The

Summer’s

Editorial Board

Geoff Mutton

Jeff Smit

Technical Editor

Jeff Smit

Sub-Editor

Cameron McGavin

Scan Data Director

Rod Maher

Technical Research

Brendan Sorensen

Technical Assistance Moderator

Scott Thomas

Technical Contributors

Brendan Sorensen

Mark Rabone

Frank Massey (UK)

Jack Stepanian

Sam Nazarian

Jason Smith

Clinton Brett (Diesel Help)

Technical Assistance Team

Deyan Barrie Andrew Kollosche

Sideth Chiv Maurice Donovan

Gil Sher Anthony Tydd

Wayne Broady Jason Smith

Marty Hosie Jack Stepanian

Mark Rabone Rob Romano

Daniel Armer Jack Mackay

Gary O’Riain

Associate Team Members

Gary Homan Peter Hinds

Columnists

Geoff Mutton (TaT Biz)

Advertising Enquiries

Paul Woods,

National Advertising Manager

E: pwoods@tat.net.au

Ph: 0494 044 958

Graphic Design

Brigid Fraser

E: production@tat.net.au PH: 0413 009 122

Affiliated Associations

AAAA – info@aaaa.com.au

Capricorn Society Alliance Supplier

VASA – secretary@vasa.org.au

Jeff Smit

You might have noticed a change in the last Soapbox. Brendan Sorensen and I are now sharing our thoughts and observations for three issues each a year.

I thought Brendan’s first Soapbox was on point, challenging all workshop owners to make small changes when needed to ensure their workshops stay engaging and productive. I hope most of you took up the challenge and I hope you see continued improvement in your workshops in the future.

My life has always been busy and I’m sure that will continue, hopefully for many more years. How was 2025 for you? I hope it was productive, profitable and filled with good times and quality moments with family and friends.

I don’t know about you but for me 2025 passed quickly and certainly didn’t disappoint. As we head into the summer season, I hope you get some time off. 2026 is already looking very busy for my workshop and we have several exciting projects underway here at TaT. I’m very excited and can’t wait to get stuck into them during 2026.

Our artificial intelligence (AI) technicians, Tech Tina and Tech Tony, are certainly impressing our members, many of whom have engaged with them on challenging jobs, seeking their advice and guidance. If you haven’t had the chance to specifically ask Tina for some guidance, do yourself and your workshop a favour and give her a go.

Rod Maher has been continually improving both Tina and Tony and is currently working on even more upgrades to their abilities to assist you with those challenging diagnostic jobs. The members I have spoken to who have utilised Tina have nothing but praise for what we have developed for all members.

One of our members in New Zealand shared that his chief senior diagnostic technician had moved on and he had wondered how the workshop would continue with just himself, his younger technician and an apprentice. He said he was delighted the young technician had

been using Tech Tina and was now confidently handling every diagnostic job while seeking her guidance.

He mentioned that Tina was now being asked for advice and a diagnostic plan after the initial evaluation of each job, which had proven to be very effective. He said Tina’s responses and the detailed diagnostic flow chart she provided for each job had allowed the young technicians to excel.

Tina has given them the confidence to approach each task with the knowledge and technical support they have embraced. They have found their learning has accelerated well beyond their expectations.

Having Tina and Tony available at your call 24/7 is like having a fully trained, experienced technician with access to all of TaT’s technical data, Repair Solutions, good scope/scan data and expertise – all included in your subscription.

As our database expands, so do Tina and Tony’s capabilities. You may have noticed the number of Repair Solutions being uploaded to our fortnightly newsletters has increased considerably and we plan to keep growing as we accelerate our development.

As we approach 2026, I acknowledge that both the industry and the way we work are undergoing evolution. The ways we access information and diagnostic support are also transforming. I’m very proud of what we deliver to our subscribers every day. It’s thanks to my fellow partners and our entire technical team, who together form the backbone of TaT and everything we do.

I’m very proud of what we’ve achieved over the past 19 years and am even more excited about the years ahead. I hope everyone has a wonderful Christmas, a fantastic New Year and I look forward to catching up with as many of you as possible in 2026.

Jeff Smit

Australian automotive workshops have already experienced one major refrigerant transition – shifting from R12 to R134a in the 1990s –and we are now well into the next stage.

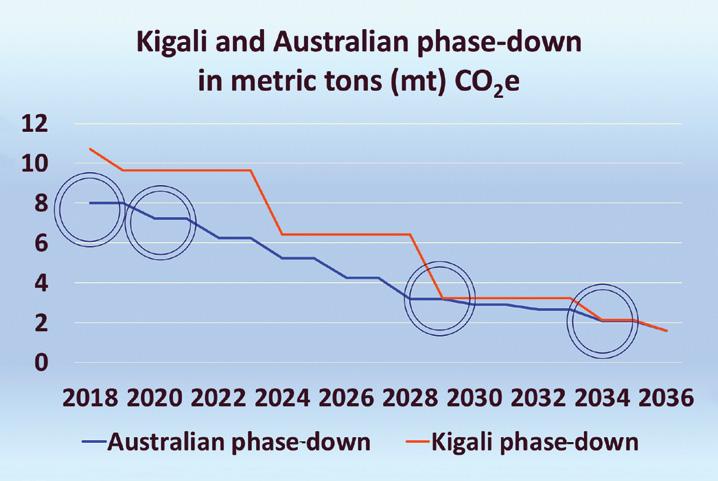

The two key trends changing automotive a/c are the adoption of ultra-low global warming potential (GWP) refrigerants and the rising use of heat-pump systems, particularly in hybrids and electric vehicles (EVs). With Australia’s legislated hydrofluorocarbon (HFC) phasedown in place, equipment choices, service procedures and refrigerant sourcing all require a new approach.

In this article, we will look at how we arrived here, what’s happening behind the scenes, why R134a supply will become tighter and what tools a modern workshop needs to stay compliant and profitable.

Australia has a national licencing scheme for refrigerant handling (ARCtick), which mandates a Refrigerant Handling Licence for technicians and a Refrigerant Trading Authorisation for businesses that buy, store or dispose of scheduled gases (pic 1).

Meanwhile, the federal HFC phase-down – an import quota measured in CO2 equivalent –has been in place since 2018 (pic 2). Since quotas are based on CO2e, gases with a high GWP ‘consume’ more of the allowance per kilogram imported. R134a (GWP ~1430) is therefore costly in terms of quota compared to the newer hydrofluoro-olefin (HFO) R1234yf (GWP ~1).

Heat pumps are becoming the new standard for automotive a/c (pc 3). In an internalcombustion engined (ICE) car, cabin heat is free because it uses waste heat from the engine.

EVs don’t have that luxury. Early electric models relied on positive temperature coefficient (PTC) resistive heaters that were simple and durable but they decreased range,

especially in cold or wet weather. A heat pump, contrastingly, transfers heat rather than generating it, resulting in much lower energy use for the same cabin temperature. In mild to cold weather, this efficiency advantage is quite significant; at very low ambient temperatures, most systems combine heat-pump operation with PTC assistance.

Internally, the heating, ventilation and a/c (HVAC) system is no longer a separate unit; it’s part of an integrated thermal-management system that also regulates the traction battery, inverter and charger. This involves more valves, sensors, multiple heat exchangers and chiller plates, as well as electrically driven compressors with variable speed control. Many of the HVAC innovations developed in EVs and hybrids are now making their way into standard ICE vehicles as the energy savings achievable in EVs can also be realised in ICE cars, making them more fuelefficient.

Globally, R1234yf has become the standard for new light vehicles because it provides the necessary thermodynamic performance with minimal environmental impact and acceptable flammability (A2L – ‘mildly flammable’) when systems are designed accordingly.

Australia hasn’t mandated R1234yf outright but an increasing number of imported models are arriving with it pre-charged, so the vehicle fleet is gradually shifting.

For workshops, the key point is straightforward: you can’t assume ‘R134a forever’ and you can’t treat R1234yf as a simple drop-in replacement for older platforms. It has different flammability characteristics, unique service ports and specific equipment and handling requirements (pic 4).

Will there be a shortage of R134a in Australia?

Two key issues suggest supply will tighten. First, the HFC import cap gradually decreases over time and each kilogram of R134a uses up more of the national quota than a kilogram of a low-GWP refrigerant. Importers tend to prefer gases that stretch their allowance further.

Second, the current fleet of R134a vehicles remains sizable, so service demand won’t disappear overnight. That demand faces a shrinking quota, which typically leads to higher prices, longer lead times and occasional shortages.

Reclamation helps, and Australia’s reclaim program is well-established by global standards, but reclaimed volumes depend on proper recovery and segregation practices at the workshop level.

The key isn’t panic – it’s planning. Expect R134a to gradually become more expensive and less available over the next decade, so plan your inventory and equipment accordingly.

One critical legal point is worth emphasising – charge systems only with their designated refrigerant. Blending, retro-gassing to a higher-GWP option or using an unapproved alternative can be illegal and unsafe, may breach the automotive code of practice and could expose workshops to liability.

A2L refrigerants are a group of substances, such as R32 and R1234yf, characterised by low toxicity, mild flammability and a low burning velocity, making them a safer and more environmentally friendly alternative to older, high-GWP refrigerants.

A = Non-toxic.

2 = Flammable.

L = Low burning velocity.

With A2L refrigerants, the system design includes mitigation features (such as lowpermeation components, charge limits, controlled ventilation strategies and software) that you don’t get by simply swapping gases.

What does it all mean for the workshop floor?

Start with your recovery, recycle and recharge (RRR) equipment. For R1234yf, you need an A2L-rated machine that meets the current SAE J2843 standards, including accuracy in charge weight, recovery efficiency, leak checks and safety features suitable for mildly flammable refrigerants.

Many workshops opt for a dual-gas unit certified to SAE J3030 so they can service both R134a and R1234yf with one machine while ensuring cross-contamination safeguards as required.

Whatever you choose, insist on traceable calibration, replaceable filter-driers and clear service procedures for switching between refrigerants. Ideally, I recommend separate machines for different gases.

Refrigerant identification is now essential. Unknown charge histories, DIY top-ups and cross-contamination are common issues, and the only way to protect your equipment and your next customer’s vehicle is to

identify and verify the gas clearly before connecting. Pair this with an electronic leak detector rated for A2L refrigerants (pic 4); check the sensitivity curve for R1234yf and ensure the sensor technology suits your workflow (heated diode, infrared or ultrasonic detection each have their role).

Since R1234yf uses distinct 12mm service couplers (pic 5), keep manifolds and hoses dedicated; do not adapt R134a tooling. Segregate recovered refrigerant into clearly labelled cylinders – ‘R134a’, ‘R1234yf’ and ‘contaminated/unknown’ – and keep accurate records so reclaimed gas can re-enter the supply chain rather than be disposed of as waste.

EVs and hybrids include electrical safety and lubricant compatibility in the checklist. Most electric compressors use a highdielectric oil (usually POE) to maintain insulation resistance between windings and the refrigerant circuit; contaminating these systems with PAG oil from an ICEera machine can lead to costly faults. Use separate oil-injection cartridges and fittings for each refrigerant and oil combination

and never assume a previous repairer was correct – test and verify.

The bottom line for Australian workshops is clear. The refrigerant market is changing because laws favour low-GWP options and penalise high-GWP imports and the vehicle market is shifting as electrification demands efficient heating.

Position your business with the right machines (A2L-rated and, ideally, separate units), a disciplined approach to refrigerant identification and segregation, EV-ready safety procedures and OEM-aware diagnostics.

Do that and you won’t just survive the R134a squeeze, you’ll turn the next decade of HVAC change into a competitive advantage.

Clinton Brett

The final part of this series of articles on fuel-control valves could possibly create controversy.

That’s because the valves and sensors attached to the fuel rail must not be replaced as individual items.

Now you all know Diesel Help is not a parts distributor and me informing you of this process means I’m not going to make a quick buck.

I just know it saves me countless wasted hours spent on the phone helping members diagnose faults – which can only mean the same outcome will also benefit you.

I’m not here to tell you what is right or wrong. I’m just passing on my knowledge based on my experience, not the piece of paper my qualification is written on.

Some of the best feedback I’ve received was after delivering training for the Tasmanian Automobile Chamber of Commerce (TACC). During this training, I had a few light-bulb moments and recalled some jobs that became clear once I’d considered how the system worked.

In my experience, the fuel pressure-limiting valve is the most common fuel-control valve to trip technicians up, even some of the best in the world.

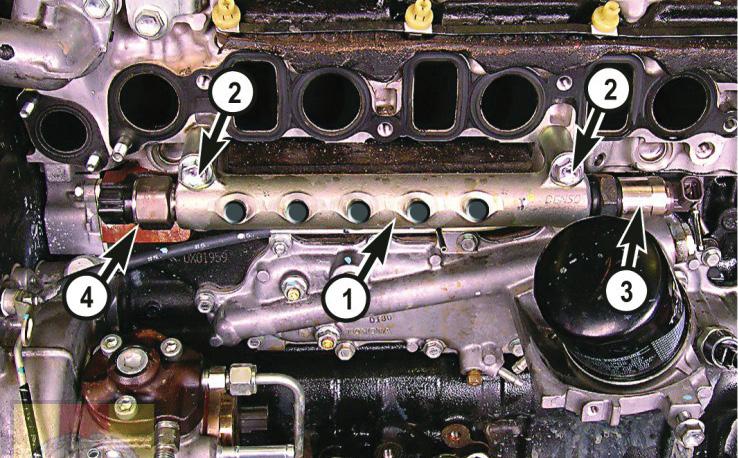

This valve, fitted to the Bosch rail (pic 1), is one of the most common to be replaced

by technicians – only to immediately create another problem in the process. Some say, ‘Oh, but I’ve replaced hundreds of these and never experienced an issue.’

