No. 9, Jingke 6th Rd., Nantun Dist., Taichung City 40852, Taiwan TEL: +886 4 2350-2590 FAX: +886 4 2350-3161 Website: www.nikki.com.tw Email: service@nikki.com.tw Product & Service Precision Locknuts for Bearings Firm Fastening Locknuts Custom Locknuts Product Design and Development Outer Thread Grinding Processing Let us know if you have a special product request.

HSIANG KAI FU CO., LTD. is a professional manufacturer of precision locknuts for bearings and precision machine components. Established in 1994 and headquartered in Taichung Precision Machinery Technological Park, Taiwan, HSIANG KAI FU’s excellent brand NIKKI Precision Locknuts has built its reputation by offering advanced locknuts and services to its global customers across Germany, Japan, the US, Italy, Australia, India, China and more.

Quality is the Key

HSIANG KAI FU CO., LTD. strives to provide global customers with the highest quality precision locknuts and services. To ensure customer satisfaction, the company pays attention to the quality of each operational aspect and reinforces a corporate culture of consistent hard work. With industry-leading expertise and outstanding services, the company provides the best products on time to help customers improve their production quality and volume. The key to NIKKI’s success has always been to focus on its customers’ success.

Sustainability

Certificate of RoHS & SVHC free (EU)

ISO 9001:2015

SGS Test Report

Usage Scenario Quality Assurance Feature ...... P.4 ...... P.5 ...... P.6 HKF HKR ...... P.8 ...... P.9

BF BFZ MF MFZ TMF SFZ ...... P.10 ...... P.11 ...... P.12 ...... P.13 ...... P.14 ...... P.15 30˚FlankLockingSeries RadialLockingSeries MR MRZ SR SRZ MRRA ...... P.16 ...... P.17 ...... P.18 ...... P.19 ...... P.20 BestFlankAngle LockingSeries

PATENT PATENT

3 CONTENTS AxialLocking

NIKKI

For light-duty transmission ...... P.21 For food, pharmaceutical, chemical and semiconductor equipment ...... P.21 NEW NEW NEW NEW MKR MA MKK MKW ...... P.22 ...... P.24 ...... P.25 ...... P.26 Customized Locknuts Mounting Tools Assembly Guide Disassembly Guide Technical Information ...... P.27 ...... P.27 ...... P.28 ...... P.28 ...... P.29 MRN

MRSSeries

Series

Customer Service

Series

Usage Scenario

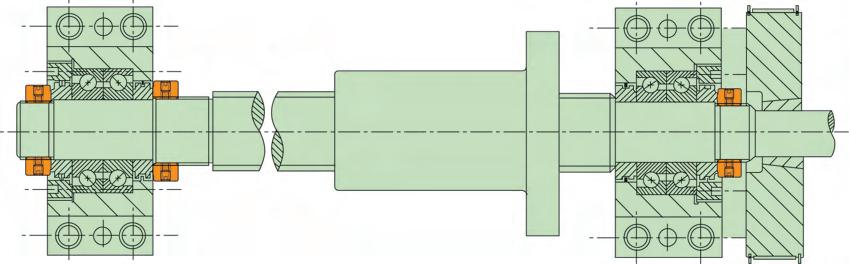

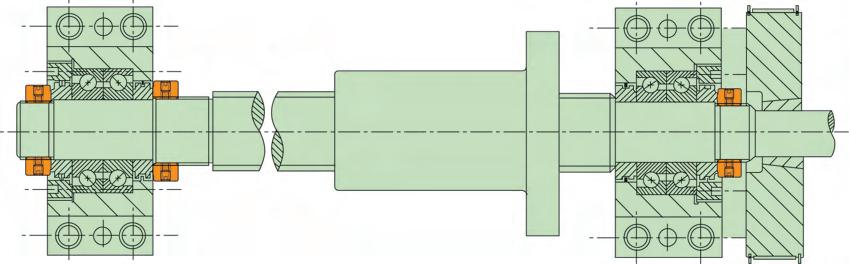

When applied to a rotating spindle / ball screw of a machine, NIKKI's precision locknuts will greatly increase the assembly precision and prevent the system from deflection.

Common challenges like measuring, adjusting, and deformation after the bolt is locked can all be improved significantly by NIKKI's precision locknuts.

NIKKI's locknuts are easy to set up and highly durable.

SpindleStructure

BallScrewStructure

ADVANTAGE BY USING PRECISION LOCKNUTS

4

Distortion (vibration)

to misalignment Spindle

due

distortion prevented

With Precision Locknuts

Without Precision Locknuts

QUALITY

ASSURANCe

High Locking, High Precision, High Stability

NIKKI Precision Locknuts

ISO 4H thread precision

High load carrying capacity

Easy correctio n to a right angle against axis

Lock without a washer or keyway

Save assembly time with increased precision and save cost

Effectively prevent spindles and ball screws from distortion

Prolong the life of bearings and machines

Easy to assemble and disassemble

Reusable if handled properly

Material Information

Materials Used: JIS SCM440 / DIN 42CrMo4 / AISI 4140

Certificate of RoHS & SVHC free (EU)

SGS Test Report

Measuring Process

Measuring Instrument

5

Measure the thicknessMeasure the inner diameterCheck the thread precision by a gauge to ensure ISO 4H

Measure the thread run-out

Universal length measuring instrument Universal measuring microscopeRoughness and contour instrument

Roughness of Contact Surface Comparison (Zoom in Sixty Times)

Theroughnessofthecontactsurface isextremelysmooth,whichprovides toplocking/anti-looseningperformance anddynamicrotarystability.Thisseries issuitableforheavyworkloadsand outstandingrigidity.

Maximumaxialrun-out:0.002mm

TurningSeries

Theroughnessofthecontactsurfaceis higher.Thisseriesissuitablefornormal workloadsandstandardrigidity.

Maximumaxialrun-out:0.005mm

Contact Surface Comparison between Different Processing Methods (Zoom in Sixty Times)

Other Brands

WithNIKKI'sspecialgrindingprocess, thecontactsurfaceisextremely smooth,providingtoplocking/antilooseningperformanceanddynamic rotarystability.

Withtraditionalgrindingprocess,the smoothnessofthecontactsurface isrelativelylower,leadingtolower locking/anti-looseningperformanceand dynamicrotarystability.

6

GrindingSeries

NIKKISpecialGrindingTechnique

TraditionalGrindingTechnique

Feature

Excellent Excellent

Grinding Thread Comparison

Excellent

Rmax:2.045

Rmax:3.7066

Other Brands

Comparison between Different Manufacturing Tolerances

Excellent

The manufacturing tolerance is in the middle of the ISO 4H standard.

Afterassemblinginternalandexternal threads,theeffectivecontactsurface islarger,causingthefrictionandaxial force to increase. NIKKI’s locknut issecuredtopreventunintentional looseningandimprovesrotarystability.

Other Brands

The manufacturing tolerance is at the upper limit of the ISO 4H standard.

Afterassemblinginternalandexternal threads,theeffectivecontactsurfaceis smaller,causingthefrictionandaxial forcetodecline,sothelocknutiseasy toloosenandreducesrotarystability.

