Part number S5HW0040E01

1st edition English October 2014

1 2 3 4 5 6 SPECIFICATIONS SECTION MAINTENANCE SECTION SYSTEM SECTION

DISASSEMBLY SECTION

TROUBLESHOOTING

ENGINE SECTION

Book Code No.

Distribution Year–Month

S5PA0105E01 2014-06

S5PW0240E01 2014-06

S5PW0340E01 2014-06

S5PX1111E01 2014-06

S5PX1212E01 2014-06

S5PW1340E01 2014-06

S5PX2112E01 2014-06

S5PW2240E01 2014-06

S5PX2312E01 2014-06

S5PW2440E01 2014-06

S5PX2512E01 2014-06

S5PA3105E01 2014-06

S5PW3240E01 2014-06

S5PW3340E01 2014-06

S5PW3440E01 2014-06

S5PX4211E01 2014-06

S5PS4314E01 2014-06

S5PW4431E02 2014-06

S5PS4613E01 2014-06

S5PX5112E01 2014-06

PW15-50001~

OUTLINE

SPECIFICATIONS

ATTACHMENT DIMENSIONS

TOOLS

STANDARD MAINTENANCE TIME SCHEDULE

MAINTENANCE STANDARD AND TEST PROCEDURE MECHATRO CONTROL (OPT.)

HYDRAULIC SYSTEM

ELECTRIC SYSTEM

COMPONENTS SYSTEM

AIR-CONDITIONER SYSTEM

DISASSEMBLING & ASSEMBLING

ATTACHMENT

UPPER STRUCTURE

TRAVEL SYSTEM

HYDRAULIC SYSTEM

ELECTRIC SYSTEM

TABLE OF CONTENTS

1.1.3DISASSEMBLINGANDASSEMBLINGHYDRAULICEQUIPMENT

FirstEditionJune,2009E10SR:PA03-05001~ S5PA0105E01 (NHK-EUR)

December,2010SK55SRX:PS02-00101~ (KOR)

January,2011SK50P:PS02-00101~ (SEAsia)

March,2011SK55SRX:PS02-00101~ (AUS)

CX55BX:PS02-00101~ (CASE-AUS)

E55BX:PS02-00101~ (NH-AUS)

September,2013SK27SR-5:PV13-34084~ (NA)

SK17SR-3:PU09-10115~ (NA)

SK35SR-5:PX15-22809~ (NA)

SK55SRX-6E:PS04-10001~ (NorthAmerica)

November,2013SK10SR-2:PA03-05001~ (EUR)

SK17SR-3:PU09-10115~ (EUR)

December,2013SK27SR-5:PV13-34084~ (EUR)

SK55SRX-6:PS03-05001~ (OCE)

SK30SR-5:PW14-46519~ (EUR)

SK35SR-5:PX15-22809~ (EUR)

January,2014SK50P-6:PS03-05001~ (SEAsia)

SK55SRX-6:PS03-05001~ (KOR)

April,2014SK55SRX-6:PS03-05001~ (EUR)

May,2014SK35SR-6E:PX17-40001~ (NorthAmerica)

June,2014SK35SR-6:PX16-30001~ (OCE)

SK30SR-6E:PW16-80001~ (NorthAmerica)

SK45SR-6:PH08-10001~ (OCE)

SK30SR-6:PW15-50001~ (OCE)

1.1.1PREPARATIONBEFOREDISASSEMBLING

(1)Understandingoperatingprocedure

ReadOPERATOR'SMANUALcarefullytounderstandtheoperatingprocedure.

(2)Cleaningmachines

Removesoil,mud,anddustfromthemachinebeforecarryingitintotheserviceshoptopreventloss ofworkefficiency,damageofparts,anddifficultyinrustpreventionanddustprotectionwhile reassembling.

(3)Inspectingmachines

Identifythepartstobedisassembledbeforestartingwork, determinethedisassemblingprocedureby yourselfconsideringtheworkshopsituationsetc.,andrequestprocurementofnecessarypartsin advance.

(4)Recording Recordthefollowingitemsforcommunicationandpreventionofrecurringmalfunction.

1.Inspectiondateandplace.

2.Modelname,applicablemachinenumber,andhourmeterread.

3.Troublecondition,placeandcause.

4.Visibleoilleakage,waterleakageanddamage.

5.Cloggingoffilters,oillevel,oilquality,oilcontaminationandlooseningofconnections.

6.Resultofconsiderationifanyproblemexistsbasedonthe operationratepermonthcalculated fromhourmeterindicationafterthelastinspectiondate.

(5)Arrangementandcleaninginserviceshop

1.Toolsrequiredforrepairwork.

2.Preparespacetoplacethedisassembledparts.

3.Prepareoilcontainersfordrainingoiletc.

1.1.2SAFETYINDISASSEMBLINGANDASSEMBLING

(1)Wearappropriateclotheswithlongsleeves,safetyshoes,safetyhelmetandprotectiveglasses.