These fuel pressure-limiting valves are what I call ‘non-electronic’ rail valves and they are found on Bosch, Denso and Delphi fuel systems. I have never seen these on a Continental fuel system.

Bosch rail with pressure-limiting valve

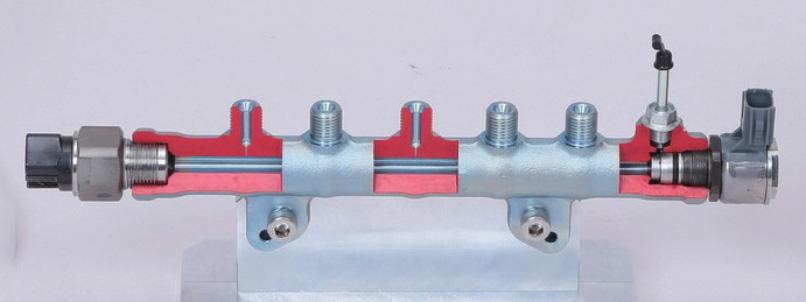

These valves are designed to relieve the pressure and not release large quantities of fuel.

In the case of the fuel-rail pressure exceeding the manufacturer’s specification, the valve pops open and drops the pressure immediately. It is designed to momentarily open and relieve the entire high-pressure (HP) fuel system of this excess pressure, thereby reducing the chance of engine failure.

A common failure is when the valve or the seat is damaged due to replacing only the valve (pic 2). The fuel often continues to leak.

We’ve experienced several fault codes including, P0089 – Fuel pump (common on Nissan Patrol ZD30 common-rail diesel [CRD] models), P0093 – Large leak and P0089 – Fuel pressure too low. In some cases, the vehicle will be difficult to start after driving for a couple of hours.

One case I recall followed a valve being replaced without the entire rail. The engine would lose power after the owner drove the kids to school, a two-hour return trip.

The technician struggled to replicate the fault until I advised him to take his test hose with him on a two-hour drive with four bags of cement in the back (load simulation).

A quick tip for testing limiting-valve failure is to get the engine warm (i.e. operating temperature), then remove the outlet hose from where the fuel leaks from in case of a failure and then crank the engine and observe for fuel leakage. These should not leak anything at all, not even during cranking.

The Delphi (pic 3) and Denso (pic 4) valves are designed for the same function and fail in similar fashion. Their distinctive design has proven to be more durable than the Bosch valve.

Denso heavy-application flow dampers

These valves are often referred to as flow dampers or differential valves and only found in commercial applications, mostly from Asian manufacturers such as Isuzu, Hino and UD. They are fitted to the rail on each cylinder’s fuel-delivery line.

The function of these valves is to assist in reducing pulsations and a loss of pressure in the event of a HP loss from an individual injector or HP pipe failure.

Note in pic 5 that the pressure-limiting valve is positioned in line with the flow dampers.

Pump-mounted fuel pressure-relief/ limiting valves

When a rail doesn’t feature a pressure-limiting valve, it is often located on the HP fuel pump. In some applications a leak can form around these fittings and the valve can be successfully removed and replaced with

new seals and a specified torque setting, in position on the vehicle.

Delphi’s HP-pump design with a limiting valve from the early 2000s (pic 7) is one of the few that can be done without removing the pump.

Denso rail electronic pressure-relief or discharge valve

In the early days of Denso CRD –specifically Toyota’s 1KD-FTV 3.0-litre engine released in 2005 in Australia – there were reliability issues.

Most were caused by the injectors mentioned earlier in series of articles. To combat the issue, Denso did away with the mechanical pressure-limiting valve,

replacing it with a fuel pressure-discharge valve that was electronically controlled by the ECU (pic 8).

This did lead to something of an improvement as less engine failures have been experienced since. But to this day the industry continues to witness engine failures/cracked pistons caused by injectors.

Strangely, Isuzu’s D-Max – which also uses a Denso fuel system – has not experienced the same level of engine failures. It too uses a mechanical fuel pressure-limiting valve in the 4JJ1 engine manufactured from 2007 to 2019.

On the modern Toyota 1GD-FTV, 1VD-FTV and some other OEM applications such as those from Isuzu, there is a new-design Denso fuel-discharge valve (pic 9). In the past two years we have been involved in several diagnostic cases where these valves or the injector drive have failed.

We are currently developing a new technical

bulletin on this failure. One of the tests involves checking the resistance on the discharge valve. Specs: 0.96 to 1.16 ohm (Ω) at 20°C.

Note: Some of the images in this article have been provided by Haynes Pro and Haynes All Access. Diesel Help Australia is an authorised Haynes Pro distributor.

• Find out more about Diesel Help’s services at dieselhelp.com.au

The Australian Automotive Aftermarket Association (AAAA) has announced the return of the Australian Auto Aftermarket Expo, co-located with the Collision Repair Expo, from May 14 to 16, 2026 at the Melbourne Convention & Exhibition Centre.

Under the theme ‘Driving what’s next’ – focused on connection, innovation and opportunity – and proudly sponsored by Repco, the event will unite Australia’s $25 billion automotive-aftermarket industry.

Across three days the expos will showcase 400-plus brands, worldclass trainers, the latest technology, tools and equipment, businessmanagement and technical training, live demonstrations, automotive personalities and the Flying Spanners Apprentice Challenge. The education program includes advanced diagnostic and advanced driver-assist system (ADAS) training to equip workshops to service and repair modern vehicles safely and efficiently.

Registration is free for anyone working in the trade, offering access to suppliers, manufacturers and interactive displays, with ticketed training for business owners, managers, technicians and apprentices. International pavilions will feature brands from established and emerging markets.

Building on record attendance of more than 13,000 at the 2024 expos, 2026 will debut a fresh logo and visual identity.

‘The expo is where our industry comes together to connect, learn and do business,’ said AAAA Chief Executive Officer Stuart Charity.

• To find out more or register go to autoaftermarketexpo.com.au

Having cars arrive on tow trucks with a crank/no-start situation is not uncommon.

However, something that is becoming strangely familiar nowadays is a car arriving with the aforementioned crank/no-start scenario and the transponder chip missing from its ignition key.

We’ve all seen some Mitsubishi models where the keys have been dropped on a hard floor, the plastic shell of the key has split open and the small transponder chip has unknowingly fallen out (pic 1). The customer reassembles the key to the best of their ability but when they attempt to start the car it just won’t start without that important chip.

This is when we are normally called in to a no-start situation. After performing initial visual and basic checks and tests, an inspection of the ignition key and a request for all the car’s keys should be part of your diagnostic sequence.

There are numerous basic and reasonably low-cost tools available to identify if a transponder is present within a key. These tools should already be a part of a modern workshop’s tool library (pic 2).

These are not programming tools and these tools can also identify radio frequency (RF) signals emitted by keyless-entry systems. They can also identify handshakes between the key and the key reader, which can quickly point a technician in the right direction. I’ve had cars come in for service with

a request to check why the spare key won’t start the engine anymore. On closer examination, the transponder chip is missing. A screwdriver and some skill are required to pull apart some keys and remove the chip. On questioning the owners about the missing chip, they normally have no idea or explanation.

The car: Suzuki Ignis GA, 09/2002.

The complaint: The customer called saying his Suzuki would crank and not start. When I asked for further details, he told me his son was driving the car, arrived home, drove up the driveway and the car just stopped and would not restart.

He asked if I would come out and have a look at the car on site. As he was not far away, I was happy to oblige, albeit with a warning I do not specialise in mobile or on-site work.

The diagnostic process: On arrival at the customer’s house (with some very basic tools), I performed some basic visual inspections.

The first thing I noticed when I put the key into the ignition and switched the ignition to the on position was the check-engine light (CEL) would flash instead of staying on steady. When the engine was cranked, the car wouldn’t start. I thought I could hear the fuel pump running when the key was initially switched to the on position.

As a quick basic test, I sprayed some accelerant into the throttle body and once again cranked the engine but it did not start. This told me there was more than likely no fault in the fuel system.

Next, I plugged a small code reader I carry in my car into the Suzuki’s diagnostic port. I made several attempts to scan the vehicle but the scan tool would not communicate with it. Next, I tested all the fuses, which appeared to be OK. Because I was unable to unclip an injector wiring connector, I unplugged one of the coils and used my SXE probe to check for pulse or coil switching, but there appeared to be no pulse present.

Next, I asked the owner for the spare key – he said he didn’t think he had one. I told him I didn’t think I’d able to get the car started there and then and it would need to be towed to the workshop. I also asked him to have a really good look for a spare key.

The next day the car arrived on the tow truck with only one master key. I connected the scan tool and this time communication was available.

One DTC was present in the engine computer, P1623 – Unregistered transponder (pic 3). There was also a code in the immobiliser, Code 13 – No transponder code transmit.

I immediately put the key into my proximity smart-key system tester. To my surprise, the tester did not pick up any transponder within the master key.

I performed a second test, then a third test with another tool and then a fourth test with a third tool. All tests revealed the same outcome – no transponder was detected. This made no sense. As far as I knew, the key was previously used to run the vehicle and the key had not been pulled apart.

So back to the vehicle. I noted the P1623 DTC, then cleared it and also performed a hard reset before attempting to restart the vehicle, but it would not start.

I closely examined the key. It looked in good condition and required a jeweller’s screwdriver to be disassembled. I carefully stripped the key down but could not find a transponder chip in the slot where the chip should live (pic 4).

I contacted the customer and asked if he could explain why there was no transponder in the key and he said no. Once again, he said the car had been driven and stopped in his driveway before failing to start.

I told him the key was never going to start the vehicle because the transponder chip was missing and that he needed to find the second (or sub) key. He didn’t think he had a second key for the vehicle.

I told him he would be in an ‘all-keys-lost’ situation and it could become very costly. The conversation went for about 10 minutes before he finally told me the real story, that he had replaced the plastic cover for the master key. I asked him where the parts from the old body were and he said they were already in the bin.

At this stage it was late in the afternoon. I told him to have a good look through his bin and try to find the old parts from the master key –and to have a good look for the second key –and let me know first thing the next morning.

Bright and early the following morning, he turned up with a small plastic bag with some broken plastic pieces – but no transponder chip. However, he did have a second or sub key.

On closer inspection, this was a shoppingmall style aftermarket key with the correct profile blade, etc. I put it into the proximity

smart-key system tester and it showed it did have a transponder in it.

I went straight over to the car, switched the ignition to the on position and noticed the CEL was glowing steady. I then cranked the engine but it would not start. Then the CEL started to flash again and the P1623 code was logged. This all happened while the customer was present.

I sent him away saying that I would need to do some more diagnostic testing to get to the bottom of what was going on. When I put the sub key into a different key tool, I noticed the transponder chip ID number was different to what it should be – it read 4C instead of 4D65 (pic 5). This key was never going to start the car.

I was unable to contact the owner by this stage because his phone wasn’t working. And even if I had been able to contact him, I was probably going to get incorrect information anyway, so I decided to perform an all-keyslost fix.

The repair: Without giving away any secure information, I obtained a new transponder chip and wrote the correct ID to it with a special tool. I then installed the new transponder chip with the correct ID into the master key before inserting it into the ignition and programming it to the vehicle.

Tested the repaired master key and it started the car fine without logging any fault codes (pic 6). Next, I fitted a new transponder chip with the correct ID and information to the sub key (pics 7 and 8).

It’s worth pointing out this aftermarket key was very difficult to separate and a razor blade was required. I then tested the sub key in the ignition and the car started fine and ran well without logging any fault codes. This job could have been done in half the time if the owner had given me all the correct information right from the beginning.

The car: Hyundai i30 (GD), 02/2012.

The complaint: The car was booked in for service and the customer asked me to check one of the keys, which was no longer starting the engine, leading to the alarm going off, even though the key still worked fine with the keyless-entry system.

When I questioned the owner, he said the key in question had just stopped working one day. I tested the key in question in my proximity smart-key tester and there was no signal from a transponder chip.

Decided to pull the key apart, which was tricky – I required a jeweller’s Phillips-head screwdriver just to remove the cover from the case – and found no transponder chip inside. Called the customer and he said nobody had tampered with the key or had it apart. He wouldn’t believe there was no transponder chip until I sent him photos.

The repair: Sourced a new transponder chip and input the correct ID and information to it. Installed the chip into the key assembly, tested it in the vehicle and it all now worked fine.

Once again, another problem with a missing transponder chip the customer couldn’t account for. And once again, in a key fob that required a jeweller’s screwdriver to pull apart.

