Lab F, Group B, Project Option A

The City as the Technology of Exchange

Yu-Jen Shih

Harjyot Singh

Yuchen Guo

1.Introduction

Team Members

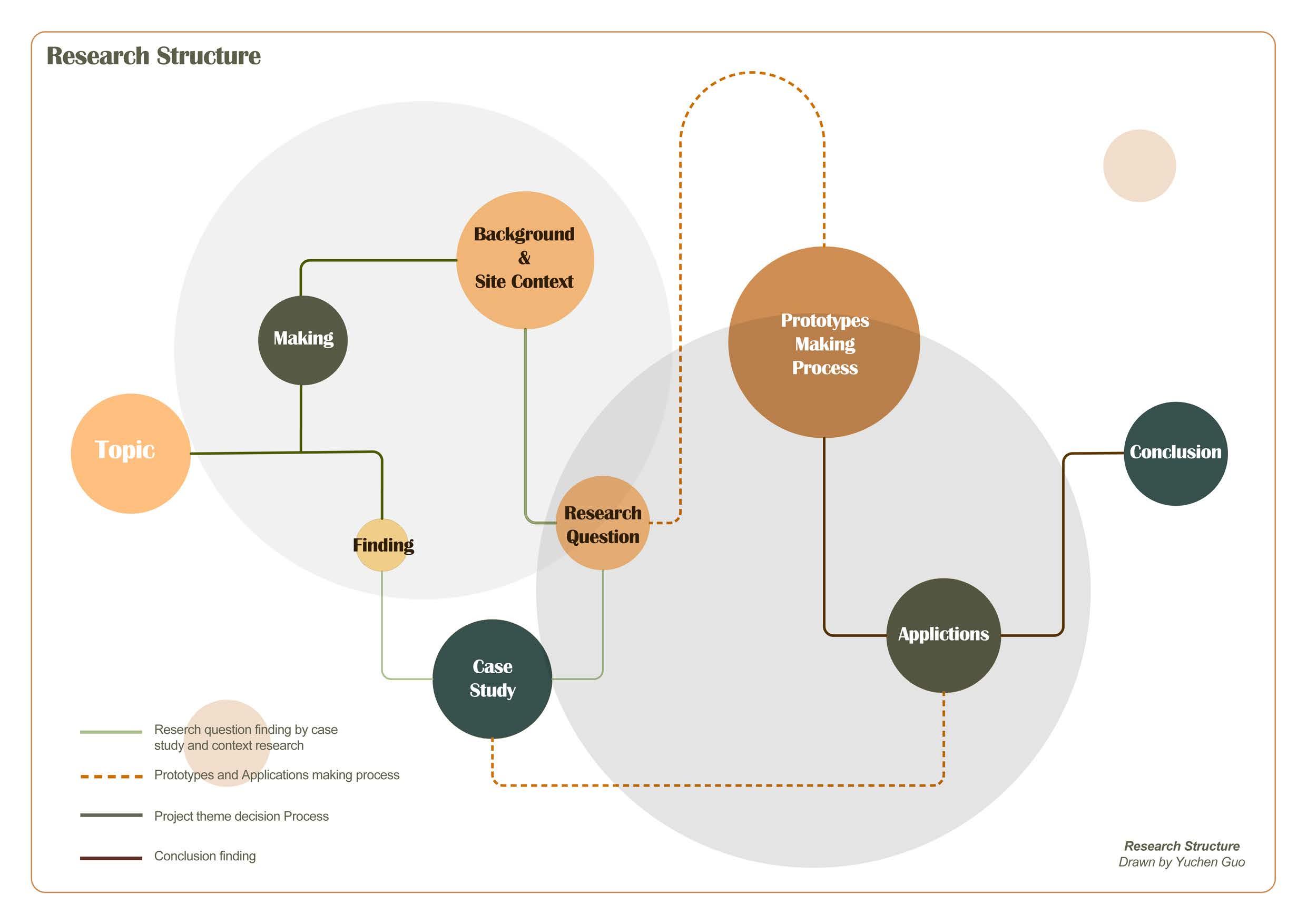

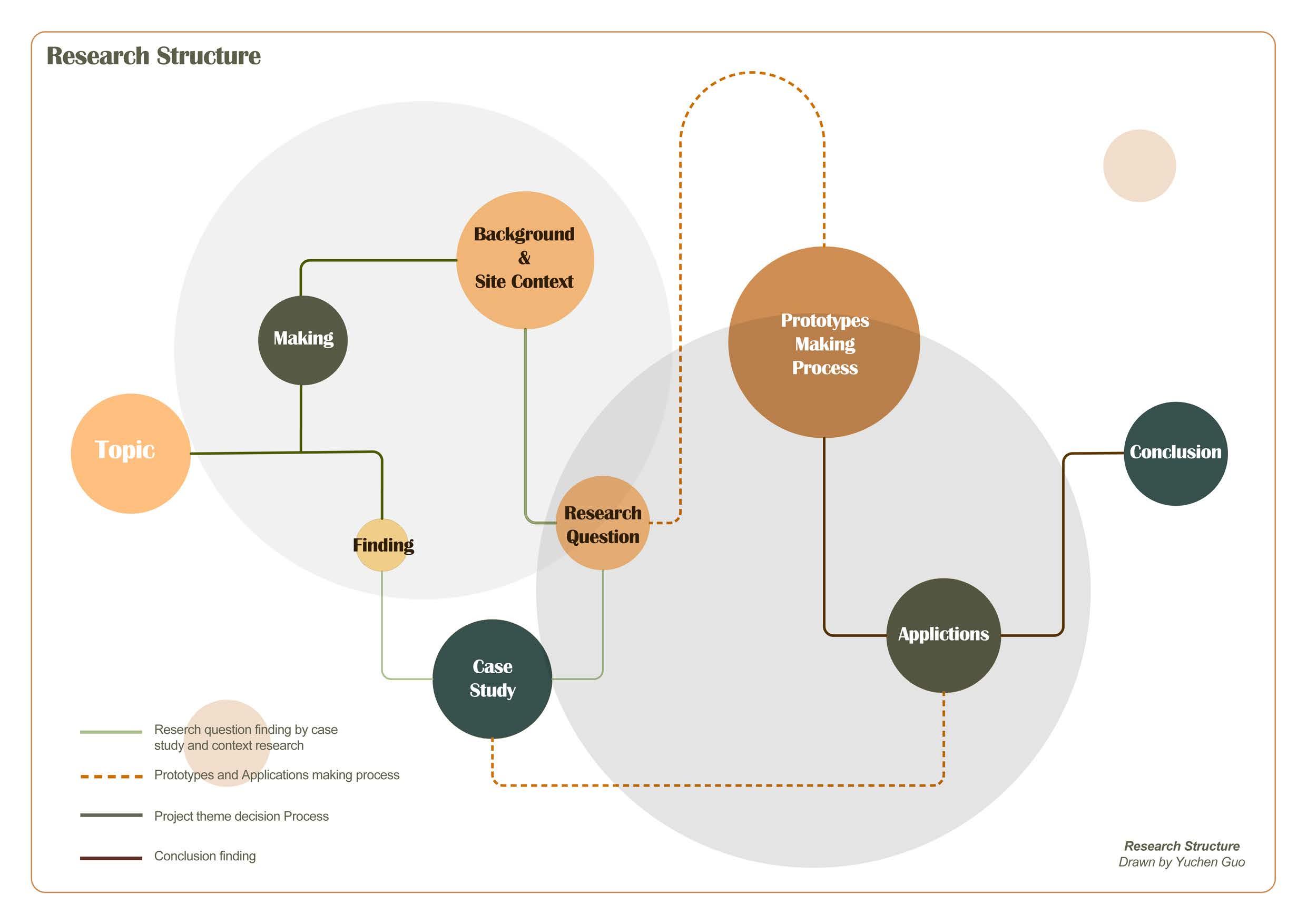

Research Structure

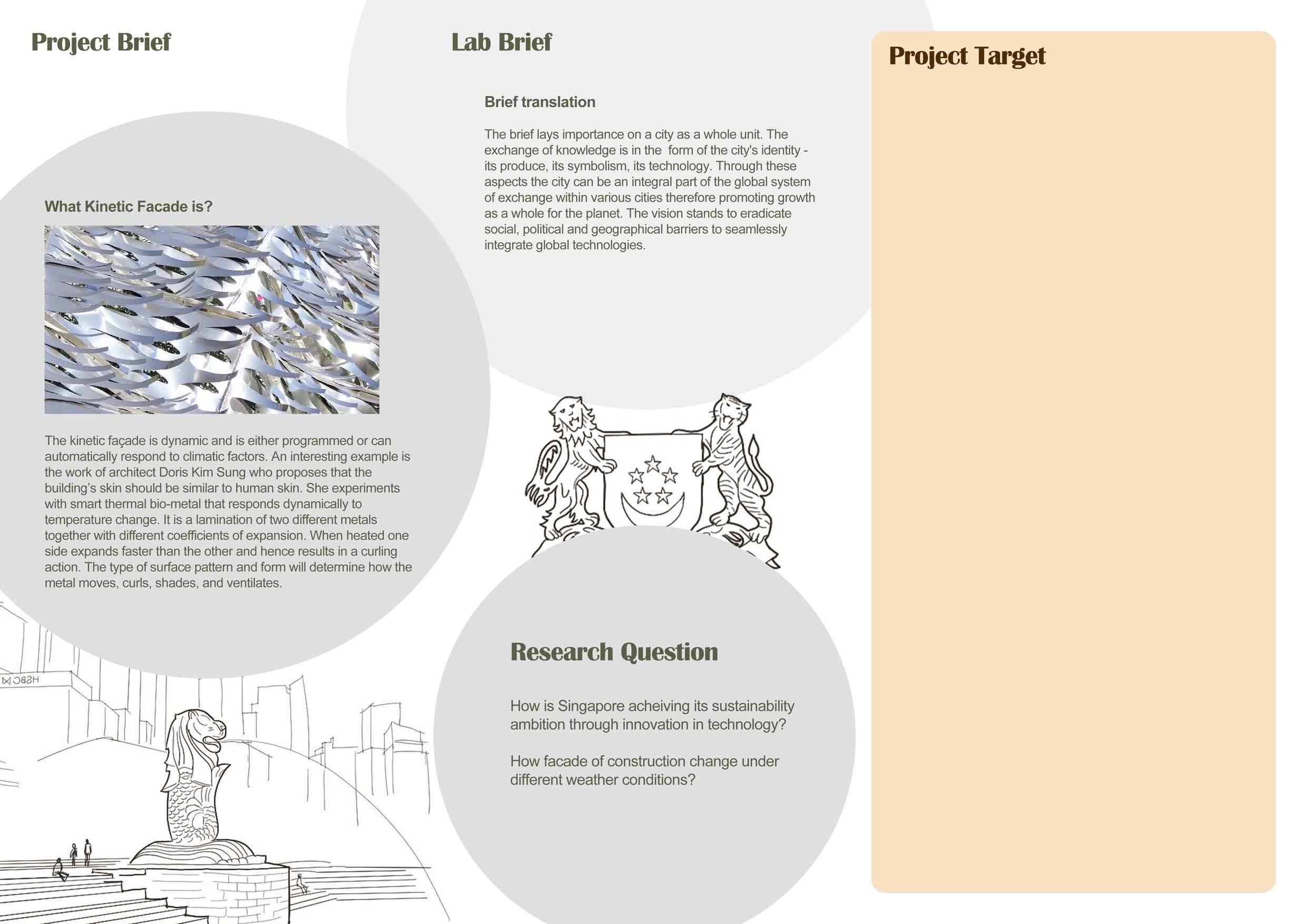

Lab Brief

Topic Selection

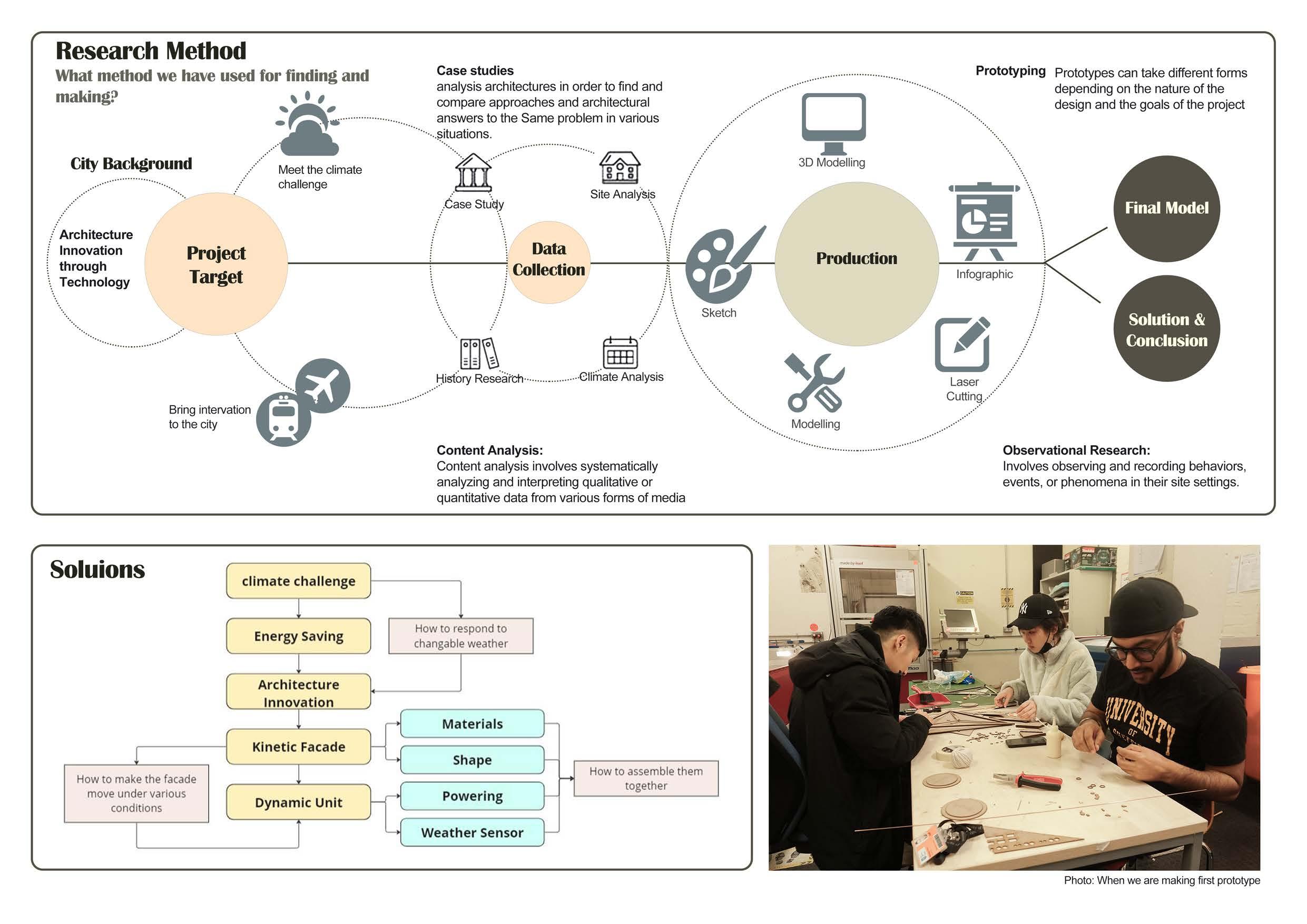

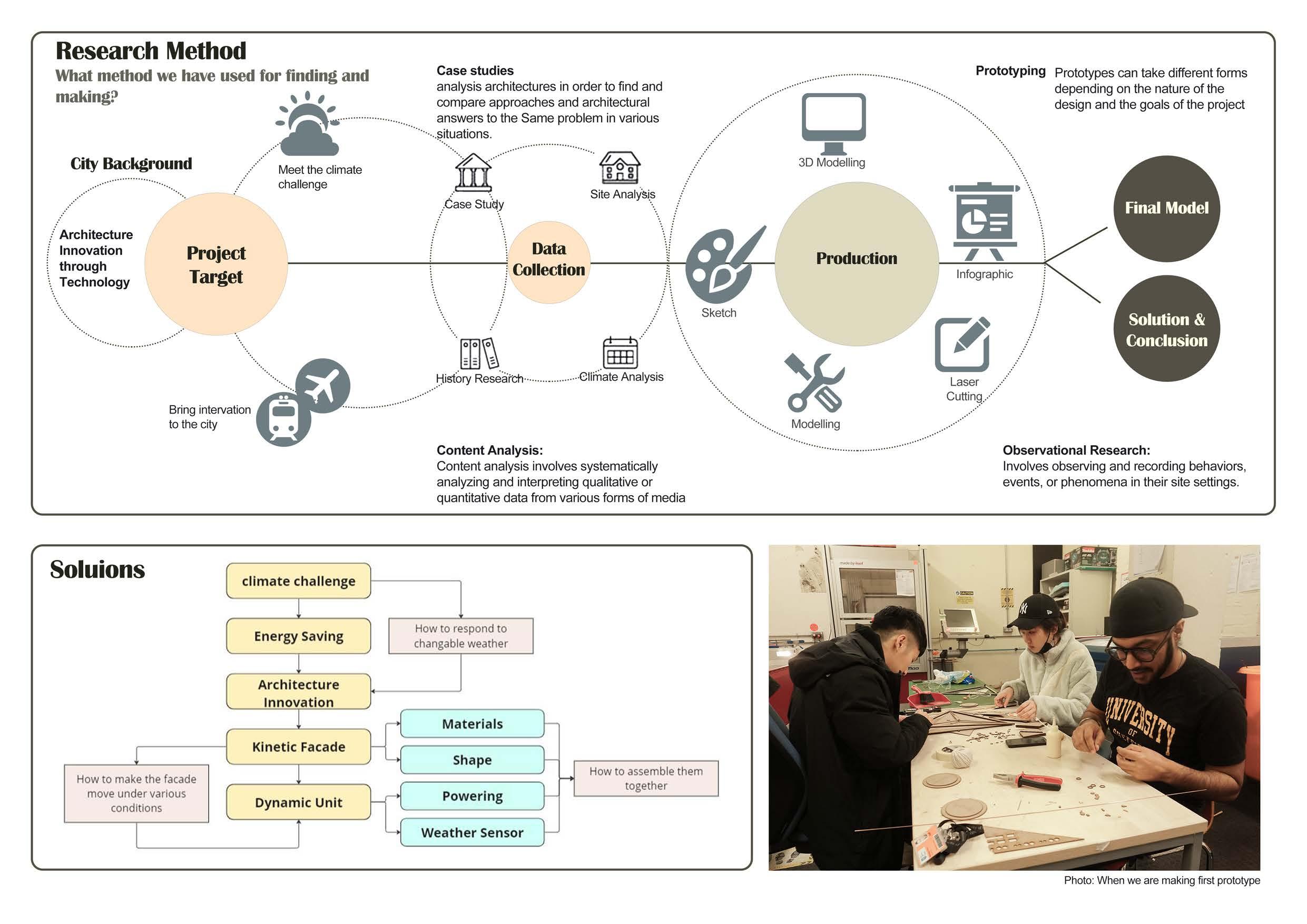

Research Method

2.Background Research

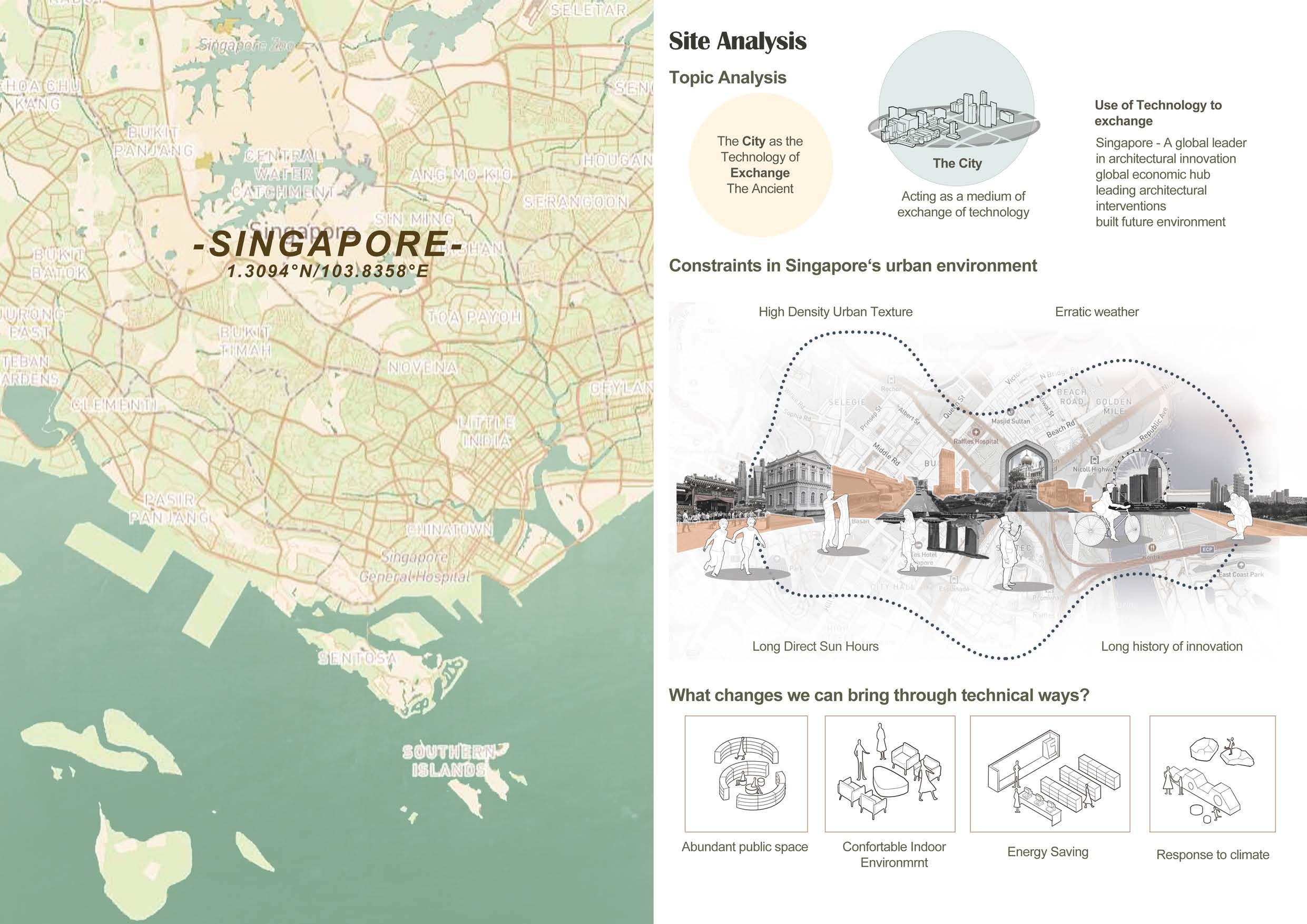

