CLUTCH KITS DRIVING POWER

Established in 1925, NAPA is a global leader in the automotive industry, known for trust, quality, and service. NAPA offers a comprehensive portfolio of quality parts and accessories — all designed, manufactured, and tested to be direct replacements for OE parts. With a rich heritage and unrivalled distribution network, NAPA continues to lead, innovate, and grow. In addition, NAPA provides expert support via our online KNOW HOW technical resources and through the direct support of TechMate, offering technical specialist knowledge and IMI certified training.

Precision-made using advanced machining technology, NAPA Clutch Kits are engineered to meet or exceed OE specifications, ensuring consistent performance and secure fitment. All components in the range are backed by a 3-year/36,000-mile no-quibble warranty* and manufactured in ISO9001 and IATF16949-certified production facilities.

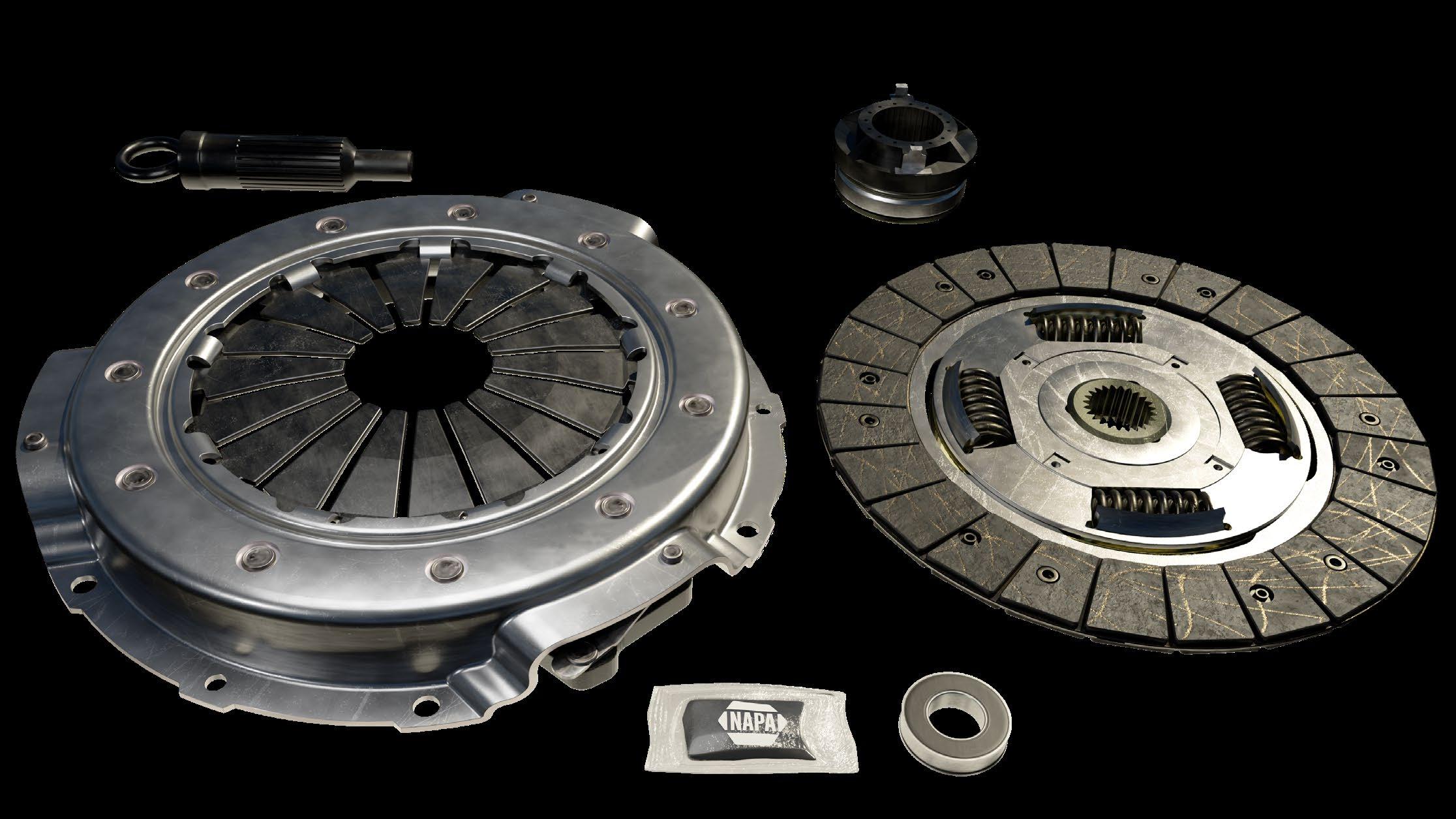

Providing a smooth gear shift experience and optimal vehicle control, NAPA Clutch Kits go above and beyond industry standards. The comprehensive 3-piece kits contain covers, discs, and the appropriate release mechanism alongside highperformance grease for a perfect first-time fit and increased spline protection.

Extra accessories are included in some kits where necessary, including spigot bearings, alignment tools, fitting tips, and technical bulletins.

The high-quality materials used throughout the kits offer maximum durability and improved performance, while rigorous testing procedures ensure the product meets or exceeds exacting OE quality standards.

NAPA Clutch Kits outperformed other leading brands by up to 37% in testing — because NAPA invests in outstanding quality.

Each NAPA Clutch Kit is meticulously crafted to meet the highest standards of performance and reliability. The range prides itself on seamless integration and quality materials, giving you the confidence to fit and forget.

The chrome vanadium diaphragm has undergone rigorous testing of up to 1.5 million actuations to guarantee long-lasting durability, while the forged clutch disc hubs offer exceptional strength to ensure reliable operation under varying conditions. With clutch disc runout kept under 0.5mm, the engagement remains smooth and comfortable.

NAPA Clutch Kits are the top-tier comprehensive solution for all your clutch replacement needs.

Release bearings

Dynamically tested to 1,500,000 cycles at 180°C

Heat-resistant grease included with every kit for smooth installation and increased protection of the splines