(2)Suspendwarningtag"DONOTOPERATE"fromthedoorknobortheoperatinglever,andhavea preliminarymeetingbeforestartingwork.

(3)Stoptheenginebeforestartinginspectionandmaintenancetopreventtheoperatorbeingcaught inmachine.

(4)Identifythelocationofafirst-aidkitandafireextinguisher,andalsowheretomakecontactina stateofemergency.

(5)Chooseahard,levelandsafeplace,andplacetheattachmenton thegroundsecurely.

(6)Usealiftersuchasacranetoremoveheavyparts(20kg[45 lbs]ormore)fromthemachine.

(7)Usepropertools,andreplaceorrepairdefectivetools.

(8)Supportthemachineandattachmentwithsupportsorblocksiftheworkisperformedinthelifted condition.

1.1.3DISASSEMBLINGANDASSEMBLINGHYDRAULICEQUIPMENT

(1)Removinghydraulicequipment

1.Beforedisconnectingpipes,releasethehydraulicpressureofthesystem,oropenthereturnside coverandtakeoutthefilter.

2.Carefullydrainoiloftheremovedpipesintoacontainers withoutspillingonthefloor.

3.Applyplugsorcapsonthepipeendstoavoidoilspillageanddustintrusion.

4.Cleanofftheexternalsurfaceoftheequipmentbeforedisassembling,anddrainhydraulicandgear oilbeforeplacingitontheworkbench.

(2)Disassemblinghydraulicequipment

1.Donotdisassemble,reassembleormodifythehydraulicequipmentwithoutthepermissionofthe manufacturer,whoisnotresponsiblefortheperformanceandfunctionoftheproductafter modification.

2.Whendisassemblingandreassemblingforunavoidablereason,refertheworktoqualified personnelwhohavethespecificknowledgeorcompletedthepartsservicetraining.

3.Providematchingmarkstofacilitatereassemblingwork.

4.Beforestartingthework,readthemanualofdisassemblingprocedure,ifitisprovided,and decidewhethertheworkcanbeperformedbyyourself.

5.Usethespecialjigandtoolswithoutfailiftheyarespecified.

6.Ifitishardtoremoveapartaccordingtotheprocedure,do nottryitbyforcebutinvestigatethe cause.

7.Placetheremovedpartsinorderandattachtagstofacilitatethereassembling.

8.Notethelocationandquantityofpartscommonlyappliedtomultiplelocations.

(3)Inspectingparts

1.Ensurethatthedisassembledpartsarefreefromseizure,interferenceandunevencontact.

2.Measureandrecordwearconditionofpartsandclearance.

3.Iftheproblemisfoundinapart,repairorreplaceitwitha newone.

(4)Reassemblinghydraulicequipment

1.TurnONtheventilationfanoropenwindowstomaintaingoodventilationpriortostartingthe cleaningofparts.

2.Performroughandfinishcleaningbeforeassembling.

3.Removewashingoilbyairandapplycleanhydraulicorgearoilforassembling.

4.AlwaysreplacetheremovedO-rings,backupringsandoilsealswithnewonesbyapplyinggrease inadvance.

5.Removedirtandmoisturefromandperformdegreasingonthesurfacewhereliquidgaskettobe applied.

6.Removerustpreventiveagentfromthenewpartsbeforeuse

7.Fitbearings,bushingsandoilsealsusingspecialjigs.

8.Assemblethepartsutilizingmatchingmarks.

9.Ensureallthepartsarecompletelyassembledafterthework.

(5)Installinghydraulicequipment

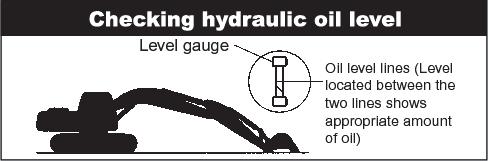

1.Ensurehydraulicoilandlubricantareproperlysupplied

2.Performairbleedingwhen:

a.Hydraulicoilchanged

b.Partsofsuctionsidepipingreplaced

c.Hydraulicpumpinstalled

d.Slewingmotorinstalled

e.Travelmotorinstalled

f.Hydrauliccylinderinstalled

3.Performairbleedingofthehydraulicpumpandslewingmotorafterlooseningtheupperdrainplug, startingtheengineandkeepitinlowidlecondition.

Completetheairbleedingwhenseepingofhydraulicoilisrecognized,andtightlyplug.

4.Performairbleedingofthetravelmotorandthehydraulic cylindersbyrunningtheengineformore than5minutesatlowspeedwithoutload.

5.Performairbleedingofpilotlinebyperformingaseriesof digging,slewingandtravel.

6.Checkhydraulicoillevelafterplacingtheattachmentto theoilcheckposition,andreplenishoilif necessary.

Operationofthehydraulicequipmentwithoutfillinghydraulicoilorlubricantorwithoutperformingair bleedingwillresultindamagetotheequipment.

Donotallowthehydrauliccylindertobottomonthestrokeendjustafterthemaintenance.