The car: Toyota RAV4 (ACA37), 06/2006.

The complaint: Another workshop contacted me and said they’d had a car towed in with a no-start situation. After performing basic checks and tests, they quickly suspected a key problem.

They’d already requested the owner present all keys for testing and this is where I came in, testing all three keys and finding the original key had the transponder chip missing. The key was a flip-style key.

The repair: Once again, installing a new transponder chip with the correct information (pic 9) solved the problem.

It’s always been important to get the correct information from the vehicle owner during the information-gathering phase of the diagnostic sequence.

However, for whatever reasons, it’s becoming more and more common for keys and key fobs to arrive damaged or with no transponder chips in them.

In all of the above-mentioned cases I required a jeweller’s screwdriver to pull the keys apart, so be mindful when a car comes in with a no-start situation – anything is possible. Check the security system. Make sure the immobiliser system is working correctly, including the keys.

The Key Guys in Queensland offers a large range of keys, consumables, remotes, parts, tools, knowledge and experience for all your automotive key needs and is a Capricornapproved supplier. It even has two dedicated key kiosks specifically designed for the automotive industry (pic 10 and 11).

Happy diagnosing!

With electric vehicles (EVs) and hybrids continuing to gain traction on Australian roads, workshops are facing new challenges in servicing these advanced drivetrains.

Access to accurate, detailed technical information is now more crucial than ever to ensure efficient and safe repairs and maintenance.

HaynesPro, a leading provider of automotive technical data, has responded to this growing need by expanding its coverage to include comprehensive high-voltage (HV) data for EVs and hybrids.

HaynesPro’s HV data set is designed to support technicians in navigating the complexities of modern electric drivetrains

and provide workshops with the tools needed to handle the vehicles of the future. It includes:

• Safety instructions – Step-by-step guidance to protect technicians from HV hazards.

• HV component locations – Clear diagrams and descriptions to identify key elements of hybrid and electric systems.

• Disconnection procedures – Safe methods to isolate HV systems before performing repairs.

• Diagnostic workflows – Structured processes to identify and troubleshoot issues efficiently.

• HV battery test – To determine the HV battery capacity

HaynesPro is integrating this data to ensure technicians are well-informed and able to maintain both safety and productivity when servicing EV and hybrid models, allowing workshops to benefit from reduced downtime, improved diagnostic accuracy

and increased confidence when working with HV systems.

The addition of EV and hybrid coverage reflects HaynesPro’s commitment to keeping pace with industry trends and equipping workshops with the resources required for the evolving automotive landscape.

For Australian workshops, this data is not just a convenience – it’s an essential step in adapting to a future where electrification plays an increasingly central role in automotive technology.

With HaynesPro’s continually expanding data offerings, workshops can confidently tackle the concerns of servicing and maintaining EVs and hybrids while keeping safety and efficiency at the forefront.

• Find out more at haynespro.com.au

Intoday’s automotive industry, change is the only constant.

From shifting refrigerant regulations to the increasing complexity of modern vehicles, workshops and technicians are being asked to adapt faster than ever before.

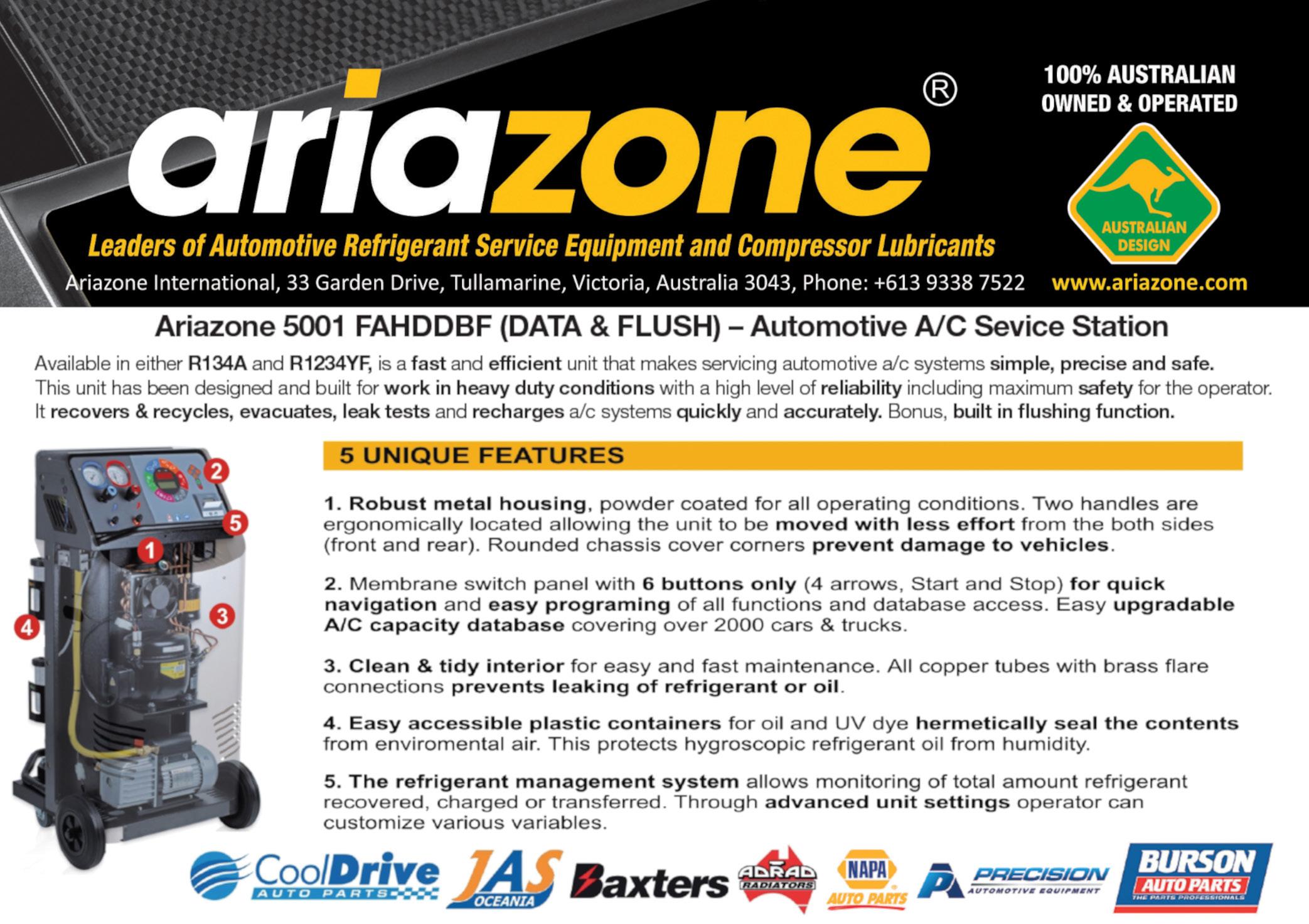

Australian designed, owned and operated for more than three decades, Ariazone has seen these challenges up close It said it believed the challenges highlighted something crucial – the industry didn’t just need reliable equipment; it needed partners committed to long-term solutions.

Offering the industry service built on three decades of reliability and innovation, Ariazone said its focus had always been a/c-service technology.

‘That’s a niche, yes, but it’s our niche,’ said Ariazone Director Bob Clark. ‘It is not enough to design a machine that gets the job done.

‘Equipment must be durable, accurate and backed by the kind of support that ensures technicians feel confident every time they roll an Ariazone machine into the workshop or are using a mobile setup out in the field.’

Ariazone said it took pride not just in the hardware but the community it had built around it.

‘From small independent garages to national dealership groups, the feedback we hear most often is about trust and reliability, said Ariazone Operations Lead Nathan Deimos. ‘Reliability that the equipment will perform on a scorching Aussie summer afternoon when every bay is full and trust that our team will be there when a question arises mid-job.’

Deimos said hybrid and electric platforms had brought new challenges for the industry.

‘Environmental responsibility demands innovation in refrigerant and recovery methods,’ said Deimos. ‘To keep you moving with the times, the classic 5001 is available in both r134a and r1234yf variants.’

Ariazone is fully Australian-owned and its global headquarters are based in Melbourne. It is part of the ROC Group.

• Find out more at ariazone.com

This month I’m discussing a success story – coil ignition systems.

Coil ignition systems have became so dependable we tend to ignore them until they fail completely.

It was the demands of ignition diagnosis that directed me to highperformance oscilloscopes back in 1985. With vehicle electronics in their infancy, tuners – as they were called – were the only tools offering a visual insight into ignition function.

I quickly realised the built-in scope function of high-end tuners was no better than a chocolate teapot. Having a long interest in electronics, I turned to that industry for a competent tool.

It soon became obvious that the costliest diagnostic platform of the day – the Crypton Cudos at $AU24,000 – was simply not able to accurately display real-time images within electronic circuits.

Two faults remain imprinted in my mind: when probing crank-angle sensors, the engine would cut out or glitch and probing lambda sensors would affect the sensor output voltage.

Today we call it probe impedance. The lack of real-time image display we call bandwidth and rise time.

Eventually, I ended up with a Tektronix TDS 3014 (pic 1) – fourchannel, 100 megahertz (MHz), one nanosecond (ns) rise time and the most amazing digital phosphor screen.

Digital phosphor screens allow persistence (the image decay time) to be adjusted. This allowed me to view several sequential events in real time with amazing detail. Imagine all high-frequency events captured into a buffer for analysis.

It enabled examination of sequential ignition events – burn time and slope – with incredible precision.

Not all ignition events are perfect. Why?

The ignition function is a complex series of events taking place within a very short period – two to three milliseconds (ms) at frequencies above 100 hertz (Hz) at 6000RPM.

The common mistake is to assume that a misfire is an ignition problem rather than a combustion problem, which brings more events into play that require perfect coordination.

1. Ignition energy

• Correct current flow within the coil primary circuit.

• Prompt interruption (point of induction).

• Efficient delivery mechanism, including the sparking plug.

2. Fuel delivery

• Perfect atomisation and quantity.

• The pintle under powertrain control module (PCM) control and not suffering mechanical disfunction.

• Correct injector current.

• Free of any supply restriction or cavitation.

3. In-cylinder events

• Correct cylinder charge air mass.

• Correct swirl or turbulence.

• Combustion temperature.

• Cylinder compression.

• Throttle load request.

• Ignition point (timing).

4. Fuel

• Quality

• Octane rating

I have probably missed a couple of things but back to the digital phosphor scope, which allows me to observe very subtle events I describe as combustion anomalies rather than outright failures. Here lies the rub. We take ignition and combustion for granted. Investigation is often prompted by DTCs. There is little or no service requirement. My own vehicle has no replaceable fuel filter and a spark-plug replacement interval of six years, with no consideration for service environment.

Observing these anomalies in the late 1980s prompted me to carry out what I called ignition preparation – removing spark plugs and checking for evidence of energy flashover.

The tell-tale brown staining emanates from the plug shell upwards. Often mistaken for compression leakage, it is actually caused by high voltage passing across a conductor in an enclosed environment.

Over time, conductive elements build across the ignition delivery path, resulting in reduced ignition burn time (pic 2).

Let me repeat that: a reduction of ignition energy delivery to the plug electrode. The vehicle may appear to drive normally, so what’s the issue?

1. Reduced performance and throttle response.

2. Reduced fuel economy.

3. Premature catalyst failure.

4. Increased lubrication contamination.

5. Reduced engine life – the turbo usually fails first. And here’s the bear trap. Manufacturers increasingly convince owners that very little maintenance is required, reducing operating costs with extended service schedules. The aftermarket service industry is directed towards ever-reducing service intervention.

I recall customers complaining about service and repair advice, often claiming they’d previously spent far less. Vehicles are more dependable now, covering distances and speeds unthinkable a few decades ago, but they still demand care and investment.

Current restrictions – time and lack of accessibility – direct diagnosis towards the serial route. Unfortunately this is not perfect, often failing to detect genuine combustion failures or reduced ignition performance.

The devil in the detail lies in live data. Look for misfire counters under load. Ignition setback is the angle of retard from the calculated set point, determined by knock-sensor feedback. Expect no more than three degrees. Fuel-trim correction should not exceed two points of adjustment. Not perfect, but a solid starting point for extended testing. And please – take the plugs out. They tell you so much about individual cylinder performance (pic 3).

My enthusiasm for scope-based diagnostics is increasingly challenged by complexity and lack of accessibility in modern vehicle design. And I’ve not even touched on lean-burn technology, cylinder select and variable valve lift and timing. These often display correction values indicating system problems; sometimes resetting correction helps highlight the issue.

I would welcome an upstream-of-catalyst exhaust-gas diagnostic port. So much can be accurately seen from carbon monoxide (CO), hydrocarbon (HC), carbon dioxide (CO2) and oxygen (O2) – it’s called the split-ratio calculation.

We exist in a throwaway world – which might be exactly where manufacturers want us.

J

une 2025 marked a significant milestone for global suspension-technology specialist Monroe with the launch of its Limited Lifetime Warranty across Australia and New Zealand.

