WorkshopManual

PrintN.604.13.542.01(III--2006)

THISALERTSYMBOLSIGNALSIMPORTANTMESSAGESINVOLVINGYOURSAFETY.

Readandheedcarefullythesafetyinstructionslistedandfollowtheprecautionsrecommendedtoavoid potentialrisksandtosafeguardyourhealthandyoursafety.

YouwillfindthissymbolinthetextofthisManualreferredtothefollowingkeywords:

WARNING --Cautionsdirectedtoavoidimproperrepairinterventionsinvolvingpotentialconsequencesfor theoperator’ssafety.

DANGER --Thesewarningsqualifyspecificallypotentialdangersforthesafetyoftheoperatororother personsdirectlyorindirectlyinvolved.

IMPORTANTNOTICE

AllmaintenanceandrepairinterventionsexplainedinthisManual mustbeperformedexclusivelybytheService OrganizationoftheManufacturer,observingstrictlytheinstructionsexplainedusing,whenevernecessary,the recommendedspecifictools.

Whoeverperformstheoperationsreportedwithoutfollowingexactlytheprecautionsisresponsibleonhisown,for thedamagesthatmayresult.

NeithertheFactorynoranyOrganizationsinitsDistributionNetwork,includingbutnotlimitedtonational,regional orlocaldistributors,areresponsibleforanyliabilityarisingfromanydamageresultingfromdefectscausedbyparts and/orcomponentsnotapprovedbytheFactoryforuseinmaintainingand/orrepairingproductsmanufacturedor merchandizedbytheFactory.

Inanycase,nowarrantyofanykindismadeorshallbeimposedwithrespecttoproductsmanufacturedor merchandizedbytheFactory,whenfailuresarecausedbytheuseofpartsand/orcomponentsnotapprovedbythe Factory.

AVOIDACCIDENTS

Mostaccidentsandinjuriesoccurringinindustry,onthefarm,athomeorontheroad,arecausedbythefailureof someindividualtofollowsimpleandfundamentalsafetyrulesorprecautions.Forthisreason,MOST ACCIDENTSCANBEPREVENTEDbyrecognizingtherealcauseandtakingthenecessaryprecautions,before theaccidentoccurs.

Regardlessofthecareusedindesignandconstructionofanytypeofequipment,theremaybeconditionsthat cannotbecompletelysafeguardedagainstwithoutinterferingwithreasonableaccessibilityandefficient operation.

Acarefuloperatoristhebestinsuranceagainstaccidents.Thecompleteobservanceofonesimplerulewould preventmanythousandsseriousinjurieseachyear.

Thisruleis:Neverattempttoclean,lubricateoradjustamachinewhileitisinmotion.

WARNING

Onmachineshavinghydraulically,mechanicallyand/orcablecontrolledequipment(suchasshowels, loaders,dozers,scrapersetc.)becertaintheequipmentisloweredtothegroundbeforeservicing, adjustingand/orrepairing.

Ifitisnecessarytohavetheequipmentpartiallyorfullyraisedtogainaccesstocertainitems,besure theequipmentissuitablysupportedbymeansotherthanthehydraulicliftcylinders,cableand/or mechanicaldeviceusedforcontrollingtheequipment.

MODELCODES

Thecompleterangeoftelescopichandlers(Telehandler)describedinthismanualisidentifiedinthetextby referencetothemaximumextensionofthetelescopicarm.

Thevehicleslistedbelowmaynotbeavailableinallcountriesormarkets,thereforeforthelatestinformation consultyourauthoriseddealer.