7

InternalThreadInternalThread ExternalThreadExternalThread

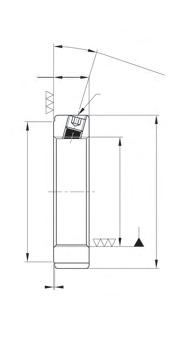

HKF Series-Best Flank Angle

Locking

Material:JISSCM440/DIN42CrMo4

HKF85andaboveHKF80andunder

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

HKF17X1.0PM17X1321627423M54.8

HKF20X1.0PM20X1381633423M68

HKF20X1.5PM20X1.5381633423M68

HKF25X1.5PM25X1.5381833523M68

HKF30X1.5PM30X1.5451840523M68

HKF35X1.5PM35X1.5521847523M819

HKF40X1.5PM40X1.558205262.53M819

HKF45X1.5PM45X1.565205962.53M819

HKF50X1.5PM50X1.570206462.53M819

HKF55X1.5PM55X1.5752268733M819

HKF55X2.0PM55X2752268733M819

HKF60X1.5PM60X1.5802273733M819

HKF60X2.0PM60X2802273733M819

HKF65X1.5PM65X1.5852278733M819

HKF65X2.0PM65X2852278733M819

HKF70X1.5PM70X1.592248483.53M819

HKF70X2.0PM70X292248483.53M819

HKF75X1.5PM75X1.598249083.53M819

HKF75X2.0PM75X298249083.53M819

HKF80X2.0PM80X2105249683.53M819

HKF85X2.0PM85X21102410283.56M819

HKF90X2.0PM90X2120261081046M819

HKF95X2.0PM95X2125261131046M819

HKF100X2.0PM100X2130261181046M819

HKF105X2.0PM105X2140281251046M1036

HKF110X2.0PM110X2145281321046M1036

HKF115X2.0PM115X2150281371046M1036

HKF120X2.0PM120X2155301421256M1036

HKF125X2.0PM125X2160301471256M1036

HKF130X2.0PM130X2165301521256M1036

HKF135X2.0PM135X2175321601256M1036

HKF140X2.0PM140X2180321651256M1036

HKF145X2.0PM145X2190321751256M1036

HKF150X2.0PM150X2195321801256M1036

HKF155X3.0PM155X3200341801466M1036

HKF160X3.0PM160X3210341901466M1036

HKF165X3.0PM165X3210341901466M1036

HKF170X3.0PM170X3220342001466M1036

HKF180X3.0PM180X3230362051676M1260

HKF190X3.0PM190X3240362151676M1260

HKF200X3.0PM200X3250382251676M1260

Whenorderingaboveproducts,pleaserefertotheName.Forexample:HKF30x1.5P Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:HKF30x1.5P-L Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:HKF30-U18

8

HKF

Outperform 30° flank locking nuts

Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhd gt 3-MMax. Torque_Nm

HKF15X1.0PM15X1301425423M54.8

A A 0.002 h 3-M Bestangle G d d0 D G 0.5 t n-g PATENT PATENT

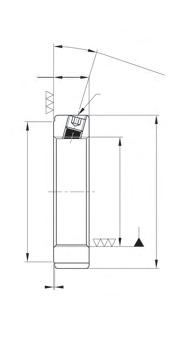

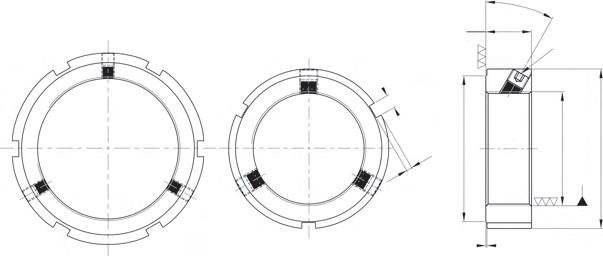

HKR Series-Best Flank Angle

Locking

Material:JISSCM440/DIN42CrMo4

HKR85andaboveHKR80andunder

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

HKR15X1.0PM15X125821323M42.2

HKR17X1.0PM17X1281023423M54.8

HKR20X1.0PM20X1321027423M54.8

HKR20X1.5PM20X1.5321027423M54.8

HKR25X1.5PM25X1.5381233523M68

HKR30X1.5PM30X1.5451240523M68

HKR35X1.5PM35X1.5521247523M68

HKR40X1.5PM40X1.558145262.53M68

HKR45X1.5PM45X1.565145962.53M68

HKR50X1.5PM50X1.570146462.53M68

HKR55X1.5PM55X1.5751668733M819

HKR55X2.0PM55X2751668733M819

HKR60X1.5PM60X1.5801673733M819

HKR60X2.0PM60X2801673733M819

HKR65X1.5PM65X1.5851678733M819

HKR65X2.0PM65X2851678733M819

HKR70X1.5PM70X1.592188483.53M819

HKR70X2.0PM70X292188483.53M819

HKR75X1.5PM75X1.598189083.53M819

HKR75X2.0PM75X298189083.53M819

HKR80X2.0PM80X2105189683.53M819

HKR85X2.0PM85X21101810283.56M819

HKR90X2.0PM90X2120201081046M819

HKR95X2.0PM95X2125201131046M819

HKR100X2.0PM100X2130201181046M819

HKR105X2.0PM105X2140221251046M1036

HKR110X2.0PM110X2145221321046M1036

HKR115X2.0PM115X2150221371046M1036

HKR120X2.0PM120X2155241421256M1036

HKR125X2.0PM125X2160241471256M1036

HKR130X2.0PM130X2165241521256M1036

HKR135X2.0PM135X2175261601256M1036

HKR140X2.0PM140X2180261651256M1036

HKR145X2.0PM145X2190261751256M1036

HKR150X2.0PM150X2195261801256M1036

HKR155X3.0PM155X3200281801466M1036

HKR160X3.0PM160X3210281901466M1036

HKR165X3.0PM165X3210281901466M1036

HKR170X3.0PM170X3220282001466M1036

HKR180X3.0PM180X3230302051676M1260

HKR190X3.0PM190X3240302151676M1260

HKR200X3.0PM200X3250322251676M1260

Whenorderingaboveproducts,pleaserefertotheName.Forexample:HKR30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:HKR30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:HKR30-U18

