Specialists

Specialists

6ix Process Design Ltd manufacture a full range of high quality hygienic stainless steel vessels, pressure vessels & thermal plate transfer technology. Industry leading quality, customer satisfaction and best in class lead times are the cornerstones of our business.

With decades of experience in the brewing sector our expert team can handle design, delivery and commissioning of any project no matter how bespoke. Our key aim is to supply high quality British manufactured products & services specialising in Dairy, Food, Beverage & Pharmaceutical sectors.

We can supply products worldwide and can offer on-site installation all over the UK & Europe.

Whether it’s our commitment to reforestation projects or treating all of our employees fairly, sustainability and our impact on both the planet and people is at the heart of what we do.

When you buy a 6ix Process design tank or brewhouse we will plant trees in accordance with the amount spent.

Fair wages for fair work. At 6ix Process design we're pleased to say we are a living wage employer. Our equipment is made right here in the UK. Buying local is always buying sustainable.

Site surveys (3D scanning and full CAD drawing packages available)

Site feasibility studies

Production growth and planning for the future

Brewery streamlining

Tailor-made Mechanical & Automation Design

Preparation of Process Documentation, PFS/FDS

Commissioning logs and Site visit reports

Full supporting documentation, both Hard Copies and via QR Code

Client Staff and Operator Training and after sale support.

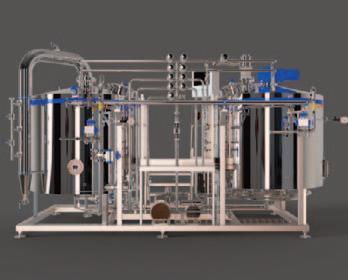

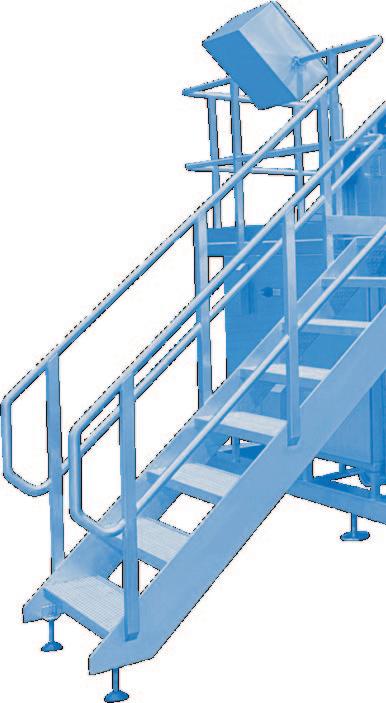

25HL 2 Tank Brewhouse

Fully Automated with sequencing

Complete 25HL production system package including twin vessel skid mounted brew block; mash/lauter combi vessel and copper/whirlpool combi vessel.

25HL 2 Tank Brewhouse

Our new, state of the art, Fully Automated Compact Brewing System, combines a mash/lauter combi vessel with a copper/whirlpool combi vessel, making it the pinnacle of efficiency and quality.

The compact design is perfect for any space, optimised installation and commissioning times, giving uncompromised quality and reliability plus less downtime for established companies.

Lore m ipsu m dol or sit amet, con s

Fully Automated - Simplified brewing and consistent batches with our user-friendly interface, Intuitive, highly flexible operating system with state-of-the-art PLC control with integrated semi-automatic capability to give the brewer full control over the system for individually crafted beers.

Easy Recipe creation, adaptation, and fully sequenced operation – allowing maximum efficiency, minimum operator input and perfect replication of new and existing products.

Our intelligent control system is equipped with a number of unrivalled features, which include self-diagnostics and preventative maintenance alerts, email notifications and warnings together with data logging and remote operation - ability to operate the brewhouse from your smartphone/tablet.

25HL 2 Tank Brewhouse Fully Automated with sequencing

Complete 25HL production system package including twin vessel s mash/lauter combi vessel and copper/whirlpool combi vessel.

Our Flexible mashing system ensures precise temperature control and consistent grist hydration, aiding higher extract potential.

The Intelligent lautering - Monitoring turbidity and differential pressure to generate high lauter efficiency and control.

An Efficient boiling system - providing reliable control of wort quality and evaporation.

And a Safe boil system - allowing one brewer to manage the cellar and packaging operations safely whilst brewing.

Finally with Automated wort aeration - providing continuous and exact control of sterile oxygenation, ensuring a reliable fermentation every batch.

We can also offer bespoke asset finance package.