SECTION55--ELECTRICALSYSTEM

Diagram1:Starter/Recharge/Warning/Indicatorslights53

Diagram3:Wheelalignment/Hydraulicsolenoids/Brakesystem57

Diagram5:Stabiliser

Diagram6:Lights/Windscreenwiper63

Diagram7:Worklamps/Roofbeaconlight65

Diagram8:Tiltingpreventionsystem/Roofwiper67

Diagram9:Heating/Soundsystem/Electricsocket/Interiorlamp69

GENERALINSTRUCTIONS

IMPORTANTNOTICE

AllmaintenanceandrepairinterventionslistedinthisManualmustbeperformedexclusivelybytheService NetworkoftheManufacturer,complyingstrictlywiththeindicationshereinandusing,whenrequired,the prescribedspecialtools. Whoeverperformsserviceoperationsdescribedhereinwithoutcomplyingstrictlywiththeinstructionsbecomes solelyresponsibleforanyconsequentialdamagethatcouldoccur.

ADJUSTINGSHIMS

Foreachadjustmentselecttheadjustingshims,measuringthemonebyonewithamicrometerandaddingto gethersubsequently,thevaluesmeasured.Donotrelyonthemeasurementoftheentirepack,thatcouldbe wrong,orthenominalvalueindicatedoneachring.

SEALSFORROTATINGSHAFTS

Forcorrectinstallationofthesealsforrotatingshafts,pleasecomplywiththefollowingprecautions: --priortoinstallation,keepthesealssoakingforatleasthalfanhourinthesameoiltheyaregoingtoseal; --cleanthoroughlytheshaftandmakesurethatitsworkingfaceisundamaged; --directthesealingliptowardthefluid;intheeventthelipisofthehydrodynamictype,thegroovesmustbe directedsothat,inrelationtotherotatingdirectionoftheshaft,theytendtoreturnthefluidtowardtheinside ofthesealingdevice;

--smearthesealinglipwithafilmoflubricant(oiltobepreferredtogrease)andfillwithgreasethegapbetween sealinglipanddustlipintwinlipseals;

--insertthesealinitsseat,pressingitwithapunchwithaflatface;neverstrikeitwithahammerormallet; --whenpressingintheseal,makesurethatitisinsertedperpendicularlyinrelationtotheseatand,oncein position,makesurethat,whenrequired,itcontactstheshoulder;

--topreventthesealinglipofthesealbeingdamagedbytheshaft,insertappropriateprotectionduringthe installationofthetwoparts.

“0--RING”TOROIDALSEALS

LubricateO--ringsbeforeinsertingthemintherelevantseatstopreventthembecomingtwistedandrolledduring installation,thusjeopardisingtheirsealingcapacity.

SELAINGCOMPOUNDS

MatingsurfacemarkedXmustbesmearedwithasealingcompoundrecommendedbytheManufactureroran adequateequivalent.

Priortoapplyingthecompound,preparethesurfacesinthefollowingmanner: --removeallpossiblescalingwithametalbrush; --degreasethesurfacesthoroughlyusingthedegreesingagentrecommendedbytheManufactureroran adequateequivalent.

BEARINGS

Wheninstallingbearings,itisrecommendedto: --warmthemupto80 –90 C(176–194 F)beforeinstallingthemontherelevantshafts; --coolthemdownbeforeinsertingthemintherelevantseatswithanouterfitting.

SPLITPINS

Wheninstallingsplitpins,makesurethatthecutispointinginthedirectionoftheloadonthepin. Ontheotherhand,spiralelasticpinsdonotrequireanyinstallationorientation.

NOTESONSPAREPARTS

Usegenuine sparepartsguaranteedbytheManufacturer only. Genuinesparepartsaretheonlyonesensuringthesamequality,thesamelifeandthesamesafetyasthe originallymountedparts,sincetheyarethesameastheonesinstalledinproduction. Onlygenuinepartsfromthemanufacturerensurethisguarantee. Ordersforsparepartsmustincludethefollowingindications: --modelofthevehicle(commercialdesignation)andserialnumber; --typeandnumberoftheengine; --partnumberfortheitemordered,asprovidedbythe“Microfiches”orthe“SparePartCatalogue”,onwhich theorderisbased.