9 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhd gt 3-MMax. Torque_Nm

HKR PATENT PATENT A A 0.002 h 3-M Bestangle G d d0 D G 0.5 t n-g

Outperform 30° flank locking nuts

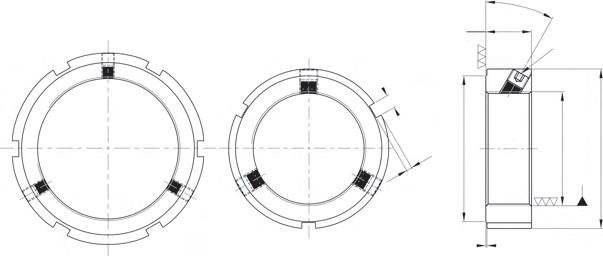

BF Series-30˚ Flank Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

BF15X1.0PM15X1301425423M54.8

BF17X1.0PM17X1321627423M54.8

BF20X1.0PM20X1381633423M68

BF20X1.5PM20X1.5381633423M68

BF25X1.5PM25X1.5381833523M68

BF30X1.5PM30X1.5451840523M68

BF35X1.5PM35X1.5521847523M819

BF40X1.5PM40X1.558205262.53M819

BF45X1.5PM45X1.565205962.53M819

BF50X1.5PM50X1.570206462.53M819

BF55X2.0PM55X2752268733M819

BF60X2.0PM60X2802273733M819

BF65X2.0PM65X2852278733M819

BF70X2.0PM70X292248483.53M819

BF75X2.0PM75X298249083.53M819

BF80X2.0PM80X2105249683.53M819

BF85X2.0PM85X21102410283.56M819

BF90X2.0PM90X2120261081046M819

BF95X2.0PM95X2125261131046M819

BF100X2.0PM100X2130261181046M819

BF105X2.0PM105X2140281251046M1036

BF110X2.0PM110X2145281321046M1036

BF115X2.0PM115X2150281371046M1036

BF120X2.0PM120X2155301421256M1036

BF125X2.0PM125X2160301471256M1036

BF130X2.0PM130X2165301521256M1036

BF135X2.0PM135X2175321601256M1036

BF140X2.0PM140X2180321651256M1036

BF145X2.0PM145X2190321751256M1036

BF150X2.0PM150X2195321801256M1036

BF155X3.0PM155X3200341801466M1036

BF160X3.0PM160X3210341901466M1036

BF165X3.0PM165X3210341901466M1036

BF170X3.0PM170X3220342001466M1036

BF180X3.0PM180X3230362051676M1260

BF190X3.0PM190X3240362151676M1260

BF200X3.0PM200X3250382251676M1260

BF210X3.0PM210X3260382451676M1260

BF220X3.0PM220X3270382551676M1260

BF230X3.0PM230X3280402581696M1260

BF240X3.0PM240X3290402681696M1260

BF250X3.0PM250X3300402781696M1260

BF260X4.0PM260X43104028820106M14100

Whenorderingaboveproducts,pleaserefertotheName.Forexample:BF30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:BF30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:BF30-U18

10 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhd g t 3-M Max. Torque_Nm

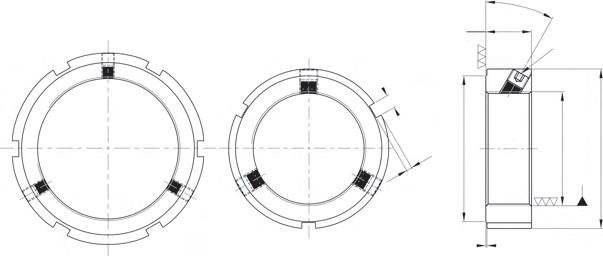

BF 3-M d0 D 0.5 G 30。 A t n-g BF85andaboveBF80andunder

A 0.002

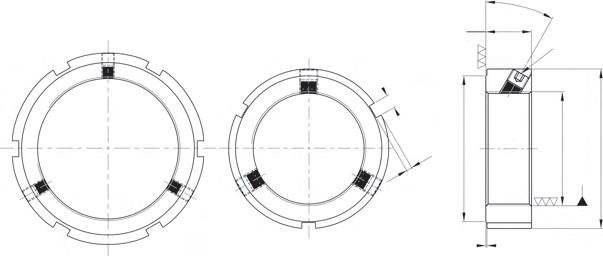

BFZ Series-30˚ Flank Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecisionturningprocess.

BFZ15X1.0PM15X1301425423M54.8

BFZ17X1.0PM17X1321627423M54.8

BFZ20X1.0PM20X1381633423M68

BFZ20X1.5PM20X1.5381633423M68

BFZ25X1.5PM25X1.5381833523M68

BFZ30X1.5PM30X1.5451840523M68

BFZ35X1.5PM35X1.5521847523M819

BFZ40X1.5PM40X1.558205262.53M819

BFZ45X1.5PM45X1.565205962.53M819

BFZ50X1.5PM50X1.570206462.53M819

BFZ55X2.0PM55X2752268733M819

BFZ60X2.0PM60X2802273733M819

BFZ65X2.0PM65X2852278733M819

BFZ70X2.0PM70X292248483.53M819

BFZ75X2.0PM75X298249083.53M819

BFZ80X2.0PM80X2105249683.53M819

BFZ85X2.0PM85X21102410283.56M819

BFZ90X2.0PM90X2120261081046M819

BFZ95X2.0PM95X2125261131046M819

BFZ100X2.0PM100X2130261181046M819

BFZ105X2.0PM105X2140281251046M1036

BFZ110X2.0PM110X2145281321046M1036

BFZ115X2.0PM115X2150281371046M1036

BFZ120X2.0PM120X2155301421256M1036

BFZ125X2.0PM125X2160301471256M1036

BFZ130X2.0PM130X2165301521256M1036

BFZ135X2.0PM135X2175321601256M1036

BFZ140X2.0PM140X2180321651256M1036

BFZ145X2.0PM145X2190321751256M1036

BFZ150X2.0PM150X2195321801256M1036

BFZ155X3.0PM155X3200341801466M1036

BFZ160X3.0PM160X3210341901466M1036

BFZ165X3.0PM165X3210341901466M1036

BFZ170X3.0PM170X3220342001466M1036

BFZ180X3.0PM180X3230362051676M1260

BFZ190X3.0PM190X3240362151676M1260

BFZ200X3.0PM200X3250382251676M1260

BFZ210X3.0PM210X3260382451676M1260

BFZ220X3.0PM220X3270382551676M1260

BFZ230X3.0PM230X3280402581696M1260

BFZ240X3.0PM240X3290402681696M1260

BFZ250X3.0PM250X3300402781696M1260

BFZ260X4.0PM260X43104028820106M14100

Whenorderingaboveproducts,pleaserefertotheName.Forexample:BFZ30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:BFZ30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:BFZ30-U18

11 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhd g t 3-M Max. Torque_Nm

BFZ

t n-g BFZ85andaboveBFZ80andunder A 0.005 h 3-M d0 D 0.5 d 30。 A

MF Series-30˚ Flank Locking

Material:JISSCM440/DIN42CrMo4

MF105andaboveMF100andunder

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

MF12X1.0PM12X1301425-423M54.8

MF15X1.0PM15X134162616423M68

MF17X1.0PM17X136162818523M68

MF20X1.0PM20X138183221523M68

MF20X1.5PM20X1.538183221523M68

MF25X1.5PM25X1.542183626523M68

MF30X1.5PM30X1.548184331523M68

MF35X1.5PM35X1.553184836523M819

MF40X1.5PM40X1.55820524162.53M819

MF45X1.5PM45X1.56520594662.53M819

MF50X1.5PM50X1.57020645162.53M819

MF55X2.0PM55X275226856733M819

MF60X2.0PM60X280227361733M819

MF65X2.0PM65X285227866733M819

MF70X2.0PM70X29224847183.53M819

MF75X2.0PM75X29824907683.53M819

MF80X2.0PM80X210524968183.53M819

MF85X2.0PM85X2112241048683.53M819

MF90X2.0PM90X211826108911043M819

MF95X2.0PM95X212326113961043M819

MF100X2.0PM100X2128261181011043M819

MF105X2.0PM105X2137261251061046M819

MF110X2.0PM110X2145301321111256M819

MF115X2.0PM115X2150301371161256M819

MF120X2.0PM120X2155301421211256M819

MF125X2.0PM125X2160301461261256M819

MF130X2.0PM130X2165301521311256M819

MF135X2.0PM135X2175301601361256M819

MF140X2.0PM140X2180321651411256M1036

MF145X2.0PM145X2190321751461256M1036

MF150X2.0PM150X2195321801511256M1036

MF155X3.0PM155X3200341801561256M1036

MF160X3.0PM160X3210341901611256M1036

MF170X3.0PM170X3220342001711256M1036

MF180X3.0PM180X3230362051811256M1036

MF190X3.0PM190X3240362201911256M1036

MF200X3.0PM200X3250362302011256M1036

MF210X4.0PM210X4270362502111256M1036

MF220X4.0PM220X4280362602211256M1036

MF230X4.0PM230X4290362702311256M1036

MF240X4.0PM240X4300362802411256M1036

MF250X4.0PM250X4310362902511256M1036

MF260X4.0PM260X4320363002611256M1036

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MF30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MF30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MF30-U18

12 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhdd1g t 3-MMax. Torque_Nm

MF A A 0.002 h 3-M d1 d0 D 0.5 d G G 30。 t n-g

MFZ Series-30˚ Flank Locking

Material:JISSCM440/DIN42CrMo4

MFZ105andaboveMFZ100andunder

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecisionturningprocess.