Site Analysis

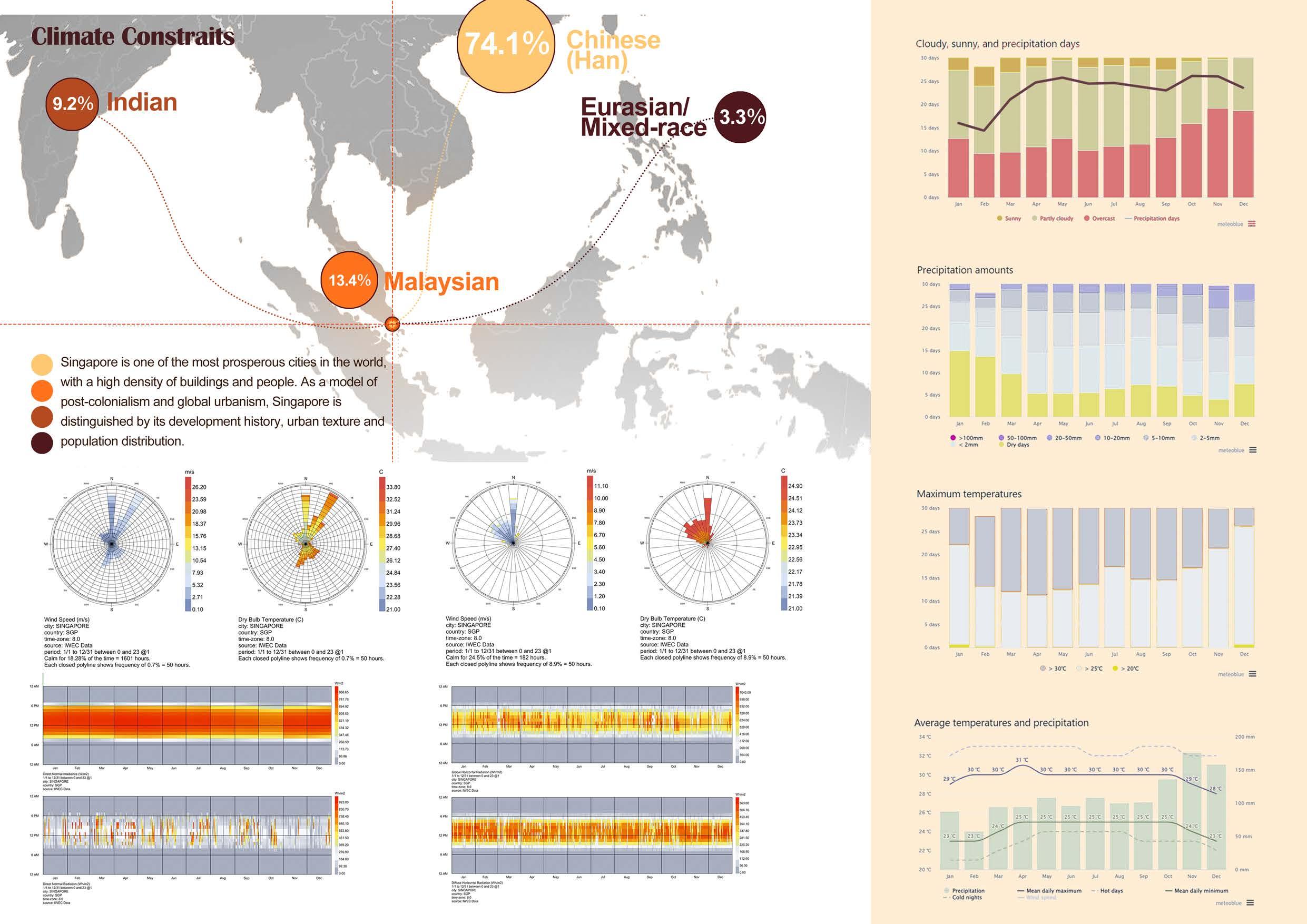

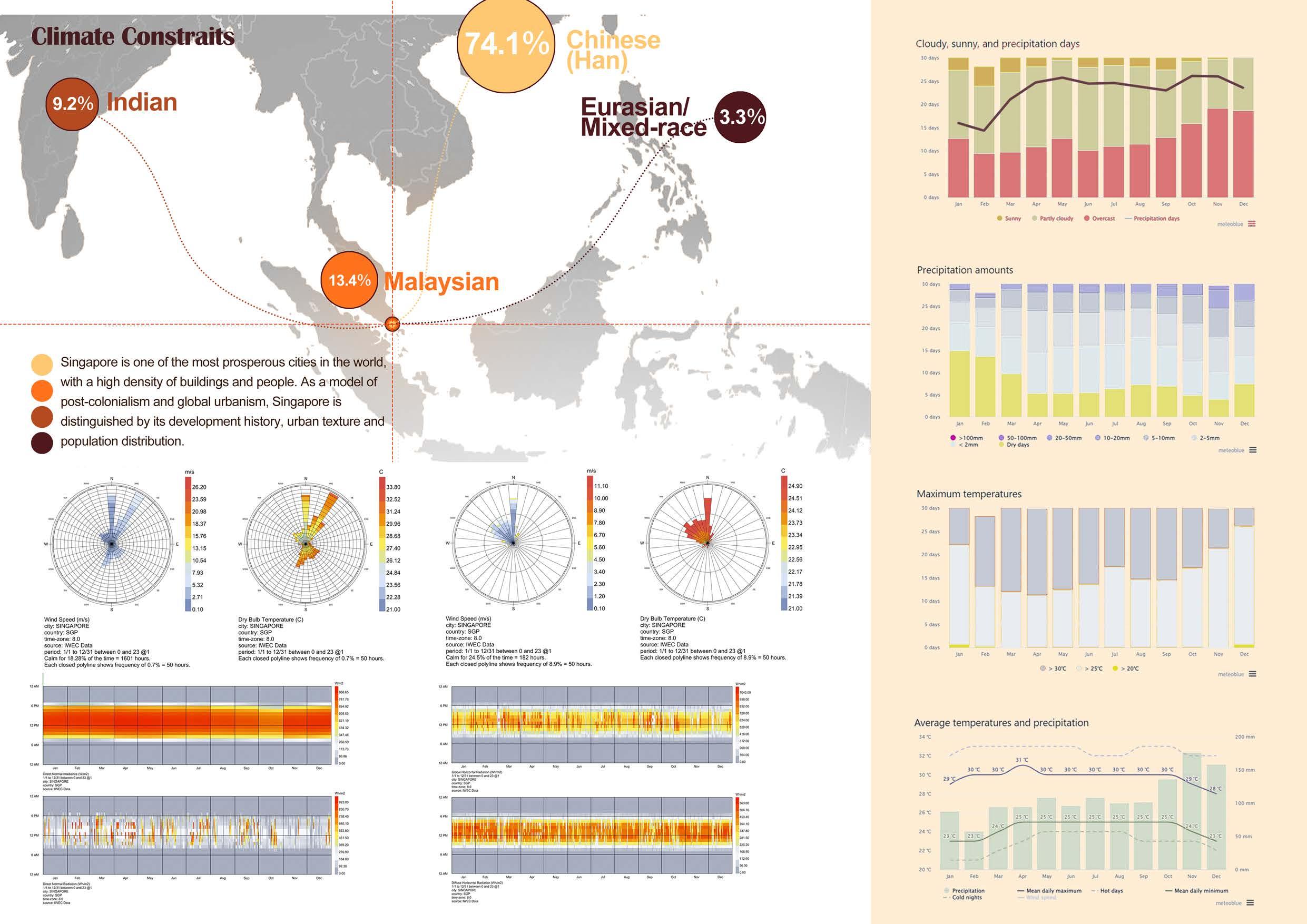

Climate Conditions

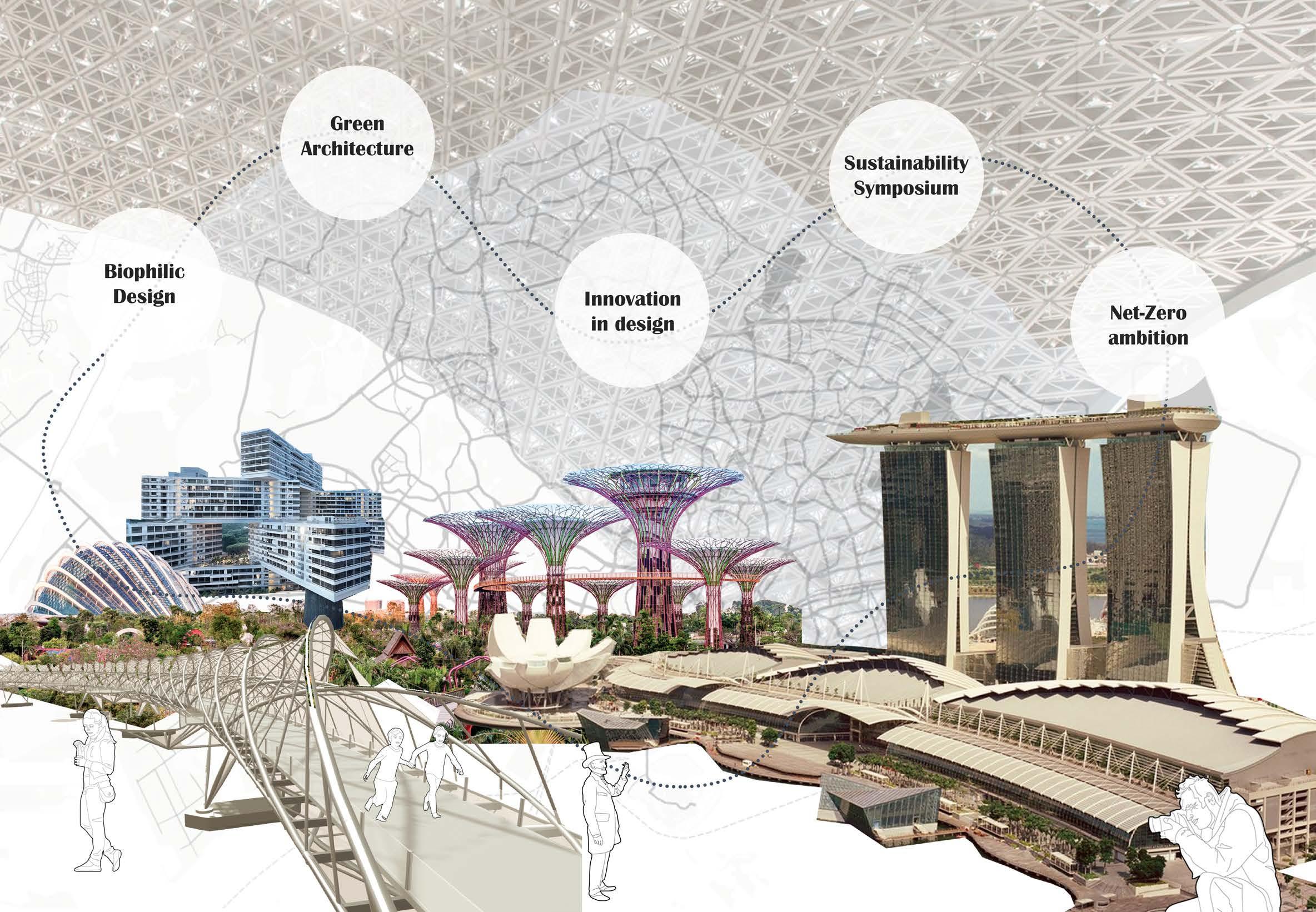

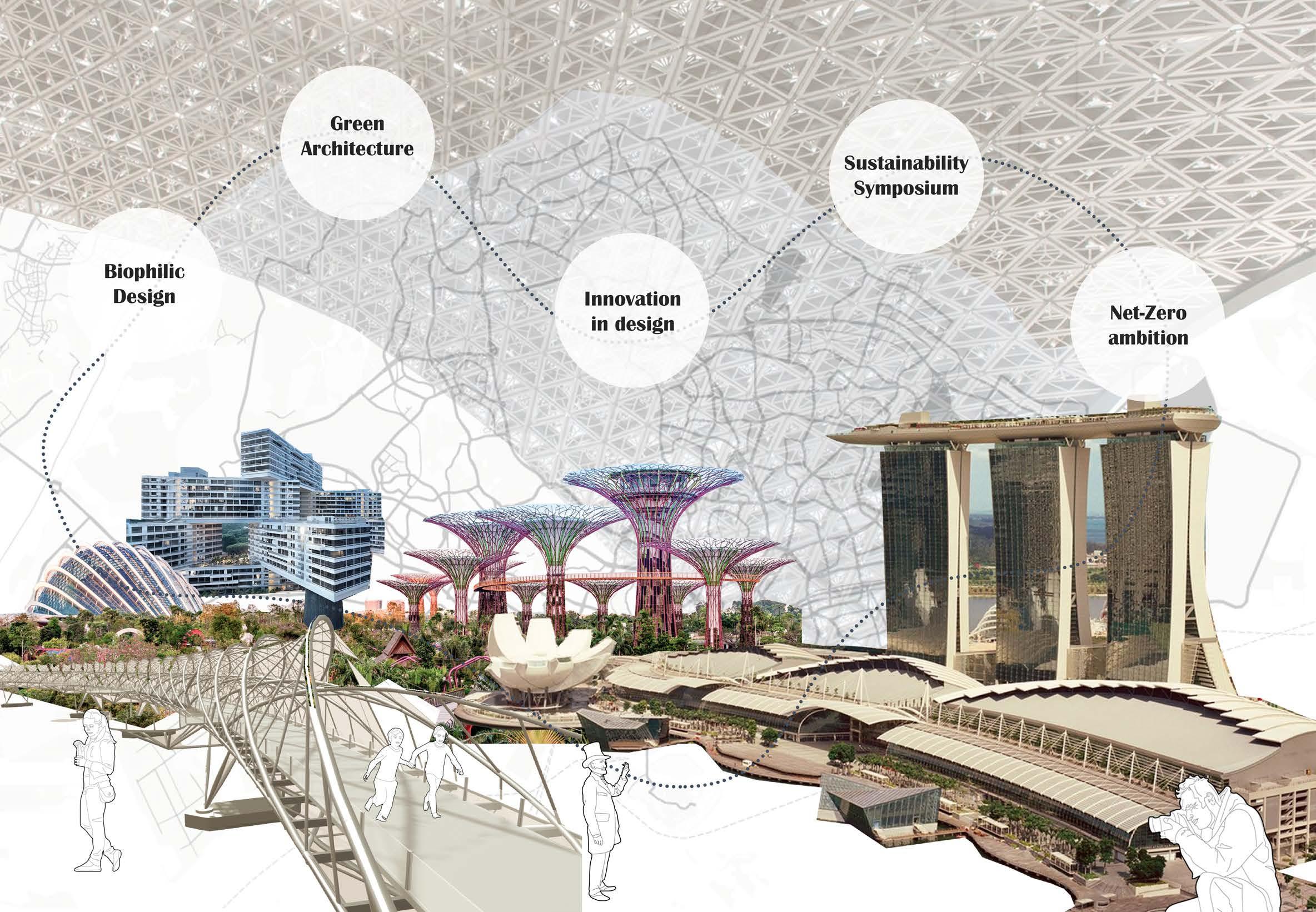

Architecture Innovation in Singapore

Case Studies

3.Design Process

Approaches

Prototype 1

Prototype 2

Prototype 3

Comparasion

4.Final Prototype

Details Diagram

Explosion

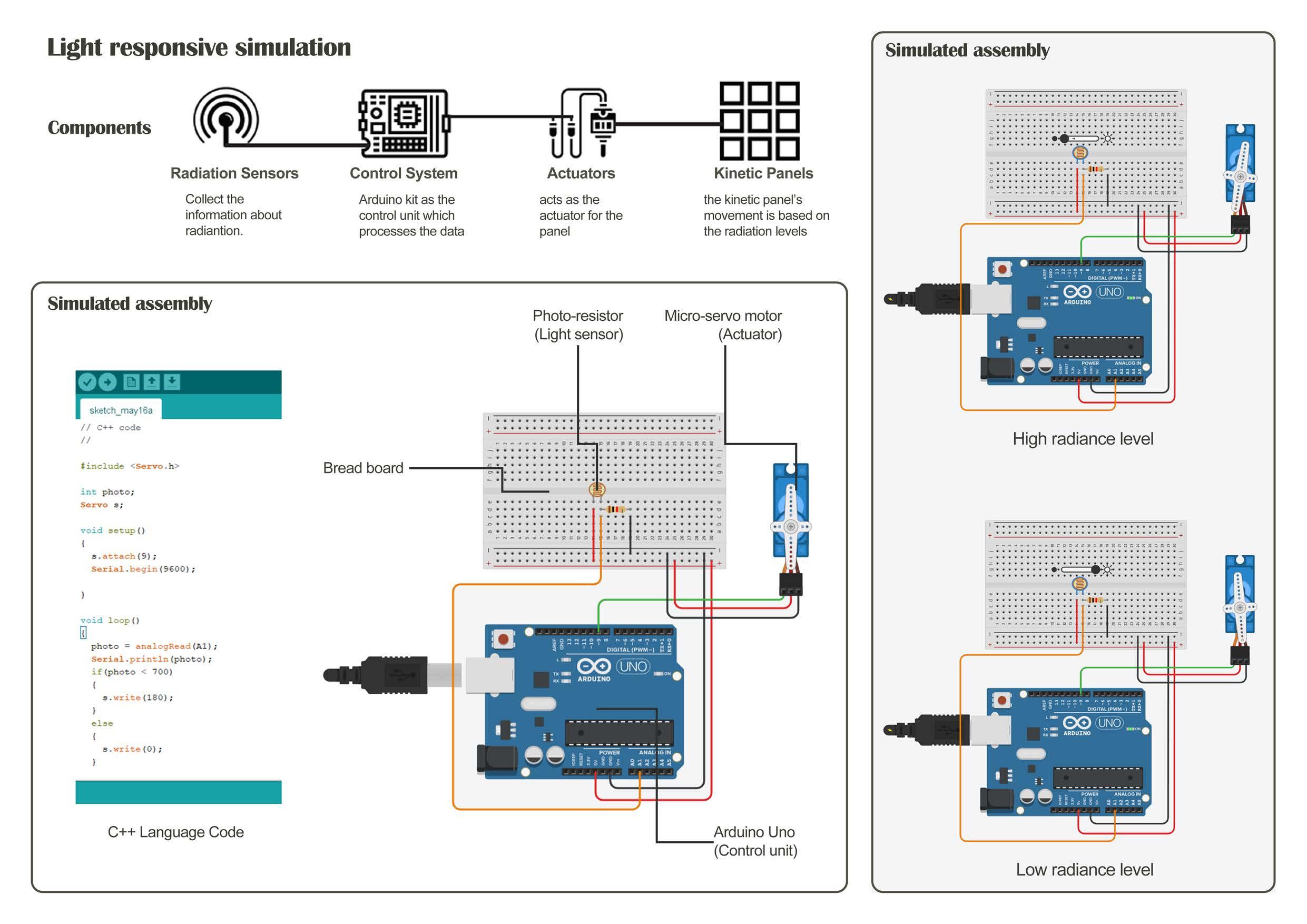

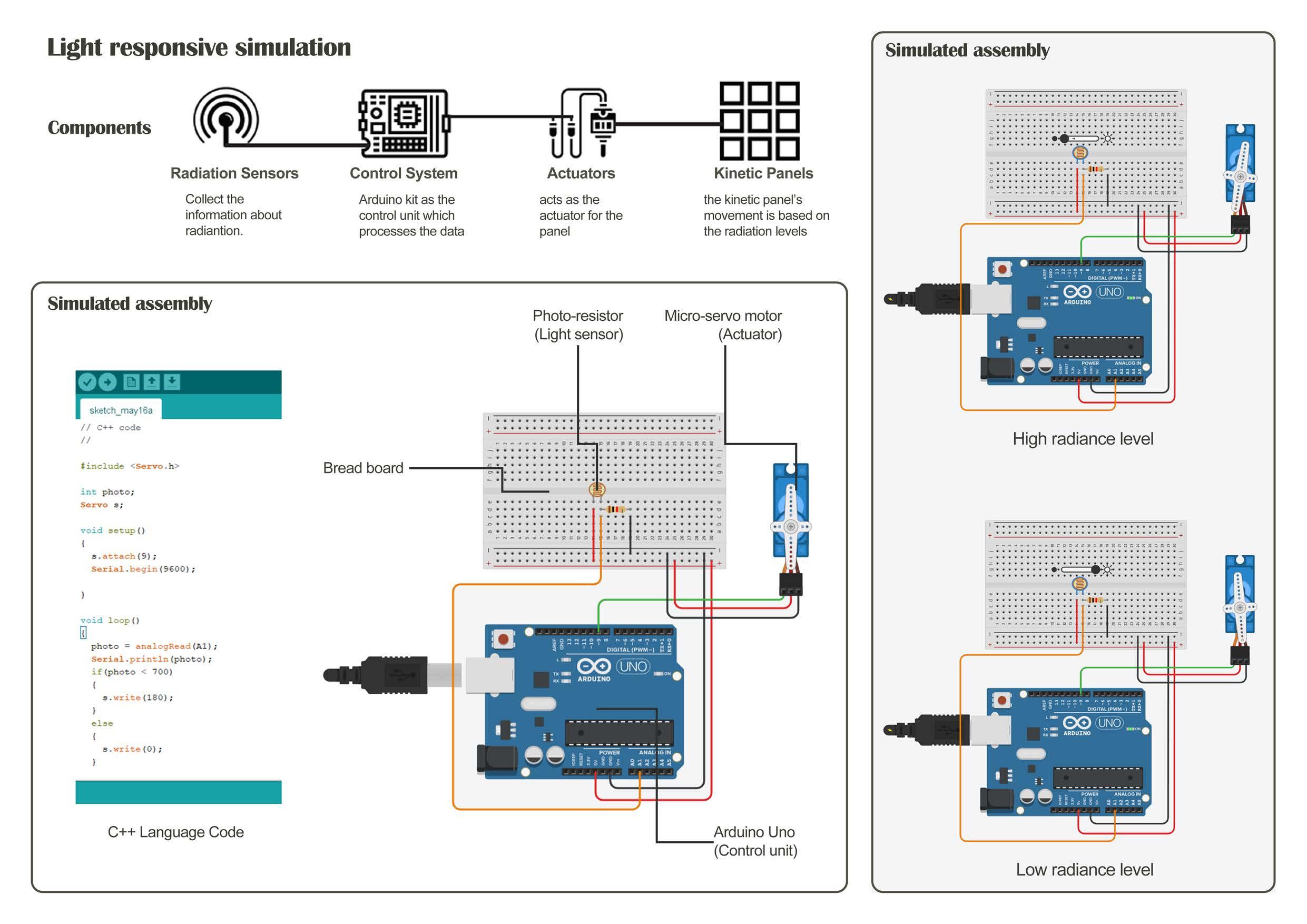