Fully assembled skid-mounted brewhouse custom built to your requirements with options for mash mixers, lauter blades & more.

Custom built to your requirements with options for mash mixers, lauter blades, step mashing etc

Automatic valves minimise dead legs

Easy to operate

4½ hours average process time from start to finish

Minimal installation on site

10 years guarantee (subject to terms and conditions)

2 years’ free servicing

Fully assembled skid-mounted brewhouse custom built to your requirements with options for mash mixers, lauter blades & more.

We can also offer bespoke asset finance package.

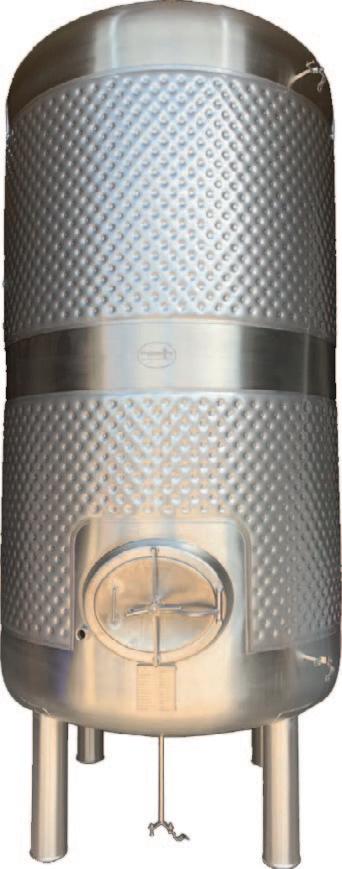

Pressurised Uni-Tank Vessels with high grade 304 stainless stee

Polyurethane non-flammable insulation secures against heat loss.

Recessed fully welded cladding around product outlets to avoid dead legs

Various cone shapes available from 30-70 degrees

Thermowell temperature pockets

Bespoke design and build options

Installation on site available or expert advice

10 years guarantee (subject to terms and conditions)

6-8 week lead time

Pressurised conditioning vessels for product clarification made with high grade 304 stainless steel throughout. Polyurethane non-flammable insulation secures against heat loss.

Pressurised Conditioning Vessels for Product Clarification

High grade 304 stainless steel throughout

Polyurethane non-flammable insulation secures against heat loss

Durable laser welded cooling panels

Optimum hygiene & CIP

Recessed fully welded cladding around product outlets to avoid dead legs

Various cone shapes available from 30-70 degrees

Thermowell temperature pockets

Bespoke design and build options

Installation on site available or expert advice

10 years guarantee (subject to terms and conditions)

6-8 week lead time

Includes 10 year guarantee

6pd specialises in manufacturing high-quality stainless steel silos perfect for a wide range of industries.

Stainless Steel Silo Manufacturers

Stainless Steel Silos with Corrugated Cladding

Stainless Steel Storage Tanks with Stainless Steel Cladding

Silos for any Industry: Milk, Oil, Powder, Dairy, Beer, Chemical & Water

High Quality Stainless Steel Silos Built to Last

Up to 200,000L Built In-House, Larger Sizes on Request

Our laser-welded plates are unique in the UK.

Plate Technology

Our laser-welded plates are unique in the UK. The steam/glycol or water flows through the integrated wrap-around thermoplates that cover the inner vessel wall.

Using 6ix Process Design’s dimple plate technology the plates are tested to high pressure for durability. These plates are used to heat and/or chill vessels.

The HOP-IX acts as an intermediary vessel for the dosing, dispersion and infusion of dry hops. Utilising a combination of pressure and counter-flow current technology, turbulence generated within the unit increases product contact coverage.

Fully packaged mobile unit, re-circulation pump, control system

Maximum extraction from hops, saving huge costs on raw materials

Rapid and effective dissolution of essential hop oils

Decrease in dissolved O2 levels & no CO2 loss, improving flavour & stability

Range of wedge wire filters to suit different products (hops/cocoa beans/fruit/spices)

Minimal installation on sitet

10 years guarantee (subject to terms and conditions)

High grade 304 stainless steel throughout

Polyurethane non-flammable insulation secures against heat loss

Durable laser welded cooling panels

Optimum hygiene & CIP

Recessed fully welded cladding around product outlets to avoid dead legs

Various cone shapes available from 30-70 degrees

Thermowell temperature pockets

Bespoke design and build options

Installation on site available or expert advice

10 years guarantee (subject to terms and conditions)