MFZ12X1.0PM12X1301425-423M54.8

MFZ15X1.0PM15X134162616423M68

MFZ17X1.0PM17X136162818523M68

MFZ20X1.0PM20X138183221523M68

MFZ20X1.5PM20X1.538183221523M68

MFZ25X1.5PM25X1.542183626523M68

MFZ30X1.5PM30X1.548184331523M68

MFZ35X1.5PM35X1.553184836523M819

MFZ40X1.5PM40X1.55820524162.53M819

MFZ45X1.5PM45X1.56520594662.53M819

MFZ50X1.5PM50X1.57020645162.53M819

MFZ55X2.0PM55X275226856733M819

MFZ60X2.0PM60X280227361733M819

MFZ65X2.0PM65X285227866733M819

MFZ70X2.0PM70X29224847183.53M819

MFZ75X2.0PM75X29824907683.53M819

MFZ80X2.0PM80X210524968183.53M819

MFZ85X2.0PM85X2112241048683.53M819

MFZ90X2.0PM90X211826108911043M819

MFZ95X2.0PM95X212326113961043M819

MFZ100X2.0PM100X2128261181011043M819

MFZ105X2.0PM105X2137261251061046M819

MFZ110X2.0PM110X2145301321111256M819

MFZ115X2.0PM115X2150301371161256M819

MFZ120X2.0PM120X2155301421211256M819

MFZ125X2.0PM125X2160301461261256M819

MFZ130X2.0PM130X2165301521311256M819

MFZ135X2.0PM135X2175301601361256M819

MFZ140X2.0PM140X2180321651411256M1036

MFZ145X2.0PM145X2190321751461256M1036

MFZ150X2.0PM150X2195321801511256M1036

MFZ155X3.0PM155X3200341801561256M1036

MFZ160X3.0PM160X3210341901611256M1036

MFZ170X3.0PM170X3220342001711256M1036

MFZ180X3.0PM180X3230362051811256M1036

MFZ190X3.0PM190X3240362201911256M1036

MFZ200X3.0PM200X3250362302011256M1036

MFZ210X4.0PM210X4270362502111256M1036

MFZ220X4.0PM220X4280362602211256M1036

MFZ230X4.0PM230X4290362702311256M1036

MFZ240X4.0PM240X4300362802411256M1036

MFZ250X4.0PM250X4310362902511256M1036

MFZ260X4.0PM260X4320363002611256M1036

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MFZ30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MFZ30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MFZ30-U18

13 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhdd1g t 3-MMax. Torque_Nm

MFZ A 0.005 h 3-M d0 30。 d1 D d 0.5 A t n-g

TMF Series-30˚ Flank Locking

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

TMF80X2.0PM80X2110309783956.481633M819

TMF85X2.0PM85X211532102881006.481733M1036

TMF90X2.0PM90X212032110931086.481733M1036

TMF95X2.0PM95X212532114981136.481733M1036

TMF100X2.0PM100X2130321201031186.481733M1036

TMF110X2.0PM110X2140321321121286.481733M1036

TMF120X2.0PM120X2155321421221406.481733M1036

TMF130X3.0PM130X3165321561321536.481733M1036

TMF140X3.0PM140X3180321661421656.4101733M1036

TMF150X3.0PM150X3190321801521756.4101755M1036

Whenorderingaboveproducts,pleaserefertotheName.Forexample:TMF30x1.5P Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:TMF30x1.5P-L Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:TMF30-U18

14 Order No. Dimensions in mm Set Screw Data Name d0_ISO 4HD hd1d2d3d4 d5 cb c1 3-M Max. Torque_Nm TMF20X1.0PM20X138183021294.341021M68 TMF25X1.5PM25X1.54220352632.54.341122M68 TMF30X1.5PM30X1.54820403240.54.351122M68 TMF35X1.5PM35X1.55320473845.54.351122M68 TMF40X1.5PM40X1.55822524250.54.351222M68 TMF45X1.5PM45X1.568225848584.361222M68 TMF50X1.5PM50X1.57024635261.54.361322M68 TMF55X1.5PM55X1.57524705866.54.361333M68 TMF60X1.5PM60X1.58424756274.55.361333M68 TMF65X1.5PM65X1.58825806878.55.361333M68 TMF70X1.5PM70X1.595268672855.381433M819 TMF75X1.5PM75X1.5100269177886.481333M819

TMF160X3.0PM160X3205321901621858.4101755M1036 TMF170X3.0PM170X3215322051721958.4101755M1036 TMF180X3.0PM180X3230322151822108.4101755M1036 TMF190X3.0PM190X3240322251922248.4101755M1036 TMF200X3.0PM200X3245322372022298.4101755M1036 Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

TMF A 0.002 h 3-M d0 G G 30。 d2 d1 D c1 b d3 d4 d5 c A

SFZ Series-30˚ Flank Locking

Maximumaxialrun-out:0.005mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecisionturningprocess.

SFZ70X2.0PM70X210028927283.5954M819

SFZ75X2.0PM75X210528977783.51004M819

SFZ80X2.0PM80X2110321008383.5-6M819

SFZ85X2.0PM85X21203211088104-6M1036

SFZ90X2.0PM90X21253211593104-6M1036

SFZ95X2.0PM95X21303212098104-6M1036

SFZ100X2.0PM100X213532125103104-6M1036

SFZ110X2.0PM110X214532134112104-6M1036

SFZ120X2.0PM120X215532144122104-6M1036

SFZ130X2.0PM130X216532154132125-6M1036

SFZ140X2.0PM140X217532164142146-6M1036

SFZ150X2.0PM150X218532174152146-6M1036

SFZ160X3.0PM160X319532184162146-6M1036

SFZ170X3.0PM170X320532194172146-6M1036

SFZ180X3.0PM180X321532204182167-6M1036

SFZ190X3.0PM190X322532214192167-6M1036

SFZ200X3.0PM200X323532224202188-6M1036

Whenorderingaboveproducts,pleaserefertotheName.Forexample:SFZ30x1.5P Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:SFZ30x1.5P-L Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:SFZ30-U18

15 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HD h d d1gtL 3-MMax. Torque_Nm SFZ10X0.75PM10X0.752814231142244M54.8 SFZ12X1.0PM12X13014251342274M54.8 SFZ15X1.0PM15X13316281642304M54.8 SFZ17X1.0PM17X13718331852344M68 SFZ20X1.0PM20X14018352152364M68 SFZ20X1.5PM20X1.54018352152364M68 SFZ25X1.5PM25X1.54420392652414M68 SFZ30X1.5PM30X1.54920443252464M68 SFZ35X1.5PM35X1.55422493852504M68 SFZ40X1.5PM40X1.56522594262.5604M819 SFZ45X1.5PM45X1.57022644862.5654M819 SFZ50X1.5PM50X1.57525685273704M819 SFZ55X2.0PM55X28525785873804M819 SFZ60X2.0PM60X29026826283.5854M819 SFZ65X2.0PM65X29528876883.5904M819