Clutch Cover

Chrome vanadium diaphragm provides maximum durability and strength

Clutch Disc Hub

Forged clutch disc hubs to ensure maximum strength, reliability, and longevity

Clutch Disc

Premium friction materials utilised to withstand maximum torque capacity

Spigot Bearing

OE-quality spigot bearings

supplied on popular applications for a complete installation

Clutch Alignment Tool

Included in over 70 kits for quick and easy alignment

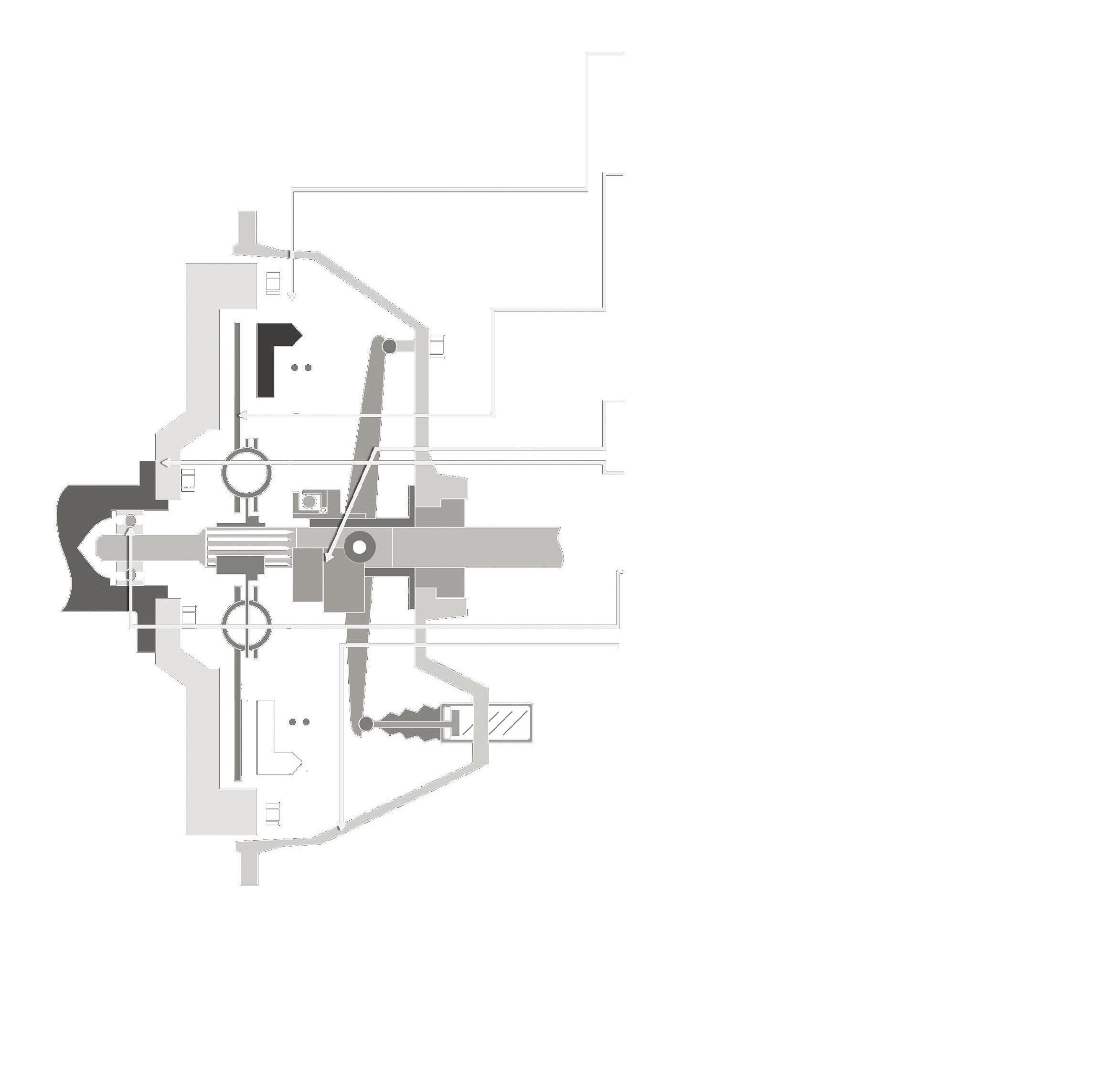

COVER ASSEMBLY

• Remove rust preventative from the pressure plate surface.

• Ensure locating dowels are fitted.

• Tighten bolts one to two turns at a time in diagonal pairs to manufacturer’s specified torque.

DRIVEN PLATE

• Keep clutch facings clean. Contamination can cause shudder and slipping.

• Ensure that the correct side of the clutch plate is facing the flywheel.

• Clean splines and lubricate with spline grease. Be careful to use a minimum of spline grease; too much will radiate outwards in operation and contaminate the clutch facings.

• Ensure clutch plate slides freely on gearbox spline.

• Use an alignment tool to centralise the clutch plate.

• Support the weight of the transmission when fitting to prevent distortion of the plate.

RELEASE BEARING

• Check the release bearing guide for wear. Wear in this area can cause a notchy or jammed pedal.

FLYWHEEL

• Inspect flywheel for hot spots, scoring, and warping.