6-8 week lead time

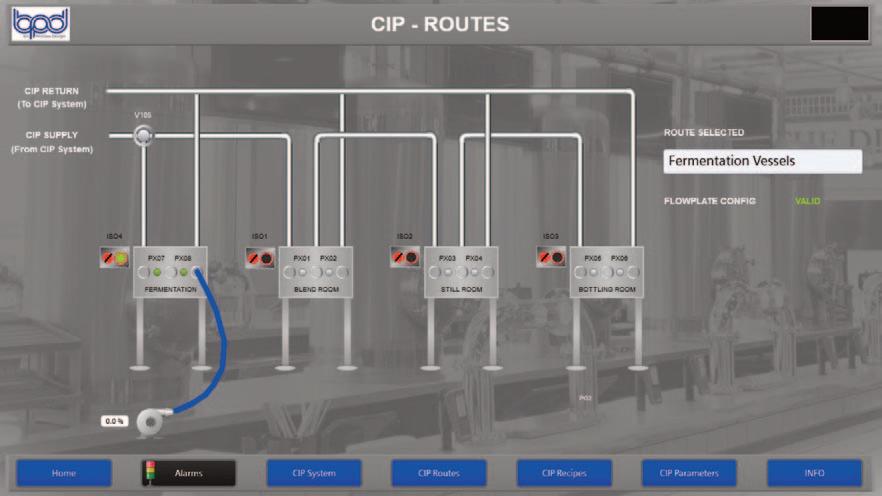

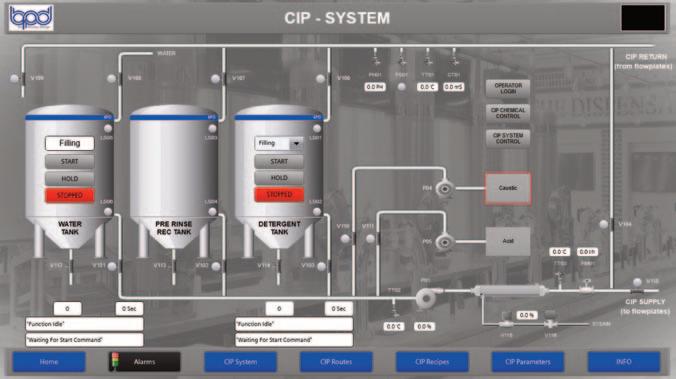

Manual or fully automated Hygienic cleaning of tanks, vessels & pipework in the dairy, food & beverage sectors.

Manual or fully automated Hygienic cleaning of tanks, vessels & pipework in the dairy, food & beverage sectors. At 6ix Process Design, we deliver both manual and fully automated CIP systems which can either come from our standard range, alternatively we can offer complete bespoke solutions to meet the requirements of our clients, from simple two tank, manually controlled skid mounted sets to three or four tank, multi-channel, fully automated systems, 6ix Process Design Ltd will have a solution.

Manual or fully automated Hygienic cleaning of tanks, vessels & pipework in the dairy, food & beverage sectors.

At 6ix Process Design, we realise that CIP is an important factor in any liquid/food production environment and the importance of minimising and limiting the duration of the CIP cycles, therefore we incorporate a number of features and benefits which help reduce the impact on production whilst providing a satisfactory clean, these are typically: -

CIP Recovery, allowing the re-use of chemicals, leading to significant reduction of chemical usage, overheads, and the environmental impact.

Variable Speed Drives for CIP Pumps, allowing full control over delivery and return flowrates, providing energy cost savings together with reduced wear and tear on components.

Automatic temperature and chemical dosing control, ensures effectiveness of CIP performance and optimised chemical consumption.

Insulated and Clad Vessels, providing minimum heat loss.

Automatic Intrinsic or ‘Self Clean’ feature together with removable internal sprayballs allows for cleaning of the CIP tanks themselves for effective removal of heavy internal soiling or scaling.

Large Hinged lockable Manway lids, allowing simple and easy tank inspections and/or manual chemical additions.