Material:JISSCM440/DIN42CrMo4

SFZ A 0.005 h 3-M d0 30。 d1 D d L t n-g A SFZ80andaboveSFZ75andunder

MR Series-RADIAL Locking

MR25X1.5PM25X1.542123626523M68

MR30X1.5PM30X1.548124331523M68

MR35X1.5PM35X1.553124836523M68

MR40X1.5PM40X1.55814524162.53M68

MR45X1.5PM45X1.56514594662.53M68

MR50X1.5PM50X1.57014645162.53M68

MR55X2.0PM55X275166856733M819

MR60X2.0PM60X280167361733M819

MR65X2.0PM65X285167866733M819

MR70X2.0PM70X29218847183.53M819

MR75X2.0PM75X29818907683.53M819

MR80X2.0PM80X210518968183.53M819

MR85X2.0PM85X2112181048683.53M819

MR90X2.0PM90X211820108911043M819

MR95X2.0PM95X212320113961043M819

MR100X2.0PM100X2128201181011043M819

MR105X2.0PM105X2137201251061046M819

MR110X2.0PM110X2145241321111256M819

MR115X2.0PM115X2150241371161256M819

MR120X2.0PM120X2155241421211256M819

MR125X2.0PM125X2160241471261256M819

MR130X2.0PM130X2165241521311256M819

MR135X2.0PM135X2175241601361256M819

MR140X2.0PM140X2180261651411256M1036

MR145X2.0PM145X2190261751461256M1036

MR150X2.0PM150X2195261801511256M1036

MR155X3.0PM155X3200281801561256M1036

MR160X3.0PM160X3210281901611256M1036

MR165X3.0PM165X3210281901661256M1036

MR170X3.0PM170X3220282001711256M1036

MR180X3.0PM180X3230302101811256M1036

MR190X3.0PM190X3240302201911256M1036

16 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HD hdd1g t 3-MMax. Torque_Nm MR6X0.5PM6X0.516811-323M42.2 MR8X0.75PM8X0.7516811-323M42.2 MR8X1.0PM8X116811-323M42.2 MR10X0.75PM10X0.7518813-323M42.2 MR10X1.0PM10X118813-323M42.2 MR12X1.0PM12X124819-323M42.2 MR15X1.0PM15X128823-323M42.2 MR17X1.0PM17X1321027-423M54.8

MR20X1.0PM20X1351030-423M54.8 MR20X1.5PM20X1.5351030-423M54.8

MR210X4.0PM210X4270302502111256M1036 MR220X4.0PM220X4280302602211256M1036 MR230X4.0PM230X4290302702311256M1036 MR240X4.0PM240X4300302802411256M1036 MR250X4.0PM250X4310302902511256M1036 MR260X4.0PM260X4320303002611256M1036

grinding process. Hardness:HRC28-32Maximumaxialrun-out:0.002mm MR A 0.002 h 3-M d0 d1 G d 0.5 t n-g G D A MR105andaboveMR100andunder

MR200X3.0PM200X3250302302011256M1036

Material:JISSCM440/DIN42CrMo4 Thecontactsurfaceandthreadareaareallproducedbyahighprecision

MRZ Series-RADIAL Locking

MRZ105andaboveMRZ100andunder

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecisionturningprocess.

MRZ30X1.5PM30X1.545124031523M68

MRZ35X1.5PM35X1.552124736523M68

MRZ40X1.5PM40X1.55814524162.53M68

MRZ45X1.5PM45X1.56514594662.53M68

MRZ50X1.5PM50X1.57014645162.53M68

MRZ55X1.5PM55X1.575166856733M819

MRZ55X2.0PM55X275166856733M819

MRZ60X1.5PM60X1.580167361733M819

MRZ60X2.0PM60X280167361733M819

MRZ65X1.5PM65X1.585167866733M819

MRZ65X2.0PM65X285167866733M819

MRZ70X1.5PM70X1.59218847183.53M819

MRZ70X2.0PM70X29218847183.53M819

MRZ75X1.5PM75X1.59818907683.53M819

MRZ75X2.0PM75X29818907683.53M819

MRZ80X2.0PM80X210518968183.53M819

MRZ85X2.0PM85X2112181048683.53M819

MRZ90X2.0PM90X211820108911043M819

MRZ95X2.0PM95X212320113961043M819

MRZ100X2.0PM100X2128201181011043M819

MRZ105X2.0PM105X2137201251061046M819

MRZ110X2.0PM110X2145241321111256M819

MRZ115X2.0PM115X2150241371161256M819

MRZ120X2.0PM120X2155241421211256M819

MRZ125X2.0PM125X2160241471261256M819

MRZ130X2.0PM130X2165241521311256M819

MRZ135X2.0PM135X2175241601361256M819

MRZ140X2.0PM140X2180261651411256M1036

MRZ145X2.0PM145X2190261751461256M1036

MRZ150X2.0PM150X2195261801511256M1036

MRZ155X3.0PM155X3200281801561256M1036

MRZ160X3.0PM160X3210281901611256M1036

MRZ165X3.0PM165X3215281951661256M1036

MRZ170X3.0PM170X3220282001711256M1036

MRZ180X3.0PM180X3230302101811256M1036

MRZ190X3.0PM190X3240302201911256M1036

MRZ200X3.0PM200X3250302302011256M1036

17 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HD hdd1 g t3-MMax. Torque_Nm MRZ6X0.5PM6X0.516811-323M42.2 MRZ8X0.75PM8X0.7516811-323M42.2 MRZ8X1.0PM8X116811-323M42.2 MRZ10X0.75PM10X0.7518813-323M42.2 MRZ10X1.0PM10X118813-323M42.2 MRZ12X1.0PM12X120818-323M42.2 MRZ15X1.0PM15X125821-323M42.2 MRZ17X1.0PM17X1281023-423M54.8

MRZ20X1.0PM20X1321027-423M54.8

MRZ20X1.5PM20X1.5321027-423M54.8 MRZ25X1.5PM25X1.538123326523M68

MRZ A 0.005 h 3-M d0 d 0.5 t n-g D d1 A

SR Series-RADIAL Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

SR10X0.75PM10X0.7518813324M42.2

SR10X1.0PM10X118813324M42.2

SR12X1.0PM12X122818324M42.2

SR15X1.0PM15X125821324M42.2

SR17X1.0PM17X1281023424M54.8

SR20X1.0PM20X1321027424M54.8

SR20X1.5PM20X1.5321027424M54.8

SR25X1.5PM25X1.5381233524M68

SR30X1.5PM30X1.5451240524M68

SR35X1.5PM35X1.5521247524M68

SR40X1.5PM40X1.558145262.54M68

SR45X1.5PM45X1.565145962.54M68

SR50X1.5PM50X1.570146462.54M68

SR55X2.0PM55X2751668734M68

SR60X2.0PM60X2801673734M68

SR65X2.0PM65X2851678734M68

SR70X2.0PM70X292188583.54M819

SR75X2.0PM75X298189083.54M819

SR80X2.0PM80X2105189583.54M819

SR85X2.0PM85X21101810283.54M819

SR90X2.0PM90X2120201081044M819

SR95X2.0PM95X2125201131044M819

SR100X2.0PM100X2130201201044M819

SR105X2.0PM105X2140221261254M1036

SR110X2.0PM110X2145221331254M1036

SR115X2.0PM115X2150221371254M1036

SR120X2.0PM120X2155241381254M1036

SR125X2.0PM125X2160241481254M1036

SR130X2.0PM130X2165241491254M1036

SR135X2.0PM135X2175261601464M1260

SR140X2.0PM140X2180261601464M1260

SR145X2.0PM145X2190261721464M1260

SR150X2.0PM150X2195261711464M1260

SR155X3.0PM155X3200281821674M1260

SR160X3.0PM160X3210281821674M1260

SR165X3.0PM165X3210281931674M1260

SR170X3.0PM170X3220281931674M1260

SR180X3.0PM180X3230302031884M1260

SR190X3.0PM190X3240302141884M1260

SR200X3.0PM200X3250322261884M1260

Whenorderingaboveproducts,pleaserefertotheName.Forexample:SR30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:SR30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:SR30-U18

18 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HD hdg t 2-MMax. Torque_Nm SR6X0.5PM6X0.516811324M42.2 SR8X0.75PM8X0.7516811324M42.2

SR8X1.0PM8X116811324M42.2

SR A 0.002 h 2-M d0 G d 0.5 D G A t n-g

SRZ Series-RADIAL Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecisionturningprocess.