This groundbreaking initiative is claimed to set a new benchmark in the automotive aftermarket, reaffirming Monroe’s ongoing commitment to durability, safety and innovation.

Starting June 1, 2025, Monroe passenger shock absorbers and struts installed in the region will be backed by this Limited Lifetime Warranty – claimed to be the first of its kind in the local market and a bold step forward for the industry.

With more than a century of global ridecontrol expertise and more than one billion vehicles covered worldwide, Monroe is a trusted name among Australian workshops, installers and consumers.

Known for its durability, superior control and comfort, the brand is a leader in providing ride-performance solutions that meet the demands of modern driving.

At the core of Monroe’s strength is its local engineering and manufacturing capability, anchored by the company’s Adelaide-based plant – claimed to be the only facility in Australia capable of producing standard replacement shock absorbers.

Monroe also designs and manufactures its Monroe Magnum TDT 4x4 range, purposebuilt for Australian vehicles and road conditions for both off-road enthusiasts and towing customers.

‘Monroe has always stood behind the quality of its products,’ said Monroe Senior Marketing Specialist Rad Rabichandran.

‘Now we’re going even further.

‘The Limited Lifetime Warranty reflects our total confidence in Monroe’s durability and performance and our commitment to supporting our trade partners with the best in safety, value and peace of mind.

‘Installing Monroe shock absorbers means peace of mind and confidently ensuring the trust of the consumers.’

Combining OE-quality, local engineering and design expertise with impressive aftermarket coverage, and now backed by a limited lifetime warranty, Monroe further reinforces the brand’s legacy – built to last a lifetime.

• Find out more at monroe.com.au/ lifetimewarranty

The EV & Hybrid Network and PNL 4WDriving are collaborating to produce informative off-roading content focused on electric and hybrid vehicles.

PNL 4WDriving, a leading Victorian 4WD training provider, has been providing accredited courses with a focus on safe, enjoyable experiences for 35 years, helping Victorians gain the skills, confidence and safety know-how to enjoy the bush.

Owned by Nyrie Butterfield, the business is built on a simple, powerful belief – people should be able to enjoy the outdoors safely and have fun while doing it.

The new partnership with the EV & Hybrid Network aims to educate course attendees about the complexities of modern vehicle technology while providing workshops and technicians with valuable insights to help

them prepare for the rapidly evolving future of automotive repair and adventure.

PNL 4WDriving’s comprehensive line-up of courses ranges from beginner through advanced 4WD techniques, with a strong emphasis on safety, environmental awareness and responsible bush experiences.

Courses cover essential vehicle handling, recovery techniques, obstacle navigation, tyre-and-vehicle maintenance and environmental stewardship. All programs align with Australian standards and are nationally recognised for accreditation.

PNL 4WDriving’s flexible delivery options

include practical on-vehicle training in suitable Victorian locations and online theory components, all dedicated to helping individuals and organisations operate 4WD vehicles safely, whether for recreation or work.

This blended approach is designed to help busy travellers, outdoor enthusiasts and employees of organisations that require 4WD capability.

Courses are accredited and designed to meet industry standards, ensuring participants receive credible credentials upon completion, and available year-round across selected Victorian locations.

• For enrolment details and prerequisites, go to pnl4wd.com.au

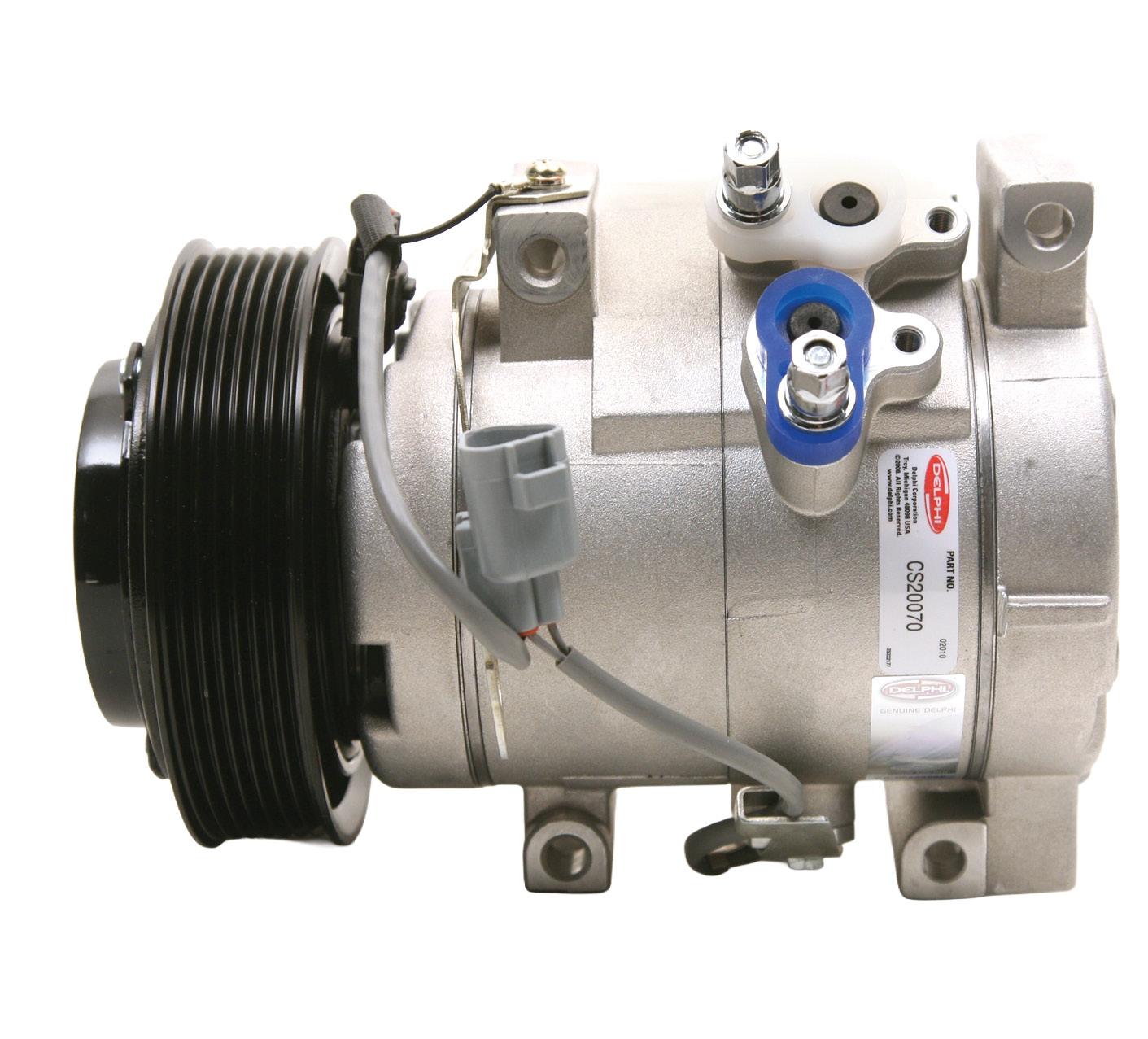

With more than 100 years of automotive-component development expertise behind it and a proud heritage of thermal-design innovation, Delphi is synonymous with automotive a/c and thermal control.

Design and innovation have been a common thread in the evolution of the company.

Back in 1954, Delphi – at that time known as Harrison Radiator, the thermal division of General Motors – developed the first ever under-bonnet automotive a/c system.

Described by Delphi as ‘a major design breakthrough that set the benchmark for how vehicle manufacturers configured a/c

systems’, many modern automotive a/c systems are still essentially based on the Delphi design fundamentals.

The under-bonnet a/c design set Delphi on a path to becoming a market leader in the supply of OE a/c systems and components such as the widely used V5 and V7 compressors. These Delphi variable-displacement compressors were designed to improve fuel economy and reduce emissions compared to traditional fixed-displacement clutched compressors.

control components to suit passenger and commercial vehicles.

Delphi continues to innovate by providing a/c products designed to meet the needs of the independent aftermarket, as well as supplying OE heating, ventilation and a/c (HVAC) components for on-highway trucks made in Australia.

Delphi offers an expanding range of

The company’s commitment to OE quality and processes is reflected by the fact every Delphi part must pass a rigorous production part approval process (PPAP) before being released to the market.

• Find out more by contacting Phinia Australia on 03 9566 4400, sales.ap@phinia.com or your nearest Delphi stockist

The vehicle’s check-engine light (CEL) was on. There were no other symptoms. The light had come on briefly approximately two weeks ago prior. It was off at the start of the next drive but had come on and stayed on.

Problem summary

A full vehicle scan retrieved the following engine fault code:

• P0471 – EGR gas pressure sensor performance.

OBD gave the description, P0471 – Exhaust pressure sensor A circuit range/performance.

OBD freeze-frame data did not show the specific sensor in question but it did show the vehicle was at key-on/engine-off (KOEO), so the engine was not actually running when the fault occured.

My initial thoughts were this would likely be an electrical-circuit issue but it was not the case

Cleared the fault code and the CEL went off. With the car running, the code did not return. This sensor in question is an exhaustpressure sensor mounted in the exhaust manifold, pre-turbo, which is fed via a metal tube from the manifold (pic 1).

I back-probed this easily accessible sensor and monitored its voltage, along with the OBD scan-tool pressure reading for ‘exhaust pressure B1’:

• KOEO – 1.01V/14.7psi: This was correct pressure for my location, 30m above sea level.

• Idle (at 24 per cent exhaust-gas recirculation [EGR]) – 1.08V/15.8psi.

• Holding 3000RPM – Rather than a sudden change in reading, the voltage and pressure just rose slowly over the course of approximately one minute, reaching 1.7V/26psi.

Despite the fact it was still slowly rising, I let off the pedal, noting the pressure slowly dropped at the same rate rather than dropping back to its original idle pressure immediately.

This suggested to me the sensor was reading plausibly.

Expecting a blockage, I removed the sensor from the metal pipe and found there was basically no exhaust flow out of the feed pipe, even when the engine was revved.

Removed the pipe and you could not blow through it (pic 2).

The EGR pressure-sensor’s metal feed pipe from the exhaust manifold to the sensor was blocked with carbon.

Fault solution

Removed the EGR pressure-sensor feed pipe and cleaned. We used our Torrent 500 parts washer, which got it flowing perfectly almost immediately.

Recommended time

Diagnostic time was one hour, taking into account preparation and research.

Repair time was 30 minutes, taking into account the location of parts and carrying out the repair to a tested outcome.

Repair solution by TaT Tech Team member Brendan Sorensen.

Share

Customer complaint

Cylinder #6 was misfiring and the checkengine light (CEL) was on.

Problem summary

The previous workshop stated it had replaced the spark plugs to hopefully fix the issue but it had made no difference. The engine warning light was on and the car was constantly misfiring.

Diagnostic sequence

Scanned the vehicle for DTCs and found the following:

• P0306 – Cylinder 6 misfire detected.

• 20B1 – Preparatory codes.

• 20B0 – Preparatory codes.

Note: From what I could determine, the preparatory codes were for when the ECM had determined a misfire but not yet confirmed the cylinder or amount of misfires.

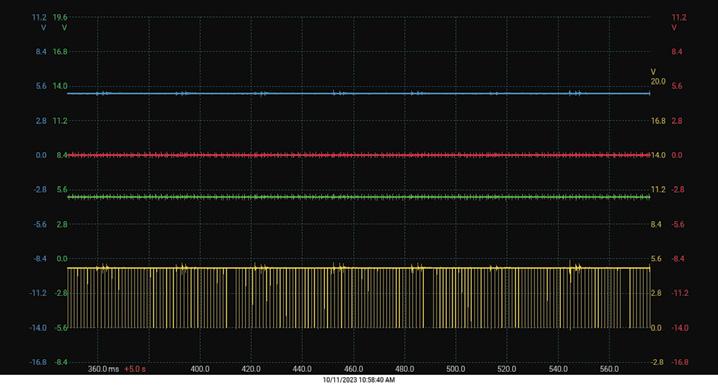

Using the bulkhead harness (right-hand side, underneath the air-inlet tube), I checked the triggers and current for the ignition coils – they were OK.

The currents all looked exactly the same, normal and correct.

Checked the current for the injectors and found the current for one injector was missing.

Inspected the wiring underneath the intake manifold and it was damaged from mice/ rats.

Checked for injector ground/control on #injector #6 – it was 12V and not switching. Disconnected the bulkhead harness and checked the resistance of injector #6 from the main connector – it was 13.2, which was OK (pic 1).

Checked this against another cylinder – it was also 13.2, so OK.

This meant there was at least some type of circuit from the bulkhead connector, under the manifold, through the injector and back to the bulkhead connector, and the fault most likely lay further towards the ECM than the bulkhead connector.

Removed the passenger-side carpet and ECM tin cover. There was no damage or corrosion at the ECM.