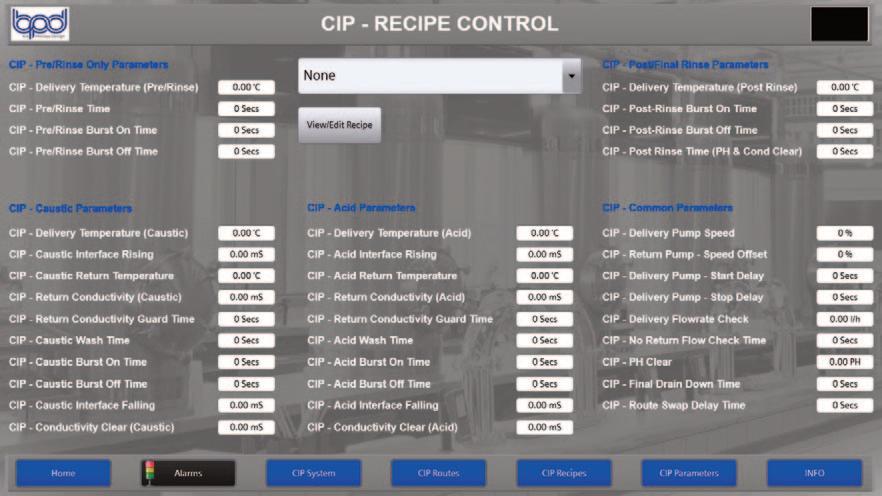

Fully sequenced CIP phases with route/recipe control and fully adjustable machine parameters, allowing maximum reliability and repeatability.

Optional Data Logging & Validation with real time and historical data, ensuring that the CIP system operates at maximum efficiency and satisfies any legislative requirements.

Optional ‘cloud based’ condition-based monitoring, remote access, and system warnings/alerts, providing the ultimate in plant diagnostics and preventative maintenance.

Manual or fully automated Hygienic cleaning of tanks, vessels & pipework in the dairy, food & beverage sectors.

At 6ix Process Design Ltd, we recognise that the operation and control of our CIP systems should be intuitive, simple to use, reliable and repeatable, our experienced team of engineers will deliver to requirement and provide a robust solution to suit the most demanding of needs.

Using high quality, branded and market leading control hardware, our systems are designed and built to last, together with smart and efficient programming, our CIP systems will deliver unrivalled benefits and maintain the hygienic cleanliness of any production plant.

For complex or bespoke CIP system requirements, we use the following approach.

Gather information/specific requirements from the client.

Consider any relevant codes of practice.

Produce a detailed line diagram and equipment schedule.

Generate a control system architecture and map out the system functions.

Create the relevant system functions for client approval.

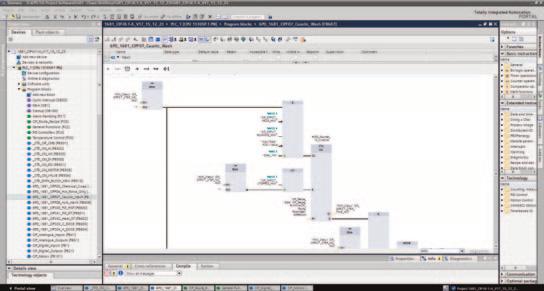

Engineer the HMI user Graphics and PLC software application.

Manual or fully automated Hygienic cleaning of tanks, vessels & pipework in the dairy, food & beverage sectors.

At 6ix Process Design Ltd, our team of automation engineers have developed and follow a standard structured approach when creating application documentation and software, this means that the structure of the PLC code or function blocks will directly represent the functional documentation and therefore providing seamless transparency between the two, this allows for efficient development of software and ease of diagnostics and support in the future.

Each system ‘function’ is given a unique identifier, this same identifier is used in the PLC program to label functions or function blocks, then, within these functions, each line of code (Typically written in ladder of FBD) will be commented using the same information from the approved documentation, allowing the user/engineer to quickly and easily identify the appropriate area of code, this method also allows simple modifications due to its flexible and modular approach.

Finally a step sequence chart is published which lists all of the necessary sequence steps, each step will have two unique step messages for the operator, one of which identifies the step, the other identifies the criteria required to progress to the next step, a dynamic step time and appropriate operator prompts, warning and alarms complete the package.

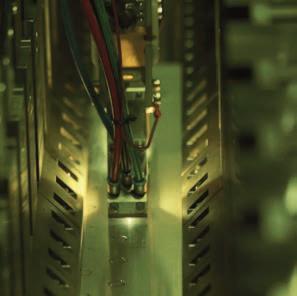

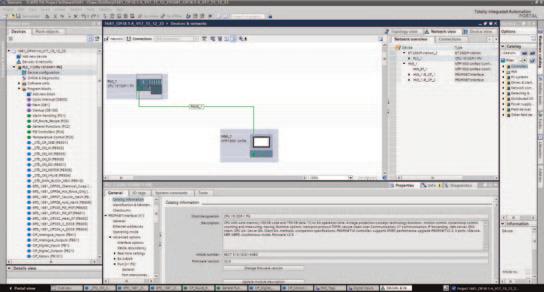

We can design and manufacture a diverse range of Control Systems and Automation solutions, offering complete turnkey solutions.