SRZ10X0.75PM10X0.7518813324M42.2

SRZ10X1.0PM10X118813324M42.2

SRZ12X1.0PM12X122818324M42.2

SRZ15X1.0PM15X125821324M42.2

SRZ17X1.0PM17X1281023424M54.8

SRZ20X1.0PM20X1321027424M54.8

SRZ20X1.5PM20X1.5321027424M54.8

SRZ25X1.5PM25X1.5381233524M68

SRZ30X1.5PM30X1.5451240524M68

SRZ35X1.5PM35X1.5521247524M68

SRZ40X1.5PM40X1.558145262.54M68

SRZ45X1.5PM45X1.565145962.54M68

SRZ50X1.5PM50X1.570146462.54M68

SRZ55X2.0PM55X2751668734M68

SRZ60X2.0PM60X2801673734M68

SRZ65X2.0PM65X2851678734M68

SRZ70X2.0PM70X292188583.54M819

SRZ75X2.0PM75X298189083.54M819

SRZ80X2.0PM80X2105189583.54M819

SRZ85X2.0PM85X21101810283.54M819

SRZ90X2.0PM90X2120201081044M819

SRZ95X2.0PM95X2125201131044M819

SRZ100X2.0PM100X2130201201044M819

SRZ105X2.0PM105X2140221261254M1036

SRZ110X2.0PM110X2145221331254M1036

SRZ115X2.0PM115X2150221371254M1036

SRZ120X2.0PM120X2155241381254M1036

SRZ125X2.0PM125X2160241481254M1036

SRZ130X2.0PM130X2165241491254M1036

SRZ135X2.0PM135X2175261601464M1260

SRZ140X2.0PM140X2180261601464M1260

SRZ145X2.0PM145X2190261721464M1260

SRZ150X2.0PM150X2195261711464M1260

SRZ155X3.0PM155X3200281821674M1260

SRZ160X3.0PM160X3210281821674M1260

SRZ165X3.0PM165X3210281931674M1260

SRZ170X3.0PM170X3220281931674M1260

SRZ180X3.0PM180X3230302031884M1260

SRZ190X3.0PM190X3240302141884M1260

SRZ200X3.0PM200X3250322261884M1260

Whenorderingaboveproducts,pleaserefertotheName.Forexample:SRZ30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:SRZ30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:SRZ30-U18

19 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HD hdg t 2-MMax. Torque_Nm SRZ6X0.5PM6X0.516811324M42.2 SRZ8X0.75PM8X0.7516811324M42.2

SRZ8X1.0PM8X116811324M42.2

SRZ A 0.005 h 2-M d0 d 0.5 D A t n-g

MRRA Series-RADIAL Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

MRRA20/52M20X1522547524M54.8

MRRA20/52M20X1.5522547524M54.8

MRRA25/45M25X1.5452040524M68

MRRA25/58M25X1.558245262.54M68

MRRA30/52M30X1.5522247524M68

MRRA30/65M30X1.565305962.54M68

MRRA35/58M35X1.558225262.54M68

MRRA35/70M35X1.570306462.54M68

MRRA40/62M40X1.562225662.54M819

MRRA40/75M40X1.575306962.54M819

MRRA45/68M45X1.568246262.54M819

MRRA45/85M45X1.5853278734M819

MRRA50/75M50X1.575256862.54M819

MRRA50/92M50X1.592328483.54M819

MRRA55/98M55X298329083.54M819

MRRA60/98M60X298329083.54M819

MRRA65/105M65X2105329783.54M819

MRRA70/110M70X21103510283.54M819

MRRA75/125M75X21253811783.54M819

MRRA80/120M80X2120351051044M819

MRRA90/130M90X2130381201044M819

MRRA90/155M90X2155381461044M819

MRRA100/140M100X2140381281254M1036

MRRA110/180M110X2180401671464M1036

MRRA130/210M130X2210402051674M1036

MRRA150/230M150X2230422151884M1256

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MRRA50/75 Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MRRA50/75-L Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MRRA50/75-U18

20 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HD hdgt 2-MMax. Torque_Nm MRRA15/32M15X1322027424M54.8 MRRA17/38M17X1382033524M54.8 MRRA20/38M20X1382033524M54.8

MRRA20/38M20X1.5382033524M54.8

MRRA A 0.002 h 2-M d0 G d 0.5 D G A t n-g

MRN Series-FOR LIGHT-DUTY

Material:JISSCM440/DIN42CrMo4

Maximumaxialrun-out:0.005mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecisionturningprocess.

MRS Series-FOR FOOD, PHARMACeUTICAL,

& SeMICONDUCTOR EQUIPMeNT

Material:JISSUS304_Fullystainlesssteel(stainlesspinandsetscrewincluded) Maximumaxialrun-out:0.005mm

MRS15X1.0PM15X125821-323M42.2

MRS17X1.0PM17X1281023-423M54.8

21 Order No. Dimensions in mm Set Screw Data Name d0_ISO 4H D hd cL 2-MMax. Torque_Nm MRN05X0.5PM5X0.512.5582.311M30.9 MRN06X0.75PM6X0.7513.5592.312M30.9 MRN08X1.0PM8X1166.5112.514M30.9 MRN10X1.0PM10X1198132.516M30.9 MRN12X1.0PM12X1228162.519M42.2 MRN15X1.0PM15X1258193.2522M42.2 MRN17X1.0PM17X1291321424M42.2 MRN20X1.0PM20X1351127430M42.2 MRN25X1.5PM25X1.5431532535M68 MRN30X1.5PM30X1.5482037640M68 MRN35X1.5PM35X1.5602147750M68 MRN40X1.5PM40X1.5622547750M68 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4H D hd d1gt 3-M Max. Torque_Nm MRS06X0.5PM6X0.516811-323M42.2

MRS08X0.75PM8X0.7516811-323M42.2 MRS08X1.0PM8X116811-323M42.2 MRS10X0.75PM10X0.7518813-323M42.2 MRS10X1.0PM10X118813-323M42.2 MRS12X1.0PM12X120818-323M42.2

MRS20X1.0PM20X1321027-423M54.8 MRS20X1.5PM20X1.5321027-423M54.8 MRS25X1.5PM25X1.538123326523M68 MRS30X1.5PM30X1.545124031523M68 MRS35X1.5PM35X1.552124736523M68 MRS40X1.5PM40X1.55814524162.53M68

MRS45X1.5PM45X1.56514594662.53M68 MRS50X1.5PM50X1.57014645162.53M68

MRN MRS A 0.005 h 3-M d1 d0 D 0.5 d A A 0.005 h c D d d0 0.5 2-M L t n-g A NEW NEW NEW NEW TRANSMISSION

CHeMICAL

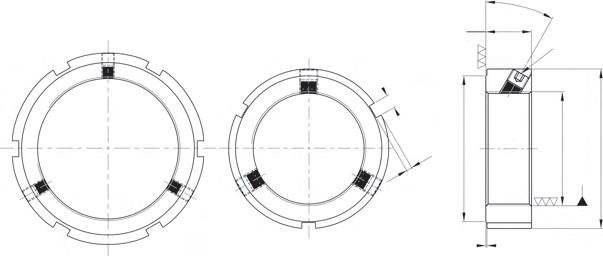

MKR Series-AXIAL Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceisproducedbyahighprecision grinding process.