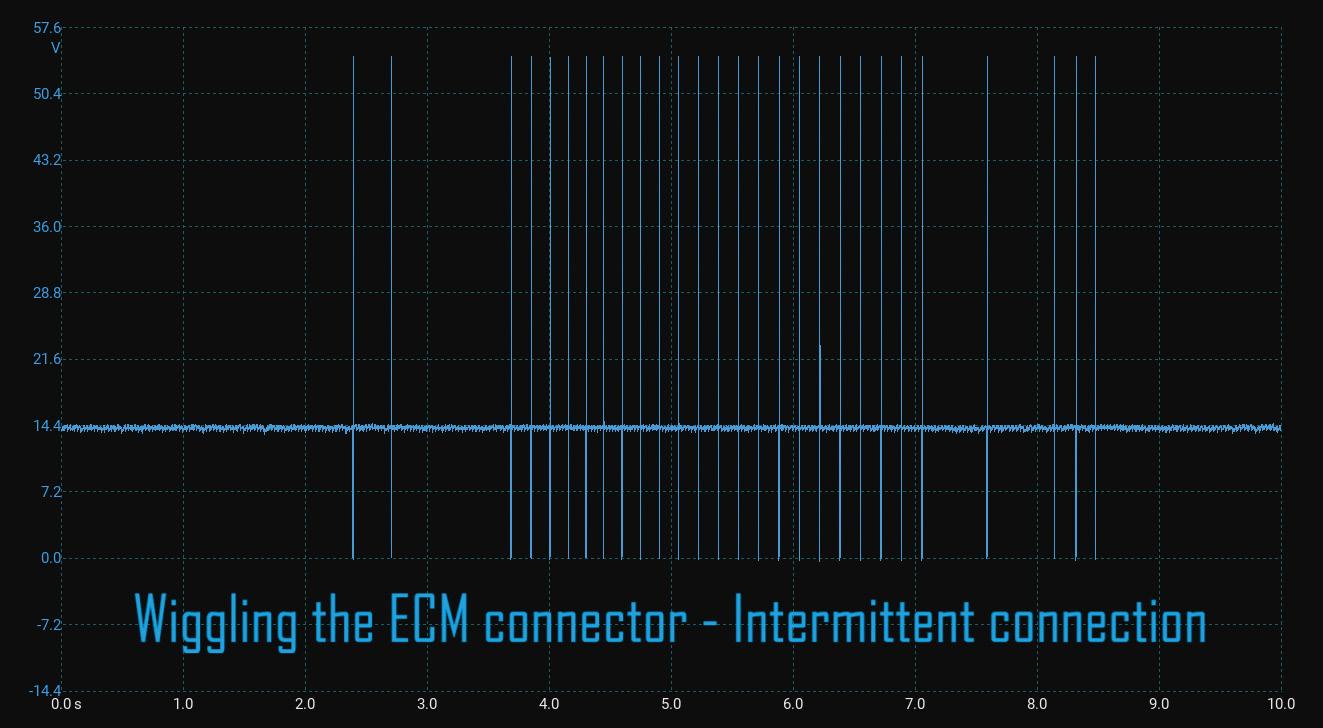

Connected the scope to the injector control at the ECM and rechecked – the injector was now working and there was no misfire.

Removed the back probe and the car started misfiring intermittently.

Checked the powers and ground of the ECM – they were OK.

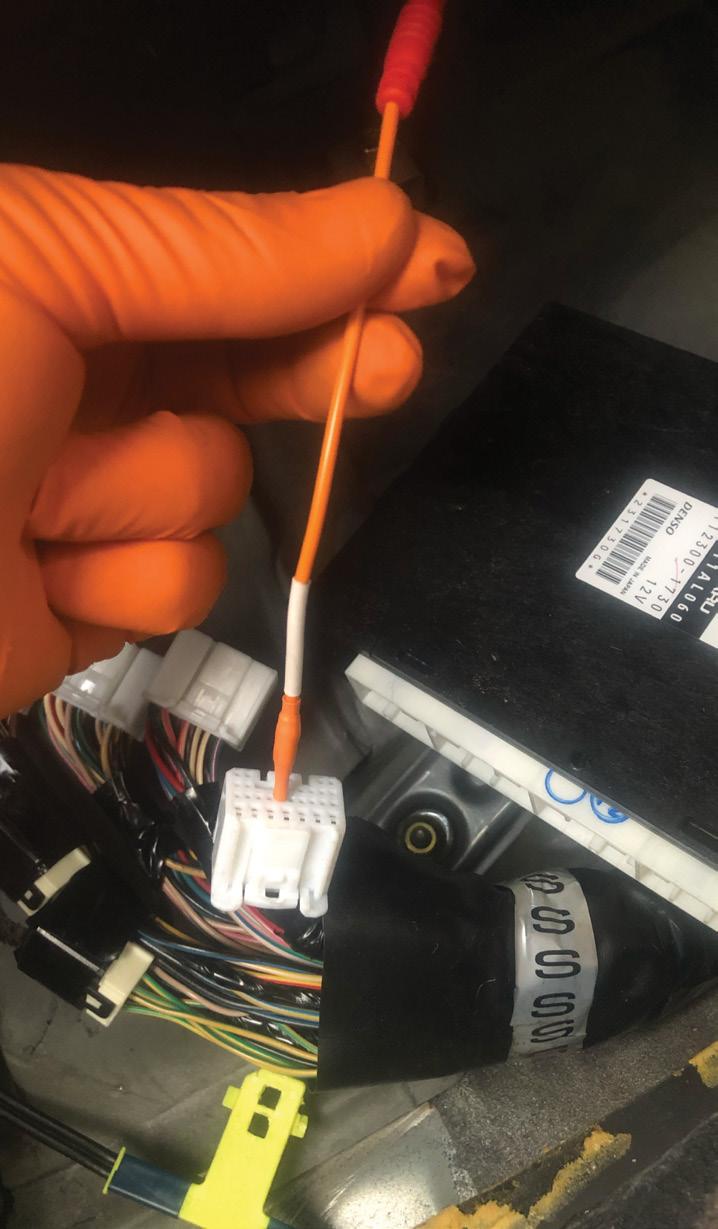

Checked all the terminal tensions of the ECM (pic 2).

Poor contact at the ECM for injector #6 terminal (pic 3).

Fault solution

De-pinned the affected terminal and re-tensioned it.

Also checked all the others and they were OK.

Recommended time

Diagnostic time approximately 70 minutes, taking into account preparation and research.

Repair time was 10 minutes, taking into account the location of parts and carrying out the repair to a tested outcome.

Repair Solution by TaT Tech Team member Gary O’Riain.

Customer complaint

The vehicle was going into limp mode when accelerating. The powertrain warning light would come on and then go out once the engine had slowed down.

Problem summary

Road-tested the vehicle and it drove normally until around 2200RPM, when it suddenly lost power. The powertrain warning light also flashed once and then went out.

Cycling the ignition brought back power until the RPM threshold was reached again.

Diagnostic sequence

Scanned the vehicle for DTCs and found the following:

• P0341-62 – Camshaft position sensor A circuit range/performance (history, not current) – PCM.

Customer complaint

The vehicle’s glow-plug light had started flashing and then car had cut out.

Problem summary

The vehicle arrived on a tow truck. Confirmed the crank/no-start condition.

Diagnostic sequence

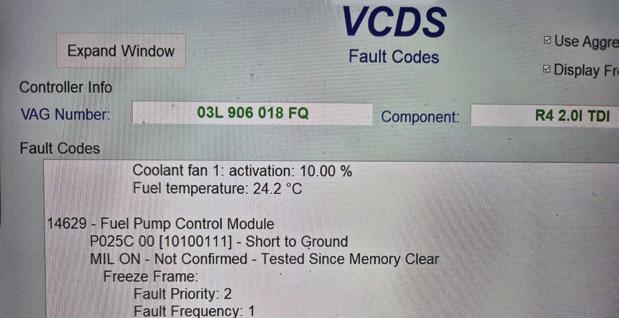

A full vehicle scan retrieved the following code:

• P025C – Fuel pump control module short to ground (pic 1).

This was a hard code – it would not clear – and data showed only 300psi of rail pressure was achieved during the crank/ no-start.

Confirmed there was no fuel delivery from the in-tank fuel pump.

Acquired a wiring diagram and found the

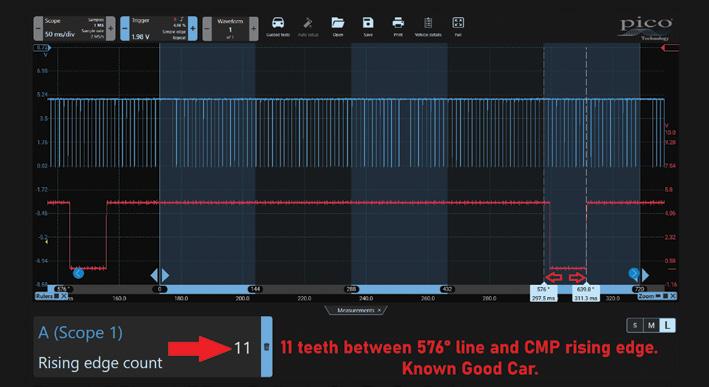

Checked the camshaft position sensor (CMP) signal at the sensor – it was OK. Checked the CMP signal at the powertrain control module (PCM) – found no signal (pic 1).

Checked the continuity between the PCM-C and CMP connectors – it was open line (OL), no circuit.

Fitted a jumper wire between the PCM-C and CMP connectors, then rechecked the CMP signal at the PCM – it was OK.

Road-tested the car again and it still faulted. Checked the pin tensions of the PCM-C and CMP connectors – they were slightly loose, so tightened the CMP connector terminals. They were now OK.

Checked the crankshaft position sensor (CKP) signal – it was OK.

Compared the CMP and CKP to a known good waveform (engine timing, pic 2) and

the faulting car appeared to be one tooth out (pic 3).

Measured the timing again and got the same result.

Fault description

The crankshaft to camshaft timing was incorrect by one tooth.

Fault solution

Fitted a new timing chain and tensioner, which fixed the issue.

Recommended time

Diagnostic time was one hour, taking into account preparation and research.

Repair time n/a.

Repair solution by TaT Tech Team member Gary O’Riain.

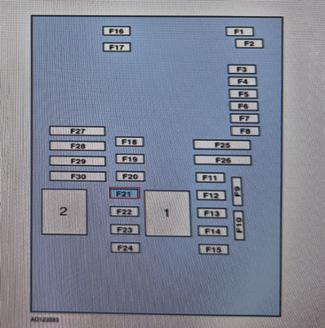

main power supply to the fuel-pump control module (accessible under the rear passenger seat and mounted on top of fuel tank).

Acquired the fuse-box diagram and determined the fuel-pump control module for this specific model was fed by fuse 21 in the underbonnet fuse box (pic 2).

Found fuse 21 was blown, so replaced fuse. After an extended crank to build rail pressure, the car started and ran.

However, after only a few seconds we saw a large amount of smoke from the radiator side of the engine so shut it off.

When the smoke stopped, we attempted to start the vehicle again but found it was again a crank/no-start situation and the fuse had blown.

Replaced the fuse again and saw the smoke again but from the top view it was difficult to determine the source of the smoke. Used

VW5N121198 VOLKSWAGEN

(5N), 2012

a thermal camera to find the source of the smoke was an external water pump (pic 3). This water pump shares the fuel-pump fuse and was causing it to blow.

Fault description

The external water pump was faulty (pic 4) and blew the shared fuel-pump fuse.

Fault solution

Replaced the external water pump.

Recommended time

Diagnostic time was one hour, taking into account preparation and research.

Repair time was 90 minutes, taking into account the location of parts and carrying out the repair to a tested outcome.

Repair solution by TaT Tech Team member Brendan Sorensen.

Customer complaint

When attempting to turn car off using the ‘start/stop’ button, the engine would shut down and the accessories would stay on as normal.

However, when you opened the door, the cluster showed ’Shift to P before exiting vehicle’ instead of shutting down.

Because of this accessories were staying on and the vehicle was unable to be locked.

Problem summary

Confirmed the cluster was showing the park (P) position on the gearshift display but the message appeared as described so was unable to power vehicle down.

Diagnostic sequence

Parked the vehicle in the carpark with the battery disconnected to stop it going flat before reconnecting the battery and confirming the fault.

A full vehicle scan showed no codes.

Power-source control module data from the body control module (BCM) showed the shift P signal was off despite the neutral (N) switch/clutch switch being on when in P or N and off when in reverse (R) or drive (D).

The data parameter ID (PID) for the parksignal suggested a mismatch.

The powertrain control module (PCM) registered the correct gear positions and the cluster physically showed the correct position.

Acquired a wiring diagram and noted a park-position switch in the interior shifter assembly that grounded out to show the

park position, separate to the inhibitor switch that was likely communicating the park position to all other modules.

Removed the centre console – which was very easy and took five minutes (pic 1) –and, looking down into the shifter assembly

at the top near the P section, you could see a micro switch (pic 2).

Used a screwdriver to depress this switch and fault was gone, confirming whatever was supposed to contact this switch was physically broken in the shifter assembly.

A new shifter assembly cost $1300, so acquired a second-hand unit for $110.

Looking into the same orifice, you could see a spring steel metal tab that contacted the switch when in P.

Fault description

The P microswitch contactor in the shifter assembly had broken off.

Fault solution

Replaced the interior shifter assembly.