NOTESONTOOLING

ThetoolingthattheManufacturerrecommendsandillustratesinthisManualis: --studiedanddesignedspecificallyforservicingvehiclesofthisrange; --requiredtoensureareliablerepair; --accuratelydevelopedandinspectedtoprovideeffectiveandlonglastingworking. Youarealsoremindedthatcorrecttoolingallowsyouto: --tooperateunderoptimisedtechnicalconditions; --toachievethebestresults; --tosavetimeandeffort; --toworkinsaferconditions.

WARNING

Thewearlimitsprovidedforsomeitemsmustbeconsideredasrecommendedvalues,butnotabsolutelybinding. Theindications“front”,“rear,“right”,“left”refertodifferentpartsasseenseatingfromintheoperator’sseat orientedinthenormaltraveldirectionofthevehicle.

HOWTOMOVEAVEHICLEWITHOUTBATTERIES

Thecablesoftheexternalpowersupplymustbeconnectedexclusivelytotherespectiveterminalsofthepositive andnegativecablesofthevehicle,usingefficientclampsprovidingadequateandsafecontact.Intheeventit isnecessarytochecktheoperationoftheelectricalsystemofthevehicle,doitexclusivelywiththepowersupply connected.Attheendoftheinspection,disconnectallactuatorsanddeactivatethepowersupplybefore disconnectingthecables.

604.13.542.01 --03--2006

SAFETYRULES

PAYATTENTIONTOTHISSYMBOL

Thisalertsymbolannouncesimportantmessagesinvolvingyoursafety.

Readcarefullythesafetyinstructionslistedandfollowtheprecautionsrecommended toavoidpotentialrisksandtosafeguardyourhealthandyoursafety. YouwillfindthissymbolinthetextofthisManualwiththefollowingkeywords:

WARNING --Cautionsintendedtoavoidimproperrepairinterventionsinvolving potentialconsequencesforthesafetyofthepersonnelperformingtherepairs.

DANGER --Thesewarningsqualifyspecificallypotentialdangersforthesafetyofthe operatororotherpersonsdirectlyorindirectlyinvolved.

AVOIDACCIDENTS

Mostaccidents,whethertheyoccurinworkshop,on thefarm,athomeorontheroad,arecausedbythe failureofsomeindividualstofollowsimpleandfundamentalsafetyrulesandprecautions.ForthisreasonMOSTACCIDENTSCANBEPREVENTEDby recognisingtherealcauseanddoingsomething aboutitbeforetheaccidentoccurs.

Regardlessofthecareusedinthedesignandconstructionofanytypeofequipment,therearemany conditionsthatcannotbecompletelysafeguarded againstwithouthinderingreasonableaccessibility andefficientoperation.

Acarefuloperatoristhebestinsuranceagainstan accident.

Thecompleteobservanceofonesimplerulewould preventmanyseriousaccidents.

DANGER. Neverattempttoclean,lubricateormaintainamachinewhileitisinmotion.

SAFETYRULES

SAFETYRULES

Readandheedallsafetyrulesbeforeanyintervention.

Donotwearrings,wristwatches,jewellery,and looseorhangingapparels,suchasties,torn clothing,scarves,unbuttonedorunzipped jacketsthatcancatchonmovingparts.Wear propersafetyequipmentasrecommendedfor thejob.Examples:hardhat,heavygloves,ear protection,safetyglassesorgoggles,reflector vests,respirator.Consultyouremployerforspecificsafetyequipmentrequirements.

Donotperformanyserviceoperationonthe machinewithapersonseatedintheoperator’s compartment,unlessheisanauthorisedoper-

atorco--operatingintheoperationtobeperformed.

Neverattempttooperatethemachineoritstools fromanypositionotherthanseatedintheoperator’sseat.

Neverperformanyinterventiononthemachine withenginerunningunlessthisisprescribed.

Cut--offtheengineandmakesurethatallpressuresinthehydraulicsystemsarereleased beforeremovingcaps,covers,valvesetc.

Allserviceinterventionsmustbeperformedwith theutmostcareandattention.

Shopand/orfieldserviceplatformsorladders mustbeconstructedandmaintainedinaccordancewithlocalandnationalregulations.