• It is recommended that the flywheel be resurfaced to manufacturer's specifications. Alternatively, replace with new flywheel prior to clutch replacement.

SPIGOT

• Inspect the spigot bearing or bush for wear and damage. Replace if necessary.

BELL HOUSING

• Thoroughly clean the interior of the bell housing.

• Dirt or other material left in the housing can contaminate the clutch facings, causing clutch shudder.

TRANSMISSION LOCATION

• Worn or missing dowel locations will cause driveline misalignment, resulting in rapid wear of the new clutch assembly.

• Ensure dowels are fitted and in good condition.

• Clean all mounting faces.

OIL SEALS

• Oil can contaminate the clutch plate facings, causing shudder and slippage.

• Inspect crankshaft and gearbox seals. Replace as necessary.

RELEASE MECHANISM

• Wear or incorrect adjustment in this area can cause non-release of the clutch.

• Inspect and adjust (or replace) clutch fork, pivot ball, clutch cable, and hydraulic cylinders.

1. Do no compress the cylinder prior to installation as this can deform and break the seals, causing premature failure.

2. Ensure the installation area is clean and free from debris to make sure the CSC sits correctly.

3. Make sure the locating bolts are evenly torqued to manufacturers specifications.

4. Before bleeding the system, it is important to make sure the gearbox is located correctly and securely.

5. Bleed the system following the manufactures guidelines, making sure to not rapidly depress the pedal as this may damage the CSC seals.