Recommended time

Diagnostic time was one hour, taking into account preparation and research. Repair time was one hour, taking into account the location of parts and carrying out the repair to a tested outcome.

Repair Solution by TaT Tech Team member Brendan Sorensen.

ADRAD now offers premium

Textar brake products, produced by global leader TMD Friction.

Textar premium braking products are engineered to provide exceptional performance, comfort and safety and are tested to exceed ECE R90 requirements, the European standard specifying design, construction, performance and packaging. Features of Textar brake pads have been developed for two specific market segments.

apad for Asian makes

Released in 2024, Textar apad ceramic brake pads are specifically developed for Asian vehicle makes to provide silent, clean and comfortable braking.

A special copper and antimony-free friction formulation is designed to be less aggressive on the brake disc to produce far less dust, giving a much cleaner result. The brake pads also employ a textured noise-dampening shim applied on the backing plate designed to significantly reduce vibration and sound. Textar apad suits Asian vehicle makes including Honda, Holden, Hyundai, Jeep, Kia, Lexus, Mazda, Mitsubishi, Nissan, Proton, Renault, Subaru, Suzuki and Toyota.

for European makes

Textar’s epad+ ceramic brake pad was released in 2023 and is a design improvement over the previous epad product.

Epad+ features a superior non-asbestos organic (NAO) friction mix which is engineered to significantly reduce brake dust even under hard braking. This NAO formulation is environmentally friendly, containing no copper or antimony, and designed to extend the life of both pads and discs.

makes including Audi, BMW, Ford, Jaguar, Land Rover, Mercedes-Benz, MG, Mini, Porsche, Range Rover, Skoda, Volvo and Volkswagen.

The unique textile composition of the Q+ Dampening Shim is designed to prevent direct contact between the brake piston and backing plate during braking for outstanding quietness and enhanced braking comfort.

Textar premium braking products provide direct-fit convenience for passenger cars, 4x4s, SUVs and light-commercial vehicles and are available from ADRAD distributors across Australia.

• To find out more go to adrad.com.au or call ADRAD on 1800 882 043

Manymodern engines use plastic valve covers (also known as rocker covers), a lightweight and affordable material that is prone to cracking, warping and allowing seal failure under extreme under-bonnet conditions.

Nissan’s QR25 and VQ engines are common examples, with their integrated tube seals often failing, leading to premature ignitioncomponent damage. Due to the OE design, replacement seals are not available separately from the manufacturer, making repair options limited and costly.

Goss provides a cost-effective valve-cover repair solution for vehicles fitted with QR25 and VQ engines.

Each kit includes all required gaskets and components, taking the guesswork out of the repair process and offering a convenient, all-in-one solution.

Common symptoms of a failing valve cover include:

• Oil leaks caused by worn gaskets or seals.

• Cracking or warping from heat and vibration.

• A blocked or stuck positive crankcase ventilation (PCV) valve

The Goss valve-cover range features more than 45 part numbers, with each kit including gaskets, seals, mounting hardware, PCVs and oil caps where required. Designed to meet or exceed OEM standards, Goss valve covers deliver a reliable, cost-effective and genuine alternative repair solution.

Choose Goss for proven reliability, OE-level performance and a complete repair solution in one box.

Part numbers to suit the above applications are VC119 (X-Trail T30, QR25), VC120 (X-Trail T31, QR25), VC131 (Maxima, VQ) and VC132 (Murano Z51, VQ).

• To find the right valve cover for a specific vehicle, scan the QR code below or go to goss.com.au/catalogue

Airbag Man has been a trusted leader in air suspension for light and heavy vehicles, trailers, caravans and motorhomes since 1995.

Its innovative air-suspension control systems are designed to suit virtually any vehicle and application, giving precise, hassle-free air management for airbags and, in some cases, tyres.

From manual inflation to fully automatic electronic height control, the range puts control at the driver’s fingertips via hardmounted dual-paddle switches, wireless keyfobs or an exclusive mobile app that enables remote inflate/deflate, ride-height presets and live diagnostics without cluttering the cab

with gauges or wiring. For convenience and precision, dual wireless kits manage left and right airbags independently at the touch of a button.

A modular architecture lets the vehicle owner add capability to existing suspension products or build a complete Airbag Man set-up. Rather than using universal bracketry, Airbag Man tailors kits to specific vehicles and applications so airbags are positioned and operated for performance and longevity.

Modularity extends to components. Compressors, switches, gauges, tanks and compressor capacities can be selected to match vehicle type and duty cycle.

Digital or analogue gauges and wireless or hard-mounted controls can be chosen to suit how the vehicle is driven. This flexibility serves 4WD owners, fleets, mining, industrial and agricultural operators.

Start by understanding the vehicle, suspension type and matching airbag kit. Manual set-ups with portable compressors suit basic needs. Wireless or app-controlled options favour frequent adjustments or off-road use. Caravan or OEM-specific setups may need guidance from the chassis/ suspension provider or Airbag Man’s sales and customer service team.

By combining modularity, modern control options and expert support, Airbag Man delivers reliable, efficient and precise air management for on-road comfort, off-road capability and heavy-duty load levelling. Partner with Airbag Man to help your clients conquer any load or terrain.

• Find out more by calling 1800 247 224 or go to airbagman.com.au

Adiesel particulate filter (DPF) traps soot and ash in a ceramic honeycomb and burns it off during regeneration.

Soot accumulates when the DPF cannot reach regeneration temperature, raising exhaust back-pressure. This not only causes loss of power but directly shortens turbocharger life through heat and flow restriction.

Here are the key effects of a restricted DPF on turbochargers:

1. Loss of power/poor boost

• Back-pressure reduces flow to the turbine, limiting boost.

• Check DPF differential pressure (around 10 millibar [mbar] – follow OEM spec), then verify boost after repair.

2. Slow turbo spool

• Restricted flow delays turbine acceleration, especially at low RPM.

• Rectify DPF restriction and inspect turbine for carbon build-up.

3. Turbo overheating

• High upstream exhaust-gas temperatures (EGTs) overheat bearings and oil.

• Clean or replace DPF and check oil feed/ return lines for coking.

4. Turbo noise

• Whistle or siren noise can indicate abnormal loading or bearing wear.

• Fix DPF blockage and inspect turbo bearings/seals.

5. Oil leaks/blue smoke

• Back-pressure forces gases past turbo seals.

• Clean or replace DPF, clean intercooler piping and replace turbo if seals fail.

6. Limp mode and boost faults (P0234/ P0299)

• ECU detects excess back-pressure or abnormal boost.

• Confirm DPF restriction with scan-tool data and repair before recalibrating variable-geometry turbocharger (VGT) or actuators.

Prolonged DPF blockage also drives soot back toward the turbine and vanes, risking seizure. Restoring DPF flow is essential before assessing any turbocharger fault.

GCG Turbos supplies OEM-replacement and performance turbochargers and components across trade, transport, performance, mining, marine and construction applications.

• Find out more at gcg.com.au

Matson has expanded its professional jump-starter range with the introduction of the new MA24000 Lithium Jump Starter – a high-capacity, heavy-duty unit engineered to deliver maximum performance and reliability in all conditions.

The MA24000 has been engineered to combine exceptional current output with advanced charging technology and give consumers professional-grade performance in a compact, portable design.

Delivering an impressive 600A starting current and hefty 3000A peak, the MA24000 is designed to give the user the confidence to start everything from small passenger cars to larger diesel 4x4s with ease.

Built with Matson’s latest safety innovations, it offers comprehensive protection against reverse polarity and comes complete with an audible alarm to alert users of incorrect connection. Rated IP65 for

water resistance (with the USB cover closed), it’s purpose-built to perform dependably in harsh Australian environments.

Beyond jump-starting, the MA24000 doubles as a powerful portable energy hub. Featuring PD100W fast charging, it recharges from zero to 100 per cent in just 45 minutes and can power multiple devices through its USB and USB-C ports.

It also includes an SC100W car charger for in-vehicle charging, a low-power USB mode and an automatic cell-warming function to maintain peak battery performance in cold climates.

Housed in a compact, impact-resistant casing, this 24,000 milliamphour (mAh) lithium starter comes in a durable storage case that neatly holds all included accessories.

With its impressive starting performance, rapid charging capabilities and robust construction, the MA24000 sets benchmarks for professionalgrade lithium jump starters in the Australian automotive market.

• Find out more by calling the Tridon Customer Service team on 1300 362 263 or go to tridon.com.au

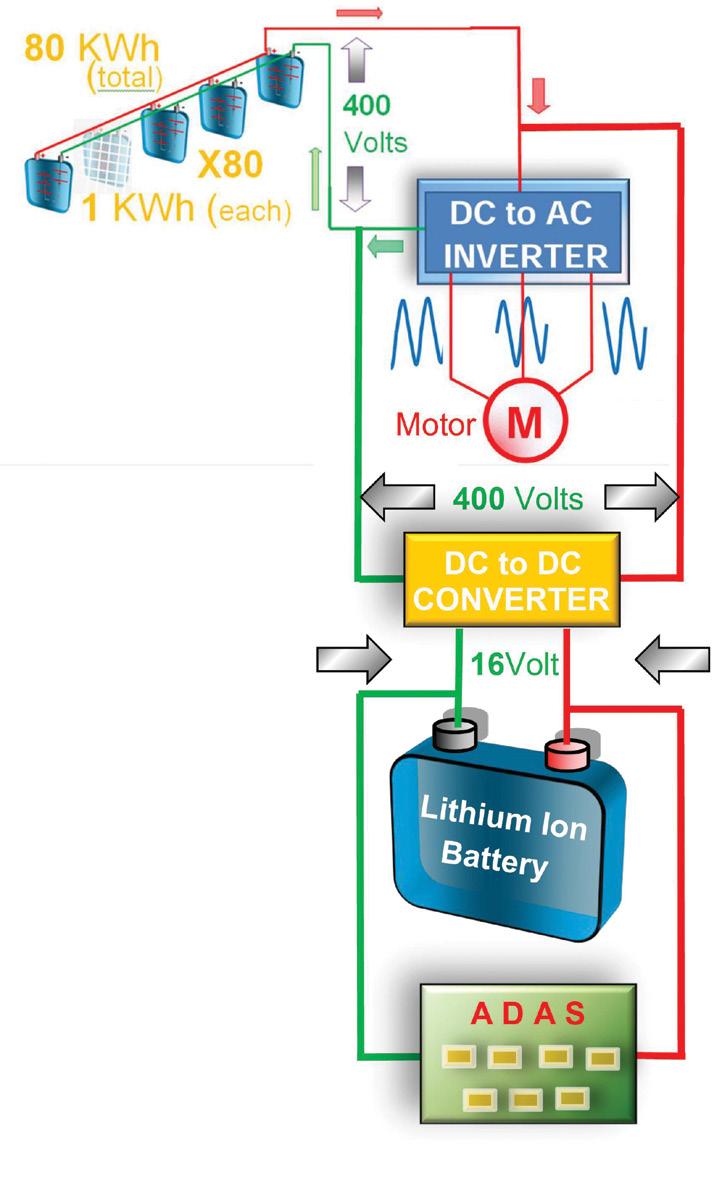

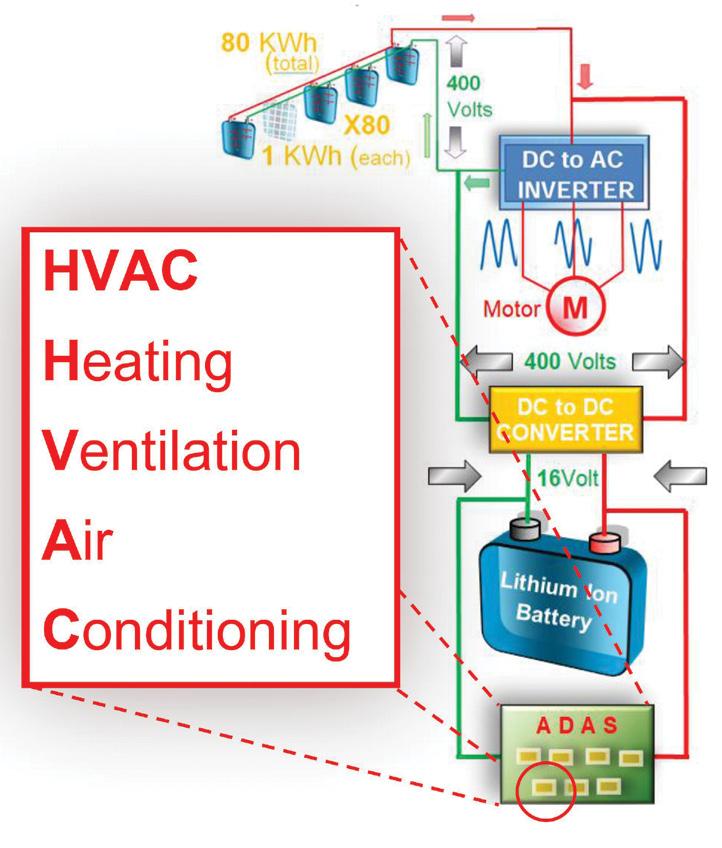

What is the fundamental difference between inverters and converters? And why do electric vehicles (EVs) still require a jump-start when the low-voltage battery goes flat?