Disconnectthebatteriesandtagallcontrolsto signalthataninterventionisinprogress.Block themachineandallequipmentthatmustbe lifted.

Donotchecknorrefillfueltanks,aswellasbatteries,norusestartingfluidwhilesmokingor nearopenflamessincethesefluidsareflammable.

Brakesareinactivewhenmanuallyreleasedfor serviceinterventions.Undersuchcircumstancesitisnecessarytomaintainthecontrolof themachineusingappropriateblocksorsimilar devices.

Thefuel--fillingnozzlemustbekeptconstantly insidethefillingneck.Keepthiscontactfromthe beginningtotheendofthefuellingoperationto avoidthepossibilitythatsparksduetostatic electricityaregenerated.

Useonlydesignatedtowingorattachingpoints. Usecareinmakingattachments.Makesurepins and/orlocksaresecurebeforepulling.Stayclear ofdrawbars,cablesorchainsunderload.

Tomoveadisabledmachine,useatrailerora low--boy,ifavailable.

Toload/unloadamachinefromtransporter, choosealevelsurfaceensuringfirmsupportto thewheelsoftruckortrailer.Anchorthemachine securelytothebedoftruckortrailerandblock wheelsortrackswithappropriatewedges.

Useonlyapprovedgroundedauxiliarypower sourcesforheaters,chargers,pumpsandsimilarequipmenttoreducethehazardsofelectrical shocks.

Liftandhandleheavypartswithaliftingdevice ofpropercapacity.

Bewareofbystanders.

Neverpourgasolineordieselfuelintoopen, wideandlowcontainers.

Neverusegasoline,solventorotherflammable fluidtocleanparts.Useexclusivelyqualified, non--flammable,non--toxiccommercialsolvents.

Whenusingcompressedairforcleaningparts, usesafetyglasseswithsideshieldsorgoggles.

Limitpressureto2.1bar,inaccordancewith localandnationalregulations.

Donotruntheengineinclosedareaswithout properventilationtoremovedeadlyexhaust fumes.

Donotsmokeorpermitanyopenflamesorspark nearwhenre--fuellingorhandlingflammable materials.

Donotuseanopenflameasalightsourceto lookforleaksorforinspectionanywhereonthe machine.

Movewithextremecarewhenworkingunderthe machine,itsattachmentsandoronornear them.Alwayswearprotectivesafetyequipment asrequired,suchashardhat,goggles,safety shoes,earplugs.

Whenperformingoperationsrequiringrunningof theengine,haveaqualifiedoperatorintheoperator’sseatatalltimeswiththemechanicon sight.Placethetransmissioninneutralandset thebrakesandsafetylock.

Forfieldservice,movemachinetolevelground, ifpossible,andblockit.Ifworkonaninclineis absolutelynecessary,firstblockmachineandits attachmentssecurely,thanmoveittolevel groundassoonaspossiblewithacertainmargin ofsafety.

604.13.542.01 --03--2006

Donottrustwornand/orkinkedchainsand cables:donotusethemforliftingorpullingoperations.Tohandlethem,alwaysuseheavy gloves.

Besurechainsandcablesareanchoredandthe anchorpointsarestrongenoughtohandlethe expectedload.Keepexposedpersonnelclearof anchorpointsandcablesorchains.No bystandersareallowednearthehookingpoints, chainsorcables.

Keeptheareawheremaintenanceoperations areperformedCLEANandDRY.Eliminate immediatelyallwaterandoilspillages.

Donotpileupoilyorgreasyrags;theyrepresent afirehazard.Storeinaclosedmetalcontainer.

Beforestartingmachine,check,adjustandlock theoperator’sseatformaximumcomfortand controlofthemachine.Besureexposed personnelintheareaofoperationareclearofthe machinebeforemovingitoritsattachments. Soundthehorn.

Donotcarrylooseobjectsinpocketsthatmight fallunnoticedintoopencompartments.

