now under strain, and estates are having to reconsider species selection, soil management and irrigation infrastructure as core components of maintenance planning rather than aesthetic afterthoughts. Many organisations are beginning to realise that

green infrastructure (trees, lawns, and planting beds) can play a critical role in heat mitigation, reducing surface temperatures and protecting users from heat stress. This is changing how grounds maintenance teams think about planting, pruning and long-term tree management. For example, as many trees were felled during the recent ash dieback outbreak, many chose to replace them with hardier drought-resistant southern European species rather than native tree species. As an aside, it’s important to note that planting for climate resistance can have numerous other benefits, such as helping to address emerging threats from invasive species and diseases and can be conducted as part of efforts to improve biodiversity and crucially help businesses meet biodiversity net gain commitments. Being a good environmental steward

can be good business too.

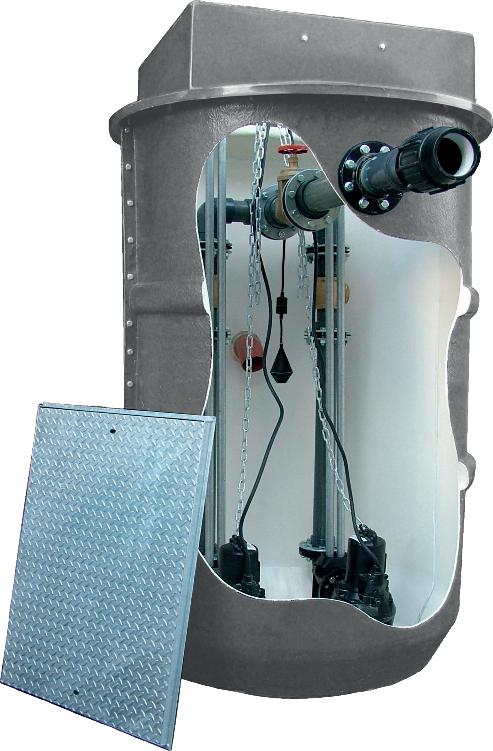

The most visible symptom of our shifting climate, however, is the increasing frequency of high-impact rainfall events. The Met Office has reported a clear upward trend in days where rainfall exceeds the 95th and 99th percentile of historical totals, meaning that the heaviest downpours are now even heavier.⁷ When intense rain falls on already saturated ground, traditional drainage systems can quickly become overwhelmed, causing more frequent flooding of car parks, service yards and pedestrian routes. The solution is not simply to enlarge drainage pipes or add more gullies, but to rethink the estate as a hydrological system, incorporating permeable surfaces, swales, attenuation basins and other Sustainable Drainage Systems (SuDS) features that can manage water close to where it falls. These environmental shifts have implications for cost planning and asset management, especially given the assumed lifespans of the materials that make up outdoor: asphalt roads might be expected to last twenty years, concrete slabs thirty, lighting columns forty. But when estimates are based on historic temperature and rainfall ranges, actual lifespans may be far shorter as extremes intensify (materials expand and contract more frequently, corrode faster, suffer more freeze–thaw cycles). Budgets based on steady depreciation no longer hold true and prudent estate managers can’t assume that “average

year” conditions will persist.

So what does resilience look like? At OUTCO we believe that data will be key – for example, by overlaying historical weather records with site-specific incident data (e.g. areas of repeated flooding, frequent ice formation or recurrent surface failure). This will make it possible to map vulnerability hotspots across an estate. This type of analysis lets clients target investment where it will have the greatest effect: regrading a problematic entrance road, adding localised drainage capacity, or adjusting the frequency of maintenance visits in high-risk zones. We also encourage clients to plan maintenance cycles around seasonal risk profiles rather than calendar dates. A flexible, data-driven schedule that responds to real-time forecasts and ground conditions is far more effective than a fixed routine built on outdated assumptions.

At OUTCO we think in terms of moving from reactive to predictive maintenance. By using weather data, forecasting models and local site intelligence, we can help clients build maintenance plans that are both efficient and climate resilient. This approach reduces unplanned downtime, improves safety for users, and ultimately delivers cost savings through longer asset life and fewer emergency callouts.

The climate is changing. Facilities and estate managers must plan not for the weather they remember, but for the weather they will face. This means expecting volatility, integrating climate data into

strategic decision-making, and embedding resilience and flexibility into maintenance planning. The good news is that the data and tools already exist. The Met Office, Copernicus Climate Service and WMO all provide open access to historical and projected climate datasets. When combined with on-the-ground insight from experienced maintenance teams, these resources enable the proactive, data-driven approach that’s needed.

As the climate data makes clear, extremes are becoming the baseline. By embedding climate intelligence into everyday maintenance decisions, we can ensure our estates remain functional, safe and sustainable - whatever the weather brings next.

For more information on how OUTCO can bring an innovative approach to your Grounds Maintenance and winter gritting, contact 0800 0432 911 email enquiries@outco. co.uk or visit www.outco.co.uk

References:

1. World Meteorological Organization (2025). State of the Global Climate 2024.

2. Copernicus Climate Change Service (2025). European State of the Climate 2024.

3. European Commission, 2025. Europe’s Warmest Year on Record: Striking East–West Contrast and Flooding.

4. Met Office, 2024. State of the UK Climate 2023.

5. Met Office, 2021. UKCP18 Overview Slide Pack.

6. Met Office, 2022. UKCP18 Headline Findings v4.

7. Met Office, 2024. Temperature Extremes and Records Most Affected by UK’s Changing Climate.

Building & Facilities Management editorial content covers all the major FM areas of interest within the workplace and the built environment.

To find out more information about BFM Magazine or to subscribe, please visit www.bfmmagazine.co.uk

Specifying CFA members for your flooring projects means you’ll be gaining a wealth of experience from vetted contractors with the knowledge and products to fulfil your specification with a sustainability criteria.

CFA members are part of a supply chain that includes specialist contract flooring contractors, manufacturers and distributors, all of whom promote the highest standards and expertise.