Our In-House team of Automation Engineers have experience of the following industrial controls software: Siemens Step Step 7 and TIA Portal V17/18, Allen Bradley RS Logix 500 and 5000 series, Mitsubishi GX Developer or IEC Developer, Omron CX Programmer, and various others.

At 6ix Process Design, we also design and manufacture a diverse range of control and automation systems in-house, offering complete turnkey solutions for typically:-

Brewhouses & Distilleries.

Liquid and Food Production Factories/Facilities.

Mixing and Blending.

Dairy Equipment.

Cheese Making Machinery.

Cleaning in Place (CIP).

Pasteurisation, Homogenisation, Filtration & Fermentation.

Product Tracking and Traceability.

Check weighing.

Data Logging.

Barcode Reading and Labelling.

Remote Access for Diagnostics and Troubleshooting.

We can design and manufacture a diverse range of Control Systems and Automation solutions, offering complete turnkey solutions.

Our control panels are designed to customers’ requirements and specifications utilising components from industry recognised and trusted suppliers. These can range from simple relay logic panels to fully automated PLC and HMI panels.

All panels are supplied with CAD schematic drawings and documentation and are fully tested before they leave our facility.

Our standard documentation typically includes.

Control Circuit Diagrams.

Recommended Spare Parts List.

Mechanical P&ID Drawings.

Mechanical Equipment Schedules.

Vendors Literature.

Operating Guides.

We can design and manufacture a diverse range of Control Systems and Automation solutions, offering complete turnkey solutions.

We are experienced in developing control system specifications such as URS & FDS Documentation using standard templates outlining the automation design for approval. Our Software style can be written using proven standard templates or to specific customer specification.

Complete Ownership & Copyright of all application software belongs to our clients by default. All of our application software is fully commented and can be compiled in ‘ladder’ or ‘FBD’, with or without our own Standard or tailor-made function blocks.

Siemens – S7 (Classic).

Siemens – S7-1500 (TIA Portal).

Siemens – S7 (Classic).

Allen Bradley – PLC5 / SLC500 / RSLogix 500 / ControlLogix / CompactLogix / MicroLogix / Micro800.

Mitsubishi – An, Q & FX series.

Omron – CX Programmer for the complete range.

Networks – most of our control systems have at least one network and we have experience of setting up and configuring the following:

Ethernet TCP/IP (Local & Wide area Networks) ControlNet/Devicenet.

Profibus – DP (PA for instrumentation).

Profinet.

Modbus.

I/O Link

We can design and manufacture a diverse range of Control Systems and Automation solutions, offering complete turnkey solutions.

Our Purpose Built 5,500 square foot Manufacturing Facility has a separate Electrical Design, Assembly & Test Facility, allowing Electrical Control Systems to be built and tested in a clean environment. Our assembly areas are large enough to accommodate full project assembly and production trials, ensuring complete satisfaction in terms of quality and performance.

We have developed an adaptive standard for control panels that form our core business and have created common build methods, meaning that all of our manufactured panels.

For compliance with the appropriate UKCA Safety Directives, we can offer: -

UKCA marking, automation machine risk assessment and technical file compilation.

Upgrading of existing automation machinery for machinery directive and UKCA compliance.

Designing new machine multi zone safety control systems – including safety PLC’s and Networks.

Upgrading of control circuits and machine wiring for UKCA compliance.

Manufacture of fixed guarding for UKCA compliance.

Installation and integration of safety devices – Safety switches, Light guards, Laser scanners and Safety Camera Systems.

Full compliance surveys including SISTEMA.

We can design and manufacture a diverse range of Control Systems and Automation solutions, offering complete turnkey solutions.

At 6ix process Design, our fully qualified and experienced team of Electrical Engineers are able to install and test the necessary field wiring and hardware to compliment the control system, from smaller installation work at our premises typically for ‘skid’ mounted machinery to much larger site-based projects and solutions. Our electrical engineers have a diverse background and have particular expertise and knowledge of Hygienic installations and methodology. They are qualified to the current IEE Wiring regulations and carry specific qualifications/certification for most site requirements. With the use of quality materials, a high attention to detail and a flexible approach, our engineers will provide quality work to meet the requirements whilst maintaining consistent high standards.