Light responsive simulation

Light responsive assembly

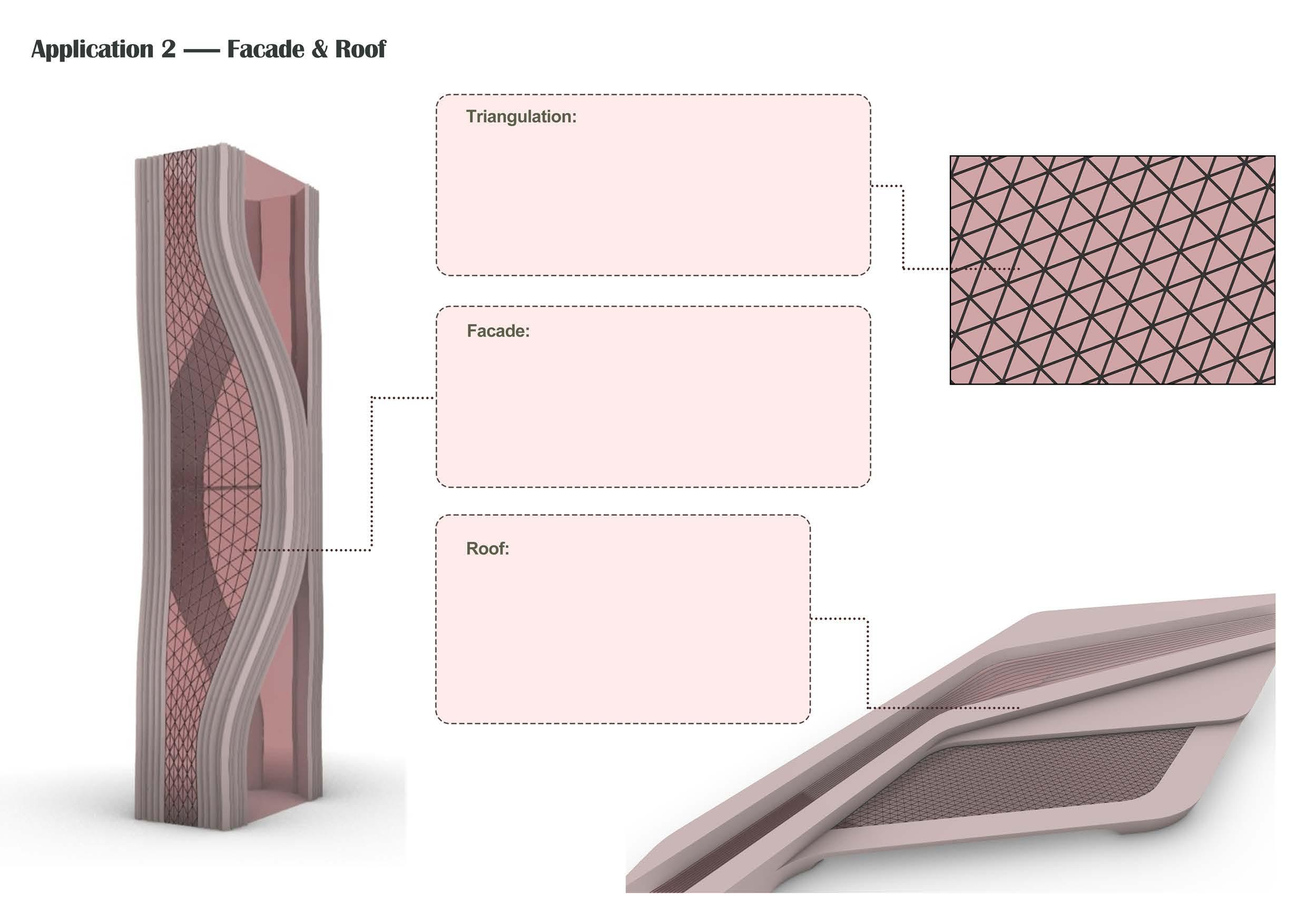

5.Application

Pavilion Design

Roof &Facade

5.Conclusion&Relection

Conclusion

Bibliography

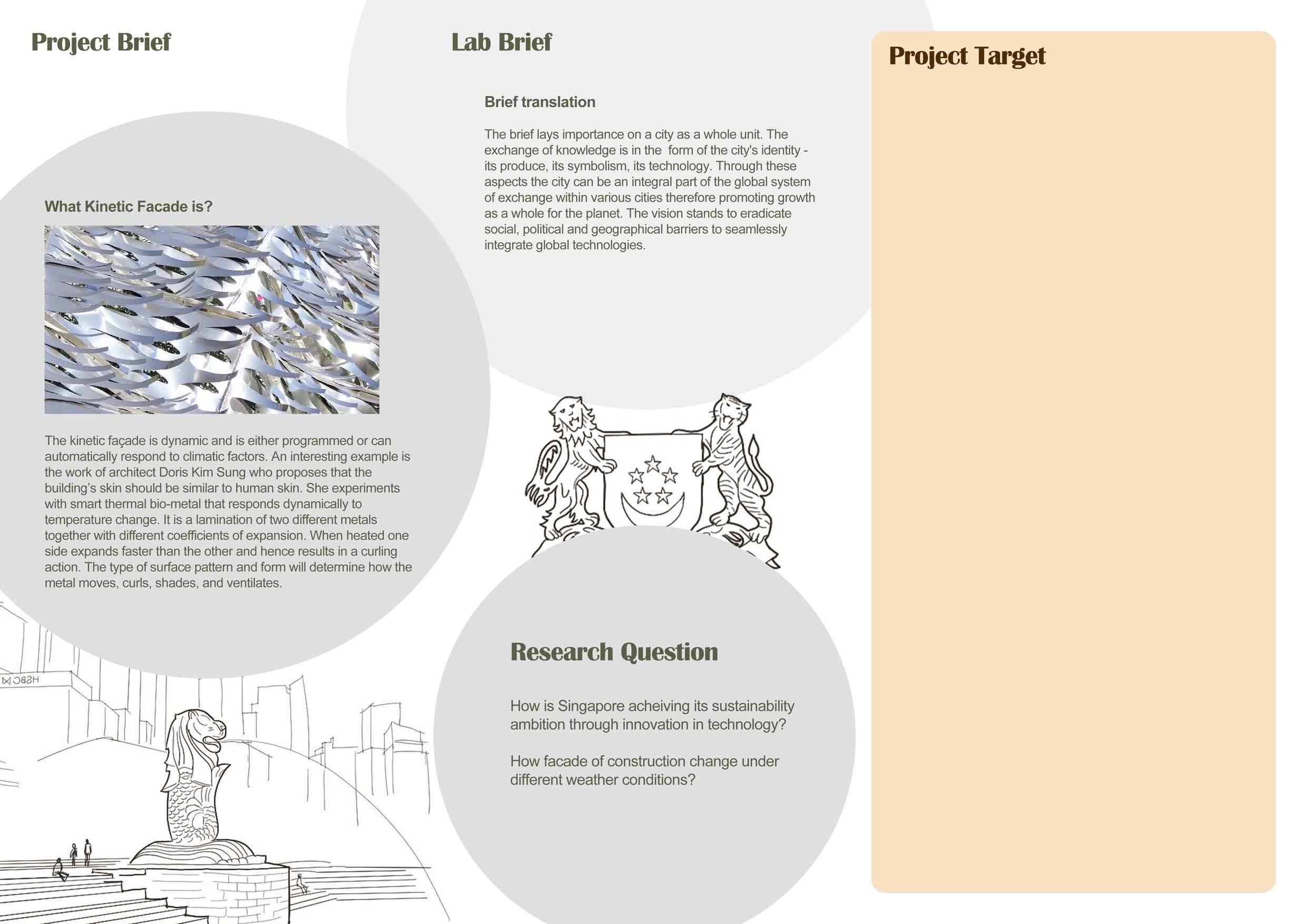

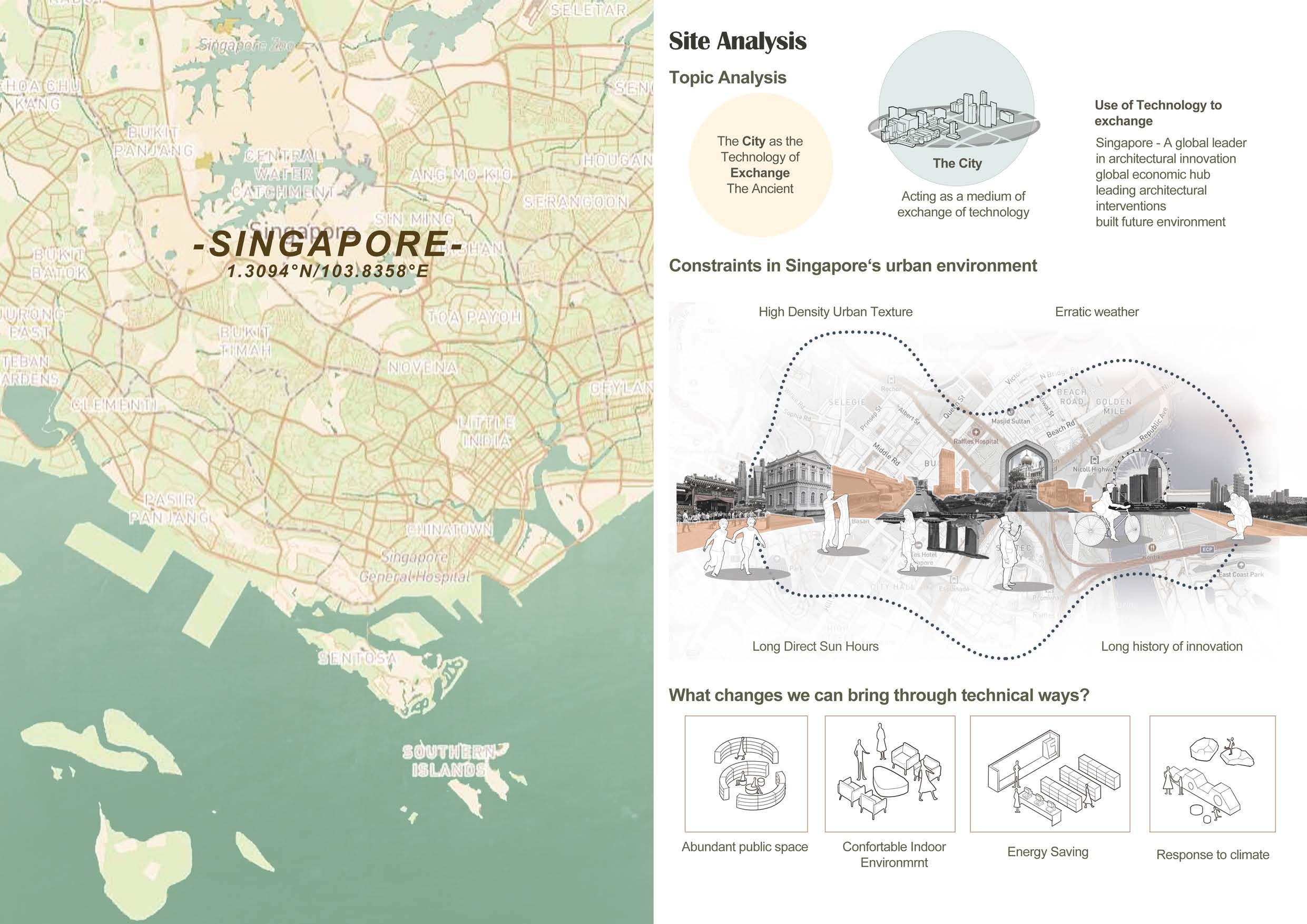

Expanding upon the brief, the project tries to identify a global leader of innovation and technology in architecture. The concept tries to represent the high form of architectural innovation in the selected city in order to inspire similar intervention in other global cities acting as a medium of exchange of technology for the city.

Singapore - A global leader in architectural innovation

Singapore is a global economic hub and consequently has leading architectural interventions on a city level. The whole country represents high standards in innovation and technology from using path breaking construction techniques to adopting net-zero and sustainability principles.