EVs are built around a traction battery pack that stores enormous amounts of energy –often 80 kilowatt hours (kWh) or more – at high voltage levels of 400-800V DC.

In this article, we continue from our previous publication, building on the foundation of underpinning knowledge that professional mechanics and auto electricians already possess, and advancing further into the complexities of EV systems.

This high-voltage (HV) energy is routed into two very different paths:

• DC-AC inverter – Converts HV DC into multi-phase AC to drive the traction motor (see part 2, TaT issue 103 and part 5, TaT issue 106).

• DC-DC converter – Steps down HV DC into a safe, stable low-voltage (LV) supply of 12-16V to power ECUs, relays, advanced driver-assist system (ADAS) modules, the anti-lock braking system (ABS), sensors, headlights, and infotainment (pic 1).

This arrangement seems straightforward in principle but in practice involves:

• Sophisticated embedded software.

• A CAN bus communication backbone.

• Continuous feedback loops between ECUs.

• Strict HV isolation and fail-safe control logic.

• Coordination with the batterymanagement system (BMS, pic 4).

This raises a key diagnostic question: If the traction pack is fully charged, why do EVs still require a jump-start when the LV/ auxiliary battery is flat?

Could this have something to do with the ‘main contactors’ inside the battery pack (see part 4, TaT issue 105, pic 1a)?

The core difference

Mechanics are familiar with inverters from aftermarket accessories that generate 240V AC from a 12-16V battery.

In an EV, the inverter is far more advanced, creating three-phase AC waveforms from HV DC (ref 1) to precisely control motor torque and regenerative braking (see part 6, TaT issue 107).

The converter, on the other hand, reduces the traction battery’s HV to a manageable LV supply. This is the EV’s replacement for the alternator in internal combustion engine (ICE )vehicles. Without it, ECUs and safetycritical systems would not function (ref 2). Where inverters deal with waveform shaping and AC motor control, converters deal with step-down transformation, galvanic isolation and LV bus stability (pic 1).

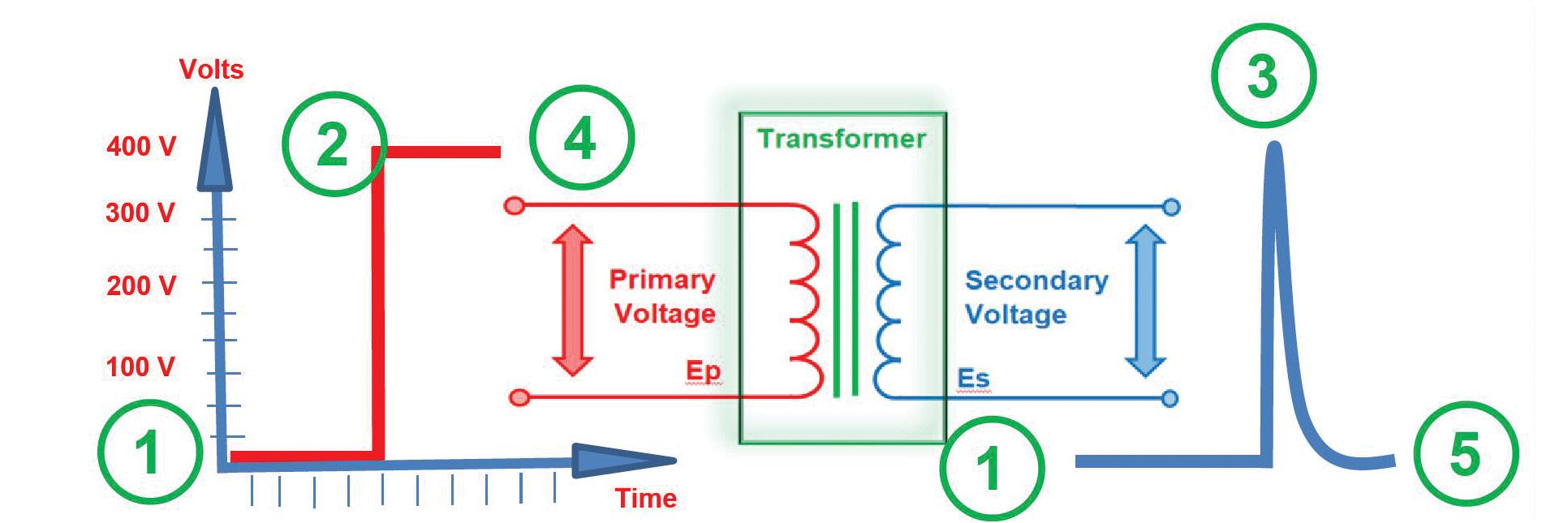

Why transformers don’t work on DC

A common misconception is that a transformer could simply reduce 400V DC down to 16V DC. In reality, transformers only work on alternating current.

Apply steady 400V DC across a primary winding and only an initial magnetic field spike occurs. Once the field stabilises, no further induction takes place. With no time-varying magnetic field, the secondary winding produces no output.

For example, diagrammatically represented, if a pure DC supply (of say 400V) from the EV’s HV battery pack:

• Is applied across the primary coil winding (pic 2 – red 1) and…

• As the initial magnetic field is produced by the step voltage (pic 2 – red 2)…

1• Then the ‘change’ in the magnetic field produced in the primary winding…

• Will induce a voltage in the secondary (pic 2 – blue 3)…

• But then nothing happens – steady DC voltage (pic 2 – red 4)…

• And since there is no more time-required change in the magnetic field…

• The voltage drops back down to where it started from (pic 2 – blue 5).

This is why iron-core transformers are useless for pure DC supplies.

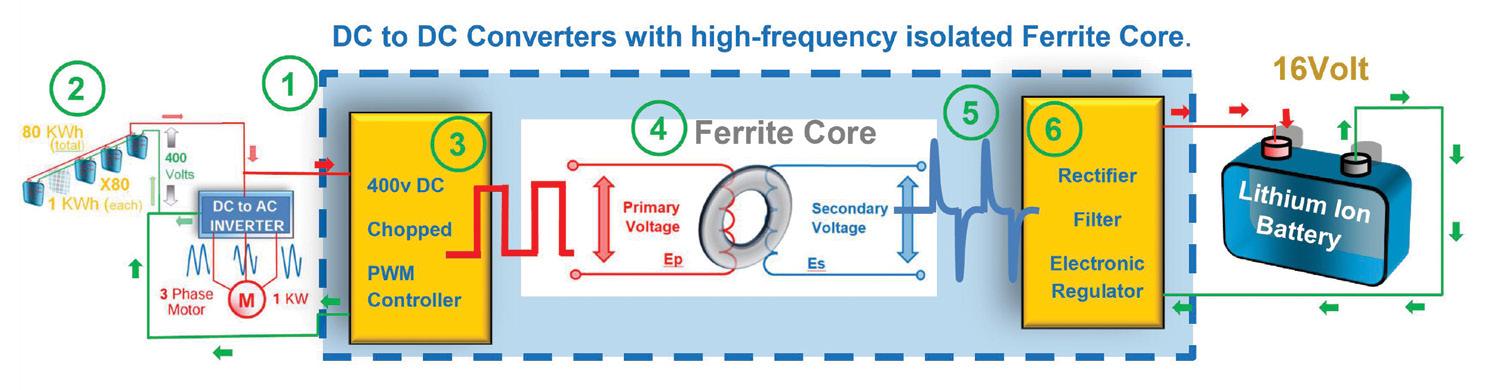

How EV DC-DC converters actually work

Modern converters use high-frequency (HF) ferrite-core isolation (pic 3 – 1, dotted blue).

The process is as follows:

1. The 400V DC bus from the traction pack (pic 3 – 2)…

2. Is chopped by MOSFETs or IGBTs into HF AC, typically tens to hundreds of kilohertz (kHz, pic 3 – 3).

3. This AC passes through a ferrite-core transformer, which provides:

• Complete galvanic isolation between HV and LV sides (pic 3 – 4).

• A large step-down ratio of approximately 30:1 (pic 3 – 5).

4. On the secondary side, the AC is rectified, filtered and regulated back into DC (pic 3 – 6).

5. A control module adjusts MOSFET/IGBT duty cycles (pulse width modulation, PWM) to maintain stable LV output despite HV fluctuations. This architecture provides efficiency, safety and compact size – all essential for EV packaging.

Why the auxiliary 12-16V battery still matters

With HV packs storing hundreds of volts, why do we still rely on a small 12-16V battery? The reasons are both historical and functional:

1. Legacy standardisation

For decades, 12V was the global automotive standard. Many modern EVs now use 14-16V lithium auxiliary systems. Lighting, relays, airbags, locks, heating, ventilation and a/c (HVAC) blowers and infotainment are still designed around the LV architecture. EVs adopted this to remain compatible.

2. Safety and redundancy

A LV network ensures that critical safety functions (e.g. hazard lights, airbags, ABS) remain powered, even when the HV system is isolated.

3. Boot-up sequence dependency

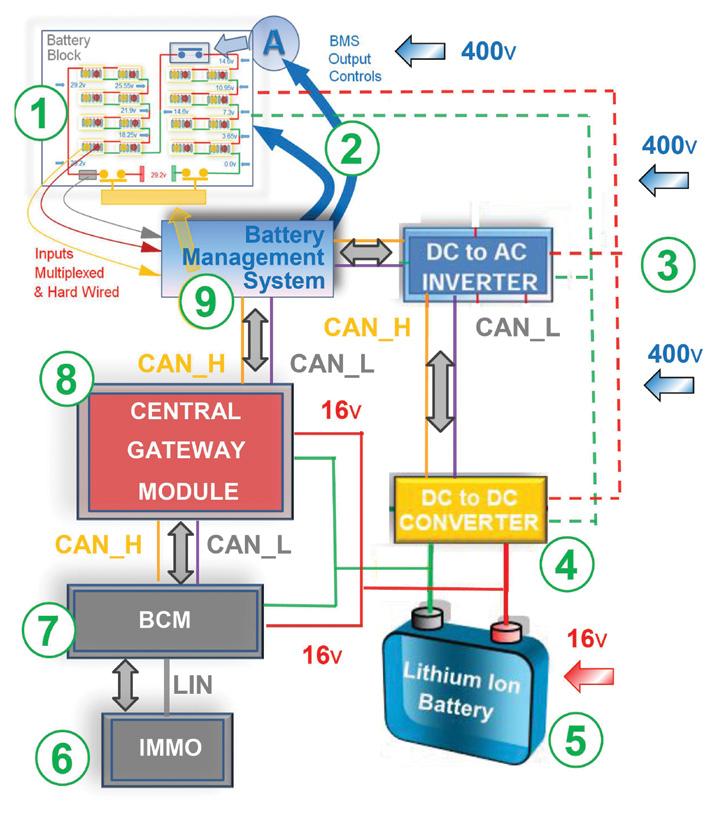

The traction pack cannot be connected directly to the vehicle until the main contactors close. These high-current relays require LV power to energise. If the auxiliary battery is flat, the ECUs and BMS cannot initialise and the contactors remain open –leaving the HV pack locked away (pic 4). Therefore, a weak auxiliary battery results in a dead vehicle, even if the traction pack is fully charged (to 400V).

CAN bus and the chain of command

The CAN bus is essentially an EV’s nervous system. While the physical layer is the same two-wire differential bus used in ICE vehicles, the application layer differs significantly:

• The BMS, inverter, converter, ABS, ADAS, HVAC and safety ECUs all exchange data continuously.

• Wake-up and shutdown sequences rely on tightly timed CAN messages.

• If a critical ECU fails to report readiness, the HV contactors remain open (pic 4a) From a diagnostic standpoint, understanding the topology of CAN communication is vital. Just as wiring diagrams show how components are physically linked, CAN topology diagrams map the flow of data between ECUs (pic 4). Without LV power, this communication cannot begin and the HV system cannot come online (ref 3).

Contactors and pre-charge circuits

Inside every HV battery pack are:

• Main contactors – Heavy-duty relays that connect/disconnect the traction pack from the power electronics (pic 4a).

• Pre-charge circuit – A resistor/relay system that gradually charges the inverter’s DC bus capacitors to avoid damaging inrush currents.

Both are controlled by LV circuits. Without a healthy 12-16V supply:

• Pre-charge cannot occur.

• The main contactors cannot close.

• The traction pack remains electrically isolated.

This explains the need for jump-starting. The auxiliary battery must first provide the energy to boot ECUs, initiate CAN communication and drive the contactors. Only then does the DC-DC converter recharge the LV system from the HV pack.

Technician insights – Flat 12-16V scenarios in EVs

The following scenarios are commonly seen in a workshop environment:

• Parasitic drain – Telematics and security systems continue drawing current when parked for long periods.

References

• Ageing auxiliary batteries – Many EVs still use 12V lead-acid units, which are subject to the same failure modes as ICE vehicles.

• Software update loads – Firmware or OTA updates may run with ignition off, depleting the LV battery.

The remedy is straightforward but often overlooked – a simple 12V (and/or 16V) jump-start or external charge is required before HV systems can re-engage (ref 4).