Wearproperprotectiveequipmentsuchas safetygogglesorsafetyglasseswithside shields,hardhat,safetyshoes,heavygloves whenmetalorotherparticlesareapttoflyorfall.

Wearweldersprotectiveequipmentsuchas darksafetyglasses,helmets,protectiveclothing,glovesandsafetyshoes,whenweldingor burning.Weardarksafetyglassesnearwelding zones.DONOTLOOKATARCWITHOUT PROPEREYEPROTECTION.

Steelcablesarefrayedafterprolongeduse; alwayswearappropriateprotections(heavy gloves,gogglesetc.).

Handleallpartscarefully.Keephandsand fingersawayfromstructures,gearsormoving parts.Useandwearalwaystheappropriate protections,suchassafetygoggles,glovesand safetyshoes.

STARTING

Donotruntheengineinclosedareaswithout properventilationtoremovedeadlyexhaust fumes.

Donotplacehead,body,limbs,feet,handsor fingers,nearrotatingfansorbelts.Beespecially alertnearpusherfans.

ENGINE

Loosentheradiatorcapveryslowly,torelease pressurefromthesystem,beforeremovingit.All coolantleveltop--upsmustbeperformedwith engineinoperativeoratlowidle,ifwarm Donotrunenginewhenrefuellingandusecare iftheengineishotduetotheincreasedpossibilityofafireiffuelisspilled.

Neverattempttocheckoradjustfanbeltswhen engineisrunning.Donotadjustenginefuel pumpwhenmachineismoving.

Neverlubricatethemachinewithenginerunning.

ELECTRICALSYSTEM

Shouldboosterbatteriesbeused,rememberto connectbothendsoftheboostercablesinthe propermanner(+)with(+)and(--)with(--).Avoid short--circuitsoftheterminals.Followthoroughly theinstructionsofthisManual. Avoidshortcircuitingtheterminals.BATTERY GASISHIGHLYFLAMMABLE.Leavebattery boxopentoimproveventilationwhenrecharging batteries.Nevercheckchargebyplacingmetal objectsacrosstheposts.Keepsparksoropen flamesawayfrombatteries.Donotsmokenear batterytoguardagainstthepossibilityofcausing anexplosion.

Beforeanyintervention,makesurethatthere arenofuelorelectrolyteleakages;eliminate thembeforeproceedingwithfurtherwork. Whenrechargingbatteriesinclosedambient, makesurethatthereisappropriateventilationto preventpossibleaccidentalexplosionsdueto theaccumulationofgasesgeneratedduringthe recharge.

Beforeanyintervention,makesurethatthemain switchisOFF.

HYDRAULIC SYSTEM

Fluidescapingunderpressurefromaverysmall holecanbealmostinvisibleandcanhavesufficientforcetopenetratetheskin.Useapieceof cardboardorwoodtosearchforsuspectedpressureleaks.DONOTUSEHANDS.Ifinjuredby escapingfluid,seeadoctoratonce.Serious infectionorreactioncandevelopifpropermedicaltreatmentisnotadministeredimmediately. Incasepressuresmustbemeasured,use instrumentsofadequatecapacity.Alwaysfollow therecommendedprocedures.

WHEELSANDTYRES

Makesurethattheinflationpressureofthetyres isaccordingtothespecificationsissuedbythe Manufacturerandcheckitperiodically.

Shouldthepressurebechanged,standonthe sideofthetyreatasafedistance.

Pressurecheckoperationsmustbeperformed withunloadedmachineandcoldtyres.Never usereconditionedtyrerims,sinceeventual weldings,heat--treatmentsorrepairsnotperformedcorrectlycanweakenthewheel,thus causingsubsequentdamagesordangers.

Donotperformtorchcuttingorweldingoperationsonrimswithinflatedtyresinstalled.

Beforeoperatingontyres,blockallwheels,front andrear.Afterjackingthemachine,blockitwith standsaccordingtocurrentsafetyrulesand regulations.

Beforeremovingobjectsfromthetyretread, deflateit.

Neverinflatetyreswithflammablegas; explosionsandseriousbodilyinjuriesmay result.