Singapore is the selected city for the project because it is imperative for the global architectural community to learn how the city's architecture and sustainability drive is shaping the future of built environment. In our project we want to represent the architectural innovation standards of the city along with its use of technology for sustainable design.

Architecture innovation in Singapore

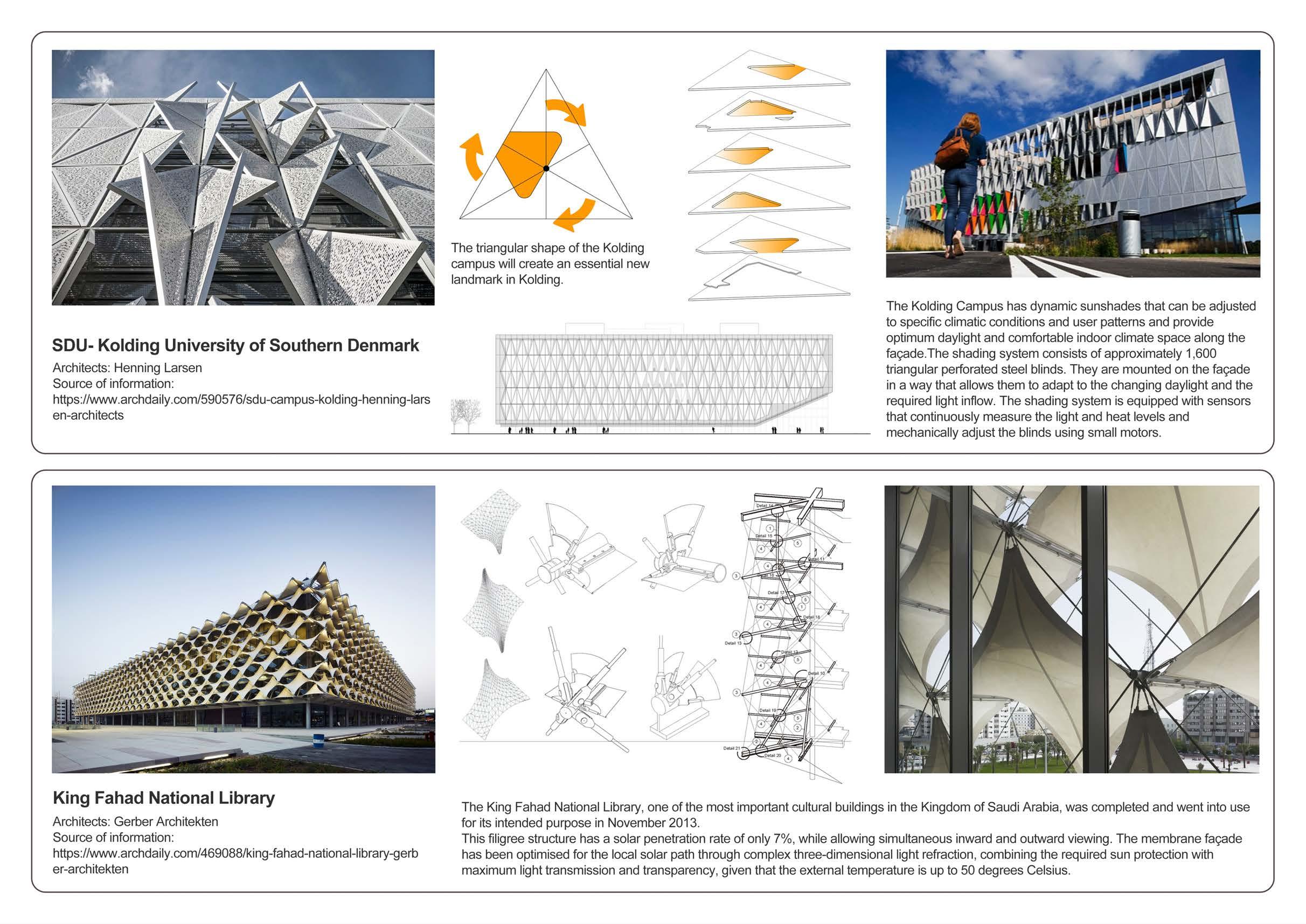

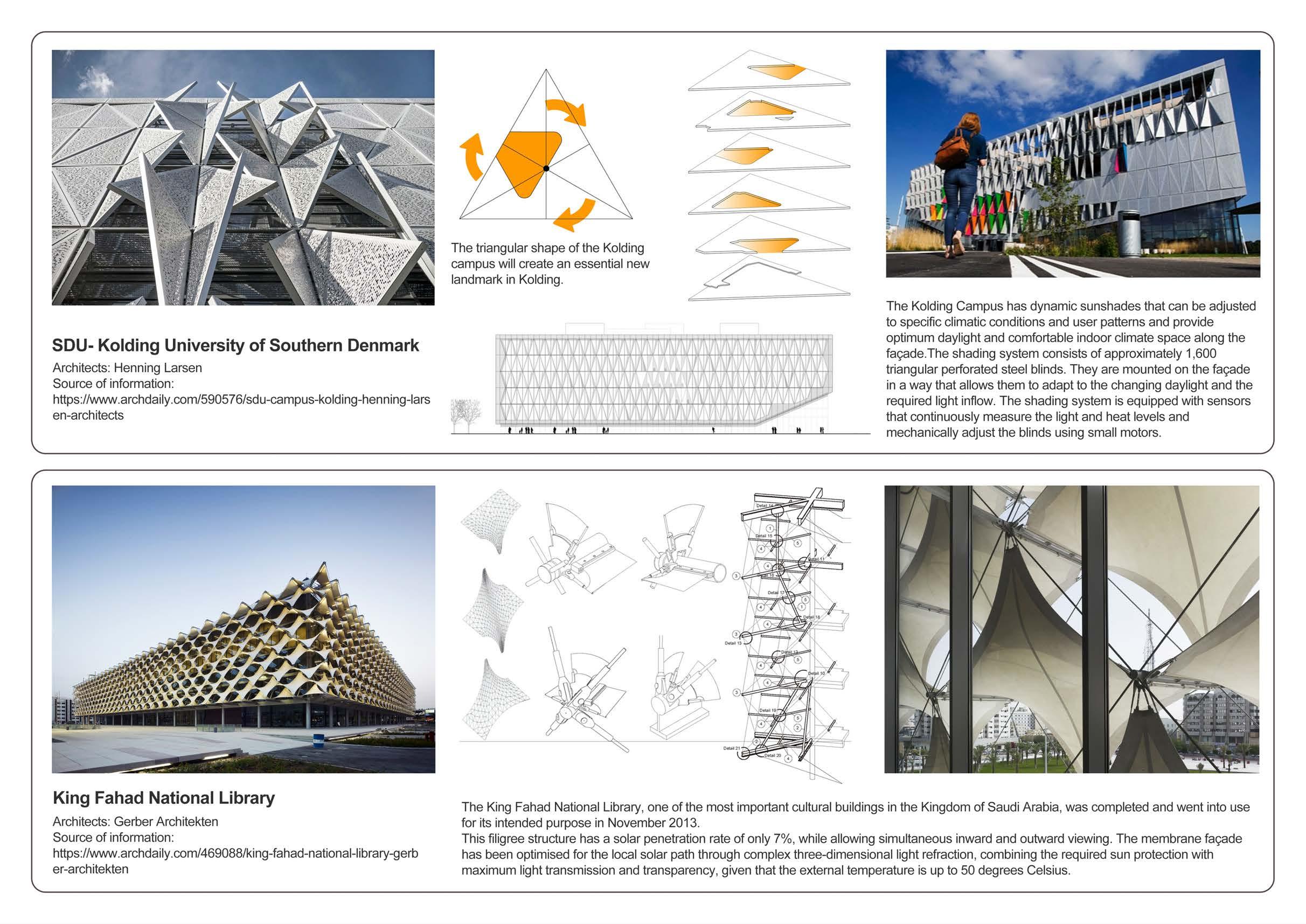

Case Study

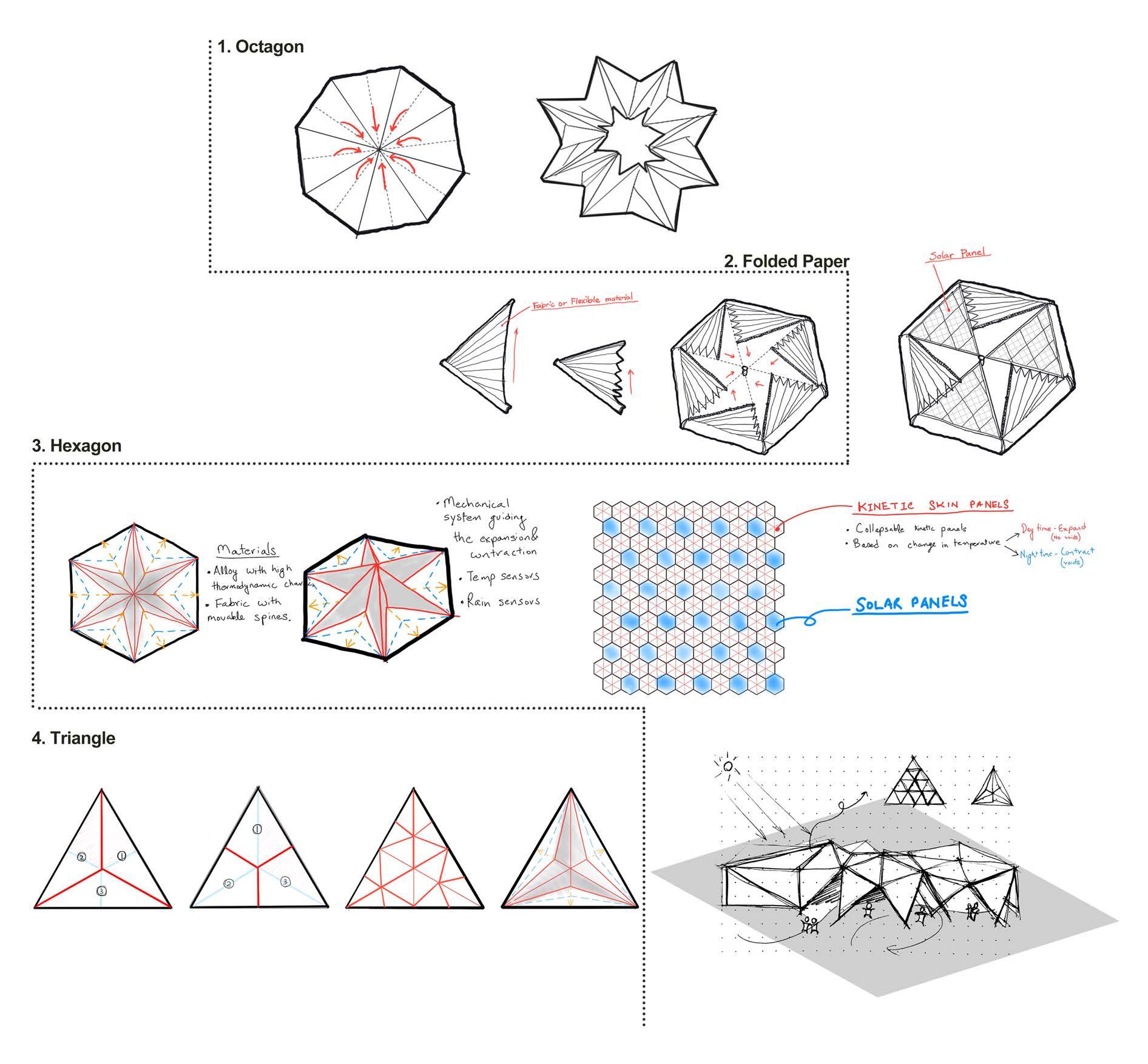

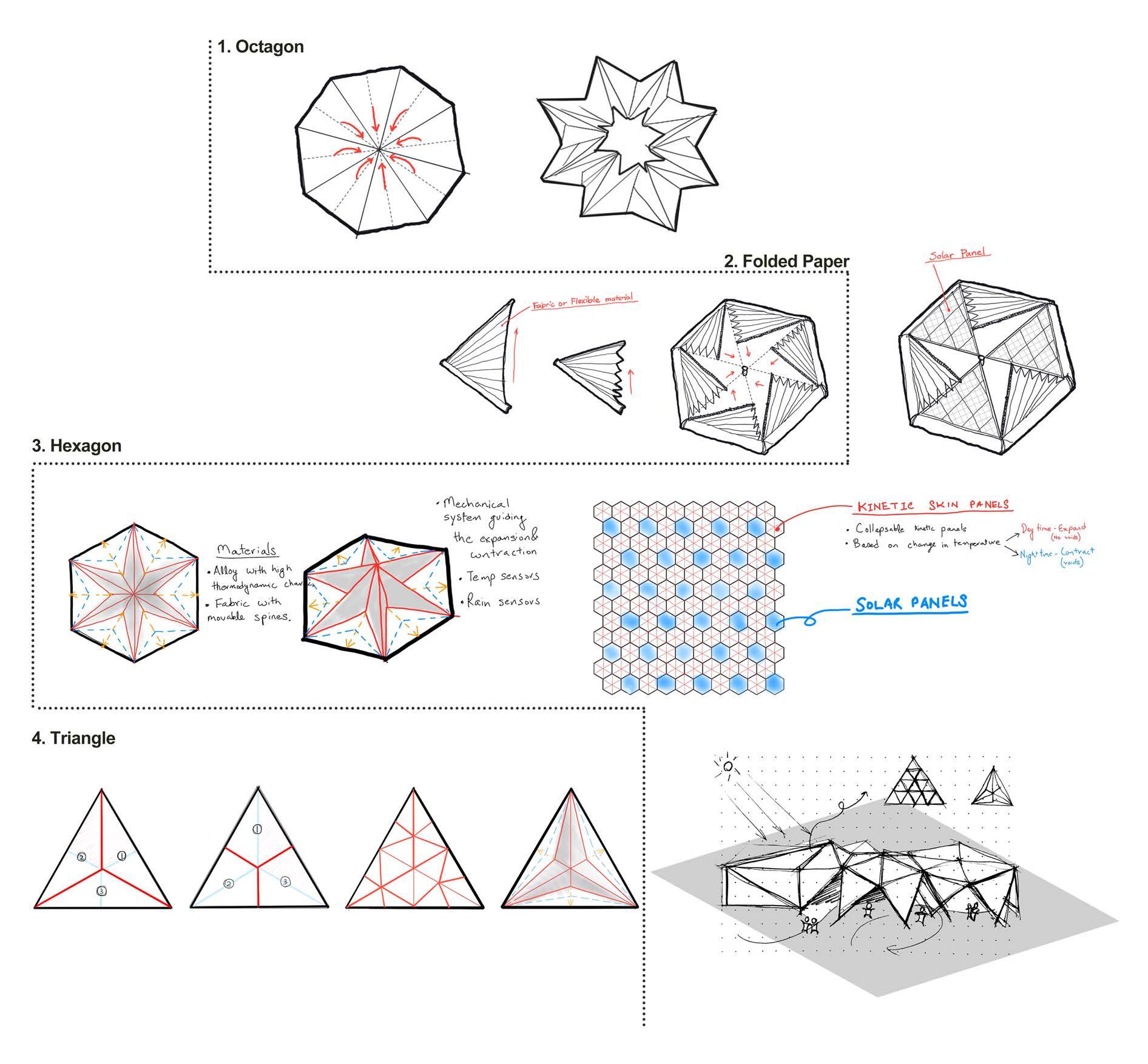

Unit Evolution

How we decide the movement of unit for responding the climate conditions

The prototype was designed with a hexagonal shape combined with solar panels in mind. The shape is divided into equal triangles, with one half using solar panels and the other half using a fan-opening design to allow sunlight to pass through.