Looking ahead

Until our next article, see if you can examine the order of CAN bus chain-of-command from one to nine (pic 4) regarding the:

• Relevance of high-speed CAN (HSCAN).

• Order of ECU wake-up commands.

• Interaction between auxiliary supply, CAN topology and HV contactors.

• And why LV-system health is central to EV reliability and diagnostics.

These articles aim to improve a qualified technician’s understanding of EV systems. Contact with high voltage is lethal. If testing or working on HV systems:

• Always use CAT IV-rated meters.

• Wear insulated gloves and PPE.

• Follow OEM de-powering protocols.

• Work only after completing certified HV training.

For more, refer to TaT’s EV training resources.

1 https://www.ti.com//lit/an/slua963b/slua963b.pdf?ts=1757895640268

2 https://www.researchgate.net/publication/346073347_Battery_Management_System_Integrated_ with_CAN_BUS_Safety_Control_Environment_for_Electric_Vehicle

3 https://www.researchgate.net/publication/338989146_CAN_BUS_BASED_BMS_CONTROL_CARD_ DESIGN_AND_IMPLEMENTATION_BY_USING_STM32f103_SERIES_MICROCONTROLLER

4 https://www.webthesis.biblio.polito.it/33956/1/tesi.pdf

Interested in a hands-on course where you actually pull things apart, service them and then restore them in the vehicle? A course delivered by experts in their field who have worked on numerous electric vehicles (EVs) and hybrids?

SkillBuild can assist. Its senior trainer, Neil, has 10 years’ experience working on EVs and hybrids and is a qualified heavy-diesel mechanic. He has studied in the US, the UK and China and holds an Institute of the Motor Industry (IMI) Level 4 qualification as well as a Certificate IV in Automotive Mechanical Diagnosis (EVs).

‘Neil manages our EV workshop in Albury and delivers training at our centres in Sydney,

Perth, Melbourne, Albury and Brisbane,’ said SkillBuild Training Co-ordinator Bill Gammon.

‘The standard we use is AS 5732:2022 –Electric Vehicle Operations – Maintenance and Repair.’

Gammon said SkillBuild’s background was renewable energy, so it understood highvoltage (HV) batteries because it had been installing them for 10 years.

‘We ran the first EV charging course in Australia in 2019 and install charging systems,’ said Gammon. ‘Auto technicians are taught the principles of how the vehicle HV battery is charged and sizing chargers.’

Gammon said SkillBuild was happy to run courses in its customers’ premises or in its centres in Adelaide, Albury, Sydney, Brisbane, Darwin and Perth.

‘Many of our customers are mining companies moving to EVs as their fleet, as well as crash repair and automotive technicians,’ said Gammon.

Gammon said SkillBuild not only delivered practical courses in the maintenance and servicing of EVs, it had a workshop in Albury doing this work with hoists, a battery analyser, battery lifter and fireproof room. He said the workshop also undertook battery replacements and upgrades, as well as Volkswagen conversions.

• To find out more or enrol go to skillbuild.edu.au/product-category/ electric-vehicles

Brendan Sorensen

Ifyou have not yet opened an electric vehicle (EV) scan-tool data list, you are not alone.

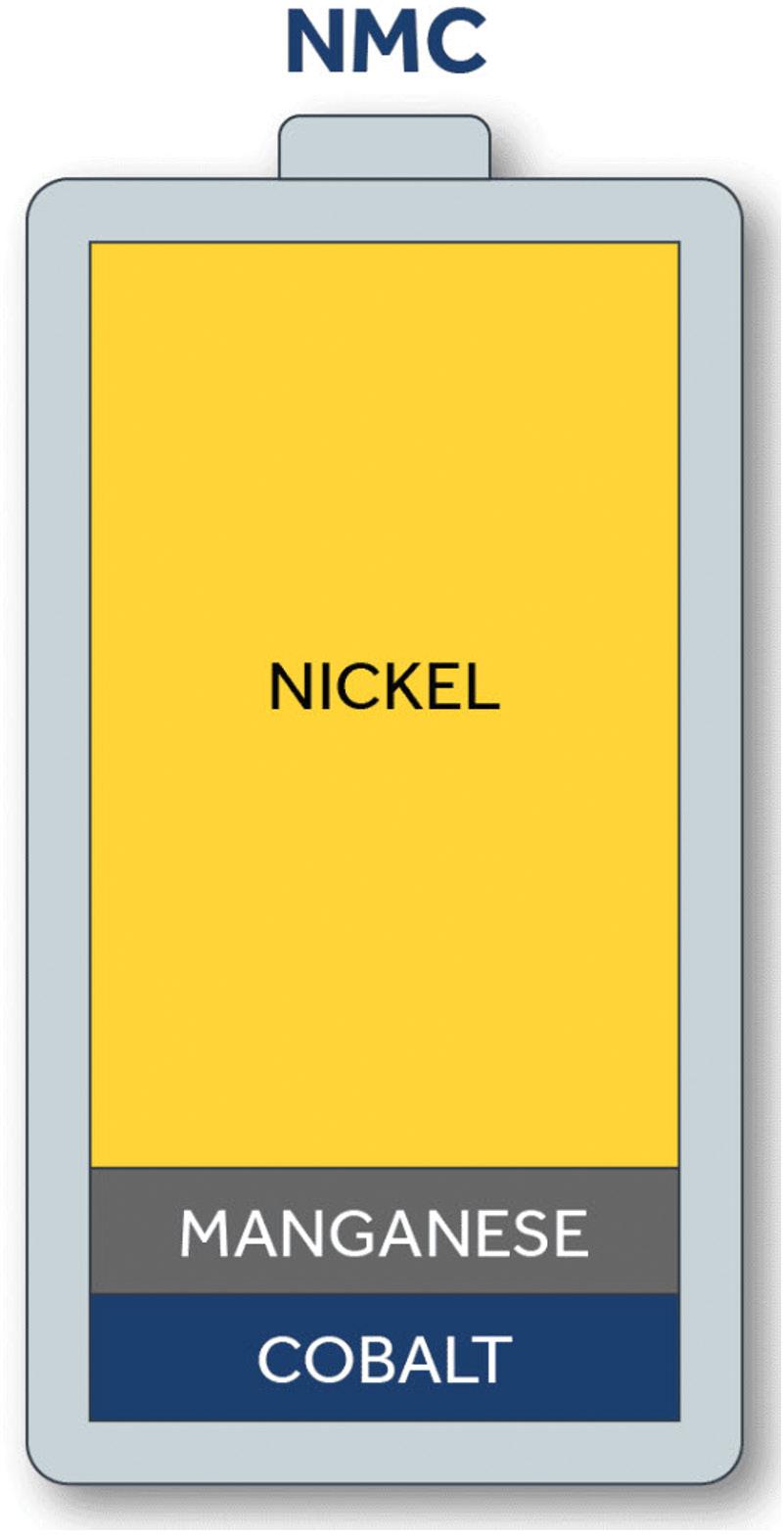

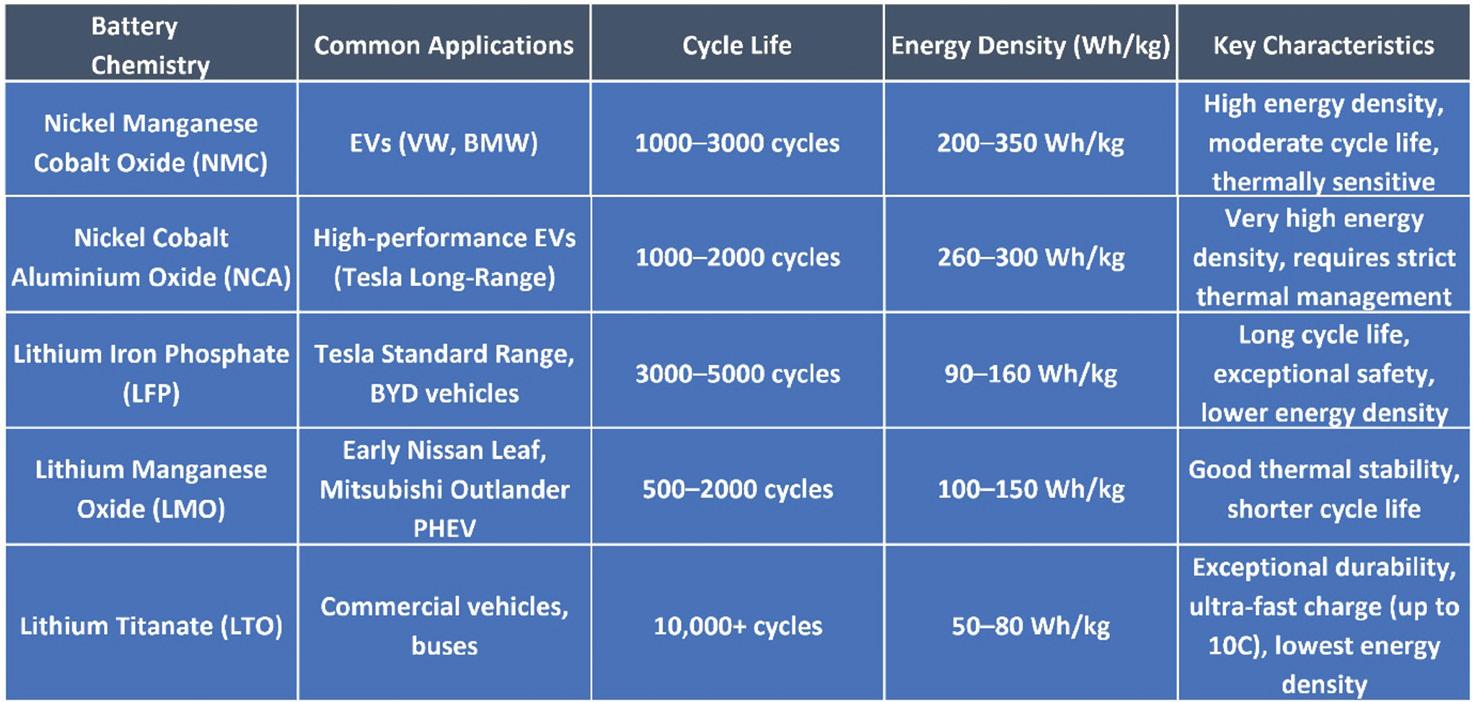

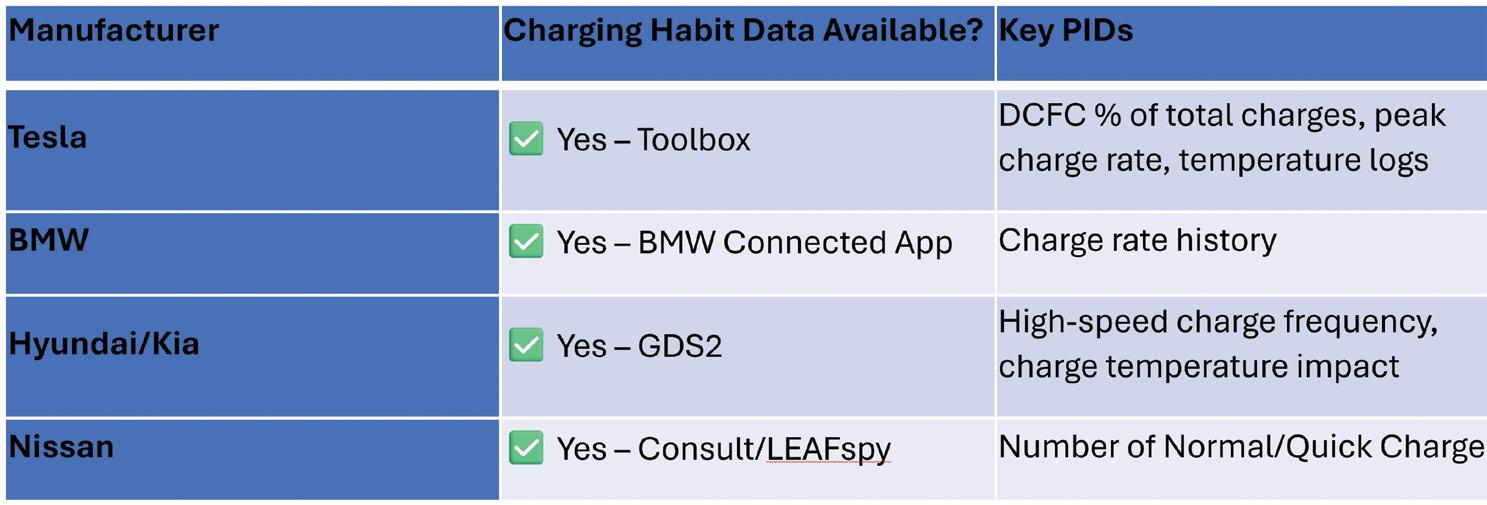

Most independent workshops are seeing hybrids regularly now, with plug-in hybrids (PHEVs) and full EVs only just beginning to trickle in for servicing, while proper diagnosis is not a common occurrence at all shops yet. Before diving into EV data parameter IDs (PIDs), it helps to know what sits inside these high-voltage packs.