MKR45X1.5PM45X1.56822--584.366.50.626-M4X165.5

MKR48X1.5PM48X1.56825--59.54.3690.586-M4X185.5

MKR50X1.5PM50X1.57025--61.54.3690.566-M4X185.5

MKR52X1.5PM52X1.57225--63.54.3690.546-M4X185.5

MKR55X1.5PM55X1.57525--66.54.3690.516-M4X185.5

MKR55X2.0PM55X27525--66.54.3690.686-M4X185.5

22 Order No. Dimensions in mm Helical Angle Clamping Screw Data Name d0_ISO 4HDhed1d2d3d4c n-MMax. Torque_Nm MKR10X0.75PM10X0.7524146.622173.22.531.443-M3X103 MKR10X1.0PM10X124156.622173.22.531.953-M3X103 MKR12X1.0PM12X126146.625193.2331.613-M3X103 MKR12X1.5PM12X1.526156.625193.2332.483-M3X103 MKR14X1.5PM14X1.532167.63022.54.3432.103-M4X105.5 MKR15X1.0PM15X133167.63123.54.3431.273-M4X105.5 MKR16X1.5PM16X1.53418--24.54.3451.824-M4X125.5 MKR17X1.0PM17X13518--25.54.3451.214-M4X125.5 MKR18X1.5PM18X1.53618--26.54.3451.614-M4X125.5 MKR20X1.0PM20X14018--30.54.3450.944-M4X125.5 MKR20X1.5PM20X1.54018--30.54.3451.444-M4X125.5 MKR22X1.5PM22X1.54018--30.54.3451.304-M4X125.5 MKR24X1.5PM24X1.54218--32.54.3451.194-M4X125.5 MKR25X1.5PM25X1.54520--36.54.356.51.144-M4X145.5 MKR26X1.5PM26X1.54520--36.54.356.51.094-M4X145.5 MKR28X1.5PM28X1.54620--38.54.356.51.014-M4X145.5 MKR30X1.5PM30X1.54820--40.54.356.50.944-M4X145.5 MKR32X1.5PM32X1.55022--42.54.3570.884-M4X165.5

MKR35X1.5PM35X1.55322--45.54.3570.804-M4X165.5 MKR38X1.5PM38X1.55822--48.54.3570.744-M4X165.5 MKR40X1.5PM40X1.55822--50.54.3570.704-M4X165.5 MKR42X1.5PM42X1.56022--52.54.3570.674-M4X165.5

MKR A 0.005 h d0 G n-M e d4 c d1 D d2 d3 A MKR10-MKR15

MKR Series-AXIAL Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceisproducedbyahighprecision grinding process.

MKR75X2.0PM75X210028--886.488.50.506-M6X2012

MKR80X2.0PM80X211032--956.48110.466-M6X2012

MKR85X2.0PM85X211532--1006.48110.446-M6X2012

MKR90X2.0PM90X212032--1086.48110.416-M6X2012

MKR95X2.0PM95X212532--1136.48110.396-M6X2012

MKR100X2.0PM100X213032--1186.48110.376-M6X2012

MKR105X2.0PM105X213532--1236.48110.356-M6X2012

MKR110X2.0PM110X214032--1286.48110.346-M6X2012

MKR115X2.0PM115X214536--1336.48130.326-M6X2512

MKR120X2.0PM120X215536--1406.48130.316-M6X2512

MKR125X2.0PM125X216036--1486.48130.296-M6X2512

MKR130X3.0PM130X316536--1536.48130.436-M6X2512

MKR140X3.0PM140X318036--1656.410120.408-M6X2512

MKR150X3.0PM150X319036--1756.410120.378-M6X2512

MKR160X3.0PM160X320540--1858.410140.358-M8X3025.5

MKR170X3.0PM170X321540--1958.410140.338-M8X3025.5

MKR180X3.0PM180X323040--2108.410140.318-M8X3025.5

MKR190X3.0PM190X324040--2248.410140.298-M8X3025.5

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MKR30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MKR30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MKR30-U18

23 Order No. Dimensions in mm Helical Angle Clamping Screw Data Name d0_ISO 4HDhed1d2d3d4c n-MMax. Torque_Nm MKR58X1.5PM58X1.58226--72.55.3690.486-M5X189 MKR60X1.5PM60X1.58426--74.55.3690.466-M5X189 MKR60X2.0PM60X28426--74.55.3690.626-M5X189 MKR62X1.5PM62X1.58628--76.55.3610.50.456-M5X209 MKR65X1.5PM65X1.58828--78.55.3610.50.436-M5X209 MKR65X2.0PM65X28828--78.55.3610.50.576-M5X209 MKR68X1.5PM68X1.59528--835.389.50.416-M5X209 MKR70X1.5PM70X1.59528--855.389.50.406-M5X209 MKR70X2.0PM70X29528--855.389.50.536-M5X209 MKR72X1.5PM72X1.59828--866.488.50.396-M6X2012 MKR75X1.5PM75X1.510028--886.488.50.376-M6X2012

MKR200X3.0PM200X324540--2298.410140.288-M8X3025.5

MKR MKR16-MKR200 A 0.005 h d0 G n-M d4 c D d2 d3 A

MA Series-AXIAL Locking

Material:JISSCM440/DIN42CrMo4

Hardness:HRC28-32Maximumaxialrun-out:0.002mm

Thecontactsurfaceandthreadareaareallproducedbyahighprecision grinding process.

MA35X1.5PM35X1.5521747524.54M54.8

MA40X1.5PM40X1.558195262.55.24M68

MA45X1.5PM45X1.565195962.55.24M68

MA50X1.5PM50X1.570196462.55.24M68

MA55X2.0PM55X2752168735.24M68

MA60X2.0PM60X2802173735.24M68

MA65X2.0PM65X2852178735.24M68

MA70X2.0PM70X292238583.574M819

MA75X2.0PM75X298239083.574M819

MA80X2.0PM80X2105239583.574M819

MA85X2.0PM85X21102310283.574M819

MA90X2.0PM90X21202510810474M819

MA95X2.0PM95X21252511310474M819

MA100X2.0PM100X21302512010474M819

MA105X2.0PM105X2140271261258.74M1036

MA110X2.0PM110X2145271331258.74M1036

MA115X2.0PM115X2150271371258.74M1036

MA120X2.0PM120X2155291381258.74M1036

MA125X2.0PM125X2160291481258.74M1036

MA130X2.0PM130X2165291491258.74M1036

MA135X2.0PM135X21753116014610.74M1256

MA140X2.0PM140X21803116014610.74M1256

MA145X2.0PM145X21903117214610.74M1256

MA150X2.0PM150X21953117114610.74M1256

MA160X3.0PM160X32103318216710.74M1256

MA170X3.0PM170X32203319316710.74M1256

MA180X3.0PM180X32303520318810.74M1256

MA190X3.0PM190X32403521418810.74M1256

MA200X3.0PM200X32503722618810.74M1256

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MA30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MA30x1.5P-L

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MA30-U18

24 Order No. Dimensions in mm n Set Screw Data Name d0_ISO 4HDhdg t d12-MMax .Torque_Nm

MA20X1.0PM20X1321527423.54M42.2

MA17X1.0PM17X1281523423.54M42.2

MA25X1.5PM25X1.5381733524.54M54.8 MA30X1.5PM30X1.5451740524.54M54.8

MA A 0.002 h d0 G G D d1 n-g t 2-M d 0.5 A

MKK Series-AXIAL Locking

A 0.005 h G

n-M d0 D A K

Material:JISSCM440/DIN42CrMo4

MKK45MKK40andunder

andabove

Hardness:HRC28-32Maximumaxialrun-out:0.005mm

Thecontactsurfaceisproducedbyahighprecision grinding process.