Given the different axis spacing of each fan opening and closing, achieving a smooth opening and closing of each triangle would be difficult. We have therefore continued to develop the next prototype based on this concept.

Given the different axis spacing of each fan opening and closing, achieving a smooth opening and closing of each triangle would be difficult. We have therefore continued to develop the next prototype based on this concept.

?

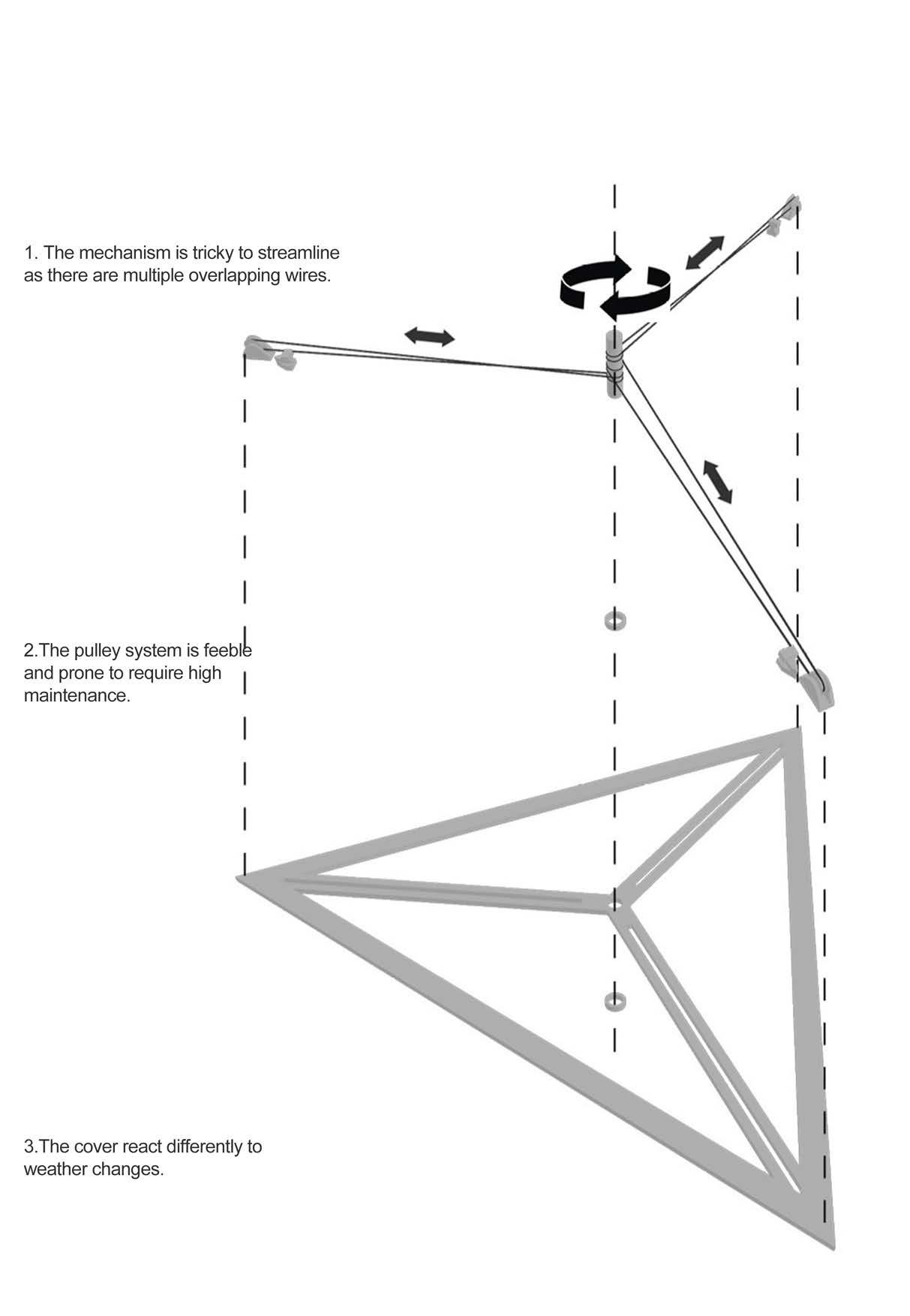

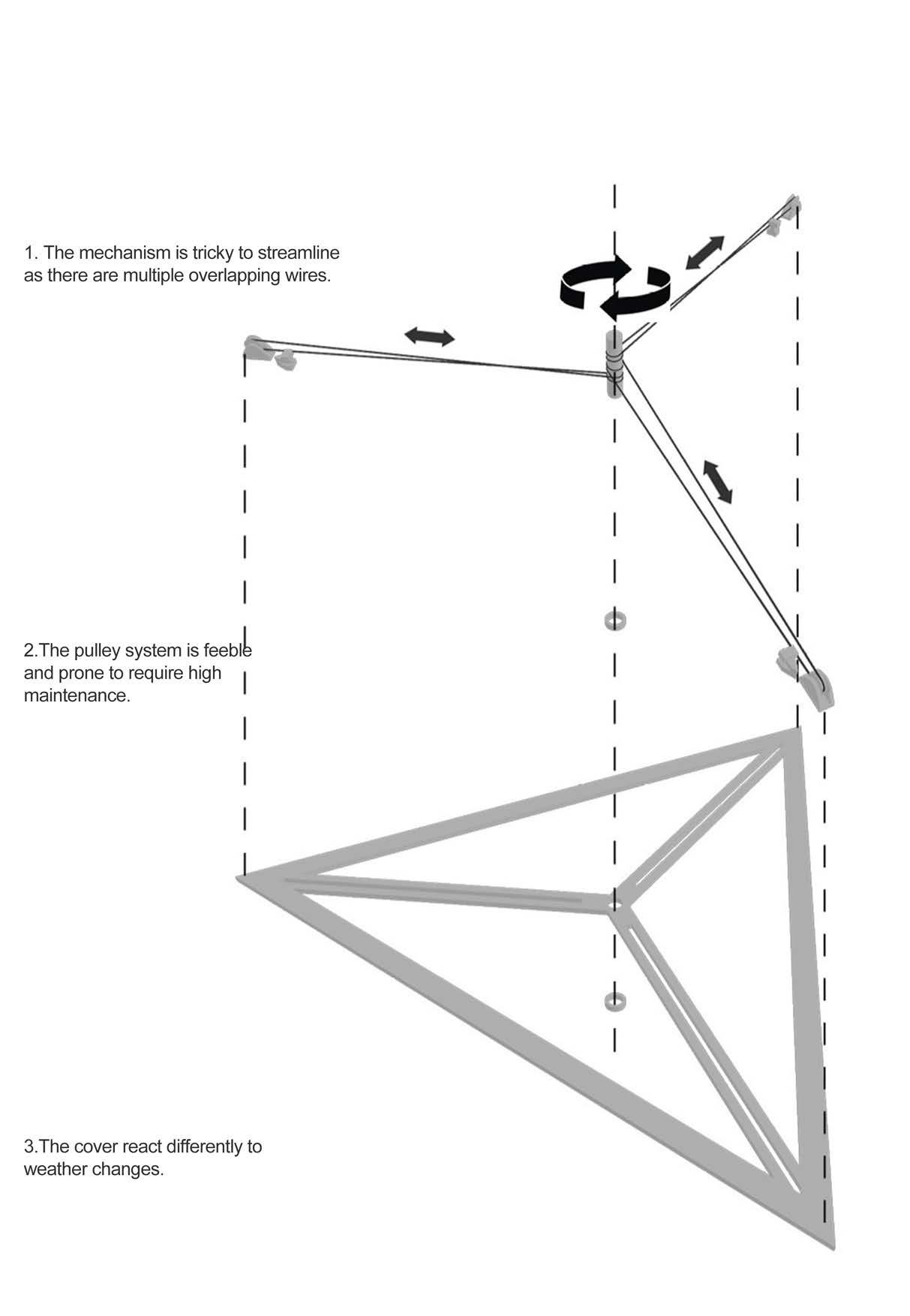

Prototype 1

Introduction and mechanism

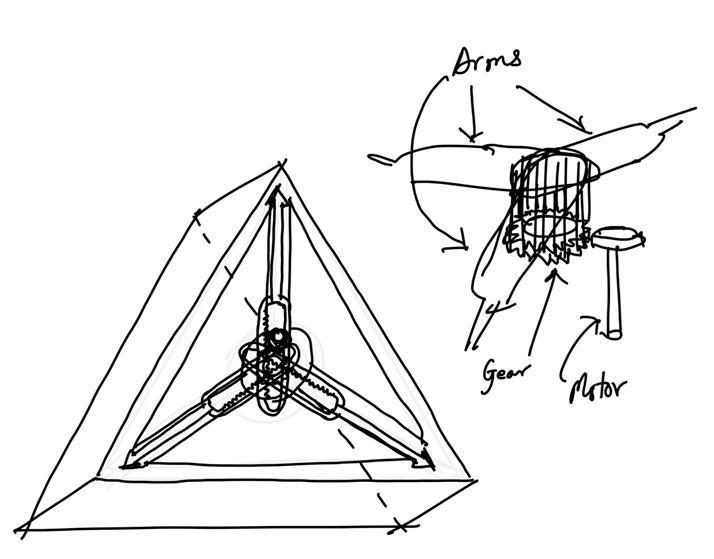

The initial attempt for prototyping was based on the principle of folding geometry of the kinetic panel. The triangle is divided into various little triangles using half points on nodes to get a collapsible geometrical shape. The idea is to keep the center of the triangle fixed and stationary while the three edges are attached onto the pins which are housed inside a track system. In the center of the triangle there is a rod which acts as the actuator. The movable pins are connected to this rod through a loop using wires. These wires are guided by the pulleys located on each edge of the triangular frame. The rotational movement of the central rod pulls and pushes the pins according to its clockwise or anti-clockwise rotation. Therefore, opening and closing the kinetic panel.