REMOVALSANDINSTALLATIONS

Liftandhandleallheavypartswithliftingdevices ofadequatecapacity.Makesuethattheparts areattachedtoliftingdevicesareproperly slinged.Usetheliftingeyesprovided.Bewareof personsinthevicinity.

Handleallpartscarefully.Keephandsand fingersawayfromstructures,gearsormoving parts.Useandwearalwaystheappropriate protections,suchsgoggles,glovesandsafety shoes.

Preventchainsandcablesfromkinking.To handlethem,alwaysuseheavygloves.

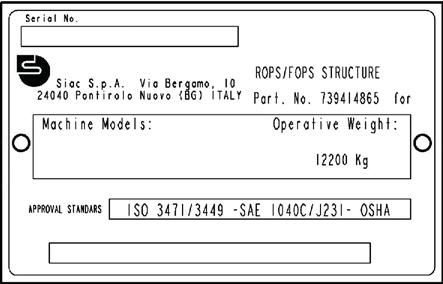

PRODUCTIDENTIFICATION

TheTelehandleranditsmaincomponentsareidentifiedbyvariousnumbersandlettersprovidingits identificationbytheServicenetwork.Thefollowing informationgivesthelocationoftheidentification plates,ofthenumbersstampedonthemachineand variousexamplesofwhatcanbefoundonthe machine.

VEHICLESERIALNUMBER

Theserialnumberisstampedonthefrontpartofthe machine,ontheuppersideofthemainframe,right side.

NOTE: Theserialnumberandtheidentification numberofthecomponentscanberequestedbythe DealerwhenSparePartsareorderedorinterventionsarerequired.Thesenumbersarealsorequired ashelpinidentifyingthemachineintheeventoftheft. Keeptheminasafeplace.

VEHICLEIDENTIFICATIONPLATE

Themachineidentificationplateislocatedontheleft handoftheseatpod.Recordthedataofyour machinebelow.

TECHNICALTYPE/MODEL

ENGINEIDENTIFICATION

Theengineidentificationinformationislocatedon theleft--handsideoftheengineblock.Recordthe informationbelowforquickreferenceincaseof necessity.

MODELNO.

SERIALNO.

DATECODE

FRONTAXLEIDENTIFICATION

Theserialnumberandaxletypeisprintedonthe plate(1)locatedonthefrontoftheaxlehousing. Recordtheinformationbelowforquickreferencein thecaseofnecessity.

AXLETYPE

SERIALNO.

DATECODE

4x3POWERSHIFTTRANSMISSION IDENTIFICATION

Theserialnumberandtypeisprintedontheplate(1), onthelowersideofthetransmission.Recordthe informationbelowforquickreferenceinthecaseof necessity.

MODELNo.

SERIALNo.

DATECODE

IDENTIFICATIONOFREAR TRANSMISSION

Theserialnumberisindicatedonplate(1)secured onthereartransmissionhousing.Copyherethe serialnumber,forapromptconsultationincaseof necessity.

AXLETYPE

SERIALNo.

DATECODE

IDENTIFICATIONOFCAB

Thecabidentificationplateincludestheserial numberandadditionaldataandislocatedonthe frontsideoftheseat.Pleasecopyherebelowthe serialnumberforapromptconsultationincaseofnecessity.

SERIALNo.

DATECODE

604.13.542.01 --03--2006

ENVIRONMENTALCONSIDERATIONS

Thefollowingrecommendationscanbeuseful:

Becomefamiliarandmakesureyouhavewell understoodtherelevantlegislationineffectin yourcountry.

Intheeventnoregulationsexist,askforspecific informationwiththesuppliersoflubricants,antifreezeanddetergentsregardingtheireffectson humansandtheenvironmentandhowtostore, handleanddisposeofthesesubstancessafely.

4.Avoidspillagewhendrainingusedcoolantmixtures,engineoils,transmissionandhydraulic fluids,brakefluid.Afterdraining,donotmix brakefluidorfuelwithlubricants.Storethemina riskfreemanneruntilwhentheycanbedisposed ofinanadequateway,inaccordancewithlocal regulationsandtheresourcesavailable.