In conjunction with our Automation team, our electrical engineers will be involved with the initial testing and commissioning of our control systems, I/O Checking and rotation checks of motors and drives form part of their responsibility to ensure that the installation meets the specification and is ready for commissioning with water and product. Once happy with the infrastructure, the automation engineers will perform operational sequence testing of the software, flush and test the plant with water, ensuring that any necessary cleaning regime is carried out before finally checking the performance under process conditions and customer validation checks.

To complement and improve upon traditional wiring systems, 6ix Process Design have adopted the use of the latest wiring technologies and methods which deliver many benefits to our clients, these include.

Reduced Site Installation time

Simplified Electrical Connection Process

Quick and Flexible Modifications & Expansion

Smart and Intuitive Diagnostics

Easy Rectifications and Repairs

6ix Interface technology is compatible with virtually any common fieldbus system, it utilizes robust and proven network components and allows the simple connection of all actuators, sensors and field instruments, Process data is transferred in a digital format between the field devices and PLC control system, this vastly reduces errors in transmission and provides both fast and precise process data giving the highest level of accuracy.

We can design and manufacture a diverse range of Control Systems and Automation solutions, offering complete turnkey solutions.

During the commissioning phase it is normal to provide training to various disciplines including operators, engineers and technical production staff, our engineers can deliver ‘hands on’ training using the operational plant together with more in depth knowledge sharing for fault finding and maintenance purposes, documentation which typically comprises of Electrical Schematics, Recommended Spares and Vendors literature is provided with every control system, we can also produce and deliver Functional Specifications and User Operating Guides on request.

To complete our range of services, 6ix Process Design Ltd can offer support for all our control systems, this is typical for initial start-up of a new installation or going forwards could become regular site visits to carry out ‘health checks’ or perhaps remote access for fault finding and diagnostic purposes.

We can offer bespoke service support agreements to suit the requirements of the system or indeed the client, our aim is to respond within a specified timeframe to resolve any issues quickly and efficiently, all system documentation related to the installation is organised and stored on our servers for easy access when required to help us resolve matters effectively.

All reported issues are logged together with the solution and shared with our clients, collecting, and recording this data allows us to respond to repeat faults and or find permanent solutions to fix the problem efficiently.

Pipework installations and on-site services. skid & vessel installations.

Key Features

Process design

P & ID drawings

Project management

Skilled in-house pipe fitters

Fully purged & hygienically welded

In-house welding procedure in accordance with BS EN ISO 15614-1 : 2017 and ASME section IX

Welder qualification in accordance with BS EN ISO 9606-1 : 2017 and ASME section IX

IPAF

SSSTS (site supervisor safety training scheme)

SMSTS (site management safety training scheme)

RAMS provided with all work if required

Big job experience

Mobile shipping container workshop

We can also offer bespoke asset finance package.

Our dedicated professional design team is committed to the engineering excellence required from its extensive and varied client base in today’s manufacturing and construction environment. Our in-house resources gives us the capability to make one-off projects, as well as fabricate a batch of specific metal work and deliver higher volume production.

Our use of the latest technolagy combined with our highly skilled world class manufacturing trained workforce allows us to deliver precision - engineering metal work on time, to your exact specification and within budget.

At 6ix Process Design we pride our self on our customer service and quality of work, All vessels, skid products, bespoke and pipework supplied by us are guaranteed for 10 years with all moving parts covered for 3 years. We are able to offer this due to our highly skilled labour force and the fact we also possess a large spares warehouse consisting off most parts used on our products.

In addition to our standard guarantees, maintenance contracts can be supplied by us and offer planned preventative maintenance schedules to suit your budget and running hours. We are available via phone and email 24/7 365 days a year. Any urgent needs and assistance will be dealt with in a timely manner.

Here at 6ix Process Design, we have engineers on hand to service both equipment provided by ourselves and equipment supplied by other companies. We also offer service contracts with all our skid mounted equipment. Our service engineers are based at our South West facility and can be on-site anywhere within the UK in 24 hours or less.

At our South West, facility we have a large spares warehouse, stocking a large range of products, such as valves, fittings and pumps. As we supply our very own plate heat exchanger’s for inline cooling and heating products, replacement parts for this product are at hand. We offer next day delivery on skid mounted parts, ensuring you piece of mind that potential disruption to your business will be minimised.

As we are confident in the standard of our manufacturing and engineering practice, all 6ix Process Design products come with industry leading warranties. We also work alongside a carefully selected group of suppliers of moving parts, all of which come with their own manufactures warranty and advocacy of 6ix Process Design.