Inferences

Inferences

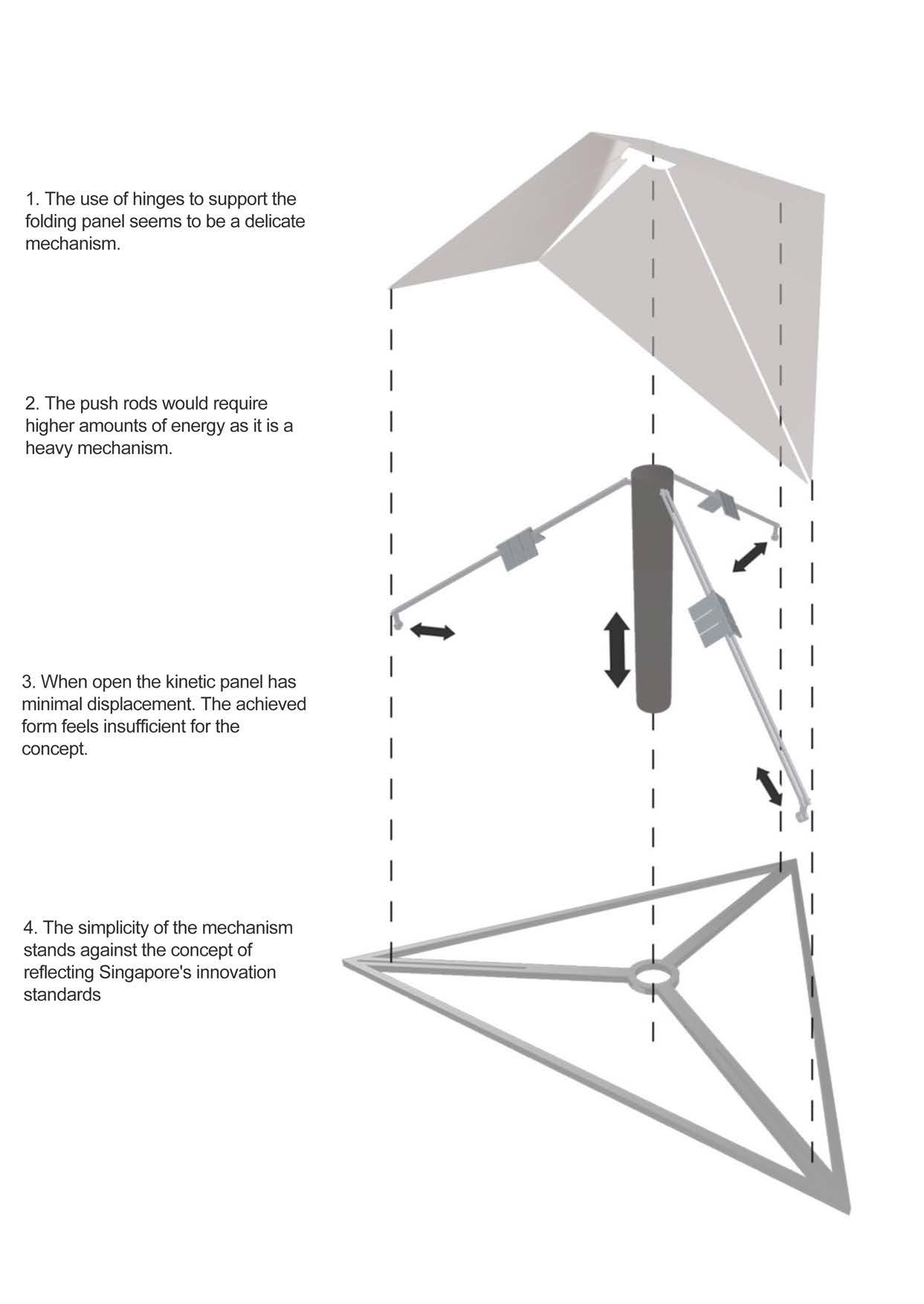

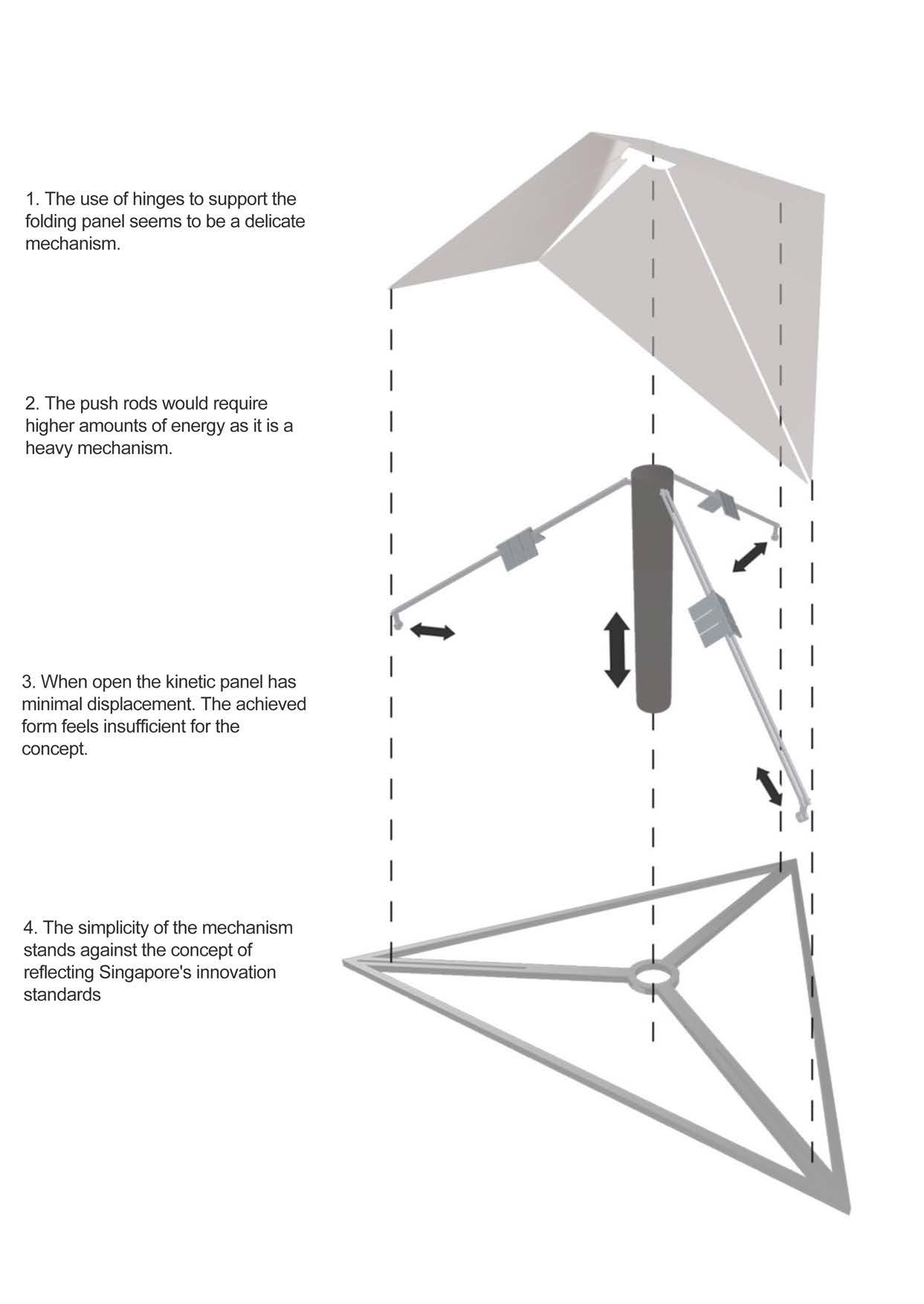

Prototype 2

Introduction and mechanism

The second attempt tried using a more simplified movement along with less complex geometry of the triangular panel. The mechanism uses a push rod system which moves up and down through the center of the triangular frame through guided motion from actuators. The geometry of the kinetic panel is based on folds occurring when the surface is pushed upwards from the center. In contrast to the previous prototype the folding surface is anchored to the center of the push rod's cross-sectional face. The flaps are attached to metal arms which have guided to and fro movement from the edges of the triangular frame. Hinges are anchored onto these arms which further support the folding movement of the panel.

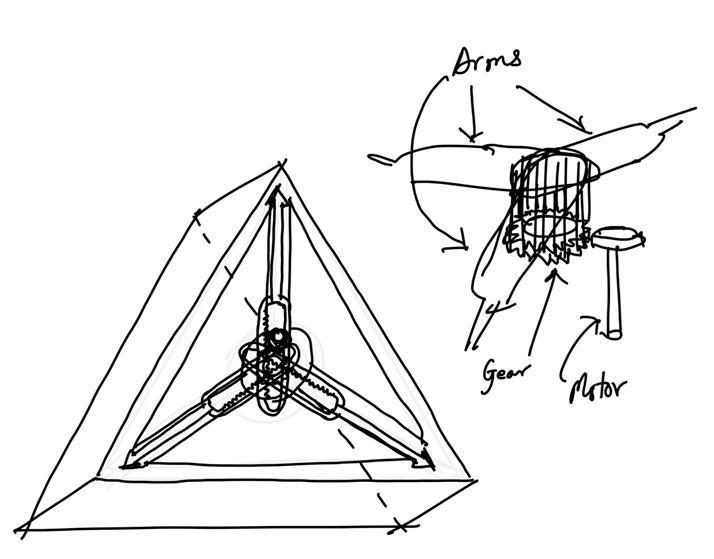

Prototype 3

Introduction and mechanism

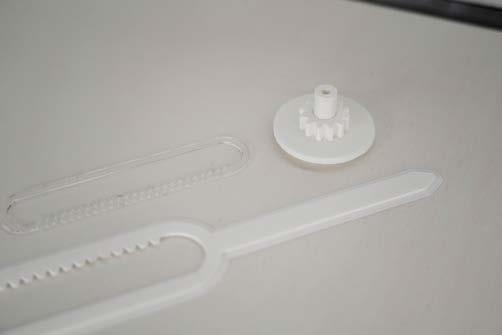

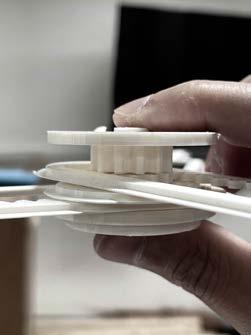

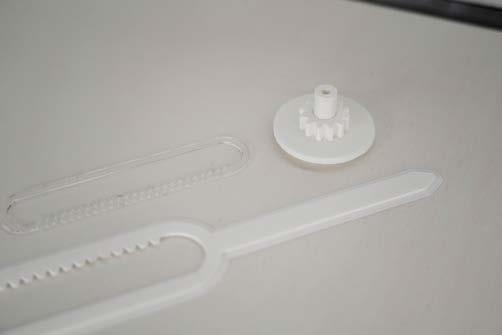

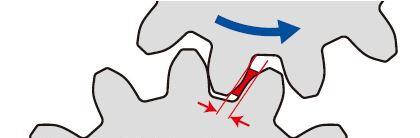

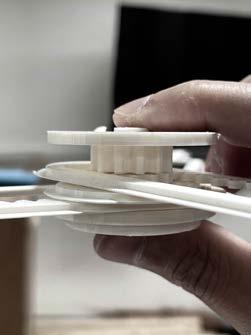

The third attempt was driven by the idea that it needs to reflect innovation at best. This prototype was made of homogenous material in order to streamline the mechanism. The mechanism was inspired by the movement of yoke arms along a gear. We had already established the horizontal movement of the pins on the arms of the triangular grid in prototype 1. Expanding on that we derived arms with pitches on one side which would guide its movement along a central rotating gear. The edges of the folding surface would be anchored onto the edges of these arms. The rotating movement of the central gear is actuated through the use of a micro-servo motor.

Inferences

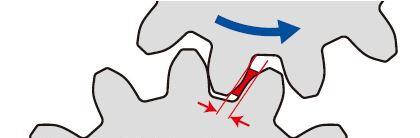

Tolerance between gears for smooth functioning.

The gear assembly and yokes worked seamlessly due to the use of homogenous material.

The calculated formation of gears, yokes and their pitches made the mechanism very accurate.

The use of this mechanism also shortened the depth of the prototype therefore making it more stable.

The components of the mechanism are easily replicable.

The functioning of the mechanism requires less energy when compared to previous prototypes.