5.Moderncoolingmixtures,suchasantifreezeand otheradditives,mustbechangedeverytwo years.Maximumattentionmustbepaidtopreventthattheyspillovertheground.Theymustbe collectedanddisposedofsothatdonotcreate anydanger.

6.Donotunsealairconditioningsystembyyourselves,sincetheycancontaingasesthatmust notbereleasedintotheatmosphere.Thepersonnelspecialisedinairconditionersuses specialequipmenttochargeanddischargeair conditioningsystems.

Usefulindications

1.Donotfilltankswithinadequatecanistersordispensingpressurisedsystemsthatcouldcause considerablespillage.

2.Ingeneral,avoidthecontactoftheskinwithany fuel,oil,acid,solventetc.Themajorityofthem containsubstancedangerousforyourhealth.

3.Modernlubricantscontainadditives.Donotburn contaminatedfuelsand/orwedoilsinnormal heatingburners.

7.Repairatonceanyleakageordefectofthe enginecoolingsystemorhydraulicsystem.

8.Donotincreasethepressureofanypressurised system,sincethiscouldcauseseriousproblems tothecomponentsofthesystem.

9.Protecthoseswhenperforminganywelding, sinceasplashofweldingmaterialscouldpenetrateandburnthem,causingaholeorweakeningthewallwithsubsequentleakagesofoil, coolantetc.

MAINTENANCETECHNIQUES

GENERALNOTICES

Cleantheoutsideofallthecomponentspriortoperforminganytypeofrepair.Dirtandabrasivedustcan reducetheefficientlifeexpectancyofacomponent andresultinexpensiverepairs.

Thetimespentinpreparingandcleaningworking surfacesisgivingresults,makingworkeasierand safer,andthecomponentsoverhauledwillbemore reliableandoperatebetter.

Usecleaningfluidsproventobesafe.Sometypesof fluidcancauseseriousproblemstoO--Ringsandirritatetheskin.Itisnecessarytocheckthatthesolventsaresuitabletocleanthecomponentsandthat oftheyarefreeofrisksforthehealthofworkers.

ReplaceO--Rings,sealingringsandsealseverytime theyaremoved.NeveruseoldO--Ringsorsealsand newonestogether,independentlyfromtheirconditions.AlwayslubricatenewO--Ringsandsealswith hydraulicoilbeforeinstallingthem.

Whenreplacingcomponents,alwaysusethetooling requiredbythistypeofwork.

HOSESANDSTEELPIPES

Alwaysreplacehosesandsteelpipeswhenthetaper endorconnectionsaredamaged.

Whenanewhoseisinstalled,connectitwithout tighteningtheendsandmakesurethatitisroutedin thecorrectmanner,beforetighteningtheends.Fixturesmustbetightenedjustenoughtoholdthehose withoutsqueezingit,avoidingrubbingaswell. Afterreplacingahoseofmovingcomponents,make surethatthehoseisnotdisturbedbythemovement ofthecomponentinanyposition.

Makesurethatallhosesinstalledarenotchokedor bent.

Ifhoseconnectionsaredamaged,dented,chokedor leaking,decreasetheflowofoilandtheproductivity oftherelevantactuators.Connectionsshowing signsofdisplacementfromtheiroriginalpre-pressedpositionmustbeconsideredasalready broken,sincetheyaregoingtofailorseparatesoon. Ahosewitharaggedoutersleeveallowswaterto penetrate.Thus,hiddencorrosionofthereinforcing wirewilldevelopalongtheentirelengthofthehose, withthesubsequentfailureofthehoseitself.

Ifahoseswells,thisindicatesthatthereisaninternal leakageduetoastructuralfailure.Thiscondition deterioratesveryquicklyandcausesthefailureof thehose.

