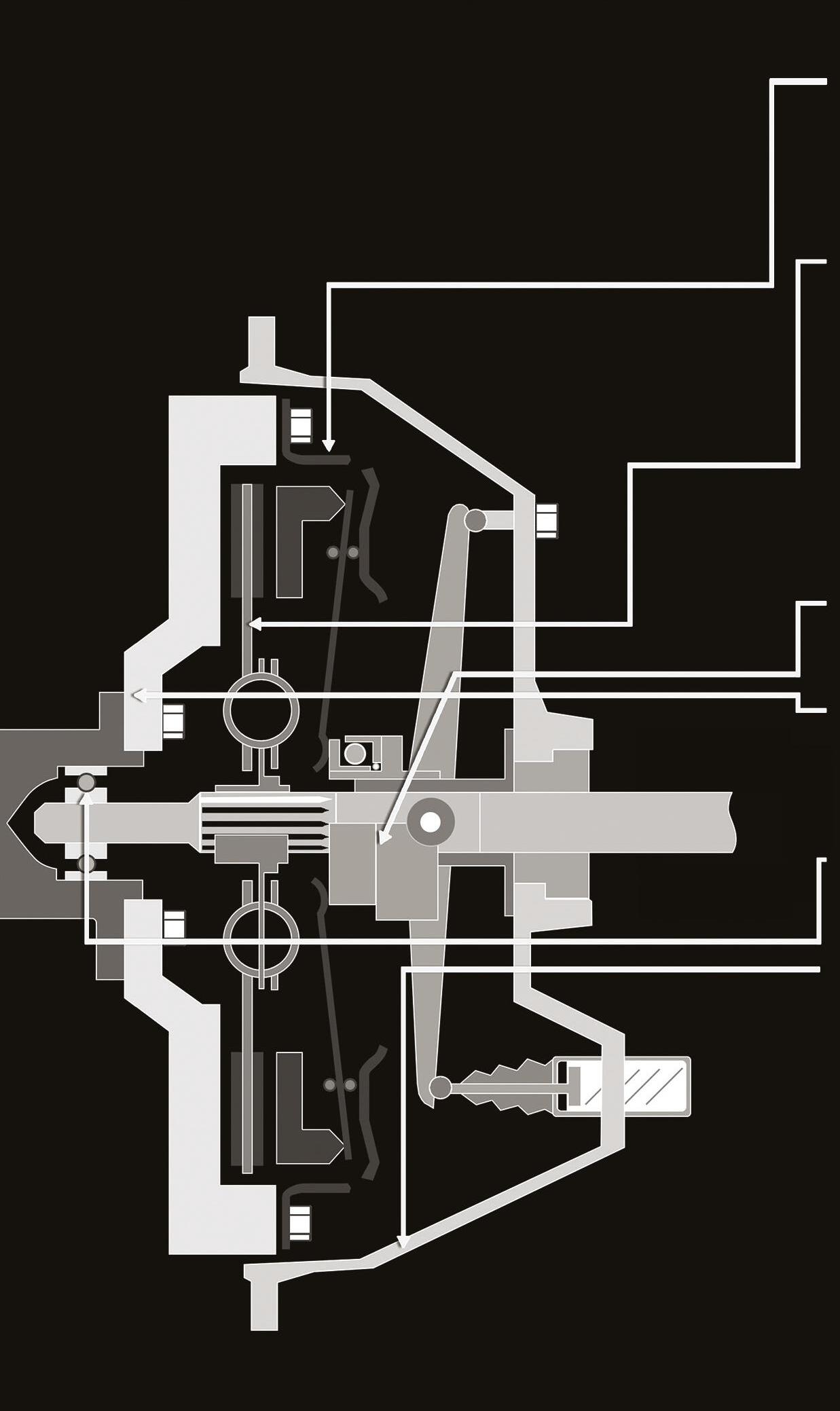

CLUTCH FITTING GUIDE .

COVER ASSEMBLY

● Remove rust preventative from the pressure plate surface.

● Ensure locating dowels are fitted.

● Tighten bolts one to two turns at a time in diagonal pairs to manufacturer’s specified torque.

DRIVEN PLATE

● Keep clutch facings clean. Contamination can cause shudder and slipping.

● Ensure that the correct side of the clutch plate is facing the flywheel.

● Clean splines and lubricate with spline grease, Be careful to use a minimum of spline grease - too much will radiate outwards in operation and contaminate the clutch facings.

● Ensure clutch plate slides freely on gearbox spline.

● Use an alignment tool to centralise the clutch plate.

● Support the weight of the transmission when fitting to prevent distortion of the plate.

RELEASE BEARING

● Check the release bearing guide for wear. Weat in this area can cause a notchy or jammed pedal.

FLYWHEEL

● Inspect flywheel for hhot spots, scoring and warpage.

● It is recommended the flywheel be resurfaced to manufacturer’s specifications or replace with new flywheel prior to clutch replacement.

SPIGOT

● Inspect the spigot bearing or bush for wear and damage. Replace if necessary.

BELL HOUSING

● Thoroughly clean the interior of the bell housing.

● Dirt or other material left in the housing can contaminate the clutch facings, causing clutch shudder.

TRANSMISSION LOCATION

● Worn or missing dowel locations will cause driveline misalignment, resulting in rapid wear of the new clutch assembly.

● Ensure dowels are fitted and are in good condition. Also clean all mounting faces.

OIL SEALS

● Oil can contaminate the clutch plate facings, causing a shudder and slipping.

● Inspect crankshaft and gearbox seals and replace as necessary.

RELEASE MECHANISM

● Wear or incorrect adjustment in this area can cause non-release of the clutch.

● Inspect and adjust or replace clutch fork, pivot ball, clutch cable and hydraulic cylinders.