Draft about how the gears work

Prototype 3

Introduction and mechanism

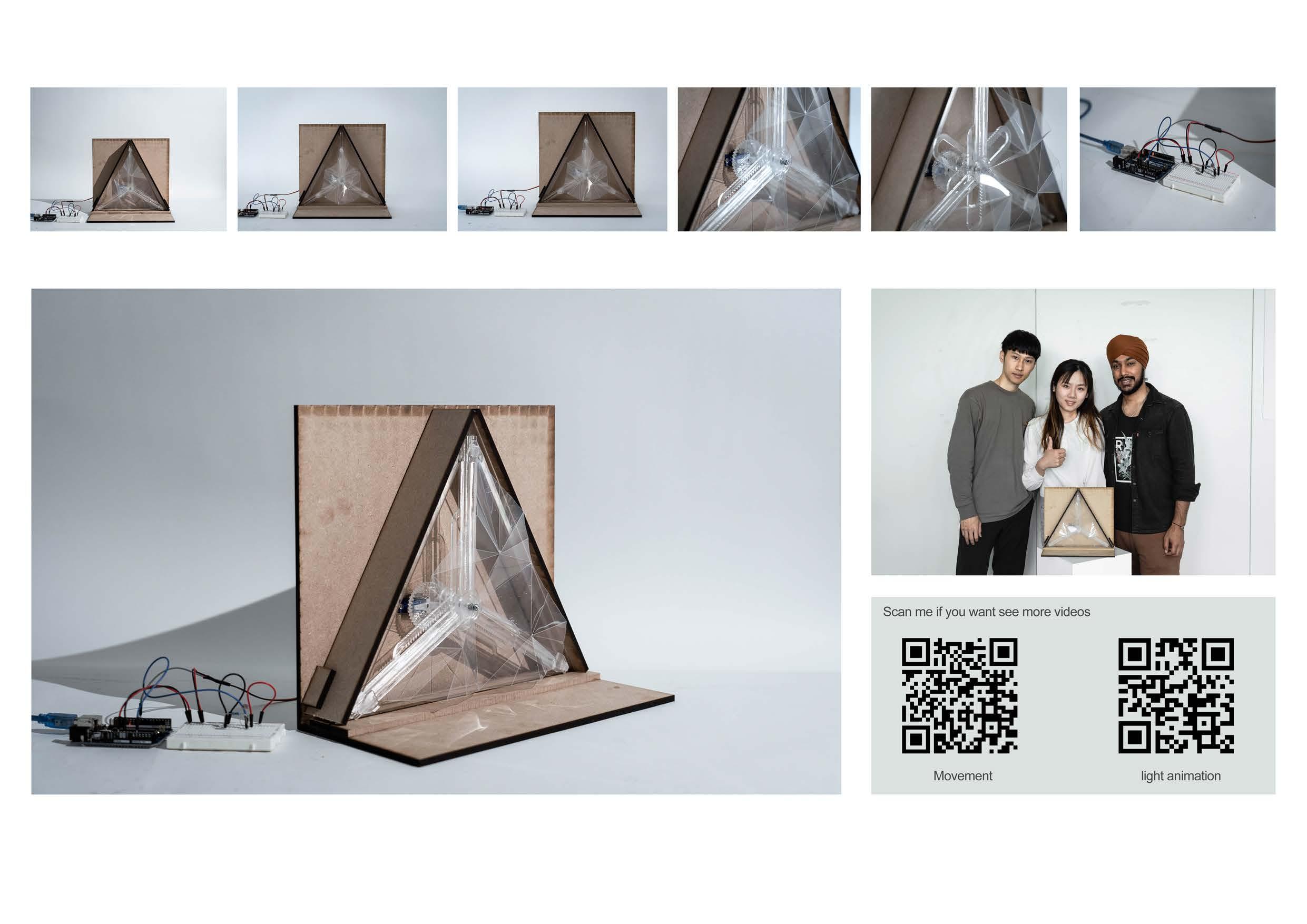

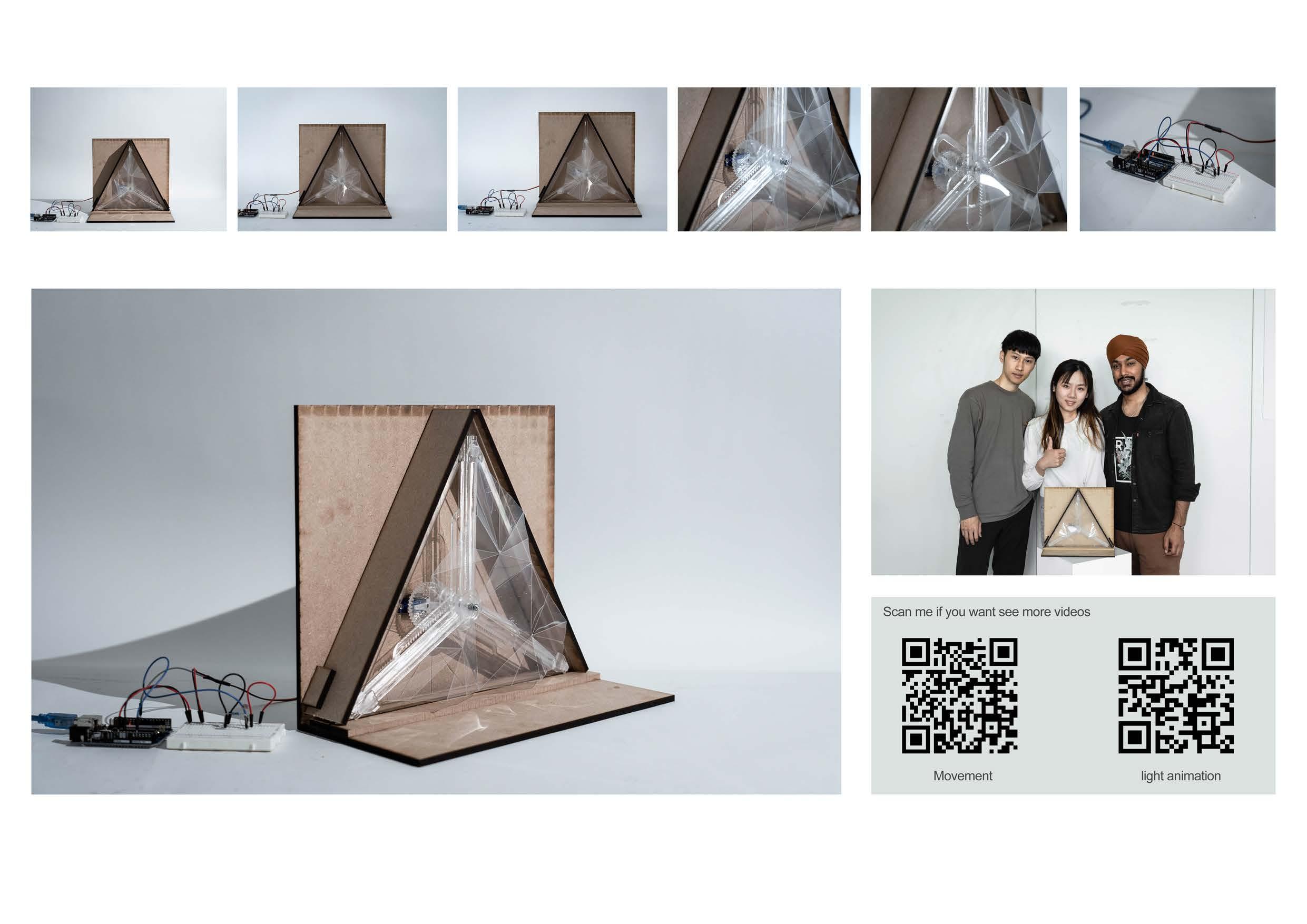

The final prototype is primarily based on the third prototype. It is a n evolutionary version of the previous one. The mechanism is the same where it is using a central gear assembly to dictate the movement of the yokes and eventually the foldable surface of the kinetic panel. The system is more streamlined according to the material tolerances and additional components are introduced like washers and guide supports. A translucent sheet is used for the foldable surface in order to expose the mechanism below. The central gear assembly is actuated through the use of a micro-servo motor.

Components

Assembly

Prototype

Explosions Photo of

3

· The folding geometry works better and has larger void space when collapsed.

· The movement of pins on guides allows better accuracy.

· The geometry of the foldable panel is much simpler.

· The push rod system is much easier to manage.

· The gear assembly is very accurate.

· Homogenous material use creates uniform tolerances.

· Reduced depth and a more streamlined prototype.

· The use of overlapping wires can create problems.

· The pulley system is too fragile.

· The system is too simple and does not advocate innovation.

· The simplified geometry creates lesser voids when at maximum shrinkage.

Rotating central rod pulling wires attached to the foldable panel and guided on tracks.

Central push rod moving the center of the foldable panel up and down.

Yoke arms moving up and down on guides through a central gear assembly.

Comparision

1. Arduino Uno: The board acts as a microprocessor which converts the analog input of photoresistor into voltage output for the micro-servo motor according to the coded script uploaded on it.

3. 10K resistors: These resistors help slow down and expand the range of input received by the photoresistor.

4. Micro-servo motor: The micro-servo motor rotates according to the output generated by the arduino board which in turn converts the input from the resistors as per the code.

5. Jumper wires: These wires help build the circuits and connect any two points together. The different colours help in segregating paths from each other.

6. Power and interface: The Arduino board can be powered through the USB port when connected to the computer. The Arduino IDE is an app through which we can programme the Arduino.

2. Bread-board: The bread board helps in creating a circuit loop between the resistors and the motor.

Final

Outcome

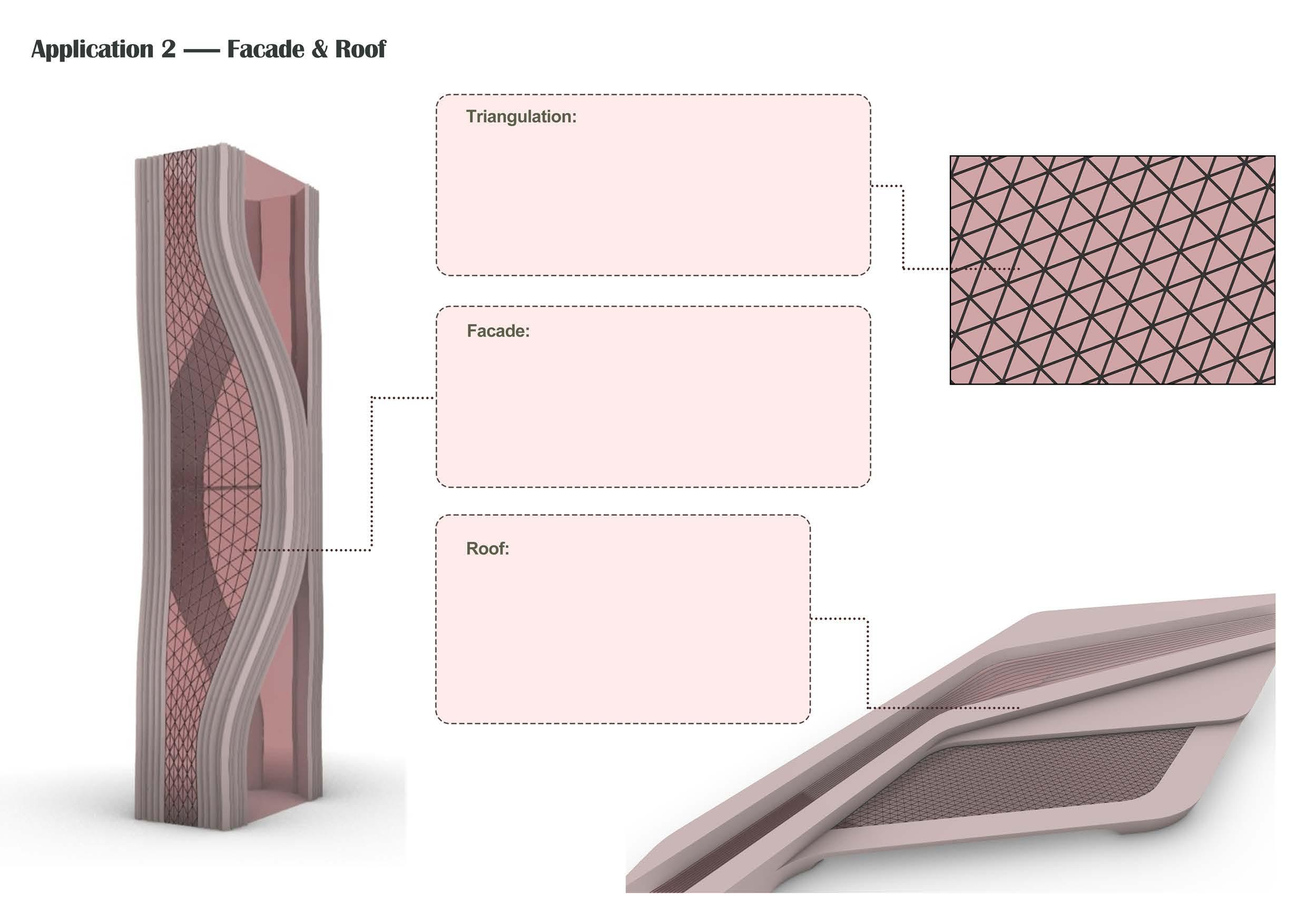

Surface division in order to achieve a grid for the housing of the kinetic panels. Triangulation is the most efficient way of surface division as any complex surface can be divided through it.

Using a triangulated grid allows maximum flexibility for application on surfaces. The panels can be applied on facades. The radiation based kinetic panels will also contribute towards reducing heat gain in the building.

Similarly using the same concept on complex roofs or domes can enhance the radiation protection in the space below while adding to the technological aesthetic of the design.

Reflection

The whole process enlightened me with the use of technology in architecture. The method of combining technology with architectural thought was rewarding and opened up a new perspective to resolve environmental constraints. The prototyping stage really challenged us to try and resolve the mechanism of the kinetic panels along with its geometry. Research about the different mechanisms revealed the use of gear assemblies which formed the basis of our final prototype. The use of the Arduino board illustrated how prototypes can be actuated. The use of tinkerCAD software allowed us to establish a better understanding about C++ and the logical sense behind writing a code. The whole experience of this group project added new technological skills and polished team working and collaboration skills. To summarise, it was a good and educational experience.

A minor adjustment in architectural technology can result in significant innovation, which is what we try to find out through the making process. Modeling serves as a powerful tool for visualization in our whole process. By creating physical or digital models, we were able to better understand the geometrical feature, movement, and operation. We started with two-dimensional sketches and truly grasp how our ideas would translate into the real world. Reflecting on my experience with teamwork, I am struck by the Collaboration with a diverse group of individuals to achieve a common goal. I learned something which I am not good at from others and also play my role well. Collaborative modeling with others generated a sense of shared ownership and enhanced the entire design process. I am so appreciated that I can have an experience like this.

Throughout the module process, we learn and use many practical tools. For example, 3d printing, laser cutting and the application of circuit boards. Based on this technology, we have completed a dynamic façade unit. Although we started by thinking about reference cases, we made a model based on a gear structure that someone else had made. Initially, we wanted to use 3d printing for the gearing but found that the gearing was incorrectly printed in 3d. In addition, 3d printing would produce excess material on the edges of the gears, affecting the gears’ smoothness. Based on this test, we switched to laser cutting for the kits and other parts and searched for a suitable material thickness. A stack of 3mm acrylic sheets was used to form the components with sufficient thickness. In making the model, we also found that the material used affected the outcome of our mechanical work. Overall, we used many tools for this project, and it was a very challenging and exciting process.

Concept:

Translate the brief “City as a technology of exchange”The project summarises the concept to represent Singapore as an innovative architectural tech hub. The research focused on various ways this can be translated into an architectural element. The climate analysis of the city implored us to design with environmental sympathy. The design concept was based on the idea of curbing the high amounts of radiation experienced by the city.

Kinetic Panels:

The architectural element to carry forward the concept was thought of as a universal component which would be easy to install on various surfaces. Therefore we thought of devising a kinetic panel which could be replicated on a grid. The form explorations suggested the use of a triangular shape as the triangulation method can solve almost any complex surface forms.

Prototypes:

The progressive prototypes explored different mechanisms for the functioning of the kinetic panels. Each stage informed us of various inferences which carried forward onto the next progressive prototype. Comparing all the prototypes we went forward with the one which used gear assemblies and yokes for the mechanism as it provided the most accurate movement.

Radiation Simulation:

The next step involved actuating the kinetic panel. This process incorporated a circuit loop with information exchange between a photoresistor and a micro-servo motor through the use of an Arduino Uno. The simulation was first designed in TinkerCAD software and once we achieved the desired result we uploaded the code onto the hardware.

Assembly and functioning:

The hardware was then connected to the kinetic panel with the micro-servo motor acting as the actuator for the kinetic panel. The motor was capped with the larger gear which dedicated the rotation of the smaller central gear assembly. The photoresistor provided the data for the varying light levels and the code was scripted to act according to high or low intensity of light. This data was then converted into output for the servo motor. Therefore, when testing, the kinetic panel functioned according to the change in lux levels.

Conceptual application:

To apply these panels in real world scenarios we imitated its use at three different levels. The first was a pavilion with complex doubly curved surfaces. The second was to apply it on the facade of a building. And the third was to apply it on the roof of an atrium. All of these applications involved solving the surface geometry using triangulation in order to act as the base grid for housing the triangular kinetic panels. The method advocated the universal use of these panels in applications.

Brose, D.A., National Research Council (U.S.). Committee On Regional Approaches To Urban Sustainability: A Focus On Portland, National Research Council (U.S.). Science And Technology For Sustainability Program and National Research Council (U.S.). Policy And Global Affairs (2014). Pathways to urban sustainability : perspective from Portland and the Pacific Northwest : summary of a workshop. Washington, D.C.: National Academies Press.

Duc Nguyen, B.V. (n.d.). Green BIM Integrated Design Process. University of Sheffield.

Francis, L. (2023). Unfolding the form from within: East and Southeast urban Asia, its postcolonial condition, and its ephemeral architectural ‘displayness’. Journal of Asian Architecture and Building Engineering, [online] 22(2), pp.390–401. doi:https://doi.org/10.1080/13467581.2022.2046000.

King Fahad National Library / Gerber Architekten" 22 Jan 2014. ArchDaily. Accessed 26 May 2023. <https://www. archdaily.com/469088/king-fahad-national-library-gerber-architekten> ISSN 0719-8884

Koon, W.H. (2020). The Emergence of the global and social city: Golden Mile and the politics of urban renewal. Planning Perspectives, [online] 35(4), pp.689–718. doi:https://doi.org/10.1080/02665433.2019.1581835.

Patrick Lynch. "Aperture-Style Retractable Roof at Atlanta’s Mercedes-Benz Stadium Closes for the First Time" 01 Aug 2017. ArchDaily. Accessed 26 May 2023. <https://www.archdaily.com/876888/aperture-style-retractable-roof-atatlantas-mercedes-benz-stadium-closes-for-the-first-time> ISSN 0719-8884

Schwerdtfeger, E. (2018). Custom Computational Workflows for BIM Design Implementation. Autodesk university.

SDU Campus Kolding / Henning Larsen" 30 Jan 2015. ArchDaily. Accessed 26 May 2023. <https://www.archdaily. com/590576/sdu-campus-kolding-henning-larsen-architects> ISSN 0719-8884

Shahin, H. (n.d.). Al Bahr Towers | Aedas - Arch2O.com. [online] Arch20. Available at: https://www.arch2o.com/albahr-towers-aedas/.

Singapore’s Green Buildings. (2018). Building and Construction Authority.

Steel, J., Drogemuller, R. and Toth, B. (2010). Model interoperability in building information modelling. Softw Syst Model, [online] 11(1), pp.99–109. doi:https://doi.org/10.1007/s10270-010-0178-4.

Xinyue, W. (n.d.). BIM Management and Analysis. University of Sheffield.