MKK15X1.0PM15X1301845454-M54.8

MKK17X1.0PM17X1321845454-M54.8

MKK20X1.0PM20X1381845464-M68

MKK25X1.5PM25X1.5452056564-M68

MKK30X1.5PM30X1.5522056574-M68

MKK30/65M30X1.5653066684-M68

MKK35/58M35X1.5582056574-M68

MKK35X1.5PM35X1.5652266684-M68

MKK40X1.5PM40X1.5652266684-M68

MKK40/85M40X1.5853266684-M68

MKK45X1.5PM45X1.5702266686-M68

MKK50X1.5PM50X1.5752568686-M68

MKK55X2.0PM55X2852668686-M819

MKK60X2.0PM60X2902668686-M819

MKK65X2.0PM65X210026888106-M819

MKK70X2.0PM70X210028898106-M819

MKK75X2.0PM75X2115308108106-M1036

MKK80X2.0PM80X2110308108106-M1036

MKK85X2.0PM85X2115308108106-M1036

MKK90X2.0PM90X2130328138106-M1036

MKK95X2.0PM95X2130308108108-M1036

MKK100X2.0PM100X2130308108108-M1036

MKK110X2.0PM110X2140308108108-M1036

MKK120X2.0PM120X2155308108108-M1036

MKK130X2.0PM130X2165308108108-M1036

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MKK30x1.5P

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MKK30x1.5P-L

25 Order No. Dimensions in mm Clamping Screw Data Name d0_ISO 4HDhKE F Gn-MMax. Torque_Nm

MKK

Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MKK30-U18 G F E

MKW Series-AXIAL Locking

Material:JISSCM440/DIN42CrMo4 Thecontactsurfaceisproducedbyahighprecision grinding process.

Hardness:HRC25-28Maximumaxialrun-out:0.005mm

MKW50-46M50X1.59546756104116-M4X145.5

MKW55-46M55X1.510046806104126-M5X169

MKW60-46M60X1.510046856104126-M5X169

MKW65-46M65X1.511046906104126-M5X169

MKW70-46M70X1.511546956104126-M5X169

Whenorderingaboveproducts,pleaserefertotheName.Forexample:MKW40-28

Ifalefthandthreadisrequired,pleasenotify“L”aftertheName.Forexample:MKW40-28-L Ifaninchthreadisrequired,pleasenotify“U”aftertheName.Forexample:MKW40-28-U18

26 Order No. Dimensions in mm Clamping Screw Data Name d0_ISO 4HDhd1ng t Ln-MMax. Torque_Nm MKW20-28M20X1.5422838462.5114-M4X145.5 MKW25-28M25X1.5472843473114-M4X145.5 MKW30-28M30X1.5522848473114-M4X145.5 MKW35-28M35X1.5602853483.5114-M4X145.5 MKW40-28M40X1.5652858683.5116-M4X145.5 MKW45-28M45X1.5702863683.5116-M4X145.5 MKW50-32M50X1.5753268683.5116-M4X145.5 MKW20-40M20X1.5524042473114-M4X145.5 MKW25-40M25X1.5624047483.5114-M4X145.5 MKW30-44M30X1.5684452483.5114-M4X145.5 MKW35-44M35X1.5734460483.5114-M4X145.5 MKW40-44M40X1.5754462683.5116-M4X145.5 MKW45-44M45X1.59044706104116-M4X145.5

MKW35 and under MKW40 and above A 0.005 h d0 G D d1 L n-g t A

MKW

CUSTOMIZeD LOCKNUTS

Full Grinding Locknuts

ODM Projects

Outer Locknuts

MOUNTING TOOLS

HSIANG KAI FU provides turnkey locking solutions. NIKKI mounting tools can effectively prevent the single point of force applied to the locknuts compared with traditional tools. With NIKKI mounting tools, our clients assemble the precision locknuts more conveniently and accurately while saving the locking workforce.

Applicabletothefront/rearendofaspindleorthe pre-tensioned/motorendofaballscrew

Applicabletotherearendofaspindleorthe pre-tensionedendofaballscrew

Highlydurable

Convenientandeasytouse

Increaseaccuracyoflocknutassembly

27

NIKKI Collar

NIKKI Socket

Locknutswithsetscrews

Step 1: Wash the spindle / ball screw and locknut with oil cleaner and air dry them Step 2: Add lubricating oil onto the thread of the spindle / ball screw and locknut Step 3: Use appropriate tool and torque wrench to do the fixation Step 4: Drive the setscrews tightly

Locknutswithclampingscrews

assembly guide disassembly guide

Step 1: Wash the spindle / ball screw and locknut with oil cleaner and air dry them; loosen the clamping screws of the locknut Step 2: Add lubricating oil onto the thread of the spindle / ball screw and locknut Step 3: Use appropriate tool and torque wrench to do the fixation Step 4: Drive the socket head screws tightly

Locknutswithsetscrews

Step1:Loosenthesetscrews andcleanthespindle/ ballscrew

Locknutswithclampingscrews

Step2:Loosenthelocknutby

28

1. cleaner 2. 3. 4.

1. 2. 3. 4. cleaner 1. 2. 3. 4. 1. 2. 3. 4. 1. 2. 3. 4.

TorqueandForceCalculationFormula

T = F * K ( N*M )

K = 1/2 { dp * tan ( P*+ß ) + dw * uw } x 10-3 (m)

T: Nut locking torque

F: Nut tightening force

dp: Nut effective diameter (mm)

P*: Thread friction angle, P* = tan-1µs

ß: Nut lead angle, ß = tan-1 ( pitch/3.142*dp )

µs: Coefficient of friction for nut connecting face ; uw = us ≒ 0.15

dw: The average diameter of friction torgue for nut connecting face.

D+d (mm) ; dw = –––––2

StaticAxialLoadCalculationFormula

F = A * Sh * n

F: Axial Load

A: The area of each thread

Sh: Allowed shearing stress ( Safety factor = 4 )

n: Number of effective thread

Loosening Torque

Static Axial Load

Remarks:

(1)Thedataareforreferenceonly.

(2)1N*M=10.2kgf*cm=0.73lb*ft

ThreadingProfile

29

Traditional threading surface profile

Threading surface profile by NIKKI’s precision grinding process

TEchnical

(Kg*cm)

information

HSIANG KAI FU CO., LTD .

No. 9, Jingke 6th Rd., Nantun Dist., Taichung City 40852, Taiwan

TEL: +886 4 2350-2590

FAX: +886 4 2350-3161

Email: service@nikki.com.tw

CAT.NO. 2022 JULY 1000-66