Clogged,squeezed,excessivelytensionedor deformedhosesaregenerallyeasilysubjecttoflow reduction,decrementoftheoperationalspeedofthe fluidandthefinalfailureofthehose.

Loosehosesmovefreelyandmustbeprevented fromtouchingeachotherandnearbysurfaces.This causesarubbingactionshorteningtheusefullifeof thehose.

CONNECTIONSWITHFRONTSEALING O--RINGS

Whenrepairingconnectionswithfrontsealing O--Rings,pleasecomplywiththefollowingprocedures.

WARNING:NEVERDISCONNECT,NOR TIGHTENAHOSEORASTEELPIPEUNDER PRESSURE.IFINDOUBT,MOVETHECONTROL LVERSSEVERALTIMESWITHTHEENGINE INOPERATIVEBEFOREDISCONNECTINGA HOSEORASTEELPIPE.

1.Loosentheconnectionsandseparatethehose orsteelpipe,thenremoveandeliminatethe O--Ringsfromtheconnection.

2.DipanewO--Ringinclean,hydraulicoilbefore installingit.InstallthenewO--Ringintheconnectionand,ifnecessary,holditinitsposition withvaseline.

3.Installanewhoseorsteelpipeandtightenmanuallytheconnectionholding,atthesametime, thepipestilltopreventitfromturning.

4.Usetwowrenchestotightentheconnectionto thetorqueprescribedforitssize.Pleasereferto thetabletofollowforthetighteningtorques.

NOTE:toensurethatajointdoesnotleak,itis importantthattheconnectionsareneither excessivelytightenednortoolittle.

604.13.542.01 --03--2006

SPECIFICSEALINGCOMPOUNDS

Thefollowingsealingcompoundsmustbeused,complyingwiththeindicationsprovidedbytheManual:

SEALANTSCOMMERCIALNAME

AnaerobicsealantLOCTITE518(liquidgasket)

RTVsiliconsealantLOCTITESUPERFLEX593,595or596 LOCTITEULTRABLUE587DOWCORNINGSILASTIC 732GENERALELECTRICRTV103or108

PipesealantPST592(pipesealantwithteflon)

Lockingcompoundfor threads LOCTITE243/RED(sealant/lockingforthreads)

TIGHTENINGVALUESFORFASTENERS

Checkperiodicallythatthefastenersareproperly tightened.

Baseduponthetablestofollow,determinethecorrecttighteningtorquewhenpartsofthefastening componentsarechecked,adjustedorreplaced.

IMPORTANT:DONOTusethevalueslistedinthe tableswhentheManualindicatesadifferenttorque

ortighteningprocedureforaspecificapplication.The torquevaluesareprovidedforgeneraluseonly. Makesurethatthethreadsofthefastenersareclean andundamaged.

NOTE: useatorquewrenchtotightenfastenerscorrectly.

METRICBOLTSANDLOCKNUTS

IDENTIFICATION

HEXSCREWS(WITHOUTNUT)ANDROUNDHEADBOLTS

CLASS5.6ANDHIGHER

IDENTIFICATIONOFTHEMANUFACTURER

HEXNUTSANDTIGHTENINGNUTS CLASS05ANDHIGHER

IDENTIFICATIONOFTHEMANUFACTURER

DIMENSION

INCHMEASUREMENTSCREWSANDLOCKNUTS GRADESAE2GRADESAE5GRADESAE8

GRADESAE2 GRADESAE5 GRADESAE8

GRADEIDENTIFICATION

GRADEA:NOCUTS

GRADEB:ONEPERIMETERCUT

GRADEC:TWOPERIMETERCUTS

NORMALNUTS HEXNUTS GRADESAE5 HEXNUTS GRADESAE8

GRADEIDENTIFICATION

GRADEA:NEWMARK

GRADEB:THREEMARKS

GRADEC.SIXMARKS

THEMARKSARENOTCOMPULSORILY LOCATEDINTHECORNERS

GRADEA.NOMARKS

GRADEB:LETTERB GRADEC:LETTERC

GRADEIDENTIFICATION

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please